Abstract

This paper describes an acoustic trap consisting of a multi-foci Fresnel lens on 127 μm thick lead zirconate titanate sheet. The multi-foci Fresnel lens was designed to have similar working mechanism to an Axicon lens and generates an acoustic Bessel beam, and has negative axial radiation force capable of trapping one or more microparticle(s). The fabricated acoustic tweezers trapped lipid particles ranging in diameter from 50 to 200 μm and microspheres ranging in diameter from 70 to 90 μm at a distance of 2 to 5 mm from the tweezers without any contact between the transducer and microparticles.

Contactless particle trapping has many potential applications in biology, physical chemistry, and bio-medical research. Among the various approaches, optical tweezers is the most well developed and commonly investigated technique.1 However, particle trapping based on optical manipulation has several limitations: the high energy of a highly focused laser can damage living cells. Second, the size of the largest particle which can be trapped by an optical tweezers is limited to tens of micrometers. Finally, the use of optical tweezers is confined to optically transparent objects or shallow region of opaque medium.

Research into ultrasonic tweezers seeks to provide an alternative to optical tweezers. Ultrasound is more attractive than light, because it imparts much higher energy (or impact force) and also offers greater spatial range, consequently providing the ability to capture larger particles over a wider range. However, ultrasonic tweezers has not been widely pursued, possibly due to lack of good focusing technology. An acoustical tweezing system was pioneered by Wu2 with a device capable of stably capturing latex particles of diameter 270 μm. The tweezers utilized two counteracting acoustic transducers to create a force potential well that could capture microparticles. More recently, a highly focused transducer was used to capture a lipid particle that was already confined on a mylar sheet in water.3

This paper describes microparticle trapping on a liquid surface by a single ultrasonic transducer. We designed and fabricated transducers that could generate a Bessel beam containing a region of a negative axial radiation force.4 Though Bessel beams can be generated by an Axicon lens,5 the fabrication of an Axicon lens for microparticle trapping can be challenging due to the steep lens angle required. Thus, we fabricated both an aluminum alloy Axicon lens and a multi-foci Fresnel lens employing an air-reflector6 that has wide tolerance to the lens thickness unlike the stepped plate structure7 and also has wide tolerance to manufacturing imprecision. Both of the fabricated lenses were shown to trap microparticles, and the trapping was considered as one major evidence of a Bessel beam, as a positive pressure field expels particles out of the spot. The trapping by the Fresnel lens device was strong and stable, and the trapped particles follow the movement of the acoustic tweezers within our experimental boundary.

When a Fresnel lens is designed to have multiple focal points, the acoustic waves passing through the lens produces a Bessel beam with a micron sized region where the radiation force is negative. The wave equation ψB for a scalar-wave Bessel beam is an axisymmetric solution of the free-space wave equation.4

| (1) |

where ψo, κ, Jo, and μ are the wave amplitude, axial wave number, zeroth-order Bessel function, and radial wave number, respectively.

Marston mathematically proved that negative axial radiation force exists in a Bessel beam under certain conditions4 as shown experimentally by Whitworth.8 To explain the condition for the negative axial radiation force, Marston defined the parameter domain (k, a, β) where k, a, and β are the wave number, radius of trapping particle, and cone angle, respectively. The cone angle β is an important parameter in the characterization of a Bessel beam, and linked to the parameters of Eq. 1 by

| (2) |

The square of the wave number k, i.e., k2, is equal to κ2 + μ2, and also equal to (ω/c0)2, where ω and c0 are angular frequency and the phase velocity of the acoustic wave in the liquid, respectively.

Observing the working mechanism of an Axicon lens, we can see that the wave closer to the lens center is focused at a shorter distance from the lens. In the other end, the wave farther from the lens center is focused at a longer distance from the lens. A Bessel beam is formed in the region where the focused wave is uniformly distributed.

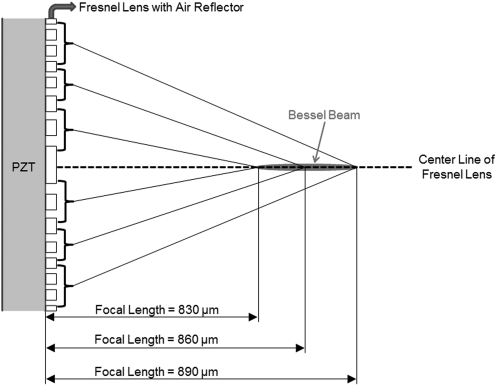

To emulate the behavior of an Axicon lens described above, a multi-foci Fresnel lens with an air-reflector based on a single-focus Fresnel tranducer6 was designed and fabricated on a 127 μm thick lead zirconate titanate (PZT) sheet. The Fresnel lens has 7 rings in total. The 2 inner most rings, next 2 rings, and remaining 3 rings have focal lengths of 830 μm, 860 μm, and 890 μm, respectively (Fig. 1). As a control experiment, an acoustic tweezers with Fresnel lens having only one focal length of 800 μm and the same number of rings was fabricated. When the control transducer was actuated, particles above the control transducer were immediately expelled from the region due to positive axial radiation force and the stirring effect and no particle was trapped.

Figure 1.

(Color online) Side-view schematic of the multi-foci Fresnel lens.

The acoustic tweezers with an aluminum alloy Axicon lens was also designed and fabricated to compare the performance. To have the cone angle β = 60°, the Axicon lens angle α was set to 63°.

