Abstract

In static secondary ion mass spectrometry (SIMS) experiments, an analysis dose of 1012 ions/cm2 typically produces optimum results. However, the same dose used in dual beam depth profiling can significantly degrade the signal. This is because during each analysis cycle a high-energy beam is rastered across the same x-y location on the sample. If a sufficient amount of sample is not removed during each sputter cycle, the subsequent analysis cycle will sample a volume degraded by the previous analysis cycles. The dimensionless parameter R’ is used to relate the amount of damage accumulated in the sample to the amount of analysis beam dose used relative to the etching beam. Depth profiles from trehalose films spin-cast onto silicon wafers acquired using Bi1+ and Bi3+ analysis beams were compared. As R’ increased, the depth profile and the depth resolution (interface width) both degraded. At R’ values below 0.04 for both Bi1+ and Bi3+, the shape of the profile as well as the depth resolution (9 nm) indicated that dual beam analysis can be superior to C60 single beam depth profiling.

Keywords: Bi, C60, cluster beams, depth profiling, chemical damage, trehalose

Introduction

The use of molecular depth profiling with time-of-flight secondary ion mass spectrometry (ToF-SIMS) is increasing in biology for the mapping of cellular structures or the detection of biological markers in three-dimensional space. Traditionally, depth profiling in microelectronics applications has focused on the detection of atomic species. In contrast biological applications typically require the detection of molecular species that are present in low concentration and are prone to fragmentation. Therefore it is important to determine parameters that provide the best depth profiles with maximal sensitivity and minimal sample damage.

ToF-SIMS depth profiling is frequently performed in the dual beam mode, where the analysis is decoupled from the sputtering/etching event by alternatively using two or more ion beams [1]. Although the dose of the analysis beam is usually kept well below the static SIMS limit of 1013 ions/cm2 (i.e., the dose limit below which every ion hits a fresh area of the sample), repeated analysis at the same sample location will increase the likelihood of sampling a damaged area. This is especially true for high energy analysis beams where the primary ions penetrate much deeper into the sample than the depth of material the sputter beam etches away [1]. However, since complex biological samples often contain nanoscale features and limited amount of material, it is desirable to keep the volume etched per cycle at a minimum. By setting the sputter beam dose to a constant value, we can then change the analysis beam dose to explore its effect on sample damage.

In this paper, we explore the effect of increasing the analysis beam dose during dual beam depth profiling on the degradation of the trehalose signal. Previously, a similar study was performed using a plasma polymerized tetraglyme as a model sample [2]. Extending this investigation to a non-polymeric sample is an intermediate step towards the analysis of biological cells and tissues. A ~150 nm thick trehalose film was spin-cast onto a silicon wafer and then depth profiled in the single beam and dual beam modes using different primary ions (Bi1+, Bi3+, C60+) at different analysis doses. The quality of ToF-SIMS depth profiles was assessed by the quantitative comparison of secondary ion yields and depth resolutions of the resulting depth profiles.

Experimental

ToF-SIMS experiments were performed using an ION-TOF TOF.SIMS 5–100 (IONTOF GmbH, Münster, Germany) equipped with a 25 kV Binq+ source (n = 1, 3, 5 and 7; q = 1–2) and a 10 kV C60q+ source (q = 1–3). In dual beam depth profiling, the Bin+ beam was rastered over a 100 × 100 µm2 area centered inside a 500 × 500 µm2 C60+ crater. In single beam depth profiling, a high-current bunched C60+ beam was rastered over a 25 × 25 µm2 area inside a 500 × 500 µm2 crater etched by C60+ in the sputtering mode. This raster size was experimentally determined to yield the best depth resolution [2]. The C60+ beam was switched from analysis to sputter modes using a batch job written in house. Depth profiles were acquired in the non-interlaced mode (analysis and sputtering are active in separate ToF cycles). Target currents were adjusted so that the total secondary ion count rate was ~200,000 counts/second: Bi1+ was set at 0.5 pA, Bi3+ was set at 0.08 pA, and the C60+ analysis beam was set at 0.04 pA. The analysis beam dose was varied from 5.1 × 1010 to 7.7 × 1011 ions/cm2 for Bi+, and from 8.3 × 109 to 1.2 × 1011 ions/cm2 for Bi3+. The dose of the C60+ analysis beam was 6.5 × 1010 ions/cm2. The current of the C60+ sputter beam was ~ 0.7 nA, and its dose was kept constant for all runs at 2.5 × 1012 ions/cm2.

