Abstract

Over 13 million ha of former cropland are enrolled in the US Conservation Reserve Program (CRP), providing well-recognized biodiversity, water quality, and carbon (C) sequestration benefits that could be lost on conversion back to agricultural production. Here we provide measurements of the greenhouse gas consequences of converting CRP land to continuous corn, corn–soybean, or perennial grass for biofuel production. No-till soybeans preceded the annual crops and created an initial carbon debt of 10.6 Mg CO2 equivalents (CO2e)·ha−1 that included agronomic inputs, changes in C stocks, altered N2O and CH4 fluxes, and foregone C sequestration less a fossil fuel offset credit. Total debt, which includes future debt created by additional changes in soil C stocks and the loss of substantial future soil C sequestration, can be constrained to 68 Mg CO2e·ha−1 if subsequent crops are under permanent no-till management. If tilled, however, total debt triples to 222 Mg CO2e·ha−1 on account of further soil C loss. Projected C debt repayment periods under no-till management range from 29 to 40 y for corn–soybean and continuous corn, respectively. Under conventional tillage repayment periods are three times longer, from 89 to 123 y, respectively. Alternatively, the direct use of existing CRP grasslands for cellulosic feedstock production would avoid C debt entirely and provide modest climate change mitigation immediately. Incentives for permanent no till and especially permission to harvest CRP biomass for cellulosic biofuel would help to blunt the climate impact of future CRP conversion.

Keywords: land-use change, renewable energy, carbon balance, agriculture, nitrous oxide

Projections of reduced fossil fuel availability and increasing appreciation of the environmental impacts of fossil fuel use have stimulated interest in renewable energy sources from agricultural crops (1, 2), which would likely lead to the expansion of cropland to satisfy new production demands (3). A likely side effect of cropland expansion is an increase in greenhouse gas (GHG) emissions due to land-use conversion (4, 5). In the United States, ∼13 × 106 ha of former cropland are in the Conservation Reserve Program (CRP) (6) but this amount is subject to change as CRP and additional acreage now unmanaged will increasingly be converted to biofuel crops in response to the current US ethanol mandate (7). Modeled estimates of the carbon cost (C debt) of converting CRP grassland to agriculture have ranged from ∼30 to 200 Mg CO2 equivalents (CO2e)·ha−1, requiring from 3 to >50 y to repay depending on GHG emissions following conversion vs. the net production of biofuels to offset fossil fuel use (fossil fuel offset credit) (4, 8–10). However, the lack of direct measurements of GHG fluxes during conversion of CRP lands makes such estimates highly uncertain.

Here we report a full GHG accounting during the year of conversion of a 22-y-old CRP perennial grassland dominated by smooth brome grass (Bromus inermis) to a no-till soybean (Glycine max) system. No-till soybean is a recommended breakout crop for CRP conversion because of weed control and soil carbon conservation advantages. Our analysis includes all major components of the C balance including the CO2e costs of agricultural inputs such as fuel, fertilizer, herbicides, seeds, and other agronomic inputs; changes in C storage as measured by net ecosystem CO2 exchange adjusted for grain C; and net ecosystem fluxes of the greenhouse gases N2O and CH4. We credit the C balance with a fossil fuel offset credit based on biodiesel yield from soybeans grown at the converted sites and published life cycle comparisons of fossil vs. biodiesel production (11–13) (SI Text), which include coproduct credits. To calculate the C debt payback time we project forward from the conversion year using the life cycle analysis (LCA) of biofuel and fossil fuel production and long-term county crop yields, together with data for soil GHG fluxes and soil carbon from nearby fields on the same soil series studied for a decade or more.

We consider five contrasting scenarios for subsequent management: continuous corn and corn–soybean rotations, each either tilled or in permanent no-till. A fifth scenario is CRP grassland harvested for cellulosic ethanol production. We recognize that only a small fraction of US soils are today in permanent no-till and that even a single tillage event can rapidly destroy an accumulated soil C benefit (14, 15). We present the permanent no-till scenario as a best-practice option, agronomically realistic with the proper incentives (16). Likewise, using the grassland for cellulosic ethanol production will not be practical without nearby biorefineries that can accept cellulosic feedstocks. Nevertheless, such scenarios are important for framing potential outcomes in light of ongoing policy discussions.

