Abstract

Recent advances in fabricating controlled-morphology vertically aligned carbon nanotubes (VA-CNTs) with ultrahigh volume fraction create unique opportunities for markedly improving the electromechanical performance of ionic polymer conductor network composite (IPCNC) actuators. Continuous paths through inter-VA-CNT channels allow fast ion transport, and high electrical conduction of the aligned CNTs in the composite electrodes lead to fast device actuation speed (>10% strain/second). One critical issue in developing advanced actuator materials is how to suppress the strain that does not contribute to the actuation (unwanted strain) thereby reducing actuation efficiency. Here our experiments demonstrate that the VA-CNTs give an anisotropic elastic response in the composite electrodes, which suppresses the unwanted strain and markedly enhances the actuation strain (>8% strain under 4 volts). The results reported here suggest pathways for optimizing the electrode morphology in IPCNCs using ultra-high volume fraction VA-CNTs to further enhanced performance.

Keywords: electroactive polymer actuator, vertically aligned carbon nanotubes, nanocomposite, electromechanical strain, actuation speed

1. Introduction

Ionic electroactive polymers (i-EAPs) are attractive transduction materials because relatively large electromechanical actuation can be generated under low voltage (a few volts).[1, 2] Hence, they can be directly integrated with microelectronic controlling circuits, which have operation voltage of several volts, to perform complex actuation functions, and the low operation voltage also makes them safe to use. These i-EAP actuators hold promise for applications including artificial muscles, robots, micro- and nano-electromechanical systems (MEMS and NEMS), and multi-scale mechanical energy harvesting.[1, 2] On the other hand, one critical issue in applying the i-EAPs for these applications is how to significantly improve the electromechanical performance, including the actuation speed, actuation strain level and efficiency.[1-3]

Recent advances in fabricating controlled-morphology aligned carbon nanotubes (VA-CNTs) with ultrahigh volume fraction create unique opportunities for markedly improving the electromechanical performance of i-EAPs.[4-6] Here, we report on developing i-EAPs utilizing continuous aligned CNTs with high packing fraction and will show that this unique morphology enhances electroactive device performance in three distinct ways: creating continuous paths through inter-VA-CNT channels for fast ion conduction, minimizing electrical conduction resistance due to the continuous CNTs, and by tailoring modulus anisotropically to enhance actuation strain. These advantages are in contrast to the i-EAPs with randomly-dispersed conducting inclusions such as the ionic polymer metal composites (IPMC) that create tortuous ionic transport paths, discontinuous charge transfer, and non-optimal isotropic moduli.[7-14] We will show that by making use of the highly aligned and high volume fraction VA-CNTs, significant improvement in the electromechanical performance, including the strain level and actuation response time, of i-EAPs is achieved.

The i-EAP actuator investigated here has a three-layer structure, as illustrated in Figure 1a, consisting of VA-CNT/ionomer nanocomposite electrodes (porous nanocomposite electrodes, referred to as conductive network composite (CNC) in this paper) attached to an ionomer layer which acts as a physical and electronic insulating spacer. In the i-EAP actuators, the accumulation of excess ions at one CNC electrode and depletion at the other electrode create opposite volume strains in the two regions, resulting in bending actuation as shown in Figure 1b where cations are assumed to be the mobile ions. For this type of actuator (referred to as the ionic polymer conductor network composite (IPCNC) actuator in this paper), a high concentration of the excess ions in the electrode regions is necessary to generate high strain (and large force) in the i-EAP actuators. Hence, a high volume fraction of VA-CNTs in the ionomer matrix is highly desirable since it provides a large specific electrode surface area in the CNCs for the storage of these excess ions. As will be shown later, the anisotropic elastic modulus of the aligned-CNT CNC also contributes to enhancing actuator performance.

