Abstract

By applying a voltage pulse to a scanning tunneling microscope tip the surface under the tip will be modified. We have in this paper taken a closer look at the model of electric field induced surface diffusion of adatoms including the van der Waals force as a contribution in formations of a mound on a surface. The dipole moment of an adatom is the sum of the surface induced dipole moment (which is constant) and the dipole moment due to electric field polarisation which depends on the strength and polarity of the electric field. The electric field is analytically modelled by a point charge over an infinite conducting flat surface. From this we calculate the force that cause adatoms to migrate. The calculated force is small for voltage used, typical 1 pN, but due to thermal vibration adatoms are hopping on the surface and even a small net force can be significant in the drift of adatoms. In this way we obtain a novel formula for a polarity dependent threshold voltage for mound formation on the surface for positive tip. Knowing the voltage of the pulse we then can calculate the radius of the formed mound. A threshold electric field for mound formation of about 2 V/nm is calculated. In addition, we found that van der Waals force is of importance for shorter distances and its contribution to the radial force on the adatoms has to be considered for distances smaller than 1.5 nm for commonly used voltages.

Introduction

A voltage pulse between a scanning tunneling microscope (STM) tip and a surface will modify the surface under the tip creating either a mound or a pit on the surface, see ref. [1], [2] and Table 1.

Table 1. Mound or pit formation for different tip and surface materials and tip polarity.

| Reference | Tip | Surface | Effect of negative tip | Effect of positive tip |

| Mamin (1990) [3] | Au | Au | Mound | Mound |

| Hsiao (1994) [5] | Au or Cu | Si | Au or Cu mound1 | Non-metallic mound1 |

| Bessho (1994) [9] | PtIr | Au | Pit | Mound |

| Mascher (1994) [8] | Au | Au | Pit2 | Mound2 |

| Chang (1995) [24] | Au, W, PtIr | Au | Mound, Crater3 | Mound, Crater3 |

| Kondo (1995) [17] | W or Pt | Various4 | Pit | - |

| Ohi (1995) [12] | Au | Au | Pit, Mound5 | Mound |

| Hu (1998) [7] | Al | Si | Mound | Mound |

| Mayer (1999) [14] | W | Au | Mound | - |

| Zhang (2001) [6] | Au | Au | Mound, Crater | Mound, Crater |

| Park (2002) [10] | Al | Si | Erasure of mound | Increased mound size |

| Park (2002) [10] | Au | Si | Incresed mound size | Erasure of mound |

| Fujita (2003) [11] | Ag | Si | Mound | Mound |

: Element determination by scanning Auger microprobe spectra.

: For triangular voltage pulse. Rectangular pulse used elsewhere.

: Nonconducting liquid between tip and surface.

: Au, Ag, In, Si, Pt, W, C, SiO , MoS

, MoS or Bi

or Bi Sr

Sr CaCu

CaCu O

O .

.

: Pit created at larger tip-surface distance, mound at smaller.

The surface atoms on the tip or sample are subjected to an electrostatic force and this can lead to two different scenarios: either field evaporation [3]–[12] or field enhanced diffusion [4], [13]–[16] of atoms. However, field evaporation as Tsong [4] and others [17] has pointed out, is less likely compared to diffusion for the low voltages used in the experiments. In field evaporation an electric field of 20–50 V/nm is required [18] while typical voltages use in these experiments are 1–5 V/nm. In field enhanced diffusion, surface atoms (adatoms) are hopping between equivalent equilibrium positions due to lattice vibrations [19], [20], and if they posses dipole moments they may be attracted towards the tip by the inhomogeneous electric field between the tip and the surface making a mound.

At tunneling distances the van der Waals force is also of importance because it grows as the inverse fourth power of distance [21], see equation (5). However, this contribution has been little discussed in the literature [22]. The situation is complicated by the proximity between tip and sample, which is only about one nanometer when tunneling occur, that might lead to the formation of a neck between tip and sample [6], [23], [24]. At larger distances, however, we can neglect the neck formation mechanism [12].

The experimental results, summarized in Table 1, seems to be somewhat contradictory but can be understandable if considering the complexity of the system: different set of parameters make different mechanisms dominate. We have several parameters to take into consideration: 1) tip-to-surface distance, 2) tip radius, 3) applied voltage polarity and magnitude and 4) material in the tip and sample.

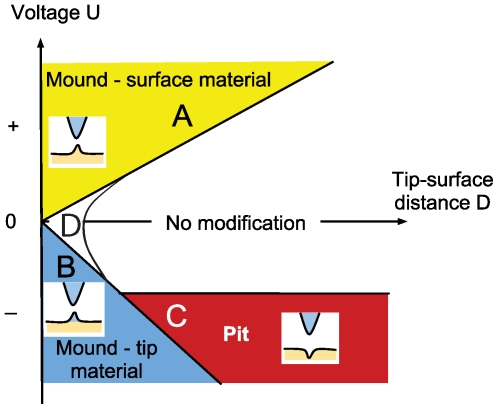

The phase diagram in fig. 1 is a schematic of the formation of mounds and pits using the tip-surface distance and the voltage as parameters. It is mainly constructed using ref. [5], [12] and ref. [17]. For positive tip we get mounds, area A in the phase diagram of fig. 1. For negative tip mounds form at shorter distances, area B, while pits are formed at larger distances, area C. This diagram is consistent with the references in Table 1, except for ref. [10]. However, the possibility of transport of positive as well as negative ions may likely explain this disagreement; negative ions are transported from negative to positive electrode and vice versa [4].

Figure 1. Phase diagram showing STM induced surface modifications at different tip voltage  and different tip-to-surface distance

and different tip-to-surface distance  mainly constructed using ref. [5], [12] and ref. [17].

mainly constructed using ref. [5], [12] and ref. [17].

In drawing the lines for mound formation we have assumed that it is the electric field  that decides if some particular kind of mound will be formed. Mounds will form at positive voltages, area A. From our model assuming field induced diffusion of adatoms we can calculate the threshold electric field for mound formation for area A to

that decides if some particular kind of mound will be formed. Mounds will form at positive voltages, area A. From our model assuming field induced diffusion of adatoms we can calculate the threshold electric field for mound formation for area A to  2 V/nm. In area B we have transfer of tip materials to the surface making a mound of tip material on the surface. For pits, area C, we have assumed that they are formed at constant

2 V/nm. In area B we have transfer of tip materials to the surface making a mound of tip material on the surface. For pits, area C, we have assumed that they are formed at constant  independent of the tip-to-surface distance

independent of the tip-to-surface distance  in agreement with Kondo et al.

