Abstract

Fracture strength of denture base resins is of great concern and many approaches have been made to improve the fracture resistance of acrylic resin dentures by strengthening them. Purpose of the study was to assess the effect of a Novel pre-impregnated glass fiber reinforcement system and nylon fiber reinforcement on the flexural strength of conventional heat-polymerized poly(methylmethacrylate) [PMMA] denture resin under dry and wet storage conditions. Forty specimens of standard dimensions were prepared for each of the four experimental groups; unreinforced conventional acrylic resin and the same reinforced with unidirectional Stick (S) glass fibers, woven Stick Net (SN) glass fibers and nylon fibers. Each group was further subdivided into two groups of 20 specimens each on the basis of storage conditions (dry and wet). All 160 specimens were then subjected to a 3-point bending test and flexural strength was calculated. Statistical analysis was carried out using student t test and 1-way analysis of variance (ANOVA). Stick and Stick Net glass fiber reinforcements enhanced the flexural strength of conventional heat-cured PMMA denture resin. Specimens reinforced with Stick glass fibers exhibited highest flexural strength followed by those reinforced with Stick Net glass fibers. Nylon fiber reinforcement decreased the flexural strength of acrylic resin. All the specimens in the four groups stored under wet conditions showed decrease in flexural strength in comparison to those stored in dry conditions. The reinforcement of denture base resin with pre-impregnated glass fibers may be a useful means of strengthening denture bases. Use of nylon as a reinforcement fiber is not desirable as it decreased the flexural strength of acrylic resin.

Keywords: Denture base material, Flexural strength, Glass fibers, Nylon fibers

Introduction

Acrylic resin is currently the most widely used denture base material. Introduction of poly (methyl methacrylate) [PMMA] for use as denture base material dates back to the year 1937 when Dr. Walter Wright clinically evaluated PMMA and found that it fulfilled all the requirements of an ideal denture base material [1]. Ever since its introduction, PMMA continues to be used because of its favorable working characteristics, processing ease, accurate fit, stability in oral environment, good color stability, superior esthetics, and use with inexpensive equipment. However, despite these advantages it has certain poor mechanical properties. Fractures may occur in use because of its unsatisfactory transverse strength, impact strength, or fatigue resistance.

Most dentures fracture inside the mouth, primarily due to resin fatigue, with midline fractures being commonly encountered [2, 3]. Outside the mouth, fracture occurs due to impact of falling.

Various modifications have been suggested to overcome these shortcomings, which included plasticization [4], copolymerization with rubber [5], use of crosslinking agents such as polyethylene glycol dimethacrylate and reinforcement with metal strengthener’s [6, 7].

Last two decades has seen a dramatic increase in the use of fiber-reinforced composites with different fibers such as glass [8–12], aramid [10, 11], carbon [10, 13–15], nylon [11, 16], whiskers [17] and ultra-high modulus polyethylene fibers [10, 18, 19], being incorporated in the acrylic resin.

Matthews and Smith [20] described the use of nylon as a denture base material fabricated using the injection molding technique. Very few studies in the past have tested the effect of nylon as a reinforcement fiber on the flexural strength of acrylic resin [11, 16].

However, studies have been carried out using the Novel glass fiber reinforcement system-Stick and Stick Net (Stick Tech Ltd, Turku, Finland) to find their effect on the flexural strength of acrylic resin.

In the absence of any study which evaluated the effect of nylon fiber reinforcement and glass fiber reinforcement system on the flexural strength of acrylic resin specimens stored under dry and wet conditions, the present in vitro study aimed to evaluate the same and compare it with the flexural strength of the unreinforced conventional PMMA resin.

Materials and Method

Materials used in the study were:

Heat-cured acrylic resin (Trevalon, Dentsply International)

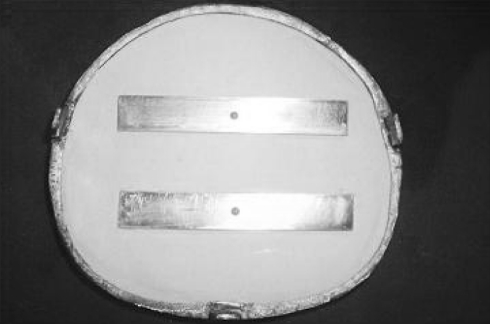

A Novel glass fiber reinforcement system [Stick (S) and Stick Net (SN)-Stick Tech Ltd, Turku-Finland] (Fig. 1)

Nylon fibers (Gujarat nylon company, Gujlon-Kim, Gujarat, India) (Fig. 2).

