Abstract

Veneer chipping and fracture are common failure modes for porcelain-veneered zirconia dental restorations. We hypothesized that the graded glass/zirconia/glass with external esthetic glass (e-GZG) can increase the lifetime and improve resistance to veneer chipping and fracture relative to porcelain-veneered zirconia, while providing necessary esthetics. Previously, we have demonstrated that a graded glass-zirconia surface possesses excellent resistance to occlusal-like sliding contact fatigue. Here, we investigated the sliding contact fatigue response of this graded glass-zirconia surface with external esthetic glass. This external glass is essential for shade options, for preventing excessive wear of opposing dentition, and for protecting Y-TZP from hydrothermal degradation. e-GZG plates were bonded to composite blocks and subjected to prolonged sliding contact up to 10 million cycles at 200 N in water. The resistance to sliding contact fatigue of e-GZG matches that of monolithic Y-TZP, and both of these materials demonstrated lifetimes that were orders of magnitude longer than that of porcelain-veneered zirconia. Graded e-GZG is a promising restorative material.

Keywords: graded glass-zirconia structure, external esthetic glass, all-ceramic restorations, sliding contact loading, fatigue damage

Introduction

All-ceramic dental restorations have been widely used in dentistry because of their improved esthetics and biocompatibility compared with those of metal-ceramic retainers (Vult von Steyern et al., 2001; Olsson et al., 2003; Lawn et al., 2004). In particular, zirconia-based restorations hold a special place because of their excellent mechanical properties (Jeong et al., 2002; Pilathadka et al., 2007). Because of its opacity, zirconia is usually veneered with a more translucent porcelain layer to obtain a shade similar to that of natural teeth (Sailer et al., 2007b). However, chips and fracture of the veneer are consistently reported in clinical trials on a variety of brands of zirconia-based fixed partial dentures (FPDs) and crowns (Pospiech et al., 2003; Vult von Steyern et al., 2005; Larsson et al., 2006, 2010; Raigrodski et al., 2006; Sailer et al., 2007a; Crisp et al., 2008; Edelhoff et al., 2008; Molin and Karlsson, 2008; Ohlmann et al., 2008; Tinschert et al., 2008; Ortorp et al., 2009; Schmitter et al., 2009; Bornemann, 2003).