[17]. At short distances and low electric fields, area D, the van der Waals force will contribute in creating a mound [22]. Close to the U-axis (not shown) at electrical fields above 20–50 V/nm field evaporation will occur [18].

in agreement with Kondo et al.

[17]. At short distances and low electric fields, area D, the van der Waals force will contribute in creating a mound [22]. Close to the U-axis (not shown) at electrical fields above 20–50 V/nm field evaporation will occur [18].

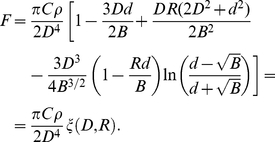

In area A with positive tip, we obtain mounds, made up of sample material likely created by field enhanced surface diffusion of adatoms. The mounds created using positive tip are unstable lasting only an hour in the experiment of ref. [5]. Mayer et al.

[14] made a computer simulation of such a field enhanced diffusion of adatoms under an STM tip. From our model (see below) on electric field induced diffusion we can calculate the threshold electric field for mound formation for area A: inserting equation (25) for the threshold voltage  into equation (18) for the electric field

into equation (18) for the electric field  yields for

yields for  the threshold field for mound formation

the threshold field for mound formation  2 V/nm.

2 V/nm.

In area B, at short distances and negative tip voltage, mounds made of tip materials are formed as found by Hsiao et al [5]. The transport of tip material is due to field enhanced diffusion on the tip toward the gap, leading to a neck formation, that result in a mound when retracting the tip [5]. If the applied voltages is increased high enough, field evaporation of tip material will instead occur [5].

In area C, the experiments by Kondo et al.

[17], [25] show a strong correlation between the threshold voltage for pit formation and the binding energy for ten different materials: for example Au with a binding energy of 3.8 eV has a threshold voltage of  3.5 V, while W with binding energy of 8.8 eV has

3.5 V, while W with binding energy of 8.8 eV has  8.7 V. Their explanation for this mechanism is sublimation induced by tunneling electrons.

8.7 V. Their explanation for this mechanism is sublimation induced by tunneling electrons.

In area D, for short distances and low electric fields, Erts et al. [22] measured the force between a gold coated atomic force microscope (AFM) tip and a gold tip using an AFM cantilever placed inside a transmission electron microscope (TEM). They could in this way image the system while manipulating it. They found an anomalous high value of the jump-to-contact distance indicating a larger force than expected from the distances using the van der Waals force. Closer inspection revealed a thin neck formed between the tip and sample. Their interpretation was that the van der Waals force caused field induced surface diffusion leading to shorter gap which in turn increased the van der Waals force, and this avalanche of adatoms quickly formed the neck.

In this paper, we describe a field enhanced surface diffusion model (area A) and also a model at short distances and low electric fields where van der Waals forces are contributing (area D).

We develop a simple analytical model to calculate the static electric forces from the tip governing the motion of the adatoms. We extend the model of Mayer et al. [14] by including the surface induced dipole moment which introduces a force on the adatoms that depend on the polarity of the applied voltage between the tip and the surface. We find a novel formula for the threshold voltage for mound formation for positive tip as well as a relation between the mound radius and the applied voltage. In addition we include the van der Waals force described in ref [21], [22]. We find that its contribution to the radial force on the adatoms is small for distances larger than 1.5 nm for commonly used voltages.

Analysis

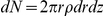

Van der Waals force

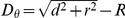

In this section we will calculate the van der Waals interaction energy of an adatom with a parabolic tip, representing an STM tip, and thereafter the force. The (non retarded) van der Waals interaction energy between two atoms at distance  from each other is given by [21], [26]

from each other is given by [21], [26]

| (1) |

An approximate value of the constant  for identical atoms is given by

for identical atoms is given by  , see ref. [26], where

, see ref. [26], where  is the energy of the strongest optical absorption line and

is the energy of the strongest optical absorption line and  is the polarizability of the atoms. Following Israelachvili [21] we have for a ring-shaped element in the tip around the z-axis at radius

is the polarizability of the atoms. Following Israelachvili [21] we have for a ring-shaped element in the tip around the z-axis at radius  the volume

the volume  , see fig. 2. The number of atoms in the ring is then

, see fig. 2. The number of atoms in the ring is then  where

where  is the number density of the tip material. The interaction energy between the ring and an adatom on the surface at

is the number density of the tip material. The interaction energy between the ring and an adatom on the surface at  is then

is then

| (2) |

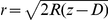

using  . If the ring is a segment in a parabolic tip given by

. If the ring is a segment in a parabolic tip given by  with apex at

with apex at  and extending into infinity, the interaction energy for the adatom at

and extending into infinity, the interaction energy for the adatom at  with the tip is

with the tip is

| (3) |

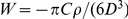

Integrating we obtain

| (4) |

where  and

and  .

.

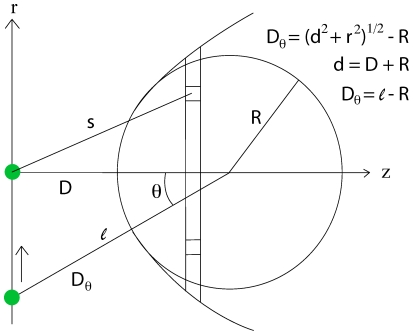

Figure 2. Calculation of van der Waals force on an adatom by a massive paraboloid tip with radius of curvature  at the apex.

at the apex.

For a adatom sitting off-axis on the surface the distance to the tip is  . The letters denoting distances,

. The letters denoting distances,  and

and  are placed at the midpoint of the distances they represent.

are placed at the midpoint of the distances they represent.

A plot of  as a function of

as a function of  shows that it varies monotonically from

shows that it varies monotonically from  at

at  to

to  as

as  . The force on the adatom right under the tip is then

. The force on the adatom right under the tip is then  , so that the force is directed towards the tip. Using this equation (4) yields

, so that the force is directed towards the tip. Using this equation (4) yields

|

(5) |

This equation can be used to calculate the van der Waals force on a adatom right under the tip. Plotting  in equation (5) as a function of

in equation (5) as a function of  shows that it decreases monotonically from

shows that it decreases monotonically from  at

at  towards zero as

towards zero as  approaches infinity. A plot of

approaches infinity. A plot of  as a function of

as a function of  yields

yields  at

at  and then increases monotonically towards

and then increases monotonically towards  as R approaches infinity.

as R approaches infinity.