Fig. 1.

Unidirectional Stick and Woven Stick Net glass fibers (Stick Tech Ltd., Finland)

Fig. 2.

Nylon fibers (Gujarat Nylon–Kim–Gujarat)

The test specimens were made with dimensions of 65 mm × 10 mm × 3 mm complying with the ADA specification no. 12 for denture base polymers [21]. This enables the specimen to be tested for flexural strength on a 3-point bending apparatus (Universal Testing Machine).

A total of 160 specimens were fabricated for the study, which were divided into four groups (Group A, B, C & D) of 40 specimens each. Group A(Control) comprised of unreinforced acrylic resin specimens; Group B & C comprised of acrylic resin specimens reinforced with Stick (S) and Stick Net (SN) glass fiber reinforcement system; and Group D comprised of acrylic resin specimens reinforced with nylon fibers.

Specimens in each group were further subdivided into two groups (20 specimens each), based on dry (D—at room temperature) and wet (W—in distilled water for 7 days) storage conditions. The groups were then designated as Group A—D & A—W; Group B—D & B—W; Group C—D & C—W; and Group D—D & D—W.

Two fabrication conditions were kept constant for all the specimens.

Polymer: monomer ratio for each specimen was 2.4 g: 1.0 ml in all groups.

Polymerization of all specimens was carried out in two stages in a Hanau curing unit. Firstly, the temperature was raised slowly to 73°C and maintained for half an hour and then raised to 100°C and kept for another half an hour.

Fabrication of Standard Test Specimens

Two stainless steel dies (65 mm × 10 mm × 3 mm) coated with petroleum jelly were used to prepare dental plaster molds using the conventional flasking technique (Fig. 3).

Fig. 3.

Stainless steel dies used to prepare mold spaces of standard dimensions

Control group (Group A) test specimens were fabricated using the conventional heat-cured acrylic resin.

Group B and Group C acrylic resin specimens were reinforced with the Novel glass fiber reinforcement system (Stick and Stick Net). This system is based on pre impregnation of reinforcing fibers with a highly porous polymer allowing good impregnation of fibers with the polymer matrix. The highly porous polymer must be wetted with a mixture of polymer and monomer, subsequently allowing the porous pre-impregnated polymer to be plasticized by dissolution. The fibers could then be packed close to each other and polymerization of resin formed a dense fiber-reinforced composite. Stick (S) reinforcement was made from silanized continuous unidirectional glass fibers and Stick Net (SN) was made from silanized woven glass fibers. Silane coupling agent cured on these reinforcements is 3-methacryloxypropyl trimethoxysilane (3-MPS) which facilitates bonding with the resin.

S fibers were cut to a length of 60 mm and SN fibers cut to a length of 60 mm and width of 8 mm. Fibers were wetted with polymer-monomer mixture and sandwiched between two halves of acrylic resin packed in the mold spaces.

In Group D, nylon fibers were randomly oriented in the specimen. The amount of nylon fiber added in each specimen was 2% by weight of the polymer: monomer ratio. The fibers were cut into 1 cm long pieces and wetted in monomer for 10 min to ensure proper bonding with the acrylic resin. These fibers were then mixed in the polymer powder to which the monomer was added and the mixture was properly kneaded and packed in the mold cavity and cured.

The retrieved specimens were properly finished. Exposed fibers at the periphery were trimmed with diamond burs to avoid delamination. Specimens were then stored in dry and wet conditions respectively.