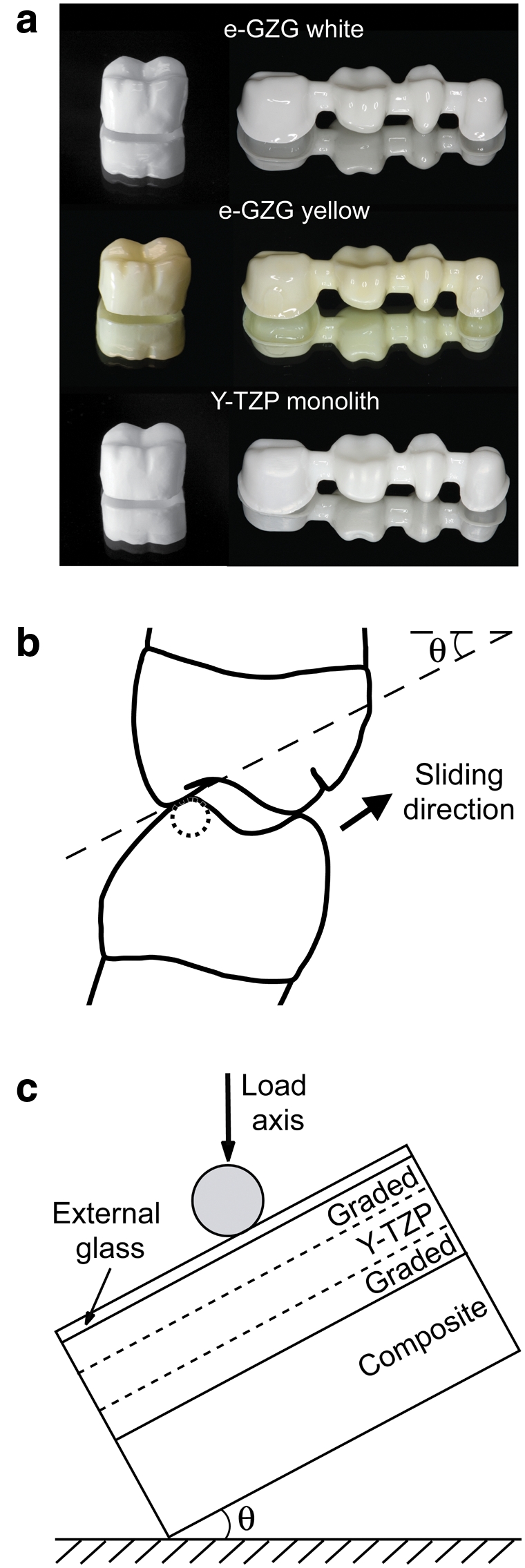

We have developed a graded glass-zirconia restorative material with superior contact and flexural damage resistance using a glass-ceramic infiltration technique (Zhang and Kim, 2009). The graded glass-zirconia structure at the cementation surface of zirconia dissipates bending stresses, thus increasing the flexural capacity of zirconia (Zhang and Ma, 2009). The graded structure at the occlusal surface exhibits fatigue sliding damage resistance comparable with that of monolithic zirconia and orders of magnitude better than that of porcelain-veneered zirconia. Additionally, the graded glass-zirconia layer along with the external residual glass layer can greatly improve the esthetic appearance (Fig.1a).

Figure 1.

Illustrations of full-contour graded glass-zirconia restorations and load-slide action simulating molar tooth occlusal contact. (a) Esthetic superiority of glass/zirconia/glass (with external glass) crowns and fixed partial dentures over their monolithic Y-TZP counterparts. (b) A chewing cycle at the molar region involves an eccentric contact of the mandibular buccal cusps with the inner inclines of the maxillary buccal cusps, followed by a sliding movement through centric occlusion, and then liftoff. Arrow indicates sliding direction. (c) Experimental set-up for simplified mouth simulator with a straight-line motion of a spherical indenter on a flat layer, supported by a compliant substrate with an inclination angle θ.

In our prior work, the external residual glass layer was gently removed by polishing before damage evaluation (Zhang and Kim, 2010). However, in a clinical setting this procedure cannot be easily achieved because of geometric complexities. Additionally, the external glass layer plays important roles in providing shade options, preventing excessive wear of the opposing dentition, and protecting Y-TZP from hydrothermal degradation. The question then arises: Would this external glass compromise the resistance to sliding contact of graded glass/zirconia/glass (GZG)? In this study, we examined the resistance to cyclic sliding contact damage of graded GZG with an external esthetic glass layer (e-GZG).

Materials & Methods

Material Preparation

Green compacts were prepared from high-purity 3 mol% Y2O3-stabilized tetragonal zirconia powder (TZ-3Y-E grade, Tosoh, Tokyo, Japan) by means of a cold isostatic press at 200 MPa. The green compacts were pre-sintered in air at 1350°C for 1 hr, with a heating and cooling rate of 10°C/min. The top and bottom surfaces of the pre-sintered compacts were ground and polished to ~1.5 mm thick with a 1-µm finish. A silicate glass slurry was then uniformly brushed onto both top and bottom surfaces of the pre-sintered Y-TZP templates. The glass composition was selected to have a coefficient of thermal expansion (CTE) matching that of zirconia (10.5 x 10−6/°C, from 25 to 450°C). The glass-coated Y-TZP templates were heat-treated at 1450°C for 2 hrs in a muffle furnace (ST-1700C-6612, Sentro Tech Corp., Berea, OH, USA) with a heating and cooling rate of 14°C/min. e-GZG plates (12 x 12 x 1.5 mm, with the external glass polished away, 6 μm and then 1 μm, from their cementation surfaces) were then bonded to composite blocks (15 x 15 x 4 mm, Z100, 3M ESPE, St. Paul, MN, USA) with a thin layer of epoxy adhesive (~20 µm). We prepared monolithic Y-TZP (12 x 12 x 1.5 mm) controls by sintering green compacts at 1450°C for 2 hrs; porcelain-veneered Y-TZP samples (1 mm porcelain, 0.5 mm zirconia) were obtained (3M ESPE). Top and bottom surfaces of monolithic Y-TZP and porcelain-veneered Y-TZP plates were polished to a 1-µm finish before being bonded to the composite blocks.