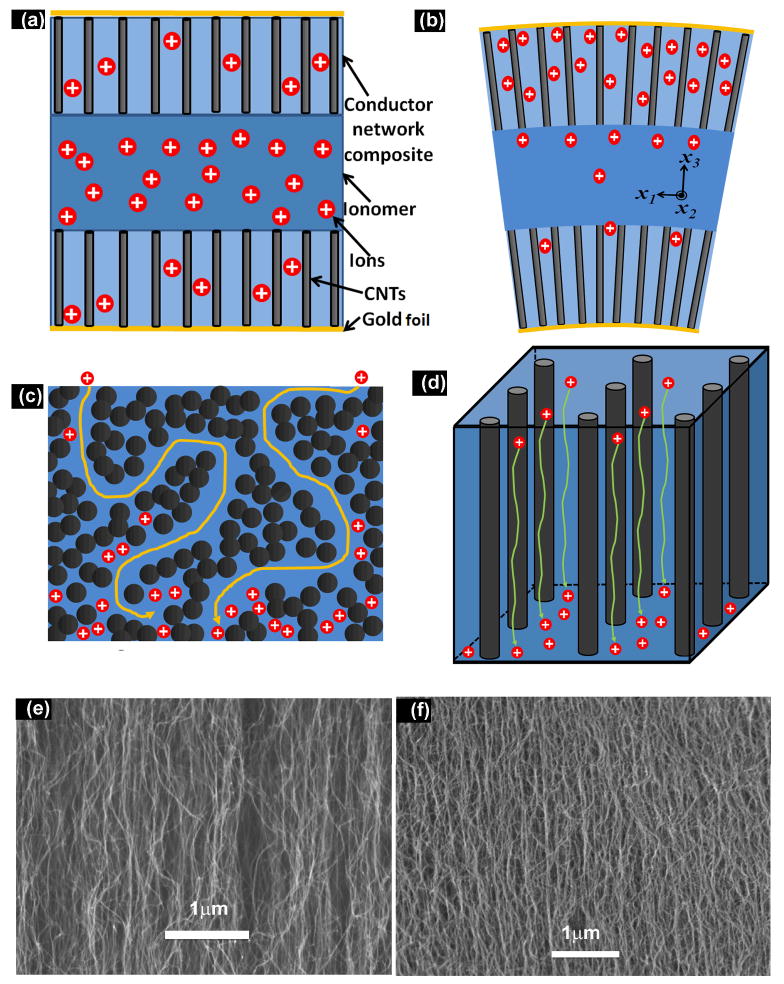

Figure 1.

Schematic drawing of (a) a CNC/ionomer/CNC three-layer bimorph actuator with VA-CNTs in the CNC layers (no voltage applied), (b) a bent actuator with excess ions on cathode side with voltage applied (x3 axis in the thickness direction and x1 axis along length direction, i.e. actuation direction). In the actuator, the mobile ions are assumed to be cations. (c) tortuous ion transport paths in nanoparticle/Nafion CNCs, where black dots are conductive nanoparticles, and (d) direct ion transport paths in VA-CNT/Nafion CNCs. SEM image of (e) 1% Vf as-grown CNT forest before densification, and (f) 10% Vf CNT forest after densification.

2. Results and Discussion

The actuation principle for the IPCNC actuator investigated here is analogous to that of ionic polymer metal composite (IPMC) actuators which have been investigated since the early 1990s.[8-13] However, there is a fundamental difference in the electrode morphology of the VA-CNT/ionomer nanocomposites in this paper and the composite electrodes developed in the studies of IPMC actuators.[7-14] For example, one widely investigated IPMC uses conductive nanoparticle/ionomer nanocomposites as the CNC layers to form bending actuators.[7, 14] The electrodes thus formed have tortuous transport paths for ion motion in and out of the porous electrode regions, as schematically illustrated in Figure 1c. Moreover, in these randomly mixed particulate nanocomposites, imperfect contacts between the conductive nano-fillers incur relatively large electric resistance. All of these effects reduce ion transport speed in CNC layers under applied voltages, decreasing actuator efficiency. In contrast, the VA-CNT based CNCs, as schematically illustrated in Figure 1d, form continuous intra-CNT (non-tortuous) transport pathways for the mobile ions to move into and out of the CNCs.[15] Hence, much shorter ion transport path lengths and much reduced ion transport resistance in the VA-CNT based CNCs lead to faster actuation speeds. In addition to the straight ion transport paths, electrical conductivity within the CNCs is enhanced by the continuous nature of the long CNTs.[16]

