Abstract

Peptidomimetic-based macrocycles typically have improved pharmacokinetic properties over those observed with peptide analogs. Described are the syntheses of 13 peptidomimetic derivatives that are based on active Sansalvamide A structures, where these analogs incorporate heterocycles (triazoles, oxazoles, thiazoles, or pseudoprolines) along the macrocyclic backbone. The syntheses of these derivatives employ several approaches that can be applied to convert a macrocyclic peptide into its peptidomimetic counterpart. These approaches include peptide modifications to generate the alkyne and azide for click chemistry, a serine conversion into an oxazole, a Hantzsch reaction to generate the thiazole, and protected threonine to generate the pseudoproline derivatives. Furthermore, we show that two different peptidomimetic moieties, triazoles and thiazoles, can be incorporated into the macrocyclic backbone without reducing cytotoxicity: triazole and thiazole.

Keywords: Peptide, Macrocycle, Peptidomimetic, Sansalvamide A, Triazole, Oxazole, Thiazole, Pseudoproline

1. Introduction

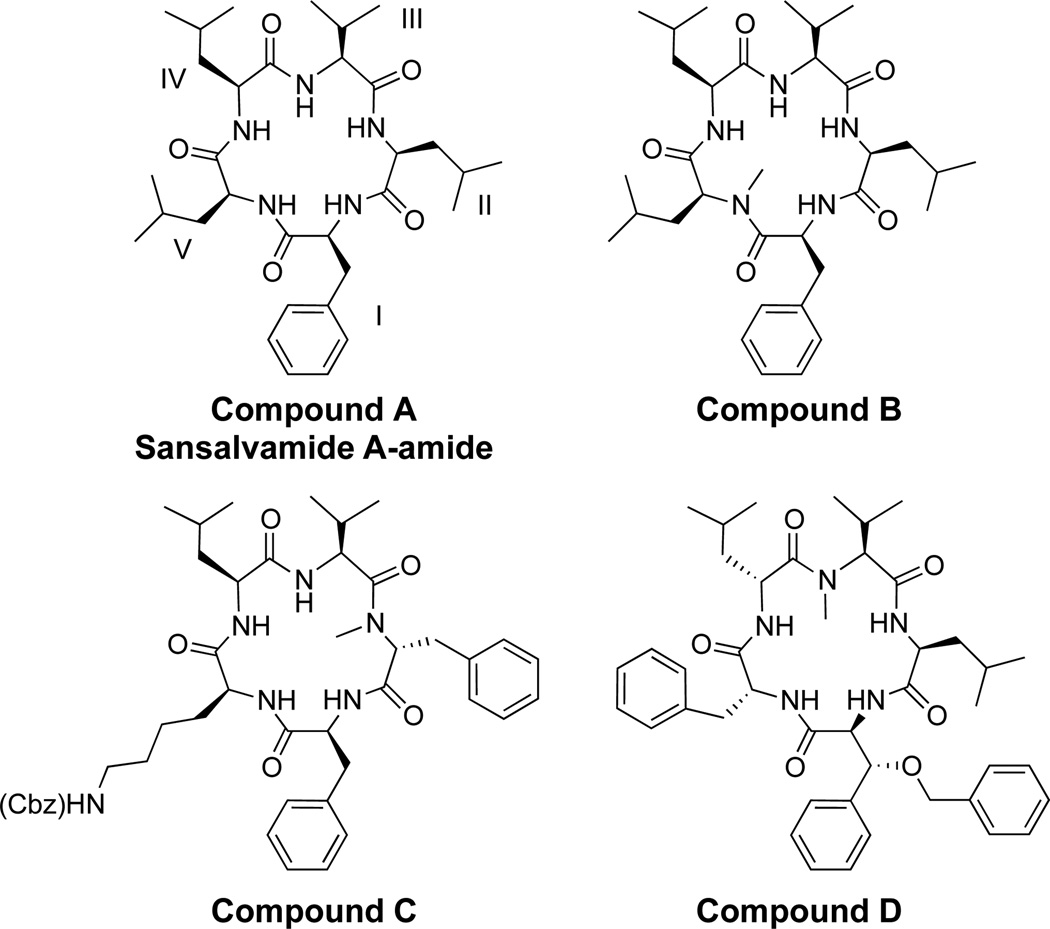

Recent work describing the synthesis and biological activity of pentapeptide derivatives that are based on the natural product Sansalvamide A (San A), has brought attention to this compound class.1–4 San A was isolated from a marine fungus of the genus Fusarium by Fenical and co-workers.3 The pentapeptide structure (San A-amide, compound A, Figure 1) has been used extensively as a template for the synthesis of compounds, where a number of these molecules exhibit cytotoxicity.1,5–7 We have discovered that in addition to San A-amide, three derivatives (compounds B, C, and D, Figure 1) are cytotoxic against numerous cancer cell lines, and these compounds inhibit a key protein that enables many proteins involved in tumor progression: Heat shock protein 90 (Hsp90).1,8

Figure 1.

San A compounds

Hsp90 is a well-established chemotherapeutic target that modulates client proteins involved in cellular growth, angiogenesis, and apoptosis.9–14 The redundancy of pathways involved in cancer cell growth means targeting multiple mechanisms simultaneously improves it's chances as a successful therapy. Hsp90 controls approximately 200 client proteins and co-chaperones, many of which are involved in multiple cancer-related cell signaling pathways.15–17 There are currently fifteen Hsp90 inhibitors in development, with two of these in phase III clinical trials.18–23 We have previously reported that San A-amide (A, Figure 1) is a cytotoxic molecule that modulates the activity of Hsp90. This modulation of Hsp90 acts via an allosteric effect, where San A-amide binds to the N-middle region and inhibits C-terminal client proteins.8 This mechanism of action is unique to Hsp90 inhibitors, making San A and its derivatives valuable molecular tools and potential lead structures for future chemotherapeutic studies.

In order to prepare these compounds to move into the next stage of development (mice models) the pharmacokinetic (PK) properties of these molecules should be improved as they are relatively poor.1 One mechanism for improving PK is to introduce peptidomimetic features, or structural motifs that mimic the peptide backbone, where these mimics often improve the solubility and stability of the molecule without impacting the cytotoxicity.24,25 Introduction of these motifs into the macrocyclic backbone has been shown to rigidify the macrocycles, as well as improve the absorption, distribution, metabolism and excretion (ADME) properties.26–29 Some common heterocycles that are known to improve stability of the peptide backbone include: triazoles, oxazoles, thiazoles and pseudoprolines.30–33

The inclusion of a triazole, particularly in cyclic peptide backbone, has demonstrated an improvement in biological activity.27,32 Further, triazoles induce a rigid conformation by mimicking trans amide bonds.27,30 Studies have shown that a single N-methyl, D-aa or N-methyl D-aa play a critical role in locking the San A-amide macrocyclic analogs into a single conformation.34,35,5–7,36,37,1 If this conformation induces an advantageous presentation of the side chains to their biological target, locking it into place via one of these structural features will likely improve binding between the compound and the protein target. Likewise, there is also precedence for oxazole and thiazole pepidomimetic moieties improving biological stability when substituted within peptide backbones.27 Similarly to triazoles, pseudoprolines induce a rigid conformation by mimicking cis amide bonds, and thus make structurally interesting comparisions to triazoles.38,39,26,40

Herein we describe the synthesis of 13 peptidomimetics that are based on San A-amide and the potent analogs B–D (Figure 1). These compounds were chosen because they have demonstrated appropriate cytotoxicity, and they inhibit Hsp90.1,8 The synthesis of compounds that incorporate a triazole, oxazole, thiazole, or pseudoproline involved both solution and solid-phase approaches. These peptidomimetic residues are substituted for different features within the San-A structure. The triazole replaces an amide bond, whereas the oxazole and thiazole replace both an amide bond as well as the adjacent amino acid side chain, and the pseudoproline replaces only the amino acid side chain. We discuss a series of synthetic strategies for these four unique classes of Sansalvamide peptidomimetics, where these methods can be applied as general approaches for the conversion of macrocyclic peptides into peptidomimetic compounds. Further, biological testing of our peptidomimetic compounds allowed us to evaluate which of these heterocyclic features are ideal for incorporation into future potent analogs and how their position in the macrocycle affects their cytotoxicity.