Fatigue Tests

Our study attempted to simulate the chewing motion that a molar will undergo. During mastication, the mandibular buccal cusps come into contact with the inner inclines of the maxillary buccal cusps, followed by a sliding movement toward the central occlusion, and then liftoff (Fig. 1b). The sliding movement can be described as a straight-line motion of a spherical indenter on a flat layer, supported by a compliant substrate with an inclination angle (Fig. 1c) (JH Kim et al., 2008; JW Kim et al., 2008).

Sliding contact fatigue tests were conducted on a mouth-motion simulator (Elf 3300, EnduraTEC Division of Bose, Minnetonka, MN, USA) in water. The specimens were mounted at an inclination θ = 30°. Fatigue loading of 200 N (nominal biting force) was delivered through a spherical tungsten carbide (WC) indenter (1.5 mm radius) on the specimen top surface with a contact-load-slide-liftoff profile, i.e., the indenter coming into contact with the specimen, loading to maximum while sliding down the surface to create a wear facet just over 1 mm in length, unloading, and lifting off from the specimen surface. We tested 7 e-GZG specimens to predetermined fatigue cycles: 1 x 106 (n = 3), 2 x 106 (n = 3), and 1 x 107 (n = 1). Parallel studies were performed on 9 monolithic Y-TZP specimens (6 for 1 x 106 and 3 for 2 x 106 cycles) and 10 porcelain-veneered Y-TZP specimens (all fatigue-loaded to failure). After fatigue tests, all specimens were subjected to post mortem damage examination from both occlusal and cross-sectional views by SEM (Hitachi 3500N, Tokyo, Japan) and optical microscopy. Specimens were sectioned across the center line of the wear crater along the sliding direction.

Statistical Analysis

Fatigue resistance of the 10 porcelain-veneered Y-TZP specimens served as the reference group. After it was shown that those observations were normally distributed, the probability that each specimen of monolithic zirconia or e-GZG came from that reference distribution was determined.

