Introduction

Molecular Pharming represents an unprecedented opportunity to manufacture affordable modern medicines and make these available at a global scale. The area of greatest potential is in the prevention of infectious diseases, particular in underdeveloped countries where access to medicines and vaccines has historically been limited. This is why, at St. George's, we focus on diseases such as HIV, TB and rabies, and aim to develop production strategies that are simple and potentially easy to transfer to developing countries.

The Hotung Molecular Immunology Unit at St. George's Hospital is the only plant biotechnology group in the world embedded within a medical school where medical and human health is the primary focus of research activity. This places us in a unique position to perform highly translational research in collaboration with colleagues at the cutting edge of medical research. It has driven a research strategy in which plant biotechnology is a tool and not a research topic per se. Thus the research group is composed of scientists from a range of disciplines, with an emphasis on immunology and vaccinology.

Our research is not purely oriented towards product development. In order to gain acceptance in the commercial sector, progress in regulatory affairs is required, particularly in Europe, and specifically in the area of achieving manufacturing compliance with the industry standard of current Good Manufacturing Practice (cGMP). To this end we have targeted the performance of Phase 1 clinical trials as a focus. Our strategy to develop affordable medicines for the poor in developing countries is complemented by a research effort that examines how academic institutions (like St. George's) and research consortia can use intellectual property and licensing agreements to maximize the chances that any research outcomes will be available for humanitarian use. In many respects, development in this area is just as important as any of our more conventional scientific research activities. Without new developments in IP management, we do not believe that the benefits of Molecular Pharming will reach their intended targets, and yet few academic technology transfer offices are engaging in this opportunity to contribute to a worthy humanitarian cause.

Major Research Activities

In this section we will summarize five major areas of research activity in our group to exemplify our approach to Molecular Pharming. The first area addresses regulatory compliance and clinical trials because an understanding of this target is required as a framework for all the research and development work that is carried out with a potential product in mind. An example of such a product—a rabies monoclonal antibody cocktail—is then described as a potential solution to improving the control of rabies in South East Asia and Sub-Saharan Africa. A third area of interest is a novel approach to vaccines, in which the ability of plants to assemble multimeric immunoglobin complexes is exploited to produce self-adjuvanting vaccines. We then describe an approach to manufacturing that combines contained hydroponic cultivation of plants with recombinant protein rhizosecretion. This is a low tech manufacturing solution that is readily amenable to regulatory compliance and potentially transferable to developing countries for local production and processing. Finally, the fifth example of our research describes our approach to investigating IP management, particularly in the emerging field of plant biotechnology.

Regulatory Compliance and Clinical Trials

The progression of Molecular Pharming products into human clinical trials is an important priority for the field. It demonstrates that the technology is moving beyond basic scientific proof of concept studies and towards clinical development of products. For most products this represents the first time that the manufacturing process will have come under any form of scrutiny from regulatory assessors. In the UK, all clinical trials are conducted according to ICH GCP guidelines, specifically in accordance with the ethical principles in the Declaration of Helsinki, the regulatory requirements of the UK National Medicines Regulatory Agency (MHRA), the Association of British Pharmaceutical Industry (ABPI) guidelines and the UK Department of Health ‘Research Governance Implementation Plan’.

Our work in this area has been performed in collaboration with a number of groups as part of the EU funded Pharma-Planta project. The most important of these collaborators are Professor Rainer Fischer and Dr. Juergen Drossard at the Fraunhofer IME, Aachen, and Professor David Lewis at the Vaccine Institute at St. George's, London. One of the primary project aims was to develop a cGMP compliant manufacturing process for a monoclonal antibody that was to be used as a topical vaginal microbicide. A further aim was to advance this to a Phase 1 clinical trial to assess tolerance, safety and potential adverse reactions.

The choice of a monoclonal antibody target product was for several reasons. At present monoclonal antibodies (mAb) are the most straightforward class of recombinant proteins to manufacture in most plant biotechnology systems. From a regulatory perspective, mAbs are well understood and there are several examples that are licensed for commercial use. The downside is that mammalian cell culture for production of mAbs is firmly established and represents a formidable gold standard against which to be compared.

With the prevailing attitude towards GM across Europe, it was prudent to introduce manufacture by Molecular Pharming in a stepwise manner. Even in an area that is apparently driven by innovation and cutting edge technology, gradual change provides reassurance for scientists and regulators alike. Whilst others have chosen plant cell culture systems to establish broad regulatory parameters for Molecular Pharming, our goal is to develop whole plant manufacturing systems. And whilst large scale cultivation in open field is an exciting prospect to address important global diseases, an initial approach based on greenhouse containment was selected. Whilst still allowing us to address important issues specifically related to recombinant protein production in plants, it also allowed us to defer addressing a range of questions regarding plant cultivation, as well as environmental containment to a later point.

In committing to developing a plant-derived mAb for clinical trial, the Pharma-Planta consortium has been able to interrogate relevant regulatory guidelines in Europe and identify the gaps where development work was required.1,2 An example is the development of a banking system for GM plant material that provides an equivalent level of genetic and phenotypic stability to that required by current master cell banking systems for CHO or bacterial cells. A further example is the control of plant cultivation to deliver product batches that are uniform and reproducible. It was essential to determine the requirements of a cGMP-compliant production system and define the parameters within which to work. A European Guideline document covering these and other relevant issues has now been published by the European Medicines Evaluation Agency (CHMP/BWP/48316/2006). A manufacturing process compliant with these guidelines was then established by the group at Fraunhofer IME under Professor Rainer Fischer, and the next step to gain successful approval for GMP manufacture of a plant-derived mAb and demonstration of safety in a first human clinical trial will be an important milestone. It will demonstrate feasibility and compatibility of a mAb production process in plants. It will also act as the starting point for regulatory approvals for other plant manufacturing platforms, such as those based on hydroponic cultivation, transient expression and open field cultivation.

