1. Introduction

Coinage metals, such as Au, Ag, and Cu, have been important materials throughout history.1 While in ancient cultures they were admired primarily for their ability to reflect light, their applications have become far more sophisticated with our increased understanding and control of the atomic world. Today, these metals are widely used in electronics, catalysis, and as structural materials, but when they are fashioned into structures with nanometer-sized dimensions, they also become enablers for a completely different set of applications that involve light. These new applications go far beyond merely reflecting light, and have renewed our interest in maneuvering the interactions between metals and light in a field known as plasmonics.2–6

In plasmonics, the metal nanostructures can serve as antennas to convert light into localized electric fields (E-fields) or as waveguides to route light to desired locations with nanometer precision. These applications are made possible through a strong interaction between incident light and free electrons in the nanostructures. With a tight control over the nanostructures in terms of size and shape, light can be effectively manipulated and controlled with unprecedented accuracy.3,7 While many new technologies stand to be realized from plasmonics, with notable examples including superlenses,8 invisible cloaks,9 and quantum computing,10,11 conventional technologies like microprocessors and photovoltaic devices could also be made significantly faster and more efficient with the integration of plasmonic nanostructures.12–15 Of the metals, Ag has probably played the most important role in the development of plasmonics, and its unique properties make it well-suited for most of the next-generation plasmonic technologies.16–18

1.1. What is Plasmonics?

Plasmonics is related to the localization, guiding, and manipulation of electromagnetic waves beyond the diffraction limit and down to the nanometer length scale.4,6 The key component of plasmonics is a metal, because it supports surface plasmon polariton modes (indicated as surface plasmons or SPs throughout this review), which are electromagnetic waves coupled to the collective oscillations of free electrons in the metal.

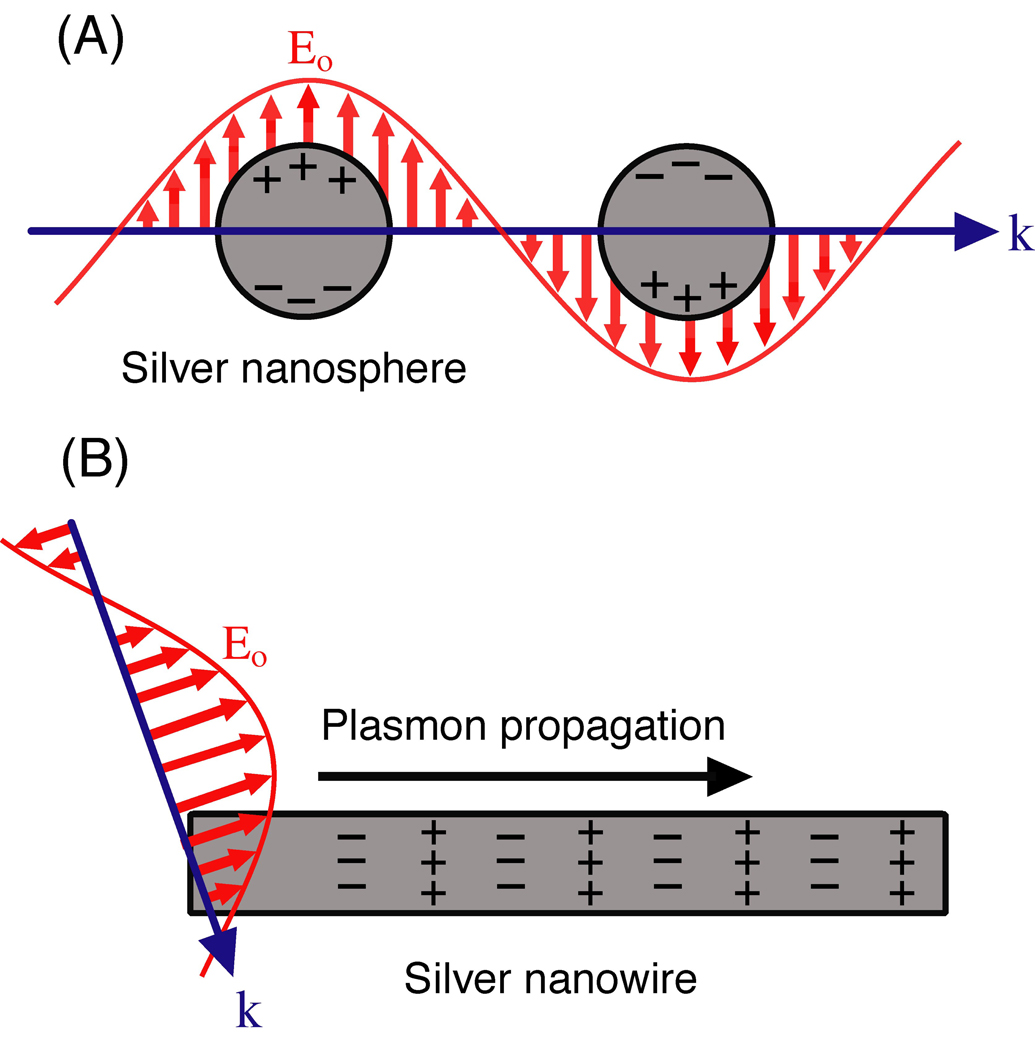

While there are a rich variety of plasmonic metal nanostructures, they can be differentiated based on the plasmonic modes they support: localized surface plasmons (LSPs) or propagating surface plasmons (PSPs).5,19 In LSPs, the time-varying electric field associated with the light (Eo) exerts a force on the gas of negatively charged electrons in the conduction band of the metal and drives them to oscillate collectively. At a certain excitation frequency (w), this oscillation will be in resonance with the incident light, resulting in a strong oscillation of the surface electrons, commonly known as a localized surface plasmon resonance (LSPR) mode.20 This phenomenon is illustrated in Figure 1A. Structures that support LSPRs experience a uniform Eo when excited by light as their dimensions are much smaller than the wavelength of the light.

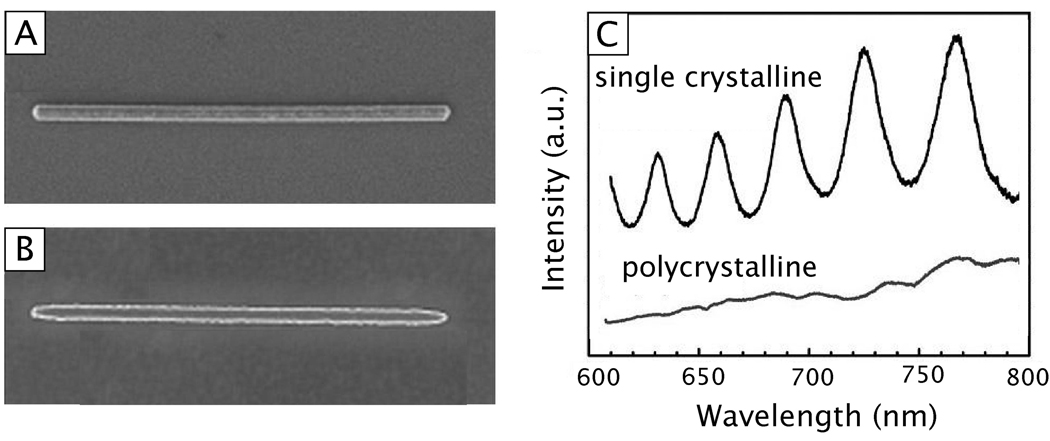

Figure 1.

Schematic illustration of the two types of plasmonic nanostructures discussed in this article as excited by the electric field (Eo) of incident light with wavevector (k). In (A) the nanostructure is smaller than the wavelength of light and the free electrons can be displaced from the lattice of positive ions (consisting of nuclei and core electrons) and collectively oscillate in resonance with the light. This is known as a localized surface plasmon resonance (LSPR). In (B) the nanostructure has one dimension much larger than the wavelength of light. In this case, light coupled to the nanostructure will excite the free electrons to create a propagating surface plasmon (PSP) that can travel along the surface of the metal nanostructure.

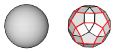

In contrast, PSPs are supported by structures that have at least one dimension that approaches the excitation wavelength, as shown in Figure 1B.4 In this case, the Eo is not uniform across the structure and other effects must be considered. In such a structure, like a nanowire for example, SPs propagate back and forth between the ends of the structure. This can be described as a Fabry-Perot resonator with resonance condition l=nλsp, where l is the length of the nanowire, n is an integer, and λsp is the wavelength of the PSP mode.21,22 Reflection from the ends of the structure must also be considered, which can change the phase and resonant length. Propagation lengths can be in the tens of micrometers (for nanowires) and the PSP waves can be manipulated by controlling the geometrical parameters of the structure.23

1.2. Plasmonics in Nanoscience and Nanotechnology

In the past the ability to focus light was solely in the realm of dielectric materials. These materials, however, cannot localize light to areas smaller than half a wavelength of light (λ/2) or confine electromagnetic modes to volumes less than (λ/2)3. In contrast, surface plasmon modes are primarily limited by the size of the plasmonic structure that supports them: a nanostructure can thereby focus and guide light down to the nanometer regime. By tailoring the size, shape, and environment of a metal nanostructure, light can be manipulated in many unique ways.24,25 It is no surprise that recent advances in the preparation and assembly of metal nanostructures have opened new doors to precise manipulation/control of light, and consequently to applications that were previously considered impossible.2

As an optical phenomenon, SP has been known for more than 150 years, with the first demonstration being documented by Michael Faraday in 1857.26 Its connection with nanoscale science and technology was not widely or actively explored until recently.27 Plasmonics is part of nanotechnology because nanostructures are used i) as active components to focus, guide, and manipulate light, and ii) as building blocks for larger, more complex “metamaterials” sought for controlling light. While the interaction of light and metal nanoparticles has long attracted interest of scientists, plasmonics represents a relatively new level of control and study involving both nanostructures and light. In contrast to simply establishing the valuable optical properties of metal nanostructures, this interaction is now controlled for a specific purpose to manipulate the propagation of light. Plasmonics is also a burgeoning field of nanoscience because sophisticated models, theories, and methods are being developed to understand the interaction between a metal nanostructure and light.3,7

Plasmonics is also different from many past applications and studies of nanoparticles that rely on the material properties of the nanostructure or its small size. These non-plasmonic applications include, for example, electron confinement,28 electron tunneling,29 ballistic transport,30 and superparamagnetism.31 In contrast to these applications, plasmonics requires a coupling between an electromagnetic wave and the metal nanostructure to generate a surface plasmon. Without incident light, the structure does not have a plasmonic function. More importantly, plasmonics is unique in that it can use nanostructures of many different sizes (tens to hundreds of nanometers) and thus bridge the gap between the micrometer and nanometer levels. This is best seen in the example of Ag nanowires, which can guide light at deep-subwavelength scales over micrometer distances.23 Plasmonics is therefore a new subfield of nanoscale science and technology that aims to understand and control light using metal nanostructures in novel ways.

1.3. What is Unique about Silver?

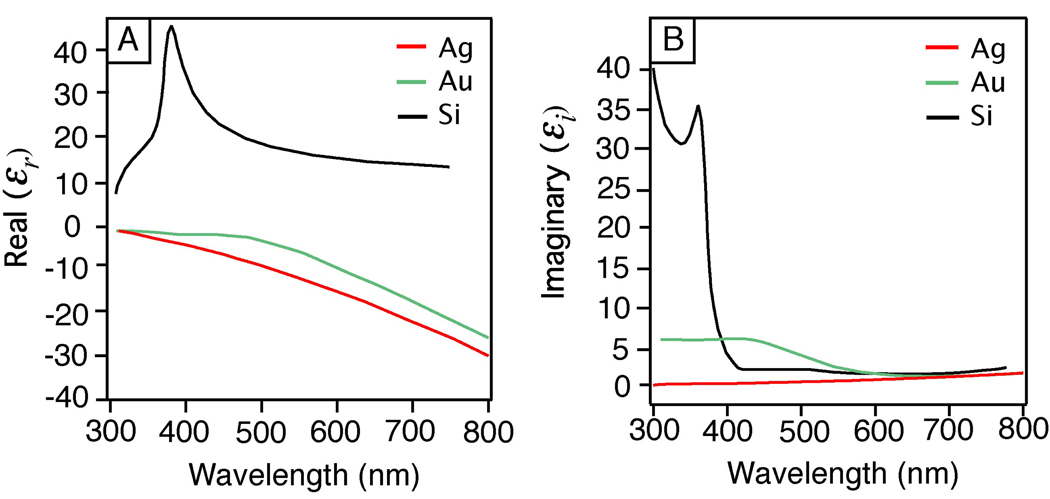

Silver is probably the most important material in plasmonics. It offers many advantages over Au, Cu, Li, and Al – other metals known to support SPs in the visible (vis) and near-infrared regions (NIR).16,32 In terms of plasmonics, it is important to choose a metal that can support a strong SP at the desired resonance wavelength.5,33 Silver is able to do so across the spectrum from 300 to 1200 nm. The ability of a metal nanoparticle to support an SP is dependent on its dielectric function ε, which includes real part (εr) and imaginary part (εi) and both vary with excitation wavelength (λ). The dielectric function of a material reflects the unique interaction between its electrons and the light.

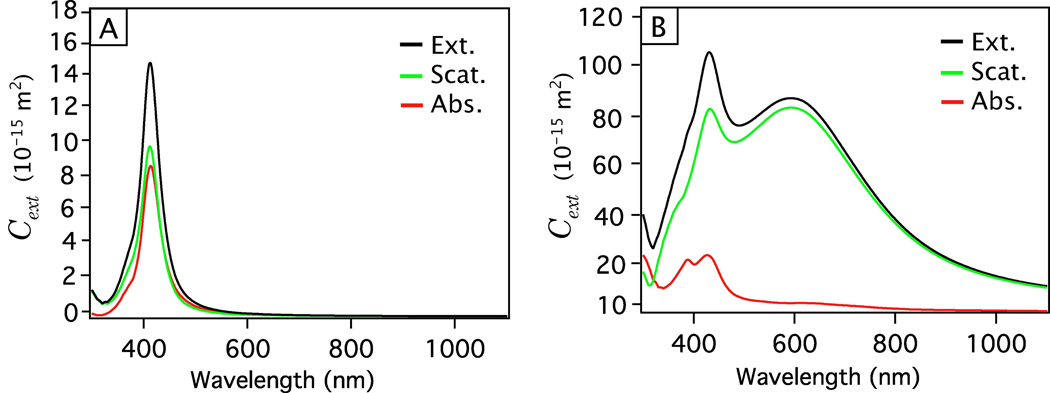

The simplest way to describe LSPR can be found in Mie theory for calculating the extinction (absorption + scattering) cross section of a metal nanosphere:34

| (1) |

where Cext is the extinction cross section, R is the radius, and εm is the relative dielectric constant of the medium surrounding the nanosphere. This equation shows that the interaction between a metal nanoparticle and light depends strongly on its dielectric properties (εr and εi). While other factors are also important, from an engineering perspective the material properties of the plasmonic structure are the key, as the environment and other parameters (like excitation wavelength) are often fixed. When the denominator of the bracketed expression in Equation (1) approaches zero, Cext will become extremely large and the optical absorption and scattering at this particular frequency would also be exceedingly strong. This is known as a resonance condition. In order to achieve this, εr must be close to −2εm, which is not possible for standard dielectrics and non-metals that typically have εr values between 1 and 50.35 Figure 2 plots εr and εi for Ag, Au and Si, showing that Si has large positive values for εr, similar to other non-metal materials. Equation (1) also indicates that εi should be close to zero in order to support a strong resonance, a condition that can only be satisfied by some of the metals.36 In general, no LSP or PSP sufficiently strong for plasmonic applications can be formed without a negative εr, and large εi values mean a lossier or weaker plasmon. The SP strength (or damping) can be described using the quality factor (Q):32

| (2) |

Figure 2.

