Abstract

Long-term clinical failures of cemented prosthesis depend, to a large extent, on the integrity of the luting agent. The causative factors that lead to microfracture and, hence, failure of the luting agents are the stresses acting inside the oral cavity. Therefore, the present study was designed to develop an understanding of the relationship between stresses in the tooth and the failure potential of the luting agent. Two-dimensional finite element stress analysis was performed on the mandibular second premolar. The behavior of zinc-phosphate and glass-ionomer were studied under different crowns (metal–ceramic and metal crown) and loading conditions (mechanical force of 450 N acting vertically over the occlusal surface, thermal loads of 60° and 0°C). It was observed from the study that failure threshold of the luting agent was influenced both by the elastic modulus of the luting agent and by the type of the crown.

Keywords: Finite element, luting agent, metal-ceramic crowns, stress distribution

Introduction

Longevity of the restoration inside the oral cavity requires appropriate material properties that can withstand intraoral changes like temperature fluctuations with intake of hot/cold food and drinks and intermittent forces during mastication. Keeping this in view, a variety of materials have been developed for restorative crowns and bridges. These materials must satisfy a number of mechanical, thermal and optical criteria to withstand the rigors of application. Functional occlusal loading during mastication and temperature variations within the oral cavity can generate stresses in the teeth, and the distribution of stresses is affected by the type of the crown and the nature of the luting agent. As the failure threshold of the dental cement

This research is a part of Thesis-Finite Element Stress Analysis in Metal-Ceramic and Metal crown using two different cements, Nov. 2005 submitted by Hema Agnihotri to the faculty of All India Institute Of Medical Sciences in the partial fulfillment of the requirements for the degree of Master of dental Surgery( Prosthodontics) is less than that of the restoration and dentin, the most vulnerable sites for fracture are either within the cement layer or at the cement interface, thereby leading to microleakage and changes in the stress distribution to the supporting structures. Although many attempts have been carried out to improve dental restorative materials, there is still a big difference, particularly in the mechanical and the physical properties of the tooth and the restorative materials. These mismatches can result in excessive stresses, leading to the failure of the restoration. With respect to luting agents, Finite Element Analyses (FEA) studies conducted so far have been focused primarily on parameters like elastic moduli[1–7] and thickness of the cementing medium,[2,5,8,9] with the main concern on the resulting stresses of the overlying crown. For the success of the indirectly fabricated restoration, it is essential to have an understanding of the factors that are detrimental to the integrity of the luting agent.

Therefore, the present study has been designed to develop an understanding of the relationship between stresses in the tooth and the failure potential of the luting agent, thereby reducing or eliminating the factors contributing to the failure of restoration. The objective behind the study is to know about the favorable distribution of stresses so as to predict a compatible combination of crown material and luting agents that can help a clinician in providing a more durable choice of restoration to the patients, thereby lessening the extra expenditure and inconvenience involved in refabrication.

Materials and Methods

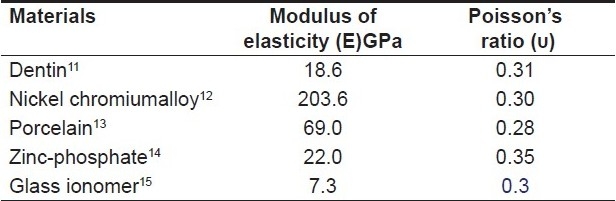

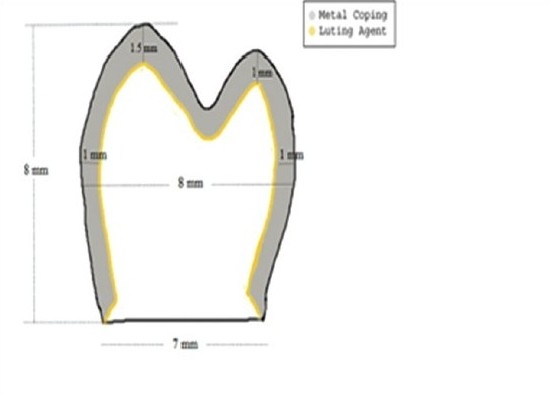

To study the effect of thermal and mechanical stresses, luting agents chosen were zinc-phosphate (which, despite its well-documented disadvantages,[10] is still most commonly used) and conventional glass-ionomer cement (GIC, which offered the advantages of chemical bonding to the tooth along with minimal disintegration in the oral cavity). The behaviors of the luting agents were studied under metal–ceramic (Ni–Cr and feldspathic porcelain) and metal (Ni–Cr) crown. The metal crown is the most favored choice of restoration in the posterior region, which combines strength of the metal with minimal involvement of natural tooth structure, whereas the metal–ceramic crown combines strength and esthetics altogether in a single restoration. The mechanical and thermal properties of the materials under study were obtained from the previous literature [Tables 1 and 2].