Monoclonal Antibodies (mAbs)

Alongside the establishment of a GMP manufacturing process for GM plant-derived mAbs, it is important to develop a pipeline of mAbs to ensure continuity of technology development. We have a long-term interest in the use of mAbs to prevent infection, either as microbicides or in passive immunization. In many respects passive immunization represents a safer approach than the more widely used strategy of active immunization, i.e., vaccination. Different individuals often respond differently to vaccination, particularly in the presence of concurrent disease. Thus in populations where gastrointestinal parasitic infections are common, responses to orally delivered vaccines can be poor.3 Similarly, immunosuppressed patients and particularly those with HIV/AIDS may not respond appropriately to vaccination. Both of these examples are particularly pertinent to health control in developing countries.

A further advantage to passive immunization is immediacy. In general, vaccines take at least one week to elicit a protective response and often multiple vaccine doses are required. In contrast passive immunization can provide immediate protection even though that protection may not be long lasting. One example where the immediate protective effect of passive immunization is an absolute requirement, is rabies, a disease that is a predominant problem in underdeveloped countries in South East Asia and Sub-Saharan Africa.

Rabies post-exposure prophylaxis.

Rabies is a zoonotic disease caused by the neurotropic rabies virus, a member of the Lyssavirus genus, and is characterized by an acute, fatal, rapidly progressive infection of the central nervous system. In humans, the worldwide burden of deaths due to rabies is estimated to be between 40,000 and 70,000 annually (WHO Fact Sheet No. 99; www.paho.org/common/Display.asp?Lang=E&RecID=10209), with half of the infections occurring in children, although the actual figures may be significantly higher due to under-reporting.4 Following the onset of symptoms, patient survival rarely lasts beyond 7 days.5 Rabies virus transmission and infection can be controlled by limiting the infection in animal reservoirs, by pre-exposure vaccination of at-risk individuals or by post-exposure prophylaxis (PEP) of individuals after contact with a potentially infected animal. Following the bite of an infected animal, PEP consists of intramuscular administration of inactivated rabies virus vaccine (either from cell culture or nerve tissue origin), together with simultaneous infiltration into the wound site of rabies immunoglobulin (RIG) derived either from immunized human (HRIG) or equine (ERIG) sources.6 RIG provides passive immunity at the wound site until active immunity, stimulated by the vaccine, takes over.

In the developing world, where the vast majority of deaths occur, rabies vaccine is costly and needs to be administered repeatedly (three times for pre-exposure vaccination and up to five times for PEP). Serum-derived polyclonal antibodies (HRIG and ERIG) often suffer from drawbacks including limited production capacity, batch-to-batch variation, high cost, contamination with blood-borne adventitious agents and/or risk of adverse reactions. These issues of safety, quality, availability and cost, particularly associated with RIG have led to calls for the development of alternative biologics that can be used for PEP of rabies. Recently, the World Health Organisation Rabies Collaborating Centres (WHO RCCs) have published recommendations for a rabies post-exposure prophylaxis product based on monoclonal antibodies (mAbs), which would replace the currently used RIG preparations.6 A combination of at least two mAbs has been deemed a minimum requirement, and the hope is that such mixtures of mAbs could be developed as a safer, higher quality product that would be more widely available and affordable, for the replacement of RIG in post-exposure prophylaxis and prevention of rabies in humans. Monoclonal antibodies may constitute an attractive alternative to RIG, provided they perform equally well with respect to potency, coverage of a wide variety of viral strains and do not allow the emergence of resistant viral strains.

The conventional approach for monoclonal antibody production is the use of mammalian (e.g., CHO) cell fermentation. The costs involved in mAb production using mammalian cell-based fermentation are significant and a product such as a rabies PEP cocktail, where two or more mAbs are required, becomes increasingly prohibitive. As a result, it is recognized that the market will not achieve high profitability because the target population is disproportionately the poor people in developing countries. Thus, the selection by Crucell of a two-mAb cocktail7 and the recent recommendation from the WHO RCC that a rabies PEP cocktail should comprise a mixture of two mAbs6 is likely to be, in large part, an economic compromise. As an alternative to fermentation technology, we are advocating transgenic plants as a means of producing high quality pharmaceutical products at low cost, while avoiding the scale-up limitations of the bioreactor platforms. Together with the WHO RCCs, we have embarked on a programme to develop a mAb cocktail, using plants as the production platform, that may ultimately be deployed as part of a successful post-exposure regimen in the developing world.

This cocktail will comprise at least the two neutralizing mAbs E559.9.14 and 62-71-3, but our technology allows the addition of further mAbs. The variable heavy (VH) and light (VL) domains of each mAb were isolated from the corresponding hybridoma cell lines by RT-PCR, using a standard set of degenerate murine primers. In order to prevent unwanted immune responses directed against the murine constant domains during PEP, the VH and VL domains of each mAb were fused, respectively, to the constant γ1 and κ domains of a human IgG1κ mAb. The resulting mouse-human chimeric genes were cloned into plant expression vectors for the production of stable nuclear transformants of Nicotiana tabacum and Zea mays and for transient infiltration of N. benthamiana.19 The plant-expressed chimeric antibodies have been purified and demonstrate the expected neutralising activity to rabies virus. We currently await results from in vivo protection studies, before initiating product development under cGMP.

Developing Novel Self-adjuvanting Vaccines

Vaccine development and adjuvants.

