Abstract

A monotonic decrease in viscosity with increasing shear stress is a known rheological response to shear flow in complex fluids in general and for flocculated suspensions in particular. Here we demonstrate a discontinuous shear-thickening transition on varying shear stress where the viscosity jumps sharply by four to six orders of magnitude in flocculated suspensions of multiwalled carbon nanotubes (MWNT) at very low weight fractions (approximately 0.5%). Rheooptical observations reveal the shear-thickened state as a percolated structure of MWNT flocs spanning the system size. We present a dynamic phase diagram of the non-Brownian MWNT dispersions revealing a starting jammed state followed by shear-thinning and shear-thickened states. The present study further suggests that the shear-thickened state obtained as a function of shear stress is likely to be a generic feature of fractal clusters under flow, albeit under confinement. An understanding of the shear-thickening phenomena in confined geometries is pertinent for flow-controlled fabrication techniques in enhancing the mechanical strength and transport properties of thin films and wires of nanostructured composites as well as in lubrication issues.

Keywords: rheology, jamming, shear diagram

An increase in viscosity of fluids with increasing flow rate termed as “shear thickening” (ST) is of tremendous interest in basic sciences as well as for many applications which include the design of smart materials like soft body armors and shock absorbers (1). Traditionally, the candidates for shear-thickening fluids have been dense suspensions of Brownian/non-Brownian, nonaggregating, monodisperse spherical or rod-like particles (2–6). This trend is further encouraged by recent experimental and theoretical studies which surmised that a strong ST will not be observed in flocculated suspensions because the attractive interactions that drive flocculation increase the yield stress and mask the ST behavior, leading to a monotonic shear-thinning viscosity curve (7–9). Consistent with this picture, a shear-thinning behavior is always seen, for example, in flocculated suspensions of carbon nanotubes (10, 11).

The rheophysics of flocculated suspensions formed by colloidal particles with attractive interactions also raises several interesting issues. A universal jamming phase diagram proposed for attractive particles (12) with particle volume fraction Φ, interparticle attraction U, and stress σ as the control parameters is consistent with the nonequilibrium shear diagram for multiwalled nanotubes mapped out using rheooptical studies (11). Here, the nanotubes, which are entangled at low shear stress to exhibit a solid-like behavior, transform to a liquid-like state by dispersing the nanotubes that align along flow to form a nematic phase above a critical shear stress. However, the feasibility of achieving a reentrant jamming phase behavior by tuning the attractive interactions in these systems has not been examined. In fact, ST behavior was not known for flocculated suspensions until recently, where a modest continuous ST (when the viscosity increases by a factor of 3) was reported in flocculated fumed colloidal suspensions at low weight fractions (> 2 wt %) (13, 14). Nevertheless, the consistent shear-thinning behavior of flocculated multiwalled carbon nanotubes (MWNT) suspensions in aqueous medium, organic solvents, as well as polymeric melts (10, 15) indicate that predicting the conditions and the mechanism that drive shear-thickening behavior in non-Brownian flocculating suspensions has yet to be understood. The mechanism of ST in non-Brownian flocs will be distinct from that of Brownian particles where ST arises from the clustering of particles around the compression axis of shear flow when the hydrodynamic viscous force dominates over Brownian forces above a shear rate  where a is average particle size. Shear thickening is also associated with the formation of percolated clusters above a critical shear rate (16). The statistical properties of stress and energy fluctuations in these dense suspensions in shear-induced jammed state identify it as a self-organized critical system. Interestingly, a strong analogy has been observed in the flow of dense non-Brownian suspension and granular rheology (4, 5, 17, 18). It is relevant to examine whether this analogy will carry over to flocculated suspensions where frictional contact forces between micron-sized flocs can have a crucial role in forming percolated structures at low volume fractions.

where a is average particle size. Shear thickening is also associated with the formation of percolated clusters above a critical shear rate (16). The statistical properties of stress and energy fluctuations in these dense suspensions in shear-induced jammed state identify it as a self-organized critical system. Interestingly, a strong analogy has been observed in the flow of dense non-Brownian suspension and granular rheology (4, 5, 17, 18). It is relevant to examine whether this analogy will carry over to flocculated suspensions where frictional contact forces between micron-sized flocs can have a crucial role in forming percolated structures at low volume fractions.

We have addressed these issues in a flocculated suspension of MWNT dispersed in a low-viscosity Newtonian fluid where a discontinuous ST occurs above a critical stress at very low weight fractions (> 0.5%), by forming a percolated structure of MWNT flocs. The enhanced shear and normal stress fluctuations observed in the shear-thickened state (at constant shear rate) is consistent with the presence of sustained frictional contacts between the flocs under flow. We construct shear diagrams where shear-thinning, shear-thickened, and jammed states could be obtained by tuning Φ, σ, and the gap thickness (d) of the shear cell.