In addition to the electrical and ion transport considerations, the high volume fraction VA-CNTs based CNCs can also lead to high elastic anisotropy, which is highly desirable for the bending actuators developed in this paper. For an i-EAP actuator, it is highly desirable that the strain is generated only along the actuation direction (or directions) while the strains along the other directions (unwanted strain) are suppressed. The high elastic CNT modulus combined with the high volume fraction of the VA-CNTs gives rise to CNC that is stiff in the CNT alignment direction compared with that in perpendicular directions.[17, 18] As a result, the strain generated in the bending actuators due to the accumulation or depletion of the excess ions in the CNCs will be predominantly along the directions perpendicular to the CNT alignment direction, e.g., referring to Figure 1b, the volumetric expansion due to the ions will be suppressed in the unwanted x3-direction and therefore enhanced in the desirable x1- and x2- direction(s) for the device. The superscripts 1, 2 and 3 are used in this paper for x1-, x2- and x3- directions in Figure 1b. Since the volume strain generated by excess ions is Sv= S1 + S2 + S3 (see Fig. 1b for the coordinate system), a smaller S3 will increase the strain level S1 for actuation, improving the actuation efficiency. By contrast, if the CNCs possess isotropic elastic properties (as in the case of nanofiller-type concepts), the strain generated due to the excess ions in the CNCs will also be isotropic. However, the strain generated along the x3-direction (see Fig. 1b) does not contribute to the actuation of the bending actuators. It is noted that in general, for electroactive materials in which induced strains S3 and S1 have the same sign, reducing the strain S3 will enhance the strain S1, and vice versa. This is the case for the materials studied here where the aligned CNTs in the x3 direction give rise to reduced strain S3 relative to S1. However, for electroactive materials such as piezoelectric materials in which S3 and S1 have opposite signs, reducing strain S3 will restrict S1 strain (See supporting information). Such materials would require a different morphology CNC to be optimal.

In order to take full advantage of the high volume fraction VA-CNTs/ionomer nanocomposite CNCs, the nanocomposites must be fabricated free of voids, which requires careful design of fabrication process to avoid the formation of voids during infiltration of the polymer dispersion and evaporation of the solvent. In this study, VA-CNT forests were grown by a modified chemical vapor deposition method, which produces highly aligned CNTs (average 8 nm in dia.) with approximately 1% volume fraction (Vf) as shown in Figure 1e.[4, 5] High volume fraction VA-CNTs were prepared by a specially designed mechanical densification process that preserves the alignment of the CNTs and uniformity of CNT packing (volume fraction).[4, 5] In this study, 10% Vf VA-CNT forests (Fig. 1f) were used in order to create relatively large size actuators given CNT synthesis constraints. Nafion was selected for the ionomer matrix because of high ionic conductivity and desired mechanical properties.[19, 20]

For the bending actuators investigated here, the strain generated in the two electrodes has the same magnitude with opposite signs. As a result, the anisotropic strain generation property of the VA-CNT/Nafion composite cannot be directly measured as it depends on structural (actuator) dimensions. Therefore, this property was directly assessed by measuring the strain generated along the x3-direction (the CNT alignment direction), and perpendicular to x1-direction (the actuation direction) via the absorption of Imidazolium ionic liquids (ILs). For comparison, pure Nafion films were also fabricated under the same condition and the strain due to the absorption of ILs was also characterized along and perpendicular to the film thickness x3 direction. Here the imidazolium based IL, 1-ethyl-3-methylimidazolium trifluoromethanesulfonate (EMI-Tf), was chosen because it has been investigated very extensively as the electrolytes for i-EAP actuators.[14, 21] It has been shown that due to the negligible vapor pressure, the utilization of ILs as the electrolytes for IPMC actuators enables the IPMC actuators to be operated in air for long periods (>106 actuation cycles).[14] Furthermore, the large electrochemical window and high ionic mobility can also lead to improved i-EAP actuator performance.[7, 14, 21] Among various imidazolium based ILs, earlier studies have shown that the i-EAP actuators with EMI-Tf display high actuation strain and fast actuation speed.[7, 14]