One of the approaches that we have adopted in Molecular Pharming is to design and engineer proteins which exploit the plant's manufacturing abilities, thereby developing new pharmaceutical candidates that are best suited for production by plants. One such example is the development of monoclonal recombinant immune complexes (RICs), which build on our experience with mAb expression in plants.

An ideal vaccine would not require formulation in an exogenous adjuvant but would be designed to have intrinsic adjuvanticity. One approach would be to design novel systemic and mucosal vaccine candidates with ‘in-built’ adjuvanticity, based on direct targeting of cellular receptors. We hypothesized that this could be achieved by targeting a vaccine to Fc immunoglobulin receptors (FcIgR) on antigen-presenting cells (APCs) and have developed RICs to achieve this goal. Adjuvanting protective antigens by molecular engineering rather than chemical modification could augment their uptake and processing, through a natural presentation pathway. This in turn could lead to the development of both systemic and mucosal immunity, neutralizing antibodies, CD4+ T-cell helper responses and cross-presentation for MHC class I-restricted CD8 T-cell responses. The near-term goal of our studies is to demonstrate, for the first time, that RICs can induce protective immunity against an infection in the absence of exogenous adjuvants. We are conducting our studies in a murine model but the strategic principles of RICs can readily be translated into a self-adjuvanting immunogen for humans.

Immune complexes as vaccines.

Immune complexes are typically formed during the natural course of an infection, specifically delivering antigens to antigen-presenting cells via Fc and complement receptors, for uptake and subsequent presentation to antigen specific T cells. In principle, pre-prepared immune complexes between antibodies and target antigens of interest could therefore be used as vaccines that would be appropriately and inherently targeted to the immune system without the use of exogenous adjuvants. It has long been known that primary and secondary antibody responses to model antigens can be enhanced by immunization with immune complexes compared to antigen alone.8–10 Importantly, it is now well established that immune complexes can be cross-presented by dendritic cells and can stimulate potent MHC class I as well as MHC class II—restricted T-cell responses.10,11 Indeed, antibody-mediated enhancement of simian immunodeficiency (SIV) virus Gag antigen processing and cross presentation in SIV infected rhesus macaques, has recently been demonstrated.12 However, it is not feasible to prepare ‘natural’ immune complexes easily, as this would require immune sera or an expensive cocktail of monoclonal antibodies. It would be desirable therefore to design recombinant immune complexes that could functionally mimic natural immune complexes. To that end, we have developed a transgenic plant-based approach for generating such recombinant immune complexes.

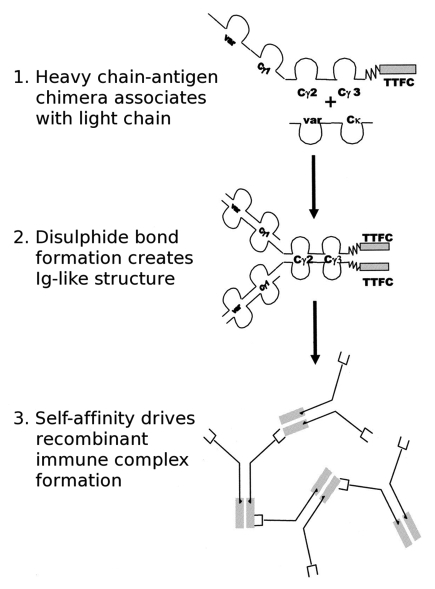

RIC subunits consist of an antigen moiety linked to an autospecific antibody by a short, flexible oligonucleotide linker region. Linkage of both moieties as a single molecule creates a subunit capable of self-polymerization, eliminating the requirement for polyclonal sera or mAb cocktails to achieve complex formation. A schematic representation of RIC structure and assembly is shown in Figure 1.

Figure 1.

Schematic of RIC molecules, showing proposed complex formation through self-affinity.

Plants might be well suited to the production of such RICs, as the efficiency in planta for protein folding and antibody assembly is well established. In addition, they can perform a range of post-translational modifications, including glycosylation, palmitoylation,13 myristoylation,14 isoprenylation15 and the addition of the GPI anchor.16 Together, these considerations provide a rationale for exploring the production of RICs in plants.

RICs were first produced by conventional crossing of transgenic plant lines.17 In one example, TT-RIC heavy chain (tetanus toxin fragment C—IgG2agamma) and light chain (Igkappa) were expressed in tobacco (N. tabacum) under the control of the cauliflower mosaic virus 35S promotor and in the context of a murine Ig signal peptide. RICs accumulated in the crude leaf extract to a level of 0.8% TSP (∼50 µg/g leaf FW) and assembled into multimeric complexes. Subsequent efforts to improve protein yield have focussed on the use of transient expression systems in combination with elements designed to increase transcription (matrix/scaffold attachment regions, viral UTRs and viral RNA-dependant RNA polymerases). Transient expression systems employ direct agroinfiltration of cultures containing plasmids encoding both heavy and light chains of the RIC, significantly reducing the time frame between cloning and batch production by removing plant growth from the critical path of the experiment. We have compared the yield obtained using two such systems; a geminivirus-derived dual replicon system,18 and a plasmid based on a minimal enhancer sequence identified from Cowpea mosaic virus (CPMV).19 In both cases, RICs comprised of a glycoprotein fragment from Ebola virus and a relevant antibody (Ebola-RIC) were found to accumulate to a level of approximately 1% TSP in N. benthamiana leaves.

In vitro characterization of RICs.