Results

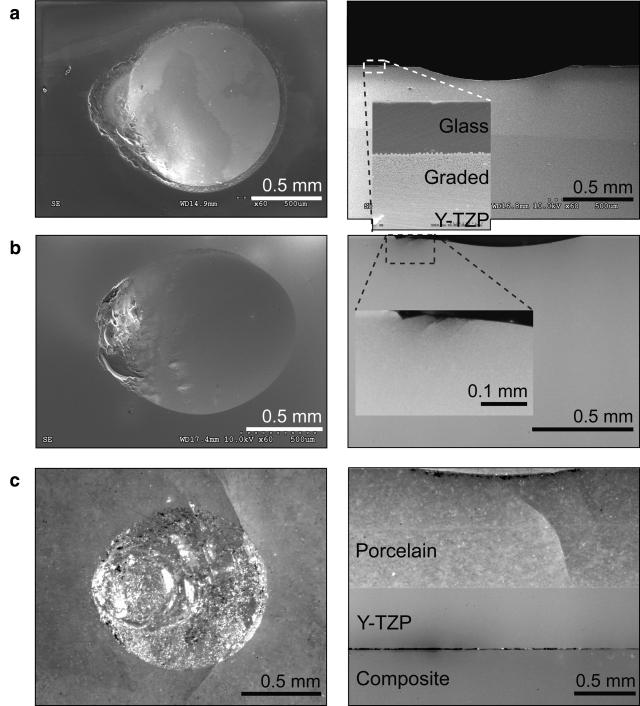

Typical damage features, from the occlusal and cross-sectional views of e-GZG and Y-TZP, after 106 cycles of sliding contact are illustrated in Figs. 2a and 2b, respectively; sliding direction is from right to left in the images. For comparison, a porcelain-veneered Y-TZP following 105 sliding contact cycles is also included (Fig. 2c). Partial cone cracks have developed and propagated through the entire porcelain layer, arresting at the veneer/core interface (Fig. 2c). e-GZG and monolithic Y-TZP had a shallow elongated wear crater, with the crater slightly deeper and larger in e-GZG than in Y-TZP. The contact area on the Y-TZP surface was smooth, but the leading edge of the crater appeared to be relatively rough; some microcracks were evident in the cross-sectional view (Fig. 2b and inset). The e-GZG specimen demonstrated a smooth mirror-like crater with a relatively rough, but shallow, nose at the leading edge (Fig. 2a). Although the external glass was partially removed because of the sliding wear caused by the hard WC indenter, no cracking or spalling was observed. The cross-sectional view revealed no cracks in either the external glass layer or the interior Y-TZP. Higher magnification SEM image of e-GZG revealed an external glass layer (~20 µm), a graded glass-zirconia layer, and the interior zirconia.

Figure 2.

SEM and optical images of the occlusal surface view (left) and cross-sectional view (right) for (a) e-GZG and (b) monolithic Y-TZP after 1 x 106 cycles of sliding contact loading. (c) Porcelain-veneered Y-TZP following 105 cycles of sliding contact loading. A high-magnification image for the area marked by dashed box in (a), showing the structure of e-GZG consisting of external glass, graded glass-zirconia, and interior of Y-TZP.

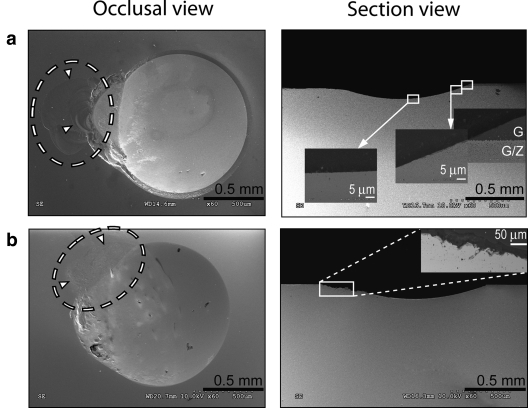

Representative fatigue damage sustained in e-GZG and monolithic Y-TZP specimens after 2 x 106 cycles of sliding contact loading is shown in Fig. 3. For e-GZG, no significant difference can be seen between damage features after 106 and 2 x 106 cycles of loading. Some minor material spalling was observed in the front of the moving indenter (highlighted by a dashed circle). In addition, a series of incomplete ring hackles was observed. These are associated with expanding median cracks caused by compressive stresses ahead of a moving indenter. Interestingly, the median cracks propagated within the esthetic glass layer, eventually intersected with the free surface, and resulted in material spalling. Higher magnification SEM along the sliding direction, from the rim to the bottom of the crater, revealed a smooth transition from the external glass to the bulk zirconia (see inserts in Fig. 3a, section view). In comparison, monolithic Y-TZP had a smooth wear crater at the trailing edge and a relatively coarse leading edge with minor material spalling and cracks (highlighted by the dashed circle and rectangular box in Fig. 3b).

Figure 3.

SEM images of the occlusal surface view (left) and cross-sectional view (right) for (a) e-GZG and (b) monolithic Y-TZP after 2 x 106 cycles of sliding contact loading. Material spalling is indicated by white dashed circles in the left-hand images. Insets on the right represent the higher magnification of the specific sites.