A 10 cm silicon wafer (Silicon Valley Microelectronics, CA) was cut into 1 × 1 cm2 square pieces using a Kuliche & Soffa 780 dicing saw with a 15 µm diamond impregnated blade (Willow Grove, PA). Distilled water was used to wash away any dicing dust. Silicon pieces were soaked in 5% hydrofluoric acid (Aldrich Chemical Co.) for five minutes to remove the native oxide layer. Trehalose (Aldrich Chemical Co., Milwaukee, WI) films were prepared by spin casting 150 µL of 0.5 M solution onto these wafers (Ted Pella Inc., Redding, CA) at 6000 R.P.M. for 20 seconds. This casting process produced films with a thickness of ~ 150 nm.

The film thickness was measured by first gently scratching the film with a clean razor blade (Ted Pella Inc.) producing a channel that was approximately 5 µm in width, then using atomic force microscopy (AFM, Dimension 3100, Veeco Metrology Inc., Santa Barbara, CA) to measure the step height. An area of 50 × 50 µm2 was scanned to make sure that the step height was being measured relative to the flat, unperturbed part of the trehalose sample. The AFM was equipped with a 315 kHz, 42 N/m PointProbe Plus silicon tip (Nanosensors, Neuchâtel, Switzerland), and operated in the intermittent contact mode in air. At least five locations on the sample were scanned to determine the average thickness. The root mean square roughness of the cast trehalose film was < 0.7 nm (measured over a 400 µm2 area) across the sample surface.

Results and discussion

Previously, the ion dose density relationship between the analysis beam and the etching beam was normalized and defined as the R parameter [2]:

| Equation 1 |

where Φ is the per-cycle ion dose of the respective primary ion beam. Because of its simple design however, the R parameters could not be compared directly for Bi1+ and Bi3+ due to the large differences in the target currents and sputter yields of the two beams. In dual-beam depth profiling of inorganic samples, for example, the R parameter took into account the sputter ratios of the analysis and etching beams [3]. Similarly, this manuscript will attempt to correct for the differences in target currents by introducing a modified normalization scheme, the R’ parameter that will take into account the sputter ratio of the two beams:

| Equation 2 |

where Y is the sputter yield of the respective primary ion beam, measured in atoms sputtered per incident ion. The measured sputter yields were roughly 8.0 × 103 and 14.0 × 103 atoms/ion for Bi1+ and Bi3+ at an incident kinetic energy of 25 keV, and 9 × 103 atoms/ion for C60+ at 10 keV. The lower sputter yield of C60+ in comparison to the tri-atomic Bi ion is probably due to the large energy difference, which was also seen in an experimental study by Russo et al. [4]. A detailed discussion of sputter yields will not be made here. However, the sputter ratios are expected to be similar for other organic materials.

R’ varies from 0 for depth profiling in the C60 single-beam mode to 1 for profiles acquired using just the analysis beam. Increasing both the analysis and sputter beam doses while keeping R’ constant (e.g., doubling both doses) produced similar depth profiles (unpublished studies). We designated R’ = 0 for C60 single beam depth profiling since: 1) this study investigates the effect of Bin+ dose on the quality of depth profiles, so R’ = 0 would serve as a reference for comparing the quality of dual-beam depth profiles; and 2) increasing the dose of C60 analysis beam had no effect on the degradation of the signal observed in the profile, suggesting that C60+ ions induce much less damage than Bin+ ions.