A plot of the (A) real, εr, and (B) imaginary, εi, components of the dielectric function of Ag, Au, and Si as a function of wavelength.

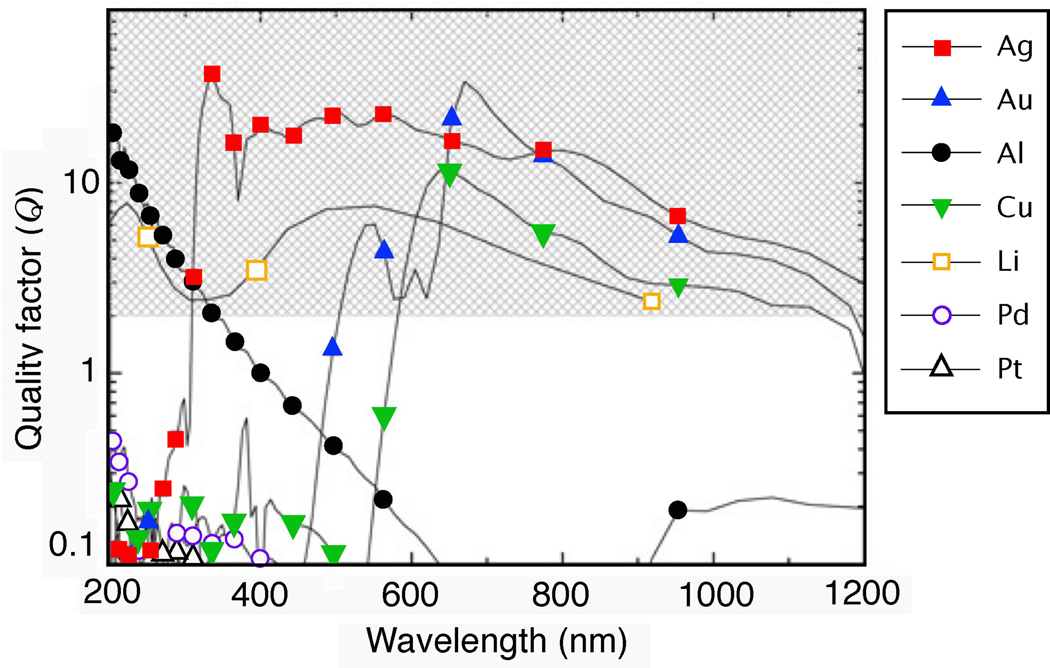

The SP strength is directly proportional to Q, and large values of Q mean strong plasmons (both LSPs and PSPs) and small values indicate a lossy or weak SP with a a small Cext. In general, Q should be larger than ~10 for most plasmonic applications. The quality factors for a number of metals are plotted in Figure 3. Obviously, Ag has the largest quality factor across most of the spectrum from 300 to 1200 nm. In contrast, Al is only suitable for applications in the ultraviolet (UV) region. Interband transitions, where electrons are excited from the conduction band to higher energy levels, also play an important role in dampening the SP modes.37 Typically, these transitions take place at much higher frequencies than the LSPRs, as in the case of Ag. For Au and Cu, however, these transitions limit their LSPR excitation to wavelengths longer than 500 and 600 nm, respectively.38

Figure 3.

The quality factor (Q) of the LSPR for a metal/air interface. A higher Q denotes less damping and a stronger plasmon resonance. The shaded area represents the region of interest to many plasmonic applications. Reproduced with permission from [32]. Copyright 2009 Elsevier.

In practical applications, the material properties of metals may out-weigh their differences in plasmonic properties. Based on the quality factor, Li should be a candidate as good as Au and Cu in supporting surface plasmons. However, this metal is so reactive and hard to handle that it is seldom considered and explored for plasmonic applications. Historically, Ag has been known for its widespread use in photography and staining of biological tissues due to the black color associated with the large aggregates of Ag nanoparticles.39 Silver also has the highest electrical and thermal conductivity among all metals, making it an ideal component for electrical interconnection. When exposed to air, Ag is not oxidized, but forms a silver sulfide film on its surface, which should be more or less transparent to the visible light.40,41 This thin film of silver sulfide can form in one day and, over a month, can become 60 Å in thickness for thin films of silver. It is worth pointing out that the black coating commonly observed on the surface of silverware is due to sulfuration with the sulfur in air,42 not oxidation.

As a disadvantage, Ag nanostructures (or more appropriately, Ag+ ions coming off from the nanostructures) are considered to be toxic, although passivating the surface can greatly increase their stability and thus attenuate or eliminate their toxicity.43 Instability and toxicity are also two major concerns for Cu, especially for the nanoscale structures. In contrast, Au is well-known for its bio-inertness, and its surface is believed to be oxide free. For these reasons, Au nanostructures are well-suited for in vivo applications with humans.44 In contrast, Ag nanostructures are largely used in plasmonic applications outside a human body (e.g., plasmonic antennas and circuits for concentrating and guiding light), where they have consistently reported much better performance than Au-based nanostructures.45–48

The difficulty of fabricating nanostructures, and thier cost, will also determine the usefulness of a metal for plasmonic applications, especially for large-scale applications. As shown in Table 1, the cost varies dramatically across the metals from ~$1,207 (per ounce) for Pt to ~$0.049 for Al. Silver is relatively cheap (~$13.4) among the metals that support plasmons. While both Al and Cu are cheaper, they have limitation in terms of the plasmons they can support, as discussed above. More importantly is the precedent and ease with which these metals can be prepared as nanostructures with controllable sizes and shapes. Over the past decade, Au, Ag, and Pd have all been prepared in a large variety of nanostructures using chemical methods.49 Taking into account the unsuitability of Pd for plasmonic applications, Au and Ag are the most promising, and indeed the most widely used materials in plasmonics. Gold is, however, almost 50 times more expensive than Ag is. While the application and scale of production will ultimately decide which metal is the best, Ag compared with the other metals is unique for its excellent qualities in terms of plasmonic ability, available nanostructures, and material cost.

Table 1.

Comparison of the suitability of different metals for plasmonic applications.

| Metal | Plasmonic Ability | Stability | Nanostructure Formation |

Cost (per ounce) |

|---|---|---|---|---|

| Aluminum (Al) | Good in UV region | Stable after surface passivation | Very few nanostructures; used in lithographic patterning | $0.049 |

| Copper (Cu) | Interband transisitons below 600 nm | Easy oxidation | Very few nanostructures | $14.8 |

| Gold (Au) | Interband transistions below 500nm; High quality factor | Very stable; biocompatible | Many nanostructures | $950 |

| Palladium (Pd) | Low quality factor; Not suitable for plasmonics | Stable | Many nanostructures | $265 |

| Platinum (Pt) | Low quality factor; Not suitable for plasmonics | Stable | Many nanostructures | $1,207 |

| Silver (Ag) | Highest in quality factor | Oxidation; biocompatibilty issues | Many nanostructures | $13.4 |

1.4. Scope and Organization of the Review

This review discusses a variety of Ag nanostructures prepared via solution-phase methods, with a minimal discussion of lithographic approaches in the context of their use in fabricating plasmonic nanostructures. It mainly focuses on both LSPRs and PSPs on nanostructures (not thin films). This review also discusses how engineering the physical properties (size, shape, etc), environment, and assembly of Ag nanostructures can affect their ability to support SPs and their potential for plasmonic applications. It emphasizes advancements made over the past five years (2004–2009), and while examples specific to Ag nanostructures are highlighted, fundamental studies using Au nanostructures are also cited for comparison or completeness. The objectives of this review are: i) to review the chemical methods used for generating Ag nanostructures; ii) to illustrate how light can be controlled by Ag nanostructures through SP coupling; iii) to discuss the limits and unknown variables associated with understanding and control of SPs with Ag nanostructures and; iv) to sketch some of the interesting applications and research directions involving Ag nanostructures.

2. Preparation of Silver Nanostructures

2.1. Chemical Synthesis

The size and shape of nanostructures define and control their unique plasmonic properties. The ability to make Ag nanostructures with well-controlled morphologies makes it possible to study the plasmonic phenomenon discussed in Section 4. At present, a wealth of methods are available for generating Ag nanostructures with different sizes and shapes.50–52 Table 2 provides an overview of the many structures that have been synthesized in the solution phase. Here, we will focus our discussion on synthetic approaches that primarily use chemical reduction to generate elemental Ag from a precursor and consequently generate Ag nanostructures. When a Ag precursor is mixed with a reducing agent and a colloidal stabilizer under appropriate conditions, we are able to generate Ag nanostructures with different sizes and shapes. In past studies, AgNO3 was the most commonly used precursor but our most recent work demonstrates that CF3COOAg may be a better choice because it has a lower reaction temperature, it eliminates NO2 dervided from the decompostion of NO3−, it is insensitive to trace impurities from the solvent (ethylene glycol), and it allows the reaction to be scaled up.53 Chemical reducing agents, such as sodium borohydride, alcohols, and sodium citrate, are typically used to reduce the dissolved Ag+ ions to Ag atoms which grow into small clusters and eventually nanostructures.54–56 Polymers and surfactants are used to stabilize the nanostructures during and after formation, and in some cases, they can also play the role to direct particle growth to the desired shapes.

Table 2.

A summary of the shapes, LSPR absorption peaks, demonstrated applications, and methods for synthesis of Ag nanostructures discussed in this review.

The red lines in the illustration refer to a crystalline plane and the dark faces are {100} and the light faces are {111}.

| Shape | Illustration | LSRBa | Applicationsb | Method of Synthesis | Ref# |

|---|---|---|---|---|---|

| Sphere and quasi-sphere |  |

320 – 450 | SERS; LSPR sensing assembly | Polyol process (single-crystal); Citrate reduction (quasi-sphere) | 58, 85, 94, 330, 358 |

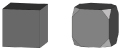

| Cube and truncated cube |  |

400 – 480 | SERS; LSPR sensing assembly | Polyol process; Seed-mediated growth | 53, 80, 96, 200, 214, 371 |

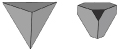

| Tetrahedron and truncated tetrahedron |  |

350 – 450 | SERS | Polyol process; Light-mediated growth | 113 |

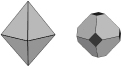

| Octahedron and truncated octahedron |  |

400 – 500 | Assembly | Polyol process; seed-mediated growth; light-mediated growth | 105, 334, 346, 364 |

| Bar | 350 – 900 | SERS | Polyol process | 93 | |

| Spheriod | 350 – 900 | SERS | Polyol process | 93, 529 | |

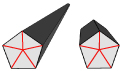

| Right bipyramid |  |

500 – 700 | - | Polyol process | 81, 112 |

| Beam | - | Electron transport | Polyol process | 73 | |

| Decahedron |  |

350 – 450 | - | Seed-mediated growth; light-mediated growth; citrate reduction | 101 |

| Wire and rod |  |

380 – 460 | Wave guiding electronics; SERS; assembly | Seed-mediated growth | 17, 47, 63, 83, 98, 99, 100, 222, 244, 256, 329, 357 |

| Polygonal plates and disc |  |

350 – 1000 | SERS; LSPR sensing | Light-mediated growth; polyol process | 18, 92, 111, 123, 126, 134, 183 |

| Branched structures |  |

400 – 1100 | SERS | Seed-mediated growth | 251 |

| Hollow structures |  |

380 – 800 | SERS; LSPR sensing | Template-directed growth | 131, 137, 146, 192, 262 |

The main absorption peak (nm).

Assembly means the nanostructure has been assembled into larger structures for plasmonic applications or studies.

2.1.1. Citrate Reduction

Lee and Meisel first reported the synthesis of Ag colloids by reducing AgNO3 with citrate in an aqueous solution in 1982.57 This method remains a popular approach to quickly generating Ag colloids as it does not require extensive synthetic skills.58–60 In a typical synthesis, Ag nanoparticles are obtained by adding a set amount of aqueous sodium citrate into a boiling aqueous solution of AgNO3 and waiting for 1 h before cooling down the system. In this process, the citrate ions serve as both a reducing agent and a stabilizer, and they may also complex with Ag+ ions or Ag2+ dimers in the early stages of the reaction.60 Unfortunately, this simple process tends to produce a large variety of sizes (20–600 nm) and a diversity of shapes (polyhedrons and plates) in a single reaction. While useful for studies of single nanoparticles, the products are not well-suited for studies involving the whole colloidal suspension as it would be very difficult to correlate an observation to specific properties of the Ag nanoparticles.58,59

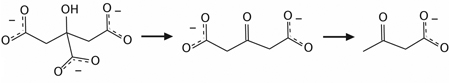

In fact, mechanistic study of the citrate reduction reaction is rare, though there have been a small number of studies. Previously, the oxidation and decomposition of citrate has been investigated with 1H-NMR for thermal and light-mediated methods (discussed in Section 2.1.5) and similar reaction pathways were observed.56,60,61 Typically, citrate is oxidized into acetonedicarboxylate, a transitory intermediate, which then decomposes rapidly into acetoacetate. Formate and/or CO2 are released as byproducts during the reactions:

|

(3) |

Beyond this fundamental study, a few shape-control approaches have been reported by changing the pH of the solution due to the different protonation states associated with citrate ion.60,61 To this end, it has been shown that the reduction rate, and consequently the particle morphology, depended on the pH of the solution. At pH=5.7, the reaction was slow (~2 hours) and the product was primarily triangular plates or polygonal particles, while at pH=11.1, the reaction was fast (a few minutes) and the product was a mixture of spherical and rod-like particles.62 Unfortunately, the overall quality and uniformity of the Ag nanoparticles made using this method were very poor. It has also been demonstrated that it is possible to direct the citrate synthesis to give a predominant product of wires by adding small amounts of NaOH to the synthesis.63 Moderate amounts of NaOH increased the pH from 5.5 to 6.5, which is just above the pKa3 of the citrate ion (6.4). The shape control was partially attributed to the fact that the citrate ions were primarily deprotonated and could coordinate to Ag+ ions more strongly, resulting in a higher quality product with fewer random aggregates. On the other hand, large amounts of NaOH resulted in a mixture of polydisperse particles, suggesting that the OH− ions might also interfere with binding directly if too much solution was added.

Today, the primary use of the citrate synthesis is in the light-mediated synthesis,56 and in preparing bulk quantities of Ag colloids for commercial applications. Further systematic investigations are necessary in order to obtain well-defined and uniform products.