We now consider the van der Waals forces on the adatom when it is located on a conducting surface under the tip. The van der Waals force on an adatom by the surface is always perpendicular to the surface balancing the z-component of the force from the tip. To see how the adatom is moving it is thus more interesting to study the r-component. If we have the force  directed towards the center of the sphere approximating the parabolic tip, the force components on an adatom sitting off-axis on the surface are

directed towards the center of the sphere approximating the parabolic tip, the force components on an adatom sitting off-axis on the surface are

| (6) |

| (7) |

where  is the off-axis angle counted from the center of the sphere, see fig. 2.

is the off-axis angle counted from the center of the sphere, see fig. 2.  is obtained from equation (5) by replacing

is obtained from equation (5) by replacing  with the expression

with the expression  . This is the radial distance

. This is the radial distance  from the tip to the surface for an off-axis angle if the tip is approximately considered spherical seen from a point on the surface.

from the tip to the surface for an off-axis angle if the tip is approximately considered spherical seen from a point on the surface.

Approximating with  in (5) we obtain a simpler formula which yields a upper limit of the van der Waals force. The radial component becomes

in (5) we obtain a simpler formula which yields a upper limit of the van der Waals force. The radial component becomes

| (8) |

Electrostatic dipole force

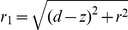

In this section we will calculate the static electric dipole force on an adatom when we have a voltage applied between the tip and the surface. To obtain a simple model we approximate the field as given by a point charge  located at a distance

located at a distance  over an infinite flat conducting surface. The midpoint of the adatom is located a distance

over an infinite flat conducting surface. The midpoint of the adatom is located a distance  over the surface, see fig. 3. The potential

over the surface, see fig. 3. The potential  at a point is then given by

at a point is then given by

| (9) |

where we have  and

and  . The first term is the potential due to the charge

. The first term is the potential due to the charge  and the second term is the potential due to the mirror of the charge

and the second term is the potential due to the mirror of the charge  in the conducting surface.

in the conducting surface.  is the permitivity of the medium between the charge and the surface. To obtain a useful model we must find an expression for the charge

is the permitivity of the medium between the charge and the surface. To obtain a useful model we must find an expression for the charge  as a function of the applied voltage

as a function of the applied voltage  between the tip and the conducting surface. On the line connecting the charge

between the tip and the conducting surface. On the line connecting the charge  and its mirror

and its mirror  (i.e.

(i.e.  ) we have at the distance

) we have at the distance  from

from  :

:

| (10) |

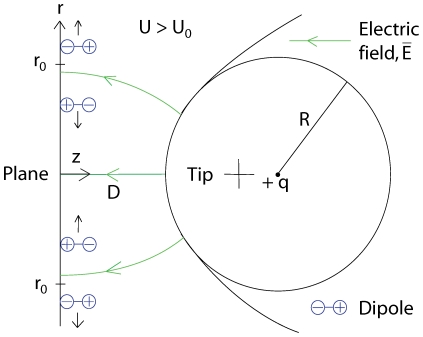

Figure 3. Adatoms with dipole moments on the surface for  .

.

The dipole moment  are tending to align to the strong field inside

are tending to align to the strong field inside  on the surface and points away from the surface outside

on the surface and points away from the surface outside  where the field is weaker, see equation (20). The radial force on the dipole on the surface is due to this effect attractive inside

where the field is weaker, see equation (20). The radial force on the dipole on the surface is due to this effect attractive inside  and repulsive outside, tending to create a mound made of surface material with maximum radius

and repulsive outside, tending to create a mound made of surface material with maximum radius  .

.

We see from equation (10) that if  , that is we are in the surface, we have

, that is we are in the surface, we have  . The voltage between the tip apex, at a distance

. The voltage between the tip apex, at a distance  from

from  , and the surface is then given by

, and the surface is then given by  . So

. So

| (11) |

using  .

.

We here assume as a model that the equivalent charge  is fixed at the center of curvature of the tip independent of the tip-to-surface distance

is fixed at the center of curvature of the tip independent of the tip-to-surface distance  . This is only approximately true but leads to equation (18) that is true both in the limit of

. This is only approximately true but leads to equation (18) that is true both in the limit of  where we obtain

where we obtain  and in the limit

and in the limit  where we obtain

where we obtain  .

.

We can now calculate  if we know

if we know  ,

,  and

and  .

.  and

and  yields

yields

| (12) |

| (13) |

| (14) |

It is interesting to study the field close to the surface, that is when  (implying

(implying  ). To do so we expand equation (12) and (13) in Taylor series around

). To do so we expand equation (12) and (13) in Taylor series around  . We then obtain

. We then obtain

|

(15) |

| (16) |

At  we have

we have  because on the surface right under the charge by symmetry the only field component that exists is

because on the surface right under the charge by symmetry the only field component that exists is  .

.  . Dividing equation (16) with (15) we obtain

. Dividing equation (16) with (15) we obtain

| (17) |

Because  may be of about the same order as

may be of about the same order as  and because we in the Taylor expansion have assumed that

and because we in the Taylor expansion have assumed that  this quota is small compared to unity. Thus we may neglect

this quota is small compared to unity. Thus we may neglect  compared with

compared with  when calculating

when calculating  . Using equation (11) in equation (15) for the z-component of the electrostatic field we then obtain in the surface (where

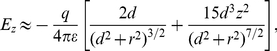

. Using equation (11) in equation (15) for the z-component of the electrostatic field we then obtain in the surface (where  ) using

) using  :

:

|

(18) |

The dipole moment  for an adatom in an electric field

for an adatom in an electric field  is given by Tsong and Kellogg [20]:

is given by Tsong and Kellogg [20]:

| (19) |

where  is the surface-induced dipole moment of the adatom,

is the surface-induced dipole moment of the adatom,  is its polarizability and

is its polarizability and  is its hyperpolarizability.

is its hyperpolarizability.  always points away from the surface that it sits on, see ref. [27], [28], so

always points away from the surface that it sits on, see ref. [27], [28], so  is always positive in our calculations regardless of the polarity of the voltage

is always positive in our calculations regardless of the polarity of the voltage  . We have for the