Table 1.

Mechanical properties of the materials used in finite element model

Table 2.

Thermal properties of the materials used in finite element model

Finite element modeling and loading conditions

The problem of stresses in the tooth is complicated because of the non-homogenous, anisotropic and unsymmetrical character of the tooth structure and large variations of chewing forces and temperature fluctuations. For this reason, conventional methods (experimental and analytical) are inadequate to give correct results about the true distribution stresses in the tooth. Promising results for such complex problems is offered by the FEA, which is a highly precise technique to analyze the structural stress distribution in any complex system. The present study has been carried out on 2-D plane strain finite element formulation to study the mandibular 2nd premolar using software ABAQUS 6.5v.[19]

Although 3-D finite element modeling offers a better solution for the complex structures, it relies on the axisymmetric configuration, which is obtained by revolving the half section of the tooth about the Z-Z axis, and then it offers reasonable approximation. The accuracy of the 3-D results will hold true for the complex structures that are axisymmetric but, for the mandibular premolar which has a complex structure and is non-axis-symmetric, results obtained from 2-D analysis will be a close approximation to those obtained with the 3-D analysis. Keeping these factors in view, a 2-D analysis was performed on non-axisymmetric models. This will help reduce the computational time.

The following assumptions were made in the study:

Materials used in the study were considered homogenous, isotropic and linearly elastic.

Loads acting on the restored tooth were static in nature.

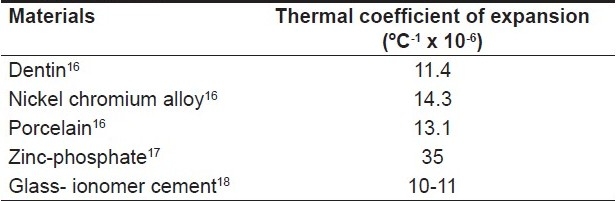

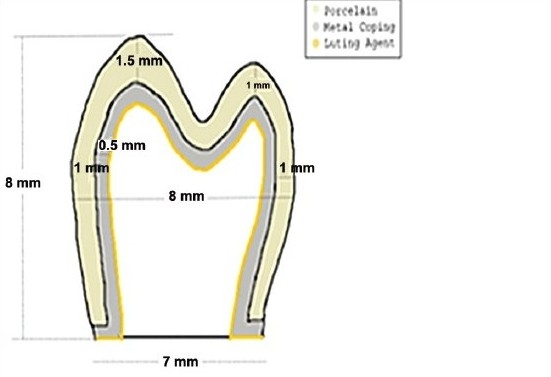

The first and foremost step in FEA involves construction of geometry. Schematic views of metal–ceramic and metal crown (B-L view) as seen in Figures 1a–2a have dimensions that stimulate true anatomic configurations so as to obtain true realistic loading conditions.

Figure 1a.

Schematic view of Metal-ceramic crown use in FE Simulation[20,22,23]

Figure 2a.

Schematic view of metal crown used in FE Simulation[20,21,23]

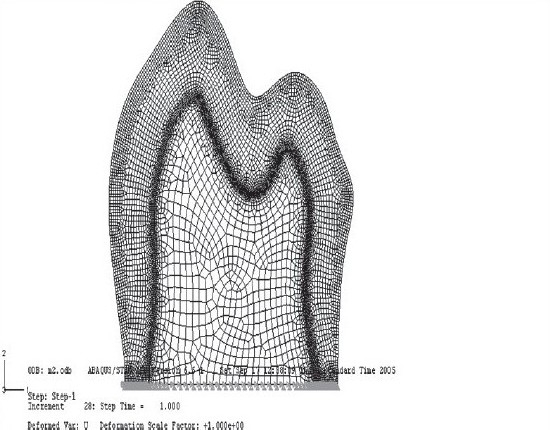

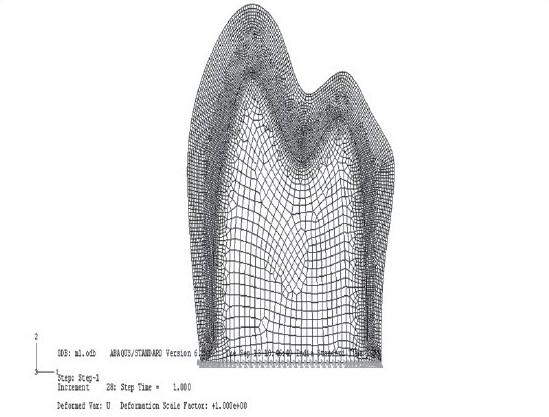

Finite element mesh obtained by discretisation resulted in finite element models [Figures 1b–2b] characterized by 3 nodes triangular element and 4 nodes quadrilateral elements. The length of the luting agent at the interface was 25 μm. Boundary conditions were applied at the cemento–enamel junctions [Figures 1b and 2b]. FE models comprised of restorative crown, luting agent and dentin, while the root portion was ignored. Both linear displacement and rotation degrees of freedom were considered zero at the boundary conditions.