2.1.2. Silver Mirror Reaction

Since the invention of silvered glass mirror by Justus von Liebig in 1835,64 the Ag mirror reaction has become a popular method for chemical deposition and mass production of Ag coatings on various types of substrates. In this reaction, AgNO3 is used as a precursor to form the Tollen’s reagent, Ag(NH3)2OH, which is subsequently reduced by a sugar (e.g., glucose) or an aldehyde compound to generate elemental Ag:

| (4) |

When the reaction is successful, it produces a shiny mirror. Because the reaction can quickly generate a shiny coating on the inner surface of a reaction container (e.g., a test tube), it serves as a popular demonstration of redox reactions and a detection method for aldehyde groups in classrooms.65

It is possible to perform the Ag mirror reaction with commercial silvering solutions under sonication to generate stable suspensions of quasi-spherical Ag nanoparticles with a relatively narrow size distribution.66 However, no shape control has been demonstrated with this technique, limiting its use in the synthesis of high-quality Ag nanostructures. Nevertheless, the Ag mirror reaction is still finding use in a number of niche applications, including the coating of large objects such as telescopes, the formulation of different types of Ag coating, and the fabrication of smooth micro- or nanostructured Ag surfaces.67,68 For example, the reaction has been adapted to prepare Au-Ag alloyed thin films for conventional SPR sensing, as well as smooth films of Ag for use with microcontact printing of alkanethiols.69 The morphology of these films is typically granular, and as a result, different microstructures and micropatterns, such as leaf or flower-like fractal structures, can also be created.70 It is also practical to use the Ag mirror reaction to coat a variety of micro- and nanoscale objects with small particles or continuous thin films of Ag, including fiber optic probes, silica beads, polymer capsules, and semiconductor particles for photocatalytic applications.71,72

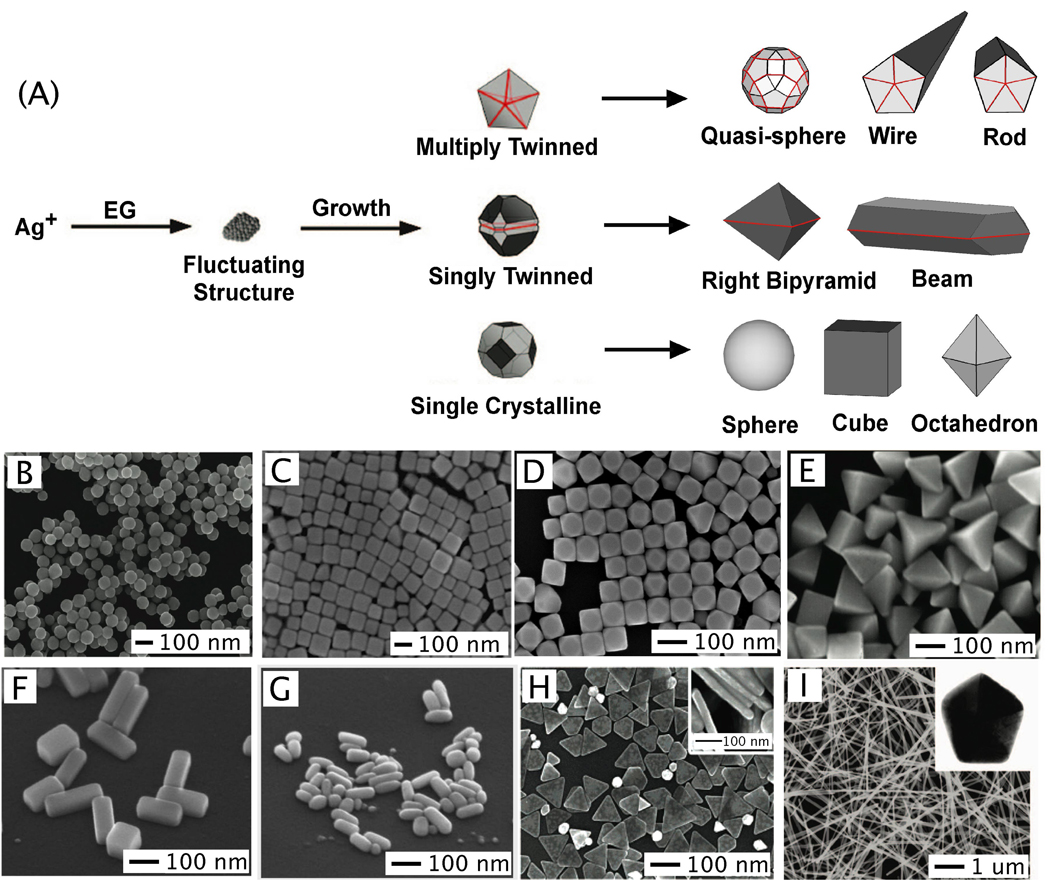

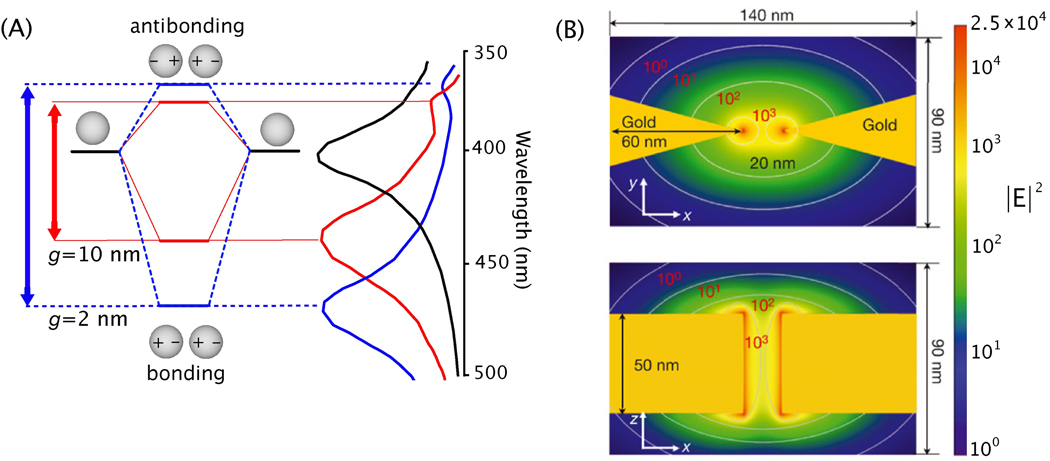

2.1.3. Polyol Process

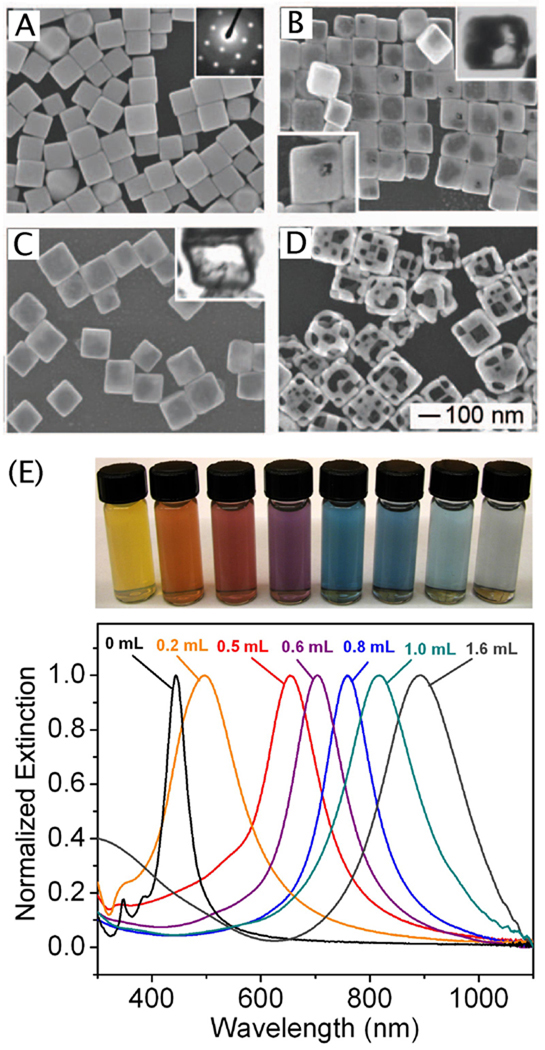

The polyol process represents a robust and versatile method for generating Ag nanostructures with a wide variety of sizes and shapes.16,49,51,73,74 By varying the reaction conditions, such as temperature, reagent concentration, and presence of trace ions, it is possible to achieve a high degree of control over both nucleation and growth and thus the final products. Figure 4 presents a number of morphologies that have been synthesized using this process, which will be discussed in greater detail below. In a typical synthesis, a polyol, such as ethylene glycol, 1,2-propylene glycol, or 1,5-pentanediol, serves as both a solvent and a reducing agent.16,50 A capping agent and a Ag precursor are injected into a pre-heated polyol, and the reduction of Ag+ ions results in the nucleation and growth of Ag nanostructures. By having a separate reductant and a capping agent, it is possible to have a tighter control over the reaction than is possible in the citrate-based synthesis. The details of the reduction mechanism have recently been studied for the system based on ethylene glycol.75 Although ethylene glycol alone can reduce a typical Ag precursor at an elevated temperature, upon closer investigation the primary reducing agent was found to be glycoaldehyde. This compound forms when ethylene glycol is heated in the presence of oxygen (typically from air). The relevant reaction is:

| (5) |

Glycoaldehyde, a stronger reductant than ethylene glycol, is considered to be responsible for the polyol reduction. To confirm the involvement of glycoaldehyde in the reaction, we developed a spectroscopic method to measure the amount of this intermediate compound by converting glycoaldehyde to glyoxal bis-2,4-dinitrophenylhydrazone, which strongly absorbs light at 570 nm. When oxygen- or air-saturated ethylene glycol was heated at 150 °C for 1 h, a clear peak developed at this wavelength. When argon-saturated ethylene glycol was tested, however, no such a peak was observed. Additionally, the amount of glycoaldehyde present decreased slightly when AgNO3 was added, though the details of this reaction are complicated by the catalytic abilities of Ag nanoparticles.75 In comparison with the Ag mirror reaction, the polyol process uses a similar reduction scheme but proceeds with a much lower but stable level of reductant due to the fact that glycoaldehyde is consumed immediately after its formation.

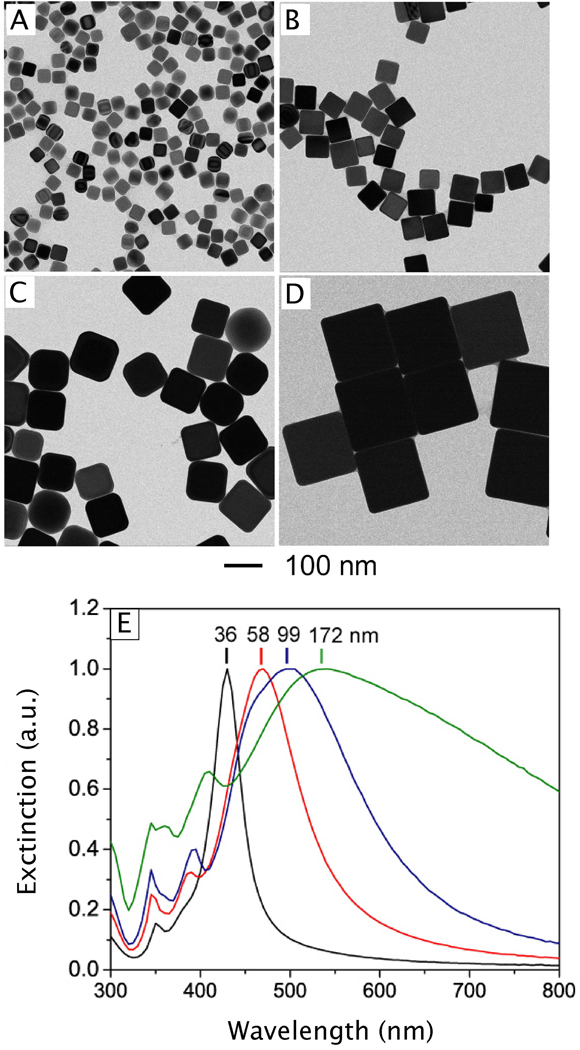

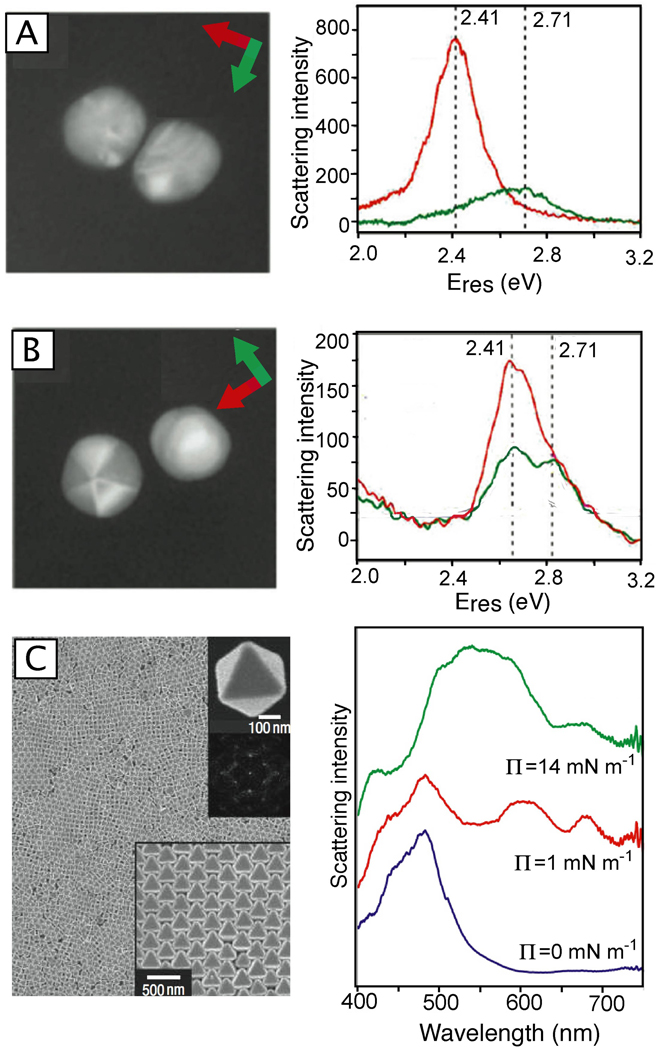

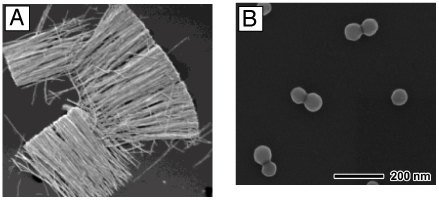

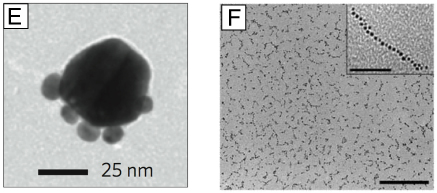

Figure 4.