Results and Discussion

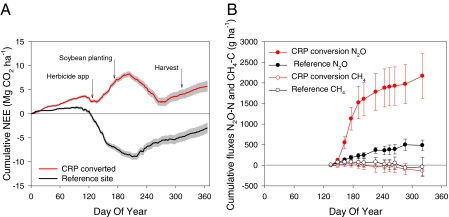

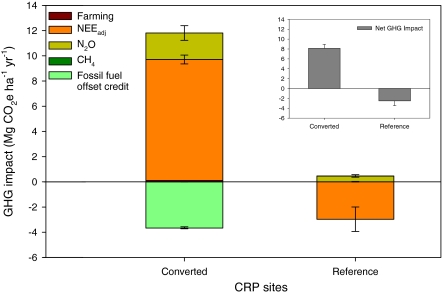

The largest first-year C cost of CRP conversion to no-till soybean is the change in ecosystem C stocks as measured by net ecosystem CO2 exchange (NEE) (defined here as positive for net C emission to the atmosphere and negative for net C sequestration from the atmosphere) (Fig. 1A and Table 1). Over the course of 2009, emissions in excess of photosynthetic uptake totaled 9.60 ± 0.35 Mg CO2e·ha−1 (NEEadj; Table 1 and Eq. 1), which represents a net loss of ecosystem C for the conversion year. Additionally, the converted fields emitted a substantial amount of N2O (Fig. 1B and Table S1), which contributed another 2.10 ± 0.58 Mg CO2e·ha−1 to the net GHG balance. Methane oxidation, on the other hand, was negligible, on the order of −0.008 ± 0.005 Mg CO2e·ha−1 (Table S1). GHG farming costs were also minor: the total CO2e cost of fuel, fertilizer, pesticides, and seeds summed to 0.10 Mg CO2e·ha−1 (Table S2 and SI Text for details). The direct first-year carbon cost of conversion was thus 11.80 ± 0.68 Mg CO2e·ha−1 (Fig. 2).

Fig. 1.

Cumulative fluxes of greenhouse gases from the studied systems. (A) Average cumulative NEE from three CRP grasslands converted to no-till soybean (red line) compared with a CRP grassland reference site (black line) during 2009. Positive values indicate net CO2 emission from the ecosystems. Gray areas show the SD of cumulative NEE. Herbicide was first applied to the CRP grassland on day of year (DOY) 125; soybeans were sown on DOY 160 and harvested on DOY 310. (B) Average cumulative emissions of N2O (N2O − N g·ha−1; solid symbols) and CH4 (CH4 − C g·ha−1; open symbols) at the study sites during the 2009 growing season. Black lines and symbols represent the CRP reference site and red lines and symbols represent converted sites. Error bars are quadratic sums of component SEs (n = 3 replicate fields for converted CRP and n = 4 replicates within one field for reference CRP; see SI Text for details). Note different units in A and B.

Table 1.

Net ecosystem exchange (NEE) for the year 2009 in CRP grasslands converted to no-till soybean and in an unconverted reference site

| Mg CO2e·ha−1·y−1 |

|||

| NEE | Cbio | NEEadj | |

| CRP converted grassland | 5.18 (0.30) | 4.43 (0.01) | 9.60 (0.35) |

| CRP reference* | −2.97 (0.97) | — | −2.97 (0.97) |

NEE is measured by eddy covariance adjusted for harvested grain respired off site (Cbio) to provide NEEadj (Eq. 1) (mean ± SEM, n = 3 replicate sites except as noted). NEE as defined here is positive when the net flux is to the atmosphere.

*One replicate, error propagated by quadratic sum of component errors (17).

Fig. 2.

Conversion year GHG impact for Conservation Reserve Program (CRP) fields converted to no-till soybeans in 2009. NEEadj includes the net release of soil and grain C in the converted site and the net capture of soil C in the reference site. Not shown for the converted sites is foregone C sequestration, which is equivalent to the net GHG impact for the reference site, shown in the Inset. Also not shown is future debt created by the subsequent decomposition of CRP biomass (8.9 Mg CO2·ha−1) and future foregone soil C sequestration (49 Mg CO2·ha−1). Error bars are quadratic sums of component SEs (see SI Text for details).

To this initial conversion cost an additional 2.50 ± 0.98 Mg CO2e·ha−1 of foregone sequestration must be added. This is the amount of carbon that would have been sequestered during the conversion year by soil and plants in the converted sites had they been left unconverted and is based on the net greenhouse gas balance of the reference site (Fig. 2, Inset). This value includes the net amount of CO2e captured by the reference site, measured as the cumulative annual NEE (−2.97 ± 0.97 Mg CO2e·ha−1; Fig. 1A and Table 1) less emitted N2O (0.46 ± 0.10 Mg CO2e·ha−1) and methane (0.009 ± 0.022 Mg CO2e·ha−1) (Fig. 1B and Table S1). The total first-year carbon cost thus sums to 14.31 ± 0.86 Mg CO2e·ha−1.

Against this initial cost can be credited 3.66 ± 0.08 Mg CO2e·ha−1 or 227 g CO2e·MJ−1 for avoided fossil fuel C use following biodiesel production. To determine this fossil fuel offset credit we used published results of life cycle analyses and models to estimate the CO2 displaced both by direct production of soybean biodiesel and by coproduct allocations based on mass and energy allocation methods (11) (SI Text). This method brings the net first-year carbon cost of conversion to 10.65 ± 0.79 Mg CO2e·ha−1 (Fig. 2 and Table S3).

In addition to first-year carbon costs are two additional sources of C loss that will contribute to overall debt. The first is CO2 that will be emitted in the years following conversion from the eventual decomposition of grass biomass killed during the conversion year. This estimate is based on the conservative assumption that ∼33% of brome grass biomass fully decomposed during the conversion year (Table S4 and SI Text), yielding CO2e that is already included in NEE measurements. The remaining 8.92 ± 0.22 Mg CO2e·ha−1 would then decompose in subsequent years less a very small percentage that would be expected to become sequestered in passive soil carbon pools.