Figure 1b.

Finite Element model of metal-ceramic crown

Figure 2b.

Finite element model of metal crown

A simulated average biting force of 450 N vertically over the occlusal surface and thermal stimulation of 60° and 0°C were applied on the mandibular 2nd premolar.

Results and Discussion

Luting agents zinc-phosphate and GIC were compared under the following conditions:

Two different crown materials: metal and metal–ceramic.

Loading conditions: mechanical, under 450 N, acting vertically over the center of the tooth, thermal load at 60° and 0° C.

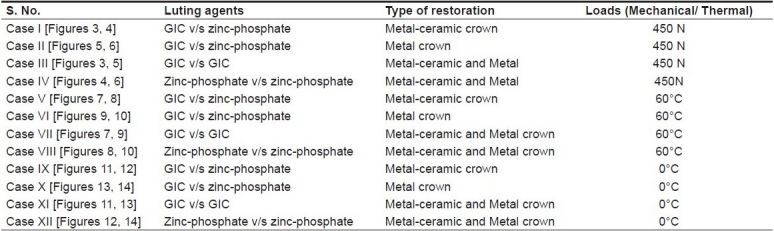

Corresponding to the above-mentioned variables, the underlying test cases were compared for the results [Table 3].

Table 3.

Test cases for comparative evaluation

Observations

1. Stress distribution between the GIC and the zinc-phosphate luting agents with metal–ceramic crown.