The polyol method for synthesizing Ag nanostructures. In (A) the reduction of Ag+ ions by ethylene glycol (EG) leads to the formation of nuclei which are highly volatile. As the nuclei grow, fluctuations cease and their structure becomes static and contains multiply twinned boundary defects, single twinned boundary defects, or single crystalline with no boundary defects. These seeds are then grown into different nanostructures like (B) spheres, (C) cubes, (D) truncated cubes, (E) right bipryamids, (F) bars, (G) spheroids, (H) triangular plates, (I) and wires. The red lines in the illustration refer to a twin plane and the dark faces are {100} and the light faces are {111}. (A, C–G, H, I) Reproduced with permission from [16]. Copyright 2007 ACS. (B) Reproduced with permission from [95]. Copyright 2009 ACS.

The identification of glycoaldehyde as a reducing agent helps explain the strong temperature dependence of the polyol process. A temperature difference of less than 5 °C can determine the success or failure of a reaction, making precise temperature control critical for achieving good reproducibility. According to our spectroscopic study, the amount of glycoaldehyde increased significantly as the temperature for preheating ethylene glycol was increased from 140 to 160 °C. This sensitivity has a great impact on the reduction kinetics of a polyol system, and consequently the product morphology.

As the polyol process has been discussed in a number of recent reviews,16,49,76,77 here we only provide a brief account of the nucleation and growth mechanisms. At the initial stage of the reduction process, Ag atoms form small clusters of fluctuating structure. The ease at which the structure of such small clusters can change has also been demonstrated by HRTEM (high resolution transmission electron microscopy) imaging, where the structure was observed to change during exposure to an electron beam.78,79 As the Ag clusters grow larger, they become more stable and emerge to one of the three predominant structures: single crystalline, single twinned, and multiply twinned. Here, these larger clusters of Ag atoms are typically called seeds, from which they will ultimately grow into nanostructures with different shapes (Figure 4A).16 Typically, the single crystalline seeds will initially grow into cuboctahedrons with more or less a spherical profile. As additional atoms are added, the corners start to sharpen, resulting in the formation of nanocubes enclosed by {100} side faces.80 If single twin seeds are formed, the growth will lead to right bipyramids with a truncated and ultimately sharp morphology.81 In contrast, if multiply twinned seeds are formed, the growth will occur more rapidly at the twin defects of the seed, resulting in the formation of wires with a pentagonal cross section.50,82,82 As such, the most commonly observed shapes from polyol synthesis are cubes, right bipyramids, and pentagonal wires, although other morphologies are also possible with these seeds depending on the specific reaction conditions.

For the nanostructures discussed so far, their surfaces are capped primarily by {100} facets. This selectivity can be attributed to the preferential binding of poly(vinyl pyrrolidone) (PVP), a capping agent, to the Ag(100) surface.84 Most polyol syntheses of Ag nanostructures use PVP as a stabilizer because it has been shown to promote the growth of a variety of high-quality particle morphologies. The role of this polymer in shape control has been examined both in the synthesis of Ag nanowires via a polyol process,84 and in the seed-mediated overgrowth of Ag spheres in an aqueous system.85 As will be discussed in Section 2.1.4, when Ag cuboctahedrons enclosed by a mix of {100} and {111} facets were used as seeds for further Ag reduction with ascorbic acid, the final morphology depended on which capping agent was present in the solution. When citrate was used, {111}-capped octahedrons would be the primary product, while {100}-capped cubes would become the primary product when PVP was used instead.

Reducing AgNO3 in a polyol reaction in the presence of PVP will result in a mixture of the three morphologies described above: pentagonal wires, right bipyramids, and cubes. However, it has been demonstrated that it is possible to force the reaction to proceed along one of the three pathways shown in Figure 4A by controlling the type and amount of an oxidative etchant added into the reaction system. In general, single twinned and multiply twinned seeds are more susceptible to oxidative etching due to the greater number of defects in these structures. This is particularly true for multiply twinned seeds, due to the high strain intrinsic to the five-fold twinned structure. This structure is typically described as a combination of five tetrahedrons, each with an interior angle of 70.5°. When the tetrahedrons are assembled into a pentagonal structure, a gap of 7.5° will be left behind, creating an unstable structure with many distortions and defects that will be highly susceptible to etching.86,87 These defect sites may also play a role in the preferential growth of wires along the axial direction, as they will be more favorable sites for atom deposition.84

The amount of oxidative etchant in a system is typically controlled through the introduction of trace ions. Coordination ligands such as Cl− or Br− ions can be introduced and combined with the oxygen from air to provide enough etching to influence the relative proportions of different Ag seeds. Since Cl− is a stronger ligand than Br−, the Cl−/O2 pair will dissolve both multiply twinned and singly twinned seeds, leading to a final product of cubes.80 As Br− is slightly weaker, the Br−/O2 pair will only dissolve multiply twinned seeds, resulting in a product predominant by right bipyramids.81 Conversely, Fe2+/Fe3+ can reduce the extent of oxidative etching in a polyol synthesis of Ag nanostructures,83 promoting the growth of nanowires. Given that ethylene glycol is often stored in stainless steel vessels, Fe contamination is a common problem.88 As a general rule, it is critical to use high-purity solvents and reagents as the starting materials in a polyol reaction. Other compounds such as CuCl and CuCl2 have also been found to have the ability to promote wire growth through a similar mechanism.52

Other trace ions have also been shown to have strong influences on the polyol synthesis of Ag nanostructures. One ion that has proven exceptionally useful is sulfide (S2−) or hydrosulfide (HS−).89 This ion has been shown to dramatically increase the reduction rate of AgNO3 in the polyol system, making large-scale production of Ag nanocubes considerably easier. In this case, Ag2S nanocrystallites are thought to form immediately upon the introduction of AgNO3 due to the extremely low solubility of Ag2S, which can then serve as both catalyst and seeds for further growth in a polyol synthesis.69,90,91 Clearly, controlling the concentrations of trace ions plays one of the most important roles in determining the success of a synthesis.

Controlling the reduction kinetics is another approach to alter the yields of Ag nanostructures with different morphologies. In addition to temperature control, it is possible to control the rate of reduction by limiting the availability of Ag+ ions via addition of polyacrylamide to a typical polyol synthesis.92 The amine groups of polyacrylamide can coordinate to free Ag+ ions to slow down the reduction, enabling kinetic control of product morphology. In this case, stacking faults generated in the early stage of reduction can lead to the formation of thin plates instead of the thermodynamically more favorable products such as cuboctahedrons.

Interestingly, it is also possible to generate Ag nanostructures with novel shapes by slightly modifying the polyol reaction. For example, by increasing the amount of Br− added to a polyol reaction we were able to obtain Ag nanobars.93 Although the reaction could be affected by many factors, a plausible mechanism is that localized oxidative etching preferentially occurred on one side of the seed, leading to enhanced growth along one particular direction. Localized etching has also been implicated in the growth of an unusual structure lacking centrosymmetry: i.e., asymmetrically truncated octahedrons.94 Unlike a regular octahedron, three adjacent sharp points have been significantly truncated, creating a structure that is half truncated cube and half octahedron. In this synthesis, an additional aliquot of AgNO3 was added to a sulfide-mediated cube synthesis after the growth of the initial nanocubes was completed. Localized etching in a corner region was thought to activate the three adjacent faces of the nanocube for more rapid growth, leading to the nanostructure with a low symmetry. Additionally, controlled etching and aging can also be used to tune the sharpness of nanostructures created using the polyol method. For example, by aging Ag nanobars in a 5% PVP solution for one week at room temperature, it is possible to create Ag nanorice, as shown in Figure 4G.93 This approach has also been extended to make Ag nanospheres through truncation at corners and edges.95

Over the last couple of years, important advancements have been made in the synthesis of Ag nanocubes that make large scale, routine production considerably easier. First, our group found that the volume of this reaction could be scaled up ten times by introducing argon into the sulfide-mediated synthesis shortly before the injection of the reagents.96 This modification increases the production scale to 0.1g without any decrease in the quality of the products. Our group has also begun to explore the use of silver trifluoroacetate (CF3COOAg) as an alternative to the more commonly used AgNO3 precursor.53 With this new precursor, we are able to produce high-quality Ag nanocubes from 30–70 nm by adding PVP and trace amounts of NaHS and HCl to the polyol synthesis. This method has a number of advantages over other nanocube syntheses. While the speed of the sulfide-mediated reduction is generally a positive attribute, with AgNO3 the reaction typically took place in less than 10 min, to short to effectively monitor the reaction and quench it once a specific size of cube had been reached. With CF3COOAg, however, the reaction takes 20–60 min to complete and is robust enough to tolerate frequent sampling, allowing us to quench the synthesis at a specific, controllable size (as determined by UV-vis measurement of the LSPR peak position). Additionally, this reaction is less sensitive to variations in trace impurities (such as Fe), making it more robust and reproducible.

2.1.4. Seed-mediated Growth

Another synthetic approach that has become increasingly popular in recent years is the use of pre-formed nanocrystals as seeds for further growth. Unlike the methods discussed so far, the nucleation and growth steps are separated in this type of synthesis, allowing for a greater control over the final morphology.49 This method is highly versatile, and can be used to manipulate the size, aspect ratio, and shape of the resulting nanostructures.97–100 If the metal being deposited has the same crystal structure and lattice constant as the seed, the crystal structure of the seed will be transferred to the product via epitaxial overgrowth. Despite this, the final shape of the nanostructure can deviate from that of the initial seed as the crystal habit is also governed by the growth rates of different crystallographic facets, making this a versatile and interesting system.

There are two main categories of seed-mediated syntheses: homogeneous and heterogeneous growth. If the seed crystal is composed of the same metal as the atoms being deposited onto the surface, then this is a homoepitaxial process, e.g., the growth of Ag on Ag seeds. This approach has been exploited by several groups to achieve more precise control over the size and aspect ratio of Ag nanostructures. For example, our group recently demonstrated the synthesis of Ag nanocubes with edge lengths controllable in the range of 30–200 nm by employing spherical or cubic single crystalline seeds.97 The size of the resultant Ag nanocubes could be reliably controlled by any one of the following means: i) quenching the reaction once the LSPR peak had reached a specific position (as the position of the primary dipole peak is linearly related to the size); ii) varying the amount of AgNO3 mixed with a specific quantity of Ag seeds; and iii) varying the quantity of Ag seeds added into a solution containing a specific amount of AgNO3. Mechanistic studies indicated that oxidative etching also played an important role in this synthesis. When AgNO3 was used as the precursor, nitric acid was formed during the synthesis, which served as an oxidative etchant to block the homogeneous nucleation of Ag atoms and evolution of single crystalline seeds into twinned nanoparticles.

Successful size control has also been reported in the seed-mediated synthesis of Ag decahedrons. Pietrobon and Kitaev demonstrated a photochemical method to tune the size of Ag decahedrons via overgrowth on multiply twinned seeds.101 First, they produced a suspension of ~35 nm Ag decahedral particles by irradiating a precursor solution containing a mixture of AgNO3, sodium citrate, L-arginine, PVP, and NaBH4 with a 0.5 mW/cm2 metal halide lamp filtered to give wavelengths ranging from 380–510 nm. Controlled overgrowth into larger decahedrons could be achieved by combining the resulting seeds with additional precursor solution and exposing the mixture to 0.1–0.2 mW/cm2 unfiltered lamp (white light) for 20 h. By repeatedly performing this growth step, this technique could produce Ag decahedrons as large as 120 nm.101

Seeded growth is also a viable method for controlling the aspect ratio of rods and bars.98,99 Decahedrons (synthesized as described above) can serve as seeds in the synthesis of Ag nanorods with a pentagonal cross section. In this case, the decahedrons grew along the five-fold twinning axis into faceted, pentagonal nanorods through a kinetically-controlled pathway. The aspect ratio of the pentagonal nanorods could be controlled in the range of 1–12 through Ag deposition in an aqueous solution at 95 °C with citrate as the reducing agent, and the aspect ratio could be pushed even higher than 40 if an additional purification step was included between different growth stages.99 The diameter of these nanorods was found to match that of the seeds, while the lengths could be varied from 50 nm to 2 µm depending on the amount of Ag precursor added into the solution. Other seed-mediated growth methods for generating Ag nanorods and nanowires have also been reported. By using a micellar template comprised of cetyltrimethylammoniun bromide (CTAB), rounded Ag nanorods with a diameter of 10–15 nm and an aspect ratio of 2.5–15, as well as nanowires with a diameter of 12–18 nm with lengths in the range of 1–4 µm could be formed.98

Control over seed-mediated growth not only allows for manipulation of the size or aspect ratio of a nanostructure, but also provides a robust route to new shapes by maneuvering the growth rates of different crystallographic facets. Recent studies have revealed that the growth rates of specific facets in Ag nanostructures depend on the capping agent.85 In this demonstration, single crystalline Ag nanospheres were used as seeds for the growth of Ag in the presence of L-ascorbic acid (the reducing agent) and AgNO3. Introduction of citrate led to the formation of Ag octahedrons, while addition of PVP led to the growth of nanocubes/nanobars. Theoretical studies suggest that citrate binds more strongly to Ag(111) than Ag(100) surfaces at room temperature, which fits well with these experimental results.102 Due to stronger binding of citrate, the {111} facets are expected to grow more slowly than the {100} facets during seed-mediated growth when citrate ions are present. As a result, the {100} facets will disappear gradually while the {111} facets will become increasingly dominant on the surface, eventually leading to the formation of Ag octahedrons capped {111} facets. Conversely, PVP binds more strongly to the {100} than {111} facets of Ag, and can thereby reduce the growth rate along the <100> direction. This makes the {111} facets disappear more quickly than the {100} facets, resulting in the formation of nanocubes/nanobars capped by {100} facets. These results clearly demonstrate that one can control the shape of Ag nanostructures simply by adding a specific capping agent into a reaction system to take advantage of its different binding strengths with different facets. Adding a capping agent that has a stronger binding energy to a specific facet should result in a slower growth rate for this facet, and this facet will take up a larger proportion of the surface in the final product. Large (250–300 nm) Ag octahedrons have also been obtained in the overgrowth of truncated Ag cubes in a polyol reaction due to more rapid growth on the {100} facets.51 However, the origin of the facet selectivity in this reaction is unclear, as PVP was used as a capping agent, and may be related to kinetic factors.