Results and Discussion

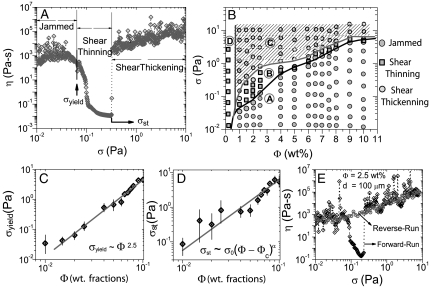

The flow curves were obtained in a cone-plate geometry by varying the shear stress in the range of 0.01–20 Pa. The MWNT suspensions at weight fraction Φ > 1% exhibit a yield stress region below a well-defined stress (σyield). The finite viscosity at applied stress below the yield stress arises due to rearrangement of the flocs (19). Above the yield stress, a sharp decrease in viscosity is followed by further shear thinning. The typical flow curve is shown (Fig. 1A) for nanotube weight fractions for Φ = 2 wt %, where subsequent increase in shear stress leads to a sharp rise in viscosity (by six orders of magnitude), accompanied by an order of magnitude fluctuations signifying a shear-induced jammed state (henceforth referred to as the shear-thickened state). At much higher stress values (> 15 Pa), a sharp decrease in viscosity is seen corresponding to a fracture of the ST state, which is similar to the fracture mechanism or the brittle failure with inhomogeneous flow, proposed for a jammed state at a high shear stress (20). The yield stress demarcating the boundary between the jammed region (region A, where there is no flow) and shear-thinning region (region B) was found to scale with Φ as σyield ∼ Φ2.5 (Fig. 1C). The value of the exponent is comparable to that reported earlier for fibers and nanotube suspensions, which lies in the range of 2.5–3.5 (10, 21). A shear-thickened region (region C) always occurs over the range of nanotube weight fractions (1–10%) studied though the critical stress for the onset of ST (σst) increases with Φ, and could be fitted to a functional form σst = σ0(Φ - Φc)α with σ0 = 780 Pa, Φc = 0.005, and α ∼ 2. The thin wedge in region B of the shear diagram (Fig. 1B) indicates that, on increasing Φ, the regime of shear thinning between the jammed (region A) and shear-thickening region (region C) (which is bounded by σyield and σst) decreases. Also, for very low values of Φ, only shear thinning is observed (region D). The shear diagram presented here for flocculated MWNT should be contrasted with that obtained for dense nonaggregating suspensions where ST occurs only at high volume fractions (Φ > 35%) (6), as well as that proposed earlier for flocculated nanotube suspensions, which consisted only of jammed and shear-thinning regions (11). On examining the reversibility of the shear-thickened state, a strong hysteresis effect was observed where, in the decreasing stress ramp, the viscosity of the initial jammed state is reached, without the intervening shear-thinning region (Fig. 1E). The behavior of G′ as a function of applied stress resembles the viscosity plot as in Fig. 1A (see SI Appendix, Text S1 and Fig. S1A). In jammed and shear-thickened state, G′ > G′′ at all frequencies (see SI Appendix, Text S1 and Fig. S1 B and C), whereas in shear-thinning state, G′′ > G′. G′ increases by two orders of magnitude in the shear-thickened state (for Φ = 5 wt %, see SI Appendix, Fig. S1) as compared to that in the yield stress region. The value of G′ attained in the shear-thickened state at low weight fractions when an external steady shear stress (σDC) is imposed is still higher than that obtained in the yield stress region at a higher Φ( = 7 wt %) (see SI Appendix, Text S6 and Fig. S6). At a still higher Φ, the G′ of the jammed state can compare with that of shear-thickened state obtained for lower Φ. The percolated clusters obtained in the shear-thickened state is a nonequilibrium state with an enhanced elasticity, possibly due to the increase in the number of floc–floc contacts along the compression axis of shear in the presence of σDC. In another experiment, after reaching the shear-thickened state when the shear stress was reduced to zero, the storage modulus (G′) decreases by an order of magnitude in 500 s and eventually approaches a value nearly that of the initial jammed state (see SI Appendix, Text S2 and Fig. S2). This observation confirms that the shear-thickened state observed in the present system is metastable and does not lead to a permanently jammed state as seen in concentrated non-Brownian suspensions (22).

Fig. 1.

Steady-shear behavior of dilute MWNT suspension in NMP. (A) Viscosity (η) vs. applied shear stress (σ) for 2 wt % MWNT in NMP. (B) Shear diagram in σ - Φ plane (explained in the text) constructed out of the η vs. σ curves for different weight fraction (Φ) of MWNT in NMP; the solid lines indicate the approximate boundaries for yield stress (σyield), shear-thickening stress (σst), and region showing only shear thinning at very low Φ. Different symbols show different states of the system (indicated in the figure). (C) Log–log plot of σyield vs. Φ; solid line indicates a power-law fit with exponent 2.5. (D) Log–log plot of σst vs. Φ; solid line indicates the fit to the expression shown in the figure. The error bars indicate the range of (C) σyield and (D) σst obtained in repeated measurements. (E) Viscosity vs. shear stress curves showing the hysteresis obtained in an increasing and decreasing stress ramp for Φ = 2.5 wt % in a parallel-plate geometry with a gap d = 100 μm. The flow curves were obtained with increasing and decreasing stress ramp and the duration for each measuring point fixed at 100 s.