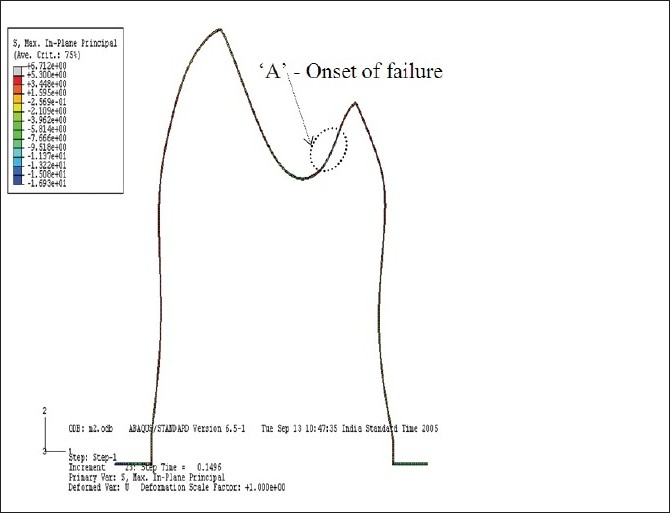

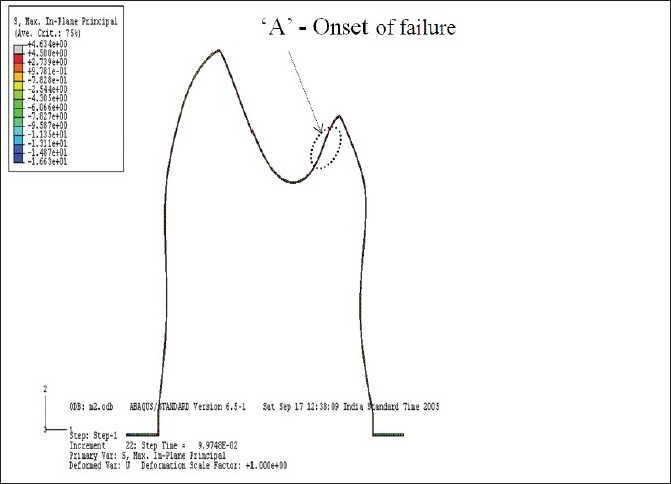

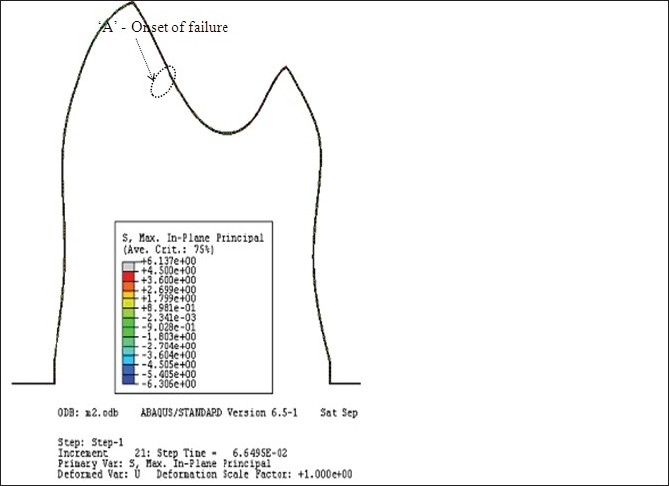

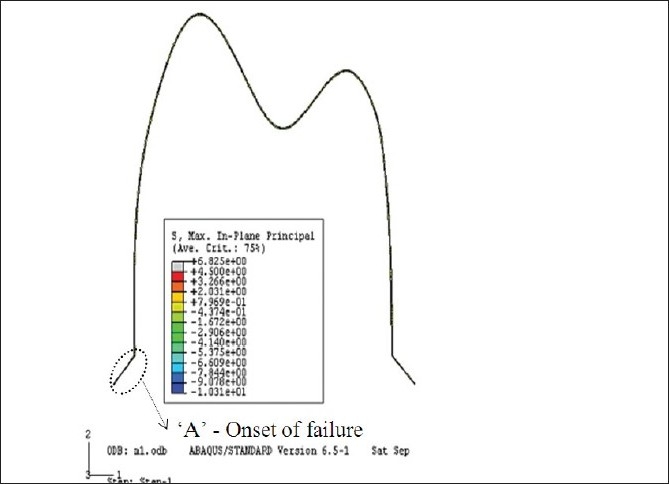

Under a mechanical load of 450 N, it was observed that zinc-phosphate failed earlier at an increment of 22 whereas the increment of failure for GIC was 23, although the site was similar. Thus, failure of zinc-phosphate occurred earlier than GIC [Figures 3–4].

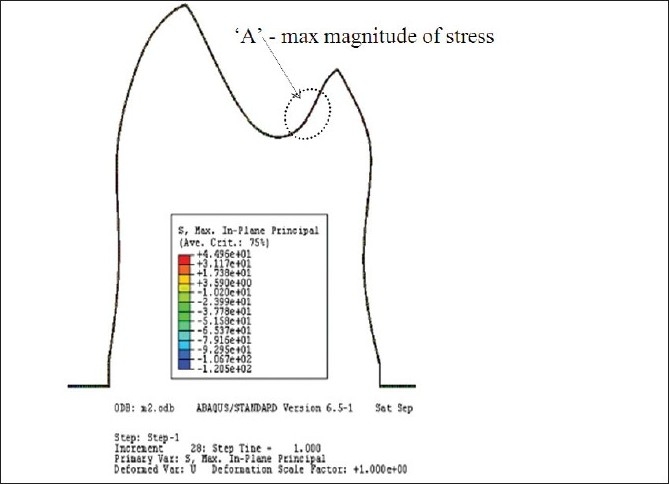

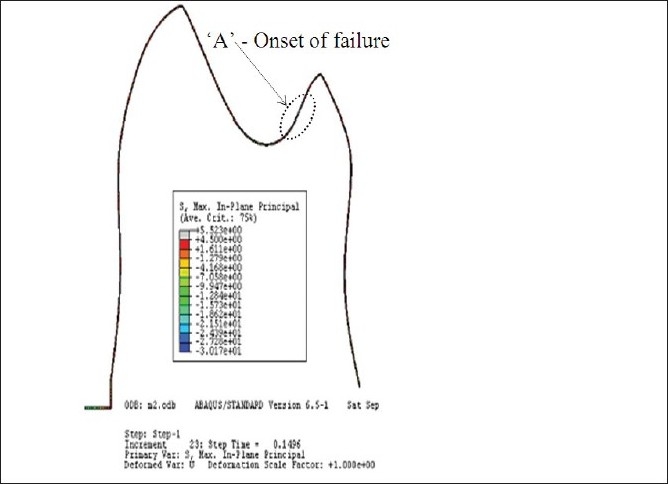

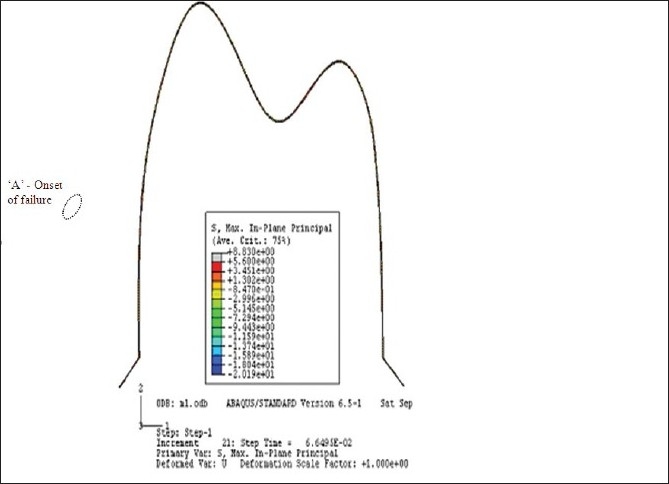

Observation at 60°C temperature showed that GIC in comparison with zinc-phosphate better resisted the thermal stresses. At increment 28, there was no sign of failure in GIC whereas zinc-phosphate failed much earlier at increment 23, and the site of failure was on the occlusal surface near the site of loading [Figures 5–6].