In vitro analysis of the antibody-related effector functions of the RIC was based on the initial molecular interactions through which the proposed functions are mediated. The potential for antibody-dependant cellular cytotoxicity (ADCC) or phagocytosis (ADCP) was inferred from the level of RIC binding to the low affinity Fc receptor FcγRIIa as measured by surface plasmon resonance, while complement-dependant cytotoxicity (CDC) through the classical pathway was assessed through binding to component C1q. The C1q binding represents the first reaction in immune complex mediated activation of the complement. Only complexes containing two or more immunoglobulins can efficiently bind to C1q. In both of the above assays, TT-RICs complexes were found to significantly outperform an equimolar quantity of the same uncomplexed monoclonal antibody. Interestingly, dynamic light scattering measurements indicate that the complexes contain an average of 4–6 subunits, suggesting that it may not be necessary to form large RIC complexes to effectively bind C1q and Fc receptors.

An important aspect of functional in vitro characterization of the assembled RICs is their ability to bind to FcR-bearing cells and to activate immature dendritic cells (DC). We demonstrated in a cell binding assay using the mouse macrophage J774 cells or mouse bone marrow derived dendritic cells (BMDC), that RICs typically bound to 60% or more of cells while the antibody alone exhibited only background binding. Most importantly though, following binding of RICs, the dendritic cells displayed an increased expression of the key co-stimulatory molecules CD40 and B7.2, which is indicative of their activation. Therefore, targeting the RICs to dendritic cell FcIγ receptors has the potential to stimulate these important antigen presenting cells in vivo and facilitate antigen presentation to T cells. In addition, immune complexes attached to the surface of these cells could play a role in B cell selection in germinal centers during clonal expansion.

Immunogenicity of RICs in mice.

We tested tetanus toxin plant RICs for immunogenicity in mice. Typically, 1–10 µg of purified RICs have been delivered either systemically (subcutaneous and peritoneal routes) or mucosally (intranasal, oral and intra-vaginal routes). Unlike antigen alone, high titres of specific antibody were elicited, even at low doses of RIC, and this subsequently proved to be sufficient to protect 100% of mice against lethal challenge.17

Second generation RICs and future prospects.

The design of RIC heavy chains must balance immunogenic properties with stability within the cells and tissues of the plant. In general, we have observed that although immunoglobulin fusions can act to stabilize and improve the bioaccumulation of certain antigens,20 this advantage tends to be lost as the molecular size increases past a certain limit. It is also reasonable to hypothesize that significant IC formation may be physically inhibited by very large antigen moieties, due to the distance between the antibody binding sites and the epitope within the antigen. Conversely, it is also possible that small, compact antigens may be rendered inaccessible in the context of a C-terminal fusion with an antibody, through steric hinderance.

The design of a second generation of RIC complexes will be informed by a combination of in vitro evaluation based on the assays mentioned above, and the observed immunogenic potential of the complex in vivo. Several general aspects of the RIC complexes may be optimized and tested in vitro. At the most fundamental level, the selection of an antigen/antibody pair may allow fine-tuning of the immune response by concealing prominent epitopes on the antigen. In the case of tetanus toxin, concealing an epitope in this way has been shown to prevent the subsequent loading of masked T-cell determinants onto MHC molecules, and in certain cases promote the display of neighboring epitopes.21 Hence, it may be possible to redirect an immunodominant but non-protective humoral response or to skew the immune response towards a Th1 profile.

Rational design of the antibody moiety of the RIC may improve antibody-mediated effector functions of the complex. It has been shown that a chimeric Fc composed of IgG3 and IgG1 retains the high C1q affinity of the IgG3 subclass while retaining protein A binding characteristic of IgG1.22 Furthermore, a panel of mutant antibodies with enhanced Fc receptor binding properties has been reported.23 Due to the well-defined domain structure of antibodies, it may also be possible to enhance CDC and ADCC/P functions by duplicating certain Fc domains within the RIC monomer. This latter approach also has the potential to change the conformation of the molecule and hence improve the display of the antigenic moiety. Exchanging the IgG Fc region for IgA, the predominant immunoglobulin found on mucosal surfaces, may produce RIC complexes that are more suited for the environment and receptors of the mucosa, and thus a more effective mucosal vaccine.

Development of a Simplified Contained Molecular Pharming Strategy with Low Regulatory Burden

Downstream processing and purification of protein pharmaceuticals from plant tissues has been estimated to account for 80–90% of the cost of production.24 An important initial consideration is the action of indigenous plant proteases in degrading recombinant proteins, and in particular their release during sample preparation, which may exacerbate degradation of target proteins.25

One approach to minimizing the potential release of proteases is to develop secretion-based systems for recombinant proteins, to simplify harvest. For example, single chain Fv and monoclonal antibody heavy chain have been recovered from the surrounding growth medium of genetically-modified tobacco cell suspensions26,27 and Agrobacterium rhizogenes-derived hairy roots of tobacco were used to secrete assembled full-length IgG1 mAb.28 In general however, protein yields from cell suspensions have been low, averaging 1–5 mg/L cell suspension culture. In addition, cell suspension cultures are frequently genetically unstable, whilst hairy root culture requires expensive bioreactors and cannot exploit the autotrophic capacities of the whole plant.

An alternative to these methods is to use the natural rhizosecretion mechanism of the plant, which in nature has a role in the processes of nodulation, mycorrhizal colonization, growth inhibition of neighboring plants, acquisition of nutrients from soil and defense against toxic metals.29 Rhizosecretion was first exploited for production of recombinant proteins in 1999, when tobacco plants were engineered to secrete either green fluorescent protein (GFP) from the jellyfish Aequorea victoria, human placental secreted alkaline phosphatase (SEAP) or xylanase from the thermophylic bacterium Clostridium thermocellum.30 Rhizosecretion of SEAP and GFP into hydroponic medium around the base of the roots reached a rate of 20 and 1 µg/g root dry weight/24 h respectively.