. We have for the  and

and  components of the dipole moment

components of the dipole moment  , neglecting the hyperpolarizability term:

, neglecting the hyperpolarizability term:

| (20) |

where  is positive.

is positive.  and

and  may therefore be positive or negative. The force on a dipole in an electric field is

may therefore be positive or negative. The force on a dipole in an electric field is

| (21) |

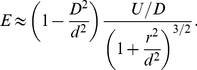

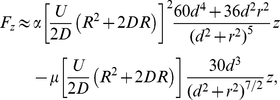

Using equation (11), (20) and (15)–(16) and their derivatives into equation (21) we obtain to order

|

(22) |

|

(23) |

where  is the height over the surface for the center of the adatom, about one adatom radius. The distance

is the height over the surface for the center of the adatom, about one adatom radius. The distance  are only affecting

are only affecting  , not

, not  , as we see from equations (22) and (23). We are now able to calculate the electrostatic forces on the adatom on the surface under the tip. The calculation above is valid for the first step in the mound formation where the surface still may be considered as flat. Mayer et al.

[14] use

, as we see from equations (22) and (23). We are now able to calculate the electrostatic forces on the adatom on the surface under the tip. The calculation above is valid for the first step in the mound formation where the surface still may be considered as flat. Mayer et al.

[14] use  in their model so they do not obtain the polarity dependence.

in their model so they do not obtain the polarity dependence.

Results and Discussion

To calculate the force we need to estimate the surface-induced dipole moment and the polarizability of an adatom. For metal atoms we have  Debye and

Debye and  Å

Å , see ref. [20]. We use the average values

, see ref. [20]. We use the average values  Debye and

Debye and  Å

Å . Using SI-units this is

. Using SI-units this is  Cm and

Cm and  Cm

Cm /V. We assume that the adatom is a gold atom with a center height over the surface of about an atomic radius of gold so

/V. We assume that the adatom is a gold atom with a center height over the surface of about an atomic radius of gold so  = 0.14 nm. Atoms are detaching from steps on the substrate and becomes adatoms [14]. In this paper we only assume that the adatoms are on the surface and calculate how they move.

= 0.14 nm. Atoms are detaching from steps on the substrate and becomes adatoms [14]. In this paper we only assume that the adatoms are on the surface and calculate how they move.

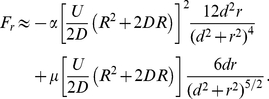

If a dipole in a inhomogeneous electric field is free to rotate or is created due to polarization by an electric field, the dipole is always attracted towards stronger field i.e  is positive. But the component of the dipole moment which is due to surface induction

is positive. But the component of the dipole moment which is due to surface induction  always points away from the surface[27], [28], making the electric force in equation (23) repulsive at some voltages and distances. This means that we may have an attractive force from the center under the tip out to some equilibrium radius where the force change sign and becomes repulsive. The force calculated from (23) is small for the commonly used voltage and distances, of order of 1 pN, see fig. 4, fig. 5 and fig. 6, but because the adatoms are hopping on the surface due to thermal vibration even a small net force can be significant in the drift of adatoms [19], [20]. Setting

always points away from the surface[27], [28], making the electric force in equation (23) repulsive at some voltages and distances. This means that we may have an attractive force from the center under the tip out to some equilibrium radius where the force change sign and becomes repulsive. The force calculated from (23) is small for the commonly used voltage and distances, of order of 1 pN, see fig. 4, fig. 5 and fig. 6, but because the adatoms are hopping on the surface due to thermal vibration even a small net force can be significant in the drift of adatoms [19], [20]. Setting  in equation (23) then yields

in equation (23) then yields

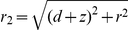

|

(24) |

where

| (25) |

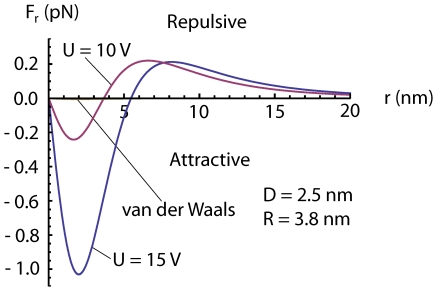

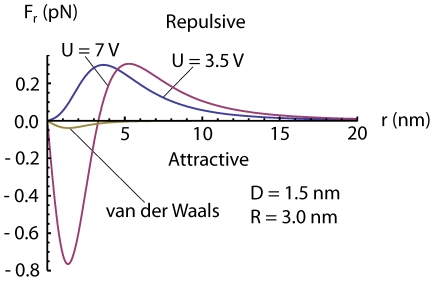

Figure 4. Radial dipole force on an adatom obtained from equation (23)using  nm and

nm and  nm and our values of

nm and our values of  and

and  for two different voltages

for two different voltages  6.5 V.

6.5 V.

Increasing all the distances  ,

,  and

and  and the voltage

and the voltage  by a factor of 10 yields a reduction of the force

by a factor of 10 yields a reduction of the force  to 1/10. The radial van der Waals force calculated using equation (7) is barely visible in the figure at this “large”

to 1/10. The radial van der Waals force calculated using equation (7) is barely visible in the figure at this “large”  nm.

nm.

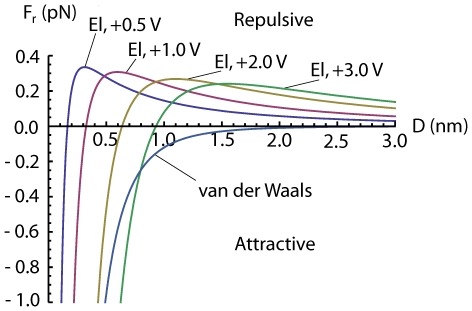

Figure 5. Radial dipole force on an adatom obtained from equation (23) using  nm and

nm and  nm and our values of

nm and our values of  and

and  for two different voltages

for two different voltages  , one above and one below

, one above and one below  3.7 V.

3.7 V.

The van der Waals force has been calculated using equation (7) and plotted in the figure using  nm. For

nm. For  nm the van der Waals force becomes important for the radial force on the adatoms.

nm the van der Waals force becomes important for the radial force on the adatoms.