A second and substantially larger future cost is the loss of soil C sequestration in the converted sites that would have continued to have been sequestered had those sites not been converted. We estimate future foregone soil C sequestration to add an additional C debt equivalent to the difference in soil C concentration between the preconverted sites and the saturation C content of area soils of the same series in late successional, unmanaged ecosystems (18–21). We thus expect that future soil C sequestration would have been 49 ± 7 Mg CO2e·ha−1 (Tables S5 and S6 and SI Text) on the basis of current soil concentrations of 25.5 g C·kg−1 for the Ap (surface) horizon that would eventually, in the absence of conversion, have reached a saturation soil C concentration of ∼30 g C·kg−1 as for nearby soils of the same series (22). Other estimates of foregone soil C sequestration for conservation lands range from ∼27 (10) to 104 (23) Mg CO2e·ha−1. Foregone soil C sequestration thus makes one of the largest contributions to overall C debt.

Summing both conversion year (Fig. 2) and future debt as discussed above brings the total C debt for CRP land converted to no-till agriculture to 68 ± 7 Mg CO2e·ha−1, with 9.6 Mg CO2e·ha−1 from decomposing soil and plant carbon during the conversion year, 2.1 Mg from changes in N2O and CH4 fluxes, 0.1 Mg from farming activities, −3.7 Mg of conversion year fossil fuel offset credit, 2.5 Mg of foregone C sequestration during the year of conversion, 8.9 Mg of future brome grass decomposition, and 49 Mg of foregone future soil C sequestration.

Our calculation of C debt is higher than Piñeiro et al.’s estimate for conversion of CRP land (∼30 Mg CO2·ha−1 ) (10) and similar to Fargione et al.’s (69 Mg CO2·ha−1) (9), even though our conversion entailed no-till management and thus conserved a substantial amount of soil C that was estimated to have been oxidized in the earlier studies. As well, our measurement is lower than that estimated by Searchinger et al. (4) for conversion of native grassland with its higher soil C content (111–200 Mg CO2·ha−1). Were our fields tilled rather than under no-till management during the conversion year, our debt would be substantially higher, as described below.

The time it takes for a biofuel cropping system to produce enough GHG savings to offset the GHGs emitted due to conversion is the C debt payback time. Payback time for a given debt depends on subsequent agricultural management practices and biofuel production offset credits. To bracket the range of times for a realistic range of grain-based production systems in our area we estimate payback times under four different rotation and tillage scenarios: continuous corn vs. corn–soybean rotations, each with either tillage or permanent no-till soil management. A fifth scenario is harvesting the CRP grassland directly for cellulosic ethanol production.

We base our estimates on long-term results from nearby experiments, as well as on average agricultural grain yields from 2007 to 2009 for Kalamazoo County, Michigan (7.7 ± 0.8 Mg·ha−1·y−1 and 2.5 ± 0.2 Mg·ha−1·y−1 for corn and soybean, respectively, at standard moisture contents) (Table S6). Under all four grain-based scenarios we assume grain is used for ethanol (corn) or biodiesel (soybeans). Additionally we assume that 17% of continuous corn residues are removed for the production of cellulosic ethanol and no residues are removed from corn–soybean rotations. These rates of stover removal leave sufficient corn residue to maintain (but not build) long-term soil carbon stores: 5.2 Mg·ha−1·y−1 for continuous corn and 7.8 Mg·ha−1·y−1 for corn–soybean rotations in southwest Michigan (24, 25).

Fossil fuel offset credits account for fossil fuel CO2 emissions displaced by both direct production of renewable energy and feedstock coproducts. We used published results of life cycle analysis (LCA) and models (11–13) to estimate fossil fuel offset credits of 194 and 33 g CO2e·MJ−1 for biodiesel from soybeans and ethanol from corn grain, respectively (SI Text). For cellulosic ethanol from stover and CRP grasses we used the GREET model (GREET 1.8d.0) (11) to estimate fossil fuel offset credits of 101 and 90 g CO2e·MJ−1, respectively (SI Text).

If postconversion-year management were permanent no-till continuous corn, we estimate that our system’s C debt of 68 Mg CO2·ha−1 could be repaid within 40 ± 11 y (Table 2, Table S6, and SI Text). Including a no-rotation yield penalty of 10% of harvestable biomass (26, 27) (cf. ref. 16), our estimate of a 40-y payback time for no-till continuous-corn ethanol is somewhat shorter than Fargione et al.’s (8) estimate of 48 y. This result is in part due to our assuming no additional soil C loss on the basis of no-till results at nearby sites (22) vs. their assuming loss of all CRP-accumulated soil C due to tillage. Our estimate would be substantially shorter without the inclusion of foregone future soil C sequestration, as in Fargione et al. (8), i.e., an additional loss of ∼49 Mg CO2e·ha−1 (Table S5 and SI Text) that must also be repaid.

Table 2.

Carbon debt payback times under different scenarios of conversion of Conservation Reserve Program (CRP) grassland to annual cropping systems at a site in southwest Michigan

| Carbon debt payback time: years |

||

| Agronomic management | Conventional tillage | Permanent no-till |

| Continuous corn | 123 (43) | 40 (11) |

| Corn–soybean rotation | 89 (26) | 29 (5) |

The management system noted follows a first-year conversion of grassland to no-till soybeans as noted in Fig. 1. Projections are based on observations made during the establishment year plus projections of historical productivity and greenhouse gas fluxes from nearby sites under conventional tillage and permanent no-till rotations. Carbon debt payback times include coproduct offsets (SI Text). SEs (in parentheses) are based on the propagation of errors associated with the various components of carbon debt.

