Abstract

We assess the economic value of life-cycle air emissions and oil consumption from conventional vehicles, hybrid-electric vehicles (HEVs), plug-in hybrid-electric vehicles (PHEVs), and battery electric vehicles in the US. We find that plug-in vehicles may reduce or increase externality costs relative to grid-independent HEVs, depending largely on greenhouse gas and SO2 emissions produced during vehicle charging and battery manufacturing. However, even if future marginal damages from emissions of battery and electricity production drop dramatically, the damage reduction potential of plug-in vehicles remains small compared to ownership cost. As such, to offer a socially efficient approach to emissions and oil consumption reduction, lifetime cost of plug-in vehicles must be competitive with HEVs. Current subsidies intended to encourage sales of plug-in vehicles with large capacity battery packs exceed our externality estimates considerably, and taxes that optimally correct for externality damages would not close the gap in ownership cost. In contrast, HEVs and PHEVs with small battery packs reduce externality damages at low (or no) additional cost over their lifetime. Although large battery packs allow vehicles to travel longer distances using electricity instead of gasoline, large packs are more expensive, heavier, and more emissions intensive to produce, with lower utilization factors, greater charging infrastructure requirements, and life-cycle implications that are more sensitive to uncertain, time-sensitive, and location-specific factors. To reduce air emission and oil dependency impacts from passenger vehicles, strategies to promote adoption of HEVs and PHEVs with small battery packs offer more social benefits per dollar spent.

The electrification of passenger vehicles has the potential to address three of the most critical challenges of our time: plug-in vehicles may (i) produce fewer greenhouse gas (GHG) emissions when powered by electricity instead of gasoline, depending on the electricity source; (ii) reduce tailpipe emissions, which impact people and the environment; and (iii) reduce gasoline consumption, helping to diminish dependency on imported oil. Recognizing these benefits, US policymakers have provided federal tax credits of up to $7,500 per vehicle to encourage electrified transportation, with additional supporting policies enacted in many states (1, 2). Ideally, these policies would compensate for the externalities of energy use, such as damages to human health and to resources caused by emissions or oil consumption. Because such externality damages are not priced explicitly in the marketplace, they are not adequately accounted for in decision making, and users consume and emit more than they would have if they had born the full costs (3). Policymakers understand the impossibility of eliminating all externality damages; instead, laws favor determining which externality-reducing measures are worth paying for and which approaches reduce externality damages most efficiently.

In this study we assess, under a wide range of scenarios, how much externality damage reduction plug-in vehicles can offer in the US and at what cost. To answer this question, we gathered data on (i) the quantity and location of emissions released from tailpipes and from upstream processes to produce and operate vehicles, (ii) the externality costs of damages caused by the release of these emissions, and (iii) estimates of externalities and other costs to the US associated with oil consumption. We compare externality and oil consumption costs to the costs of owning and operating these vehicles and to subsidies designed to encourage their adoption. SI Text provides a detailed review of relevant literature.

Results

Emissions Damage Reduction Potential.

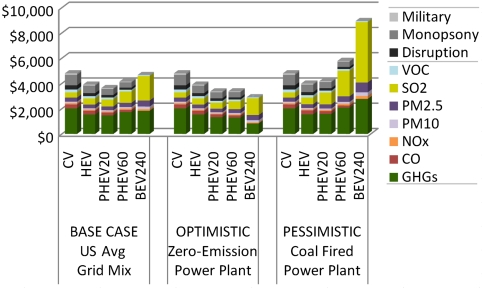

We estimate life-cycle emissions damages for comparable new midsize vehicles, including a conventional vehicle (CV), a hybrid-electric vehicle (HEV), plug-in hybrid-electric vehicles (PHEV) with battery packs sized for storing 20 km (PHEV20) or 60 km (PHEV60) of grid electricity (with the remainder powered by gasoline), and a battery electric vehicle (BEV) with a 240-km pack (and no gasoline engine). We estimate location-specific externality damages for releases of CO, nitrogen oxides (NOx), particulate matter (PM), SO2, and volatile organic compounds (VOCs) using data from a 2010 National Research Council (NRC) study (3, 4) with their $6 million estimate for value of statistical life, and we examine a range of estimates for damages from GHG emissions (3, 5). We combine these externality values with data on US driving patterns from the 2009 National Household Travel Survey (NHTS) (6) and data on manufacturing, fuel cycle, and operation emissions from Argonne National Laboratory (ANL) (7, 8) to estimate US life-cycle damages for each vehicle. Fig. 1 summarizes the results. In our base case, we assume average US values for emissions and damage valuation of electricity generation, oil refining, vehicle and battery production, driving location, and upstream supply chain emissions, we use a medium global valuation for GHG emissions, and we assume the battery will last the life of the vehicle. Although gasoline production and combustion produce significant emissions, battery and electricity production emissions are also substantial. We find that, in the base case, plug-in vehicles (PHEVs and BEVs) may produce more damage on average than today’s HEVs. This fact is due in large part to SO2 and GHG emissions from coal-fired power plants.

