Abstract

Chopper presence and then chopper speed was varied during wet high shear granulation of a placebo formulation using a PMA-1 granulator while also varying the impeller speed. The granules were extensively analyzed for differences due to the chopper. The effect of the chopper on the granules varied with impeller speed from no effect at a low impeller speed of 300 rpm to flow interruptions at an impeller speed of 700 rpm to minimal impact at very high impeller speeds as caking at the bowl perimeter obscured the effect of the chopper on the flow pattern. Differences in the granule flowability were minimal. However, it was concluded that the largest fraction of optimal granules would be obtained at an impeller speed of 700 rpm with the chopper at 1,000 rpm allowing balances between flow establishment, segregation, and centrifugal forces.

KEY WORDS: chopper, flowability, granules, high shear granulation, impeller

INTRODUCTION

Wet granulation is a common step in the manufacture of many solid dosage pharmaceuticals. Wet granulation can be accomplished in a mixer granulator. A mechanical impeller moves the powder while a liquid binder is applied onto a moving powder bed. Addition of the liquid binder starts the formation of granules. The granulator also has a chopper.

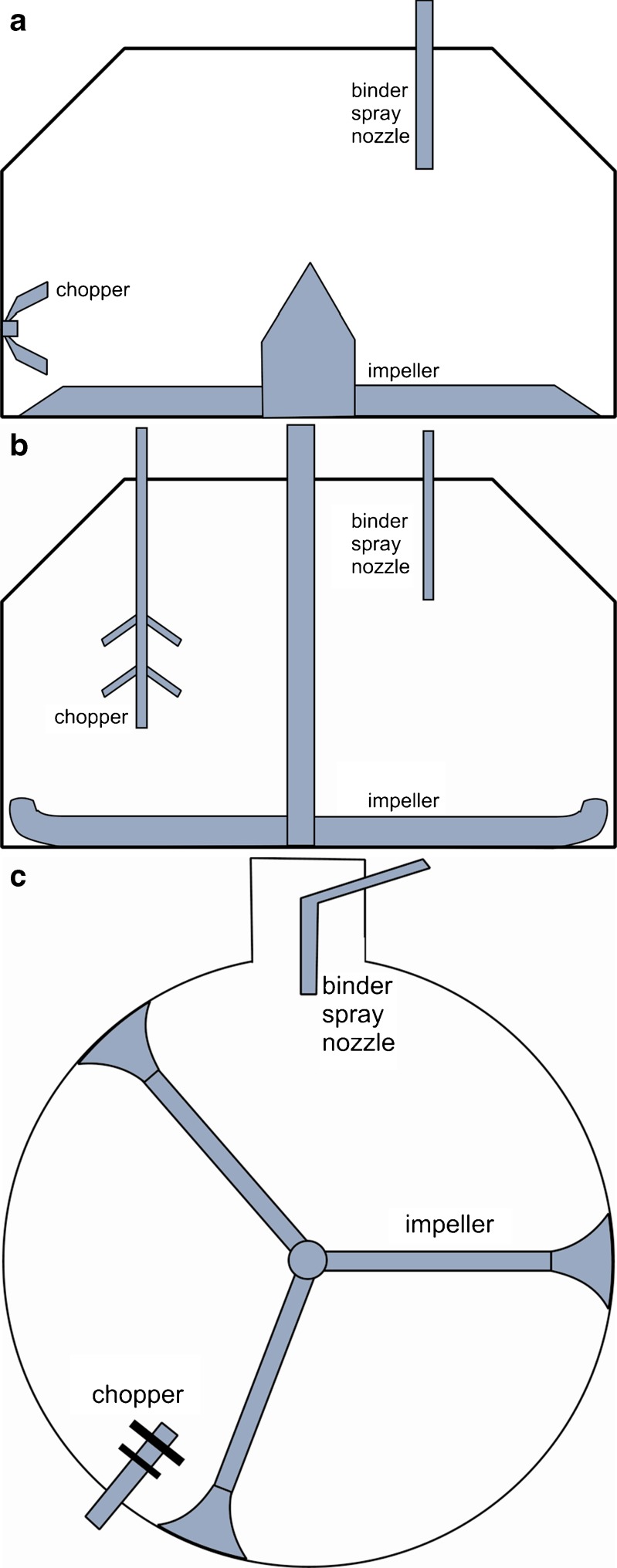

There are two main types of batch wet mixer granulators: vertical shaft and horizontal shaft (Fig. 1). In vertical shaft granulators, an impeller is located at the bottom of the bowl with a chopper located at or near the side of the bowl. The impeller can be bottom or top mounted and the chopper can be side or top mounted. The impeller rotates the powder bed under the spray zone of the liquid binder. In horizontal shaft granulators, an impeller lifts and distributes the powder under the liquid binder spray while the chopper is located near the bottom of the bowl (1).

Fig. 1.

Schematic drawings of the main types of wet high-shear mixer granulators: a vertical high-shear mixer with bottom-mounted impeller and side-mounted chopper, b vertical high shear mixer with top mounted impeller and chopper, and c horizontal high shear mixer

The differences in the types of batch wet mixer granulators combined with a range of impeller and chopper designs affect the granulation process. The powder flow in the mixer bowl and the applied shear rates vary. This can affect the distribution and dispersion of the liquid binder, the granulation mechanism (coalescence versus layering), and granulation regime (growth versus breakage and attrition) which can all then affect the granule properties.