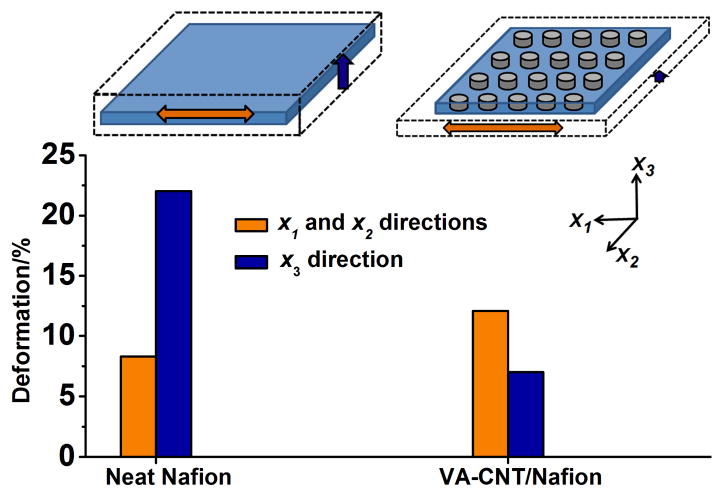

After soaking with IL, the VA-CNT CNCs exhibit a very different and anisotropic deformation than the Nafion films, as shown in Figure 2. The pure Nafion films, upon absorption of 35 wt% of EMI-Tf, exhibit a large thickness strain S3=Δl/l0∼22%, where l0 is the original thickness and Δl is the thickness change, and a much smaller lateral strain (perpendicular to the thickness direction, S1 and S2= 8.3%). In addition, a commercial Nafion film (Nafion NR211, fabricated from solution cast by DuPont) was also studied and similar results were obtained. In contrast, the VA-CNT/Nafion nanocomposite films exhibit much smaller thickness strain (S3=7%), while the desirable lateral strains S1 and S2 are increased to 12.1%. Strains were characterized using a linear variable differential transformer (LVDT) displacement sensor. These results demonstrate that the high volume fraction VA-CNTs can markedly reduce the strain in the composites along their alignment direction while enhancing the strain in the perpendicular directions, both characteristics highly desirable for the actuators developed here.

Figure 2.

Schematic drawing of deformation and strains generated from the absorption of ILs in the VA-CNT/Nafion (the CNTs are aligned along the x3-direction as shown in the figure) composite and neat Nafion under the same conditions. Neat Nafion exhibits larger (undesirable) strain along the thickness (x3) direction, while the VA-CNTs/Nafion nanocomposite film exhibits much smaller strain along the thickness (x3) direction due to the high elastic modulus and high volume fraction of VA-CNTs and higher strain in the (x1 and x2) directions.

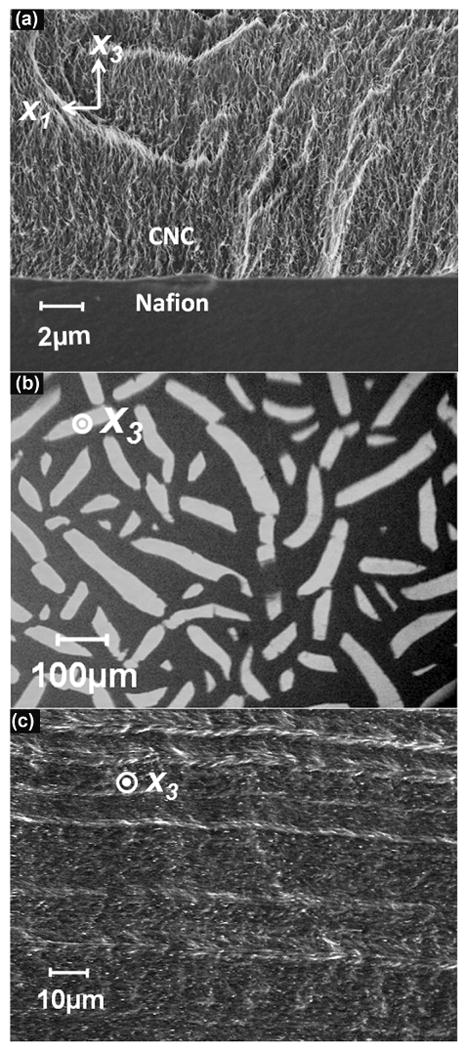

The typical dimensions of VA-CNTs/Nafion composites fabricated are 3 mm × 5 mm in the lateral directions and several millimeters thick. In order to fabricate CNCs for the intended bimorph actuators in Figure 1a, the CNC layer thickness should be much smaller than the beam length (x1-direction) as well as width (x2-direction, which should also be smaller than the length). A microtome was employed to cut the CNC composites into thin layers to be used in the actuators of Figure 1a, so that the bending actuation under applied voltages can be easily observed and characterized.[22] The actuators investigated in this paper have final CNC layer thickness of 12 μm on a 25 μm thick Nafion film (commercial Nafion NR-211) and hence the total thickness of the actuator is 49 μm. An SEM image of the interface between the CNC and Nafion film is shown in Figure 3a, where aligned CNTs in the CNC layer and good mechanical contact (no voids) between the CNC and Nafion layer are observed.