Fig. 1.

Value of life-cycle emissions externality damages and oil premium costs from vehicles ($2010). PHEVx, plug-in hybrid-electric vehicle with an x-km battery pack; BEVx, battery electric vehicle with an x-km battery pack.

Power plant emissions associated with charging a plug-in vehicle could be higher or lower than today’s US average grid mix, depending on region, time of day, regulations, such as caps on SO2 emissions or renewable portfolio standards, and anticipated plant retirement and new plant construction. Additionally, considerable variation in electricity emissions factors exists for each charging location depending on the geographic boundary chosen for analysis (9). To put bounds on these factors, Fig. 1 presents a hypothetical optimistic case, where zero-emission electricity is used to charge the vehicle, and a pessimistic case, where coal-fired power plants are used to charge the vehicle. In the pessimistic case, the BEV could be responsible for more than a $5,000 increase in lifetime damages over the HEV (all costs are in year 2010 US dollars, notated $2010). In the optimistic case, the BEV could reduce lifetime air emissions damages by about $100. Although the costs of damages from vehicle-associated emissions are significant, the damage reductions that can be gained through electrification are small compared to the total cost of owning and operating a vehicle (10). Additional sensitivity cases are described in the SI Text.

Oil Premium.

Because the US consumes about 23% of global oil production, US light-duty vehicles account for 45% of US oil consumption, and oil-fired power plants represent less than 1% of US electricity production, there is great interest in electrified transportation for displacing oil consumption (11, 12). The economic competitiveness of plug-in vehicles depends on gasoline prices; however, the economic cost to the US of its gasoline consumption includes at least three components beyond market price: (i) risk of losses due to oil supply disruptions, (ii) higher costs due to the effect of US demand on world oil prices, and (iii) the cost of existing policies meant to enhance oil security (13).

First, sudden disruptions of oil supply have the potential to cause price spikes. These spikes reduce US ability to generate economic output, cause temporary losses associated with dislocation and reallocation of resources, and cause additional wealth transfers to foreign countries. Brown and Huntington (14) estimate the externality portion of these costs at $5.24 (with a range of $1.16–$15.01) per barrel (bbl) of imported oil by estimating disruption frequency and magnitude from historical data. The gasoline portion of this cost, allocated on an energy basis, is $0.09 ($0.02–$0.28) per gallon.

The second component is the monopsony premium: Because the US demands a large portion of world oil consumption, if the US were to reduce oil consumption, world oil prices would likely fall, reducing the cost of the remaining oil consumed. Although this consideration is not an externality, it is a cost over which the US has some control. The effect on world oil prices of a drop in US demand depends on the reaction of oil producers, including the Organization of the Petroleum Exporting Countries. Leiby estimates the premium at $10.26 ($3.35–$21.21) per bbl of oil, or $0.22 ($0.07–$0.45) per gallon of gasoline (13).

The third component is cost of oil security policies, particularly military spending to protect oil supplies. The relevant literature and government rule-making have often assumed these costs to be nonlinear and coupled with other US strategic objectives, and they are often omitted from gasoline externality analyses (15–17). However, work by Delucchi and Murphy estimate the portion of these costs due to oil consumption from the Persian Gulf at $0.03–$0.16 per gallon of gasoline on average (18). We use the low end as an estimate of marginal cost in our base case, assuming that economies of scale result in marginal costs lower than average, and we examine a range in sensitivity analysis.

Fig. 1 shows the oil premium associated with supply disruption, monopsony power, and military spending added to air emission externality costs for each vehicle. With the oil premium added, the lifetime emissions externality and oil premium benefits of plug-in vehicles over HEVs remain small or negative. In the optimistic and pessimistic scenarios, plug-in vehicles provide up to $1,000 in savings or up to $4,000 in additional costs relative to HEVs, respectively. Although we account here for global damages from GHG emissions, we examine US oil premium costs, including costs of additional transfers to foreign countries. Implications and additional sensitivity cases are described in the SI Text.

