Abstract

Ferromagnetic Ge1−xMnxTe is a promising candidate for diluted magnetic semiconductors because solid solutions exist over a wide range of compositions up to xMn≈0.5, where a maximum in the total magnetization occurs. In this work, a systematic study of molecular beam epitaxy of GeMnTe on (1 1 1) BaF2 substrates is presented, in which the Mn concentration as well as growth conditions were varied over a wide range. The results demonstrate that single phase growth of GeMnTe can be achieved only in a narrow window of growth conditions, whereas at low as well as high temperatures secondary phases or even phase separation occurs. The formation of secondary phases strongly reduces the layer magnetization as well as the Curie temperatures. Under optimized conditions, single phase GeMnTe layers are obtained with Curie temperatures as high as 200 K for Mn concentrations close to the solubility limit of xMn=50%.

Keywords: A1. Crystal structure, A1. X-ray diffraction, A3. Molecular beam epitaxy, B1. Tellurites, B2. Magnetic materials, B2. Semiconducting ternary compounds

1. Introduction

Carrier induced ferromagnetism in diluted magnetic semiconductors has attracted tremendous interest for applications in spintronic materials and devices [1,2]. Among the less explored materials, Ge1−xMnxTe is a promising candidate, as already in bulk material ferromagnetism at temperatures up to 150 K was shown [3]. Moreover, recent work has found Curie temperatures as high as 190 K in the heteroepitaxial layers [4,5]. In contrast to Mn-based III–V compounds, Mn2+ ions are isoelectronic to the group IV elements in IV–VI materials. Therefore, the carrier concentration can be tuned independently of Mn content and solid solutions exist over a wide range of compositions up to xMn≈0.5 [3,5,6], where a maximum in the total magnetization was theoretically predicted [7].

The solubility limit of the GeMnTe system is due to different crystal structures of the constituent binary compounds, where GeTe exhibits a rhombohedrally distorted rock salt lattice with a lattice constant of 5.99 Å and a rhombohedral distortion angle of α=88.4° [3], and bulk MnTe crystallizes in the hexagonal NiAs structure with lattice constants of a=4.15 Å and c=6.73 Å [8]. MnTe can be also stabilized in the cubic zinc blende structure with a lattice parameter of 6.338 Å [9]. Both pure MnTe phases are antiferromagnetic with Néel temperatures TN=310 and 65 K, respectively [8,9]. GeTe is a narrow gap semiconductor with high intrinsic p-type carrier concentration due to native cation vacancies. For Mn concentrations between xMn=20% and 60%, bulk GeMnTe adopts the cubic rock salt structure [3,6] with its lattice constant decreasing with an increase in Mn content. At higher Mn concentrations phase separation occurs [6].

Molecular beam epitaxy (MBE) has only been recently employed for the growth of GeMnTe layers [4,5,10–14]. However, the reported data on magnetic properties of the layers, in particular, Curie temperatures TC have varied over a wide range. While most studies have found highest TC values for Mn concentrations near 50% [5,11,12], Fukuma et al. [4] have recently reported the best results for Mn concentrations around 10% when MBE growth is performed at low growth temperatures. To resolve this issue, in the present work, a systematic growth study of GeMnTe was performed, in which the Mn concentration as well as growth conditions were varied over a wide range. The results demonstrate that for single phase GeMnTe growth only a narrow window of growth conditions exist. In particular, at low as well as high substrate temperatures, secondary phases or even phase separation occurs. Under optimized conditions, high quality GeMnTe layers are obtained with Curie temperatures as high as TC=200 K for Mn concentrations of xMn=46%.