2. Results and discussion

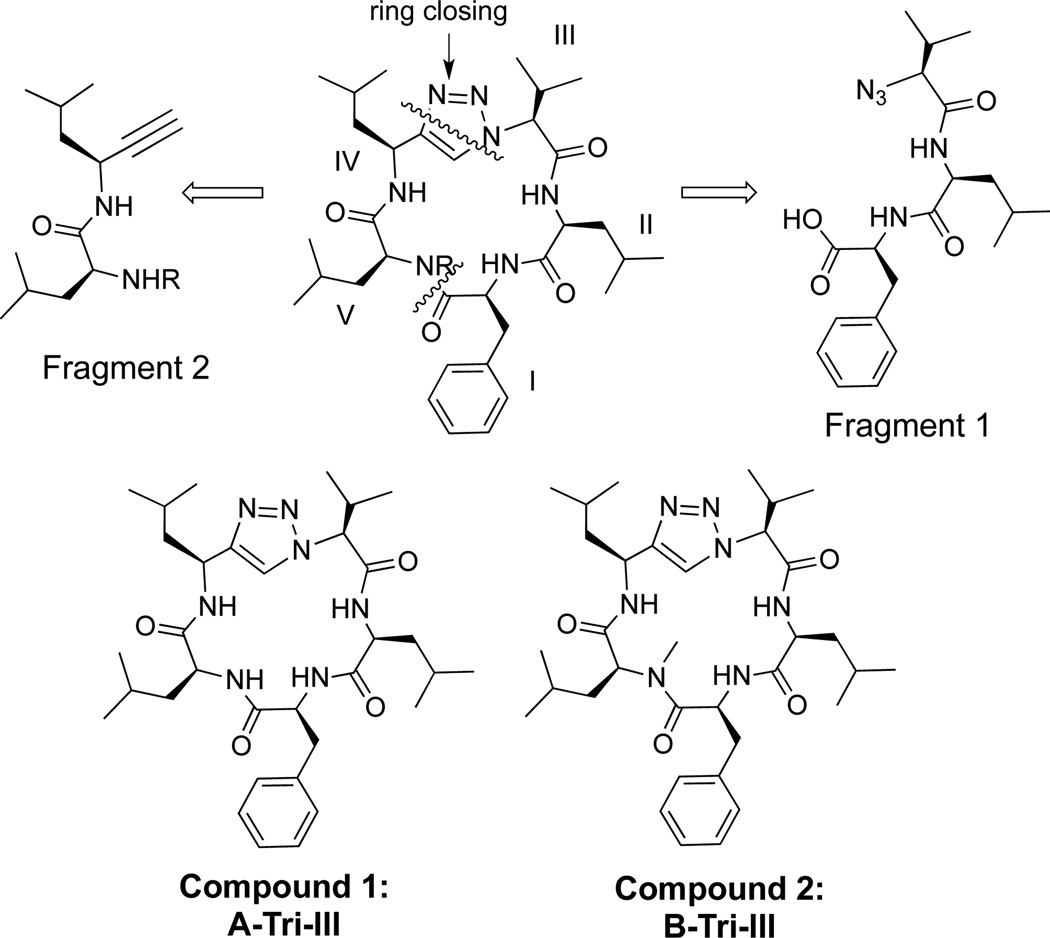

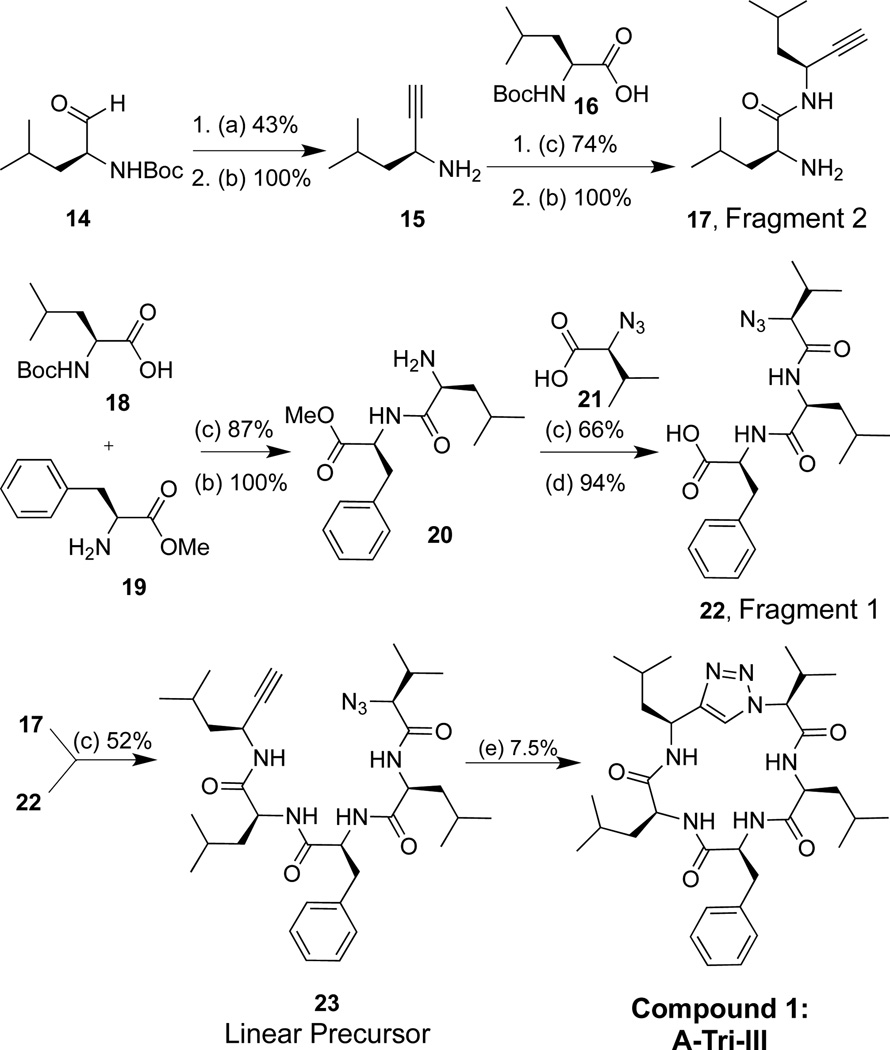

Two triazole peptidomimetics (Tri), compounds 1 and 2 (Figure 2), were synthesized via a convergent solution phase approach. Forming the triazole at the cyclization step has been reported as a successful strategy to synthesize cyclic triazole peptidomimetics.33,41–43 The synthetic strategy involved making two fragments, a tri- and dipeptide; conversion of the amine moiety of the tripeptide to an azide yielded fragment 1, and formation of an alkyne on the dipeptide yielded fragment 2. Both fragments were coupled via a peptide bond to form the linear molecule between residues I and V, and the macrocycle was then clicked shut to generate a single 1,4-disubstituted triazole analog.42

Figure 2.