Other Externalities and Factors.

Environmental damages from oil extraction, such as the recent Gulf oil disaster, although costly, are nonetheless small when divided by the volume of crude oil consumed in the US (19). The largest vehicle externality costs are associated with congestion and accident rates (15, 19). If the marginal cost of driving is reduced (e.g., via electrification), people may drive more, increasing externalities associated with congestion, accidents, and emissions. However, it is not yet known how the limited range of plug-in vehicles may affect driving behavior. Other externalities, such as noise and water pollution are not considered here due to lack of data with sufficient resolution (we discuss the magnitude of these effects in the SI Text); nor do we place economic value on equity issues with externality burdens (20).

There may be additional arguments for supporting plug-in vehicles in the US, including the following: reducing the trade deficit by shifting from foreign to domestic fuel sources, enabling a distributed storage resource to balance intermittent renewable electricity (21), reducing oil revenues to states hostile to US interests (16), hedging against an anticipated oil-scarce or carbon-constrained future (22, 23), improving regulatory control over emissions associated with poor vehicle maintenance (24), generating positive externalities by encouraging innovation (25), encouraging domestic development of strategic technical competency and intellectual property, manufacturing learning curve effects, reducing nonfinancial political and human suffering effects from war and political instability (18), and promoting international environmental justice. Quantification of these factors and estimates of life-cycle benefits of electrification would facilitate comparisons, and we encourage such analysis.

Lifetime Ownership Costs and Damages.

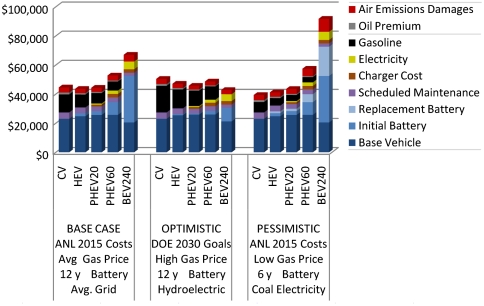

Fig. 2 summarizes lifetime private cost paid to own and operate each vehicle type plus the cost of the oil premium and damages caused by lifetime emissions charged to the owner at the time of purchase, assuming no change in driving patterns. In the base case, we use US average grid emissions, average gasoline prices in the period 2008–2010, a long battery life, scheduled maintenance costs estimated by Oak Ridge National Laboratories (26), charging infrastructure cost estimates based on installation data, and ANL estimates of vehicle costs in the year 2015. Although the lifetime costs of conventional, HEV, and PHEV20 are comparable, it is clear that the high costs of vehicles with larger battery packs are not balanced by fuel cost savings or emissions damage and oil premium reduction. We compare an optimistic scenario, using the highest historical weekly US gasoline price, US Department of Energy targets for vehicle costs in 2030 (which ANL calls “very optimistic”), long battery life, and zero-emission charging. In the optimistic scenario, plug-in vehicles with large battery packs could offer lower damage at lower lifetime cost. But competitiveness in this case is driven by direct costs, not externality damages, and market forces would presumably drive adoption in such a case. Conversely, in a pessimistic scenario using low gasoline prices, shorter battery life, coal-powered charging, and ANL 2015 cost estimates, plug-in vehicles could produce more damages at substantially higher cost.

Fig. 2.

Net present value of lifetime private ownership cost, emissions externality damages, and oil premium costs ($2010). ANL 2015 costs, Argonne National Laboratory cost estimates for the year 2015; DOE 2030 goals, US Department of Energy targets for vehicle cost in the year 2030; high, low, and average gas prices are for US weekly averages in 2008–2010; vehicle life is assumed to be 12 y.

We also examine a range of other factors that affect costs and damages, such as urban vs. rural driving, oil supply source, refinery location, emissions valuation, oil premium estimates, and discount rate (see SI Text). Although large battery packs offer the largest emissions and oil consumption reductions at lowest cost in the most optimistic scenarios, they result in high costs and increased damages if not all of the right factors fall into place, including high gasoline prices and achievement of low battery costs, long battery life, and low electricity production emissions. In contrast, HEVs and PHEVs with small packs are robust, providing emissions reductions and oil displacement benefits at low cost with less infrastructure investment and lower uncertainty.