2. Experimental

GeMnTe was grown onto BaF2 (1 1 1) substrates by molecular beam epitaxy using a stoichiometric GeTe effusion cell and elemental Mn and Te beam flux sources. For all samples, the GeMnTe growth rate was set to 0.5 monolayers (ML) per second (=0.6 μm/h). The substrate temperature was carefully calibrated using an optical pyrometer with an accuracy better than ±5 °C and was varied in the range from 260 to 310 °C. All flux rates were measured precisely using a quartz crystal microbalance moved into the substrate position. The ratio of the Mn flux to the GeMnTe growth rate yields the ternary Ge1−xMnxTe composition of the layers, which was varied between xMn=20% and 50%. To retain the correct stoichiometry, excess Te flux (=difference between Te and Mn flux) between 0.1 and 0.3 ML/s was used for growth. For the employed substrate temperatures, the entire excess Te flux re-evaporates from the layer surface due to the high Te vapor pressure. On the contrary, the GeTe and Mn re-evaporation rates are small for substrate temperatures below 330 °C. Therefore, a unity sticking coefficient of GeTe and Mn was assumed.

The growth and structural properties of the samples were studied using in situ reflection high-energy electron diffraction (RHEED) and high resolution X-ray diffraction. For the latter, a Seifert XRD3003 PTS diffractometer with a channel cut Ge monochromator and a collimating X-ray mirror in front of the detector was used. For selected samples, additional structural information was obtained by transmission electron microscopy (TEM) using a JEOL 2011 FasTEM operated at 200 keV. The magnetic properties were determined using a superconducting quantum interference device (SQUID) magnetometer (Quantum Design MPMS2), measuring the magnetization M(T) as function of temperature T, as well as M(H) hysteresis loops at fixed T. The diamagnetic background of the substrate was carefully subtracted in these measurements.

3. Results

To determine the dependence of the magnetic properties on the MBE growth conditions, three series of samples were grown with three different Mn concentrations of xMn=20%, 30% and 46%. In the first two series, the substrate temperature Ts was varied from 260 to 300 °C and the excess Te flux JTe from 0.1 to 0.3 ML/s. For the xMn=46% series, Ts was varied between 290 and 310 °C and the excess Te flux was set to 0.2 ML/s.

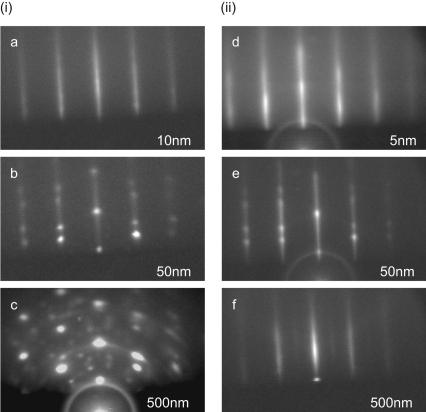

For all samples, GeMnTe growth on BaF2 (1 1 1) starts in a 2D manner. This is exemplified by the RHEED patterns depicted in Fig. 1 for GeMnTe with xMn=20% grown at Ts=260 °C (left hand side) and 280 °C (right hand side). Immediately upon growth initiation, 2D streaks appear as demonstrated by Fig. 1(a) and (d) for 10 and 5 nm GeMnTe thickness, respectively. During further growth, the streaks become spotty due to a roughening of the growing surface, as illustrated by the RHEED patterns of Fig. 1(b) and (e) recorded after 50 nm GeMnTe deposition. For low growth temperature at 260 °C, the 2D streaks subsequently disappear and a completely spotty transmission diffraction pattern is formed (see Fig. 1(c)). Moreover, additional diffraction spots appear, indicating not only a strong surface roughening but also the formation of secondary phases. On the contrary, at higher growth temperatures a 2D streaked RHEED pattern is reformed during further deposition, such that at the end of the growth process at 500 nm GeMnTe the 2D surface is regained (see Fig. 1(f)). The same general trend is also observed for samples with higher Mn content, indicating that for low-temperature growth below 280 °C precipitation of secondary phases occurs.

Fig. 1.