In heteroepitaxial, seed-mediated growth, the seeds and added atoms are chemically different. Heteroepitaxy has long been used in gas-phase deposition to prepare functional heterostructures or junctions, but had not been extended to the solution phase until recently.103,104 In this method, alloy, core-shell, and other complex nanostructures can evolve from the nucleation and growth of foreign seeds. Similarly to homoepitaxial methods, the growth can be forced into unique patterns by varying the types of reductant, precursor, and capping agent.105 As a prerequisite for heteroepitaxial growth, there must be a close match in lattice constant between the seed and the deposited metal (e.g., Au and Ag have a lattice mismatch of only 0.25%). Large differences in lattice constants can lead to non-epitaxial growth and unexpected structures with very different geometries from the original seeds.105,106

A number of different types of Au seeds have been used as templates for Ag deposition due to their similar lattice constants.107–109 For example, Au plates have been coated with Ag to create thicker, faceted plates (triangular bifrustums) with {111} facets on the surface and an average edge length of 150±20 nm. The thickness could be varied by adjusting the amount of Ag reduced onto the Au seeds.107 It is also possible to generate hybrid pentagonal rods with similar morphologies to the homogeneous Ag rods described above.109 Through the addition of AgNO3 and PVP to Au decahedral seeds hosted in ethylene glycol, nanorods with an estimated length of 194±17 nm and with a 76±9 nm diameter were demonstrated with distinct Au cores and Ag tips. In a different system, smaller Au nanorods of ~20 nm in diameter were coated with Ag in an aqueous system containing AgNO3, ascorbic acid, PVP, and CTAB. Instead of being deposited only at the tips of the Au rod, the Ag coated the entire rod on all sides, eventually developing into an octahedral morphology.106

When there is a large lattice mismatch between the seeding and the deposited metals, such as with Pt and Ag (4.15%), isotropic growth is unfavorable due to high strain energy. As a result, anisotropic growth ensues, giving rise to shapes not necessarily corresponding with the structure of the seed. For example, Pt nanocrystallites can be used as seeds for the growth of Ag nanowires.100 These wires grow through a heterogeneous nucleation process, evolving from 0D nanoparticles to 1D nanorods and nanowires. Solutions of PVP and AgNO3 were added dropwise to a suspension of small (~5 nm) seeds, and grew into wires through a combination of direct nucleation onto the seed particles and Ostwald ripening of small Ag particles that form in the early stages of the reaction.100 Interestingly, lattice mismatch has also been implicated in preferential deposition during the overgrowth process. When ZnO rods were grown on the surface of truncated Ag nanocubes, growth only occurred on the {111} facets of the seed cubes. This was attributed to the much closer match in lattice constant of the ZnO with the {111} facets than the {100} facets of the Ag nanocube.110

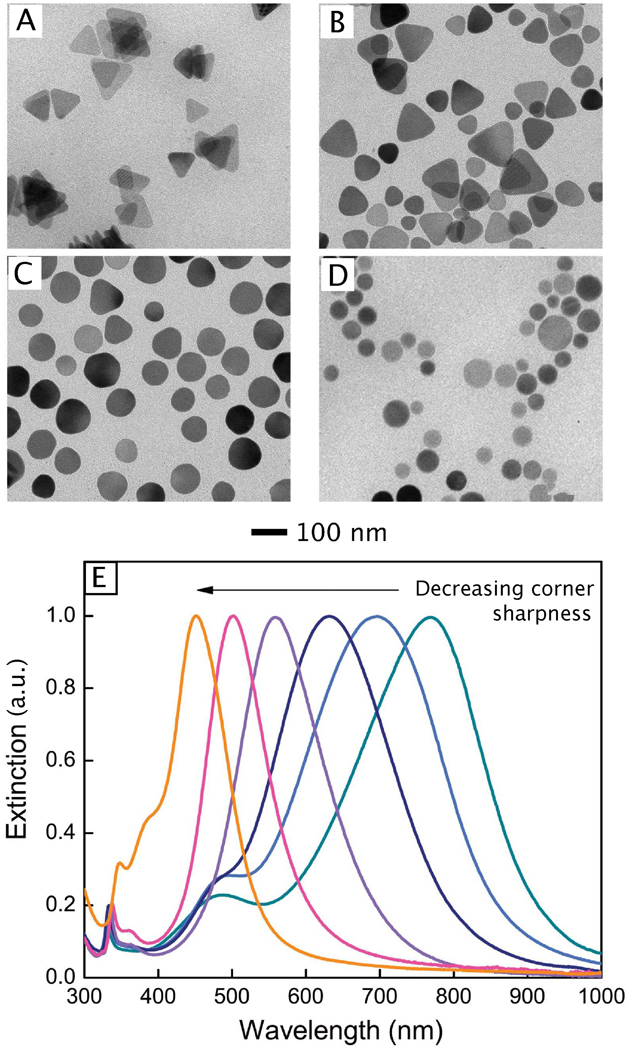

2.1.5. Light-mediated Synthesis

Silver has long been used in photography due to its interesting interactions with light.39 Recent demonstrations suggest that this photochemical approach could be used to produce high-quality Ag nanostructures including triangular plates (also known as prisms),111 decahedrons,101 right bipyramids,112 and tetrahedrons.113 It is anticipated that controlled laser irradiation of a sample of Ag colloids, in the presence of appropriate chemical species, could lead to a straightforward method for fabricating Ag nanostructures with well-defined and controllable shapes.114

Early studies showed that irradiating metal nanoparticles with an ultrafast laser can cause reshaping or fragmentation of metal nanoparticles due to photothermal melting.115 Ultrafast (femto- or nanosecond) laser pulses acting on a suspension of Au or Ag nanostructures can melt them from structured morphologies, such as nanowires, into rough spheres due to the low surface energy and thermodynamic stability of this shape.116–122 As a result of the heating, the atoms in the outer layer of the Ag structures diffuse around and subsequently form a spherical structure. Although photothermal melting provides a means to reshape a particle’s morphology, the products are typically polydisperse and this method is not very effective at generating well-defined nanostructures with different shapes.

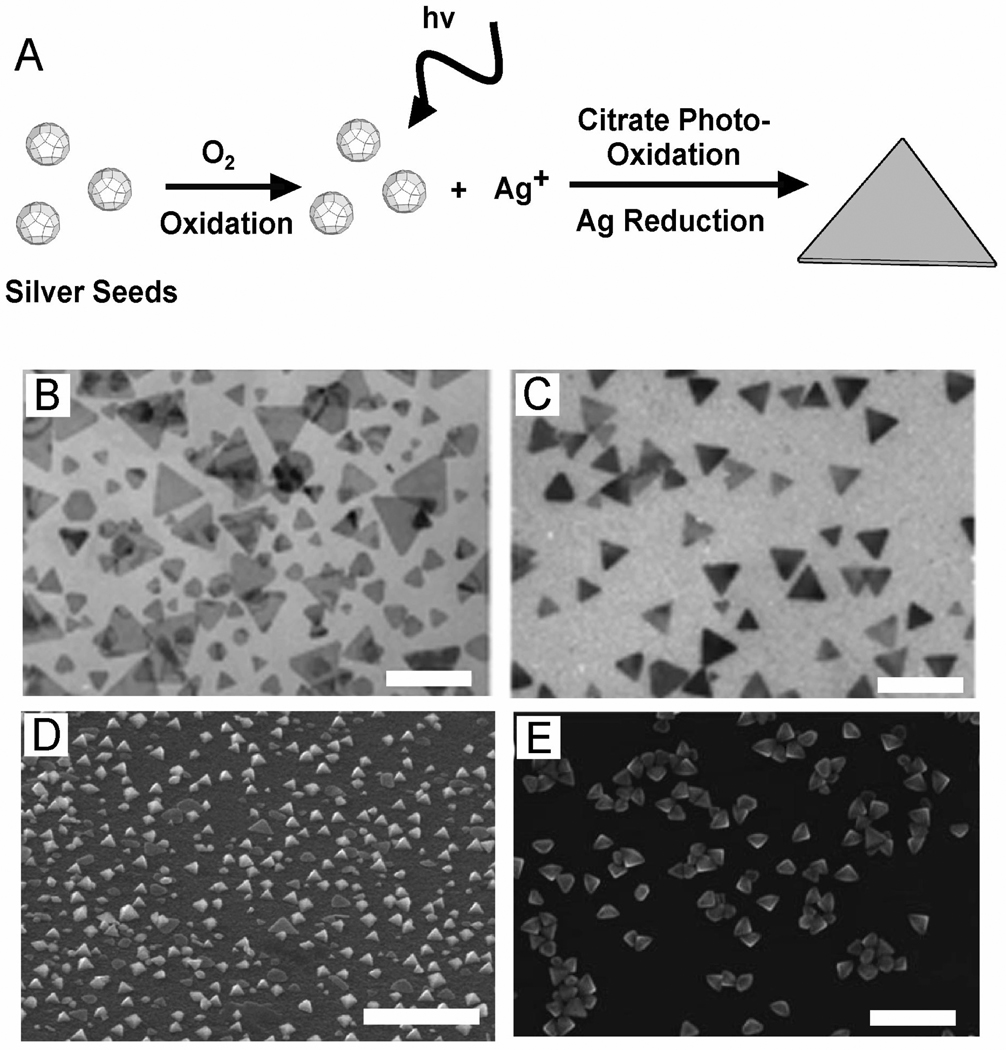

In contrast to simply melting nanoparticles, light excitation can also be used to grow or modify nanostructures in a controllable fashion, such as in the transformation of Ag nanospheres into Ag nanoplates.112,114,123–126 Recent mechanistic studies suggest that the reaction, in its most basic configuration, requires citrate, oxygen, and light as shown in Figure 5A. The proposed mechanism is as follows:56,124 First, LSPR excitation induces photo-oxidation in citrate molecules adsorbed on the surface of the nanostructure. Due to the rapid decarboxylation of the oxidized citrate product (shown in equation 3), this reaction is irreversible, and the resulting electrons are transferred into the Ag nanostructure. The resulting negative photovoltage on the Ag nanostructure increases the rate of Ag+ deposition on the surface.127 Oxidative etching can provide a source of Ag+ ions, though other compounds are sometimes added to increase the dissolution rate. Citrate may also play a shape-directing role, as similar morphologies were not observed when other carboxylate-containing molecules were used instead.56

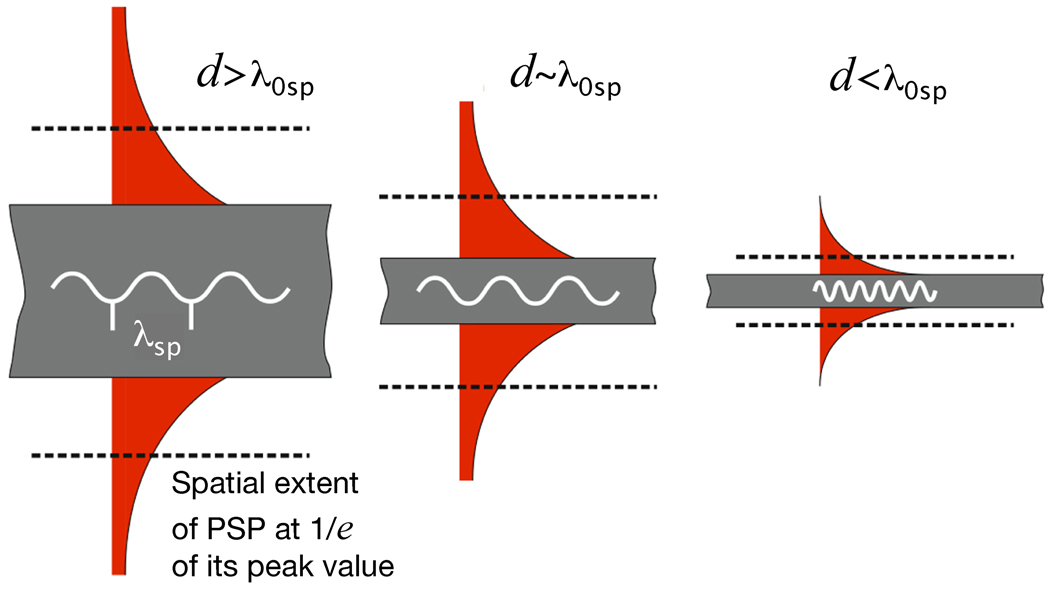

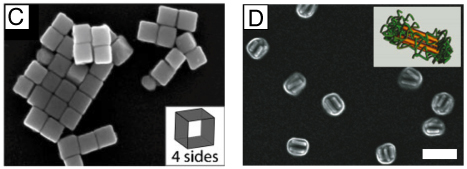

Figure 5.

(A) Schematic diagram of the proposed basic photoconversion mechanism of Ag nanocrystal seeds into triangular nanoplates. Oxidative etching of the seeds produced Ag+, which was then reduced on the seeds by citrate photo-oxidation and grown into nanoplates. Using single excitation two different sizes of nanoplates were synthesized as shown in (B). In (C) dual beam excitation produces only one size of nanoplates as the secondary beam could inhibit particle growth. The scale bar is 200 nm for (B, C). Other structures of Ag can also be synthesized via laser excitation including (D) tetrahedrons, scale bar 1 µm, and (E) right bipyramids, scale bar 100 nm. (B, C) Reproduced with permission from [111]. Copyright 2003 Nature. (D) Reproduced with permission from [101]. Copyright 2008 ACS. (E) Reproduced with permission from [112]. Copyright 2009 Wiley.

In these studies, the light is thought to excite LSPR modes of the nanoparticles, which in turn regulates their size and shape evolution.111,114,123,126 This dependence is attributed to the fact that the amount of citrate photo-oxidation depends on the strength of the plasmonic response of the Ag nanostructure to the irradiating light. While some experiments simply use a fluorescent light that excites at many wavelengths, other studies have used lasers with specific wavelengths to determine the role of the excitation wavelength. Generally, the longer the wavelength, the larger the size of the resulting plates, however a bimodal distribution of sizes was sometimes observed.111,125 It has been proposed that the morphologies observed in these studies was a result of the preferential growth of structures with the highest photovoltage (caused by the strongest plasmonic response, and consequently the greatest amount of photo-oxidation of citrate).56, 127

If a single excitation wavelength is used, particularly for visible and NIR wavelengths, the irradiating light can meet LSP resonance conditions for plates of different sizes, as plates often have multiple resonances. Laser excitation at 550 nm, for example, is resonant with both the quadrapole LSPR of 150 nm plates and the dipole plasmon of 70 nm in edge length disks. Thus two sizes can dominate for a single, fixed wavelength, as seen in Figure 5B. If two different irradiation wavelengths are used that are each resonant with a different LSPR peak of one discrete triangular plate size, then that size will likely have a higher photovoltage than other morphologies with only one resonant plasmon.56 In this situation, a single particle size should dominate, as seen in Figure 5C. Essentially, two excitation wavelengths allow for greater specificity in which particles will be excited. However, if the two resonances are not chosen carefully to excite one particular size, multiple sizes can also be observed. Other mechanisms have also been proposed, such as in early work by Mirkin and co-workers proposing edge-selective fusion growth of larger plates from small ones.111,125 The connection between excitation wavelength and particle size was also observed in these experiments. Additional studies of the mechanism underlying this particular synthesis will be very important to laser irradiation synthesis techniques.