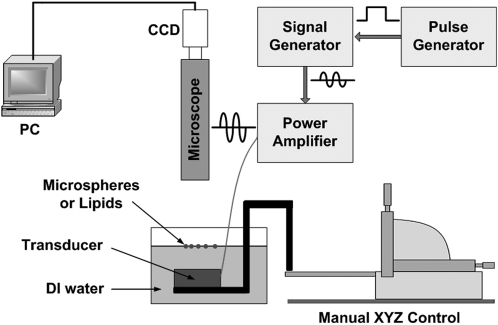

For a low energy in trapping microparticles, a pulsed 17.9 MHz sinusoidal signal, instead of continuous sinusoidal signal, was applied to the fabricated acoustic tweezers with 10–20 kHz pulse repetition frequency (PRF). The PRF was chosen for the best operating condition for capturing the particles at low power consumption and without damaging the lens and the particles. The pulse width was 2 μs, and the sinusoidal signal had 160 Vpeak-to-peak amplitude. The tweezers submerged in water was fixed to a manual XYZ moving stage, and lipid particles or microspheres were freely floating on and in the water. The movement of the microparticles was observed through a CCD camera attached to a long-working distance microscope lens, and the images and videos captured by the CCD camera were recorded with a computer (Fig. 2).

Figure 2.

(Color online) Schematic of the setup to observe the trapping of microparticles by the fabricated acoustic tweezers.

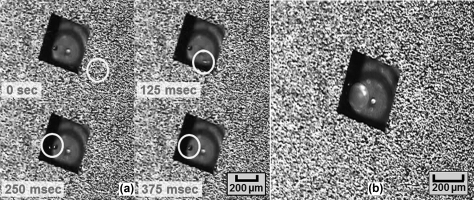

The fabricated tweezers, both the one based on the multi-foci Fresnel lens and the aluminum-alloy Axicon lens were tested to see whether they could trap lipid particles ranging from 50 to 200 μm in diameter and microspheres ranging from 70 to 90 μm in diameter. As the actuated tweezers produced acoustic waves and stirred the water as well as the microparticles in/on the water, the microparticles circled around the tweezers. Once a lipid particle hit the location where the Bessel beam was generated, the lipid particle was firmly trapped to the spot and held there even when another lipid particle hit the trapped lipid particle (Fig. 3). And we were able to move the trapped particle by moving the transducer over a wide range (limited only by the movable range of the transducer in the test apparatus).

Figure 3.

(Color online) (a) Photos taken at different times showing that a 72 -μm-diameter lipid particle was being trapped by the transducer and hit by another drifted lipid particle (circled for clarification) at 250 ms. The trapped lipid was unmoved by the impact from the other lipid, as shown in the photo taken at 375 ms. The tilted rectangle is the opening of device top cover, while the large circle inside it is due to the Fresnel lens on the device. The rough frosting dots around the rectangle are due to the rough surface of unpolished silicon-wafer backside. (b) Photo of a large 200 -μm-diameter lipid particle being trapped by the same transducer.

Of the three devices tested, only the multi-foci Fresnel lens device demonstrated consistent capturing and manipulating both the lipid droplets (50–200 μm in diameter) and the polystyrene microspheres (70–90 μm in diameter) at a distance from of 2 to 5 mm from the lens surface without any contact between the transducer and microparticles.

The reason for the aluminum alloy Axicon lens transducer’s ineffectiveness as a tweezers was the level of imprecision in the making of the Axicon lens. The machine shop which constructed the Axicon lens was not able to build it to the high level of precision with a milling machine called Tooling Lathe (from Harding Elmira), and the performance of the Axicon lens transducer was compromised. The interior surface of the lens had many imperfections and rough patches, which although very small, impacted the Axicon lens transducer’s performance. The Axicon lens transducer, though, was indeed able to capture one particle at the beginning of our tests, but quickly lost the particle and was not able to retain it for any significant period of time. In contrast, the multi-foci annular ring array was consistently able to capture particles, as it focused the waves very well over multiple spots along the focal axis. This transducer can easily be modified to capture multiple particles on demand, to eject the captured particles out of liquid surface by integrating a single-focus Fresnel ejector, etc.

In summary, a single ultrasonic transducer has been shown to capture microparticles (both lipid and polystyrene). The microparticle trapping by a single focused-ultrasonic-beam transducer is very exciting, since the transducer (or an array of multiple such transducers) can attract and hold solid particles (ranging from a few microns to several hundreds in diameter), and move and place them at precise locations for diagnostics, construction, etc.

Acknowledgments

This paper is based on the work partially supported by National Institutes of Health under Grant No. R21HG005118.

References

- Grier D. G., Nature 424, 810 (2003). 10.1038/nature01935 [DOI] [PubMed] [Google Scholar]

- Wu J. R., J. Acoust. Soc. Am. 89, 2140 (1991). 10.1121/1.400907 [DOI] [PubMed] [Google Scholar]

- Lee J., Teh S.-Y., Lee A., Kim H. H., Lee C., and Shung K. K., Appl. Phys. Lett. 95, 73701 (2009). 10.1063/1.3206910.1 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Marston P. L., J. Acoust. Soc. Am. 120, 3518 (2006). 10.1121/1.2361185 [DOI] [PubMed] [Google Scholar]

- Milne G., Jeffries G. D. M., and Chiu D. T., Appl. Phys. Lett. 92, 261101 (2008). 10.1063/1.2952833 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lee C.-Y., Yu H., and Kim E. S., 19th IEEE International Conference on Micro Electro Mechanical Systems, 2006, MEMS 2006 Istanbul (2006), pp. 170–173.

- Riera E. and Gallego-Juarez J., Ultrason. Sonochem. 13(2 ), 107 (2006). [DOI] [PubMed] [Google Scholar]

- Whitworth G., J. Acoust. Soc. Am. 91, 79 (1992). 10.1121/1.402622 [DOI] [Google Scholar]