Testing of Prepared Specimens

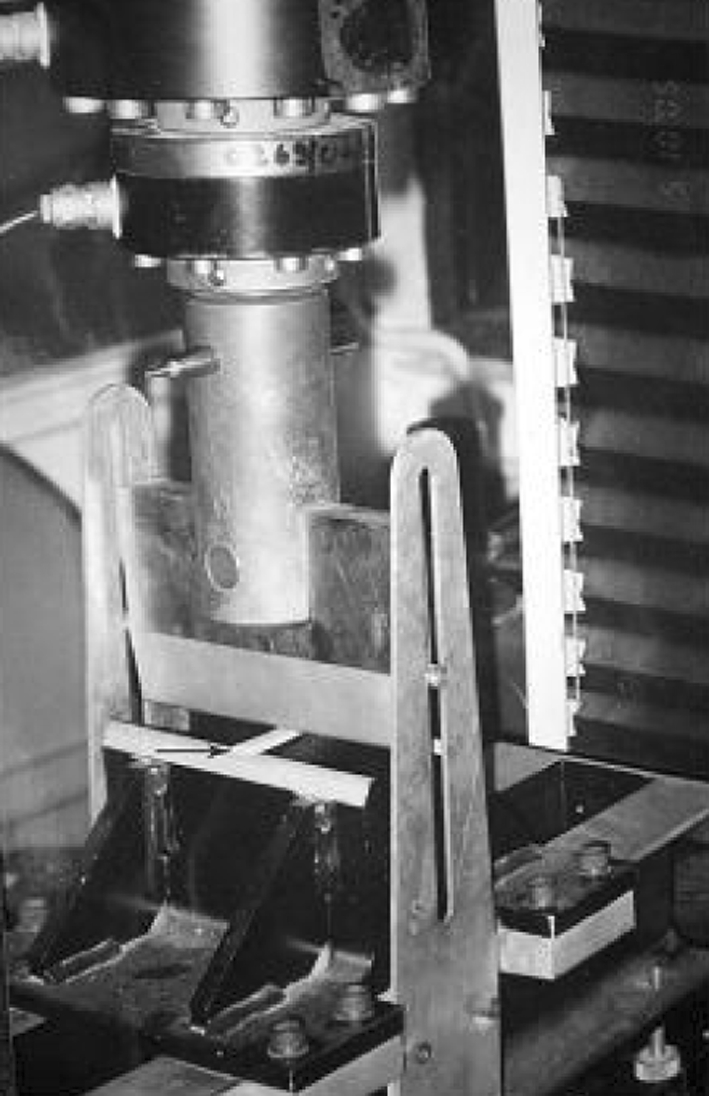

Width and thickness of each specimen was measured with a digital vernier caliper. The specimens were tested on an Instron universal testing machine (Lloyd LR 100K) at a crosshead speed of 5 mm/min (Fig. 4). The specimens were placed on jigs that were 50 mm apart (L) and then loaded at the center until fracture occurred. Maximum load at fracture was recorded and converted into flexural strength using the formula [22]

|

where F is the maximum load applied, L is span between two supports, b is width of the specimen and d is the thickness of the specimen.

Fig. 4.

Loading of specimen on the universal testing machine (Lloyd LR 100K)

Flexural strength was calculated and compared. Statistical analysis was carried out using Student t test and 1-way analysis of variance (ANOVA). Level of statistical significance was taken as P value ≤0.05.

Results

Under dry conditions, the mean flexural strength of control group specimens was 8.815 kgf/mm2, which increased to 12.02 kgf/mm2 on reinforcement with S fibers and to 9.76 kgf/mm2 on reinforcement with SN fibers. However the flexural strength decreased to 8.47 kgf/mm2 with nylon fiber reinforcement (Table 1)

Table 1.

Comparison of the reinforced groups (dry specimens) with control group A-D using Student t-test

| Group | Number of specimens | Mean transverse strength ± SD | P value (significant if ≤0.05) |

|---|---|---|---|

| Control | |||

| A-D | 20 | 8.815 ± 0.660 | 0.015 (significant) |

| B-D | 20 | 12.022 ± 1.126 | |

| A-D | 20 | 8.815 ± 0.660 | 0.401 |

| C-D | 20 | 9.761 ± 0.569 | |

| A-D | 20 | 8.815 ± 0.660 | 0.17 |

| D-D | 20 | 8.473 ± 0.508 | |

A-Group A, B-Group B, C-Group C, D-Group D, D at room temperature

Under wet conditions, the mean flexural strength of control group specimens was 8.52 kgf/mm2, which increased to 11.61 kgf/mm2 on reinforcement with S fibers and to 9.46 kgf/mm2 on reinforcement with SN fibers. However the flexural strength decreased to 8.17 kgf/mm2 with nylon fiber reinforcement (Table 2).

Table 2.

Comparison of the reinforced groups (wet specimens) with control Group A-W using Student t-test

| Group | Number of specimens | Mean transverse strength ± SD | P value (significant if ≤0.05) |

|---|---|---|---|

| Control | |||

| A-W | 20 | 8.525 ± 0.848 | 0.537 |

| B-W | 20 | 11.614 ± 0.933 | |

| A-W | 20 | 8.525 ± 0.848 | 0.001 (significant) |

| C-W | 20 | 9.467 ± 0.351 | |

| A-W | 20 | 8.525 ± 0.848 | 0.305 |

| D-W | 20 | 8.174 ± 0.727 | |

A-Group A, B-Group B, C-Group C, D-Group D, W in distilled water for 7 days

Therefore, both S and SN reinforcements under dry and wet conditions increased the flexural strength of acrylic resin but the increase is more marked with S reinforcement. Nylon fibers decreased flexural strength under dry and wet conditions.