Triazole synthetic strategy and compounds synthesized

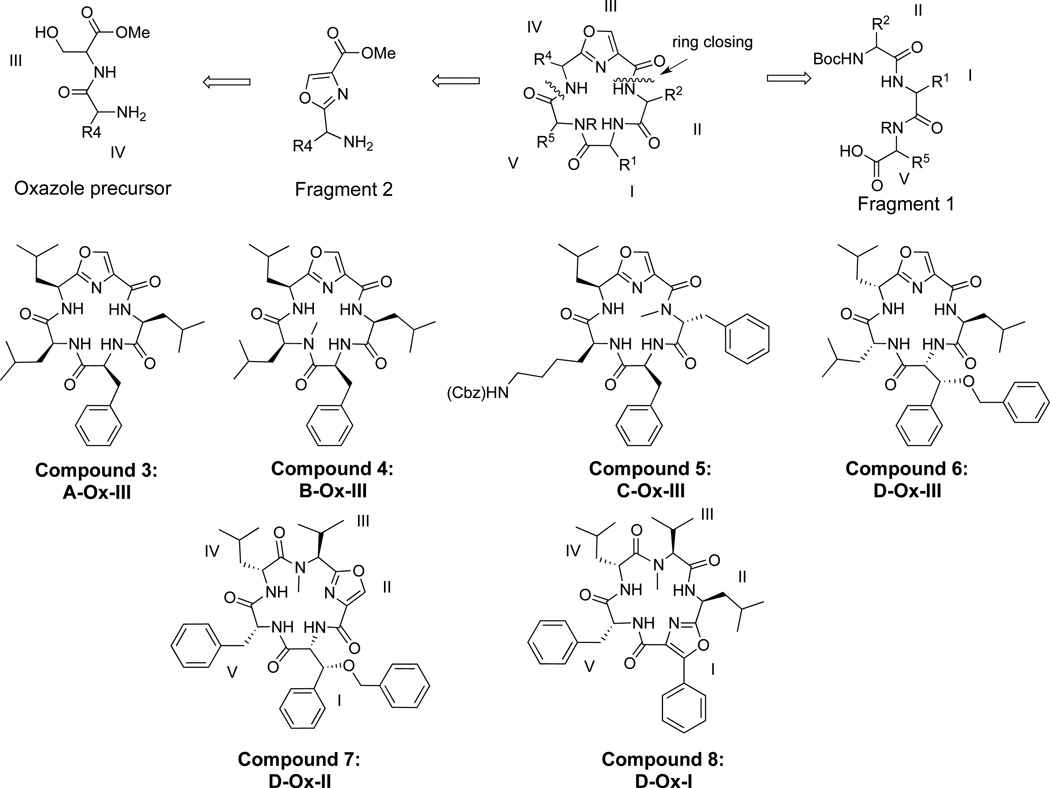

We made six oxazole peptidomimetics (Ox) (Figure 3), which were templated from molecules A–D (Figure 1). Compounds 3–6 were designed with the inclusion of an oxazole at position III based on the macrocycles A–D, whereas compounds 6–8 were only based on molecule D with the oxazole moiety placed at positions I, II, and III. These six oxazole-derived molecules were made using two different approaches, which utilized both a solid and solution phase approach. Initially our synthetic strategy involved oxazole formation after cyclization, whereupon the cyclic peptide was synthesized, and the serine was cyclized and oxidized after the formation of the macrocycle. However, the yield for this approach was extremely low for the oxazole formation (3% final yield for 8) versus an average of 74% yield for oxazole formation prior to cyclization. Presumably this was due to the rigidity of the macrocycle inhibiting the formation of an inflexible heterocycles within the backbone. Thus, the synthetic strategy for the oxazole derivatives 3–7 involved the synthesis of two fragments; fragment 1 consisted of a tripeptide, while fragment 2 incorporated the oxazole moiety. The oxazole was synthesized by coupling a serine to a leucine or valine (compounds 3–6 and 7, respectively). The oxazole was then formed via cyclodehydration upon treatment with DAST and potassium carbonate, then subsequent oxidation using bromochloroform and DBU.32,37,38 Coupling fragments 1 and 2, followed by peptide macrocyclization furnished the desired oxazole peptidomimetic derivatives.

Figure 3.

Oxazole peptidomimetic compounds

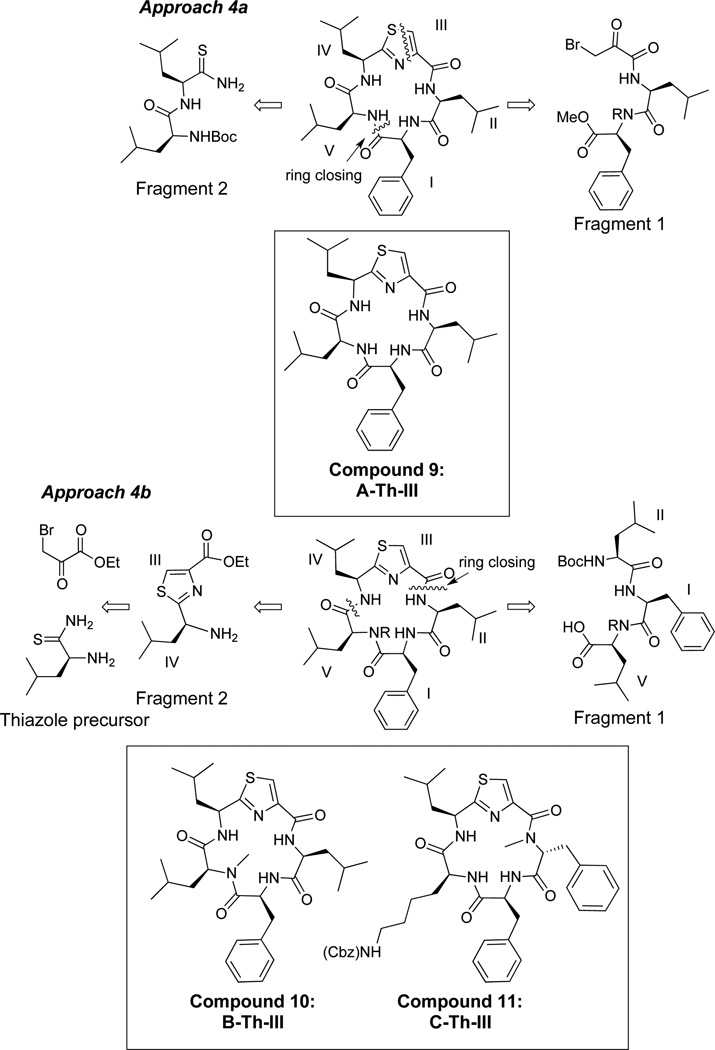

Three thiazole (Th) derivatives were synthesized using two different approaches (Figure 4). The first approach involved the synthesis of fragment 1, which incorporated a bromoketone moiety, while fragment 2 included a thioamide (Figure 4, approach 4a). A linear precursor was formed via the Hantzsch-thiazole reaction43 (Compound 9, A-Th-III), and macrocyclization was performed via peptide bond formation to yield compound 9. Given that the thiazole linear precursor had an extremely low yield (15% for thiazole formation), an alternative synthetic route was used for compounds 10 and 11 (Figure 4, approach 4b). The alternative route involved the same general synthetic approach as the oxazoles, where a solution phase procedure was used to form tripeptide fragment 1. The thiazole moiety was synthesized from two precursors, ethyl bromopyruvate and a thioamide, via the Hantzsch-thiazole reaction to yield fragment 2.44 This proved to be a successful means of synthesizing the thiazole moiety with an average of 62% yield for this reaction. Upon synthesis of these two fragments, amide bond formation between residues IV and V furnished the linear precursor followed by deprotection of the acid and amine and subsequent peptide cyclization between residues II and III generated compounds 10 and 11.

Figure 4.

Thiazole peptidomimetic compounds: 2 approachs

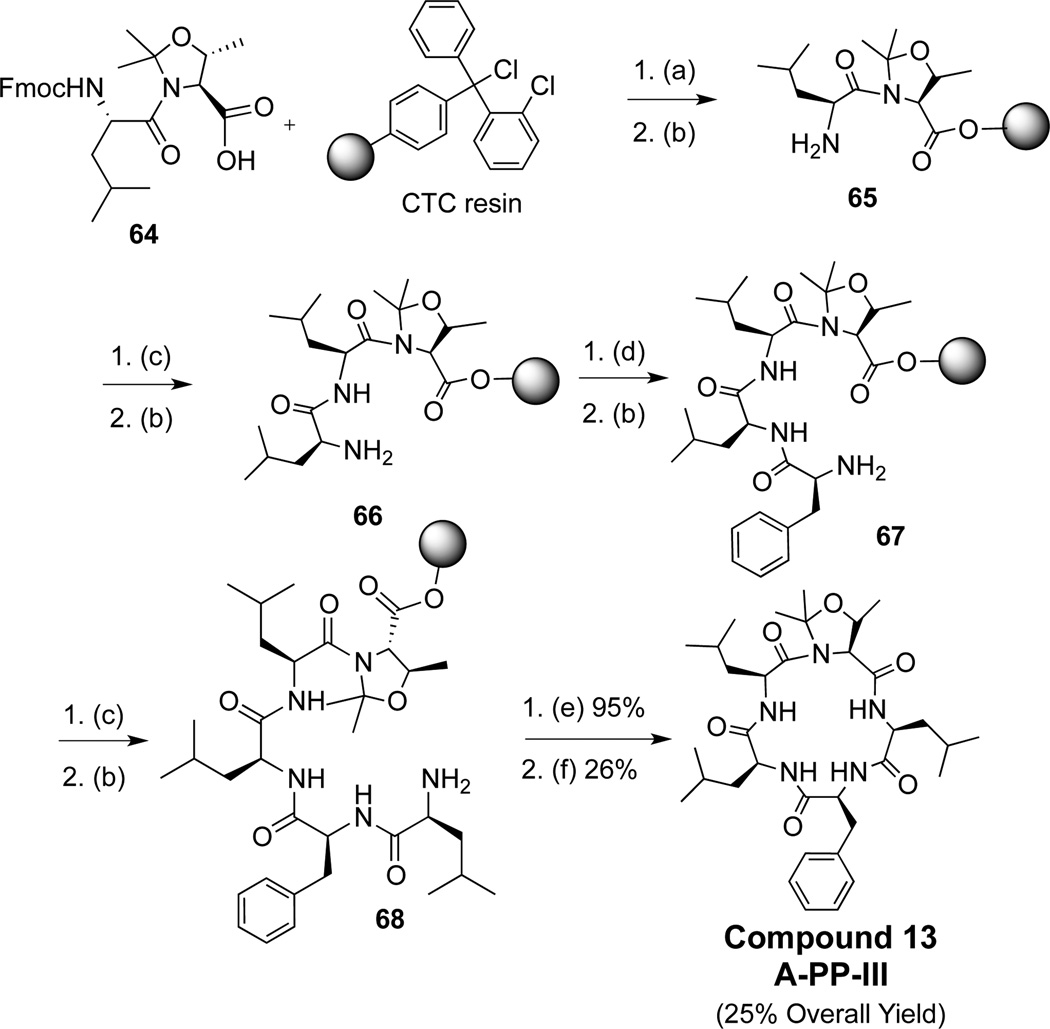

We synthesized two pseudoproline (PP) derivatives based on the compound A scaffold, where the pseudoproline was placed at positions II and III, respectively (12 and 13, Figure 5). These compounds were made via Fmoc solid phase synthesis through sequential peptide coupling from chlorotritylchloride resin loaded with the appropriate pseudoproline dipeptides.43 Upon formation of the linear pentapeptide, the compounds were cleaved, cyclized, and purified.