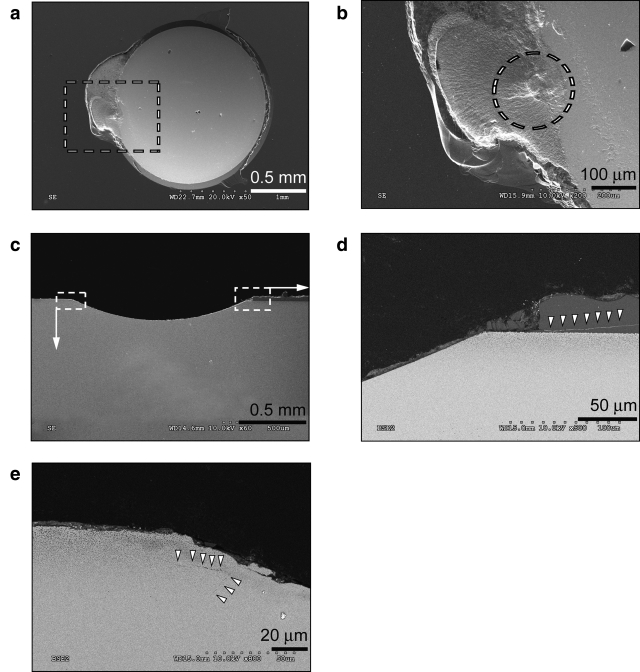

Damage features in e-GZG after 107 loading cycles are shown in Fig. 4. The occlusal surface view reveals lateral chipping and associated cracking of the external glass, along the rim of the crater at the trailing edge. An enlarged view (Fig. 4b) of the highlighted area in Fig. 4a shows a number of fine hackles originating from a dominant flaw at the leading edge of the wear crater (marked by a dashed circle). Cross-sectional view (Fig. 4c) reveals that the depth of the crater was ~180 µm. Higher magnification images of the regions highlighted in Fig. 4c are shown in Figs. 4d and 4e. The external glass layer on the crater rim was crushed, and glass debris was found on the wear surface. Cracks, indicated by the triangles, propagated laterally into the glass layer (Fig. 4d). Yet, no cracks formed in the graded layer or interior Y-TZP at the trailing edge. At the leading edge of the wear track, two fine cracks have advanced forward and downward. The forward crack may eventually intersect with the surface and result in lateral chipping, while the downward crack would be harmlessly arrested in the tough zirconia interior.

Figure 4.

SEM images of the (a) occlusal surface view and (c) cross-sectional view for the e-GZG specimen after 1 x 107 cycles of sliding contact loading. Note: Image (b) is the high magnification of the dashed-line marked area in (a); the white dashed-line circle indicates the origin of the hackles. Images (d) and (e) give the details at the trailing edge (dashed line site on the right) and the leading edge (dashed line site on the left) of the crater. Cracks in images (d) and (e) are indicated by solid white triangles.

As a point of reference, we first evaluated the fatigue resistance of the control porcelain-veneered Y-TZP specimens. The mean ± SD lifetime of these controls was 62,000 ± 28,500 cycles. Several of these specimens failed around 25,000 cycles, but even the two longest surviving specimens failed at 100,000 cycles. In contrast, all e-GZG and monolithic Y-TZP specimens survived their programmed tests to 1 x 106, 2 x 106, and even 1 x 107 (e-GZG only) cycles. Since the distribution of the control specimens gave no indication of skew (z = -0.17, p = 0.43), the probability that each of the experimental specimens was sampled from the reference distribution was determined under normal distribution assumptions. For example, the survival of a specimen to 106 cycles is more than 32 SDs above the mean of the reference distribution. While the probability of such an occurrence is non-zero, its exact level is infinitesimal, given that an observation only 5 SDs above the mean, 204,500 cycles, would be expected to occur within this distribution less than 0.0001%. Survival times longer than 106 would, of course, have an even lower probability of occurrence. Thus, it is quite improbable that the lifetimes exhibited by the monolithic Y-TZP or e-GZG specimens were the result of sampling variability within the reference distribution. Rather, data analysis suggests that both monolithic Y-TZP and e-GZG provided both statistically and clinically meaningful improvements in fatigue resistance relative to that of porcelain-veneered zirconia systems.

