Abstract

Impressions are important sources of cross contamination between patients and dental laboratories. As a part of infection control impressions contaminated with variety of micro-organisms via blood and oral secretions should be cleaned and disinfected or sterilized before being handled in dental laboratory. The purpose of this study was to determine the effect of autoclaving on dimensional stability of elastomeric impression material (polyvinyl siloxane—Affinis). In this in vitro study standardized stainless steel die as per ADA specification number 19 was fabricated. Polyvinyl siloxane (Affinis) light body and putty viscosity elastomeric impression materials were used. A total of 40 impressions of the stainless steel die were made and numeric coding system was used to identify the samples. Measurements were made using a measuring microscope. Distance between the cross lines CD and C′D′ reproduced in the impression were measured before autoclaving, immediately after autoclaving and 24 hours after autoclaving and dimensional change was calculated. The data obtained was subjected to statistical analysis. The mean difference in dimensional change between the three groups was not statistically significant (P > 0.05). However the results revealed that there was higher mean dimensional change immediately after autoclaving when compared to the other 2 time intervals. It is desirable to delay the casting of an autoclavable elastomeric impression material by about 24 hours. Though disinfection of impression is routinely followed autoclaving of impression is an effective method of sterilization.

Keywords: Dimensionalstability, Autoclavable, Elastomeric impression material

Introduction

Impressions are important sources of cross contamination between patients and dental laboratories. As a part of infection control impressions contaminated with variety of micro-organisms via blood and oral secretions should be cleaned and disinfected or sterilized before being handled in dental laboratory [1]. Autoclaving is considered to be the most effective method of sterilization however, the accuracy of the polyvinyl siloxane elastomeric impression material after autoclaving have not been extensively studied. The purpose of this study was to determine the effect of autoclaving on dimensional stability of elastomeric impression material (polyvinyl siloxane- Affinis).

Materials and Methods

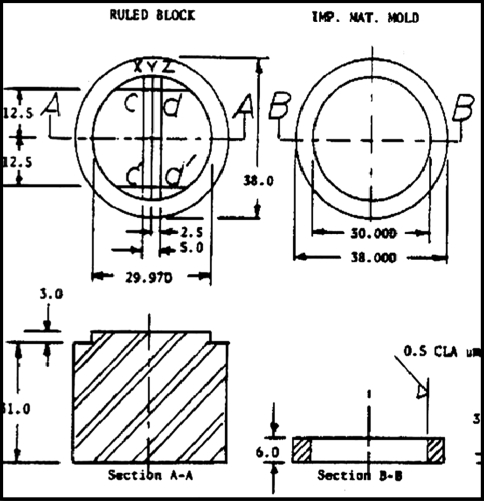

Standardized stainless steel die as per ADA specification number 19 was fabricated as shown in Figs. 1 and 2. Three lines X, Y and Z were inscribed on the superior surface of the die. The distance between X and Z lines was 5 mm. The width of the lines was 0.020 mm. The die has a stainless steel ring that fits around the borders as a mold for the impression material [2]. The impression material used in this study was polyvinyl siloxane (Affinis) light body and putty viscosities.

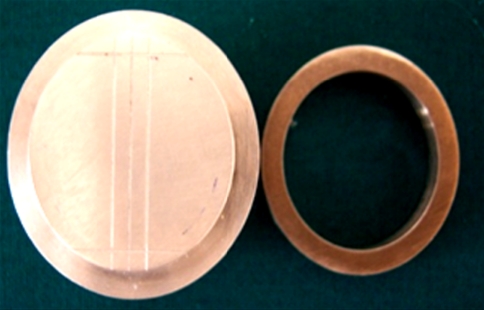

Fig. 1.

Stainless steel metal die with stainless steel ring

Fig. 2.

Measurements of ADA specification number 19 for the fabrication of stainless steel die

A total of 40 impressions of the stainless steel die were made as shown in Fig. 3. A stainless steel ring to be used as a mould to make an impression was placed on the die. Double mix single impression method was used to make the impressions. Impression material was mixed according to the manufacturer’s instructions and was loaded into the mold to make an impression of the die. After loading the mold, impression material was immediately covered by a thin sheet of polyethylene followed by application of sufficient force on a rigid flat metal plate to seat it firmly against the mold. To compensate for polymerization at room temperature rather than at mouth temperature, the impressions were allowed to set for twice the manufacturer’s recommended setting time (4 min) as indicated in ADA specification number 19 for laboratory testing [2, 3, 4]. The impression was then recovered from the mold and numeric coding system was used to identify the samples.

Fig. 3.

Impression of the metal die

Measurements were made using a measuring microscope. The distance between the cross lines CD and C′D′, on the ruled stainless steel die was measured to the nearest 0.005 mm and the measurement was recorded as reading A. Distance between the cross lines CD and C′D′ reproduced in the impression were measured before autoclaving, immediately after autoclaving and 24 hours after autoclaving and the measurements were recorded as B1, B2 & B3 respectively. The measurements were made at the edges of the cross lines. The same yard stick was used to make all the measurements. Dimensional change was calculated using the following formula:

|

The data obtained was subjected to statistical analysis. A student “t” test was used to ascertain statistical difference between the groups.