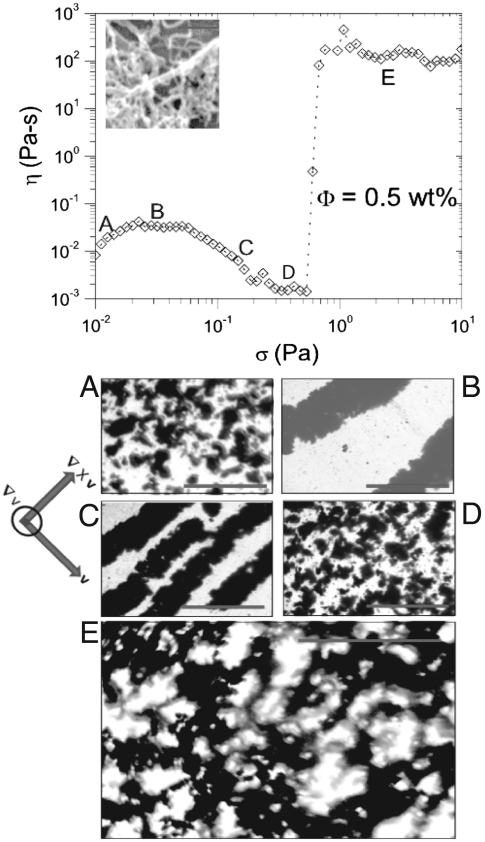

Rheological measurements in conjunction with optical microscopy were carried out to correlate the flow curve obtained in the stress-controlled mode with the suspension microstructure. The optical micrographs of the suspension at a weight fraction of 0.5%, obtained at different stages of the stress-controlled flow curve in a transparent parallel-plate geometry with a gap of 50 μm, are shown in Fig. 2. In the quiescent state, floc size is 25–100 μm (Fig. 2A) with a fractal dimension approximately 1.8. For shear stress > 0.01 Pa, MWNT flocs aggregate under flow to form denser structures which transform to rolling log-like flocs with a width comparable to the gap of the geometry, aligned along the vorticity direction (Fig. 2B). The average length of the log-like flocs vary in the range of 200–500 μm (13, 23). Reported earlier in different flocculated systems and manifesting as a weak ST in the flow curve where viscosity increases by a factor of 3, the microstructure was proposed to arise from the elastic instability of the flocs aggregating under shear in confinement. The shear-induced aggregation driven by frictional contact forces between aggregates at low shear rates or stresses has been dealt with in detail in earlier studies and hence will not be discussed here any further (21, 24). The onset of shear thinning at 0.05 Pa corresponds to the decrease in the width of the bands (Fig. 2C) and a subsequent breakup of the clusters (Fig. 2D). The cluster size decreases further with increase in the shear stress applied, consistent with the expected inverse dependence of the cluster size on the applied stress.† A decrease in fractal dimension (from approximately 1.8 to 1.4) leading to the overall increase in volume fraction as well as surface area of the flocs enhances the floc–floc contact with increasing shear stress. Above a critical shear stress of 0.5 Pa, the discontinuous rise in viscosity by about six orders of magnitude is accompanied by a percolated structure spanning the gap of the geometry which persists (Fig. 2E) up to a shear stress of 10 Pa. Percolated structures have been observed in dense colloidal suspensions below the yield stress at volume fractions > 20% (25). However, above the yield stress, the floc size decreases with the imposed shear stress as discussed earlier and only a steady shear thinning is observed. Hence a crucial aspect of the present study is the direct observation of the formation of a percolated structure under shear, leading to ST that has not been reported yet. The percolated structure was absent in a controlled-shear rate run where no remarkable ST was obtained (see SI Appendix, Text S3 and Fig. S3). The entanglement between the nanotubes is retained over the range of applied stress or shear rate, in contrast with an earlier study where the flocculation of the nanotubes could be suppressed above a critical stress (11).

Fig. 2.

Optical micrographs showing the distribution of flocculated clusters in the different regions (marked by A, B, C, D, and E) in the viscosity (η) vs. applied shear stress (σ) curve for Φ = 0.5 wt % MWNT suspension in NMP. The black and gray regions represent the MWNT flocs and the white regions indicate the bare solvent. (Scale bar: 200 μm.) The set of arrows indicate the direction of flow (v), vorticity (∇ × v), and velocity gradient (∇v) for all the optical micrographs. Inset of the flow curve shows the typical scanning electron micrograph of a dry MWNT cluster. (Scale bar: 250 nm.)