Research Using Vertical Shaft Granulators

The effect of the chopper on granule size has been investigated by several researchers. Lindberg and Jönsson (2) granulated lactose/corn starch/povidone (66%:31%:3%) with water as a binder in a Diosna P25 mixer. The median granule diameter was found to increase as the chopper speed was varied from 200 to 4,200 rpm. Bock and Kraas (3), using a smaller Diosna mixer and a different formulation, found that the chopper had no effect on granule size. Their tested chopper speeds were lower at 1,000 and 2,000 rpm. Michaels et al. (4) compared the size distribution of a formulation of lactose monohydrate/microcrystalline cellulose/hydroxypropyl cellulose/croscarmellose/active drug (73%:20%:3%:3:1%) granulated without a chopper and with a chopper at a speed of 2,000 rpm in a 25 L Fukae mixer; no significant differences in the size distributions were found. Holm (5) also found that the chopper had no effect on size distribution. Chitu et al. (6) found that the effect of the chopper depends on the impeller speed. They granulated microcrystalline cellulose with water as a binder in a small scale MiPro mixer. The chopper only had an effect at a low impeller speed of 100 rpm. The chopper broke up larger agglomerates helping to redistribute moisture and material throughout the mixture. At higher impeller speeds of 200–950 rpm, the forces from the impeller were sufficient for breakage and the chopper had no significant effect on the granule size. The chopper in their MiPro mixer had multiple blades and was suspended vertically offset near the side of the bowl. The location and chopper geometry were very different from the more common single blade chopper attached to the side of the bowl and therefore could have contributed to the unique observations.

Wang et al. (7) examined the effect of the chopper on granule shape. Three different formulations were granulated in a small-scale MicroGral mixer using a vertically mounted chopper at speeds of 1,200–3,600 rpm or removing the chopper in the last stages of the granulation. Granules formed without the chopper at the end of the process were more spherical than granules formed using the chopper throughout the entire process. The chopper interfered with the toroidal or “roping” flow pattern and therefore disrupted the granulation process.

Kiekens et al. (8) showed that the chopper had no effect on granule friability and porosity. A formulation of lactose monohydrate and microcrystalline cellulose was granulated with water in a ProCepT mixer. The tested chopper speeds were 1,000, 2,000, and 3,000 rpm.

Research Using Horizontal Shaft Granulators

Hoornaert et al. (9) studied the impact of the chopper on the mean diameter of granules formed in a Lödige mixer with an enzyme-based formulation. Trials were conducted with the chopper off and with the chopper on at a speed of 3,000 rpm. When the chopper was off, significant granulation did not occur. The shear forces provided by the chopper were required for coalescence for granule growth. The larger relative size and the different location and flow patterns in a horizontal shaft granulator could contribute to the larger influence of the chopper on granulation compared to vertical shaft granulators.

Only a few research studies on the effect of the chopper during high shear granulation have been conducted. Most studies were limited to the chopper effects on granule size, shape, friability, and porosity using vertical shaft granulators and the conclusions varied. The effect of the chopper on granule properties, specifically flowability, has not yet been studied using a vertical shaft PMA-1 high shear granulator. The objective of this research was therefore to investigate the effect of the chopper on granules formed using a PMA-1 granulator. The effect was investigated at different impeller speeds as flow patterns can change with impeller speed and therefore the influence of the chopper might also vary. Measurements focused on granule properties related to flowability as improving flowability is one of the most important goals of granulation.

MATERIALS AND METHODS

Product Formulation

A placebo formulation consisting of 50 wt.% (dry basis) lactose monohydrate (Merck, dpsm of 113 μm), 45 wt.% microcrystalline cellulose (Alfa Aesar, dpsm of 77 μm), 4 wt.% hydroxypropyl methylcellulose (Alfa Aesar, dpsm of 48 μm), and 1 wt.% croscarmellose sodium (Alfa Aesar, dpsm of 139 μm) was used for all the trials. A dry mass of 1.5 kg was used for each trial. Distilled water was added as a liquid binder at 24°C.

Granulator Configuration

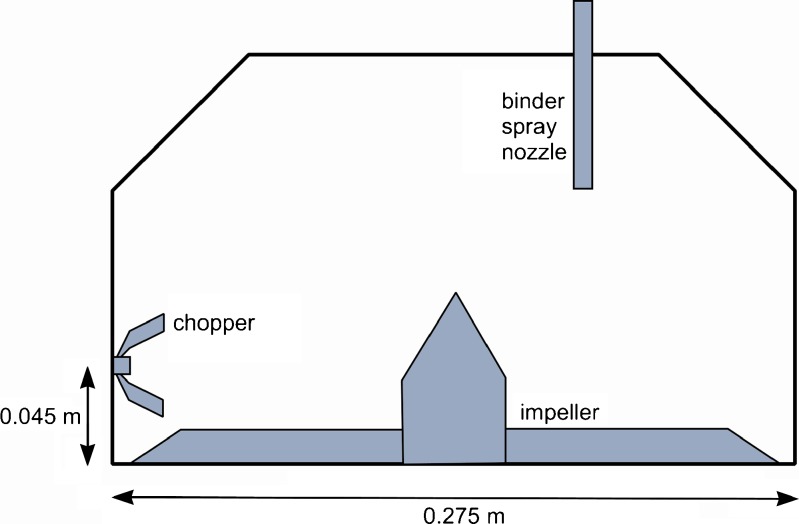

All trials were performed using a Niro-Fielder PMA-1 high-shear granulator shown schematically in Fig. 2. This is a vertical shaft granulator with a 10-L bowl. A three-bladed impeller was mounted on the bottom of the bowl. A chopper with geometry shown in Fig. 3 was mounted on the bowl side opposite to the binder addition nozzle. The chopper was mounted 0.045 m above the base of the bowl.

Fig. 2.

Schematic diagram of the high-shear mixer used in the trials

Fig. 3.

Detailed diagram of the chopper used in the trials

Granulator Operation

The impeller and chopper were operated without water addition for the first 2 min of each trial to mix the dry powder. The chopper speed was constant for each trial at either 1,000 or 3,000 rpm. Additional trials were run with the chopper removed from the bowl. The impeller speed was constant for each trial at 300, 700, 1,100, or 1,500 rpm.