If subsequent management were a corn–soybean rotation under permanent no-till, we estimate that our system’s C debt of 68 Mg CO2·ha−1 would require 29 ± 5 y to repay (Table 2). This faster payback is because the corn–soybean rotation produces higher average fossil fuel offset credits (301 ± 35 g CO2·MJ−1·y−1 for bioethanol plus biodiesel averaged over 2 y vs. 232 ± 43 g CO2e·MJ−1·y−1 for bioethanol from continuous corn; calculated by Eq. 3, Eq. S5, and Eq. S6) (SI Text). Annual net CO2e balances are −2.37 ± 0.36 and −1.69 ± 0.44 Mg CO2e·ha−1·y−1 for corn–soybean and continuous corn, respectively (Table S6 and SI Text).

Tillage, for either rotation scenario, increases the payback time substantially. Were the subsequent agricultural systems to be tilled following our no-till conversion year, the payback times would be ∼123 and 89 y for the continuous corn and corn–soybean rotations, respectively (Table 2 and Table S6). This payback time is two to four times longer than those estimated by Piñeiro et al. (∼30 y) (10) and Fargione et al. (48 y) (9) and is closer to that estimated by Searchinger et al. (167 y) (4), which, unlike others, including ours, also includes the cost of indirect land-use change. Our longer payback time is because tillage will cause the complete oxidation of the soil carbon pool accumulated under CRP management (25) (Table S5), much of which will be released during the first 2–3 y of initial tillage (15). This will add considerably to the system’s carbon debt, increasing payback time accordingly: Soil C differences between our CRP sites and nearby historically tilled fields under continuous cultivation indicate that at least 4.2 kg C·m−2 to 1-m depth (Table S5) will be lost; oxidation of this amount of soil C is equivalent to ∼153 Mg CO2e·ha−1 of additional debt.

Thus, if the biofuel production entails annual tillage, the system’s resulting carbon debt will triple from 68 ± 7 Mg CO2e·ha−1 for no-till conversion to 222 ± 56 Mg CO2·ha−1, not including the additional debt associated with the increase in N2O emissions likely to occur following tillage (15). Tillage of CRP lands thus creates substantial local C debt—not repayable for almost a century if subsequent crops are used for biofuel and never repaid if intermittently tilled and used for food crop production. Irrespective of future crop use, policies to protect CRP carbon on conversion should be a national priority to avoid further atmospheric CO2 loading.

An alternative to converting CRP grasslands to annual crops for biofuel production is to use these lands to produce perennial crop biomass for cellulosic biofuel feedstocks (5, 28). The aboveground net primary production of our unfertilized reference site was 3.86 Mg dry mass·ha−1 in 2009 (Table S4). This dry biomass is sufficient to produce between 17 ± 1 and 25 ± 1 GJ·ha−1 of cellulosic ethanol depending on harvest efficiencies (55–83%) (29, 30), resulting in fossil fuel offset credits between 1.53 ± 0.05 and 2.31± 0.08 Mg CO2e·ha−1 (Table S6).

Additionally, the soil C sequestration potential of our sites is 6.97 Mg CO2e·ha−1·y−1 (to 1 m depth) on the basis of the rate of soil C accumulation over 22 y at our CRP reference site (Table S5). This potential will diminish over time, eventually to nil as soil C concentrations reach equilibrium (21). After this point, our CRP land would provide a continuous GHG mitigation capacity of at least 2.33 Mg CO2e·ha−1·y−1 from fossil fuel offset credits and lower N2O emissions, together with other ecosystem services (Tables S1, S3, and S6 and SI Text). This mitigation could be significantly greater were the fields fertilized or coplanted to legumes to increase productivity (so long as N2O production does not increase substantially as a result) or were they replanted without tillage to a more productive species mix (5, 31). Additionally, cellulosic biofuel crops could be grown on land less or not suitable for food crops—a criterion for CRP lands, thus avoiding food vs. fuel competition for highly productive land as well as the GHG emissions associated with indirect land use change (4), whereby land elsewhere is converted to agricultural production to offset the loss of food production where biofuels are newly grown.

Estimation of net CO2e emissions per unit of biofuel energy produced (GHG emission intensity; Eq. S4) allows comparison of the environmental impacts of different energy sources (12). We estimate that production of 1 MJ of biofuel energy from CRP conversion to grain-based biofuel crops would emit 661 g CO2e (Table S7) during the year of conversion alone. This GHG impact is seven times higher than the emissions from an equivalent amount of fossil fuel-derived gasoline, including production, distribution, and combustion (94 g CO2e·MJ−1) (12). Even with the establishment of a no-till continuous-corn system, the GHG impact of biofuel production will stay very high, 1148 g CO2e·MJ−1 in the first year and decreasing thereafter until the C debt of conversion and foregone C sequestration are repaid, and only after that would it stabilize at −39 g CO2e·MJ−1. During this same period, the use of CRP lands for cellulosic biofuel feedstock production from perennial grassland would result in a consistently negative GHG emission intensity of −121 to −137 g CO2e·MJ−1 of energy produced (Table S7), although at a lower energy yield (17 ± 1 to 26 ± 1 GJ·ha−1 for CRP biomass vs. 60 ± 10 GJ·ha−1 for continuous corn grain; Table S7) in the absence of improved cellulosic crop varieties and management to provide better yields.