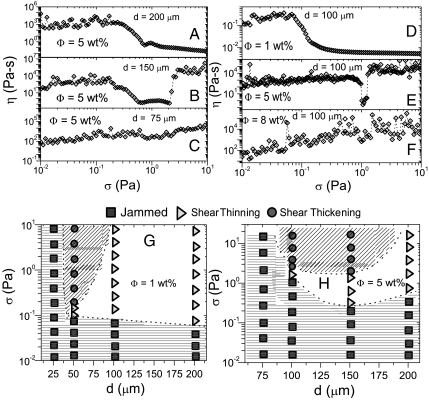

The formation of a percolated structure suggests that confinement will have a crucial role on the ST of the flocculated suspensions as seen in the controlled shear stress flow curves at Φ = 5% carried out in a parallel-plate geometry (Fig. 3 A–C). The phase diagrams in σ-d parameter space for Φ = 1 wt % (Fig. 3G) and Φ = 5 wt % (Fig. 3H) suggest that Φ and d are the tunable parameters to achieve shear-induced thickening in flocculated systems. The yield stress also decreases with the increasing gap at a fixed weight fraction (Fig. 3 G and H) An increase in the yield stress when the gap thickness is comparable to the particle or floc size has been seen earlier in both nonaggregating (26) as well as flocculating suspensions (11). In dense non-Brownian suspensions, increasing the confinement up to two particle diameters for spheres drives a transition from shear-thickened to yield stress dominated regime (26), and ST → Newtonian regime for rods on decreasing the gap size below the average length of the rods. In comparison, in the present system, a transition occurs from shear-thinning → shear-thickening → jammed behavior at a given stress on decreasing the gap—a phenomenon not reported hitherto. It is equally noteworthy that the same sequence of transitions can be attained by increasing Φ at a fixed gap (Fig. 3 D–F).

Fig. 3.

Gap dependence of shear thickening. (A–C) Viscosity (η) vs. applied shear stress (σ) for different gap thicknesses d between the parallel-plate geometry for Φ = 5 wt % MWNT in NMP. (D–F) Viscosity η vs. σ for different Φ for d = 100 μm. Shear diagram in σ-d plane for (G) Φ = 1 wt % and (H) Φ = 5 wt % MWNT in NMP. For G and H, the shaded regions are the guide to the eye and the dotted line marks the approximate boundaries.

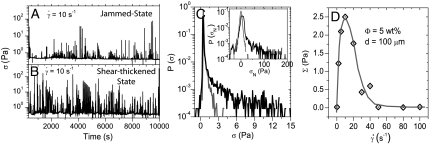

Closely associated with the jammed states formed in the present study is the concept of stress bearing chains arising from the contact between individual grains (particle–particle contact) spanning the system size, introduced initially for granular systems and later extended to others (18, 27). The percolated structures observed presently in the shear-thickened state are likely to be the stress bearing chains visualized as a network arising from floc–floc contacts spanning the system size (see Fig. 2E). The dynamics of the stress chains in a jammed state often manifest as large stress fluctuations in a steady shear flow (at constant shear rate) due to the slow motion and rearrangement of these individual grains (28). This feature is clearly seen presently, in the jammed state below yield stress (Fig. 4A) as well as the shear-thickened state (Fig. 4B) from the time evolution of the stress at an imposed shear rate of 10 s-1. The standard deviation (Σ) of stress fluctuations is maximum at approximately 10 s-1 (Fig. 4D). It is equally relevant to note that the probability distribution of the stress fluctuations in the shear-thickened state is spread over a large amplitude, as seen from the long tail of the distribution compared to the jammed state (Fig. 4C). Similar differences are present for the case of normal stress fluctuations in the two states (see Fig. 4C, Inset), indicating the enhanced floc–floc contacts in the shear-thickened state. For example, comparison of Fig. 2 A and E shows cluster–cluster contacts are less in the jammed state as compared to the shear-thickened state. A similar feature of the stress distribution, also seen in dense granular flow and in the shear-thickened state of nonaggregating colloidal suspension at high volume fraction, is taken as a signature of a critical system (16, 18). The present analysis of stress fluctuations emphasize the crucial role of sustained interfloc contacts spanning the system size in driving a shear-thickening transition. The low fractal dimension (approximately 1.4) before the onset of ST (Fig. 2D) in the suspension under study further ensures that frictional contacts between micron-sized nanotube flocs are established even at a low weight fraction (Φ ∼ 0.5%).

Fig. 4.

Statistics of stress fluctuations in shear-thickened and jammed states. Time evolution of stress (σ) for an applied shear rate of 10 s-1 in (A) jammed state below the yield stress and (B) shear-thickened state. (C) Probability distribution function of the shear stress (σ) and normal stress (σN, shown in inset) at a shear rate of 10 s-1 in the jammed state (gray solid line) and shear-thickened state (black solid line). (D) Standard deviation of the stress fluctuation of the jammed region below yield stress, at different shear rates. The solid line is a guide to the eye. All the measurements were carried out in a parallel-plate geometry with the gap (d) fixed at 100 μm and Φ = 5 wt % MWNT in NMP.