RHEED patterns observed during GeMnTe growth on BaF2 (1 1 1) with xMn=20% at substrate temperatures of 260 °C (left column) and 280 °C (right column). The RHEED patterns were recorded at 10, 50 and 500 nm GeMnTe for Ts=260 °C (a–c) and at 5, 50 and 500 nm for Ts=280 °C (e–f). The used Te excess flux of JTe=0.3 ML/s and growth rate of 0.5 ML/s was the same for both samples.

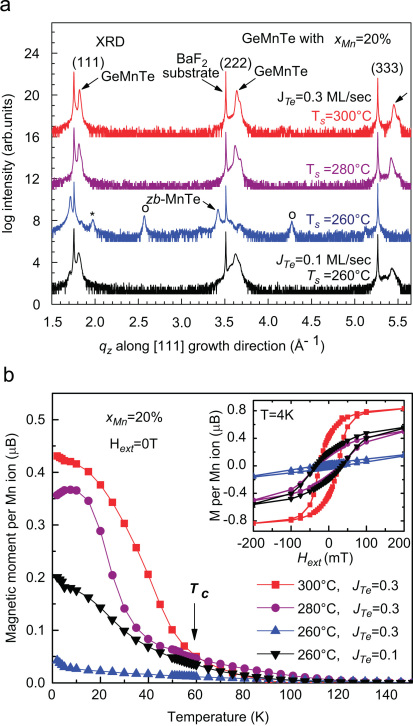

Fig. 2(a) summarizes the structural properties of the xMn=20% samples, as revealed by X-ray diffraction scans along the qz-direction normal to the surface, spanning the whole q-space from the (1 1 1) to (3 3 3) Bragg reflection. Evidently, the Ge0.8Mn0.2Te samples grown at 300 and 280 °C (upper traces in Fig. 2(a)) are single phase, exhibiting only the expected (1 1 1), (2 2 2) and (3 3 3) GeMnTe layer peaks located at the right hand side of the sharp BaF2 substrate peaks, without any signatures of other secondary phases. The normal lattice constant of the Ge0.8Mn0.2Te layers is determined as 6.0 Å and the small right hand side shoulder of the layer peaks is due to the rhombohedral GeMnTe lattice distortion present when the Mn concentration is lower than 30%. From X-ray reciprocal space maps around the (2 2 2) and (1 5 3) reflections (not shown), the lattice distortion angle was deduced as 89.5° for xMn=20%. The full width at half maximum of the peaks is smallest for the sample grown at 300 °C, indicating a better structural quality as the substrate temperature is increased.

Fig. 2.

Structural (a) and magnetic properties (b) of 500 nm Ge1−xMnxTe layers on BaF2 (1 1 1) with xMn=20% grown at different substrate temperatures of Ts=300, 280 and 260 °C with excess Te flux of JTe=0.3 ML/s and of Ts=260 °C with JTe=0.1 ML/s (red, purple, blue and black lines, respectively). Panel (a) shows high resolution X-ray diffraction scans along the qz growth directions from the (1 1 1) to the (3 3 3) Bragg reflection. Panel (b) shows the temperature dependent remanent magnetization M(T) of the samples measured at zero external field Hext after 1 T field cooling to 4 K. The insert displays the corresponding hysteresis loops recorded at 4 K. (For interpretation of the references to colour in this figure legend, the reader is referred to the web version of this article.)

When for the same excess Te flux of JTe=0.3 ML/s the growth temperature is lowered, the GeMnTe layer peaks almost completely disappear and several other peaks emerge. This is shown by the second lowest XRD scan in Fig. 2(a). The peaks left to the substrate peaks indicated by arrows are identified to arise from zinc-blende (zb) MnTe, whereas the other peaks originate from other Ge-rich phases. The peak marked “⁎” roughly fits to the (1 1 1) peak of pure Ge, but the other two peaks marked “o” could not be fitted to any of the known Ge–Mn–Te phases [15–17], on which, however, only limited amount of literature exists. When the excess Te flux is reduced to 0.1 ML/s, the structural quality of the sample significantly improves and the ternary Ge0.8Mn0.2Te peaks are partially regained (see lowest trace in Fig. 2(a)). This indicates that the driving force for phase decomposition at low growth temperatures is reduced at small Te overpressures, i.e., a closely stoichiometric flux composition. In fact, when high excess Te fluxes exceeding ∼1 ML/s are used a similar phase decomposition is also found even at higher growth temperatures. Thus, only a narrow window of growth conditions for single phase GeMnTe growth exist.