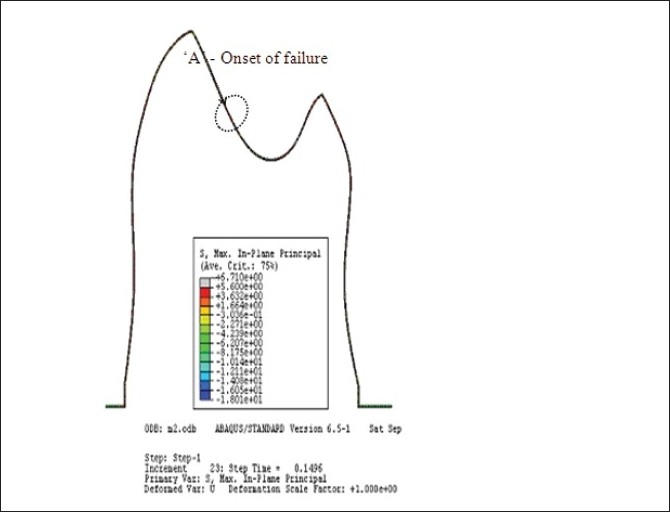

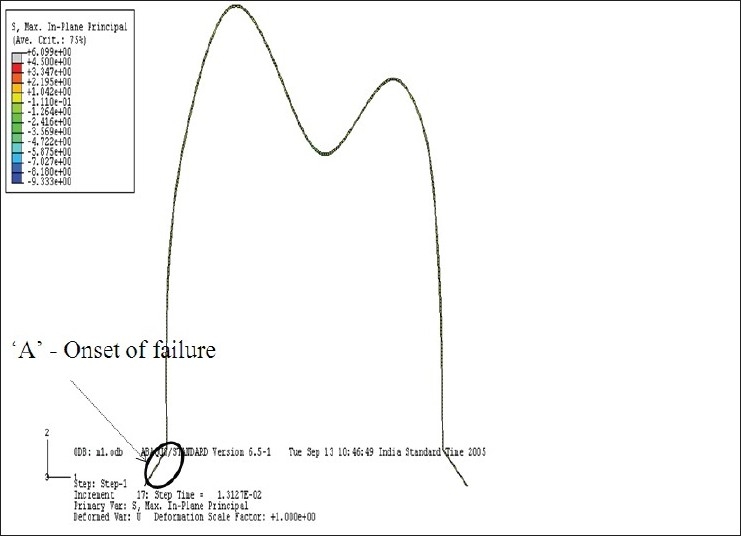

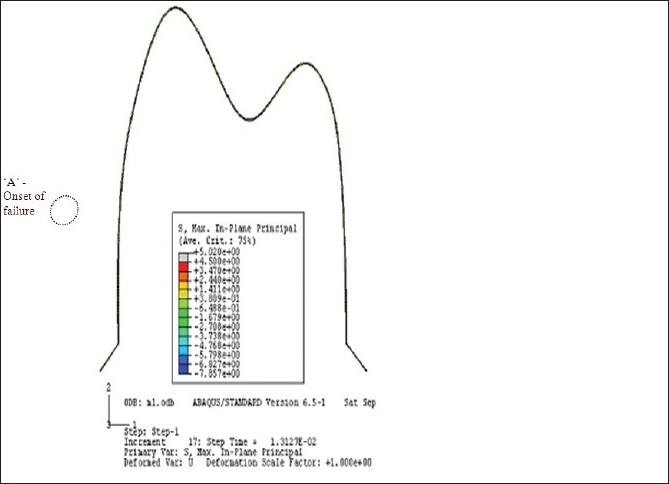

Observation at 0°C temperature showed failure of zinc-phosphate earlier at increment 21 in comparison with GIC, where failure occurred at increment 23 and the site of failure was near the point of loading [Figures 7–8].

Figure 3.

GIC with metal-ceramic crown at 450N force

Figure 4.

Zinc-phosphate luting agent with metal-ceramic crown at 450N force

Figure 5.

GIC luting in Metal-Ceramic crown at 60°C

Figure 6.

Metal-Ceramic crown with Zinc-phosphate at 60°C

Figure 7.

GIC luting agent in Metal-Ceramic crown at 0°C

Figure 8.