Figure 6. Radial van der Waals force from equation (7) and radial electric forces (El) from equation (23) for different tip voltages, at  as a function of tip-to-surface distance

as a function of tip-to-surface distance  .

.

nm.

nm.

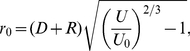

Using for example  nm and

nm and  nm we obtain

nm we obtain  V.

V.  is the equilibrium radius on the surface at voltage

is the equilibrium radius on the surface at voltage  where the force changes sign from attractive to repulsive as we are moving out from the center right under the tip towards infinity, see fig. 3. For voltages

where the force changes sign from attractive to repulsive as we are moving out from the center right under the tip towards infinity, see fig. 3. For voltages  between zero and

between zero and  the electrostatic force is repulsive for all distances

the electrostatic force is repulsive for all distances  , that is there is no equilibrium distance.

, that is there is no equilibrium distance.

Inserting equation (25) for the threshold voltage  into equation (18) for the electric field

into equation (18) for the electric field  yields for

yields for  (a small mound with radius zero is barely formed according to the definition of threshold voltage, equation (24)) the threshold field for mound formation

(a small mound with radius zero is barely formed according to the definition of threshold voltage, equation (24)) the threshold field for mound formation  2 V/nm.

2 V/nm.

We have thus two novel findings for positive tip voltages: a threshold field for mound formation of about 2 V/nm and a voltage dependent radius of the mound, equation (24).

For negative voltages, in contrast to positive voltages, the force  is attractive for all distances, except at

is attractive for all distances, except at  where the force is zero, as we see from equation (23), so negative voltage is tending to creating a mound on the surface with no threshold voltage. This due to that in this case the dipole moment

where the force is zero, as we see from equation (23), so negative voltage is tending to creating a mound on the surface with no threshold voltage. This due to that in this case the dipole moment  does not change sign at a certain field as we have at positive tip.

does not change sign at a certain field as we have at positive tip.

The experimental findings are somewhat contradictory: a more or less sign independent threshold voltage of about 3.5 V is observed according to ref. [3], [24]. However, mound formation is less reproducible with positive voltage at the tip [11], [24]. A mound created by a tip-positive pulse could be removed by applying a negative pulse in some cases [9]. Using a gold (copper) tip over a silicon surface, a negative voltage on the tip yields a gold (copper) mound on the surface, but for positive voltage the mound are not made up of metal [5]. This indicates that at negative tip, materials from the tip are transferred to the surface while at positive tip surface material are attracted towards the area under the tip creating a mound. Using a gold tip and a gold surface, at high tunneling resistance (large tip to surface distance) at a negative tip a hole was created and at positive tip a mound was created [12].

However, at low tunneling resistance (small tip to surface distance) a mound adjacent to a pit was often created by a negative tip where the current kept flowing even after the voltage pulse, indicating necking between surface and tip [12]. Transfer of material between tip and surface seems to be possible both ways depending on the materials used, see ref. [10] and table 1.

Mayer et al.

[14] simulated the diffusion of adatoms on a surface using  25 nm,

25 nm,  38 nm and

38 nm and  −100 V at the tip. (They also measured experimentally the size of a mound while it was growing under the tip.) They obtained a mound diameter (at which the growth rate is zero) of 40 nm. Their simulation model was independent of the sign of the voltage so

−100 V at the tip. (They also measured experimentally the size of a mound while it was growing under the tip.) They obtained a mound diameter (at which the growth rate is zero) of 40 nm. Their simulation model was independent of the sign of the voltage so  +100 V would have given the same result. To compare this with our model we calculate the threshold voltage using equation (25) in our paper and the

+100 V would have given the same result. To compare this with our model we calculate the threshold voltage using equation (25) in our paper and the  and

and  in the simulation using our estimate

in the simulation using our estimate  Cm and

Cm and  Cm

Cm /V for a metal adatom. We then obtain

/V for a metal adatom. We then obtain  65 V. Thereafter we calculate the equilibrium radius at

65 V. Thereafter we calculate the equilibrium radius at  100 V using (24). We then obtain a radius of

100 V using (24). We then obtain a radius of  36 nm in good agreement with the simulation result. However, this should be a coincidence because the mechanisms are different in the two cases.

36 nm in good agreement with the simulation result. However, this should be a coincidence because the mechanisms are different in the two cases.

is the maximum radius of the mound in our model because no adatoms can be attracted from outside of this radius. In the simulation made by Mayer et al. adatoms are attracted from all radius making the mound thickness grow inside some radius etching away surface material outside this radius. The similar results though increases the reasonability of our approach to the field induced diffusion model.

is the maximum radius of the mound in our model because no adatoms can be attracted from outside of this radius. In the simulation made by Mayer et al. adatoms are attracted from all radius making the mound thickness grow inside some radius etching away surface material outside this radius. The similar results though increases the reasonability of our approach to the field induced diffusion model.

Calculating the van der Waals force, we find that it is relatively small compared to the dipole force for distances larger than  1.5 nm using voltages commonly used in experiments. However, at small distances the van der Waals force will dominate over the electrostatic dipole force [22], [29], see fig. 4, fig. 5 and fig. 6. For the van der Waals force we have

1.5 nm using voltages commonly used in experiments. However, at small distances the van der Waals force will dominate over the electrostatic dipole force [22], [29], see fig. 4, fig. 5 and fig. 6. For the van der Waals force we have  , see ref. [21], and the number density of the material in the tip is estimated as

, see ref. [21], and the number density of the material in the tip is estimated as  yielding the value of the factor

yielding the value of the factor  pN for

pN for  nm in equation (5). The radial component on an off-axis adatom will be smaller than this according to equation (7). An upper limit for the radial van der Waals force is given by equation (8). Van der Waals induced surface diffusion dominates for this small distances for commonly used voltages. This effect may explain the neck formation obtained by Erts et al., [22], see text for area D in the introduction. The effect of adding the radial van der Waals force to the dipole force is that it tends to lower the threshold voltage for mound formation at positive tip making the mounds larger at a given applied voltage.

nm in equation (5). The radial component on an off-axis adatom will be smaller than this according to equation (7). An upper limit for the radial van der Waals force is given by equation (8). Van der Waals induced surface diffusion dominates for this small distances for commonly used voltages. This effect may explain the neck formation obtained by Erts et al., [22], see text for area D in the introduction. The effect of adding the radial van der Waals force to the dipole force is that it tends to lower the threshold voltage for mound formation at positive tip making the mounds larger at a given applied voltage.