The magnetic properties of the four Ge0.8Mn0.2Te samples are summarized in Fig. 2(b), which displays the remnant magnetization M(T) measured as a function of temperature after 1 T field cooling from room temperature to 4 K. Evidently, the sample grown at the highest temperature of 300 °C (red line) shows the highest remanent magnetization and the highest ferromagnetic Curie temperature TC of around 60 K as indicated by the arrow. For the samples grown at a lower Ts=280 °C (purple line), the remanent magnetization decreases more rapidly with increase in temperature and the sample grown at 260 °C is nearly non-magnetic (blue line). Reducing the excess Te flux to 0.1 ML/s partially recovers the ferromagnetism in the sample (black line in Fig. 2(b)), which agrees with the X-ray data. Thus, ferromagnetism arises exclusively from the ternary GeMnTe alloy in the samples. The same trend is also observed in the 4 K hysteresis loops M(H) of the samples shown in the insert of Fig. 2(b), where the sample grown at 300 °C shows the largest opening and the highest saturation magnetization value.

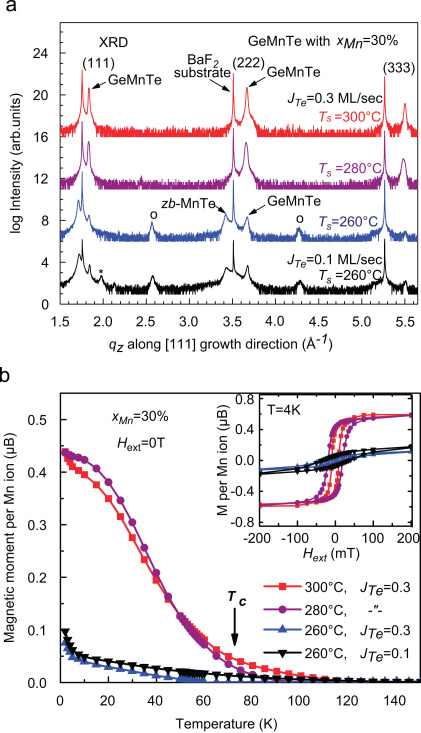

For GeMnTe layers with higher Mn content of xMn=30%, a similar sample series was grown with Ts varying from 260 to 300 °C and the same excess Te flux conditions. As shown by the X-ray scans displayed in Fig. 3(a), the same basic trend as for the xMn=20% samples is observed, namely, single phase growth for substrate temperatures of 280 and 300 °C, and multiphase growth at 260 °C. For the single phase samples (upper two curves of Fig. 3(a)), Ge0.7Mn0.3Te is practically cubic with a lattice constant of 5.94 Å, whereas for the 260 °C samples (lowest two traces of Fig. 3(a)), the same secondary peaks appear as already observed for the xMn=20% samples (cf. Fig. 2(a)). In particular, at low temperature a zinc blende MnTe phase is formed as indicated by the arrows, as well as additional phases with the same peak positions at qz=1.84, 1.98, 2.57 and 4.27 Å−1 as marked by “⁎” and “o” in Fig. 3(a). For the xMn=30% samples grown at 260 °C, weak peaks from the ternary GeMnTe still remain and the reduction of the excess Te flux did not yield the same marked improvement of structural quality as for the xMn=20% samples.

Fig. 3.