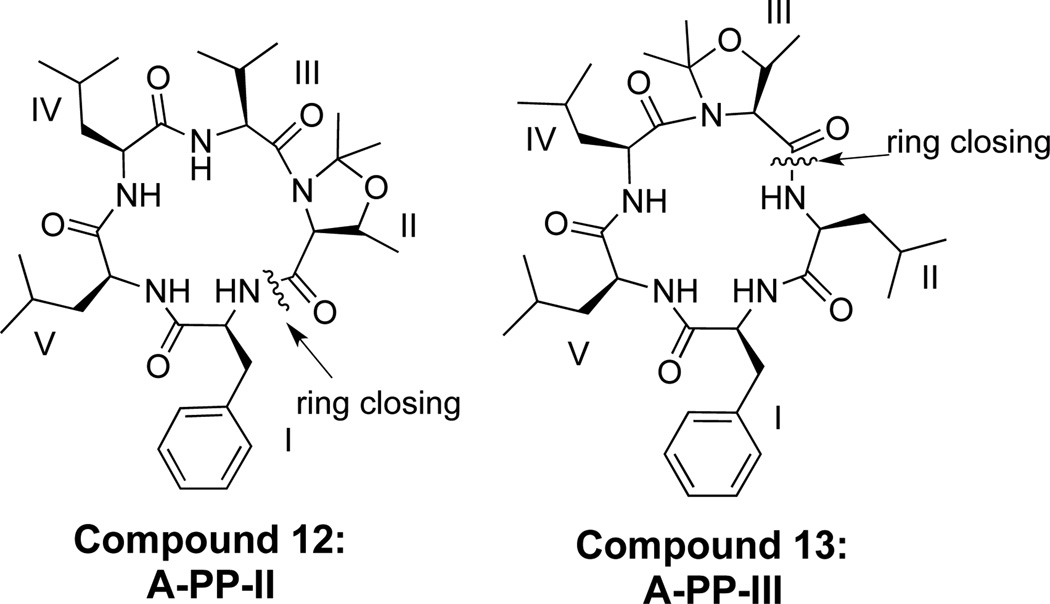

Figure 5.

Pseudoproline compounds

3. Synthesis

3.1. Synthesis of triazole compound 1

Aldehyde 14 was converted to an alkyne by treatment with p-toluenesulfonyl azide and di-methyl (2-oxopropyl) phosphonate (Scheme 1). Removal of the Boc protecting group with TFA furnished alkyne 15 in a 43% yield over two steps. Alkyne 15 was coupled to amino acid 16 and the Boc group was removed to yield 17, fragment 2 (74% yield over two steps). Standard coupling of amino acids 18 and 19 and deprotection methods produced 20 (87% yield over two steps). Dipeptide 20 was then coupled to azide 21 and subsequently deprotected using lithium hydroxide to yield free acid 22, Fragment 1 (62% yield over two steps). Amine 17 and acid 22 were coupled using peptide coupling conditions to produce linear precursor 23 (52% yield). Treatment of 23 with catalytic amounts of copper produced 1 in 7.5% purified yield of cyclized compound.

Scheme 1.

Synthesis of 1. (a) p-toluenesulfonyl azide (3 equiv), dimethyl (2-oxopropyl) phosphonate (3 equiv), potassium carbonate (3 equiv), 0.25 M in acetonitrile/methanol (1:1); (b) 20% trifluoroacetic acid/dichloromethane (0.1 M); (c) TBTU (1.2 equiv), DIPEA (8 equiv), methylene chloride (0.1 M); (d) LiOH (2 equiv), H2O2 (3.4 equiv), methanol (0.1 M), 0 °C; (e) L-ascorbic acid (9 equiv), NaHCO3 (9 equiv), CuSO4·H2O (0.3 equiv), 0.007 M in methanol/water (1:1)

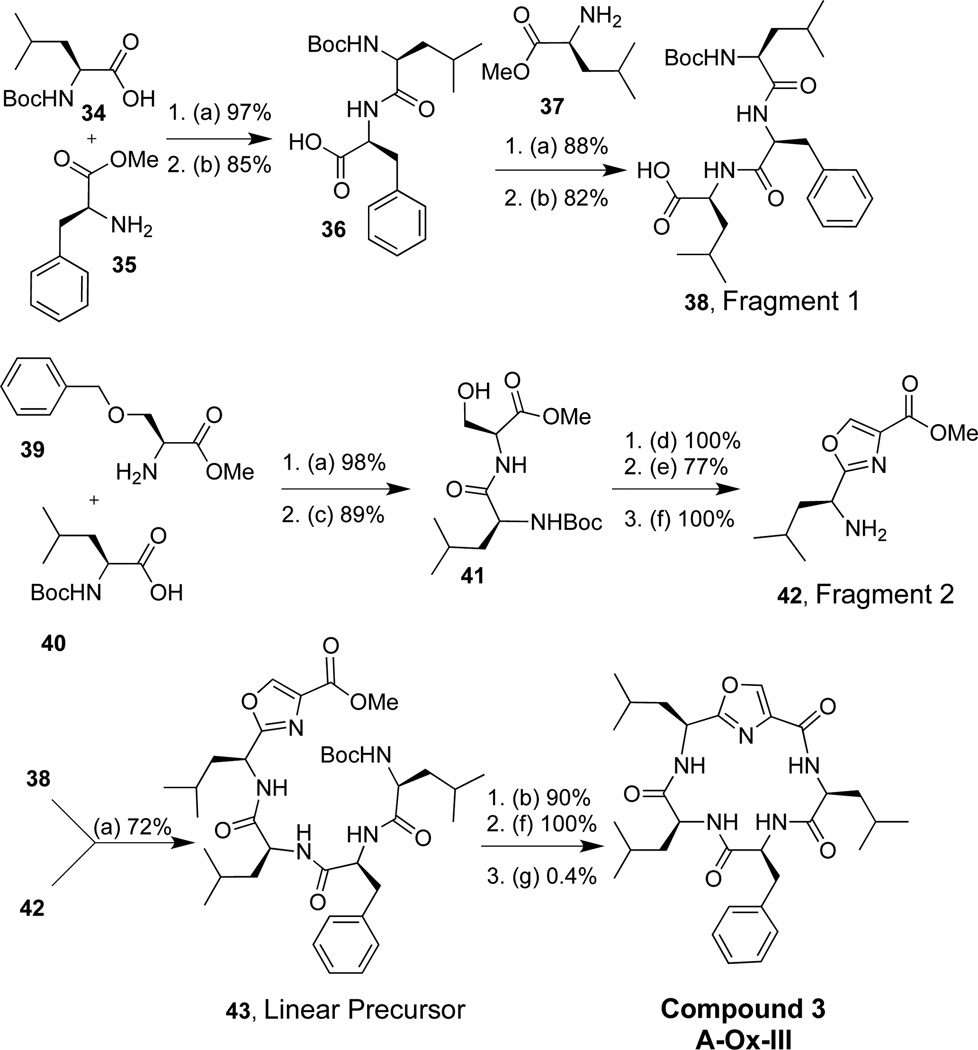

3.2. Synthesis of triazole compound 2

Compound 2 was synthesized using a linear approach. The yield from this linear approach was then compared to the yield using the convergent approach used for compound 1 (Scheme 2). Aldehyde 24 was converted into an alkyne with the treatment of p-toluenesulfonyl azide and di-methyl (2-oxopropyl) phosphanate in acetonitrile and methanol. The Boc protecting group was removed to produce 25 (53% yield for two steps). Alkyne 25 was coupled to amino acid 26 upon treatement with O-(Benzotriazol-1-yl)-N,N,N',N'-tetramethyluronium tetrafluoroborate (TBTU) and N,N'-Diisopropylethylamine (DIPEA). The Boc protecting group was removed to furnish 27 (70% yield for two steps). This was coupled to amino acid 28, and deprotected to generate alkyne 29 (60% yield over two steps). Coupling 29 to 30 and subsequent deprotection furnished tetrapeptide 31 in good yields (80% yield over two steps). Linear precursor 33 was produced by coupling tetrapeptide 31 to 32 (29% yield). Finally, the macrocyclization step used a copper catalyst to click the 1,4-disubstituted triazole heterocycle and close the macrocyclic ring (7% yield for compound 2).