On comparison of the three reinforced groups with the control group using student ‘t’-test (Tables 1, 2), the results were significant for specimens reinforced with S fibers stored under dry conditions (Group B—D) and specimens reinforced with SN fibers stored in wet conditions (Group C—W); while insignificant for rest of the groups on comparison with the control group.

An analysis of the difference in flexural strengths was performed with 1-way analysis of variance (ANOVA) for all the specimens in four groups (both under dry and wet conditions), and the results were found to be highly significant (Tables 3, 4).

Table 3.

One-way analysis of variance (ANOVA): dry specimens in all four groups

| Source | D.F. | Sum of squares | Mean squares | P value (significant if ≤0.05) |

|---|---|---|---|---|

| Between groups | 3 | 153.342 | 51.114 | <0.001 (highly significant) |

| Within groups | 76 | 43.4127 | 0.5712 | |

| Total | 79 | 196.7547 | – |

Table 4.

One-way analysis of variance (ANOVA): wet specimens in all four groups

| Source | D.F. | Sum of squares | Mean squares | P value (significant if ≤0.05) |

|---|---|---|---|---|

| Between groups | 3 | 143.3198 | 47.7733 | <0.001 (highly significant) |

| Within groups | 76 | 42.5866 | 0.5604 | |

| Total | 79 | 185.9064 | – |

Discussion

Glass fibers amongst the many types of reinforcement fibers has been tested in various studies and was found to be suitable for use in dentures. Nylon was used as a reinforcement fiber in studies carried out by Kelly [16], John et al. [11].

Problem constantly faced with the fiber reinforcement of acrylic resin is to achieve adequate impregnation of reinforcing fibers with resin; which is a prerequisite for proper bonding of fibers to the polymer matrix and thus for the strength of composite [23, 24].

This problem is solved to a great extent with the use of a Novel glass fiber reinforcement system (Stick and Stick Net) tested in this study. Other factors affecting the strength of fiber composites are quantity of fibers, orientation of fibers and adhesion of fibers to the polymer matrix [25].

Quantity of glass fibers used in this study is in consensus with a study carried out by Aydin et al. [12] who used the same Novel system. S and SN glass fibers in the present study were oriented perpendicular to the direction of applied force providing greatest potential for improvement of flexural fatigue and bending properties of the denture base resins [15]. The quantity of nylon fibers added in each specimen was 2% by weight of the polymer: monomer ratio [26].

S glass fibers gave highest strength to the fiber composite and are suitable in applications where the direction of highest stress is known. These fibers efficiently reinforce the polymer in only one direction, that is, in the direction of fibers in contrast to the bidirectional woven glass fibers which reinforce polymer in two directions and are therefore useful when it is difficult to predict the direction of highest stress. Therefore, the reinforcing effects of unidirectional fibers are anisotropic while woven fibers give orthotropic mechanical properties to the composite. The efficiency of woven fibers is one-half in contrast to the unidirectional fibers which have a reinforcing efficiency of one. This theoretical estimate of efficiency of fiber reinforcement is known as Krenchel’s factor [9, 25].

Results of the present study are in agreement with the Krenchel’s factor as the improvement of flexural strength with S reinforcement is more marked than with SN reinforcement. Similar conclusions have been drawn by Aydin et.al. [12] and Vallittu [9] in their studies carried out using these fibers. Advantage of being dissolved by dimethacrylate monomers permit the use of these reinforcements in fiber reinforced composite (FRC) crown and fixed partial dentures (FPD’s) [25].

Nylon is a type of thermoplastic polymer belonging to the class known as polyamides. It has outstanding features of toughness, low density, abrasion resistance, high melting point, high strength coupled with ductility and resistance to chemical attack [20]. However, their use as a denture base material was found unsatisfactory principally due to high molding shrinkage leading to warpage, high water sorption and yellowing [2].

Pre-impregnated nylon fibers are not commercially available. To ensure proper bonding of nylon fibers with acrylic resin, they were wetted with methyl methacrylate monomer for 10 min. No coupling agent was used with nylon fibers as based on the concept of solubility parameters for polymers [27, 28], any two polymers are miscible or compatible with each other if the difference in their solubility is ≤3.5 × 103 J1/2 M−3/2. When calculation of solubility of PMMA and nylon was done, it was found that the difference in solubility was <3.5 × 103 J1/2 M−3/2, thereby negating the need of a coupling agent.