Discussion

A graded GZG structure with esthetic external glass demonstrates markedly enhanced damage resistance to sliding contact fatigue relative to porcelain-veneered zirconia systems, and also exhibited damage resistance comparable with that of monolithic Y-TZP after prolonged sliding contact. Our findings revealed that only fine cracks formed in e-GZG after 10 million sliding cycles at 200 N in water. In veneered zirconia, cracks propagated through the entire porcelain veneer (1 mm thick) following ~105 sliding cycles under the same load. The lower strength and toughness of porcelain, combined with residual thermal stresses induced from both CTE mismatch and low thermal diffusivity of Y-TZP, made the veneer layer more susceptible to sliding contact damage, leading to the high incidence of veneer chipping and fracture (Swain, 2009).

In e-GZG, the matched CTE between the infiltrating glass and Y-TZP produces a continuous transition from the external glass layer to the graded glass-zirconia structure and to dense Y-TZP interior without introducing substantial thermal stresses. Although sliding contact can induce cracks in the surface glass layer, damage is primarily lateral fracture and is confined to the thin external glass layer―cracks propagate parallel to the surface and then intersect the surface, resulting in spalling. Because of the limited thickness of this external glass layer (~20 μm), the size of the spalling is small. Additionally, lateral cracks do not preferentially propagate along the interface of external glass and graded glass-zirconia, even after 10 million cycles, suggesting a strong interfacial bond (Fig. 4d). Once the indenter advances through the external glass and reaches the graded glass-zirconia layer, the superior sliding contact damage resistance of the graded structure provides a long-term structural stability (Kim et al., 2010; Zhang and Kim, 2010). This is further verified after 10 million sliding cycles, when only a few fine cracks formed in the graded layer (Fig. 4e). If any of these cracks tend to propagate deep into the materials, they will be harmlessly arrested in the tough zirconia interior.

In an effort to prevent veneer chipping and fracture, some dental laboratories have developed monolithic Y-TZP restorations. While these new monolithic zirconia restorations have improved translucency compared to that of traditional dental zirconia, they do not have the shade options and the optical depth that porcelain-veneered zirconia restorations can offer. Changing the color of monolithic Y-TZP involves introducing additives to the starting material. However, these “impurities” also lower the strength of Y-TZP (Hjerppe et al., 2008; Shah et al., 2008). Additionally, the superior hardness and modulus of the monolithic zirconia can cause excessive wear of the opposing dentition.

Esthetics demands for dental restorations can be realized by this novel e-GZG structure. The external glass layer has desirable translucency and shade options, thereby compensating for monolithic Y-TZP’s opaque, unnatural white appearance. Furthermore, the shade of e-GZG can be modified by changing the glass composition, while the translucency of the material can be improved by infiltrating a translucent Y-TZP. The lower hardness and modulus glassy surface of e-GZG also protects the opposing dentition from excessive wear by the hard monolithic Y-TZP. The glass-rich cementation surface could facilitate a HF etching-silane procedure.

We acknowledge that the current fatigue tests were conducted with a WC indenter, which is much stiffer and harder than human dentition or porcelain veneers. Thus, the damage sustained in e-GZG represents the most severe case. Even in such harsh conditions, e-GZG survived 107 sliding contact cycles at 200-N load. At an average of 2000 biting cycles per day, 107 cycles is equivalent to 14 years of occlusion (Zhang et al., 2006). To assess the extent of wear, we conducted sliding fatigue on polished surfaces of porcelain-veneered and monolithic zirconia. To facilitate direct comparison, we also polished surfaces of pre-sintered zirconia before glass infiltration. We are aware that polishing restorations with complex shapes is much more difficult. Thus, in our anatomically correct e-GZG restoration, we infiltrated CAD/CAM machined and pre-sintered zirconia surfaces without polish. Additionally, investigation into the sliding damage resistance and esthetics of anatomically correct crowns is forthcoming. While e-GZG shows impressive improvements in fatigue resistance, results were based on relatively few specimens, and further corroboration is needed. Nonetheless, our findings suggest that e-GZG is a promising candidate for the next generation of all-ceramic restorations.