Scheme 2.

Synthesis of 2. (a) p-toluenesulfonyl azide (3 equiv), dimethyl (2-oxopropyl) phosphonate (3 equiv), potassium carbonate (3 equiv), 0.25 M in acetonitrile/methanol (1:1); (b) 20% trifluoroacetic acid/dichloromethane (0.1 M); (c) TBTU (1.2 equiv), DIPEA (8 equiv), methylene chloride (0.1 M); (d) L-ascorbic acid (9 equiv), NaHCO3 (9 equiv), CuSO4·H2O (0.3 equiv), 0.007 M in methanol/water (1:1)

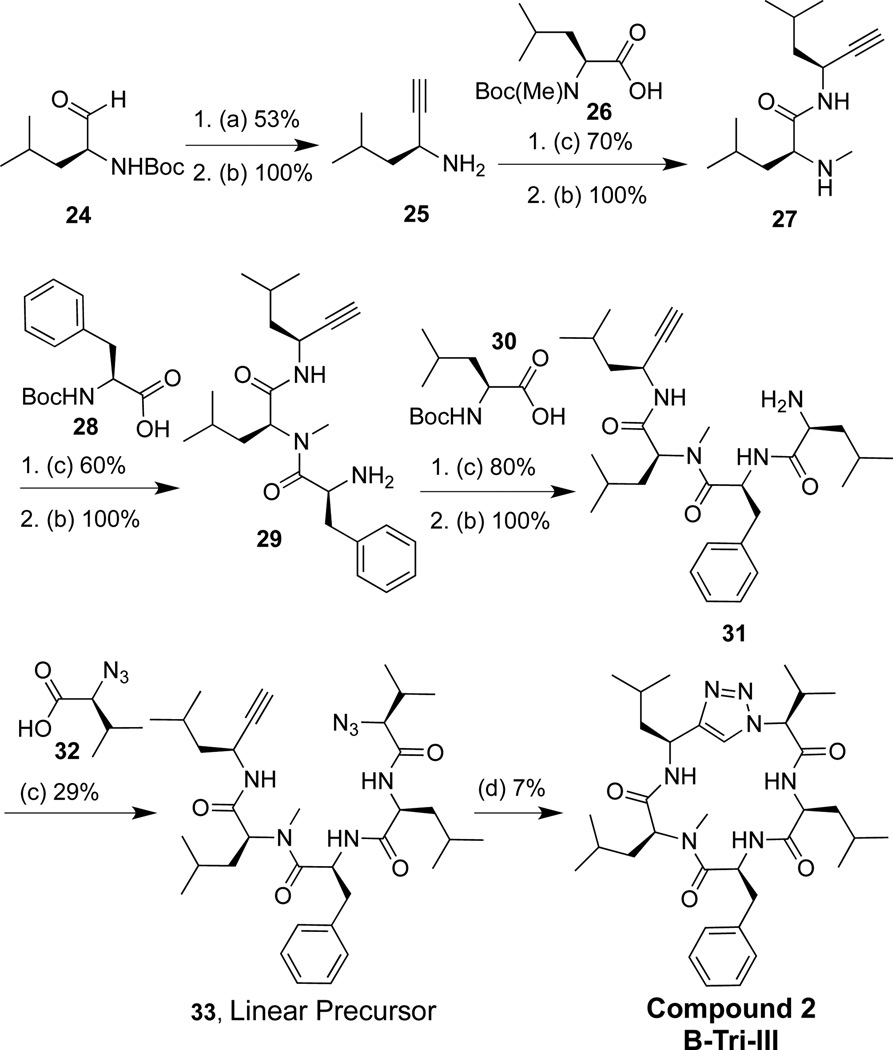

3.3. Optimal synthesis strategy for oxazole derivatives

The most optimal synthesis for the oxazole derivatives is described. This approach was used on compounds 3–7 and described is the synthesis of analog 3 where the oxazole is formed prior to closing the macorcycle (Scheme 3). Amino acid 34 was coupled to 35 and then underwent methyl ester hydrolysis to furnish 36 (82 % yield over two steps). Coupling 36 and 37 generated a tripeptide, whereupon treatment with lithium hydroxide and hydrogen peroxide formed 38, fragment 1 (66% yield over two steps). Amino acids 39 and 40 were coupled and subjected to hydrogenation to remove the benzyl protecting group, yielding 41 (87% yield). The oxazole was formed on the dipeptide 41 by treatment of DAST and K2CO3, which generated the oxazoline, whereupon treatment with DBU and bromotrichloromethane produced the desired oxazole (in 77% overall yield for two steps). Deprotection of the amine furnished 42 (100% yield), fragment 2. Fragments 1 and 2 were coupled together to form 43, the linear precursor in 72% yield. The acid and amine deprotection and cyclization generated compound 3. Synthesis of compound 8 is described in the supplementary material (page 46–48).

Scheme 3.

Synthesis of 3. (a) TBTU (1.2 equiv.), DIPEA (8 equiv), methylene chloride (0.1 M); (b) LiOH (2 equiv), H2O2 (3.4 equiv), methanol (0.1 M), 0 °C; (c) H2/Pd (0.03 equiv), ethanol (0.1 equiv); (d) DAST (1.1 equiv), K2CO3 (2 equiv), methylene chloride (0.01 M), −78 °C; (e) DBU (2 equiv), BrCCl3 (2 equiv), methylene chloride (0.2 M), −47 °C; (f) 20% trifluoroacetic acid/methylene chloride (0.1 M); (g) TBTU (0.7 equiv), O-(7-Azabenzotriazol-1-yl)-N,N,N',N'-tetramethyluronium hexafluorophosphate (HATU) (0.6 equiv), 3-(Diethylphosphoryloxy)-1,2,3-benzotriazin-4(3H)-one (DEPBT) (0.7 equiv), DIPEA (10 equiv), 0.007 M in methylene chloride/acetonitrile (1:1)