Structural (a) and magnetic properties (b) of 500 nm Ge1−xMnxTe layers on BaF2 (1 1 1) with xMn=30% grown at substrate temperatures of Ts=300, 280 and 260 °C with excess Te flux of JTe=0.3 ML/s and of Ts=260 °C with JTe=0.1 ML/s (red, purple, blue and black lines, respectively). Panel (a) shows high resolution X-ray diffraction scans along the [1 1 1] growth directions from the (1 1 1) to (3 3 3) Bragg reflection. Panel (b) shows the temperature dependent remanent magnetization M(T) of the samples measured at zero external field Hext after 1 T field cooling to 4 K. The insert displays the corresponding hysteresis loops recorded at 4 K. (For interpretation of the references to colour in this figure legend, the reader is referred to the web version of this article.)

The M(T) magnetization curves of the xMn=30% samples depicted in Fig. 3(b) clearly show ferromagnetic behavior for the layers grown at Ts=280 and 300 °C, with critical temperature TC of around 75 K as indicated by the arrows. Obviously, there also exists a weak ferromagnetic signature at temperatures up to 110 K. This deviation from the classical mean field behavior is attributed to local non-uniformities of the alloy composition [5]. The multiphase samples grown at Ts=260 °C exhibit only a very small, i.e., a factor of five times smaller, remanent magnetization. Thus, the secondary structural phases are either non-magnetic or antiferromagnetic such as zb-MnTe and the residual ferromagnetic signal arises from the small fraction of GeMnTe regions in the samples. Indications for the presence of antiferromagnetic zb-MnTe in the samples are also found in the magnetization measurements at nonzero external fields (not shown), in which a small peak in the M(T) curves appears at temperatures around 50 K, which is close to the antiferromagnetic Neél temperature TN of zb-MnTe [8].

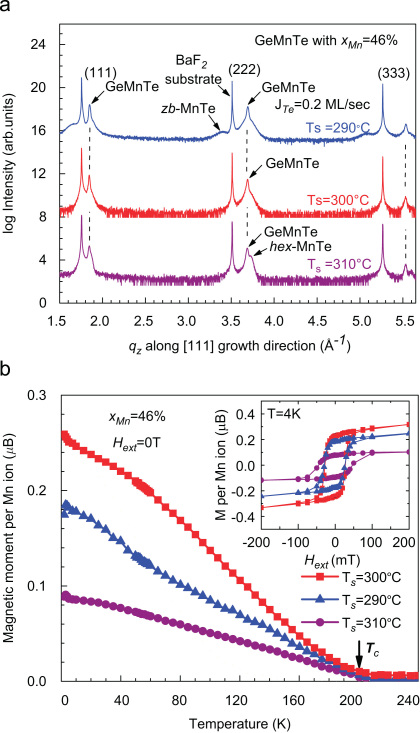

Increasing the Curie temperature requires further increase in Mn content. To this end, we have grown a set of samples with xMn=46% under optimized growth conditions at Ts=290, 300 and 310 °C with an excess Te flux of 0.2 ML/s. According to the X-ray diffraction scans depicted in Fig. 4(a), all three samples exhibit strong and quite sharp diffraction peaks from ternary Ge0.54Mn0.46Te (vertical dashed lines in Fig. 4(a)) with a cubic lattice constant of 5.90 Å. The Ts=300 °C sample (middle trace) is single phase without any traces of secondary phases, whereas the 290 °C sample (upper trace of Fig. 4(a)) shows an additional small and broad hump at qz=3.42 Å−1, corresponding to zb-MnTe with a0=6.36 Å. This indicates that a small fraction of the material is incorporated as MnTe clusters in the layer. The sample grown at Ts=310 °C (lowest curve of Fig. 4(a)), on the contrary, exhibits a small additional shoulder on the left hand side of the cubic GeMnTe peak. This peak arises from the presence of an additional hexagonal MnTe phase in the sample, with a corresponding lattice constant of c=6.71 Å.