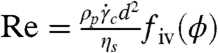

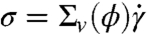

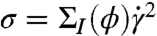

It is relevant to mention here that a modest, continuous ST (viscosity increasing by a factor of 10) at low weight fractions (approximately 1%) has also been seen in micellar systems (29). Here the quiescent state, which consists of well-dispersed, Brownian flexible cylinders, transforms above a critical shear stress to a percolating network (30). The proposed mechanism for the ST is through the aggregation of micelles into bundles due to intermicellar interactions (31) or to the presence of closed micellar loops that form a linked network under shear (32). However, these mechanisms are not likely to be relevant to the flocculated nanotubes presently under study. At the outset, we submit that a quantitative understanding of the discontinuous ST observed by us is lacking. Here we outline only a few promising avenues. We note that, because of the fractal nature of the flocs as discussed earlier, the effective volume fraction at the onset of ST is measured to be approximately 0.6‡ (see Fig. 2D), which is much larger than the actual volume fraction, which is only 0.0025. Hence, to explain the physical mechanism of discontinuous ST in our case, it is tempting to invoke the mechanisms proposed recently for dense non-Brownian suspensions (5). For non-Brownian particles, above a critical shear rate ( ), inertial effects can dominate over viscous effects, which can be quantified in terms of a dimensionless Reynolds number;

), inertial effects can dominate over viscous effects, which can be quantified in terms of a dimensionless Reynolds number;  where the system size d ∼ 100 μm, the particle density ρp = 2,000 kg/m3, the viscosity of the solvent ηs is 3 mPa·s, and the function fiv(ϕ) depends on the effective volume fraction ϕ (4). Presently, we have chosen the gap size d as the relevant length scale in the system because the average floc size is comparable to the gap size for the system under study (see, for instance, Fig. 2A). Assuming fiv(ϕ) = 1 for a dilute system, Re estimated from the shear rates just before the onset of ST lie in the range of 0.01–0.3. With regard to the ST at such low values of shear rates (5), it has been proposed recently that the flow of dense non-Brownian suspensions are analogous to granular rheology, where the viscous (inertial forces) forces are balanced by the frictional particle–particle contact forces at low (high) shear rates . In the viscous regime

where the system size d ∼ 100 μm, the particle density ρp = 2,000 kg/m3, the viscosity of the solvent ηs is 3 mPa·s, and the function fiv(ϕ) depends on the effective volume fraction ϕ (4). Presently, we have chosen the gap size d as the relevant length scale in the system because the average floc size is comparable to the gap size for the system under study (see, for instance, Fig. 2A). Assuming fiv(ϕ) = 1 for a dilute system, Re estimated from the shear rates just before the onset of ST lie in the range of 0.01–0.3. With regard to the ST at such low values of shear rates (5), it has been proposed recently that the flow of dense non-Brownian suspensions are analogous to granular rheology, where the viscous (inertial forces) forces are balanced by the frictional particle–particle contact forces at low (high) shear rates . In the viscous regime  , whereas in the inertial regime

, whereas in the inertial regime  . Numerical simulations have shown that both ΣI(ϕ) and Σv(ϕ) diverge near the jamming packing fraction with different diverging exponents (17), indicating that the critical shear rate for the crossover from viscous to inertial regime can vary with the volume fraction. In fact, recent experimental observations in a dense non-Brownian suspension (5) show that the critical shear rate goes to zero linearly with ϕ and the stress at the onset of ST remains independent of ϕ. Hence low values of Re( < 1) obtained in the flocculated system presently studied does not rule out the role of inertial effects in driving the shear-thickening transition. Shear thickening in dense suspensions can also arise from dilation effects (33), which manifests as a sharp increase by a few orders of magnitude in the normal stress (3) at the onset of ST. In comparison, the normal stress does not increase sharply at the onset of ST (see SI Appendix, Text S5 and Fig. S5). Further, the onset stress for ST σst for a given weight fraction and gap thickness is the same for both underfilled and overfilled conditions (see SI Appendix, Fig. S8)—i.e., σst is independent of the boundary condition at the outer edge. As shown in SI Appendix, Fig. S7, the dilation of the sample and the roughness of the interface in the shear-thickening region (C) as compared to the jammed region (A) can be clearly seen. Hence, we suggest that the inertial as well as dilation effects can be responsible for the shear-thickening transition.

. Numerical simulations have shown that both ΣI(ϕ) and Σv(ϕ) diverge near the jamming packing fraction with different diverging exponents (17), indicating that the critical shear rate for the crossover from viscous to inertial regime can vary with the volume fraction. In fact, recent experimental observations in a dense non-Brownian suspension (5) show that the critical shear rate goes to zero linearly with ϕ and the stress at the onset of ST remains independent of ϕ. Hence low values of Re( < 1) obtained in the flocculated system presently studied does not rule out the role of inertial effects in driving the shear-thickening transition. Shear thickening in dense suspensions can also arise from dilation effects (33), which manifests as a sharp increase by a few orders of magnitude in the normal stress (3) at the onset of ST. In comparison, the normal stress does not increase sharply at the onset of ST (see SI Appendix, Text S5 and Fig. S5). Further, the onset stress for ST σst for a given weight fraction and gap thickness is the same for both underfilled and overfilled conditions (see SI Appendix, Fig. S8)—i.e., σst is independent of the boundary condition at the outer edge. As shown in SI Appendix, Fig. S7, the dilation of the sample and the roughness of the interface in the shear-thickening region (C) as compared to the jammed region (A) can be clearly seen. Hence, we suggest that the inertial as well as dilation effects can be responsible for the shear-thickening transition.