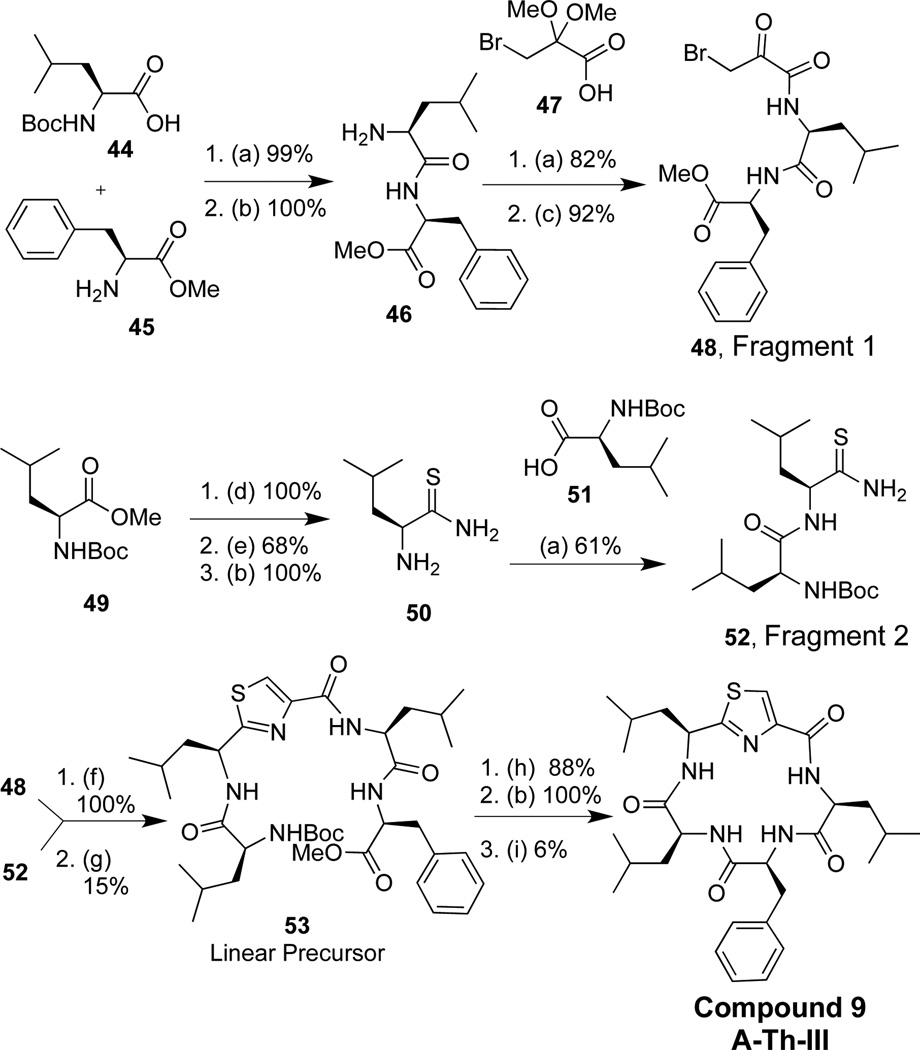

3.4. Synthesis of thiazole compound 9

Following the synthetic approach described in 4a (Figure 4), we outline the synthetic method used to form thiazole compound 9 (Scheme 4). Dipeptide 46 was produced by the coupling 44 and 45, followed by a Boc removal reaction (99% yield over two steps). Further, coupling 46 to 3-bromo-2,2-dimethyoxypropanoic acid 47 and treatment with formic acid furnished ketone 48, fragment 1 (75% yield over two steps). Amino acid 49 was converted to thioamide 50 (68% yield over three steps), which was subsequently coupled to amino acid 51 to yield fragment 2, 52 (61% yield). Linear precursor 53 was formed using Hantzsch-thiazole conditions, where potassium bicarbonate generated the thiazoline intermediate, followed by an elimination reaction in the presence of pyridine, trifluoroacetic anhydride and triethylamine, which furnished the desired thiazole moiety (15% yield over two steps). Finally, compound 9 was generated by deprotection of the acid and amine of 53, followed by subsequent peptide macrocyclization (5.3% overall yield).

Scheme 4.

Synthesis of 9. (a) TBTU (1.1 equiv), DIPEA (4 equiv), methylene chloride (0.1 M); (b) 20% trifluoroacetic acid/methylene chloride (0.1 M); (c) formic acid (0.1M) (d) (1:1) ammonium hydroxide/methanol (0.1 M);(e) Lawesson’s Reagent (1 equiv), 1,2-dimethoxyethane (.15 M); (f) KHCO3 (8 equiv), 1,2-dimethoxyethane (0.1 M); (g) pyridine (9 equiv), TFAA (4 equiv), TEA (2 equiv), 1,2-dimethoxyethane (0.1 M) 0 °C; (h) LiOH (2 equiv), H2O2 (3.4 equiv), methanol (0.1 M), 0 °C; (i) TBTU (0.7 equiv), HATU (0.7 equiv), DEPBT (0.7 equiv), DIPEA (6 equiv), methylene chloride (0.007 M).

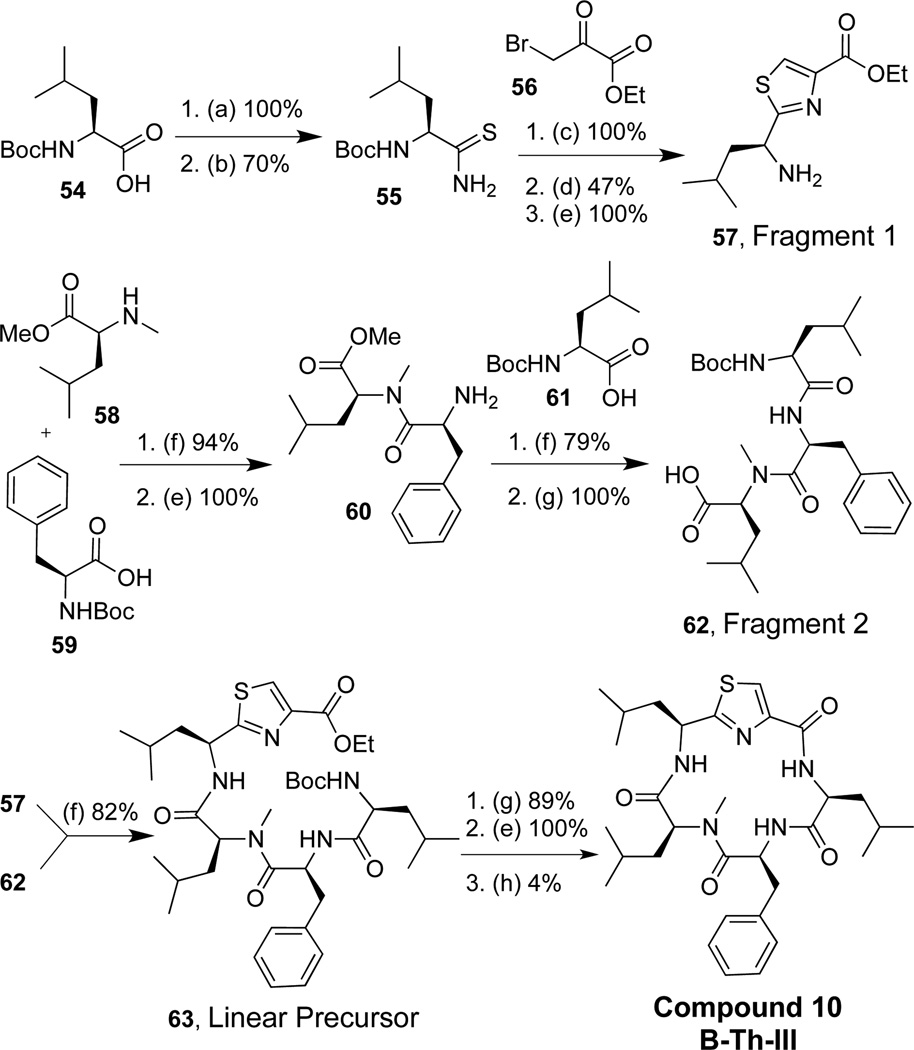

3.5. Synthesis of thiazole compounds 10 and 11

The synthesis of compounds 10–11 was accomplished using the approach described in Scheme 5. Compound 54 was converted to an amide by the treatment of ammonium hydroxide and methanol (100% yield). Thioamide 55 was generated using Lawesson’s Reagent (70% yield), whereupon 55 was reacted with 56 (100% yield) using Hantzsch-thiazole conditions (47% overall yield for thiazole formation). Subsequent amine deprotection furnished 57, fragment 1. Amino acid 58 was coupled to 59, and the amine was deprotected to produce dipeptide 60 (94% over two steps). The free amine on 60 was coupled to acid 61, and the dipeptide underwent methyl ester hydrolysis to furnish 62, fragment 2 (79% yield over two steps). Fragments 1 and 2 (57 and 62 respectively) were coupled together to yield the linear precursor 63 (82% yield). The amine and acid were subsequently deprotected and macrocylization produced compound 10 (3.5% yield for three steps). Synthesis of compound 11 utilizes this strategy and is described in the supplementary data.

Scheme 5.

Synthesis of 10. (a) (1:1) ammonium hydroxide/methanol (0.1 M); (b) Lawesson’s Reagent (1 equiv), 1,2-dimethoxyethane (0.15 M); (c) KHCO3 (8 equiv), 1,2-dimethoxyethane (0.1 M); (d) pyridine (9 equiv), TFAA (4 equiv), TEA (2 equiv), 1,2-dimethoxyethane (0.1 M) 0 °C; (e) 20% trifluoroacetic acid/methylene chloride (0.1 M); (f) TBTU (1.1 equiv), DIPEA (4 equiv), methylene chloride (0.1 M); (g) LiOH (2 equiv), H2O2 (3.4 equiv), methanol (0.1 M), 0 °C; (h) TBTU (0.7 equiv), HATU (0.7 equiv), DEPBT (0.7 equiv), DIPEA (6 equiv), methylene chloride (0.007 M).

3.6. Synthesis of pseudoprolines 12 and 13

The synthesis of compound 13 involved loading commercially available compound 64 onto 2-chlorotritylchloride resin, followed by subsequent Fmoc removal from leucine, generating 65. Subsequent coupling and deprotection of three additional amino acids generated compound 66. The linear pentapeptide was cleaved from the resin by treatment with 2,2,2-trifluoroethanol (TFE) providing the double deprotected peptide in an overall yield of 95%. The linear precursor was cyclized to produce the final compound 13 in 25% overall yield from the starting compound 64. Synthesis of compound 12 utilizes this strategy and is described in the supplementary data.