Zinc-phosphate luting agent in Metal-Ceramic crown at 0°C

2. Stress distribution between GIC and zinc-phosphate luting agents with metal crown.

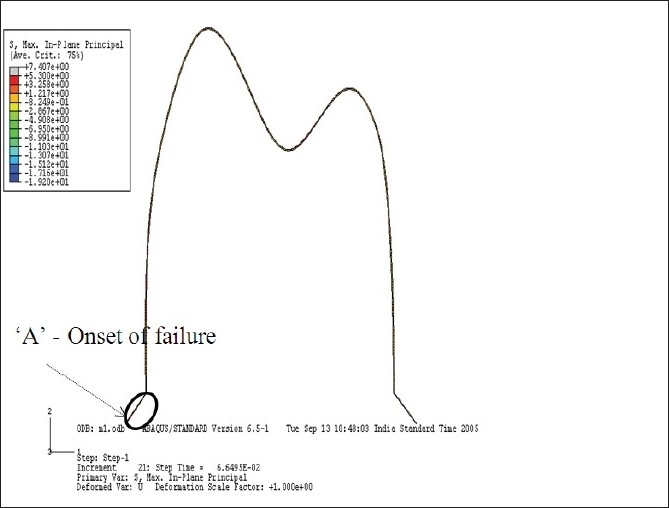

Under mechanical load of 450 N, it was seen that zinc-phosphate failed much earlier at increment 17 whereas GIC failed at increment 21, and the site of failure was similar in both cases [Figures 9–10].

Observation at 60°C temperature again showed better thermal resistance of GIC in comparison with zinc-phosphate. GIC failed much later at increment 28 while zinc-phosphate failed at increment 17, which indicates better performance of GIC even under metal crowns [Figures 11–12].

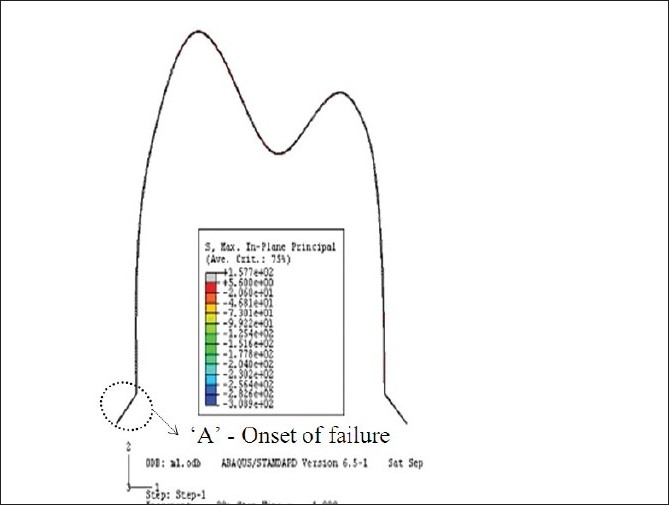

Observation at 0°C temperature showed better performance of GIC in comparison with zinc-phosphate [Figures 13–14].

Figure 9.

GIC with Metal crown at 450N force

Figure 10.

Zinc-phosphate luting agent with Metal crown at 450N load

Figure 11.

GIC luting agent in Metal crown at 60°C

Figure 12.

Metal crown with Zinc-phosphate as luting agent at 60°C

Figure 13.

GIC luting agent in Metal crown at 0°C

Figure 14.

Zinc-phosphate luting agent in Metal crown at 0°C

3. Stress distribution in GIC luting agent with metal–ceramic and metal crown.

Under mechanical load of 450 N, GIC failed at an increment of 23 under metal–ceramic crown near the point of loading whereas under metal crown, it failed slightly earlier at an increment 21 near the tip of the chamfer margin. Therefore, performance of the GIC was better under metal–ceramic crown [Figures 3, 4, 9].

Observation at 60°C temperature showed highest magnitude of stresses in the GIC at increment 28 without failure whereas in the metal crown, GIC failed at this time increment. Thus, GIC had better behavior under metal–ceramic crown in comparison with the metal crown [Figures 5, 6, 11].

Observation at 0°C temperature showed better thermal resistance of GIC under metal–ceramic crown than under the metal crown [Figures 7–8, 13].

4.Stress distribution in the zinc-phosphate luting agent with metal–ceramic and metal crown.

Under mechanical load of 450 N, comparative analyses revealed better tolerance of stresses under the metal–ceramic crown, where failure was observed at increment 22 whereas under the metal crown, failure occurred at increment 17 [Figures 4, 9, 10].

Observation at 60°C revealed that the failure threshold of the luting agent was higher under the metal–ceramic crown with time increment at 23 whereas under the metal crown, failure occurred much earlier at increment 17 [Figures 6, 11, 12].

Observation at 0°C temperature again revealed higher tolerance of stress under the metal–ceramic crown, where the failure was observed at increment 21, while under the metal crown, it occurred at increment 17 [Figures 8, 13, 14].

Thus, it was concluded that GIC had better mechanical and thermal behavior than zinc-phosphate under both metal–ceramic and metal crowns. The failure potential of the GIC was less as compared with zinc-phosphate under similar conditions. However, both luting agents demonstrated better performance under the metal–ceramic crown than under the metal crown. Thus, from the results, the metal–ceramic crown and GIC seem to have a compatible combination together.