Results

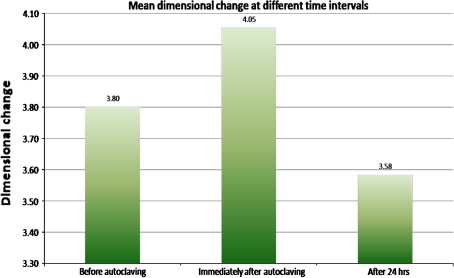

Dimensional stability was compared at three time intervals; before autoclaving, immediately after autoclaving and 24 hours after autoclaving. The statistical data is presented in Table 1 and Fig. 4.

Table 1.

Statistical data presenting the dimensional stability as compared at three different time intervals

| Time interval | Mean | Std dev | Mean difference | t | P-value |

|---|---|---|---|---|---|

| Before autoclaving | 3.80 | 2.04 | −0.254 | −0.356 | 0.724 |

| Immediately after autoclaving | 4.05 | 3.38 | |||

| Before autoclaving | 3.80 | 2.04 | 0.217 | 0.251 | 0.804 |

| After 24 hours | 3.58 | 4.37 | |||

| Immediately after autoclaving | 4.05 | 3.38 | 0.471 | 0.417 | 0.680 |

| After 24 hours | 3.58 | 4.37 |

Fig. 4.

Bar graph representing the results

The mean dimensional change before autoclaving was found to be 3.80 ± 2.04, immediately after autoclaving the mean dimensional change was found to be 4.05 ± 3.38. The difference between the mean dimensional change before autoclaving and immediately after autoclaving was not statistically significant (P > 0.05).

The mean dimensional change before autoclaving was found to be 3.80 ± 2.04, after 24 hours of autoclaving the mean dimensional change was found to be 3.58 ± 4.37. The difference between the mean dimensional change before autoclaving and after 24 hours was not statistically significant (P > 0.05).

The mean dimensional change immediately after autoclaving was found to be 4.05 ± 3.38, after 24 hours of autoclaving the mean dimensional change was found to be 3.58 ± 4.37. The difference between the mean dimensional change immediately after autoclaving and after 24 hours was not statistically significant (P > 0.05).

Discussion

Saliva and blood contaminated impressions are often a source of cross contamination between the clinic and dental laboratory. Explicit communication and observance of an infection control protocol for handling of dental impressions must exist among the office staff as well as between office and dental laboratories. Such an infection control protocol should include guidelines for proper handling and disinfection or sterilization of impressions [5–7].

As part of infection control protocol it is important to distinguish between sterilization and disinfection; Sterilization results in destruction of all forms of microbial life (viruses and fungi) where as disinfection results in destruction of specific pathogenic microorganisms. Sterilization is best achieved by physical methods such as autoclaving which is less time consuming and more reliable than chemical disinfection. Though disinfection of the impressions is routinely followed autoclaving elastomeric impressions is an effective method of sterilizing them.

This study evaluated the effect of autoclaving on elastomeric impressions at 121°C for 15 min on dimensional stability of polyvinyl siloxane impression material (autoclavable) [8] at three different time intervals; that is before autoclaving, immediately after autoclaving and 24 hours after autoclaving. Statistically no significant dimensional change was observed between the 3 different time intervals. However the results revealed that there was higher mean dimensional change immediately after autoclaving when compared to the other 2 time intervals that is before autoclaving and after 24 hours of autoclaving.

The result of this study implies that it is desirable to delay the casting of an autoclavable elastomeric impression material by about 24 hours. Though disinfection of impression is routinely followed autoclaving of impression is an effective method of sterilization.

Conclusion

Within the limitation of this study, there was no statistically significant dimensional change between 3 time intervals. However it was observed that there was a mean dimensional change immediately after autoclaving, which considerably decreased after 24 hours. This implies that it is desirable to delay the casting of an autoclavable elastomeric impression material by about 24 hours. Autoclaving of the elastomeric impressions (polyvinyl siloxane) can be used to prevent cross contamination between patients and laboratories.

References

- 1.Krygier G (1999) Infection control in dental practice, 1st edn. All India Traveller Book Seller, India

- 2.Reports of Councils and Bureaus—Revised (1977) ADA specification No 19 for non aqueous elastomeric impression materials. JADA, vol 94, April 1977

- 3.Thouati A. dimensional stability of seven elastomeric impression materials immersed in disinfectants. J Prosthet Dent. 1996;76:8–14. doi: 10.1016/S0022-3913(96)90338-8. [DOI] [PubMed] [Google Scholar]

- 4.Johnson GH. Dimensional stability and detail reproduction of irreversible hydrocolloid and elastomeric impression disinfection. J Prosthet Dent. 1998;79:446. doi: 10.1016/S0022-3913(98)70160-X. [DOI] [PubMed] [Google Scholar]

- 5.Adabo G. Effect of disinfectant agents on dimensional stability of elastomeric impression materials. J Prosthet Dent. 1999;81:621–624. doi: 10.1016/S0022-3913(99)70219-2. [DOI] [PubMed] [Google Scholar]

- 6.Walker MaryP. Surface quality and long term dimensional stability of current elastomeric impression materials after disinfection. J Prosthodontics. 2007;16:343. doi: 10.1111/j.1532-849X.2007.00206.x. [DOI] [PubMed] [Google Scholar]

- 7.MdP Rios. Effects of chemical disinfectant solutions on the stability and accuracy of the dental impression complex. J Prosthet Dent. 1996;76:356. doi: 10.1016/S0022-3913(96)90538-7. [DOI] [PubMed] [Google Scholar]

- 8.www.coltenewhaledent.com. Accessed March 2010