After 2 min of dry mixing, binder addition was started and continued at a rate of approximately 46 mL/min throughout the trial. Each trial continued for 9 min of binder wetting time. This wetting time was selected based on results from previous trials (10). Granules from each trial were oven dried at 24°C and a relative humidity of 2–3% for more than 24 h to ensure a granule moisture content of <2 wt.% and then analyzed for various characteristics. Samples from the entire granule population were used for the granule analysis.

Sensor Measurements

The granulator bowl was fitted with a thermocouple allowing temperature measurements to be recorded during each trial.

Granule Analysis

Moisture Content

A Mettler-Toledo HG63 halogen moisture analyzer was used to determine granule moisture content through loss on drying at 105°C. Samples of 5.00 g were measured in duplicate.

Size

Sieving with 18 mesh cuts ranging from 38 to 3,350 μm was performed for particle size analysis.

Shape and Morphology

Scanning electron microscopy (SEM) was used to visualize samples of the dried granules, sieved to only include the fraction between 150 and 600 μm, at 9 min wetting time. These SEM images also confirmed granule size measurements.

Flowability

Flowability measurements included density measurements to provide the Hausner ratio and Carr index, the static angle of repose, and examination of avalanche behavior.

The bulk and tapped densities of granules from the trials were measured using 100 mL samples. All density measurements were performed in duplicate. The bulk and tapped density measurements allowed the Hausner ratio and Carr index to be calculated:

|

1 |

|

2 |

Static angle of repose measurements were conducted using samples of approximately 60 mL. The samples flowed down a vibrating chute and then through a funnel with its tip suspended 0.1 m above a level surface to form a pile. The resulting powder piles were photographed and the critical angle of the pile was measured. Samples were measured in triplicate.

A Mercury Scientific Revolution Powder Analyzer was used to indicate flowability through examination of the avalanche behavior. The drum (11 cm diameter by 3.5 cm width) was loaded with a sample size of 118 cm3 and rotated at 0.3 rpm. As the drum rotated, the powder moved up the side of the drum until the powder surface collapsed downward in an avalanche, with an avalanche defined as the rearrangement of at least 0.65 vol.% of the sample in the drum. The drum was rotated until 128 avalanches had occurred. Optical measurements with a resolution of 648 × 488 at 60 frames per second monitored the powder surface. Software calculated various parameters, such as the angle of the powder surface just prior to an avalanche, to describe the behavior and avalanches of the powder during the rotation. Samples were measured in triplicate.