We have previously demonstrated rhizosecretion of a functional full-length mAb at a rate of 11.7 µg/g root dry weight/24 h.31 In a later study, we also demonstrated rhizosecretion of the anti-HIV microbicide, cyanovirin-N (CV-N), again from transgenic tobacco.32 The CV-N demonstrated high stability: it accumulated in the medium for up to 24 days, compared to only 11 days for Guy's 13 mAb.

The yields of recombinant proteins produced by rhizosecretion in these studies are too low for commercial viability.33 Several research groups have employed different strategies to attempt to increase the yield of rhizosecreted PMP, with varying results. These include the use of a root promoter30 or a plant signal sequence,34 A. rhizogenes to induce hairy roots on transgenic tobacco plants35 and co-expression of the Bowman-Birk Ser protease inhibitor.34

In our group we investigated the effects of a range of plant growth regulators, including α-naphthalene acetic acid (NAA) on rhizosecretion of Guy's 13 mAb and CV-N.33 At the molecular level, auxins, such as NAA, promote cell elongation, by increasing cell wall extensibility via the breaking of hydrogen bonds between the polysaccharide components of the cell wall. These plant growth regulators have diverse physiological effects in plants, including the stimulation of lateral and adventitious root initiation (reviewed in ref. 36). We theorized that recombinant protein secretion might therefore be enhanced by addition of NAA to hydroponic nutrient medium, due to increased root surface area and enhanced permeabilization of the cell wall. Indeed addition of NAA increased yields of Guy's 13 mAb 50-fold and of CV-N 6-fold over a 7d period. The maximum rhizosecretion rates achieved were 58 µg/g root dry weight/24 h for Guy's 13 mAb and 766 µg/g root dry weight/24 h for CV-N, the highest figures so far reported for a full-length antibody and any recombinant protein respectively.

Harvest of rhizosecreted protein pharmaceuticals allows for continuous collection throughout the life of a plant. But there are also other potentially significant advantages. Purification of mAb from vegetative tissues is a time-consuming and expensive process involving maceration and removal of undesirable contaminants prior to affinity chromatography for final purification of product.37 Analysis of hydroponic culture medium at harvest revealed significantly lower and less complex levels of proteolytic enzymes, in comparison with leaf extracts, which translated to a higher proportion of intact mAb in relation to other IgG degradation products.33 We also demonstrated that hydroponic medium could be processed directly onto a chromatography column for affinity purification allowing simple and rapid production of high purity mAb.

From a regulatory perspective, production by rhizosecretion under contained cultivation is also attractive. Manufacturing variability can be controlled much better through consistency of environmental factors (e.g., light, day length, temperature and CO2) which affect plant growth and recombinant protein yield and quality. The avoidance of soil and compost and the use of defined hydroponic medium also provide an even greater control over the plant cultivation process. Contained growth also facilitates plant disease management and reduces the risk of contamination from external sources. From an environmental safety view, the risk of accidental release of transgenic material into the environment is greatly minimized through contained cultivation.

Taken together with our recent technical advances, these regulatory advantages make a compelling case for further investigation of hydroponic cultivation and rhizosecretion harvest as a potentially competitive strategy for the production of plant made pharmaceuticals.

The Intellectual Property (IP) Landscape in Relation to PMP: Social Implications

An important societal activity in our group is to analyze the IP landscape in relation to plant made pharmaceuticals to research the best modes of technology transfer, sharing of knowledge, licensing and commercialization to make end products and processes in PMP accessible and affordable for low- to middle-income countries. There is significant patenting activity in the PMP arena, and therefore such analyses are essential to clear any potential barriers to ensure freedom-to-operate (FTO) and secure any necessary permission to commercialize outputs from upstream research. FTO also will potentially involve the use of our own IP and that of our partners in research collaborations as a tool for commercialization.

These activities began with the Pharma-Planta Project through collaboration with our partner organization, The Centre for IP Management in Health R&D (now assimilated into the Concept Foundation). Together we developed an access plan that we anticipate will secure access to PMP technology at affordable cost for developing countries. In the access plan a number of milestones were achieved. We included in our consortium agreement clauses on technology transfer and sharing of IP, with special consideration of developing countries and humanitarian access. We also secured a signed statement from all scientists in the Pharma-Planta consortium, that in principle all IP generated by the project would be shared for free if necessary to benefit a humanitarian cause. We also performed a detailed landscape analysis of the patents and other IP rights related to our main product target, HIV neutralizing antibodies produced through PMP technology.

We further carried out a detailed IP landscape analysis of prior art including published patent applications and granted patents that may affect future commercialization of anti-HIV monoclonal antibodies developed by the Pharma-Planta consortium of scientific institutions. These antibodies are expressed in tobacco and maize plants and are enabled through using a range of patented and non-patented technologies. This included cataloguing the claims of each patent application and the licensing and FTO implications for our own technologies. Other analytic parameters were: ownership, history of patent disputes, invalidations, revocations, lapses, term of protection, geographic scope of protection, licensing issues and a limited summary and analysis of possible legal implications.

More recently our activities have been broadened, and we have performed a detailed analysis of the international patent landscape related to PMP as a whole.38,39 Perhaps more significantly, we also research the social implications of technology transfer from the academic sector, specifically the effects on affordability and access to health technologies for poorer populations disproportionately affected by disease. In this context we particularly include PMP technology as an emerging field most likely to produce scalable medicinal products at low cost and adaptable to local manufacturing capacity.

To elaborate on some of the results of our research, we found that the public funded sector, as opposed to industry contributes to greater than 50% of patented technologies in the PMP sector, and that this is likely to reflect academic contribution to patented research in the biopharmaceutical product sector as a whole.38 Since many of the potential products are targeted towards neglected diseases that affect developing countries, we make the case that the academic sector should take note of new licensing paradigms adopted by several institutions worldwide to enable access to medicines at affordable cost. (Statement of Principles and Strategies for the Equitable Dissemination of Medical Technologies; AUTM Global Health Sample Clauses. Available on www.autm.net).