Other effects that may influence the mound formation is charge disorder effects, dipole-dipole interaction and dislocation activity which we will discuss below. Charge disorder interactions, where we have fluctuation-induced interaction between randomly charged dielectrics, is considered by ref. [30], [31]. At larger distances this effect can dominate over the van der Waals force. How does this affect the mound formation? A length scale for the total force  as a function of the distance

as a function of the distance  is the Bjerrum length,

is the Bjerrum length,  56.8 nm at room temperature, see [31]. We see from fig. 2 in [31] that for our distances

56.8 nm at room temperature, see [31]. We see from fig. 2 in [31] that for our distances  , about 1–50 nm, we have for quenched charge disorder

, about 1–50 nm, we have for quenched charge disorder  that is, the van der Waals force is dominating. For annealed charge disorder they obtain

that is, the van der Waals force is dominating. For annealed charge disorder they obtain  between 1 and 1.6 for all distances so even here is the total force of the same order as of the van der Waals force. Thus for our distances charge disorder effects can be neglected when the van der Waals force can be neglected. The dipole-dipole interaction between adatoms on the surface should be less important because their interaction should seem to average out. This due to that the adatoms position on the surface are random so their average behaviour would mainly be determined by the field from the tip. Changes in temperature should only effect the diffusion rate [19] but not the equilibrium radius

between 1 and 1.6 for all distances so even here is the total force of the same order as of the van der Waals force. Thus for our distances charge disorder effects can be neglected when the van der Waals force can be neglected. The dipole-dipole interaction between adatoms on the surface should be less important because their interaction should seem to average out. This due to that the adatoms position on the surface are random so their average behaviour would mainly be determined by the field from the tip. Changes in temperature should only effect the diffusion rate [19] but not the equilibrium radius  because it does not affect the force

because it does not affect the force  which is given by the electric field. Recently, Mordehai et al.

[32] finds, using a molecular dynamics simulation, that jump-to-contact between nanoparticles likely is due to dislocation activity. The particles are initially dislocation free and are in this state even after the jump-to-contact, they call this pseudoelasticity. This process is according to the simulation faster than competing processes like surface diffusion and may play a role in the formation of a mound in area D in fig. 1.

which is given by the electric field. Recently, Mordehai et al.

[32] finds, using a molecular dynamics simulation, that jump-to-contact between nanoparticles likely is due to dislocation activity. The particles are initially dislocation free and are in this state even after the jump-to-contact, they call this pseudoelasticity. This process is according to the simulation faster than competing processes like surface diffusion and may play a role in the formation of a mound in area D in fig. 1.

To test our model, one way would be to measure the mound radius as a function of applied voltage for tip-positive voltage pulse. In the literature we have only seen this experiment done for a negative tip, see Fujita et al. [11]. The lacking of experimental data for positive tip might be due to the experimental difficulty to reproduce mound formation for this tip polarity [11], [24].

If one wants to create mounds on a surface, using negative tip is probably more effective. The mounds seems then be made up by tip material which may make the mounds more stable [5] than mounds constructed of surface material using a positive tip. However, for dynamic use in electronics we may not want the mound to be stable. Because the size of the mound for positive tip is limited by  the mound formation may be more controlled in this case than at negative tip where we may have unrestricted growth of the mound trying to bridge the gap between tip and surface.

the mound formation may be more controlled in this case than at negative tip where we may have unrestricted growth of the mound trying to bridge the gap between tip and surface.

The same type of behaviour that we see on the surface under a STM-tip we may have on the tip itself, with mound formation above a threshold voltage. If we have two electrodes of different shape (tip radius) and material the threshold voltage for mound formation may be different on the two electrodes. By choosing a material with low mobility of adatoms as one electrode we may prevent mound formation on this electrode.

A way to monitor most of the parameters directly is to do the experiment using an STM inside a transmission electron microscope (TEM) where one can image the tip-surface system while manipulating it [33], [34]. All important parameters are accessible by TEM imaging: the tip-surface distance, tip radius, movement of tip or sample material, while the STM provide tip motion and bias voltage. In a TEM one also may see that the effective radius can be smaller than expected because there are often small asperities sitting on the large tip close to the surface [22].

The findings in this paper is not only of importance to understand the formation of structures under the STM tip, but may also be of importance in electronics applications for example recently described in ref. [16], where a temporary mound seems to be created between electrodes during a voltage pulse reducing (but not bridging) the gap and thus reducing tunneling resistance several orders of magnitude. Different resistance values can then be interpreted as digital ones and zeroes.

Another application that could be of importance is sintering of nanoparticles for use in printed electronics [35]. The ink used for defining conducting paths consists of nanoparticles that need to be sintered to achieve high enough conductivity. One method is electrical sintering [35], [36] and to model this both the electrical and van der Waals induced surface diffusion models in this paper should be of relevance.

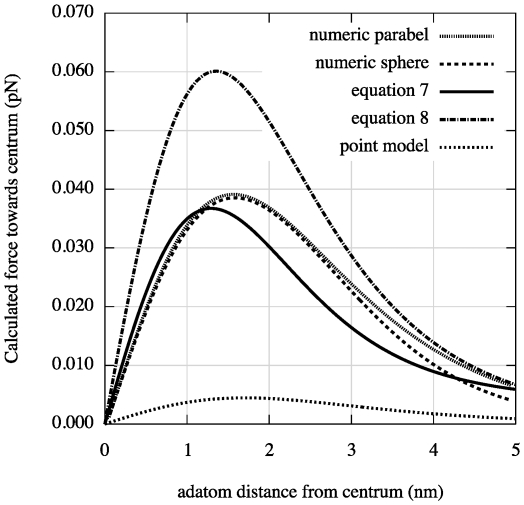

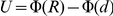

We have in this paper considered the static electric- and van der Waals forces on adatoms on a surface under a scanning tunneling microscope tip. We have described an analytical model of this system with three main conclusions: 1) the van der Waals force becomes important for tip-to-surface distances shorter than about 1.5 nm, 2) there is a threshold voltage in mound formation corresponding to a threshold electric field of about 2 V/nm, 3) and there is a relation between applied positive voltage and radius of the mound. To illustrate the result of our analysis we made plots. A plot of  from equation (7) as a function of