Discussion

Inside the oral cavity, the tooth and the restoration are subjected mainly to two types of stresses: mechanical during functional activities and thermal due to temperature fluctuations. It is therefore important to have an understanding of the stress distribution so as to enhance the longevity of the restorations.

The magnitude of mechanical load chosen was 450 N, signifying a high bite force.[24] The mean chewing force on the premolars is approximately 288 N.[25] Therefore, this analysis can be considered an estimation of the worst case scenario. Thermal stresses were evaluated at temperatures of 60° and 0°C, which represent sudden intake of hot and cold food/drinks when the tooth was initially assumed to be at a uniform temperature of 36°C. To determine the fracture threshold of the brittle material, as is the luting agent under an external load, it is necessary to determine Max. In Plane Principal Stresses, which itself is an indicator of the fracture. Thus, in the present study, Max In Plane Principal Stress were used to determine the failure threshold of the luting agents under different loading conditions and crown materials.

Mechanical stress analysis

It was observed that zinc-phosphate failed earlier than GIC under both metal–ceramic and metal crowns. Zinc-phosphate has a high modulus of elasticity as compared with GIC [Table 1]. Also, the compressive strength of zinc-phosphate is 96–133 MPa[26] lower in magnitude as compared with GIC, which has a compressive strength of 93–226 MPa,[26] thereby resulting in the fracture of zinc-phosphate earlier than that of the GIC.

Under the metal–ceramic crown, both luting agents GIC and zinc-phosphate behave favorably in comparison with the metal crown. This can be attributed to the rigidity difference between the two crowns. The laminate design of the metal–ceramic crown contributes to increased rigidity in comparison with the unilayered metal crown. The lower rigidity associated with the metal crown resulted in greater stress distribution at the metal–cement interface and the adjoining cement layer, thereby causing microfracture and failure of the luting agent.

Thermal stresses

Results of the thermal stresses were qualitatively similar to those obtained from mechanical stress analysis. The zinc-phosphate luting agent demonstrated poor thermal resistance in comparison with GIC under both metal–ceramic and metal crowns. Failure of zinc-phosphate occurred earlier than GIC. This finding can be correlated with the compressive strength of the luting agents. As comparison is made between similar crowns but with different luting agents, the amount of stress distribution within the luting agent will depend on the material properties of the cement. Increased modulus of elasticity and coefficient of expansion of zinc-phosphate resulted in more stresses as compared with GIC [Tables 1 and 2]. The compressive strength of zinc-phosphate is less as compared with GIC, resulting in failure of zinc-phosphate earlier than GIC.

Comparison of the failure threshold of the luting agents under the metal–ceramic and the metal crowns showed failure earlier under the metal crown as compared with the metal–ceramic crown. This could be explained on the basis of increased stress distribution at the crown-luting agent interface in case of the metal crown, thereby leading to an unfavorable response of the luting agent under the metal crown.

Clinical Inference

Metal–ceramic crown cemented with GIC is an optimum combination for the restoration of teeth subjected to thermal and mechanical stresses inside the oral cavity.

Clinical conditions where the metal crown is indicated, GIC luting agent may be preferred because of favorable mechanical and thermal behaviors with respect to zinc-phosphate.

For enhancing the longevity of indirectly fabricated restorations, GIC may be a better choice over zinc-phosphate by being more mechanical and thermal resistant in comparison with the latter.

Footnotes

Source of Support: Nil

Conflict of Interest: None declared.

References

- 1.Shinohara N, Minesaki Y, Mukoyoshi N, Moriyama H, Jimi T. The effect of the cementing material on the strength of the all ceramic crown. Nippon Hotetsu Shika Gakkai Zasshi. 1989;33:416–21. doi: 10.2186/jjps.33.416. [DOI] [PubMed] [Google Scholar]

- 2.Kamposiora P, Papavasilious G, Bayne SC, Felton DA. Finite element analysis estimates of cement microfracture under complete veneer crowns. J Prosthet Dent. 1994;71:435–41. doi: 10.1016/0022-3913(94)90179-1. [DOI] [PubMed] [Google Scholar]

- 3.Casson AM, Glyn Jones JC, Youngson CC, Wood DJ. The effect of luting media on the fracture resistance of a flame sprayed all-ceramic crown. J Dent. 2001;29:539–44. doi: 10.1016/s0300-5712(01)00040-9. [DOI] [PubMed] [Google Scholar]

- 4.Behr M, Rosentritt M, Mangelkramer M, Handel G. The influence of different cements on the fracture resistance and marginal adaptation of all-ceramic and fiber-reinforced crowns. Int J Prosthodent. 2003;16:538–42. [PubMed] [Google Scholar]