Discussion

Our results suggest that plug-in vehicles with large battery packs may either reduce or create more life-cycle damages than HEVs depending largely on GHG and SO2 emissions from electricity and battery production. But even if future marginal electricity production and battery manufacturing processes have substantially lower emissions than today’s averages, the emission damage and oil premium reduction potential of plug-in vehicles is small compared to ownership cost: Optimally efficient (Pigovian) fees charged to correct for externality damages would not provide much leverage for incentivizing the adoption of plug-in vehicles with large battery packs unless their costs drop to competitive levels. Even GHG emissions allowance charges as high as $100/t do not substantially change the financial incentives for electrification (27, 28).

BEVs have the potential to offer the greatest reductions in emissions and oil consumption at competitive cost if air emissions from electricity generation are substantially reduced, battery prices drop dramatically, gasoline prices rise, high-power charging infrastructure is sufficiently deployed, and battery life is increased beyond vehicle life. Strong policy and support for research and development are needed to pursue this optimistic future; however, such outcomes are not guaranteed because of uncertain technological, economic, and political factors. In the near term, larger battery packs come at higher costs with greater infrastructure requirements and diminishing returns on social benefits, and they may fail to reduce emissions damages if the vehicles are charged in coal-heavy regions or if batteries are replaced before the vehicle’s end of life. In contrast, HEVs and PHEVs with small battery packs provide substantial emission damage reduction at low (or no) additional cost over their lifetime. In the future, if there are sufficient decreases in battery costs and increases in gasoline prices, the market may drive adoption of vehicles with larger battery packs. Until then, US policy would produce more benefit per dollar spent by supporting research on battery cost reduction, enforcing air emission reductions in power generation and transportation, and encouraging adoption of HEVs and small-capacity PHEVs (and potentially advanced conventional vehicles, not studied here). Some federal policies already follow this path. The Department of Energy’s Advanced Research Projects Agency, Energy program, which was started with funds made available through the American Recovery and Reinvestment Act of 2009, has allocated significant resources to support the development of better and cheaper batteries. Similarly, the Environmental Protection Agency has issued the National Renewable Fuel Standards (first established by the Energy Policy Act of 2005) to regulate the carbon intensity of transportation fuels and is in the process of issuing several regulations to further reduce conventional air pollutants from electricity. These efforts are complemented by State Renewable Portfolio Standards, which have established targets for the percentage of electricity that must be generated with renewable fuels. HEVs have received significant support via tax credits from the federal government in the past years; however, they expired in 2010 and have been replaced by tax credits for plug-in vehicles. Although these policies encourage adoption of alternative vehicles, policies that address externalities directly (e.g., carbon taxes, cap and trade systems, or gasoline taxes) would have the added benefit of encouraging consumers to find the most efficient means of reducing damages, including purchasing smaller vehicles or reducing driving.

Although an electrified transportation system coupled with low-emission electricity generation represents a promising path to achieving reductions of air emissions and petroleum consumption in the US, plug-in vehicles will have to compete on total cost of ownership in order to offer a realistic mass-market alternative and an efficient approach to achieving these reductions. US policy provides taxpayer support of research and development aiming to achieve cost parity together with subsidies to encourage deployment. However, current subsidies of up to $7,500 for vehicles with large battery packs are far larger than our optimistic estimates of externality benefits and represent GHG abatement costs well over $100/t in our base case (28). Subsidies would produce greater reductions of emissions damages and oil premium costs per tax dollar spent if targeted to HEVs and PHEVs with small battery packs. For example, in our base case, the current subsidy of up to $7,500 for up to 200,000 plug-in vehicles (2), implying a maximum total subsidy of $1.5 billion, could pay the purchase premium for 390,000 HEVs or 290,000 PHEV20s, reducing emissions externality damages and oil premium costs by $350 million or $330 million, respectively, compared to conventional vehicles. In contrast, $1.5 billion could pay the purchase premium for only 130,000 PHEV60s or 51,000 BEV240s, reducing damages and premium costs by $86 million or $7 million, respectively (lifetime fuel costs also vary). As battery technology improves, gasoline prices rise, the electricity grid improves, and constraints on GHG emissions become stringent, BEVs and PHEVs with large battery packs may become more cost effective at reducing damages. But today’s HEVs and PHEVs with small battery packs offer more emissions reduction and petroleum displacement per dollar spent with less of a need for new infrastructure and with lower uncertainty about future costs and life-cycle implications.