Conclusions

The prospect of producing modern medicines in plants is extremely attractive. A clear advantage is that the concept and its benefits are immediately obvious to the public and non-scientists. However, the introduction of any technology, particularly into a traditionally conservative area such as the pharmaceutical industry is inevitably cautious. It was entirely predictable that the first plant-derived pharmaceuticals (Newcastle disease vaccine and glucocerebrosidase) would be produced using technologies that closely mimic existing approved production platforms. Such incremental progress allows the introduction of new approaches within the context of an existing regulatory framework and does not pose major challenges to regulatory authorities. Our adoption of approaches that allow contained cultivation of plants under highly controlled conditions represents the next step, as we move away from sterile cell cultures and into non-sterile whole plant systems grown either hydroponically or in standardized compost.

We have always advocated that plant production platforms are best suited for medical targets that are required in very large quantities, which is why our effort has been targeted towards monoclonal antibodies for passive immunization or topical microbicides. For the future though we believe that there are four important areas where plant production platforms could contribute to a step change in pharmaceutical production, and all could result in significant benefits for global health.

The first is in the production of custom molecules, specifically designed with plant production in mind. These include vaccines or antibodies with specific functional activity. Examples are the recombinant immune complex (RIC) described here, or mAbs displaying specific glycoforms which provide enhance particular effector functions, as has been described in reference 40.

The second area is the administration of a plant-derived oral vaccine in the context of a heterologous prime boost strategy. Oral boosting in systemically vaccinated individuals bypasses the issue of inducing oral tolerance. It is also a simple and convenient way to provide second, third and fourth booster immunization, which will help to improve the success of any vaccine programmes, particularly in developing countries. The approach using plant derived products has already been demonstrated for the hepatitis B and measles vaccines.41,42

The third area where plant production platforms could change pharmaceutical thinking is by the introduction of pharmaceutically regulated products prepared by minimal downstream processing. Downstream processing contributes significantly to manufacturing costs and the simplification of this step would greatly enhance the economic feasibility of many products. The regulatory issues relate to consistency of product, and this applies not only to the active pharmaceutical ingredient, but also to co-administered plant ingredients. The technical challenge therefore is to identify manufacturing processes that can comply with minimal and maximum specifications that are functionally acceptable and agreed by regulatory authorities. Our development of a rhizosecretion based production system is in part, driven by the desire to simplify the purification process.

The final important impact area for plants could be widening participation in pharmaceutical production, particularly in less developed countries with an emphasis on addressing local health issues. Any approach that offers a simplified and inexpensive route to pharmaceutical production would be of great interest to countries struggling with health issues that are of little or no interest to the developed world. Rabies is a case in point. The upstream component of a transgenic plant production platform is attractively economic and would not necessitate a large infrastructure investment. The key to success would be the ability to integrate this with appropriate downstream processing technologies. In addition, developments such as minimal processing, the will of scientists in the west to collaborate with scientists from less developed countries, and the development of technology transfer programmes at an early stage of product development will be the key to unlocking this step.

Plant Molecular Pharming offers important prospects for improving Global Access to medicines. The urgency now is to accelerate development not only for conventional products, but also for new concepts.

Acknowledgements

The authors would like to thank Sir Joseph Hotung for his generous support for all our work, and all the funding agencies who have contributed, including—The European Union (Pharma-Planta, Access to Medicines and CoMoFarm), the European COST action on Molecular Farming, NIH, the Wellcome Trust and the Bill and Melinda Gates Foundation.

References

- 1.Sparrow PA, Irwin JA, Dale PJ, Twyman RM, Ma JK. Pharma-Planta: road testing the developing regulatory guidelines for plant-made pharmaceuticals. Transgenic Res. 2007;16:147–161. doi: 10.1007/s11248-007-9074-2. [DOI] [PubMed] [Google Scholar]

- 2.Spok A, Twyman RM, Fischer R, Ma JK, Sparrow PA. Evolution of a regulatory framework for pharmaceuticals derived from genetically modified plants. Trends Biotechnol. 2008;26:506–517. doi: 10.1016/j.tibtech.2008.05.007. [DOI] [PubMed] [Google Scholar]

- 3.Cooper PJ, Chico ME, Losonsky G, Sandoval C, Espinel I, Sridhara R, et al. Albendazole treatment of children with ascariasis enhances the vibriocidal antibody response to the live attenuated oral cholera vaccine CVD 103-HgR. J Infect Dis. 2000;182:1199–1206. doi: 10.1086/315837. [DOI] [PubMed] [Google Scholar]

- 4.Cleaveland S, Fevre EM, Kaare M, Coleman PG. Estimating human rabies mortality in the United Republic of Tanzania from dog bite injuries. Bull World Health Organ. 2002;80:304–310. [PMC free article] [PubMed] [Google Scholar]

- 5.Warrell DA. The clinical picture of rabies in man. Trans R Soc Trop Med Hyg. 1976;70:188–195. doi: 10.1016/0035-9203(76)90037-7. [DOI] [PubMed] [Google Scholar]

- 6.Muller T, Dietzschold B, Ertl H, Fooks AR, Freuling C, Fehlner-Gardiner C, et al. Development of a mouse monoclonal antibody cocktail for post-exposure rabies prophylaxis in humans. PLoS Negl Trop Dis. 2009;3:e542. doi: 10.1371/journal.pntd.0000542. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Bakker AB, Python C, Kissling CJ, Pandya P, Marissen WE, Brink MF, et al. First administration to humans of a monoclonal antibody cocktail against rabies virus: safety, tolerability, and neutralizing activity. Vaccine. 2008;26:5922–5927. doi: 10.1016/j.vaccine.2008.08.050. [DOI] [PubMed] [Google Scholar]