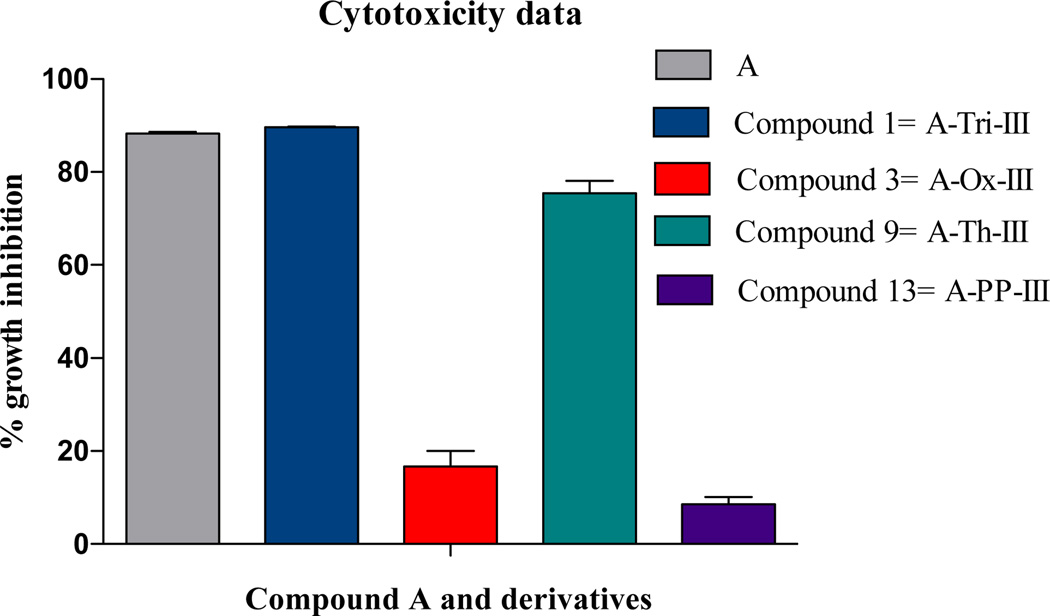

4. Biological and Modeling Data

In order to evaluate which of the heterocycles would be ideal for incorporation into the macrocyclic backbone, cytotoxicity data for molecule a peptidomimetic functional group was generated and compared to parent compound A (Figure 6). All four classes of peptidomimetic features and compound A were evaluated for their ability to inhibit growth in HeLa cervical cancer cell lines. The bar graph indicates that potency is maintained with the inclusion of a triazole or thiazole at position III. Interestingly, inclusion of an oxazole or pseudoproline in the peptide backbone decreases cytotoxicity compared to the parent compound. These data likely represent the consequence of altering the macrocyclic backbone, whereby the trans conformation that is induced by the triazole is favorable, and the cis conformation induced by the pseudoproline is not. Further, oxaozles are known to be more rigid than thiazoles, and the additional flexibility of the thiazole must be critical for the macrocycle to maintain its binding affinity with Hsp90.21,1,45

Figure 6.

Peptidomimetic compounds run at 25 µM against HeLa cervical cancer cell lines. Each data point is an average of four wells run in three separate assays using HeLa cancer cell lines. Inhibition is relative to 1% DMSO control.

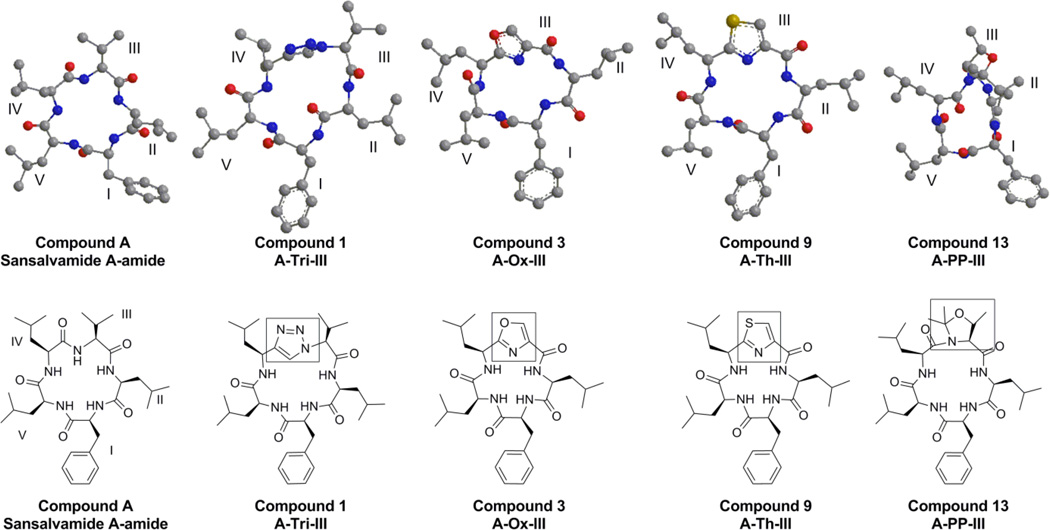

Given the unique biological data, models of the 4 molecules were completed using ChemBio3D Ultra. The lowest energy structures for each peptidomimetic molecule are shown in Figure 7. Although caution should be employed when drawing conclusions from relatively simple modle systems, these models are useful tools in developing a hypothesis to explain the highly divergent cytotoxicity data we have generated. The inclusion of the triazole provides an additional atom to the macrocycle, and this appears to allow a large ring that is significantly less puckered than the pseudoproline large macrocycle structure, compare 1 versus 13. This is logical given that the triazole induces a trans conformation, while the pseudoproline induces a cis conformation. Although structurally similar, the oxazole places the side chains at orientations that are different from the thiazole, perhaps allowing a compound-protein interaction with residue II that is unique to the thiazole compound (9) versus oxazole analog (3). Indeed, the modeling data below suggestion that compounds 1 and 9 have a conformation that places residues I and II in a similar orientations, whereas 3 and 13 have very different presentations of both residues. Although difficult to visualize, it is also possible that residues IV and V play a role in the improved cytotoxicity observed for compounds 1 and 9 by allowing an improved binding affinity for Hsp90 over that of compounds 3 and 13. Docking studies involving these molecules and Hsp90’s crystal structure are on going and will be published in due course.

Figure 7.

Molecular models of peptidomimetic compounds. Energy was miminized using the Merck Molecular Force Field 94 (MMFF94) with ChemBio3D Ultra (version 12.0) available form CambridgeSoft. Convergence criteria: atomic root mean square force 0.01 kcal/mol; static energy 82.250–115.726 kcal/mol; 500 iterations.

5. Conclusion

In summary, we have outlined the synthesis of thirteen peptidomimetics, all of which are related to a class of sansalvamide cytotoxic agents, with the anticipation that several moieties will have potency equal to that observed with the natural product. Two derivatives A-Tri-III (1) and A-Th-III (9) exhibited cytotoxicity at the same level as the parent San A-amide A. Although it is hard to predict how these peptidomimetic moieties affect the overall macrocyclic conformation, it appears that the triazole, which incorporates an additional carbon into the macrocyclic backbone as well as maintaining the side-chain at position III is a favorable option. This is likely due to its ability to induce a trans-amide conformation, versus a cis amide conformation induced by the pseudoproline.24,27,31,37 The thiazole moiety is also promising, presumably because it is a more flexible heterocycles relative to the oxazole and thus able to accomadate a favorable conformation for binding to Hsp90. Based on modeling, both compounds 1 and 9 may have improved cytotoxicity because of their similar orientation of residues I and II. Future work involves the development of compounds with triazoles and thiazoles in the backbone, with the anticipation that they will maintain their biological activity, while having enhanced PK and ADME properties. Further, docking studies using these two moieties in their backbone will provide insight into the induced conformation, and will be reported in due course.

6. Experimental Section

6.1. Cytotoxicity assays

Proliferation of HeLa cells was tested in the presence and absence of the compounds using CCK-8 assays (Dojindo, catalog# CK04-13). Cells were cultured in 96 well plates at a concentration of 2000 cells/well in DMEM (Gibco) supplemented with L-glutamine, 10% fetal bovine serum and 1% penicillin-streptomycin antibiotic. After overnight incubation, the compounds were added. The compounds were dissolved in DMSO and tested at the concentrations indicated in the manuscript with a final DMSO concentration of 1.0%. The DMSO control was also at 1.0%. The cells were incubated with compound or DMSO for 24 h upon which 10µl of CCK-8 solution was added to each well and allowed to incubate at 37 °C for an additional 2.5 h. The absorbance at 450 nm was measured using a S6 Genios Fluorimeter (Tecan). Percent growth inhibition was calculated as 1 minus the absorbance of compound-treated cells over DMSO-treated cells. All calculations including mean and SEM were performed using Prism software. Each data point is an average of four wells run in three separate assays.