More recently, synthetic methods involving laser excitation have gone beyond the fabrication of triangular plates to other nanostructures. To this end, tetrahedrons113 and right bipyramids112 have also been obtained via laser irradiation, as shown in Figure 5, D and E, respectively. These studies investigated the effect of not only the wavelength of the excitation source but also the chemical species present in the reaction. The capping agent, as in other synthesis methods, also plays an important role in shape control under laser irradiation. Laser-mediated synthesis continues to progress and with a more complete understanding of the mechanism of plasmon-assisted growth, this method may emerge as a highly tunable way for generating new, well-defined Ag nanostructures.

2.2. Template-directed Growth

Template-directed methods have been widely applied as a simple and versatile approach to the preparation of nanostructures since both the size and shape of the resulting structures can be defined by choosing an appropriate template.128,129 The templates can generally be divided into two types: soft templates and hard templates. Commonly used soft templates are micelles and reverse micelles, together called microemulsions. Such templates have been used to synthesize nanoparticles comprised of alloys, metal oxides, inorganic molecules, as well as noble metals like Ag.130 The surfactant molecules, containing amphiphilic groups, are oriented in such a way that the hydrophobic ends associate only with an organic solvent and the hydrophilic heads associate only with water, creating a well-defined structure such as a hollow sphere.131 The morphology of Ag nanostructures inside these templates will be affected by both the structure of the template, as well as trace ionic species and various reaction parameters, as we have discussed for other synthetic methods.

Micelle-based syntheses are capable of generating Ag nanostructures with many different shapes. So far, methods have been developed to generate nanoplates,132–136 hollow spheres,137 nanorods,98,138–140 nanowires,98,141,142 and dendrites or feather-like nanostructures.141,143 The morphologies of these nanostructures have a correlation with physiochemical properties of the microemulsions used in the synthesis. For example, it has been shown that an increase in the intermicellar exchange rate (Kex, the rate of exchange for the contents between microemulsion droplets) can cause a reduction in particle size, although there are exceptions.144,145 The surfactant molecules can also have a strong effect on the particle morphology. When a mixture of double hydrophilic block copolymers and sodium dodecylsulfate (SDS) was used, the morphology of the particles could be directed to be either rough nanowires, solid spheres with smooth surfaces, or hollow particles depending on the amount of SDS added.146 Other chemical species in the solution can also play a shape-directing role. In a reverse micellar solution, hydrazine was shown to induce a change to the spherical templates; forming nanoplates whose size could be controlled by varying the quantity of hydrazine added.132 These are just a few examples, but many other factors, such as the type of Ag precursor,147,148 temperature,149 reducing agent,98,141,143,150,151 concentration of Ag precursor,152 and reaction time,154 can all have a strong impact on the template-directed growth of Ag nanostructures.

Besides micelles and reverse micelles, other soft templates such as DNA, dendrimers, and peptides, can also be harnessed to direct the synthesis of Ag nanostructures. Generally speaking, the DNA-mediated synthesis of metal nanostructures is facilitated by the interactions of metal cations with DNA molecules. These bound ions can then be reduced to form structures that have a shape similar to that of the template.155,156 For example, such an approach has been explored by stretching DNA molecules between two electrodes and utilizing them as templates for the construction of Ag nanowires, which were conductive despite their granular appearance.157 Peptides can also be exploited as building blocks for the synthesis of uniform nanowires with a similar technique based on the reduction of Ag+ ions inside hollow, degradable peptide tubes.158 Other groups have also used DNA templates to produce chiral assemblies of small Ag clusters, though these clusters were often only a few atoms in size.155,159

Synthesizing Ag nanostructures with soft templates has a number of benefits. Firstly, these types of reactions can occur under mild conditions with greener reactants and solvents.150,160 Formation of a microreactor by surfactants also sterically inhibits aggregation, because it keeps the nucleation sites of nanoparticles well separated.145,148,161 However, many challenges still remain for this technique. For example, the final structures produced with this type of synthesis are almost always polycrystalline. Impurities contained in the microemulsions (e.g., Cl−) can also cause undesired anisotropic growth for Ag nanostructures.132 Of particular concern, uniform distributions of both the size and shape are still difficult to achieve for the nanostructures.

Hard templates, with more rigid structures, can also be used to provide a tight control over the dimensions of nanostructures. Porous anodic aluminum oxide (AAO) membranes are probably the most popular example. The advantages of AAO membranes are that they have nanometer-size channels (about 5 to 250 nm in diameter), high pore densities (up to 1011 pores/cm2), and controllable channel lengths (a few nanometers to hundreds of micrometers).162,163 Thus, they provide a means to synthesize uniform nanowires with a variety of sizes in high yields. By using hard templates such as AAO, it is also possible to create multi-component nanowires, with more complex geometries (e.g., stripes of different metals) than are currently possible with other synthetic approaches.164 However, with hard templates, the template must be removed after synthesis (typically with an etchant), and very few geometric shapes are available.

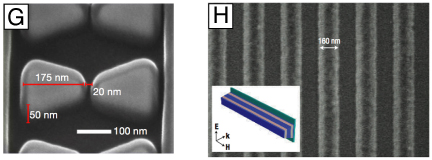

2.3. Lithographic Fabrication

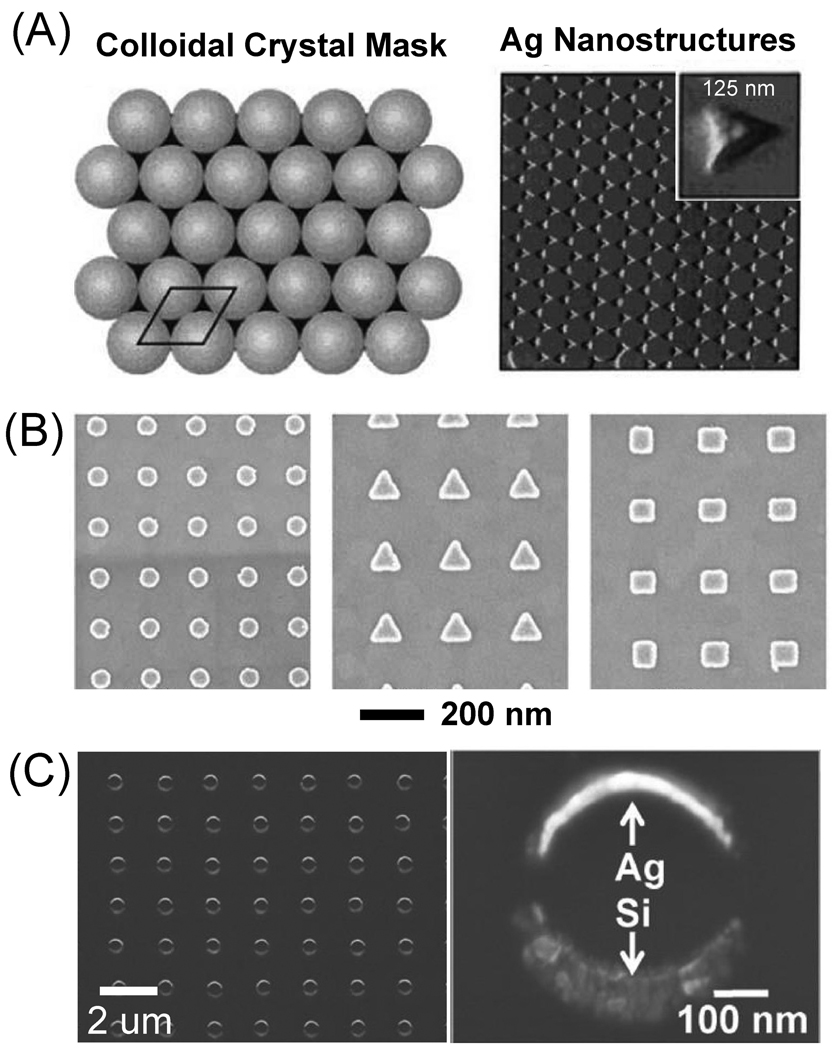

Unlike solution-phase syntheses, lithography, deposition, and other forms of nanofabrication offer precise control over the placement of Ag nanostructures and have been implemented widely.165 Conventional lithographic techniques such as electron beam lithography (EBL)166 or focused ion beam lithography (FIB)167 utilize polymeric resists to fabricate masks for deposition or etching of Ag with high resolution. In general, EBL and FIB are complex, expensive, and require highly specialized facilities. Consequently, non-conventional lithographic techniques have also been developed to save both time and cost. The most popular technique is probably nanosphere lithography (NSL)168 that involves the self-assembly of colloidal spheres into a hexagonally close-packed array on the surface of a substrate. Silver can then be deposited onto the substrate using the arrayed spheres as a mask, leaving behind triangular Ag islands after removal of the spheres (Figure 6A). Other fabrication techniques such as FIB milling169 and nanoskiving170 can also be used to fabricate arrays of metal nanostructures. In this section, we briefly discuss some of the different structures that can be created using these lithographic techniques.

Figure 6.

Lithographic nanofabrication for large-scale arrays of nanostructures. (A) Nanosphere lithography uses colloidal nanospheres crystallized on a substrate as a mask for metal deposition (left). After depositing metal to desired height, sonicating the substrate removes the nanospheres, leaving triangular islands in a regular array shown in the right AFM image. Reproduced with permission from [168]. Copyright 2001 ACS. (B) Electron beam lithography exposes a negative resist according to a predetermined pattern, here dots, triangles and squares (from left to right). After developing the resist, metal is deposited onto the substrate, and the remaining resist is lifted off, leaving arrays of metal nanoparticles. Reproduced with permission from [171]. Copyright 2008 Elsevier. (C) An array of counterfacing crescents of Ag and Si made with nanoskiving techniques. Reproduced with permission from [177]. Copyright 2010 ACS.

In traditional EBL, a focused electron beam is scanned over a substrate coated with a thin layer of resist, exposing specific regions according to a programmed pattern.165 The resist is made of a polymer that becomes either more or less soluble in a given solvent when exposed to the radiation. A common resist used in EBL is poly(methyl methacrylate) (PMMA) which, as a positive resist, breaks down when exposed to the electron beam. After removal of the exposed regions with a solvent, Ag can be deposited onto the substrate, usually by physical vapor deposition (PVD). The remaining PMMA is lifted off, taking metal not directly attached to the silicon surface with it, leaving behind an ordered array of Ag nanostructures patterned with high resolution, typically about 50 nm.169 EBL allows for a precise control over the structure and placement of Ag nanostructures, including the size, shape, and separation between them. It can generate a wide range of morphologies, including cylinders of various diameters and heights to more ellipsoidal, rectangular, or triangular shapes (Figure 6B).171 As a major drawback, EBL is a very time-consuming process, as the writing is a serial and typically slow process. In addition, the costs associated with the fabrication equipment, such as scanning electron microscopes, can be high. Another limitation is that while a variety of different shaped discs can be easily fabricated, controlling the nanostructures in the z-direction is somewhat limited, so spherical and other complex shapes are generally difficult to generate.

FIB is similar to EBL in that a highly focused beam of ions is used to form patterns on a substrate for the selective deposition or etching of metal. Gallium (Ga+) ions are typically used in FIB,172 and can be used to pattern a resist, similar to that of EBL, which can then be used as a mask for the deposition or etching of metal. However, FIB can also be used as a direct (i.e., maskless) physical patterning tool, through milling or FIB-induced deposition.169 Induced deposition is essentially a finely controlled chemical vapor deposition (CVD) process. First, a gaseous precursor is adsorbed on the substrate. When the ion beam is scanned across the surface, it decomposes the precursor, leaving behind the heavy component (metal atoms) on the substrate while the more volatile components escape away. Complex shapes can be formed in this way, including the possibility of structures with overhangs. In addition to FIB-CVD, FIB milling, or the removal of materials due to the bombardment of Ga+ ions, can be used to create very thin rectangular structures with a lateral resolution of tens of nm.167 The drawbacks of FIB are similar to EBL: high cost, time consuming, and patterning with only the possibility of fabricating disc-like structures.

NSL was developed by Fischer,173 and Deckman174 and later expanded by Van Duyne and others over the past twenty years.168,175 It is an inexpensive technique as compared to EBL and FIB. This simple method utilizes a suspension of monodisperse colloidal nanospheres, usually polystyrene, to serve as a mask. When the colloid is deposited on a substrate, capillary forces draw the nanospheres into a hexagonally close-packed monolayer as the water evaporates. Silver is then deposited onto the surface, forming a metal film over the particles as well as traveling through the interstitial voids to the substrate. The nanospheres are then removed by sonication. What remains is a regular pattern of triangular Ag nanoparticles. For shape control, a double layer of packed nanospheres can be induced by increasing the nanosphere concentration. After metal deposition and mask removal, the remaining Ag nanoparticles take a hexagonal shape. The size of the particles in both single layer and double layer nanosphere arrays are determined by the size of the nanospheres.168 In addition to triangular and hexagonal particles, other shapes such as nanorings and nanodiscs can be created by modifying the deposition scheme and angle.169

Nanoskiving is another lithography technique that was developed mainly by Whitesides and coworkers over the past decade as a simple and efficient method for fabricating arrays of metal nanostructures over large areas (cm2) with no (or limited) need for clean-room facilities.170,176,177 This technique takes advantage of the fact that an ultramicrotome, a readily available piece of equipment, can cut polymer blocks into slices as thin as 30 nm. In a simple version of this method, an epoxy layer (either smooth or patterned with relief features) is coated with Ag using standard methods such as PVD or CVD. Additional epoxy is then deposited on top to generate a solid epoxy block containing the ultrathin Ag film. After curing, this block is cut by an ultramicrotome along a direction unparallel to the Ag film, generating slabs of epoxy containing Ag nanostructures (nanowires or nanorods in this case) that can be positioned as desired. If necessary, oxygen plasma etching can be used to remove the epoxy, leaving behind a patterned array of Ag nanostructures.