It is noteworthy that the gap thickness, or in other words confinement, has a crucial role in the shear-thickening transition observed presently for flocculating suspensions. When the system size (gap between the sheared plates) increases, the network of flocs that build under shear are less likely to span the gap. This inference is supported by the absence of large amplitude stress fluctuations at gaps > 300 μm at constant shear rate. Hence ST (Fig. 3A) will not occur even at high stresses (corresponding to Re > 1) because the inertial forces are unlikely to be balanced by the floc–floc contacts spanning the gap when the system size is much larger than the floc size. The shear-thickened state being metastable, an alternative view would be to identify the shear-thickening transition as a generalized glass transition induced by shear, as proposed recently (20, 34). However, such an approach does not take into account presently the role of confinement in driving these transitions.

To bring out the role of floc size, weight fraction (Φ), and gap thickness (d), we have carried out similar experiments in carbon black. We see that for two different carbon black samples, Vulcan XC-72R (floc size approximately 20 µm) and N-762 (floc size approximately 10 µm) as shown in SI Appendix, Fig. S4, ST is observed at a higher gap thickness for the sample with larger floc size. Moreover, the same sequence of transitions shear-thinning → shear-thickening → jammed state is obtained for both carbon black and flocculated nanotube suspensions on decreasing the gap. The reason that the dramatic ST observed presently has not been reported in systems consisting of flocculated isometric particles may be because of the large gap thickness in relation to the average floc size and its fractal dimensions. The unique feature of the MWNT and carbon black suspension formed by fractal clusters is that it has a much larger effective volume fraction that helps them to mutually interlock under flow and form a connected network. Note that the modest ST (where the viscosity increases by a factor of 3) reported in an earlier study (13) is indeed recovered for larger gap sizes (see SI Appendix, Fig. S4A). We further add that the choice of solvent and additives should be such that the fractal flocs remain intact at high stress/shear rate. For example, the replacement of NMP by silicone oil in the case of MWNT does not affect the shear-thickening phenomenon (see SI Appendix, Text S9 and Fig. S9). Hence the dramatic ST observed presently at gaps comparable to floc size is a characteristic feature of suspensions formed by stable fractal flocs.

Conclusions

To summarize, we have shown that a discontinuous ST where the viscosity increases by several orders of magnitude can be achieved as a function of shear stress in flocculated suspensions of carbon nanotubes. The discontinuous shear-thickening behavior leading to the formation of a percolated structure can be identified as shear-induced jamming. MWNT are often used as fillers in polymeric materials to enhance the mechanical strength or electrical conductivity by exploiting the percolation transition in carbon nanotube suspensions above a critical volume fraction (35, 36). Processing such materials often involves flow and a shear-thinning behavior under steady shear results in a dramatic decrease in the storage modulus or electrical conductivity because of the loss of the percolated structure. Hence for many practical applications of polymer-nanotube composites, it is desirable to achieve ST or in other words, a percolated structure under flow rather than by increasing the volume fraction. Our study demonstrates that shearing flocculated nanotube suspensions in Newtonian fluids in a controlled stress mode can give rise to a percolated structure above a critical stress. Therefore, by controlling the flow processing conditions suitably in polymer-nanotube composites, we can enhance significantly their mechanical strength and electrical conductivity at low nanotube weight fractions. The present study also highlights the difference in the rheological properties of flocculated nanotube and carbon black suspensions in wide and narrow gap geometries. This difference in flow behavior when the fluid is confined to a few layers is very relevant for instance in lubrication films or flow in microchannels with pressured flow between plates, which is often encountered in industrial processes. In addition to other unique applications such as soft armors, we hope that our study will motivate further experiments on ST in flocculated suspensions as well as theoretical studies on the reentrant jamming behavior under shear in this class of systems.

Materials and Methods

MWNT with diameter 30–50 nm and average length of a few microns were procured from Sun Nanotech and used as received. Carbon black (Vulcan XC72R and N-762) was a gift from Cabot India Limited. The appropriate weight fraction (Φ = 0.1–5%) of nanotubes or carbon black were sonicated for 5 min in NMP (Aldrich) and vortex stirred before the measurements. Reproducible results could be obtained for weight fractions > 5% by homogenizing the samples through sonication over 10 min, followed by a preshear at nearly 100 s-1. Typical scanning electron micrograph of dry nanotube clusters deposited on a substrate, from a dilute nanotube suspension (Φ = 0.1%) in NMP is shown (Fig. 2). The clusters are composed of flexible nanotubes that are highly entangled rather than networks of rigid rods. Optical micrographs of the suspension at Φ = 0.1% revealed an average cluster size of 3 μm. The equilibrium cluster size increases with Φ and the suspension consists of an overlapping network of nanotube clusters at Φ > 1%. Rheological measurements were carried out using a stress-controlled rheometer (MCR 300 Anton Paar) in both cone plate (cone angle 2°, with cone diameter 50 mm; CP50-2/s, sandblasted where the average gap thickness varies between 50 and 800 μm) and plate–plate (plate diameter 25 mm) geometries. The viscosity of NMP is 3 mPa and the typical time for the settling of the suspensions (approximately 10,000 s) was larger than the duration of the experiment. Rheooptical measurements were made in a home-built, optically transparent glass parallel-plate geometry (plate diameter 43 mm) with the gap fixed at 50 μm. The sample temperature was maintained at 25 °C, with a water circulation unit around the sample chamber. The images were recorded on an eight-bit color CCD camera (Lumenera, 0.75C, 640×480 pixels ) fitted with a microscope objective (Nikon, 0.15 N.A. 10×, 0.7 N.A. 40×).