from equation (7) as a function of  is shown in fig. 4 and fig. 5 and

is shown in fig. 4 and fig. 5 and  as a function of

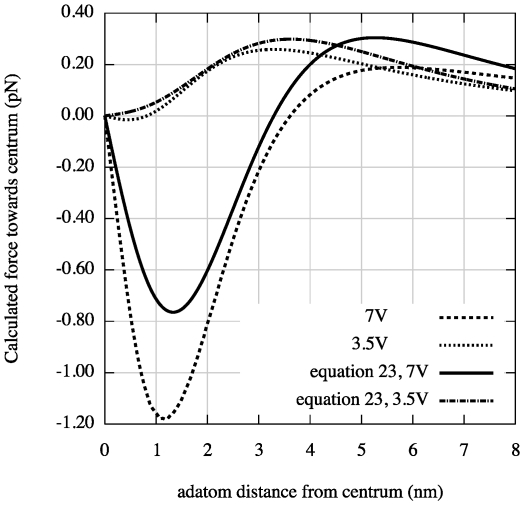

as a function of  is shown in fig. 6. To verify the van der Waals-model we made simulations. We numerically integrated the van der Waals force given by equation (1) for a parabolic and spherical tip respectively, see fig. 7. In the figure we have also plotted equation (7) and (8). To test the model for the electrostatic dipole force we made a simulation of an adatom on a conducting plane under a conducting parabolic tip. This result is compared to equation (23) in fig. 8.

is shown in fig. 6. To verify the van der Waals-model we made simulations. We numerically integrated the van der Waals force given by equation (1) for a parabolic and spherical tip respectively, see fig. 7. In the figure we have also plotted equation (7) and (8). To test the model for the electrostatic dipole force we made a simulation of an adatom on a conducting plane under a conducting parabolic tip. This result is compared to equation (23) in fig. 8.

Figure 7. Radial van der Waals force on an adatom from simulations of a parabolic and a spherical tip respectively as a function of the distance  from the centrum under the tip to the adatom using numerical integration of equation (1).

from the centrum under the tip to the adatom using numerical integration of equation (1).

Also plotted in the figure is equation (7) and (8).  nm and

nm and  nm. Even the curve of a point model has been added. We see that equation (7) agrees well with the simulated curves close under the tip but underestimates the van der Waals force somewhat for larger

nm. Even the curve of a point model has been added. We see that equation (7) agrees well with the simulated curves close under the tip but underestimates the van der Waals force somewhat for larger  where the approximation of the tip as a sphere becomes too crude. The simpler formula equation (8) assuming

where the approximation of the tip as a sphere becomes too crude. The simpler formula equation (8) assuming  overestimates the force compared with the simulations in the figure. However, even this equation should underestimate the force for even larger

overestimates the force compared with the simulations in the figure. However, even this equation should underestimate the force for even larger  because the assumption of the tip as a sphere that both equation (7) and (8) uses breaks down. That the simulated value for the parabolic tip tend to sink below the curve from equation (8) at

because the assumption of the tip as a sphere that both equation (7) and (8) uses breaks down. That the simulated value for the parabolic tip tend to sink below the curve from equation (8) at  nm is probably due to the limited size of the tip used in the simulation. In deriving equation (5), that equation (7) and (8) uses, we assume that the tip is extended to infinity.

nm is probably due to the limited size of the tip used in the simulation. In deriving equation (5), that equation (7) and (8) uses, we assume that the tip is extended to infinity.

Figure 8. Radial dipole force on an adatom simulated using a conducting parabolic tip over a conducting plane for  V and

V and  V respectively.

V respectively.

Radius of curvature of the tip is  nm and tip-to-surface distance

nm and tip-to-surface distance  nm. To calculate the electric field 400 positive charges are placed on the tip and 400 negative charges are placed on the surface. They are free to move and do so until they have reached their equilibrium positions. Thereafter the field generated by them is calculated and finally the radial force on the adatom. Also plotted is equation (23) for the same two voltages as above.

nm. To calculate the electric field 400 positive charges are placed on the tip and 400 negative charges are placed on the surface. They are free to move and do so until they have reached their equilibrium positions. Thereafter the field generated by them is calculated and finally the radial force on the adatom. Also plotted is equation (23) for the same two voltages as above.

Footnotes

Competing Interests: The authors have declared that no competing interests exist.

Funding: University funding. Martin Olsen is employed by the university as a Ph.D. student in nanotechnology. Magnus Hummelgård is a Ph.D. who is doing a post doc here. He is employed by the university. Håkan Olin is Ph.D./Professor employed by the university. No current external funding sources for this study.

References

- 1.Nyffenegger RM, Penner RM. Nanometer-scale surface modification using the scanning probe microscope: Progress since 1991. Chem Rev. 1997;97:1195–1230. doi: 10.1021/cr960069i. [DOI] [PubMed] [Google Scholar]

- 2.Tseng AA, Notargiacomo A, Chen TP. Nanofabrication by scanning probe microscope lithography: A review. J Vac Sci Technol B. 2005;23:877–894. [Google Scholar]

- 3.Mamin HJ, Guethner PH, Rugar D. Atomic emission from a gold scanning-tunnelingmicroscope tip. Phys Rev Lett. 1990;65:2418–2421. doi: 10.1103/PhysRevLett.65.2418. [DOI] [PubMed] [Google Scholar]

- 4.Tsong TT. Effects of an electric field in atomic manipulations. Phys Rev B. 1991;44:13703–13710. doi: 10.1103/physrevb.44.13703. [DOI] [PubMed] [Google Scholar]

- 5.Hsiao GS, Penner RM, Kingsley J. Deposition of metal nanostructures onto si(111) surfaces by field evaporation in a scanning tunneling microscope. Appl Phys Lett. 1994;64:1350–1352. [Google Scholar]

- 6.Zhang HL, Li HL, Liu ZF. Study on the delicate nanostructures formed on au(111) by scanning tunneling microscopy (stm). Microelectronic engineering. 2002;63:381–389. [Google Scholar]

- 7.Hu X, von Blackenhagen P. Generation and analysis of nano-scale al islands by stm. Appl Phys A. 1998;66:707–710. [Google Scholar]

- 8.Mascher C, Damaschke B. Creation of nanometer-scale structures with the scanning tunneling microscope. J Appl Phys. 1994;75:5438–5440. [Google Scholar]