These US-specific findings may not extend to other countries. For example, it is possible that, in some European countries, the combination of higher petroleum prices, lower-emission electricity, higher population density, greater use of diesel, and shorter driving distances could make plug-in vehicles more attractive both for ownership cost and externality damage reduction.

Methods

We use life-cycle assessment (LCA) to identify and compare the emissions of each vehicle in our study. LCA is framework for evaluating emissions inventories and their impacts in complex systems. We evaluate a well-to-wheel system boundary including raw materials extraction and processing, manufacturing, vehicle operation, vehicle end of life (reuse, recycling, incineration, or land filling), and transportation connections between processes. We estimate NOx, SO2, PM, CO, VOCs, and GHG air emissions, including CO2, CH4, and N2O, converted to CO2 equivalence using 100-y Intergovernmental Panel on Climate Change global warming potential values (29). Specific components in the life-cycle boundary are vehicle and battery manufacturing (assembly and upstream), energy production (petroleum refining, electricity generation, and upstream emissions), and the direct emissions from driving (tailpipe, tire wear, and brake wear).

Allocation methods can be critical to the results of life-cycle assessment. Often, there are multiple coproducts in a system. In these cases, energy and material consumption as well as wastes and emissions must be allocated among the multiple coproducts. Petroleum refineries are an example of systems where allocation is required. Gasoline, diesel, liquefied petroleum gas, kerosene, and many other products are produced within the refinery boundary. We allocate petroleum production emissions based on the energy content of the refinery coproducts (mass and volumetric allocation produce similar results; see SI Text for a discussion of alternative approaches).

Emissions quantities for vehicle and battery manufacturing were evaluated with an analysis tool called The Greenhouse Gases, Regulated Emissions, and Energy Use in Transportation Model 2.7a (7) and are determined from a materials-based life-cycle inventory that captures raw material extraction, material processing, manufacturing, and transportation for major vehicle systems including the body, powertrain, transmission/gearbox, chassis, traction motor, generator, and electronic controller. Furthermore, lifetime fluid use and battery manufacturing, including lead acid, nickel metal hydride (NiMH), and Li-ion chemistries are determined. The CV and HEV were evaluated, the HEV data were used as a proxy for PHEV and BEV base vehicle production, and batteries were considered independently. Emissions associated with production of a single battery pack were estimated using GREET, and battery replacement frequency was adjusted as a sensitivity parameter. We use the NiMH chemistry for our HEV model. To estimate emissions for the larger battery packs associated with PHEVs and BEVs, we scale the HEV Li-ion battery pack production emissions linearly with pack weight, sizing the packs to meet the stated range on the Environmental Protection Agency’s urban dynamometer driving schedule (30). (The SI Text provides additional explanation of battery pack weight and sizing.)

The well-to-pump emissions of gasoline production were evaluated with the GREET 1.8d fuel-cycle model. GREET provides the ability to model many transportation fuel pathways, and conventional gasoline production is considered in this study. However, gasoline can be produced from a variety of sources including conventional crude and oil sands. In our sensitivity analysis, we consider 9.4% (current average US mix), 0%, and 100% of crude from oil sands, with the remainder from conventional crude in each case (8). These three scenarios are intended to provide bounds on average and marginal units of oil, which may vary in composition of source by location and over time. The GREET fuel-cycle model includes evaluation from extraction of crude product to processing and distribution of finished gasoline product. For feedstock production, recovery processes are determined for conventional crude, and bitumen extraction and upgrading (including hydrogen production) are evaluated for oil sands recovery (including surface mining and in-situ production). The feedstock production phase also includes transport from the recovery sites to US refineries, where processing to the finished gasoline product occurs. The fuel refining phase in GREET evaluates refinery energy use and processes, production of additives, and final transport and distribution to the pump.

Air emissions from electricity generation include direct emissions from combustion at the power plant and upstream emissions associated with fuel supply. We estimate direct emissions using the data from the NRC study (3), which in turn used the Emissions and Generation Resource Integrated Database (31). The NRC study includes data on NOx, SO2, PM10, PM2.5, and GHGs from coal and natural gas plants, which account for 70% of US electricity generation. We assume optimistically that the remaining 30% of plants produce energy with zero emissions. We estimate upstream emission factors per unit of coal or natural gas feedstock using GREET. We compute the average emissions per kilowatt hour generated in the US by weighting emissions from each plant by its production output. When determining impacts, we identify the plants with the 5th, 50th, and 95th percentile damages based on location.