Overall, our results show that no-till conversion of CRP grassland to an annual bioenergy crop will create a C debt of 68–222 Mg CO2·ha−1 depending on postconversion tillage management. Payback times likewise depend on tillage: Shorter payback times are achievable only with permanent no-till, for which 29–40 y would be required if subsequent rotations were no-till corn–soybean or no-till continuous corn, respectively. If managed with conventional tillage, the repayment period triples to 89–123 y, respectively. The direct use of unconverted CRP grasslands for cellulosic feedstock production, on the other hand, would avoid C debt entirely and provide significant climate change mitigation immediately. Policy incentives for permanent no-till would help to attenuate the climate impact of future CRP conversion and permission to harvest CRP biomass for cellulosic biofuel would provide a net climate benefit.

Materials and Methods

Experimental sites were located in southwest Michigan, in the northeastern part of the US Corn Belt (Fig. S1). The experiment is part of the Great Lakes Bioenergy Research Center (GLBRC) and located at the W. K. Kellogg Biological Station (KBS) Long-Term Ecological Research (LTER) site (www.lter.kbs.msu.edu; 42° 24' N, 85° 24' W, and 288 m above sea level). Mean annual air temperature is 9.7 °C and annual precipitation is 920 mm, evenly distributed throughout the year. Soils are well-drained Typic Hapludalfs developed on glacial outwash (32).

Three CRP fields (13–19.5 ha; Fig. S1) were converted to no-till soybeans in spring 2009. Glyphosate was applied at a rate of 0.5 kg active compound·ha−1 [Touchdown HiTech (N-(phosphonomethyl); Syngenta Agro] at day of year (DOY) 125, with subsequent no-till planting of glyphosate-tolerant soybeans at DOY 160 with a seed drill; there was no further soil disturbance. Glyphosate-tolerant soybeans are a recommended break crop for CRP lands because perennial grasses can be effectively controlled with herbicide applications throughout the growing season as needed. All three fields had been in USDA-contracted CRP grasslands since 1987, as was an additional 9-ha field used as a reference site; before CRP enrollment the fields were in corn–soybean production for at least 50 y and in other corn–small grain rotations since first farmed in the 1800s. During CRP enrollment all sites were planted with monocultures of smooth brome grass (Bromus inermis) (33), maintained following the USDA criteria for CRP lands (www.fsa.usda.gov/FSA/).

Measurements and Calculations of Net Ecosystem CO2 Exchange.

The turbulent exchange of CO2 between the canopy and the atmosphere was measured throughout 2009 using the eddy covariance (EC) technique (Fig. 1) (34–36). The EC system consisted of a LI-7500 open-path infrared gas analyzer (Li-Cor Biosciences), a CSAT3 three-dimensional sonic anemometer, and a CR5000 data logger (Campbell Scientific). The LI-7500 was calibrated every 4 mo in the laboratory with National Oceanic and Atmospheric Administration precision CO2 standards.

The 30-min mean flux of CO2 was computed as the covariance of vertical wind speed and the concentration of CO2 after removing spikes in raw data (>6 SDs) and correcting sonic temperatures for humidity and pressure (37), with additional correction of the coordinate system with the planar fit method. The correction algorithm uses the formulation of ref. 38 in the planar fit coordinate system (39), which was defined from the entire year’s mean wind data in all studied sites. The correction was performed using the EC processor software package available at http://research.eeescience.utoledo.edu/lees/. The 30-min mean fluxes were corrected for fluctuations in air density using the Webb–Pearman–Leuning expression (40), including the term for the warming of the infrared gas analyzer above air temperature (41).

The resulting NEE of CO2, compiled at 0.5-h intervals, was averaged across the three converted fields to estimate the annual C flux for each field. We compared this C flux with the flux of the unconverted (reference) CRP field. The C debt calculations were based on these NEE estimates of replicate plots (Table 1).

For the estimation of the C debt of the CRP land conversion we calculated adjusted NEE (NEEadj; Mg CO2e·ha−1·y−1) (Table 1) from measured NEE (Mg CO2e·ha−1·y−1) plus harvested grain or biomass C (Cbio; Mg CO2e·ha−1·y−1):

Carbon in the grain or grass biomass, representing organic C removed in soybean or grass harvest, was calculated as

where Cbio is the measured C fraction in soybean grain (0.53 ± 0.05 g C·g−1 dry mass) and the C concentration in brome grass [0.44 ± 0.00 g C·g−1 dry biomass (SI Text)], and Y is soybean grain or grass yields (Mg·ha−1·y−1) (for detailed information on soybean and grass yields see Table S6). For use in Eq. 1, Cbio is recalculated to CO2.