RESULTS

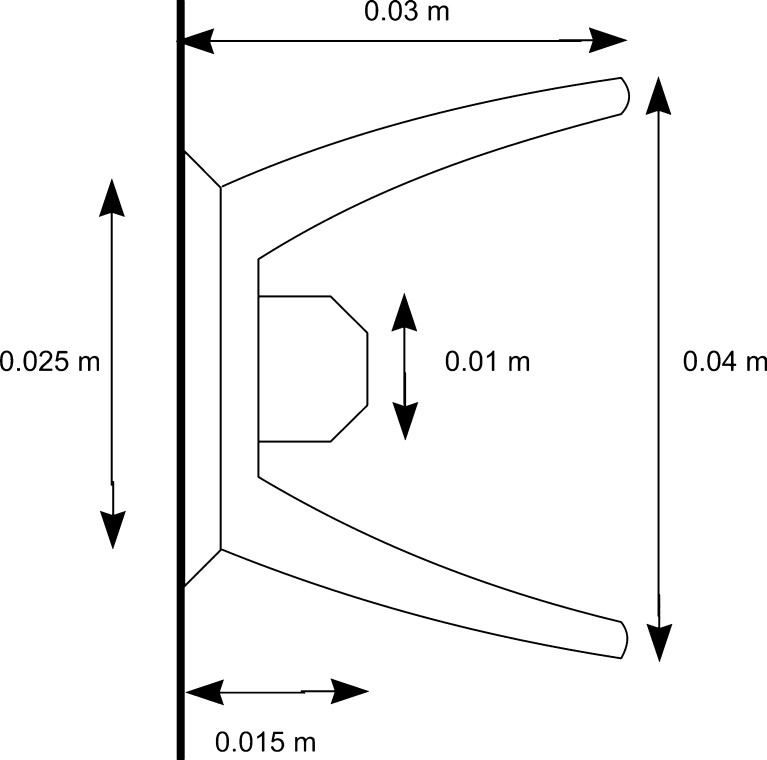

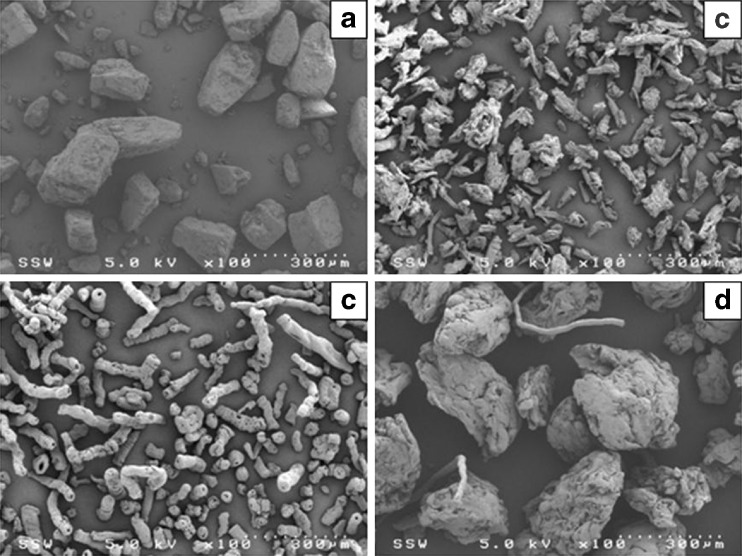

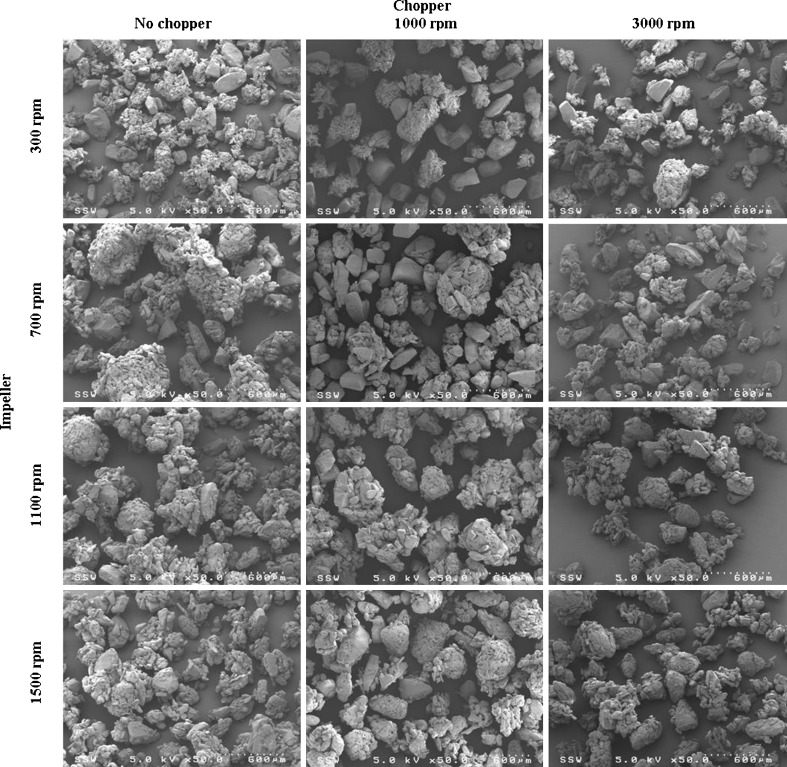

Samples from the trials were sieved to include only particles between 150 and 600 μm and then visualized through scanning electron microscopy. Scanning electron micrograph images of the placebo formulation are shown in Fig. 4 for reference. Figure 5 then shows the images of the 150–600 μm granules from the trials.

Fig. 4.

Scanning electron micrograph images of the components of the formulation: a lactose monohydrate, b microcrystalline cellulose, c hydroxypropyl methylcellulose, and d croscarmellose sodium

Fig. 5.

Scanning electron micrograph images of 150–600 μm size samples from the trials

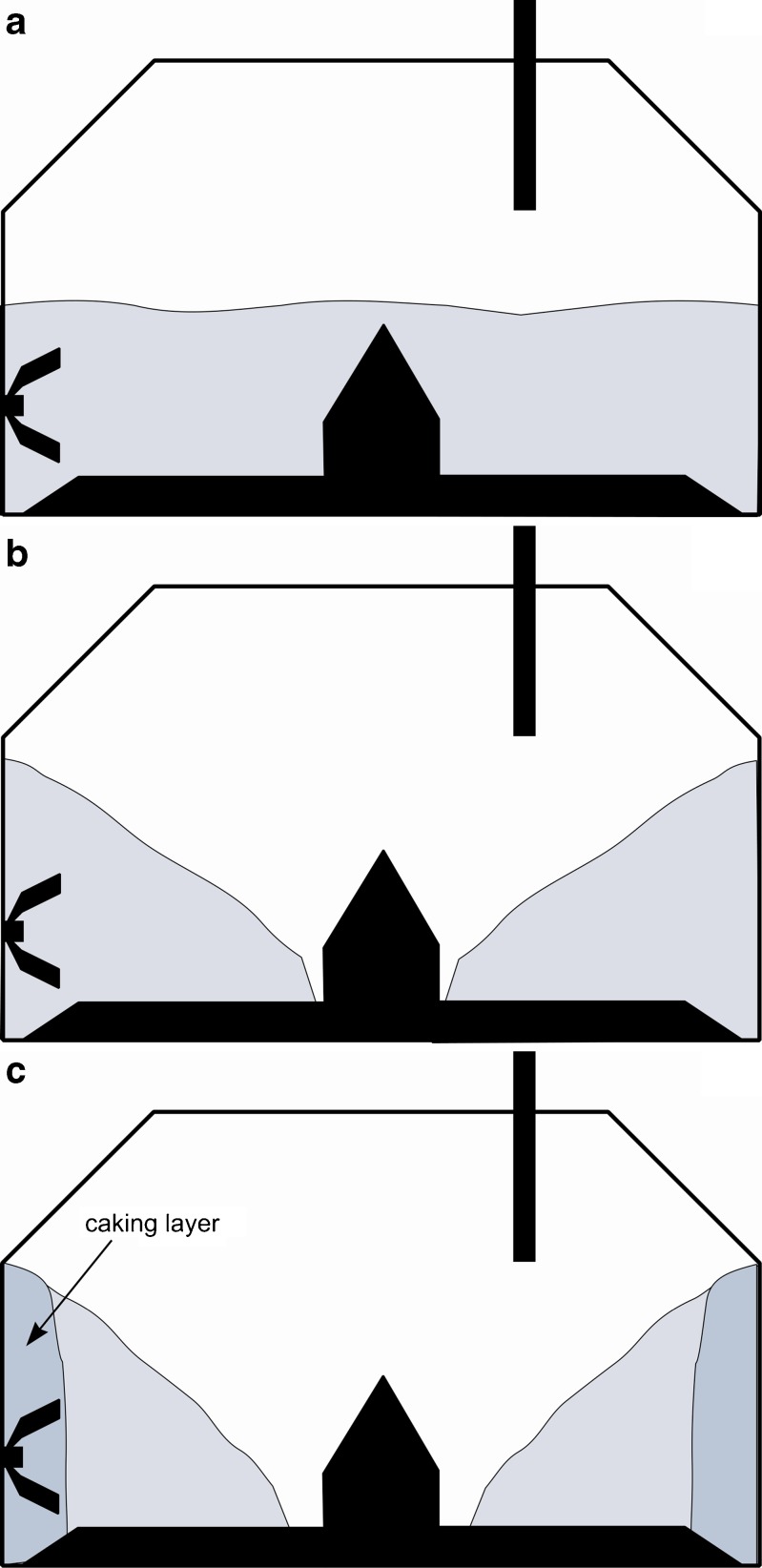

The flow regimes contributed to the different effects of the chopper on the granules. As shown schematically in Fig. 6, at an impeller speed of 300 rpm, the flow regime was “bumpy”; at the higher impeller speeds, the flow regime was “roping”. At impeller speeds of 1,100 and 1,500 rpm, although the flow pattern was “roping”, the amount of material in contact with the chopper was limited due to caking. These flow regimes were visually confirmed by visual observations through the viewport in the lid of the granulator bowl.