Supplementary Material

Acknowledgments.

A.K.S. thanks Council of Scientific and Industrial Research, India, for research support through the Bhatnagar Fellowship. R.K. thanks Department of Science and Technology, India, for the Ramanujan Fellowship. S.M. thanks University Grants Commission, India, for the Senior Research Fellowship.

Footnotes

The authors declare no conflict of interest.

*This Direct Submission article had a prearranged editor.

This article contains supporting information online at www.pnas.org/lookup/suppl/doi:10.1073/pnas.1018685108/-/DCSupplemental.

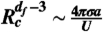

†The dependence of the cluster size on the shear stress is determined by the balance between the shear force and the attractive interaction between particles in the cluster and is given by  (Rc is the radius of the fractal cluster of fractal dimension df formed due to an attractive interaction of strength U between particles of radius a). Hence for a fixed U, the cluster size varies inversely with the applied σ.

(Rc is the radius of the fractal cluster of fractal dimension df formed due to an attractive interaction of strength U between particles of radius a). Hence for a fixed U, the cluster size varies inversely with the applied σ.

‡Fractal dimension of the flocs is estimated from the projection of the flocs in 2D using image analysis. Because the optical microscopy images are the 2D projections of the flocs, it is assumed that the fractal dimension does not change upon projection, provided the fractal dimension D < 2. The projected area fraction of the clusters in 2D (Fig. 2D) is estimated to be 0.6. Because the cluster size is comparable to the gap size, the volume fraction is expected to be nearly the same as the area fraction.

References

- 1.Wagner NJ, Brady JF. Shear thickening in colloidal dispersions. Phys Today. 2009;62:27–32. [Google Scholar]

- 2.Brady JF, Bossis G. The rheology of concentrated suspensions of spheres in simple shear flow by numerical simulation. J Fluid Mech. 1985;155:105–129. [Google Scholar]

- 3.Fall A, Huang N, Bertrand F, Ovarlez G, Bonn D. Shear thickening of cornstarch suspensions as a reentrant jamming transition. Phys Rev Lett. 2008;100:018301–018304. doi: 10.1103/PhysRevLett.100.018301. [DOI] [PubMed] [Google Scholar]

- 4.Russel N, Lemaître A, Flatt RJ, Coussot P. Steady state flow of cement suspensions: A micromechanical state of the art. Cem Concr Res. 2010;40:77–84. [Google Scholar]

- 5.Fall A, Lemaître A, Bertrand F, Bonn D, Ovarlez G. Shear thickening and migration in granular suspensions. Phys Rev Lett. 2010;105:268303–268306. doi: 10.1103/PhysRevLett.105.268303. [DOI] [PubMed] [Google Scholar]

- 6.Brown E, Jaeger HM. Dynamic jamming point for shear thickening suspension. Phys Rev Lett. 2009;103:086001–086004. doi: 10.1103/PhysRevLett.103.086001. [DOI] [PubMed] [Google Scholar]

- 7.Raghavan SR, Khan SA. Shear thickening response of fumed silica suspensions under steady and oscillatory shear. J Colloid Interface Sci. 1997;185:57–67. doi: 10.1006/jcis.1996.4581. [DOI] [PubMed] [Google Scholar]

- 8.Brown E, et al. Generality of shear thickening in dense suspensions. Nat Mater. 2010;9:220–224. doi: 10.1038/nmat2627. [DOI] [PubMed] [Google Scholar]

- 9.Gopalakrishnan V, Zukoski CF. Effect of attractions on shear thickening in dense suspensions. J Rheol. 2004;48:1321–1344. [Google Scholar]

- 10.Hobbie EK, Fry DJ. Rheology of concentrated carbon nanotube suspensions. J Chem Phys. 2007;126:124907–124913. doi: 10.1063/1.2711176. [DOI] [PubMed] [Google Scholar]

- 11.Hobbie EK, Fry DJ. Nonequilibrium phase diagram of sticky nanotube suspensions. Phys Rev Lett. 2006;97:036107–036110. doi: 10.1103/PhysRevLett.97.036101. [DOI] [PubMed] [Google Scholar]

- 12.Trappe V, Prasad V, Cipelleti L, Segre PN, Weitz DA. Jamming phase diagram for attractive particles. Nature. 2001;411:772–775. doi: 10.1038/35081021. [DOI] [PubMed] [Google Scholar]

- 13.Negi AS, Osuji CO. New insights on fumed colloidal rheology-shear thickening and vorticity-aligned structures in flocculating dispersions. Rheol Acta. 2009;48:871–881. [Google Scholar]