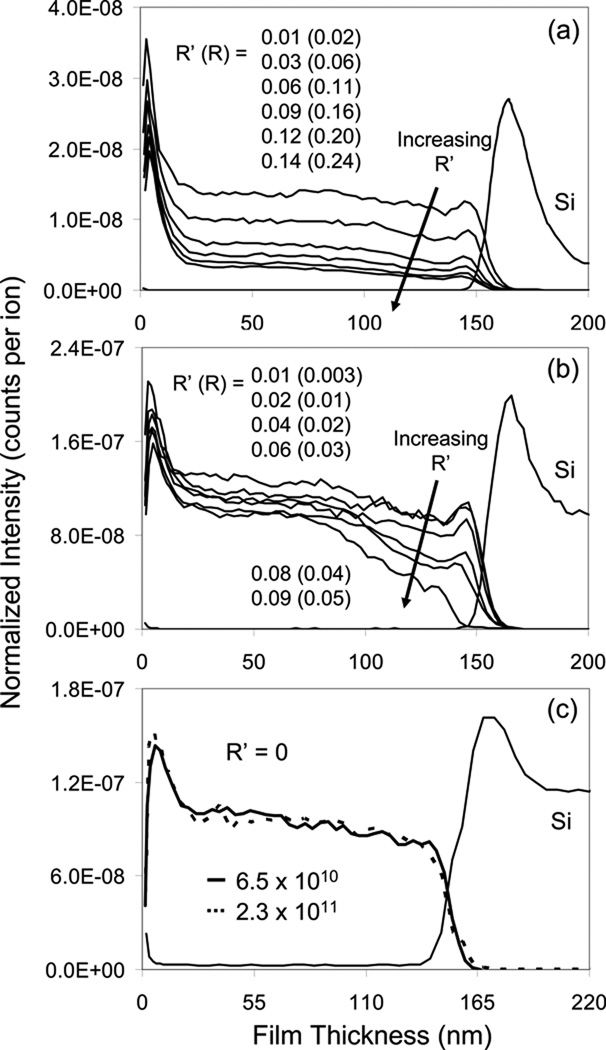

Figures 1a and 1b compare the effect of increasing Bi1+ and Bi3+ beam dose (per analysis cycle) on the degradation of the trehalose signal during dual beam depth profiling. The peak at m/z 325 was chosen to represent the trehalose signal since it is the molecular ion of trehalose ([M-OH]), having only a rate of degradation and no rate of formation. As can be seen, the depth profile of [M-OH] shows a characteristically rapid decay at the beginning, then a steady state region with a relatively constant intensity until it reaches the silicon interface. The increase in [M-OH] intensity preceding the rapid decay is mostly likely due to the presence of contaminants at the sample surface. This is believed to be the case since the event coincides with the small presence of silicon signal (PDMS) at the beginning of the depth profile.

Figure 1.

ToF-SIMS depth profiles of silicon (m/z 28) and trehalose [M-OH] (m/z 325) using (a) Bi1+, (b) Bi3+, and (c) C60+ analysis beams for all R’ values tested. The sputter beam was C60+. Note that the silicon intensities have been scaled to fit the figure. The R values are shown in parenthesis.

As can be seen in Figure 1a, increasing the Bi1+ dose resulted in an overall decrease in the steady state region. An increase from R’ = 0.011 to 0.032 showed an average signal loss within that region of about 3 × 10−9 counts/Bi1+ ion, and an increase from R’ = 0.032 to 0.062 showed an average signal loss of about 2 × 10−9 counts/Bi1+ ion. Further increase in R’ led to progressively smaller decreases in signal. On the other hand, an increase in R’ for Bi3+ did not significantly affect the initial portion of the steady state region, but degradation of the signal was seen nearer to the interface where the film had been etched to a depth of about 70 nm. As R’ was increased, the rate of this degradation increased. It should be noted that for a given analysis beam, the normalized intensities of Si (counts per ion) were the same for all R’ values investigated. These Si profiles were overlayed to make sure that the trehalose [M-OH] signals were normalized using the correct analysis beam dose.