Footnotes

This study was supported by NIH/NIDCR R01 DE017925 (PI. Zhang) and NSF CMMI-0758530 (PI. Zhang).

The authors declare no potential conflicts of interest with respect to the authorship and/or publication of this article.

References

- Bornemann G, Rinke S, Huels A. (2003). Prospective clinical trial with conventionally luted zirconia-based fixed partial dentures—18-month results (abstract). J Dent Res 82(Spec Iss B): Abstract #0842. URL available at: http://iadr.confex.com/iadr/2003Goteborg/techprogram/abstract_31779.htm (accessed 05/10/2011). [Google Scholar]

- Crisp RJ, Cowan AJ, Lamb J, Thompson O, Tulloch N, Burke FJ. (2008). A clinical evaluation of all-ceramic bridges placed in UK general dental practices: first-year results. Br Dent J 205:477-482 [DOI] [PubMed] [Google Scholar]

- Edelhoff D, Florian B, Florian W, Johnen C. (2008). HIP zirconia fixed partial dentures—clinical results after 3 years of clinical service. Quintessence Int 39:459-471 [PubMed] [Google Scholar]

- Hjerppe J, Närhi T, Froberg K, Vallittu PK, Lassila LV. (2008). Effect of shading the zirconia framework on biaxial strength and surface microhardness. Acta Odontol Scand 66:262-267 [DOI] [PubMed] [Google Scholar]

- Jeong SM, Ludwig K, Kern M. (2002). Investigation of the fracture resistance of three types of zirconia posts in all-ceramic post-and-core restorations. Int J Prosthodont 15:154-158 [PubMed] [Google Scholar]

- Kim JH, Kim JW, Myoung SW, Pines M, Zhang Y. (2008). Damage maps for layered ceramics under simulated mastication. J Dent Res 87: 671-675 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kim JW, Kim JH, Janal MN, Zhang Y. (2008). Damage maps of veneered zirconia under simulated mastication. J Dent Res 87:1127-1132 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kim JW, Liu L, Zhang Y. (2010). Improving the resistance to sliding contact damage of zirconia using elastic gradients. J Biomed Mater Res B Appl Biomater 94:347-352 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Larsson C, Vult von Steyern P, Sunzel B, Nilner K. (2006). All-ceramic two- to five-unit implant-supported reconstructions. A randomized, prospective clinical trial. Swed Dent J 30:45-53 [PubMed] [Google Scholar]

- Larsson C, Vult von Steyern P, Nilner K. (2010). A prospective study of implant-supported full-arch yttria-stabilized tetragonal zirconia polycrystal mandibular fixed dental prostheses: three-year results. Int J Prosthodont 23:364-369 [PubMed] [Google Scholar]

- Lawn BR, Pajares A, Zhang Y, Deng Y, Polack MA, Lloyd IK, et al. (2004). Materials design in the performance of all-ceramic crowns. Biomaterials 25:2885-2892 [DOI] [PubMed] [Google Scholar]

- Molin MK, Karlsson SL. (2008). Five-year clinical prospective evaluation of zirconia-based Denzir 3-unit FPDs. Int J Prosthodont 21:223-227 [PubMed] [Google Scholar]

- Ohlmann B, Rammelsberg P, Schmitter M, Schwarz S, Gabbert O. (2008). All-ceramic inlay-retained fixed partial dentures: preliminary results from a clinical study. J Dent 36:692-696 [DOI] [PubMed] [Google Scholar]

- Olsson KG, Furst B, Andersson B, Carlsson GE. (2003). A long-term retrospective and clinical follow-up study of In-Ceram Alumina FPDs. Int J Prosthodont 16:150-156 [PubMed] [Google Scholar]