Fig. 6.

Schematic diagram of the flow regimes and chopper influence: a “bumpy” flow regime at an impeller speed of 300 rpm, b “roping” flow regime at an impeller speed of 700 rpm, and c “roping” flow regime with buildup of a caking layer at impeller speeds of 1,100 and 1,500 rpm

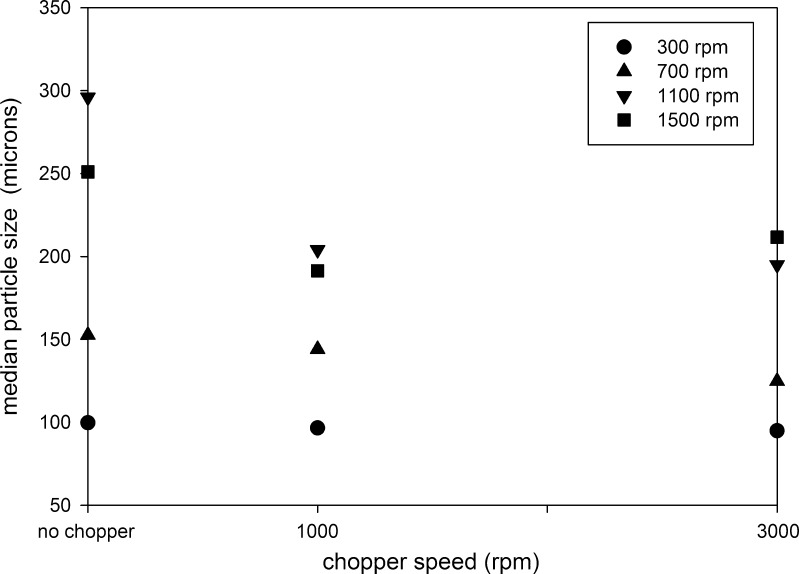

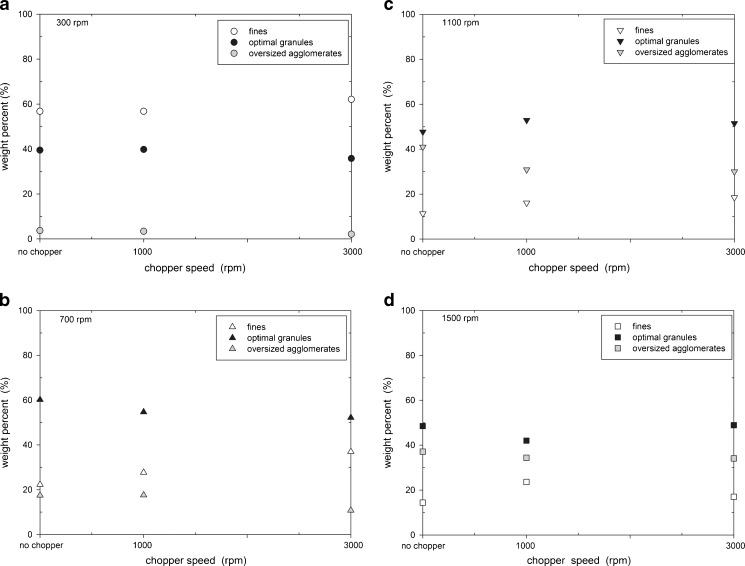

Figure 7 shows the median particle size for the trials based on the total yield recovered. Particle size distributions for the trials are shown in Fig. 8.

Fig. 7.

Median particles sizes for the trials

Fig. 8.

Particle size distributions for the trials at impeller speeds of a 300 rpm, b 700 rpm, c 1,100 rpm, and d 1500 rpm