From Figure 1, it is evident that the quality of Bin+/C60+ dual beam depth profiles is related to R’. At the lowest R’ values investigated, the profiles resembled that of the C60+ single beam, although the rate of decay in the beginning transient region was much sharper for Bi1+/C60+ dual-beam mode than for Bi3+/C60+ or C60+ single-beam. As R’ was increased, the [M-OH] intensities in the steady state region began to decrease, indicating an increase in damage accumulation as a result of increasing analysis beam dose. For Bi1+, the decrease occurred at the beginning of the steady state region, whereas for Bi3+, the decrease began at or around 70 nm into the trehalose film. Ultimately as R’ is increased to 1, the signal is expected to converge to zero before the interface is reached, which was the case in a study by Cheng et al. [5]. Since the dose of the sputter beam was kept constant at approximately 2.5 × 1012 ions/cm2 per sputter cycle for all profiles, a decrease in the [M-OH] signal as a function of R’ is attributed to the accumulation of damage within the sample by the analysis beam. More specifically, the degradation of the trehalose signal represents both the accumulation of damage by the analysis beam and the inability of 10 keV C60+ etching with 2.5 × 1012 ions/cm2 to completely remove that damage. There is a fine interplay between these two beam doses on signal degradation, and both the R and the R’ parameters were created to show this effect much more easily.