Figure 3.

Actuator and CNC morphologies. (a) SEM image of interface region, showing aligned CNTs in CNC layer. (b) Optical image of matrix-rich regions in a CNC composite due to CNT collapse (as evidenced by light grey neat Nafion regions) from fast solvent evaporation. (c) SEM image of VA-CNT/Nafion composite with CNT array in thickness (x3) direction. The image demonstrates that large-area VA-CNT/Nafion CNC films can be synthesized free of defects.

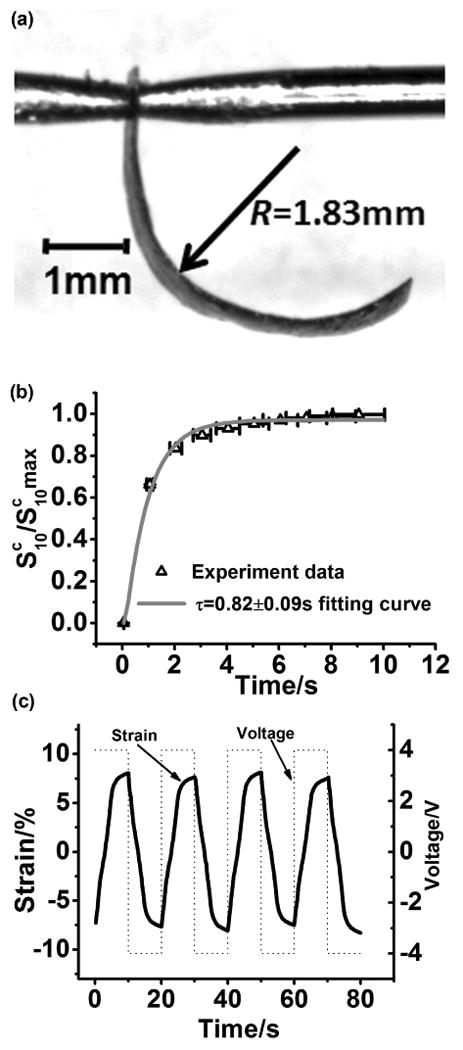

Presented in Figure 4a is the bending actuation generated for the actuator in Figure 1b with length (x1-direction) of 5mm and width (x2-direction) of 0.8 mm, from which the bending actuation radius of curvature is measured as R=1.83mm. In the bending actuator, 50 nm thick Au films were pressed to the surfaces of VA-CNT/Nafion composites as shown in Figure 1a. Au films were used here to ensure high electrical conductivity along the actuator surfaces so that there is very little voltage drop along the film surfaces (the electrical conductivity of VA-CNTs/Nafion composites perpendicular to the CNT alignment direction is ∼5-10X less than in the CNT axis direction[18]).

Figure 4.

Ionic actuator performance results. (a) Optical image of the bending actuation of the IPCNC developed in this paper under 4 volts. From the radius of curvature R, strain in the CNC layer of 8.2% is determined (see equation (1)). (b) Normalized strain versus time under a step voltage of 4 volts with fitting to an exponential function to determine the time constant τ. (c) Actuator strain versus time under an AC square-wave applied voltage.

In these actuators, the bending actuation is generated by the strain in the CNC layers. In order to extract the strain in the CNC layers, we use the relationship between the bending radius of curvature R and the strain along the film surface in the CNC layers derived in an early publication.[23] The superscripts c denotes the quantities in the composite layer, It should be noted that in the bending actuators, the actual strain is reduced from due to the stress from the ionomer layer and Au film, i.e.,

| (1) |

where is the elastic compliance and is the stress in the CNC. can be deduced from the radius of curvature, the thickness and elastic modulus of each layer (see Supplemental Information).[23] From the radius of curvature along with the elastic modulus data for each layer in the actuator of Figure 1a, was deduced to be 8.2% under an applied voltage of 4 volts. In the strain calculation formula, the thickness of each layer is assumed to be constant during actuation. However, ±6-7% thickness change in CNC layers can occur during the actuation, which causes less than 2% error in deducing . In addition, due to the measurement error (±5%) of curvature, layer thickness and modulus, the total uncertainty of strain deduced may reach ±10%.