The fossil fuel offset credit is defined here as the sum of all potential avoided CO2 emissions due to the displacement of production and combustion of fossil fuels or their coproducts by biofuels. We used results of published life cycle analyses and models for calculation of fossil fuel and coproduct offset credits (11–13). For fossil fuel offset credits associated with biodiesel we used published results from comparison of life cycle analyses by the GREET model (11). The fossil fuel offset credits estimated in this study sum to 7.60 kg CO2e·kg−1 of biodiesel, or 193.9 g CO2e·MJ−1, using a biodiesel energy content of 34.5 MJ·L−1 and a density of 0.88 g·mL−1 (42, 43) (SI Text). For the conversion year we added an additional 33.0 g CO2e·MJ−1 to the offset due to lower than assumed in GREET agricultural inputs to our site (SI Text).

For corn grain ethanol, avoided CO2e emissions were calculated from a comparison of life cycle analyses of ethanol and petroleum gasoline. Gasoline emits 94 g CO2e·MJ−1 of petroleum gasoline produced, distributed, and combusted (12), whereas the cost of bioethanol is 61.3 g CO2e emissions per MJ produced and distributed (calculated from the comparison between BESS, EBAMM, and GREET models) (12, 13), for an ethanol fossil fuel offset credit of 32.7 g CO2e·MJ−1. For cellulosic ethanol we used results of GREET (11), which show for our systems that production of 1 MJ of cellulosic ethanol will offset 90 and 101 g CO2e, for ethanol produced from grasses and stover, respectively (SI Text). To calculate energy produced from ethanol we used average corn yields (Table S6), harvestable biomass from the unconverted CRP site (Table S4), and ethanol energy content [lower heating value (LHV)] assumed to be 21.1 MJ·L−1 bioethanol. We assumed a biorefinery yield of 0.43 L bioethanol·kg−1 dry corn grain and 0.38 L bioethanol·kg−1 dry corn stover and grass biomass (GREET) (44).

The energy-equivalent amounts of fossil fuel use avoided due to the use of biofuels were calculated using LHV energy contents (34.5 and 21.1 MJ·L−1 for biodiesel and bioethanol, respectively) and the specific densities of each fuel (42, 43),

|

where DM is biomass yield as dry matter (kg·ha−1·y−1; Tables S4 and S6); X is the conversion factor for biofuel production from grain, stover, or cellulosic feedstocks; Y is a factor accounting for fuel-specific density; and Biofuelenergy is biofuel energy content (MJ·L−1 fuel).

Soil GHG Emission Measurements and Farming C Costs.

We measured soil N2O and CH4 fluxes in four replicate locations in each of the studied fields during the 186-d growing season. Biweekly fluxes were measured with static chambers (45) placed within the footprint of the eddy covariance towers (see SI Text for detailed information about methods). We calculated CO2e of soil GHG emissions using a 100-y global warming potential (GWP) time horizon as recommended by the Intergovernmental Panel on Climate Change (IPCC) (46). Other C costs were based on detailed information documenting actual farming practices in these systems in the year of conversion (Table S2). For all systems, contributions of farming practices to the net C balance (in Mg CO2e·ha−1·y−1) were based on our agronomic practices, which are typical of the region, and standard conversion factors for the production costs of fertilizers, herbicides, and field fuel use (Table S2).

Calculation of GHG Balances for Scenarios.

For the no-till and conventional tillage scenarios (SI Text), we used the average yields of either corn or soybeans for the years 2007–2009 in Kalamazoo County, Michigan (47). For estimation of CO2e emissions associated with production of biodiesel and corn ethanol from feedstocks, we used published results of LCAs (SI Text) (11–13, 45). For scenarios with conventional tillage, we assumed soil C losses to the level of nearby agricultural sites (Table S5). We estimated conversion year foregone sequestration as the cumulative annual CO2e balance of the reference site. For scenarios with no-till management, we assumed that soils maintain soil C at the levels of the conversion year (Table S5). In the calculation of payback times for all scenarios, we included potential loss of future soil C sequestration by CRP lands (SI Text).

Supplementary Material

Acknowledgments

We thank S. Bohm, J. Bronson, K. A. Kahmark, C. McMinn, J. Simmons, S. VanderWulp, and many others for field, laboratory, and data assembly assistance. We additionally thank J. Fargione, W. M. Post, T. O. West, the editor, and three anonymous reviewers for many helpful comments on an earlier version of this work. Financial support for this work was provided by the Department of Energy Great Lakes Bioenergy Research Center [Department of Energy Office of Science (Biological and Environmental Research) Grant DE-FC02-07ER64494 and Department of Energy Office of Energy Efficiency and Renewable Energy Grant DE-AC05-76RL01830], the US National Science Foundation (Long-Term Ecological Research program), and Michigan AgBioResearch.

Footnotes

The authors declare no conflict of interest.

This article is a PNAS Direct Submission.

This article contains supporting information online at www.pnas.org/lookup/suppl/doi:10.1073/pnas.1017277108/-/DCSupplemental.