As alluded to above, nanoskiving can be even more powerful when the initial Ag surface is patterned. By combining nanoskiving with soft lithography, for example, it is possible to create epoxy templates with arrays of micro- or nanoscale patterns.170 This pattern will be maintained after Ag deposition and in the final Ag nanostructures. The resulting patterned blocks can also be sliced along different directions to produce different types of nanostructures. For example, if the initial epoxy template is an array of square posts, cutting perpendicular to the surface will create a step pattern, while cutting parallel to the surface will create an array of square rings.177 This modification can be further combined with shadow deposition to generate even more complex structures.178 Figure 6C shows an array of circular structures where one half of the broken ring is made of Ag and the other half is made of Si. Each material was deposited at a 45° angle on opposite sides of the original epoxy template before the slicing process. Through simple modifications such as these, a wide variety of nanostructures have been demonstrated including L- and U-shaped structures, concentric circles, crescents, and even quasi-3D structures such as cross-bars by layering epoxy slabs. While many of these patterns were initially demonstrated with Au, this method can be easily generalized to Ag and other materials as well.177

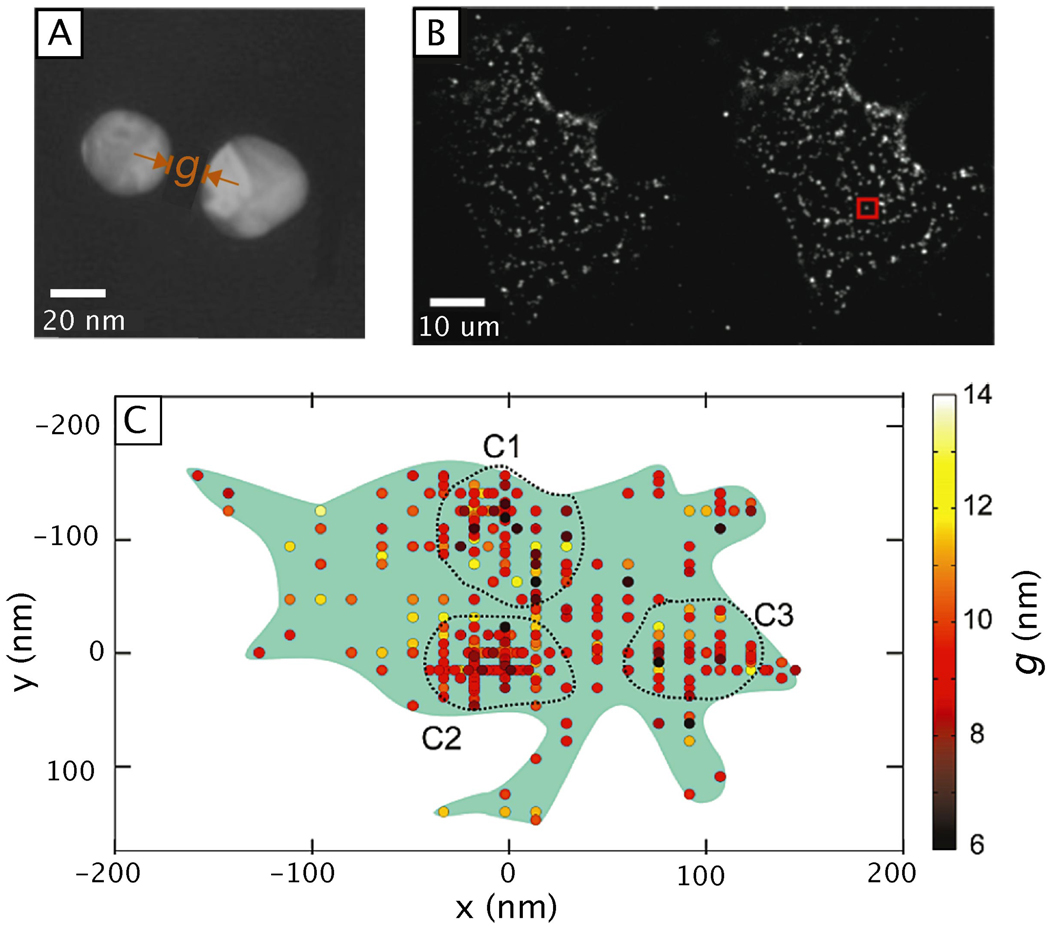

3. Characterization and Study of Surface Plasmons

Two of the primary aims of plasmonics are to understand and maneuver SPs at the nanoscale. Critical to these goals is an ability to fully characterize and model the plasmonic properties of metal nanostructures. In pursuit of this goal, a number of methods have been developed to detect and image both the far and near-field properties of plasmonic nanostructures.179,180 Some of these methods are based on traditional optical techniques, such as dark-field microscopy and UV-vis-NIR spectroscopy,33,179 while others use sophiscated new technologies to obtain extremely detailed information. Today, it is possible to detect plasmons and their associated fields by electric currents,181,182 electron beams,58,183–185 and surface-enhanced Raman scattering (SERS).186–188

Theoretical modeling represents another important approach to understanding the plasmonic properties of metal nanostructures. Theoretical models create greater understanding of the effect of experimental parameters on plasmonic properties, and have been used to describe plasmon hybridization,189 the substrate effect on plasmons,190,191 and structures composed of different kinds of nanoparticles.192,193 Furthermore, models can predict unique plasmonic responses of novel structures that are yet to be fabricated, motivating further synthetic work in these areas. In this section, we begin with discussion on a number of primary experimental techniques, followed by a brief introduction to analytical and numerical methods for modeling plasmons.

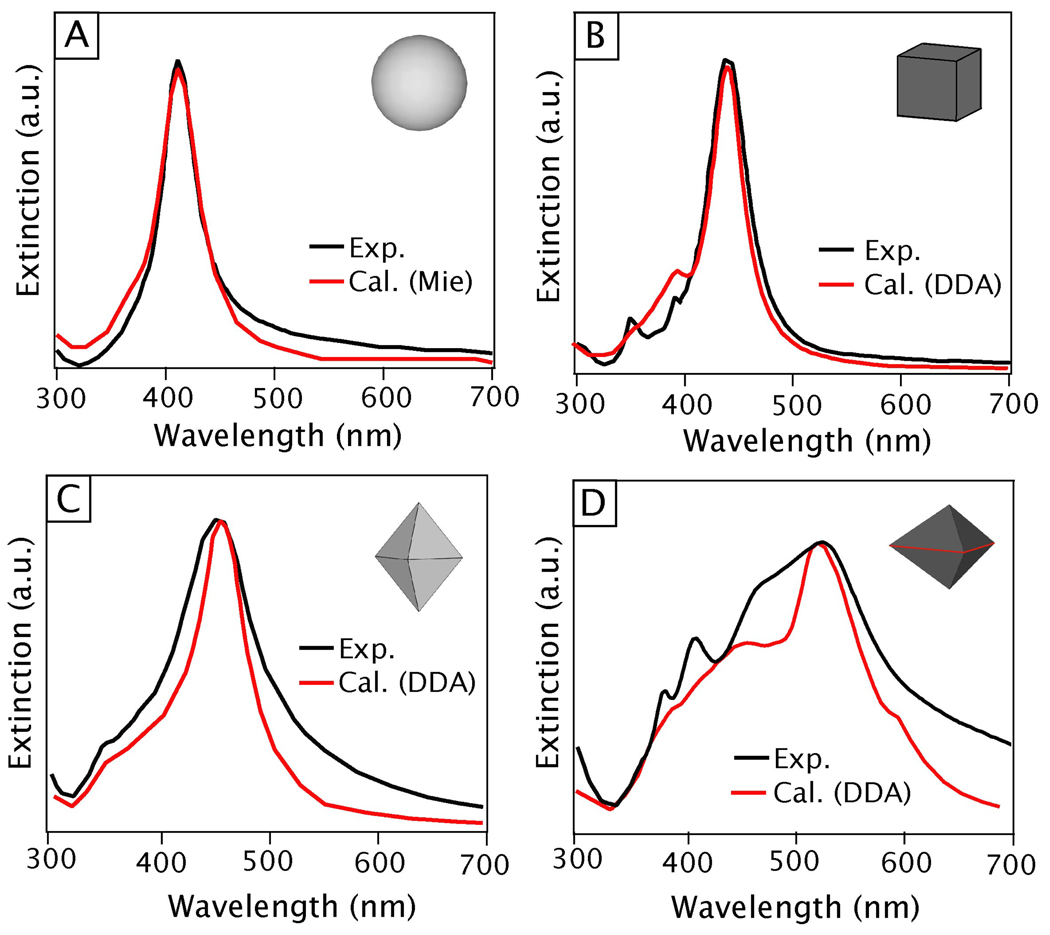

3.1. Far-field Optical Characterization

The most traditional approach to characterize the plasmonic response of metal nanostructures is to measure their extinction spectrum using a conventional UV-vis-NIR spectrometer. At their LSPR frequencies, metal nanostructures exhibit strong absorption and/or scattering, resulting in peak(s) in the extinction spectrum.34,194 As will be discussed further in Section 4, the specific location and strength of these peaks depends strongly on the morphological features of the nanostructure of interest. This fact, combined with the relatively low cost and fast operation of a typical spectrophotometer, makes measuring the extinction spectrum one of the simplest, and most prevalent, way to evaluate the size, shape, and uniformity of plasmonic nanostructures in the solution phase. For example, our group frequently uses extinction spectra to monitor the synthesis of Ag nanocubes in solution phase.97,195 Specifically, we have created a calibration curve that plots the position of the primary dipole peak of Ag nanocubes against the edge length of the cubes as reaction progresses. Using this knowledge, we can monitor the growth of Ag nanocubes and conveniently control the size of the final product.53,97

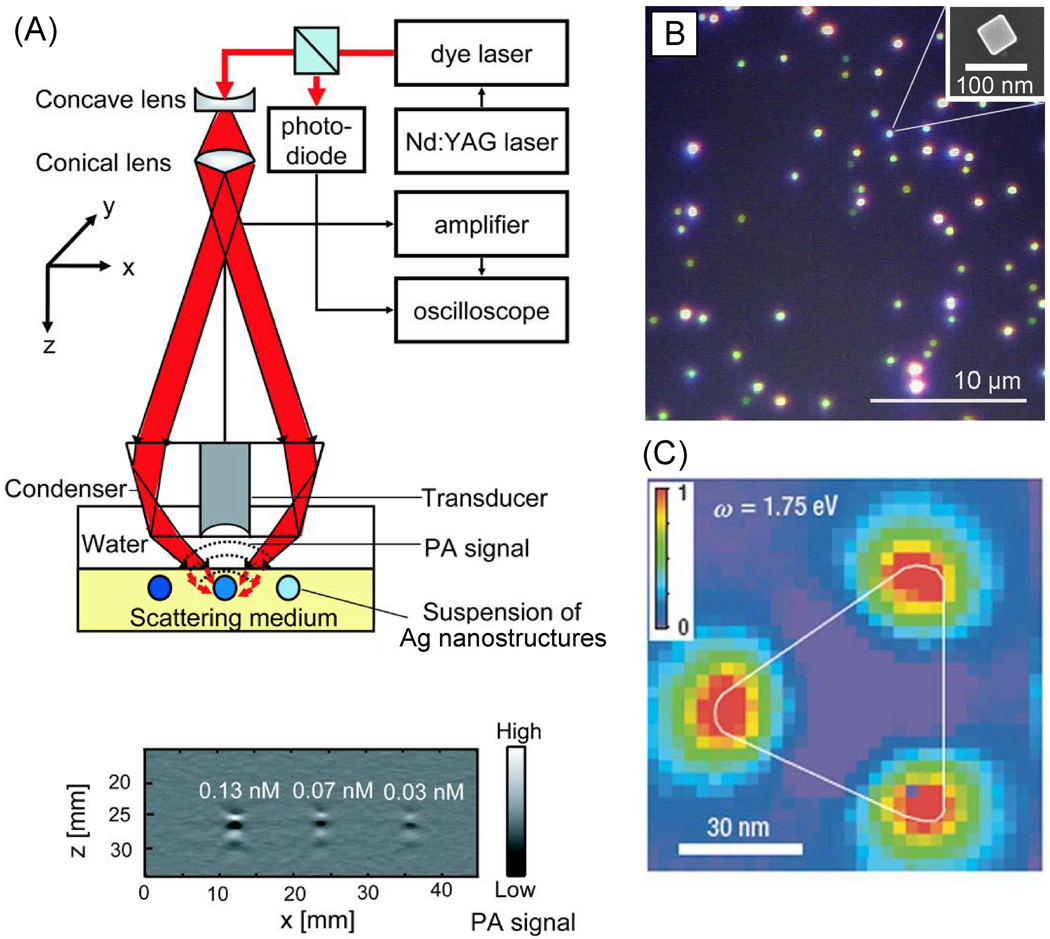

Photoacoustic (PA) techniques also present a powerful tool to measure the absorption cross sections of metal nanoparticles in a suspension.196 Critically, these techniques makes it possible to experimentally separate the absorption cross section from the overall extinction cross section, as some of the applications of plasmonic nanostructures rely exclusively on this component. Figure 7A shows a schematic of the setup we have used to measure the absorption cross sections of Au nanoparticles, nanorods, and nanocages. When irradiated with a pulsed laser, nanostructures in the suspension absorb light and convert this energy into heat, leading to a transient thermoelastic expansion that generates a PA signal, which is directly proportional to the absorption cross section and the concentration of the nanostructures. By comparing the measured PA signal with a calibration curve obtained from solutions of a molecule with a known absorption cross section, we are able to derive the absorption coefficient of the metal nanostructures quantitatively. When combined with the concentration of the nanostructures (which can be obtained using inductively-coupled plasma mass spectrometry, ICP-MS), the absorption coefficient can be converted into absorption cross section. By subtracting the derived absorption cross section from the extinction cross section measured by UV-vis-NIR spectroscopy, we can obtain the scattering cross section.197

Figure 7.

(A) A typical experimental setup of a photoacoustic (PA) system used to measure the absorption cross section of metal nanoparticles. Excitation from a laser (red beam) is absorbed by a suspension of metal nanoparticles and the resulting PA signal is recorded by a transducer and displayed on an oscilloscope and is correlated to the absorption cross section. The PA signal for three concentrations (0.13, 0.07, and 0.03 nM) of Au-Ag nanocages is shown in the bottom image. The highest signal is correlated with the 0.13 nM concentration of nanocages. Reproduced with permission from [196]. Copyright 2009 ACS. (B) Dark field optical microscopy image showing Rayleigh scattering of individual and aggregated Ag nanocubes (100 nm edge length). (C) Near field image of the spatial distribution of a LSPR mode with energy 1.75 eV supported by a Ag triangular nanoplate. A high near-field intensity is indicated by red and low intensity by blue. Reproduced with permission from [183]. Copyright 2007 Nature.

When measuring plasmonic properties in the solution phase, information is derived from an ensemble of nanostructures and is averaged over many different sizes, shapes, and structural defects, as well as any possible interactions between the nanostructures. To better correlate the plasmonic strength or LSPR to structural parameters, we also need to characterize the properties of individual nanostructures.180,198,199 In doing so, it is necessary to prepare samples with low enough concentrations to ensure that the particle-to-particle spacing is beyond the optical wavelength for negligible coupling. While this requirement can be satisfied in the solution phase, it is preferable to deposit the nanostructures on a solid substrate in order to better correlate the measured LSPR properties with a the size, shape, and morphology of a specific nanoparticle.