- 8.Abdel-Motal U, Wang S, Lu S, Wigglesworth K, Galili U. Increased immunogenicity of human immunodeficiency virus gp120 engineered to express Galalpha1-3Galbeta1-4GlcNAc-R epitopes. J Virol. 2006;80:6943–6951. doi: 10.1128/JVI.00310-06. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Polyanskaya N, Bergmeier LA, Sharpe SA, Cook N, Leech S, Hall G, et al. Mucosal exposure to subinfectious doses of SIV primes gut-associated antibody-secreting cells and T cells: lack of enhancement by nonneutralizing antibody. Virology. 2001;279:527–538. doi: 10.1006/viro.2000.0704. [DOI] [PubMed] [Google Scholar]

- 10.Regnault A, Lankar D, Lacabanne V, Rodriguez A, Thery C, Rescigno M, et al. Fc gamma receptor-mediated induction of dendritic cell maturation and major histocompatibility complex class I-restricted antigen presentation after immune complex internalization. J Exp Med. 1999;189:371–380. doi: 10.1084/jem.189.2.371. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Schuurhuis DH, Ioan-Facsinay A, Nagelkerken B, van Schip JJ, Sedlik C, Melief CJM, et al. Antigen-antibody immune complexes empower dendritic cells to efficiently prime specific CD8(+) CTL responses in vivo. J Immunol. 2002;168:2240–2246. doi: 10.4049/jimmunol.168.5.2240. [DOI] [PubMed] [Google Scholar]

- 12.Villinger F, Mayne AE, Bostik P, Mori K, Jensen PE, Ahmed R, et al. Evidence for antibody-mediated enhancement of simian immunodeficiency virus (SIV) Gag antigen processing and cross presentation in SIV-infected rhesus macaques. J Virol. 2003;77:10–24. doi: 10.1128/JVI.77.1.10-24.2003. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.Hemsley PA. Protein S-acylation in plants (Review) Mol Membr Biol. 2009;26:114–125. doi: 10.1080/09687680802680090. [DOI] [PubMed] [Google Scholar]

- 14.Traverso JA, Meinnel T, Giglione C. Expanded impact of protein N-myristoylation in plants. Plant Signal Behav. 2008;3:501–502. doi: 10.4161/psb.3.7.6039. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Crowell DN, Hemmerlin A, Gerber E, Hartmann M, Heintz D, Rohmer M, Bach TJ. A role for plastids in plant protein isoprenylation. Plant Signal Behav. 2009;4:217–218. doi: 10.4161/psb.4.3.7842. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Sherrier DJ, Prime TA, Dupree P. Glycosylphosphatidylinositol-anchored cell-surface proteins from Arabidopsis. Electrophoresis. 1999;20:2027–2035. doi: 10.1002/(SICI)1522-2683(19990701)20:10<2027::AID-ELPS2027>3.0.CO;2-A. [DOI] [PubMed] [Google Scholar]

- 17.Chargelegue D, Drake PM, Obregon P, Prada A, Fairweather N, Ma JK. Highly immunogenic and protective recombinant vaccine candidate expressed in transgenic plants. Infect Immun. 2005;73:5915–5922. doi: 10.1128/IAI.73.9.5915-5922.2005. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Chen Q, He J, Phoolcharoen W, Mason HS. Geminiviral vectors based on bean yellow dwarf virus for production of vaccine antigens and monoclonal antibodies in plants. Hum Vaccin. 7:331–338. doi: 10.4161/hv.7.3.14262. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Sainsbury F, Thuenemann EC, Lomonossoff GP. pEAQ: versatile expression vectors for easy and quick transient expression of heterologous proteins in plants. Plant Biotechnol J. 2009;7:682–693. doi: 10.1111/j.1467-7652.2009.00434.x. [DOI] [PubMed] [Google Scholar]

- 20.Obregon P, Chargelegue D, Drake PM, Prada A, Nuttall J, Frigerio L, Ma JK. HIV-1 p24-immunoglobulin fusion molecule: a new strategy for plant-based protein production. Plant Biotechnol J. 2006;4:195–207. doi: 10.1111/j.1467-7652.2005.00171.x. [DOI] [PubMed] [Google Scholar]

- 21.Watts C, Antoniou A, Manoury B, Hewitt EW, McKay LM, Grayson L, Fairweather NF, Emsley P, Isaacs N, Simitsek PD. Modulation by epitope-specific antibodies of class II MHC-restricted presentation of the tetanus toxin antigen. Immunol Rev. 1998;164:11–16. doi: 10.1111/j.1600-065x.1998.tb01203.x. [DOI] [PubMed] [Google Scholar]

- 22.Natsume A, In M, Takamura H, Nakagawa T, Shimizu Y, Kitajima K, Wakitani M, Ohta S, Satoh M, Shitara K, Niwa R. Engineered antibodies of IgG1/IgG3 mixed isotype with enhanced cytotoxic activities. Cancer Res. 2008;68:3863–3872. doi: 10.1158/0008-5472.CAN-07-6297. [DOI] [PubMed] [Google Scholar]

- 23.Lazar GA, Dang W, Karki S, Vafa O, Peng JS, Hyun L, Chan C, Chung HS, Eivazi A, Yoder SC, Vielmetter J, Carmichael DF, Hayes RJ, Dahiyat BI. Engineered antibody Fc variants with enhanced effector function. Proc Natl Acad Sci USA. 2006;103:4005–4010. doi: 10.1073/pnas.0508123103. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 24.Drossard J, editor. Downstream Processing of Plant-Derived Recombinant Therapeutic Proteins. Weinheim, Germany: Wiley-VCH Veriag GmbH & Co; 2004. [Google Scholar]