References

- 1.Robertson GP, et al. Sustainable biofuels redux. Science. 2008;322:49–50. doi: 10.1126/science.1161525. [DOI] [PubMed] [Google Scholar]

- 2.Tilman D, et al. Energy. Beneficial biofuels—the food, energy, and environment trilemma. Science. 2009;325:270–271. doi: 10.1126/science.1177970. [DOI] [PubMed] [Google Scholar]

- 3.Field CB, Campbell JE, Lobell DB. Biomass energy: The scale of the potential resource. Trends Ecol Evol. 2008;23:65–72. doi: 10.1016/j.tree.2007.12.001. [DOI] [PubMed] [Google Scholar]

- 4.Searchinger T, et al. Use of U.S. croplands for biofuels increases greenhouse gases through emissions from land-use change. Science. 2008;319:1238–1240. doi: 10.1126/science.1151861. [DOI] [PubMed] [Google Scholar]

- 5.Tilman D, Hill J, Lehman C. Carbon-negative biofuels from low-input high-diversity grassland biomass. Science. 2006;314:1598–1600. doi: 10.1126/science.1133306. [DOI] [PubMed] [Google Scholar]

- 6.USDA-FSA Conservation Reserve Program - Monthly CRP Acreage Report. 2010. (United States Department of Agriculture Farm Services Agency), Report ID MEPEGG-R1: 08-27-2010. Available at http://www.fsa.usda.gov/Internet/FSA_File/fyannual2009.pdf. Accessed July 21, 2011.

- 7.Feng H, Babcock B. Impacts of ethanol on planted acreage in market equilibrium. Am J Agric Econ. 2010;92:789. [Google Scholar]

- 8.Kim H, Kim S, Dale BE. Biofuels, land use change, and greenhouse gas emissions: Some unexplored variables. Environ Sci Technol. 2009;43:961–967. doi: 10.1021/es802681k. [DOI] [PubMed] [Google Scholar]

- 9.Fargione J, Hill J, Tilman D, Polasky S, Hawthorne P. Land clearing and the biofuel carbon debt. Science. 2008;319:1235–1238. doi: 10.1126/science.1152747. [DOI] [PubMed] [Google Scholar]

- 10.Piñeiro G, Jobbágy EG, Baker J, Murray BC, Jackson RB. Set-asides can be better climate investment than corn ethanol. Ecol Appl. 2009;19:277–282. doi: 10.1890/08-0645.1. [DOI] [PubMed] [Google Scholar]

- 11.Huo H, Wang M, Bloyd C, Putsche V. Life-cycle assessment of energy use and greenhouse gas emissions of soybean-derived biodiesel and renewable fuels. Environ Sci Technol. 2009;43:750–756. doi: 10.1021/es8011436. [DOI] [PubMed] [Google Scholar]

- 12.Farrell AE, et al. Ethanol can contribute to energy and environmental goals. Science. 2006;311:506–508. doi: 10.1126/science.1121416. [DOI] [PubMed] [Google Scholar]

- 13.Plevin RJ. Modeling corn ethanol and climate, a critical comparison of the BESS and GREET models. J Ind Ecol. 2009;13:495. [Google Scholar]

- 14.Ogle SM, Jay Breidt F, Eve MD, Paustian K. Uncertainty in estimating land use and management impacts on soil organic carbon storage for US agricultural lands between 1982 and 1997. Glob Change Biol. 2003;9:1521–1542. [Google Scholar]

- 15.Grandy AS, Robertson GP. Cultivation of a temperate-region soil at maximum carbon equilibrium immediately accelerates aggregate turnover and CO2 and N2O emissions. Glob Change Biol. 2006;12:1507–1520. [Google Scholar]

- 16.Grandy AS, Robertson GP, Thelen KD. Do productivity and environmental tradeoffs justify periodically cultivating no-till cropping systems? Agron J. 2006;98:1377–1383. [Google Scholar]

- 17.Gough CM, Vogel CS, Schmid HP, Su H-B, Curtis PS. Multi-year convergence of biometric and meteorological estimates of forest carbon storage. Agric For Meteorol. 2008;148:158–170. [Google Scholar]

- 18.Knops JM, Tilman D. Dynamics of soil nitrogen and carbon accumulation for 61 years after agricultural abandonment. Ecology. 2000;81:88–98. [Google Scholar]

- 19.Matamala R, Jastrow JD, Miller RM, Garten CT. Temporal changes in C and N stocks of restored prairie: implications for C sequestration strategies. Ecol Appl. 2008;18:1470–1488. doi: 10.1890/07-1609.1. [DOI] [PubMed] [Google Scholar]

- 20.McLauchlan KK, Hobbie SE, Post WM. Conversion from agriculture to grassland builds soil organic matter on decadal timescales. Ecol Appl. 2006;16:143–153. doi: 10.1890/04-1650. [DOI] [PubMed] [Google Scholar]

- 21.West TO, Six J. Considering the influence of sequestration duration and carbon saturation on estimates of soil carbon capacity. Clim Change. 2007;80:25–41. [Google Scholar]

- 22.Syswerda SP, Corbin AT, Mokma DL, Kravchenko AN, Robertson GP. Agricultural management and soil carbon storage in surface vs. deep layers. Soil Sci Soc Am J. 2011;75:92–101. [Google Scholar]

- 23.Hill J, et al. Climate change and health costs of air emissions from biofuels and gasoline. Proc Natl Acad Sci USA. 2009;106:2077–2082. doi: 10.1073/pnas.0812835106. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 24.National Research Council . Liquid Transportation Fuels from Coal and Biomass. Washington, DC: National Academies Press; 2009. [Google Scholar]