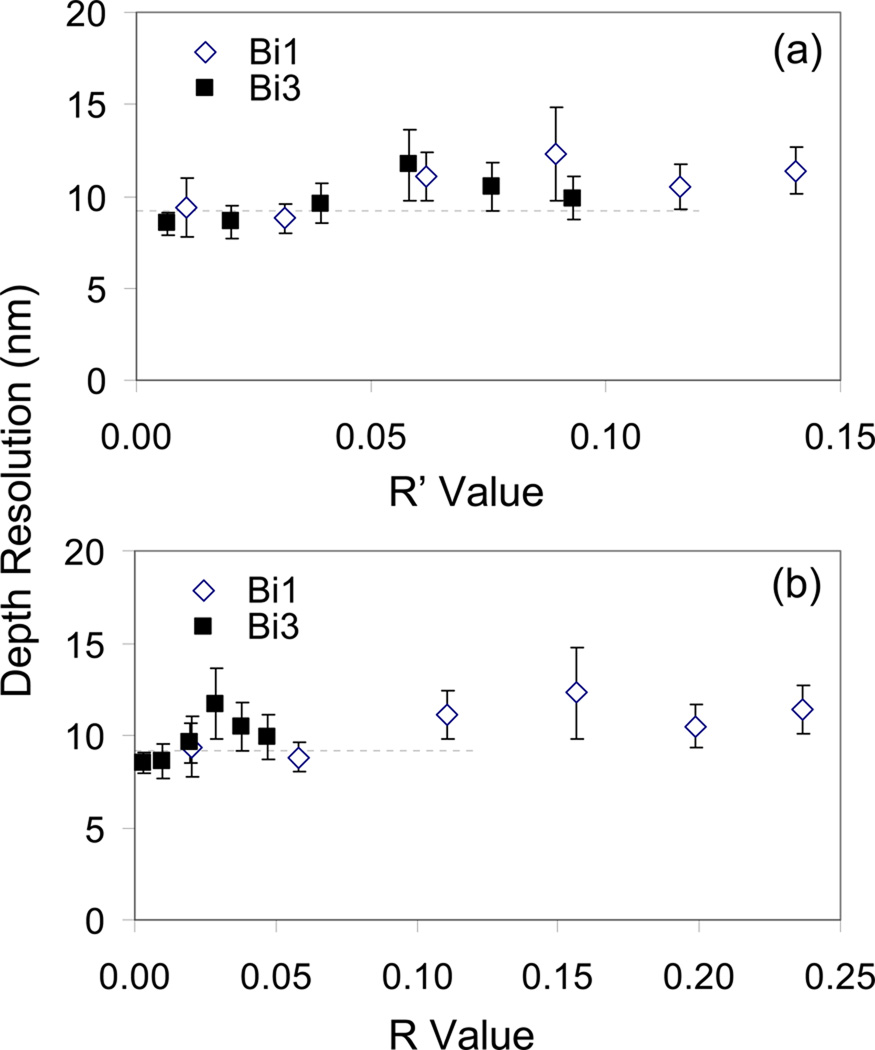

To quantitatively evaluate the quality of the depth profiles, the depth resolution at the silicon interface was used. The depth resolutions for Bi1+/C60+ and Bi3+/C60+ dual-beam depth profiles were determined for different R’ values and compared to those acquired in the C60+ single beam mode (Figure 2). As can be seen, the depth resolution worsens for increasing R’, albeit slowly, when using Bi1+ and Bi3+ analysis beams. This was expected since an increase in the dose of higher energy analysis beams would contribute to an increased degree of atomic mixing within the sample, including the interface. This result is consistent with other studies where the increased dose of the analysis beam relative to the etching beam dose resulted in the degradation of the depth resolution [2, 3, 6]. The resolution was expected to worsen more rapidly if the [M-OH] intensity did not jump at the silicon interface, which led to a sharper signal drop and consequently a better depth resolution. This is in contrast to depth profiles of plasma polymerized tetraglyme films from a previous study where the yield enhancements were present only for small R values [2]: as R increased, the jump in intensity at the interface became absent, and the depth resolution worsened quickly as a result. For C60 single beam depth profiling, this jump in intensity was not observed in the previous study as well as this study. It is not clear at this point why this phenomenon is seen only during the use of Bin+ ions, but a possible explanation may be a combination of back-scattering high energy projectiles from the hard inorganic silicon surface [7], and an ionization enhancement by the deposition of bismuth, perhaps similar to the way Cs+ enhances the ionization of a polymer overlayer [8]. Nonetheless, it was shown that if R’ was kept below 0.04, both Bi1+/C60+ and Bi3+/C60+ dual-beam depth profiles are able to produce the same depth resolutions as those obtained with a C60 single beam depth profile (~9nm). At these R’ values, dual-beam depth profiling becomes advantageous over single-beam depth profiling because of the higher mass and spatial resolutions provided by the bismuth analysis beam.

Figure 2.

Depth resolutions of the trehalose [M-OH] (m/z 325) peak as a function of (a) R’ and (b) R. The depth resolution was determined by measuring the distance between 84% and 16% of the signal intensity. The dotted line shows the depth resolution obtained using C60+ single beam depth profiling. The error bars represent standard deviations from three profiles.

As mentioned previously, a comparison of Bi1+ and Bi3+ profiles show clearly that there is a difference in the way these two beams induce chemical damage in the sample. Bi1+ lowers the intensity of the molecular ion over the entire steady state region, whereas Bi3+ degrades the signal at a film depth of ~70 nm. These observations can be attributed to the way monatomic and cluster ion sources remove material from the sample. Monatomic species penetrate much deeper than 1.5 nm of the film that is removed during each of the C60 sputtering cycle (SRIM calculations predict an implantation depth of 15 to 20 nm for a monatomic 25 keV Bi1+ ion striking a trehalose film [9]), resulting in more damage being accumulated than removed. This shows up as a decrease in intensity as a function of R’. Cluster ion sources on the other hand penetrate much less deeply and have a greater sputter yield [10, 11]. A combination of decreased damage volume and increased self-removal of that damaged volume probably results in a depth profile that shows little damage accumulation until a certain depth where damage does becomes significant. In this study, that depth was shown to be around 70 nm. In the previous study of tetraglyme films, Bi3+ dual-beam depth profiling showed little damage accumulation where, coincidentally, the tetraglyme film was only 70 nm thick. It would be interesting to compare Bi3+/C60+ dual-beam depth profiles in other organic films to see if significant damage accumulation occurs at this depth.