Emissions from vehicle use depend on vehicle efficiency as well as the portion of propulsion energy powered by electricity versus gasoline. Although CVs and HEVs use only gasoline for propulsion and BEVs use only grid electricity, PHEVs use some of each. After a PHEV battery is fully charged, a PHEV will operate in charge-depleting mode (CD mode) until the battery’s state of charge drops to a predetermined level, at which point the vehicle switches to charge-sustaining mode (CS mode). We use midsize vehicle models defined in GREET 1.8d to estimate vehicle efficiency, vehicle emissions, and battery pack size requirements (30). To estimate the portion of driving propelled by electrical power, we use the 2009 NHTS (6), which interviewed over 140,000 people across the US on details of their travel behavior. We extracted data on total daily distance traveled over the survey population weighted by vehicle to correct for demographic differences in the survey sample. We used the remaining data to calculate the portion of distance that would be traveled in CD vs. CS mode for each vehicle, assuming one charge per day and using vehicle efficiencies estimated in GREET. All daily travel shorter than the CD-mode range is traveled entirely in CD mode, whereas daily travel longer than the CD-mode range is traveled partly in CD mode and partly in CS mode.

To convert the estimated life-cycle air emissions to cost of damages, the Air Pollution Emission Experiments and Policy (APEEP) analysis model was used (3, 4). APEEP calculates the marginal human health and environmental damages from emissions of PM2.5, PM10, VOC, NOx, and SO2 on a dollar-per-ton basis. APEEP is an integrated assessment model that evaluates emissions in each US county with human and environmental exposure, physical effects, and the resulting monetary damages determined from peer-reviewed findings from broad disciplines. Physical effects include epidemiological outcomes (e.g., mortality, bronchitis, asthma, cardiac), crop loss, timber loss, materials depreciation, visibility, and forest re-creation. Ground level release heights are used to evaluate emissions from driving, whereas estimates at stack-height elevations are used to evaluate the emissions from electricity generation and petroleum refining. APEEP accounts for secondary PM production from sulfate, VOC, and ozone formation, and the costs of these secondary pollutants are attributed to the appropriate emissions. For example, most of the damages associated with SO2 emissions are caused by exposure to secondary sulfate PM and ambient exposures to SO2. For each county and each pollutant, APEEP estimates mortality, morbidity, and environmental damages. We use the highest value of statistical life: $6 million ($2000) (4). Vehicles make up the largest source of CO emissions in the US, and APEEP does not evaluate this pollutant (32). To account for this emission, the median CO valuation cost from Matthews et al. (33) was employed and scaled with the APEEP county PM10 valuation costs, because CO, similar to PM10, is primarily linked to cardiovascular effects. We examine a range of GHG cost estimates based on refs. 3 and 5, which include changes in net agricultural productivity, human health, property damages from increased flood risk, and the value of ecosystem services due to climate change.

Vehicle cost estimates for years 2015 and 2030 were adapted from the Argonne National Laboratory’s 2009 report on transportation futures (34), which consist of targets set by the Department of Energy and estimates based on literature review and interviews with experts. The report estimates costs associated with a variety of subsystems and assumes that retail prices are 1.5 times costs for all vehicles. Estimates span those summarized in ref. 35. We adopt maintenance cost estimates from Oak Ridge National Laboratories (26), which lie within the range summarized in ref. 35, and our charger cost estimates are based on a range of unpublished data (see SI Text). For use-phase energy costs, we use maximum, minimum, and average costs from 2008–2010 from the Energy Information Administration. Lifetime operating costs are calculated using a base case nominal discount rate of rN = 8% and assuming annual inflation price increases of rI = 3%, resulting in a real discount rate of rR = 4.9%. Air emissions externality and oil premium costs are discounted at the same discount rate as though the corresponding fees are charged to the consumer at the time of purchase for vehicle, battery, gasoline, and electricity, and all upstream fees are passed along to the consumer. All monetary values are converted to 2010 dollars using the Energy Information Administration Gross Domestic Product Price Deflator (36). More information on these methods, data sources, and relevant literature is available in the SI Text.

Supplementary Material

Acknowledgments.