Fig. 4.

Structural (a) and magnetic properties (b) of 100 nm Ge1−xMnxTe layers on BaF2 (1 1 1) with xMn=46% grown at different substrate temperatures of Ts=310, 300 and 290 °C (red, purple and blue lines, respectively) using the same excess Te flux of JTe=0.2 ML/s. Panel (a) shows high resolution X-ray diffraction scans along the [1 1 1] growth direction from the (1 1 1) to (3 3 3) Bragg reflection. Panel (b) shows the temperature dependent remanent magnetization M(T) of the samples measured at zero external field Hext after 1 T field cooling to 4 K. The insert displays the corresponding hysteresis loops recorded at 4 K. (For interpretation of the references to colour in this figure legend, the reader is referred to the web version of this article.)

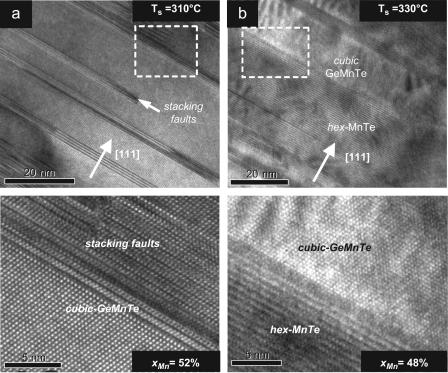

The tendency for formation of hexagonal MnTe in the layers strongly increases at temperatures above 310 °C. At Ts=330 °C and above, the hexagonal MnTe peaks completely dominate the X-ray spectra (see Ref. [5]), meaning that at higher growth temperatures predominantly hexagonal MnTe is formed instead of a mixed ternary GeMnTe alloy. This decomposition is corroborated by the cross-sectional transmission electron microscope images of two GeMnTe samples with xMn ∼50% grown at Ts=310 and 330 °C depicted in Fig. 5(a) and (b), respectively. The 310 °C grown sample exhibits only cubic GeMnTe with rock salt structure, distorted, however, by the presence of stacking faults (see high resolution TEM image in the lower panel of Fig. 5(a)), whereas the 330 °C grown sample displays large regions where hexagonal MnTe is present. As evidenced by the high resolution TEM image of Fig. 5(b), these regions can be clearly discerned from the cubic regions due to their different lattice periodicity in the [1 1 1] direction. Between the cubic and hexagonal regions apparently no lattice defects such as misfit dislocations are formed. This is due to the fact that the in-plane lattice constant of hexagonal MnTe of a=4.14 Å is practically identical to the in-plane lattice constant of cubic GeMnTe of , meaning that within the growth plane both compounds are practically lattice-matched.

Fig. 5.

Cross sectional transmission electron microscopy images of Ge1−xMnxTe layers on BaF2 (1 1 1) with (a) xMn=52% grown at Ts=310 °C and (b) xMn=48% grown at Ts=330 °C. The excess Te flux was JTe=0.2 and 0.45 ML/s. The lower panel shows the sample regions indicated by the dashed boxes with higher magnification. Also indicated in (b) are the regions with GeMnTe rock salt structure (rs) and of hexagonal (hex) MnTe with NiAs structure.

The M(T) magnetization curves of the xMn=46% sample series are summarized in Fig. 4(b). Again the sample grown at 300 °C shows the highest remanent magnetization, which is directly correlated with the observed highest GeMnTe peak intensity in the X-ray spectra of this sample. In fact, for all three samples, the measured low temperature saturation magnetization scales linearly with the (2 2 2) GeMnTe peak intensity, in agreement with our recent findings reported in Ref. [5]. What is most notable, is that the ferromagnetic transition temperature TC is at around 200 K for all three samples, which is the highest value so far reported for the Ge1−xMnxTe compounds. This indicates that under optimized growth conditions Tc values as high as those of Mn-based III–V compounds can be obtained.