- 5.Proos KA, Swain MV, Ironside J, Steven GP. Influence of cement on a restored crown of a first premolar using finite element analysis. Int J Prosthodont. 2003;16:82–90. [PubMed] [Google Scholar]

- 6.Attia A, Kern M. Fracture strength of all-ceramic crowns luted using two bonding methods. J Prosthet Dent. 2004;91:247–52. doi: 10.1016/j.prosdent.2003.12.005. [DOI] [PubMed] [Google Scholar]

- 7.Hibino Y. Influence of types and surface treatment of dental alloy and film thickness of cements on bond strength of dental luting cements. Shika Zairyo Kikai. 1990;9:786–805. [PubMed] [Google Scholar]

- 8.Tuntiprawon M, Wilson PR. The effect of cement thickness on the fracture strength of all-ceramic crowns. Aust Dent J. 1995;40:17–21. doi: 10.1111/j.1834-7819.1995.tb05607.x. [DOI] [PubMed] [Google Scholar]

- 9.Piwowarczyk A, Lauer HC, Sorensen JA. In vitro shear bond strength of cementing agents to fixed prosthodontic restorative materials. J Prosthet Dent. 2004;92:265–73. doi: 10.1016/j.prosdent.2004.06.027. [DOI] [PubMed] [Google Scholar]

- 10.Wheeler RC. Physiology and occlusion. 7thed. Philadelphia: W.B. Saunders Company; 1993. Dental Anatomy; p. 232. [Google Scholar]

- 11.Peyton FA, Mahler DB, Hershenov B. Physical properties of dentin. J Dent Res. 1952;31:366–70. doi: 10.1177/00220345520310031401. [DOI] [PubMed] [Google Scholar]

- 12.Saunsuwan N, Swain MV. Determination of elastic properties of metal alloys and dental porcelains. J Oral Rehabil. 2001;28:133–9. doi: 10.1046/j.1365-2842.2001.00642.x. [DOI] [PubMed] [Google Scholar]

- 13.Farah JW, Craig RG. Distribution of stresses in porcelain fused to metal and porcelain jacket crowns. J Dent Res. 1975;54:255–61. [PubMed] [Google Scholar]

- 14.Farah JW, Hood JM, Craig RG. Effects of cement bases on the stresses in amalgam restoration. J Dent Res. 1976;55:114–20. doi: 10.1177/00220345750540010101. [DOI] [PubMed] [Google Scholar]

- 15.Phillips RW. Science of dental material. 9th ed. Philadelphia: WB Saunders Company; 1992. p. 481. [Google Scholar]

- 16.Toparli M, Aykul H, Sasaki S. Temperature and thermal stress analysis of crowned maxillary second premolar using 3-D Finite Element Method. J Oral Rehabil. 2003;30:99–105. doi: 10.1046/j.1365-2842.2003.00971.x. [DOI] [PubMed] [Google Scholar]

- 17.Yang HA, Guckes AD, Feltol AD. The effect of thermal change on various dowel and core restorative material. J Prosthet Dent. 2001;86:74–80. doi: 10.1067/mpr.2001.115503. [DOI] [PubMed] [Google Scholar]

- 18.Sikri VK. Textbook of operative dentistry. 1st ed. New Delhi: CBS Publishers; 2002. p. 421. Year missing. [Google Scholar]

- 19.Hibbit KA. Theory and User manual. USA: Abaqus Inc; 2005. [Google Scholar]

- 20.Wheeler RC. Physiology and occlusion. 7th ed. Philadelphia: W.B. Saunders Company; 1993. Dental Anatomy; p. 232. [Google Scholar]

- 21.Thayer KF. Fixed prosthodontics. 1st ed. Chicago: Year book Medical Publishers; 1984. p. 53. [Google Scholar]

- 22.Rosenstiel SF, Land MF, Fujimato J. Contemporary fixed prosthodontics. 3rd ed. St. Louis: Mosby; 2001. p. 204. [Google Scholar]

- 23.Psillakis JJ, McAlarney ME, Deng SC, Wright RF, Urquiola J. Effect of evaporation and mixing technique on die spacer thickness: A preliminary study. J Prosthet Dent. 2001;85:82–7. doi: 10.1067/mpr.2001.113028. [DOI] [PubMed] [Google Scholar]

- 24.Toparli M, Gokay N, Aksoy T. Analysis of restored maxillary second premolar by using three dimensional Finite Element Method. J Oral Rehabil. 1999;26:157–64. doi: 10.1046/j.1365-2842.1999.00342.x. [DOI] [PubMed] [Google Scholar]

- 25.Proos KA, Swain MV, Ironside J, Steven GP. Finite element analysis studies of a Metal-Ceramic crown on a first premolar tooth. Int J Prosthodont. 2002;15:521–7. [PubMed] [Google Scholar]

- 26.Craig RG. Restorative dental materials. 7th ed. St. Louis: Mosby; 1985. p. 204. [Google Scholar]