The authors thank Andrew Burnham and Dr. Jeongwoo Han at Argonne National Laboratory, Dr. Eladio Knipping and Marcus Alexander at the Electric Power Research Institute, Dr. Hill Huntington at Stanford University, Dr. Derek Lemoine and Dr. Tim Lipman at University of California, Berkeley, Dr. H. Scott Matthews, Dr. Allen Robinson, and the members of the Green Design Institute, Vehicle Electrification Group, Design Decisions Laboratory, and Center for Atmospheric Particle Studies at Carnegie Mellon University, and two anonymous reviewers for their helpful feedback. This work was supported in part by National Science Foundation (NSF) CAREER Grant 0747911 and MUSES Grant 0628084; the Carnegie Mellon Electricity Industry Center; and the Center for Climate and Energy Decision Making Center, through a cooperative agreement between the NSF SES-0949710 and Carnegie Mellon University. Sadly, Dr. Lester Lave passed away before the final revision of this article was completed and was unable to see the final version. He is greatly missed.

Footnotes

Conflict of interest statement: The corresponding author has received research funding from Ford Motor Company and Toyota Motor Corporation; however, these funds were not used to support the research presented here, and these organizations did not participate in proposing, defining, guiding, supporting, or evaluating the research presented here.

This article is a PNAS Direct Submission.

This article contains supporting information online at www.pnas.org/lookup/suppl/doi:10.1073/pnas.1104473108/-/DCSupplemental.

References

- 1.American Recovery and Reinvestment Act of 2009. 2009. Feb. Public Law 111-5.

- 2.US Department of Energy. Alternative Fuels and Advanced Vehicles Data Center. Washington, DC: US Dept Energy; 2011. http://www.afdc.energy.gov/afdc/laws. [Google Scholar]

- 3.Committee on Health Environmental and Other External Costs and Benefits of Energy Production and Consumption and National Research Council. Hidden Costs of Energy: Unpriced Consequences of Energy Production and Use. Washington, DC: Natl Acad Press; 2010. [Google Scholar]

- 4.Muller NZ, Mendelsohn R. Measuring the damages of air pollution in the United States. J Environ Econ Manag. 2007;54:1–14. [Google Scholar]

- 5.US Interagency Working Group on Social Cost of Carbon. Technical Support Document: Social Cost of Carbon for Regulatory Impact Analysis Under Executive Order 12866. Washington, DC: US Government; 2010. [Google Scholar]

- 6.US Department of Transportation. 2009 National Household Travel Survey. Washington, DC: US Dept Transportation; 2011. [Google Scholar]

- 7.Argonne National Laboratory. The Greenhouse Gases, Regulated Emissions, and Energy Use in Transportation (GREET) Vehicle Cycle Model Version 2.7a. Argonne, IL: Transportation Technology R&D Center, US Dept Energy; 2007. [Google Scholar]

- 8.Argonne National Laboratory. The Greenhouse Gases, Regulated Emissions, and Energy Use in Transportation (GREET) Fuel Cycle Model Version 1.8d. Argonne, IL: Transportation Technology R&D Center, US Dept Energy; 2010. [Google Scholar]

- 9.Weber CL, Jaramillo P, Marriott J, Samaras C. Life cycle assessment and grid electricity: What do we know and what can we know? Environ Sci Technol. 2010;44:1895–1901. doi: 10.1021/es9017909. [DOI] [PubMed] [Google Scholar]

- 10.Delucchi MA, Lipman TE. An analysis of the retail and lifecycle cost of battery-powered electric vehicles. Transport Res D-Tr E. 2001;6:371–404. [Google Scholar]

- 11.US Energy Information Administration. Annual Energy Review 2009. Washington, DC: US Dept Energy; 2010. [Google Scholar]

- 12.Davis SC, Diegel SW, Boundy RG. Transportation Energy Data Book. Washington, DC: Oak Ridge Natl Lab, US Dept Energy; 2010. [Google Scholar]

- 13.Leiby P. Estimating the Energy Security Benefits of Reduced US Oil Imports. Washington, DC: Oak Ridge Natl Lab; 2007. [Google Scholar]

- 14.Brown, Huntington H. Estimating US Oil Security Premiums. Washington, DC: Resources for the Future; 2010. [Google Scholar]

- 15.Parry IWH, Walls M, Harrington W. Automobile externalities and policies. J Econ Lit. 2007;45:373–399. [Google Scholar]

- 16.Crane K, et al. Imported Oil and US National Security. Santa Monica, CA: RAND Corp; 2009. [Google Scholar]