Dynamic performance of the IPCNC actuators was also assessed, including actuator speed and hysteresis. Actuator speed was characterized by measuring the response of the actuator versus time under a step voltage of 4 volts and the data are presented in Figure 4b. The data fit well to the expected exponential function,

| (2) |

where is the maximum value of at t= 10s. The fitting results from several 10% Vf VA-CNTs/Nafion based bending actuators yield τ0= 0.82 ± 0.09 seconds. The strain level and actuation speed of the ionic polymer actuators developed here are much improved compared with that of the bimorph actuators with RuO2/Nafion CNC electrodes, which have been investigated extensively and have shown the highest strain response (∼3% strain) among the IPCNC actuators developed, as well as other i-EAPs studied earlier.[3, 7-12, 24-26] It is noted that although the ionic conductivity changes with humidity in the environment for Nafion membranes,[27] no observable effect occurs in the actuator response for the IPCNC actuators investigated here (strain level and speed) with change of environment humidity from 10% to 30% in which the actuators are usually tested. This is understandable since for the IPCNC actuators, the actuation response is governed by the CNC morphologies.[28] As long as the IL uptake is substantially above a critical uptake value (as herein), the IPCNC actuator performance is not affected by humidity.[26, 29] Figure 4c presents the actuator response under an AC square wave voltage with 4 volts amplitude and 0.05 Hz frequency. As shown in the figure, there was no observed change of strain with cycle time for about 10 minutes of experimental time (under 0.05 Hz AC voltage).

Last, the actuator blocking force Fbl is measured at zero displacement under 4 volts by using a load cell. In such a test the strain induced by the electrical field is counteracted by the blocking stress Tbl yielding zero total strain. For an actuator with dimensions of 5mm×0.8mm×49μm (L×w×t), a blocking force Fbl of 0.3 mN was measured. Using the Euler-Bernoulli's beam theory to model the bending actuator as tested[30]

| (3) |

where L, w and t are length, width and thickness of actuator, respectively. At 4 volts, an effective blocking stress of 4.7 MPa was deduced.

3. Conclusions

We have demonstrated that the ionic polymer nanocomposite actuators with VA-CNTs/Nafion electrodes of controlled morphology exhibit three distinct advantages compared with traditional ionic polymer actuators having nanostructured CNCs with randomly dispersed conductor nanoparticles: providing continuous ionic conduction paths through inter-VA-CNT channels, reducing electrical resistance due to the continuous CNTs (vs. percolation behavior in randomly-mixed CNCs), and creating desired elastic anisotropy to enhance strain induced along the actuation direction. The ionic actuators with EMI-Tf IL developed with the controlled CNC electrodes exhibit actuation strain of more than 8% under 4 volts with fast actuation speed and no observed degradation over 10 min. of testing at 0.5 Hz. The results also suggest that the controlled morphology ionic polymer nanocomposites can optimize electroactive device performance for other applications in sensors and actuators, energy harvesting, lithium ion batteries, ultracapacitors and PEM fuel cells.

4. Experimental

VA-CNTs Fabrication

VA-CNTs were grown using a modified chemical vapor deposition (CVD) method on silicon substrates using an Fe-on-alumina catalyst system [31, 32]. The resulting aligned CNTs have been characterized previously for alignment, CNT diameter, distribution, and spacing [33]. The as-synthesized CNTs (referred to as 1% Vf) have areal densities of 109∼1010 CNTs/cm2. The average diameter of these CNTs is 8 nm and the CNT-CNT spacing (center to center) is approximately 80 nm. For high volume fraction CNT fabrication, the released array is then subjected to mechanical biaxial densification in two orthogonal directions [5]. By varying the intertube distance via densification, variable-density CNT arrays can be obtained.

Composites Fabrication

In the fabrication process of the VA-CNT forest/Nafion composites, the alcohol solvent in a commercial Nafion dispersion purchased from Ion-Power® was replaced by dimethylformamide (DMF). The high boiling point (153°C) of DMF makes it possible to slowly evaporate the solvent when processed at room temperature. A fast evaporation of the solvent can cause collapse of the CNT arrays and leading at times to polymer-rich regions inside the CNC composite (see Fig. 3b). The DMF/Nafion solution is infiltrated into CNT arrays under vacuum for several hours to remove trapped air between nanotubes, which is extremely important to prepare high quality VA-CNT/Nafion composites. The whole evaporation process occurred over approximately one week. After removing the solvent, the composite is annealed at 130°C under vacuum for 1 h to increase crystallinity of the Nafion. The fabricated VA-CNTs/Nafion nanocomposites were embedded in an epoxy and then sectioned using a finesse microtome with VA-CNTs perpendicular to the cutting direction (See supporting information). Excess epoxy at the edges was removed by manually trimming the edges with a razor blade. Figure 3c is an SEM image of an exemplary VA-CNT/Nafion surface, showing uniform distribution of CNTs on the surface of composite.