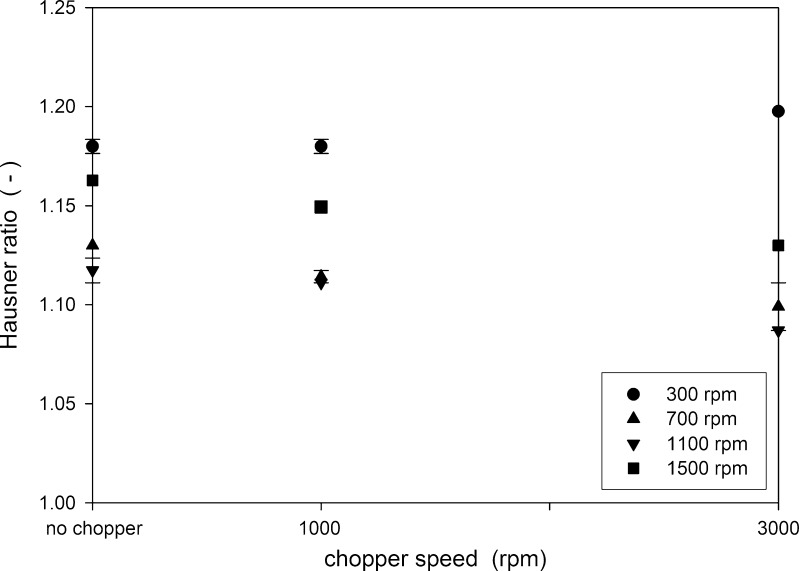

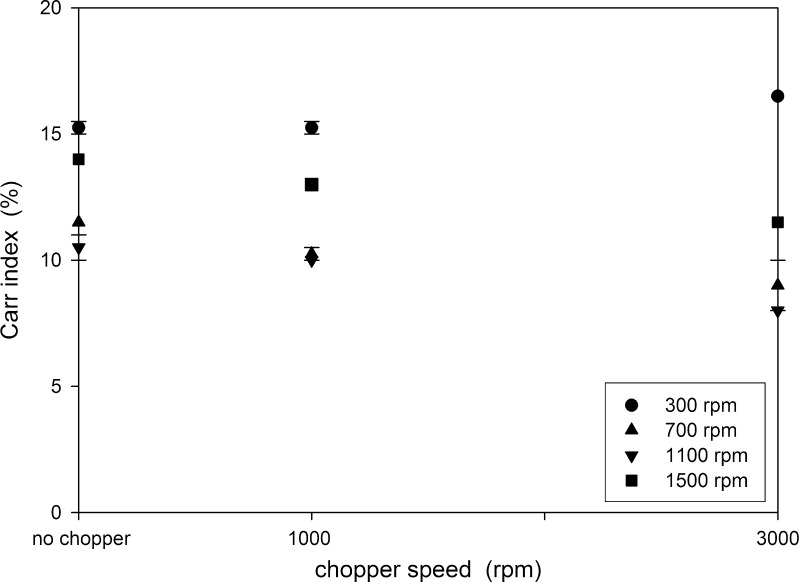

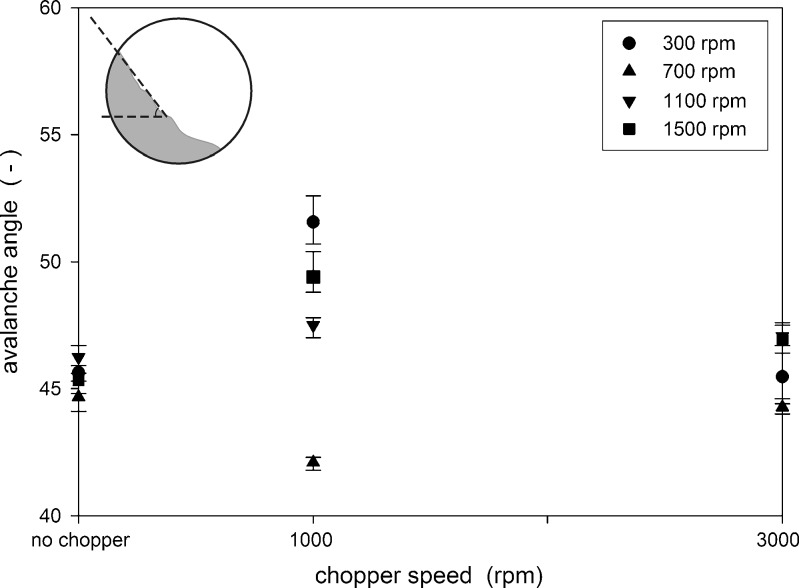

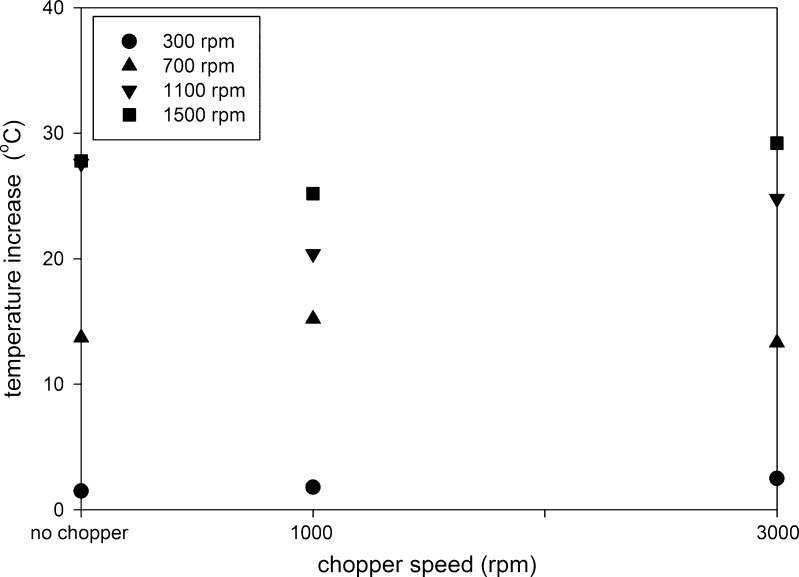

Flowability measurements included density measurements to provide the Hausner ratio and Carr index, the static angle of repose and examination of avalanche behavior through the avalanche angle. The Hausner ratio and Carr index are shown in Figs. 9 and 10 while the avalanche angle is plotted in Fig. 11. Figure 12 shows the temperature increases during the trials.

Fig. 9.

Hausner ratios for the trials

Fig. 10.

Carr index for the trials

Fig. 11.

Avalanche angle for the trials

Fig. 12.

Temperature increases during the trials

DISCUSSION

Optimal granules were defined as granules having a diameter between 150 and 600 μm, approximately spherical in shape, and incorporating all components of the formulation. Previously, it was shown that, for this placebo formulation, the initial granule nuclei were primarily microcrystalline cellulose agglomerates (10). Lactose monohydrate was absent from nearly all granule nuclei. The hydroxypropyl methylcellulose was very small and only present at 4 wt.% which made it very difficult to detect in any agglomerates. The croscarmellose sodium comprised only 1 wt.% of the formulation and, as it is water soluble, would have dissolved into the water binder and therefore not appear in any of the images.