- 17.National Highway Traffic Safety Administration. Final Regulatory Impact Analysis, Corporate Average Fuel Economy for MY2012-MY2015 Passenger Cars and Light Trucks. Washington, DC: Natl Highway Traffic Safety Admin, US Dept Transportation; 2010. [Google Scholar]

- 18.Delucchi MA, Murphy JJ. US military expenditures to protect the use of Persian Gulf oil for motor vehicles. Energ Policy. 2008;36:2253–2264. [Google Scholar]

- 19.Delucchi MA. Environmental externalities of motor-vehicle use in the US. J Transp Econ Policy. 2000;34:135–168. [Google Scholar]

- 20.O’Rourke D, Connolly S. Just oil? The distribution of environmental and social impacts of oil production and consumption. Annu Rev Env Resour. 2003;28:587–617. [Google Scholar]

- 21.Kempton W, Tomic J. Vehicle-to-grid power implementation: From stabilizing the grid to supporting large-scale renewable energy. J Power Sources. 2005;144:280–294. [Google Scholar]

- 22.Lemoine D. Valuing plug-in hybrid electric vehicles’ battery capacity using a real options framework. Energ J. 2010;31:113–143. [Google Scholar]

- 23.Brandt AR, Farrell AE. Scraping the bottom of the barrel: Greenhouse gas emission consequences of a transition to low-quality and synthetic petroleum resources. Climatic Change. 2007;84:241–263. [Google Scholar]

- 24.Beaton SP, et al. On-road vehicle emissions—regulations, costs, and benefits. Science. 1995;268:991–993. doi: 10.1126/science.268.5213.991. [DOI] [PubMed] [Google Scholar]

- 25.Transport Electrification Panel Member, Faculty, and Staff. Plug-In Electric Vehicles: A Practical Plan for Progress. Bloomington, IN: School of Public and Environmental Affairs, Indiana University; Available at http://www.indiana.edu/~spea/pubs/TEP_combined.pdf. [Google Scholar]

- 26.Cleary T, et al. Plug-In Hybrid Electric Vehicle Value Proposition Study. Oakridge, TN: Oak Ridge Natl Lab and Sentech; 2010. [Google Scholar]

- 27.Shiau C-SN, Samaras C, Hauffe R, Michalek JJ. Impact of battery weight and charging patterns on the economic and environmental benefits of plug-in hybrid vehicles. Energ Policy. 2009;37:2653–2663. [Google Scholar]

- 28.Kammen DM, Arons SM, Lemoine DM, Hummel H. Cost-effectiveness of greenhouse gas emissions reductions from plug-in hybrid vehicles. In: Sandalow DB, editor. Plug-In Electric Vehicles: What Role for Washington? Washington, DC: Brookings Inst Press; 2009. [Google Scholar]

- 29.Solomon S, et al., editors. Contribution of Working Group I to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change. Cambridge, UK: Cambridge Univ Press; 2007. [Google Scholar]

- 30.Elgowainy A, et al. Well-to-Wheels Analysis of Energy Use and Greenhouse Gas Emissions of Plug-in Hybrid Electric Vehicles. Washington, DC: Argonne Natl Lab, US Dept Energy; [Google Scholar]

- 31.US Environmental Protection Agency. EGRID Emission Data for 2005. Washington, DC: Clean Energy Office, US Environmental Protection Agency; 2007. [Google Scholar]

- 32.US Environmental Protection Agency. National Emission Inventory Air Pollutant Emissions Trends. Washington, DC: US Environmental Protection Agency; 2008. [Google Scholar]

- 33.Matthews HS, Hendrickson C, Horvath A. External costs of air emissions from transportation. J Infrastruct Syst. 2001;7:13–17. [Google Scholar]

- 34.Plotkin S, Singh M. Multi-Path Transportation Futures Study: Vehicle Characterization and Scenario Analysis. Washington, DC: Argonne Natl Lab, US Dept Energy; 2009. [Google Scholar]

- 35.Delucchi M, Lipman T. Lifetime cost of battery, fuel-cell, and plug-in hybrid electric vehicles. In: Pistoia G, editor. Electric and Hybrid Vehicles: Power Sources, Model, Sustainability, Infrastructure and the Market. Amsterdam: Elsevier; 2010. pp. 19–60. [Google Scholar]

- 36.US Department of Commerce, Bureau of Economic Analysis, and US Energy Information Administration. Implicit Price Deflator, 1949–2009. Washington, DC: US Dept Commerce; 2010. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.