- 25.Gregg JS, Izaurralde RC. Effect of crop residue harvest on long-term crop yield, soil erosion, and carbon balance: Tradeoffs for a sustainable bioenergy feedstock. Biofuels. 2010;1:69–83. [Google Scholar]

- 26.Vyn TJ, West TD, Steinhardt GC. 15th Conference of International Soil Tillage Research Organization. Fort Worth, TX: 2000. Corn and soybean response to tillage and rotation systems on a dark prairie soil: 25 year review; pp. 1–10. Available at www.agry.purdue.edu/staffbio/ISTROConf.2000Manuscript.pdf. Accessed July 21, 2011. [Google Scholar]

- 27.Trenton F, Stanger TF, Lauer JG. Corn grain yield response to crop rotation and nitrogen over 35 years. Agron J. 2008;100:643–650. [Google Scholar]

- 28.Somerville C, Youngs H, Taylor C, Davis SC, Long SP. Feedstocks for lignocellulosic biofuels. Science. 2010;329:790–792. doi: 10.1126/science.1189268. [DOI] [PubMed] [Google Scholar]

- 29.Heaton EA, Dohleman FG, Long SP. Meeting US biofuel goals with less land: The potential of Miscanthus. Glob Change Biol. 2008;14:2000–2014. [Google Scholar]

- 30.Monti A, Fazio C, Venturi G. The discrepancy between plot and field yields: Harvest and storage losses of switchgrass. Biomass Bioenergy. 2009;33:841–847. [Google Scholar]

- 31.Fornara DA, Tilman D. Plant functional composition influences rates of soil carbon and nitrogen accumulation. J Ecol. 2008;96:314–322. [Google Scholar]

- 32.Thoen G. Washington DC: USDA Soil Conservation Service, Michigan Agricultural Experiment Station, and Michigan Tehnological University; 1990. Soil Survey of Barry County, Michigan; p. 187. [Google Scholar]

- 33.Otfinowski R, Kenkel NC, Catling PM. The biology of Canadian weeds. 134. Bromus inermis Leyss. Can J Plant Sci. 2007;87:183–198. [Google Scholar]

- 34.Lee X, Massman WJ, Law B. Handbook of Micrometeorology. Dordrecht, The Netherlands: Kluwer; 2004. [Google Scholar]

- 35.Luyssaert S, et al. CO2 balance of boreal, temperate, and tropical forests derived from a global database. Glob Change Biol. 2007;13:2509–2537. [Google Scholar]

- 36.Papale D, et al. Towards a standardized processing of Net Ecosystem Exchange measured with eddy covariance technique: Algorithms and uncertainty estimation. Biogeosciences. 2006;3:571–583. [Google Scholar]

- 37.Schotanus P, Nieuwstadt FTM, Bruin HAR. Temperature measurement with a sonic anemometer and its application to heat and moisture fluxes. Boundary-Layer Meteorol. 1983;26:81–93. [Google Scholar]

- 38.Leuning R. In: Handbook of Micrometeorology: A Guide for Surface Flux Measurements and Analysis. Lee X, Massman W, Law B, editors. Dordrecht, The Netherlands: Kluwer Academic; 2004. pp. 119–132. [Google Scholar]

- 39.Wilczak JM, Oncley SP, Stage SA. Sonic anemometer tilt correction algorithms. Boundary-Layer Meteorol. 2001;99:127–150. [Google Scholar]

- 40.Webb EK, Pearman GI, Leuning R. Correction of flux measurements for density effects due to heat and water vapour transfer. Q J R Meteorol Soc. 1980;106:85–100. [Google Scholar]

- 41.Grelle A, Burba G. Fine-wire thermometer to correct CO2 fluxes by open-path analyzers for artificial density fluctuations. Agric For Meteorol. 2007;147:48–57. [Google Scholar]

- 42.Oak Ridge National Laboratory (ORNL) Bioenergy conversion factors. 2003. Available at http://www.localenergy.org/pdfs/Document%20Library/Bioenergy%20conversion%20factors.pdf. Accessed July 21, 2011.

- 43.Patzek TW. A first law thermodynamic analysis of biodiesel production from soybean. Bull Sci Technol Soc. 2009;29:194–204. [Google Scholar]

- 44.Kim S, Dale BE. Life cycle assessment of various cropping systems utilized for producing biofuels: Bioethanol and biodiesel. Biomass Bioenergy. 2005;29:426–439. [Google Scholar]

- 45.Robertson GP, Paul EA, Harwood RR. Greenhouse gases in intensive agriculture: Contributions of individual gases to the radiative forcing of the atmosphere. Science. 2000;289:1922–1925. doi: 10.1126/science.289.5486.1922. [DOI] [PubMed] [Google Scholar]

- 46.Forster P, et al. In: IPCC, Climate Change 2007: The Physical Science Basis. Contribution of Working Group I to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change. Solomon S, et al., editors. Cambridge, UK, and New York, NY: Cambridge Univ Press; 2007. pp. 129–234. [Google Scholar]

- 47.Michigan Agricultural Statistics 2010. Available at www.nass.usda.gov/Statistics_by_State/Michigan/Publications/Annual_Statistical_Bulletin/index.asp. Accessed July 21, 2001.

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.