Actuators fabrication

The VA-CNT/Nafion CNC layers were bonded to the Nafion film by an ultra-thin layer of Nafion dispersion (<0.1μm), which was deposited on the neat Nafion film surfaces by ultrasonic spraying. CNC layers were laminated on the neat Nafion film surfaces and the CNC/Nafion/CNC actuator stack was then clamped by two Kapton® films under pressure. The stacks were dried and then annealed at 130 °C to further improve the bonding. 50 nm thick gold electrodes are bonded on composite surfaces to increase surface conductivity (See supporting information).

Supplementary Material

Acknowledgments

This research is based upon work at Penn State University supported in part by the U.S. Army Research Office under Grant No. W911NF-07-1-0452 Ionic Liquids in Electro-Active Devices (ILEAD) MURI and NIH under Grant No. R01-EY018387-02. At MIT the work was supported by Airbus S.A.S., Boeing, Embraer, Lockheed Martin, Saab AB, Spirit AeroSystems, Textron Inc., Composite Systems Technology, and TohoTenax Inc. through MIT's Nano-Engineered Composite aerospace STructures (NECST) Consortium. Hülya Cebeci acknowledges support from Scientific and Technical Research Council of Turkey (TUBITAK) for a 2214-International Research Fellowship Programme.

Contributor Information

Sheng Liu, Department of Electrical Engineering, Department of Materials Science and Engineering, The Pennsylvania State University, University Park, PA 16802 (USA).

Yang Liu, Department of Electrical Engineering, Department of Materials Science and Engineering, The Pennsylvania State University, University Park, PA 16802 (USA).

Hülya Cebeci, Department of Aeronautics and Astronautics, Massachusetts Institute of Technology, 77 Massachusetts Avenue, Cambridge, MA 02139 (USA), Department of Aeronautical Engineering, Istanbul Technical University, Maslak, Istanbul 34469 (Turkey).

Dr. Roberto Guzmán de Villoria, Department of Aeronautics and Astronautics, Massachusetts Institute of Technology, 77 Massachusetts Avenue, Cambridge, MA 02139 (USA), Department of Aeronautical Engineering, Istanbul Technical University, Maslak, Istanbul 34469 (Turkey)

Jun-Hong Lin, Department of Electrical Engineering, Department of Materials Science and Engineering, The Pennsylvania State University, University Park, PA 16802 (USA).

Prof. Brian L. Wardle, Email: wardle@mit.edu, Department of Aeronautics and Astronautics, Massachusetts Institute of Technology, 77 Massachusetts Avenue, Cambridge, MA 02139 (USA), Department of Aeronautical Engineering, Istanbul Technical University, Maslak, Istanbul 34469 (Turkey).

Prof. Q. M. Zhang, Email: qxz1@psu.edu, Department of Electrical Engineering, Department of Materials Science and Engineering, The Pennsylvania State University, University Park, PA 16802 (USA).

References

- 1.Bar-Cohen Y, Zhang QM. MRS Bull. 2008;33:173. [Google Scholar]

- 2.Bar-Cohen Y. Electroactive Polymer (EAP) Actuators as Artificial Muscles. SPIE EXPRESS; Bellingham, WA: 2004. [Google Scholar]

- 3.Madden JDW, Vandesteeg NA, Anquetil PA, Madden PGA, Takshi A, Pytel RZ, Lafontaine SR, Wieringa PA, Hunter IW. IEEE J Ocean Eng. 2004;29:706. [Google Scholar]

- 4.Garcia EJ, Hart AJ, Wardle BL, Slocum AH. Nanotechnology. 2007;18:165602. [Google Scholar]

- 5.Wardle BL, Saito DS, Garcia EJ, Hart AJ, de Villoria RG, Verploegen EA. Adv Mater. 2008;20:2707. doi: 10.1002/adma.200800295. [DOI] [PubMed] [Google Scholar]

- 6.Futaba DN, Hata K, Yamada T, Hiraoka T, Hayamizu Y, Kakudate Y, Tanaike O, Hatori H, Yumura M, Iijima S. Nature Mater. 2006;5:987. doi: 10.1038/nmat1782. [DOI] [PubMed] [Google Scholar]