4. Conclusions

The systematic study of the dependence of structural and magnetic properties of ferromagnetic Ge1−xMnxTe on the MBE growth conditions has shown that only within a narrow window of growth conditions single phase ternary GeMnTe layers can be obtained. At lower or higher growth temperatures, precipitation of secondary phases or even phase separation occurs, in which zinc blende MnTe is formed at low temperatures and hexagonal MnTe at high temperatures. The use of high excess Te flux also enhances the tendency for zinc-blende MnTe precipitation. Under optimized conditions, high quality single phase GeMnTe epilayers with high Mn content and high Curie temperatures up to 200 K are obtained.

Acknowledgements

This work was supported by the Austrian Science Funds (FWF), the European Science Foundation (FoNE) and the Gesellschaft für Mikro- und Nanoelektronik of Austria.

References

- 1.Prinz G. Science. 1998;282:1660. doi: 10.1126/science.282.5394.1660. [DOI] [PubMed] [Google Scholar]

- 2.Dietl T., Ohno H. Mater. Today. 2006;9:18. [Google Scholar]

- 3.Cochrane R., Plishke M., Ström-Olsen J. Phys. Rev. B. 1974;9:3013. [Google Scholar]

- 4.Fukuma Y., Asada H., Miyawaki S., Koyanagi T., Senba S., Goto K., Sato H. Appl. Phys. Lett. 2008;93:252502. [Google Scholar]

- 5.Lechner R.T., Springholz G., Hassan M., Groiss H., Kirchschlager R., Stangl J., Hrauda N., Bauer G. Appl. Phys. Lett. 2010;97:023101. [Google Scholar]

- 6.Johnston W., Sestrich D. J. Inorg. Nucl. Chem. 1961;19:229. [Google Scholar]

- 7.Ciucivara A., Sahu B.R., Kleinman L. Phys. Rev. B. 2007;75:241201R. [Google Scholar]

- 8.Szuszkiewicz W., Dynowska E., Witkowska B., Hennion B. Phys. Rev. B. 2006;73:104403. [Google Scholar]

- 9.Hennion B., Szuszkiewicz W., Dynowska E., Janik E., Wojtowicz T. Phys. Rev. B. 2002;66:224426. [Google Scholar]

- 10.Fukuma Y., Goto K., Senba S., Miyawaki S., Asada H., Koyanagi T., Sato H. Appl. Phys. Lett. 2008;103:053904. [Google Scholar]

- 11.Chen W.Q., Lim S.T., Sim C.H., Bi J.F., Teo K.L., Liew T., Chong T.C. J. Appl. Phys. 2008;104:063912. [Google Scholar]

- 12.Chen Q., Teo K.L., Jalil M.B.A., Liew T. J. Appl. Phys. 2006;99:08D515. [Google Scholar]

- 13.Knoff W., Dziawa P., Osinniy V., Taliashvill B., Domochuchowski V., łuskowska E., Śwatek K., Story T. Materials Science-Poland. 2007;25:295. [Google Scholar]

- 14.Knoff W., Domochuchowski V., Dybko K., Dziawa P., Jakiela R., Lusakowski E., Reszka A., Taliashvill B., Story T., Szalowski K., Balcerzak T. Acta Polonica. 2009;A116:904. [Google Scholar]

- 15.Quintero M., Ferrer D., Caldera D., Moreno E., Quintero E., Morocoima M., Grima P., Bocaranda P., Delgado G.E., Henao J.A. J. Alloys Compd. 2009;469:4. [Google Scholar]

- 16.Fukumoto H., Tsunetomo K., Imura T., Osaka Y. J. Phys. Soc. Jpn. 1987;56:158. [Google Scholar]

- 17.Zhao Y.H., Xie W.-H., Zhu L.-F., Liu B.-G. J. Phys.: Condens. Matter. 2006;18:10259. [Google Scholar]