- 25.Ma JK, Lehner T, Stabila P, Fux CI, Hiatt A. Assembly of monoclonal antibodies with IgG1 and IgA heavy chain domains in transgenic tobacco plants. Eur J Immunol. 1994;24:131–138. doi: 10.1002/eji.1830240120. [DOI] [PubMed] [Google Scholar]

- 26.Firek S, Draper J, Owen MRL, Gandecha A, Cockburn B, Whitelam GC. Secretion of a functional single-chain Fv protein in transgenic tobacco plants and cell suspension cultures. Plant Mol Biol. 1993;23:861–870. doi: 10.1007/BF00021540. [DOI] [PubMed] [Google Scholar]

- 27.Magnuson NS, Linzmaier PM, Gao JW, Reeves R, An GH, Lee JM. Enhanced recovery of a secreted mammalian protein from suspension culture of genetically modified tobacco cells. Protein Expr Purif. 1996;7:220–228. doi: 10.1006/prep.1996.0030. [DOI] [PubMed] [Google Scholar]

- 28.Wongsamuth R, Doran PM. Production of monoclonal antibodies by tobacco hairy roots. Biotechnol Bioeng. 1997;54:401–415. doi: 10.1002/(SICI)1097-0290(19970605)54:5<401::AID-BIT1>3.0.CO;2-I. [DOI] [PubMed] [Google Scholar]

- 29.Gleba D, Borisjuk NV, Borisjuk LG, Kneer R, Poulev A, Sarzhinskaya M, et al. Use of plant roots for phytore-mediation and molecular farming. Proc Natl Acad Sci USA. 1999;96:5973–5977. doi: 10.1073/pnas.96.11.5973. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 30.Borisjuk NV, Borisjuk LG, Logendra S, Petersen F, Gleba Y, Raskin I. Production of recombinant proteins in plant root exudates. Nature Biotechnol. 1999;17:466–469. doi: 10.1038/8643. [DOI] [PubMed] [Google Scholar]

- 31.Drake PM, Chargelegue DM, Vine ND, van Dolleweerd CJ, Obregon P, Ma JK. Rhizosecretion of a monoclonal antibody protein complex from transgenic tobacco roots. Plant Mol Biol. 2003;52:233–241. doi: 10.1023/a:1023909331482. [DOI] [PubMed] [Google Scholar]

- 32.Sexton A, Drake PM, Mahmood N, Harman SJ, Shattock RJ, Ma JK. Transgenic plant production of Cyanovirin-N, an HIV microbicide. FASEB J. 2006;20:356–358. doi: 10.1096/fj.05-4742fje. [DOI] [PubMed] [Google Scholar]

- 33.Drake PM, Barbi T, Sexton A, McGowan E, Stadlmann J, Navarre C, Paul MJ, Ma JK. Development of rhizosecretion as a production system for recombinant proteins from hydroponic cultivated tobacco. FASEB J. 2009 doi: 10.1096/fj.09-131771. [DOI] [PubMed] [Google Scholar]

- 34.Komarnytsky S, Borisjuk N, Yakoby N, Garvey A, Raskin I. Cosecretion of protease inhibitor stabilizes antibodies produced by plant roots. Plant Physiology. 2006;141:1185–1193. doi: 10.1104/pp.105.074419. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 35.Gaume A, Komarnytsky S, Borisjuk N, Raskin I. Rhizosecretion of recombinant proteins from plant hairy roots. Plant Cell Reports. 2003;21:1188–1193. doi: 10.1007/s00299-003-0660-3. [DOI] [PubMed] [Google Scholar]

- 36.Johri MM MD. Action of plant hormones. Current Science. 2001;80:6. [Google Scholar]

- 37.Chargelegue D, Drake PM, Obregon P, Prada A, Fairweather N, Ma JK. Highly immunogenic and protective recombinant vaccine candidate expressed in transgenic plants. Infect Immun. 2005;73:5915–5922. doi: 10.1128/IAI.73.9.5915-5922.2005. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 38.Thangaraj H, van Dolleweerd CJ, McGowan EG, Ma JK. Dynamics of global disclosure through patent and journal publications for biopharmaceutical products. Nat Biotechnol. 2009;27:614–618. doi: 10.1038/nbt0709-614. [DOI] [PubMed] [Google Scholar]

- 39.Drake PM, Thangaraj H. Molecular farming, patents and access to medicines. Expert Rev Vaccines. 9:811–819. doi: 10.1586/erv.10.72. [DOI] [PubMed] [Google Scholar]

- 40.Strasser R, Castilho A, Stadlmann J, Kunert R, Quendler H, Gattinger P, et al. Improved virus neutralization by plant-produced anti-HIV antibodies with a homogeneous beta1,4-galactosylated N-glycan profile. J Biol Chem. 2009;284:20479–20485. doi: 10.1074/jbc.M109.014126. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 41.Kong QX, Richter L, Yang YF, Arntzen CJ, Mason HS, Thanavala Y. Oral immunization with hepatitis B surface antigen expressed in transgenic plants. Proceedings of the National Academy of Sciences of the United States of America. 2001;98:11539–11544. doi: 10.1073/pnas.191617598. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 42.Webster DE, Cooney ML, Huang Z, Drew DR, Ramshaw IA, Dry IB, et al. Successful boosting of a DNA measles immunization with an oral plant-derived measles virus vaccine. J Virol. 2002;76:7910–7912. doi: 10.1128/JVI.76.15.7910-7912.2002. [DOI] [PMC free article] [PubMed] [Google Scholar]