- 9.Bessho K, Hashimoto S. Fabricating nanoscale structures on au surface with scanning tunneling microscope. Appl Phys Lett. 1994;65:2142–2144. [Google Scholar]

- 10.Park JY, Phaneuf RJ. Polarity dependence in pulsed scanning tunneling microscopy fabrication and modification of metal nanodots on silicon. J Appl Phys. 2002;92:2139–2143. [Google Scholar]

- 11.Fujita D, Kumakura T. Reproducible fabrication of metallic silver nanostructures on a si(111)-(7×7) surface by tip-material transfer of a scanning tunneling microscope. Appl Phys Lett. 2003;82:2329–2331. [Google Scholar]

- 12.Ohi A, Mizutani W, Tokumoto H. Nanometer-scale modifications of gold surfaces by scanning tunneling microscope. J Vac Sci Technol B. 1995;13:1252–1256. [Google Scholar]

- 13.Girard C, Joachim C, Chavy C, Sautet P. The electric field under a STM tip apex: implications for adsorbate manipulation. Surf Sci. 1993;282:400–410. [Google Scholar]

- 14.Mayer TM, Houston JE, Franklin GE, Erchak AA, Michalske TA. Electric field induced surface modification of au. J Appl Phys. 1999;85:8170–8177. [Google Scholar]

- 15.Mendez J, Gomez-Herrero J, Pascual JI, Saenz JJ, Soler JM, et al. Diffusion of atoms on au(111) by electric field gradient in scanning tunneling microscopy. J Vac Sci Technol B. 1996;14:1145–1148. [Google Scholar]

- 16.Naitoh Y, Suga H, Horikawa M. Physical model for high-to-low resistive switching of gold nanogap junction. Jpn J Appl Phys. 2011;50:06GF10. [Google Scholar]

- 17.Kondo S, Heike S, Lutwyche M, Wada Y. Surface modification mechanism of materials with scanning tunneling microscope. J Appl Phys. 1995;78:155–160. [Google Scholar]

- 18.Tsong TT. Atom-probe field ion microscopy: field ion emission and surfaces and interfaces at atomic resolution. Cambridge University Press; 1990. [Google Scholar]

- 19.Kürpick U, Kara A, Rahman TS. Role of lattice vibrations in adatom diffusion. Phys Rev Lett. 1997;78:1086–1089. [Google Scholar]

- 20.Tsong TT, Kellogg G. Direct observation of directional walk of single adatoms and adatom polarizability. Phys Rev B. 1975;12:1343–1353. [Google Scholar]

- 21.Israelachvili JN. Intermolecular and Surface Forces. 1992. Academic press limited.

- 22.Erts D, Lohmus A, Lohmus R, Olin H, Pokropivny AV, et al. Force interactions and adhesion of gold contacts using a combined atomic force microscope and transmission electron microscope. Appl Surf Sci. 2002;188:460–466. [Google Scholar]

- 23.Pascual JI, Mendez J, Gomez-Herrero J, Baro AM, Garcia N, et al. Quantum contact in gold nanostructures by scanning tunneling microscopy. Phys Rev Lett. 1993;71:1852–1855. doi: 10.1103/PhysRevLett.71.1852. [DOI] [PubMed] [Google Scholar]

- 24.Chang TC, Chang CS, Lin HN, Tsong TT. Creation of nanostructures on gold surfaces in nonconducting liquid. Appl Phys Lett. 1995;67:903–905. [Google Scholar]

- 25.Kondo S, Lutwyche M, Wada Y. Nanofabrication of layered materials with the scanning tunneling microscope. Appl Surf Sci. 1993;75:39–44. [Google Scholar]

- 26.Kittel C. Introduction to Solid State Physics - 8th ed. John Wiley and Sons; 2005. [Google Scholar]

- 27.Linder B, Kromhout RA. Dipoles induced by physical adsorption. Phys Rev B. 1976;13:1532–1535. [Google Scholar]

- 28.Grossel P, Vigoureux JM, van Labeke D. Static dipole moment of an atom or a centrocymmetric molecule near a perfect metallic surface. Phys Rev A. 1983;28:524–531. [Google Scholar]

- 29.Erts D, Olin H, Ryen L, Olsson E, Thölen A. Maxwell and sharwin conductance in gold point contacts investigated using tem-stm. Phys Rev B. 2000;61:12725–12727. [Google Scholar]

- 30.Podgornik R, Naji A. Electrostatic disorder-induced interactions in inhomogenous dielectrics. Europhys Lett. 2006;74:712. [Google Scholar]

- 31.Naji A, Dean DS, Sarabadani J, Horgan RR, Podgornik R. Fluctuation-induced interaction between randomly charged dielectrics. Phys Rev Lett. 2010;104:060601. doi: 10.1103/PhysRevLett.104.060601. [DOI] [PubMed] [Google Scholar]

- 32.Mordehai D, Rabkin E, Srolovitz DJ. Pseudoelastic deformation during nanoscale adhesive contact formation. Phys Rev Lett. 2011;107:096101. doi: 10.1103/PhysRevLett.107.096101. [DOI] [PubMed] [Google Scholar]

- 33.Svensson K, Jompol Y, Olin H, Olsson E. Compact design of a transmission electron microscope-scanning tunneling microscope holder with three-dimensional coarse motion. Rev Sci Instr. 2003;74:4945–4947. [Google Scholar]

- 34.Nafari A, Angenete J, Svensson K, Sanz-Velasco A, Olin H. Combining scanning probe microscopy and transmission electron microscopy. In: Bhushan B, editor. Scanning Probe Microscopy in Nanoscience and Nanotechnology 2. Springer Berlin Heidelberg: NanoScience and Technology; 2011. pp. 59–99. [Google Scholar]

- 35.Hummelgård M, Zhang R, Nilsson HE, Olin H. Electrical sintering of silver nanopartikle ink studied by in-situ tem probing. PloS ONE. 2011;6:e17209. doi: 10.1371/journal.pone.0017209. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 36.Allen ML, Aronniemi M, Mattila T, Alastalo A, Ojanperä K, et al. Electrical sintering of nanoparticle structures. Nanotechnology. 2008;19:175201. doi: 10.1088/0957-4484/19/17/175201. [DOI] [PubMed] [Google Scholar]