Figure 5 shows that the effect of the chopper on the 150–600 μm granules varied with impeller speed. At an impeller speed of 300 rpm, the chopper had almost no effect on the granules. The granule size remained small and mostly composed of microcrystalline cellulose. At an impeller speed of 700 rpm, the chopper had a range of effects: without the chopper, the granules were large but only incorporated some of the lactose monohydrate, round granules incorporating all of the components were formed at a chopper speed of 1,000 rpm, and small and irregularly shaped granules were formed at 3,000 rpm chopper speed. At impeller speeds of 1,100 and 1,500 rpm, the chopper slightly reduced the size of the granules.

After each trial, the granulator bowl was inspected for material buildup or caking around the perimeter. At an impeller speed of 300 rpm, there was no caking around the perimeter. At an impeller speed of 700 rpm, there was very slight caking. However, at impeller speeds of 1,100 and 1,500 rpm, there was a significant caking layer by the end of the trials. The caking layer thickness was about 0.03–0.04 m and, therefore, the chopper blades did not reach into the granulating powder flow by the end of these trials. For the trials without the chopper present, the caking layer was continuous. For the trials with the chopper, the caking layer was only disrupted in the small area cleared by the chopper blades.

Litster et al. (11) reported two flow regimes during the granulation of lactose monohydrate in a PharmaMATRIX 25-L high-shear granulator: a “bumpy” regime with slowly rotating powder with very little vertical movement and a “roping” regime with good rotational velocity and vertical turnover. The “bumpy” regime occurred at low impeller speeds with the transition to the “roping” regime attributed to the larger rotational inertia forces overcoming the gravitational forces at the higher impeller speeds. Drawing upon the results from Litster et al. (11), Logan and Briens (10) proposed that the transition from the “bumpy” to the “roping” regime in a PMA-1 granulator with the specified lactose-based placebo formulation occurred near an impeller speed of 300 rpm.

As shown schematically in Fig. 6, the flow regimes changed with impeller speed and contributed to the different effects of the chopper on the granules. In the “bumpy” regime at an impeller speed of 300 rpm, the chopper does not contact a significant amount of material. The slower-moving powder and the low centrifugal forces do not force large amounts of the powders into contact with the impeller. At an impeller speed of 700 rpm, the flow regime was “roping”. Without a chopper, however, the larger lactose monohydrate particles that segregated to the bowl perimeter (12) were not significantly incorporated into the toroidal flow so that the granules remained primarily composed of microcrystalline cellulose. A combination of an impeller speed of 700 rpm and a chopper speed of 1,000 rpm allowed the toroidal flow to develop while forcing the lactose monohydrate into the flow for incorporation into the granules. A higher chopper speed of 3,000 rpm promoted more granule breakage causing the granule sizes to decrease and the irregular shape. The very high centrifugal forces at impeller speeds of 1,100 and 1,500 rpm promoted the formation of a caking layer around the bowl perimeter. The caking layer was continuous except for the small area cleared by the chopper blades. Although the flow pattern was “roping”, the amount of material in contact with the chopper was limited due to the caking. The “roping” flow pattern was then not significantly disrupted by the chopper allowing granules to grow. Granule growth combined with the high shear forces from the impeller formed compact and spherical granules.

The median particle size was determined based on the total yield recovered and therefore includes fines, granules, and any oversized agglomerates. The chopper had no significant effect on the median particle size for the trials at impeller speeds of 300 rpm and only a slight decrease for the trials at impeller speeds of 700 rpm. For trials at impellers speeds of 1,100 and 1,500 rpm, the chopper significantly reduced the median particle size (Fig. 7). Increasing the chopper speed from 1,000 to 3,000 rpm, however, had almost no effect. The caking layer grew during the 9 min of the binder addition period. Near the beginning of this period, when the caking layer was just building, the chopper would have contact with the granules and contributed to granule breakage lowering the final median particle size. Once the caking layer had grown to about 0.03–0.04 m, the chopper would no longer have extended into the roping flow pattern and therefore would no longer have any influence on the granulation.

Particle size distributions provide insight into granule formation and growth. With optimal granules identified between 150 and 600 μm, fines were defined as particles <150 μm and oversized agglomerates as having diameters larger than 600 μm. Particle size distributions (Fig. 8) confirmed the visual observations that there was very little granule growth beyond the initial nuclei of microcrystalline cellulose at an impeller speed of 300 rpm. At an impeller speed of 700 rpm, operating without a chopper produced the best combination of about 60 wt.% optimal granules with only close to 20 wt.% of either fines or oversized agglomerates. The chopper contributed to granule breakage throughout a trial resulting in higher amount of fines when the chopper was used. At impeller speeds of 1,100 and 1,500 rpm, the chopper maintained relatively high levels of optimal granules with a decrease in oversized agglomerates and an increase in fines. Although the chopper effect was reduced by the caking layer at the bowl perimeter, some of the material contacted the chopper near the beginning of the trials and would have broken larger agglomerates into smaller ones. The caking layer formed more rapidly at 1,500 rpm than at 1,100 rpm impeller speed. The effect of the chopper on the size distributions was therefore smaller at 1,500 rpm compared to the 1,100 rpm impeller speed trials.

The Hausner ratio is the ratio of the tapped to bulk density and indicates the cohesiveness of a powder. A Hausner ratio less than 1.25 indicates a free flowing powder (13) and therefore the results (Fig. 9) show that the granulated formulations from all trials had good flowability potential. The Hausner ratio was the highest for the trials at an impeller speed of 300 rpm possibly due to the very high percentage of fines (larger than 55%) not incorporated into granules during these trials. Differences in the Hausner ratios due to the influence of the chopper were small. These measurements were not sufficiently sensitive to detect major differences in the flowability.

The Carr index is another indicator of flowability based on density measurements and an index below about 25% indicates good flowability (14). Similar to the Hausner ratio, all trials showed good flowability and major differences due to the effect of the chopper could not be determined (Fig. 10).