Nylon fibers were randomly oriented in acrylic resin as placing them parallel to the long axis of the specimen caused some of the fibers to spread out laterally and were lost when the flasks were closed and bench pressed.

Storage of specimens in water decreased the flexural strength in all the four groups. Detrimental effects of water storage on the mechanical properties of acrylic resin have been suggested. Improper impregnation and wetting is associated with an increased water sorption [29] and inhibition of the radical polymerization of acrylic resin due to oxygen entrapment in the voids of poorly impregnated fiber composite. This might be associated with the reduced strength of the fiber composite [30]. Results of recent studies suggest that polymerization shrinkage of denture base resin between the fibers can also reduce the strength of FRC [23]. Discoloration of the reinforcement may also occur due to the penetration of oral microbes in these voids [30].

High water absorption tendency of nylon fibers [2] could be the contributing factor in decreasing the flexural strength of specimens stored in water.

Conclusion

Within the limitations of this study, results suggest that S and SN fibers are suitable for reinforcement of complete and partial dentures as they increased the flexural strength of acrylic resin. These fibers can also be used to strengthen FRC crowns, FPD’s and provisional restorations. However, further studies are suggested to assess the influence of prolonged water storage on the mechanical properties of acrylic resin reinforced with these fibers. Use of nylon as a reinforcement fiber is not desirable.

Source of support

The Novel glass fiber reinforcement system Stick (S) and Stick Net (SN) were funded by Stick Tech Ltd, Turku-Finland.

Conflicts of interest None.

References

- 1.Peyton FA. History of resins in dentistry. Dent Clin North Am. 1975;19:211–222. [PubMed] [Google Scholar]

- 2.Smith DC. Recent developments and prospects in dental polymers. J Prosthet Dent. 1962;12:1066–1078. doi: 10.1016/0022-3913(62)90162-2. [DOI] [Google Scholar]

- 3.Stafford GD, Smith DC. Flexural fatigue tests of some denture base polymers. Br Dent J. 1970;128:442–445. doi: 10.1038/sj.bdj.4802483. [DOI] [PubMed] [Google Scholar]

- 4.Jagger DC, Harrison A, Jandt KD. Review. The reinforcement of dentures. J Oral Rehabil. 1999;26:185–194. doi: 10.1046/j.1365-2842.1999.00375.x. [DOI] [PubMed] [Google Scholar]

- 5.Stafford GD, Bates JF, Hugget R, Handley RW. A review of the properties of some denture base polymers. J Dent. 1980;8:292–306. doi: 10.1016/0300-5712(80)90043-3. [DOI] [PubMed] [Google Scholar]

- 6.Ruffino AR. Effect of steel strengtheners on fracture resistance of acrylic resin complete denture base. J Prosthet Dent. 1985;54:75–78. doi: 10.1016/S0022-3913(85)80074-3. [DOI] [PubMed] [Google Scholar]

- 7.Vallittu PK, Lassila VP. Reinforcement of acrylic resin denture base material with metal or fiber strengtheners. J Oral Rehabil. 1992;19:225–230. doi: 10.1111/j.1365-2842.1992.tb01096.x. [DOI] [PubMed] [Google Scholar]

- 8.Solnit GS. The effect of methyl methacrylate reinforcement with silane-treated and untreated glass fibers. J Prosthet Dent. 1991;66:310–314. doi: 10.1016/0022-3913(91)90255-U. [DOI] [PubMed] [Google Scholar]

- 9.Vallittu PK. Flexural properties of acrylic resin polymers reinforced with unidirectional and woven glass fibers. J Prosthet Dent. 1999;81:318–326. doi: 10.1016/S0022-3913(99)70276-3. [DOI] [PubMed] [Google Scholar]

- 10.Uzun G, Hersek N, Tincer T. Effect of five woven fiber reinforcements on the impact and transverse strength of a denture base resin. J Prosthet Dent. 1999;81:616–620. doi: 10.1016/S0022-3913(99)70218-0. [DOI] [PubMed] [Google Scholar]

- 11.John J, Shivaputrappa AG, Shah I. Flexural strength of heat-polymerized polymethyl methacrylate denture resin reinforced with glass, aramid, or nylon fibers. J Prosthet Dent. 2001;86:424–427. doi: 10.1067/mpr.2001.118564. [DOI] [PubMed] [Google Scholar]