- Ortorp A, Kihl ML, Carlsson GE. (2009). A 3-year retrospective and clinical follow-up study of zirconia single crowns performed in a private practice. J Dent 37:731-736 [DOI] [PubMed] [Google Scholar]

- Pilathadka S, Vahalova D, Vosahlo T. (2007). The Zirconia: a new dental ceramic material. An overview. Prague Med Rep 108:5-12 [PubMed] [Google Scholar]

- Pospiech P, Rountree P, Nothdurft F. (2003). Clinical evaluation of zirconia-based all-ceramic posterior bridges: two-year results (abstract). J Dent Res 82(Spec Iss B): Abstract # 0817. URL available at: http://iadr.confex.com/iadr/2003Goteborg/techprogram/abstract_36651.htm (accessed 05/10/2011). [Google Scholar]

- Raigrodski AJ, Chiche GJ, Potiket N, Hochstedler JL, Mohamed SE, Billiot S, et al. (2006). The efficacy of posterior three-unit zirconium-oxide-based ceramic fixed partial dental prostheses: a prospective clinical pilot study. J Prosthet Dent 96:237-244 [DOI] [PubMed] [Google Scholar]

- Sailer I, Holderegger C, Jung RE, Suter A, Thievent B, Pietrobon N, et al. (2007a). Clinical study of the color stability of veneering ceramics for zirconia frameworks. Int J Prosthodont 20:263-269 [PubMed] [Google Scholar]

- Sailer I, Feher A, Filser F, Gauckler LJ, Luthy H, Hämmerle CH. (2007b). Five-year clinical results of zirconia frameworks for posterior fixed partial dentures. Int J Prosthodont 20:383-388 [PubMed] [Google Scholar]

- Schmitter M, Mussotter K, Rammelsberg P, Stober T, Ohlmann B, Gabbert O. (2009). Clinical performance of extended zirconia frameworks for fixed dental prostheses: two-year results. J Oral Rehabil 36:610-615 [DOI] [PubMed] [Google Scholar]

- Shah K, Holloway JA, Denry IL. (2008). Effect of coloring with various metal oxides on the microstructure, color, and flexural strength of 3Y-TZP. J Biomed Mater Res B Appl Biomater 87:329-337 [DOI] [PubMed] [Google Scholar]

- Swain MV. (2009). Unstable cracking (chipping) of veneering porcelain on all-ceramic dental crowns and fixed partial dentures. Acta Biomater 5:1668-1677 [DOI] [PubMed] [Google Scholar]

- Tinschert J, Schulze KA, Natt G, Latzke P, Heussen N, Spiekermann H. (2008). Clinical behavior of zirconia-based fixed partial dentures made of DC-Zirkon: 3-year results. Int J Prosthodont 21:217-222 [PubMed] [Google Scholar]

- Vult von Steyern P, Jonsson O, Nilner K. (2001). Five-year evaluation of posterior all-ceramic three-unit (In-Ceram) FPDs. Int J Prosthodont 14:379-384 [PubMed] [Google Scholar]

- Vult von Steyern P, Carlson P, Nilner K. (2005). All-ceramic fixed partial dentures designed according to the DC-Zirkon technique. A 2-year clinical study. J Oral Rehabil 32:180-187 [DOI] [PubMed] [Google Scholar]

- Zhang Y, Kim JW. (2009). Graded structures for damage resistant and aesthetic all-ceramic restorations. Dent Mater 25:781-790 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zhang Y, Kim JW. (2010). Graded zirconia glass for resistance to veneer fracture. J Dent Res 89:1057-1062 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zhang Y, Ma L. (2009). Optimization of ceramic strength using elastic gradients. Acta Mater 57:2721-2729 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zhang Y, Lawn BR, Malament KA, Van Thompson VP, Rekow ED. (2006). Damage accumulation and fatigue life of sandblasted dental ceramics. Int J Prosthodont 19:442-448 [PubMed] [Google Scholar]