- 14.Otsubo Y, Fujiwara M, Kouno M, Edamura K. Shear thickening flow of suspensions of carbon nanofibers in aqueous PVA solutions. Rheol Acta. 2007;46:905–912. [Google Scholar]

- 15.Kinloch IA, Roberts SA, Windle AH. A rheological study of concentrated aqueous nanotube dispersions. Polymer. 2002;43:7483–7491. [Google Scholar]

- 16.Lootens D, Van Damme H, Hèbraud P. Giant stress fluctuations at jamming transition. Phys Rev Lett. 2003;90:178301–178304. doi: 10.1103/PhysRevLett.90.178301. [DOI] [PubMed] [Google Scholar]

- 17.Lemaître A, Roux J, Chevoir F. What do dry granular flows tell us about dense non-Brownian suspension rheology? Rheol Acta. 2009;48:925–942. [Google Scholar]

- 18.Miller B, OHern C, Behringer RP. Stress fluctuations for continuously sheared granular materials. Phys Rev Lett. 1996;77:3110–3113. doi: 10.1103/PhysRevLett.77.3110. [DOI] [PubMed] [Google Scholar]

- 19.Moller PCF, Fall A, Bonn D. Origin of apparent viscosity in yield stress fluids below yielding. Europhys Lett. 2009;87:38004–38009. [Google Scholar]

- 20.Holmes CB, Cates ME. Glass transitions and shear thickening suspension rheology. J Rheol. 2005;49:237–269. [Google Scholar]

- 21.Switzer LH, Klingenberg DJ. Rheology of sheared flexible fiber suspensions via fiber-level simulations. J Rheol. 2003;47:759–778. [Google Scholar]

- 22.Bertrand E, Bibette J, Schmitt V. From shear thickening to shear-induced jamming. Phys Rev E Stat Nonlin Soft Matter Phys. 2002;66:060401–060403. doi: 10.1103/PhysRevE.66.060401. [DOI] [PubMed] [Google Scholar]

- 23.Lin-Gibson S, Pathak JA, Grulke EA, Wang H, Hobbie EK. Elastic flow instability in nanotube suspensions. Phys Rev Lett. 2004;92:048302–048305. doi: 10.1103/PhysRevLett.92.048302. [DOI] [PubMed] [Google Scholar]

- 24.Schmid CF, Klingenberg DJ. Mechanical flocculation in flowing fiber suspensions. Phys Rev Lett. 2000;84:290–293. doi: 10.1103/PhysRevLett.84.290. [DOI] [PubMed] [Google Scholar]

- 25.Bonn D, Denn MM. Yield stress fluids slowly yield to analysis. Science. 2009;324:1401–1402. doi: 10.1126/science.1174217. [DOI] [PubMed] [Google Scholar]

- 26.Brown E, et al. Shear thickening in densely packed suspensions of spheres and rods confined to few layers. J Rheol. 2010;54:1023–1046. [Google Scholar]

- 27.O’Hern CJ, Langer SA, Liu AJ, Nagel SR. Force distributions near jamming and glass transitions. Phys Rev Lett. 2001;86:111–114. doi: 10.1103/PhysRevLett.86.111. [DOI] [PubMed] [Google Scholar]

- 28.Hartley RR, Behringer RP. Logarithmic rate dependence of force networks in sheared granular materials. Nature. 2003;421:928–931. doi: 10.1038/nature01394. [DOI] [PubMed] [Google Scholar]

- 29.Liu CH, Pine DJ. Shear-induced gelation and fracture in micellar solutions. Phys Rev Lett. 1996;77:2121–2124. doi: 10.1103/PhysRevLett.77.2121. [DOI] [PubMed] [Google Scholar]

- 30.Keller SL, Boltenhagen P, Pine DJ, Zasadzinski JA. Direct observation of shear-induced structures in wormlike micellar solutions by freeze-fracture electron microscopy. Phys Rev Lett. 1998;80:2725–2728. [Google Scholar]

- 31.Barentin C, Liu AJ. Shear thickening in dilute solutions of wormlike micelles. Europhys Lett. 2001;55:432–438. [Google Scholar]

- 32.Cates ME, Candau SJ. Ring driven shear thickening in worm-like micelles? Europhys Lett. 2001;55:887–893. [Google Scholar]

- 33.Cates ME, Haw MD, Holmes CB. Dilatancy, jamming, and the physics of granulation. J Phys Condens Matter. 2005;17:S2517–S2531. [Google Scholar]

- 34.Holmes CB, Fuchs M, Cates ME. Jamming transitions in a schematic model of suspension rheology. Europhys Lett. 2003;63:240–246. [Google Scholar]

- 35.Kharchenkoi SB, Douglasi JF, Obrutzi J, Grulke EA, Migleri KB. Flow-induced properties of nanotube-filled polymer materials. Nat Mater. 2004;3:564–568. doi: 10.1038/nmat1183. [DOI] [PubMed] [Google Scholar]

- 36.Xu J, Florkowski W, Gerhardt R, Moon K, Wong C. Shear modulated percolation in carbon nanotube composites. J Phys Chem B. 2006;110:12289–12292. doi: 10.1021/jp061090i. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.