- 7.Akle BJ, Leo DJ. J Intell Mater Syst Struct. 2008;19:905. [Google Scholar]

- 8.Oguro K, Kawami Y, Takenaka H. J Micromachine Soc. 1992;5 [Google Scholar]

- 9.Shahinpoor M. J Intell Mater Syst Struct. 1995;6:307. [Google Scholar]

- 10.Shahinpoor M, Bar-Cohen Y, Simpson JO, Smith J. Smart Mater Struct. 1998;7:R15. [Google Scholar]

- 11.Paquette JW, Kim KJ. IEEE J Ocean Eng. 2004;29:729. [Google Scholar]

- 12.Nemat-Nasser S, Wu YX. J Appl Phys. 2003;93:5255. [Google Scholar]

- 13.Kim D, Kim KJ, Tak Y. Appl Phys Lett. 2007;90:184104. [Google Scholar]

- 14.Bennett MD, Leo DJ. Sens Actuators, A. 2004;115:79. [Google Scholar]

- 15.Simon P, Gogotsi Y. Nature Mater. 2008;7:845. doi: 10.1038/nmat2297. [DOI] [PubMed] [Google Scholar]

- 16.Vaddiraju S, Cebeci H, Gleason KK, Wardle BL. ACS Appl Mater Interfaces. 2009;1:2565. doi: 10.1021/am900487z. [DOI] [PubMed] [Google Scholar]

- 17.Ci L, Suhr J, Pushparaj V, Zhang X, Ajayan PM. Nano Lett. 2008;8:2762. doi: 10.1021/nl8012715. [DOI] [PubMed] [Google Scholar]

- 18.Cebeci H, de Villoria R Guzman, Hart AJ, Wardle BL. Compo Sci Technol. 2009;69:2649. [Google Scholar]

- 19.Kreuer KD. J Membrane Sci. 2001;185:29. [Google Scholar]

- 20.Mauritz KA, Moore RB. Chem Rev. 2004;104:4535. doi: 10.1021/cr0207123. [DOI] [PubMed] [Google Scholar]

- 21.Lu W, Fadeev AG, Qi BH, Smela E, Mattes BR, Ding J, Spinks GM, Mazurkiewicz J, Zhou DZ, Wallace GG, MacFarlane DR, Forsyth SA, Forsyth M. Science. 2002;297:983. doi: 10.1126/science.1072651. [DOI] [PubMed] [Google Scholar]

- 22.Xu QB, Perez-Castillejos R, Li ZF, Whitesides GM. Nano Lett. 2006;6:2163. doi: 10.1021/nl0615672. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.Liu S, Montazami R, Liu Y, Jain V, Lin MR, Heflin JR, Zhang QM. Appl Phys Lett. 2009;95:023505. [Google Scholar]

- 24.Akle BJ, Bennett MD, Leo DJ. Sens Actuators, A. 2006;126:173. [Google Scholar]

- 25.Park IS, Jung K, Kim D, Kim SM, Kim KJ. MRS Bull. 2008;33:190. [Google Scholar]

- 26.Liu S, Liu WJ, Liu Y, Lin JH, Zhou X, Janik MJ, Colby RH, Zhang QM. Polym Int. 2010;59:321. [Google Scholar]

- 27.Sone Y, Ekdunge P, Simonsson D. J Electrochem Soc. 1996;143:1254. [Google Scholar]

- 28.Liu S, Montazami R, Liu Y, Jain V, Lin MR, Zhou X, Heflin JR, Zhang QM. Sens Actuators, A. 2010;157:267. [Google Scholar]

- 29.Bennett MD, Leo DJ, Wilkes GL, Beyer FL, Pechar TW. Polymer. 2006;47:6782. [Google Scholar]

- 30.Kim KJ, Shahinpoor M. Polymer. 2002;43:797. [Google Scholar]

- 31.Hart AJ, Slocum AH. J Phys Chem B. 2006;110:8250. doi: 10.1021/jp055498b. [DOI] [PubMed] [Google Scholar]

- 32.Garcia EJ, Hart AJ, Wardle BL. AIAA J. 2008;46:1405. [Google Scholar]

- 33.Hart AJ, Slocum AH. Nano Lett. 2006;6:1254. doi: 10.1021/nl0524041. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.