Conclusion

The objectives of this investigation were to examine the effect of increasing analysis beam dose on the quality of dual-beam depth profiles of organic films, and to evaluate the effectiveness of the R’ parameter in comparing Bi1+ and Bi3+ depth profiles. The results showed that as the analysis beam dose increased relative to the sputter beam dose, the depth profile quality decreased, consistent with previous results on polymerized tetraglyme films [2]. Optimum Bin+/C60+ dual beam profiles were obtained for R’ < 4%, where the shape of the depth profile resembled that of the C60 single-beam mode, and the 84% - 16% depth resolution at the silicon interface was 9 nm. In general, the use of Bi3+ produced better dual beam depth profiles that could tolerate more dose increases than Bi1+, most likely because it produced a significantly higher yield of secondary ions that effectively removed more of the sample damage caused by its own bombardment. Finally, the R’ parameter introduced sputter rates to provide a better normalization scheme. However, the data presented here suggests that more parameters are needed to correct for the target current differences between Bi1+ and Bi3+.

Acknowledgement

This research was supported by NIH grant EB-002027. Part of this work was conducted at the University of Washington NanoTech User Facility, a member of the NSF National Nanotechnology Infrastructure Network (NNIN).

Contributor Information

Shin Muramoto, University of Washington, Department of Chemical Engineering.

Jeremy Brison, University of Washington, Department of Bioengineering.

David Castner, University of Washington, Departments of Bioengineering and Chemical Engineering.

References

- 1.Postawa Z, Czerwinski B, Szewczyk M, Smiley EJ, Winograd N, Garrison BJ. Microscopic insights into the sputtering of Ag{111} induced by C-60 and Ga bombardment. Journal of Physical Chemistry B. 2004;108(23):7831–7838. [Google Scholar]

- 2.Brison J, Muramoto S, Castner DG. ToF-SIMS Depth Profiling of Organic Films: A Comparison between Single-Beam and Dual-Beam Analysis. The Journal of Physical Chemistry C. 2010 doi: 10.1021/jp9066179. (Article ASAP) [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Grehl T, Mollers R, Niehuis E. Low energy dual beam depth profiling: influence of sputter and analysis beam parameters on profile performance using TOF-SIMS. Appl. Surf. Sci. 2003;203–204:277–280. [Google Scholar]

- 4.Russo MF, Szakal C, Kozole J, Winograd N, Garrison BJ. Sputtering Yields for C60 and Au3 Bombardment of Water Ice as a Function of Incident Kinetic Energy. Analytical Chemistry. 2007;79(12):4493–4498. doi: 10.1021/ac070105l. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Cheng J, Wucher A, Winograd N. Molecular depth profiling with cluster ion beams. Journal of Physical Chemistry B. 2006;110(16):8329–8336. doi: 10.1021/jp0573341. [DOI] [PubMed] [Google Scholar]

- 6.Szakal C, Hues SM, Bennett J, Gillen G. Effect of Cluster Ion Analysis Fluence on Interface Quality in SIMS Molecular Depth Profilingâ€. The Journal of Physical Chemistry C. 2009 [Google Scholar]

- 7.Czerwinski B, Delcorte A, Garrison B, Samson R, Winograd N, Postawa Z. Sputtering of thin benzene and polystyrene overlayers by keV Ga and C60 bombardment. Appl Surf Sci. 2006;252:6419–6422. [Google Scholar]

- 8.Mine N, Douhard B, Brison J, Houssiau L. Molecular depth-profiling of polycarbonate with low-energy Cs+ ions. Rapid Commun. Mass Spectrom. 2007;21:2680–2684. doi: 10.1002/rcm.3135. [DOI] [PubMed] [Google Scholar]

- 9.Ziegler JF. Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms. SRIM-2003. 2004;219–220:1027–1036. [Google Scholar]

- 10.Postawa Z, Czerwinski B, Szewczyk M, Smiley EJ, Winograd N, Garrison BJ. Enhancement of sputtering yields due to C-60 versus Ga bombardment of Ag{111} as explored by molecular dynamics simulations. Analytical Chemistry. 2003;75(17):4402–4407. doi: 10.1021/ac034387a. [DOI] [PubMed] [Google Scholar]

- 11.Russo MF, Garrison BJ. Mesoscale Energy Deposition Footprint Model for Kiloelectronvolt Cluster Bombardment of Solids. 2006:7206–7210. doi: 10.1021/ac061180j. [DOI] [PubMed] [Google Scholar]