- 12.Aydin C, Yilmaz H, Caglar A. Effect of glass fiber reinforcement on the flexural strength of different denture base resins. Quintessence Int. 2002;33:457–463. [PubMed] [Google Scholar]

- 13.Schreiber CK. Polymethyl methacrylate reinforced with carbon fibers. Br Dent J. 1971;130:29–30. doi: 10.1038/sj.bdj.4802623. [DOI] [PubMed] [Google Scholar]

- 14.Manley TR, Bowman AJ, Cook M. Denture bases reinforced with carbon fibers. Br Dent J. 1979;146:25. doi: 10.1038/sj.bdj.4804188. [DOI] [PubMed] [Google Scholar]

- 15.Boer J, Vermilyea SG, Brady RE. The effect of carbon fiber orientation on the fatigue resistance and bending properties of two denture resins. J Prosthet Dent. 1984;51:119–121. doi: 10.1016/S0022-3913(84)80117-1. [DOI] [PubMed] [Google Scholar]

- 16.Kelly E. Fatigue fracture in denture base polymers. J Prosthet Dent. 1969;21:257. doi: 10.1016/0022-3913(69)90289-3. [DOI] [PubMed] [Google Scholar]

- 17.Grant AA, Greener EH. Whisker reinforcement of polymethyl methacrylate denture base resins. Aust Dent J. 1967;130:29–33. doi: 10.1111/j.1834-7819.1967.tb04242.x. [DOI] [Google Scholar]

- 18.Dixon DL, Breeding LC. The transverse strengths of three denture base resins reinforced with polyethylene fibers. J Prosthet Dent. 1992;67:417–419. doi: 10.1016/0022-3913(92)90261-8. [DOI] [PubMed] [Google Scholar]

- 19.Ramos V, Runyan DA, Christensen LC. The effect of plasma-treated polyethylene fiber on the fracture strength of polymethyl methacrylate. J Prosthet Dent. 1996;76:94–96. doi: 10.1016/S0022-3913(96)90348-0. [DOI] [PubMed] [Google Scholar]

- 20.Matthews E, Smith DC. Nylon as a denture base material. Br Dent J. 1955;98:231–237. [Google Scholar]

- 21.(1975) Revised American Dental Association specification no. 12 for denture base polymers. J Am Dent Assoc 90:451–458 [DOI] [PubMed]

- 22.Anusavice KJ. Phillips science of dental materials. 11. St. Louis: WB Saunders; 2003. pp. 89–90. [Google Scholar]

- 23.Vallittu PK. Acrylic resin-fiber composite-part II: the effect of polymerization shrinkage of polymethyl methacrylate applied to fiber roving on transverse strength. J Prosthet Dent. 1994;71:613–617. doi: 10.1016/0022-3913(94)90447-2. [DOI] [PubMed] [Google Scholar]

- 24.Vallittu PK. The effect of void space and polymerization time on transverse strength of acrylic-glass fiber composite. J Oral Rehabil. 1995;22:257–261. doi: 10.1111/j.1365-2842.1995.tb00083.x. [DOI] [PubMed] [Google Scholar]

- 25.Vallittu PK. The first symposium on fibre reinforced plastics in dentistry. Finland: University of Turku, Institute of Dentistry & Biomaterials Project; 1999. pp. 4–14. [Google Scholar]

- 26.Vallittu PK, Lassila VP, Lappalainen R. Acrylic resin-fiber composite-part I: the effect of fiber concentration on fracture resistance. J Prosthet Dent. 1994;71:607–612. doi: 10.1016/0022-3913(94)90446-4. [DOI] [PubMed] [Google Scholar]

- 27.Brydson JA (1999) Relation of structure to chemical properties. In: Plastic materials, Butterworth-Heinemann, Oxford, pp 76–88

- 28.Schroeder E, Muller G Polymer characterization. Determination of solubility parameter. pp 306–311

- 29.Vallittu PK, Ruyter IE, Ekstrand K. Effect of water storage on the flexural properties of E-glass and silica fibers acrylic resin composite. Int J Prosthodont. 1998;11:340–350. [PubMed] [Google Scholar]

- 30.Vallittu PK. Oxygen inhibition of autopolymerization of polymethyl methacrylate-glass fiber composite. J Mater Sci Mater Med. 1997;8:489–492. doi: 10.1023/A:1018578210453. [DOI] [PubMed] [Google Scholar]