A static angle of repose less than 40° indicates a powder with reasonable flow potential (15). The measured static angles of repose for the trials ranged from 39° to 41°, near the transition from poor to good flow and did not provide sufficient differentiation to comment on flowability differences between the trials.

As a powder sample is rotated in a drum, the revolution powder analyzer measures various parameters of the sample under dynamic conditions. The avalanche angle is the angle of the powder surface relative to the horizontal at the moment before an avalanche; low angles indicate a powder with good flowability potential. As the powder can form an uneven surface profile, the avalanche angle was determined using the upper region of the surface. Figure 11 showed that the avalanche angle was low for trials at an impeller speed of 700 rpm and reached a minimum at a chopper speed of 1,000 rpm indicating that this combination of impeller and chopper speed produced granules with the highest flowability potential.

The flowability of the granules was determined through density measurements, the static angle of repose and the avalanche behavior. The density measurements and the static angle of repose did not show flowability differences due to the chopper; only larger differences due to the impeller speed were observed. The density measurements and the static angle of repose have large measurement errors as the volumes and angles are difficult to measure. The avalanche measurements use a larger sample volume and measure the avalanche behavior over a large number of avalanches which minimizes measurement error. Small differences in the flowability due to the effect of the chopper could therefore be detected using avalanche indicators such as the avalanche angle.

The chopper had almost no effect on the temperature increases, but the impeller speed had a large effect (Fig. 12). The higher the impeller speed, the larger the temperature increase during a trial. Therefore, although the chopper velocity was very high, the primary mechanism for contacting and moving the particles was the impeller.

CONCLUSIONS

For the range of impeller and chopper speeds investigated in the PMA-1 granulator, trials at an impeller speed of 700 rpm with a chopper speed of 1,000 rpm produced the largest fraction of optimal granules that were approximately spherical, incorporated all of the formulation components and exhibited high flowability potential. This combination of impeller and chopper speeds provided a balance that allowed establishment of good toroidal flow to promote granule growth while minimizing excessive centrifugal forces that promote caking at the perimeter and ensured that any particles that segregated at the bowl perimeter would be forced into the active flow to be incorporated into the granules while minimizing breakage from contact with the chopper.

ACKNOWLEDGMENTS

The authors would like to acknowledge the Natural Sciences and Engineering Research Council of Canada (NSERC) for their financial support.

REFERENCES

- 1.Litster J, Ennis B. The science and engineering of granulation processes. Netherlands: Kluwer; 2004. [Google Scholar]

- 2.Lindberg NO, Jönsson C. The granulation of lactose and starch in a recording high-speed mixer, Diosna P25. Drug Dev Ind Pharm. 1985;11:387–403. doi: 10.3109/03639048509056877. [DOI] [Google Scholar]

- 3.Bock TK, Kraas U. Experience with the Diosna mini-granulator and assessment of process scalability. Eur J Pharm Biopharm. 2001;52:297–303. doi: 10.1016/S0939-6411(01)00197-7. [DOI] [PubMed] [Google Scholar]

- 4.Michaels JN, Farber L, Wong GS, Hapgood K, Heidel SJ, Farabaugh J, et al. Steady states in granulation of pharmaceutical powders with application to scale-up. Powder Tech. 2009;189:295–303. doi: 10.1016/j.powtec.2008.04.028. [DOI] [Google Scholar]

- 5.Holm P. Effect of impeller and chopper design on granulation in a high speed mixer. Drug Dev Ind Pharm. 1987;12(9–11):1675–1701. doi: 10.3109/03639048709068687. [DOI] [Google Scholar]

- 6.Chitu TM, Oulahna D, Hemati M. Wet granulation in laboratory-scale high shear mixers: effect of chopper presence, design and impeller speed. Powder Tech. 2011;206:34–43. doi: 10.1016/j.powtec.2010.07.016. [DOI] [Google Scholar]

- 7.Wang S, Ye G, Heng PWS, Ma M. Investigation of high shear wet granulation processes using different parameters and formulations. Chem Pharm Bull. 2008;56:22–27. doi: 10.1248/cpb.56.22. [DOI] [PubMed] [Google Scholar]

- 8.Kiekens F, Córdoba-Díaz M, Remon JP. Influence of chopper and mixer speeds and microwave power level during the high-shear granulation process on the final granule characteristics. Drug Dev Ind Pharm. 1999;25:1289–1293. doi: 10.1081/DDC-100102301. [DOI] [PubMed] [Google Scholar]

- 9.Hoornaert F, Wauters PAL, Meesters GMH, Pratsinis SE. Agglomeration behaviour of powders in a Lödige mixer granulator. Powder Tech. 1998;96:116–128. doi: 10.1016/S0032-5910(97)03364-0. [DOI] [Google Scholar]

- 10.Logan R, Briens L. An investigation of the effect of impeller shear on granules formed through high shear granulation. Drug Dev Ind Pharm. 2011 (in press). [DOI] [PubMed]

- 11.Litster JD, Hapgood KP, Michaels JN, Sims A, Roberst M, Kameneni SK. Scale-up of mixer granulators for effective liquid distribution. Powder Tech. 2002;124:272–280. doi: 10.1016/S0032-5910(02)00023-2. [DOI] [Google Scholar]

- 12.Alkhatib AK, Briens L. Influence of initial mixing on granule properties. 5th International Granulation Workshop, Lausanne, Switzerland. 2011.

- 13.Abdullah EC, Geldhart D. The use of bulk density measurements as flowability indicators. Powder Tech. 1999;102:151–165. doi: 10.1016/S0032-5910(98)00208-3. [DOI] [Google Scholar]

- 14.Carr R. Evaluating flow properties of solids. Chem Eng. 1965;72:163–168. [Google Scholar]

- 15.Nagel KM, Peck GE. Investigating the effects of excipients on the powder flow characteristics of theophylline anhydrous powder formulations. Drug Dev Ind Pharm. 2003;29:277–287. doi: 10.1081/DDC-120018201. [DOI] [PubMed] [Google Scholar]