Once well-dispersed on a substrate, one way to study the plasmonic properties of individual nanostructures is to use dark-field optical microscopy, which is based on Rayleigh scattering.93, 200,201 Figure 7B shows a dark-field scattering micrograph of 100-nm Ag nanocubes on a Si substrate. At the optical resolution, we are able to observe scattering from Ag nanocubes with different intensities. As the sample is uniform in terms of size and shape, brighter spots correspond to enhanced scattering from aggregates formed during drying process while blueish spots originate from single Ag nanocubes. By locating nanostructures with dark-field microscopy, it is possible to collect extinction spectra from individual nanostructures, which can then be followed by characterization with electron microscopy to determine the size, shape, and relative position of the nanostructure.199,202 Furthermore, it is also possible to monitor the changes to the spectrum of a single nanostructure as a function of incident light polarization, wavelength, and variations in the dielectric environment.20

Dark-field microscopy provides a remarkably simple and versatile approach to characterize single nanostructures. However, this technique is not suitable for nanostructures with dimensions less than ~30 nm as absorption will dominate over scattering in this size regime.197,180 In addition, it is also impossible to determine absorption and extinction cross sections directly from dark-field microscopy. More recently, several techniques have been developed to measure the extinction or absorption spectra of single nanoparticles.203–205 For example, the absorption can be directly measured by monitoring the interference of the scattered wave with the incident wave, or the interference between the scattered field and a reference field.197 In spatial modulation spectroscopy (SMS), a single nanoparticle is moved into the focal spot of an optical beam and modulations in the transmitted light can be used to determine the extinction spectra as well as its geometrical properties (size and shape).206

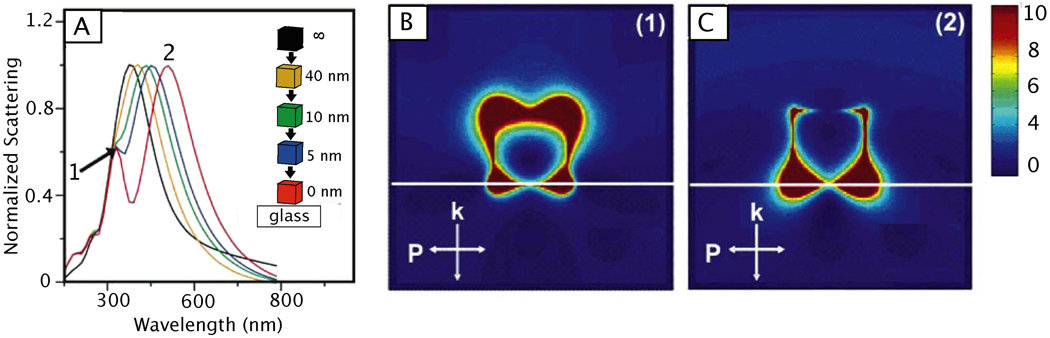

When performing single particle measurement on a substrate, it is important to keep in mind that the substrate supporting the nanostructure can have significant effects on the nanostructure’s LSPR and near-field distribution.200 As a result, the type of substrate and the distance between the nanostructure and the substrate can dramatically shift and split the LSPR.207,208 Figure 8A shows an example of the substrate effect on a Ag nanocube – the LSPR splits and two peaks appear in the UV-vis spectra as the nanocube approach the surface of a dielectric substrate such as glass.200 Additionally, simulations showed that the LSPR mode adjacent to the substrate (labeled 2) was red shifted and the mode away from the surface (labeled 1) was blue shifted, as seen in Figure 8, B and C. While interesting and useful in some circumstances, the fact that substrates introduce an anisotropic environment to nanostructures being studied also makes it challenging to fully characterize the plasmonic responses of single nanoparticles supported on a substrate.

Figure 8.

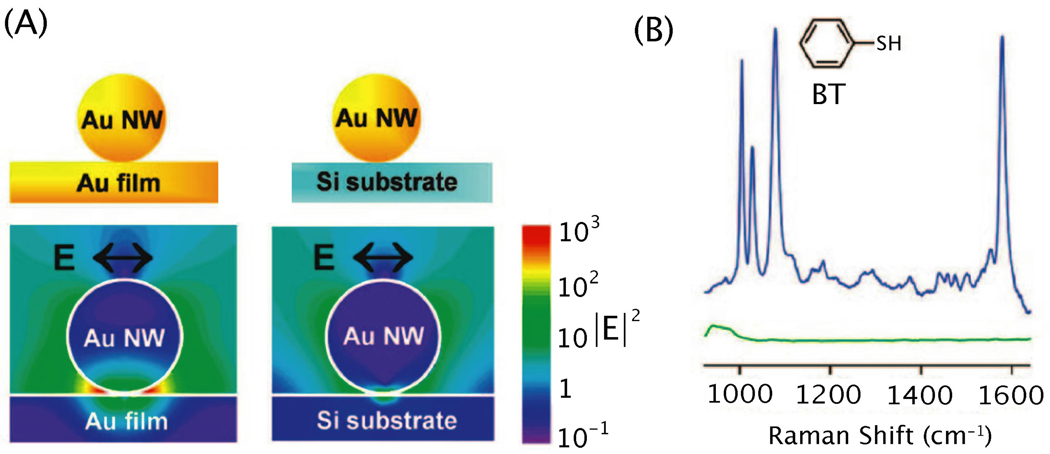

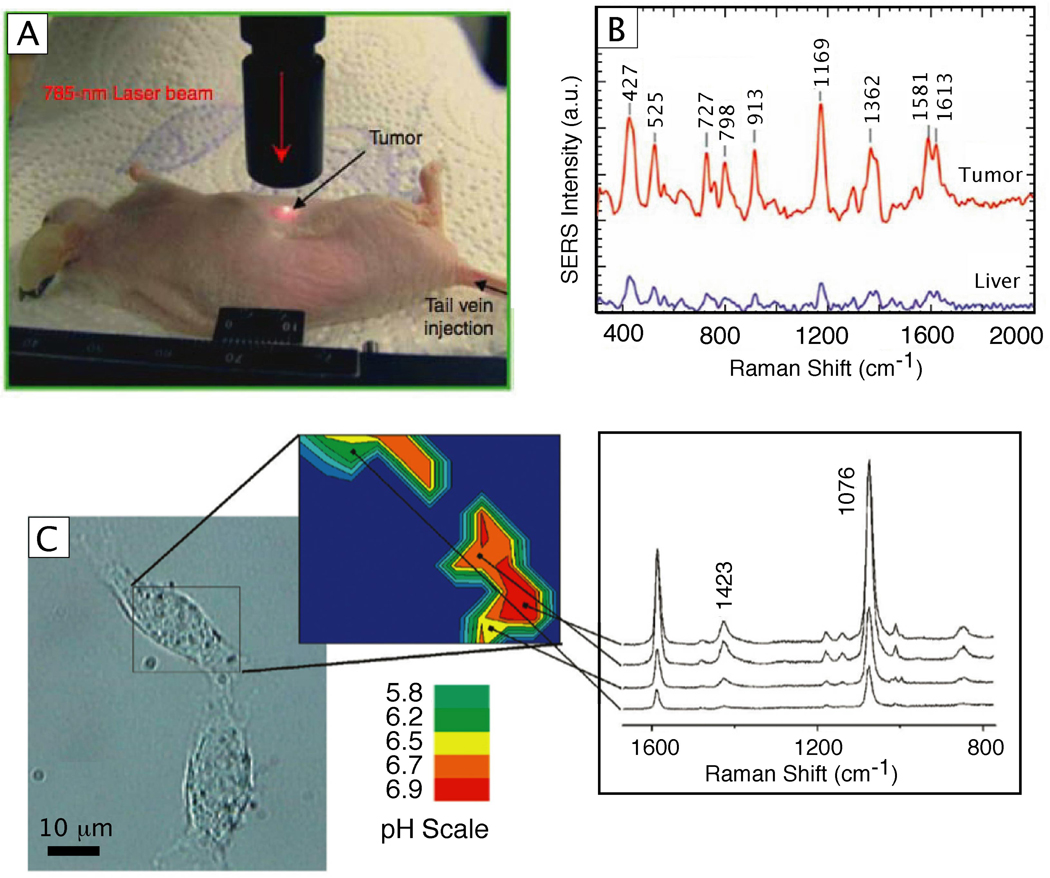

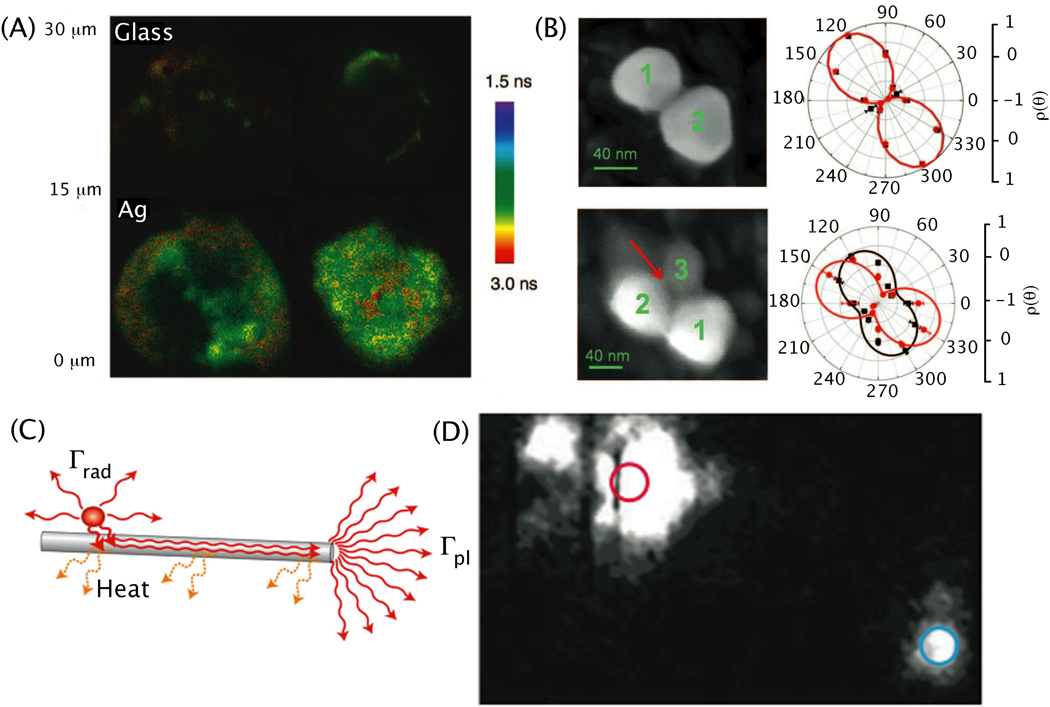

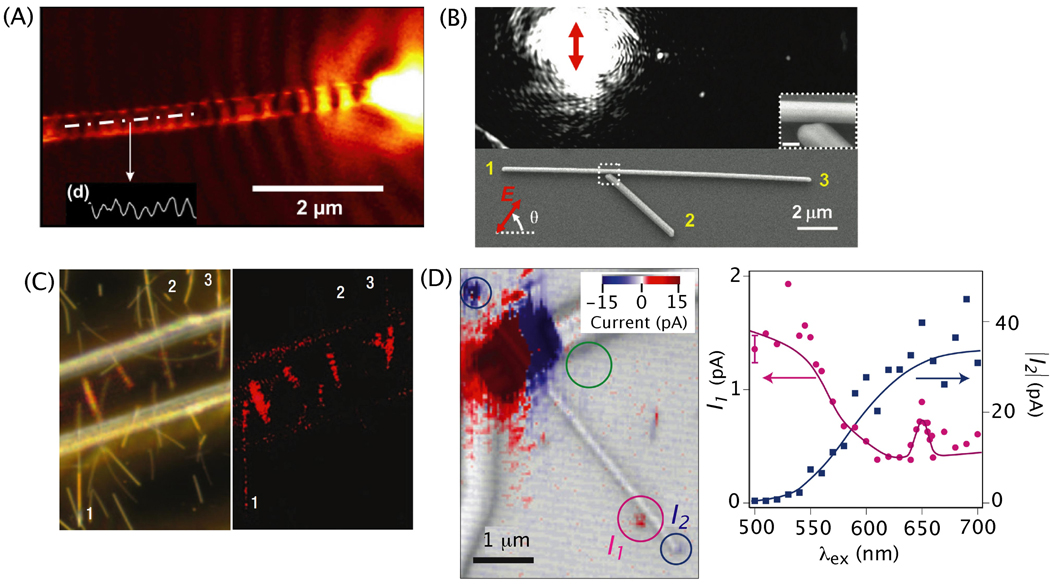

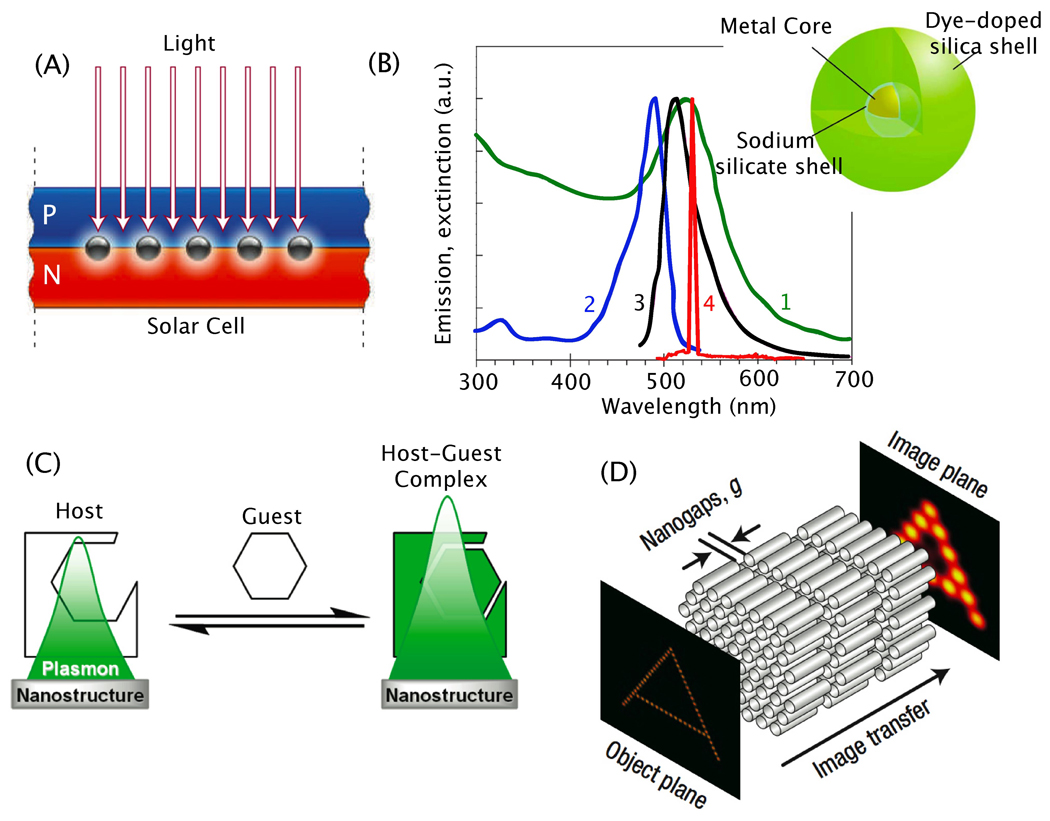

The effect of a glass substrate on a nearby Ag nanocube. (A) The calculated scattering spectra of a Ag nanocube with edge length 90 nm as it approached a glass substrate. The single peak associated with the dipolar LSPR (black line) begins to split as it approaches and touches the substrate (red line). The resulting peaks correspond to plasmon modes away from the substrate (1) and adjacent to the substrate (2). (B, C) The finite difference domain (FDTD) simulations shows the plasmon modes of a Ag nanocube (with edge length of 90 nm) associated with the spectra in (A). The white line in the simulation represent the glass substrate. Reproduced with permission from [200]. Copyright 2005 ACS.