6.2. General solution-phase peptide synthesis

All peptide coupling reactions were carried out under argon with dry solvent, using methylene chloride and/or acetonitrile for dipeptide, tripeptide, and pentapeptide couplings. The amine (1.1 equiv) and acid (1 equiv) were weighed into a dry flask along with 4–8 equiv of DIPEA and 1.1 equiv of TBTU.* Anhydrous methylene chloride and/or acetonitrile were added to generate a 0.1M solution. The solution was stirred at room temperature and reactions were monitored by TLC. Reactions were run for 1 hour before checking via TLC. If reaction was not complete an additional 0.25 equiv of TBTU was added. If reaction was complete then work-up was done by washing with 10% aqueous hydrochloric acid and saturated sodium bicarbonate. After back extraction of aqueous layers with methylene chloride, organic layers were combined, dried over sodium sulfate, filtered and concentrated. Flash column chromatography using a gradient of ethyl acetate-hexane gave our desired peptide.

* Some coupling reactions would not go to completion using only TBTU and therefore 0.2–0.5 equiv of HATU, and/or DEPBT were used. In a few cases up to 0.7 equiv of all three coupling reagents were used.

6.3. General solution-phase amine deprotection

Amines were deprotected using 20% trifluoroacetic acid in methylene chloride (0.1M) with two equiv of anisole. The reactions were monitored by TLC. Reactions were allowed to run for 1–2 h and then concentrated in vacuo.

6.4. General solution-phase acid deprotection

Acids were deprotected using 2 equiv of lithium hydroxide with 3.4 equiv of hydrogen peroxide in methanol (0.1 M). The peptide was dissolved in methanol and cooled to 0 °C. Hydrogen peroxide was added followed by lithium hydroxide. The reaction was monitored by TLC and usually done in 1–2 h. Sodium thiosulfate (3.8 equiv) was added to neutralize the peroxide and 5% hydrochloric acid was added till the solution pH was 1. The aqueous solution was extracted five times with methylene chloride, and the combined organic layer was dried, filtered and concentrated in vacuo.

6.5. General solid-phase synthesis remarks

Stepwise solid phase peptide synthesis was performed in a polypropylene solid-phase extraction cartridge fitted with a 20 µM polyethylene frit purchased from Applied Separations (Allentown, PA). 2-chlorotrityl resins were purchased in pre-loaded form with L-Leu, D-Leu, or D-Phe. In the case of compounds 12 and 13, a commercially available pseudoproline moiety was loaded onto a 2-chlorotrityl resin. Resins were swelled in dimethylformamide for 30 minutes prior to assembly of the linear five-residue peptide sequence. Solid-phase syntheses were performed on a 0.5 mmol scale based on resin-loading. All operations were performed at room temperature under open atmosphere unless stated otherwise.

6.6. General solid-phase peptide synthesis

Fmoc-protected amino acids were coupled using 3 equiv of amino acid, 3 equiv of HOBt, and 6 equiv of DIC. Couplings were performed in dimethylformamide at 0.2 M with respect to the incoming Fmoc-protected amino acid. Couplings were allowed to proceed for a minimum of two h, and were assayed via ninhydrin test to verify competition. Once complete, the coupling reaction solution was drained, and the resin subjected to Fmoc deprotection. (Note: Fmoc and N-methyl amino acids are coupled according to the cycle above, however for subsequent coupling onto the secondary amino terminus, HOBt was substituted with HOAt and the coupling was allowed to proceed overnight).

6.7. General solid-phase amine deprotection

Following coupling completion, the peptide-resin was treated as follows for removal of the Fmoc protecting group: dimethylformamide wash (3 × 1 min), 20% piperdine/dimethylformamide (1 × 5 min), 20% piperdine/dimethylformamide (1 × 10 min), dimethylformamide wash (2 × 1 min), 2-propanol wash (1 × 1 min), dimethylformamide was (1 × 1 min), 2-propanol (1 × 1 min), dimethylformamide (3 × 1 min). An ninhydrin test was performed to verify completion.

6.8. General N-terminal solid-phase deprotection

Once the final N-terminal amino acid residue had been coupled, the peptide-resin was treated as follows for removal of the Fmoc protecting group: dimethylformamide wash (3 × 1 min), 20% piperdine/dimethylformamide (1 × 5 min), 20% piperdine/dimethylformamide (1 × 10 min), dimethylformamide wash (3 × 1 min), 2-propanol wash (3 × 1 min), methanol (3 × 1 min). The fully-assembled peptide-resin was then drained and dried in vacuo overnight.

6.9. Cleavage of linear peptide from solid support

The full-length, linear peptide was cleaved from the resin by swelling and shaking the peptide-resin for 24 h in a 1:1 (v:v) TFE:methylene chloride (10 volumes/gram of dried resin). The cleavage solution was filtered through a Buchner filter, and the drained resin was washed with additional methylene chloride (5 volumes/gram of initial dried peptide-resin) to fully extract the cleaved peptide from the resin. Solvents in the combined filtrates were evaporated by rotary evaporation and the solids dried in vacuo overnight. The solids were then reconstituted in methylene chloride, evaporated by rotary evaporation and dried in vacuo overnight again to remove residual entrapped TFE.

6.10. Macrocyclization procedure (with syringe pump)

Three coupling agents (DEPBT, HATU, and TBTU) were used at ~0.5 to 0.75 equiv each. These coupling agents were dissolved in ¾ of a calculated volume of dry methylene chloride that would give a 0.001 M to 0.0007 M overall concentration when included in the volume used for the deprotected peptide. The crude, dry, double deprotected peptide (free acid and free amine) was dissolved in the other ¼ solvent volume of methylene chloride. DIPEA (8 equivs) was then added to the solution containing coupling reagents dissolved in methylene chloride. The double deprotected peptide was then added to the bulk solution dropwise using a syringe pump at a rate of 30mL/hr. The reaction was monitored via LCMS and generally complete in 1–2 h. Upon completion, the reaction was worked up by washing with aqueous hydrochloric acid (pH 1) and saturated sodium bicarbonate. After back extraction of aqueous layers with large quantities of methylene chloride, the organic layers were combined, dried, filtered and concentrated. All macrocycles were first purified by flash column chromatography using an ethyl acetate/hexane gradient on silica gel. Finally, when necessary, reversed-phase HPLC was used for additional purification using a gradient of acetonitrile and deionized water with 0.1% TFA.

6.11. Alkyne formation (Seyferth-Gilbert)46,47

Dry K2CO3 (3.0 equivs) was weighed into the flask under argon atmosphere. Calculated volume of acetonitrile was added to bring the final concentration of 0.125 M. p-tosyl azide (3.0 equivs) and dimethyl (2-oxypropyl) phosphonate (3.0 equivs) were added to the reaction mixture to generate the Bestmann-Ohira reagent. The reaction mixture stirred at room temperature and was monitored via TLC. After 2 h aldehyde (1.0 equiv dissolved in calculated amount of dry methanol to bring total reaction concentration to 0.25 M) was added. The reaction mixture was left stirring at room temperature overnight. The reaction was usually complete on the next day. Upon completion, confirmed by TLC, the reaction was concentrated in vacuo. The crude dried product was dissolved in 200 mL of ethyl acetate and washed with 150 mL of saturated sodium bicarbonate (× 2 times) and then by 100 mL of saturated sodium chloride (1 time). The organic layer was collected, dried over sodium sulfate, and concentrated in vacuo. Flash chromatography with a gradient of ethyl acetate/hexane was performed to purify the desired alkyne.

6.12. Cu(I)-catalyzed alkyne-azide cycloaddition

Sodium ascorbate was dissolved in 0.5 mL of water and put into round bottom flask. Copper sulfate was dissolved in 0.5 mL of water and added to the flask. The peptide (with azide and alkyne) was dissolved in a mixture of solvents methanol:water (1:1) at a concentration of 0.005M. 10% of this solvent mixture was added to the flask. The remaining solvent mixture was added dropwise via syringe pump to the reaction flask mixture overnight. The concentration of copper was 1.5 mM and concentration of sodium ascorbate was 45 mM for the overall reaction. Upon completion of the reaction, methanol was removed under reduced pressure and the reaction mixture was diluted with 100 mL of methylene chloride. The organic layer was collected and concentrated in vacuo. Flash chromatography with a gradient of ethyl acetate/hexane was performed to purify the desired derivative. Finally, when necessary reverse phase HPLC was used for additional purification using a gradient of Acetonitrile and distilled water with 0.1% trifluoroacetic acid.

6.13. General oxazole synthesis

DAST (1.1 equiv.) was added (0.1mL/min) to a solution of peptidyl-Ser or peptidyl-Phenylserine (1.0 equiv.) in methylene chloride (0.1M) cooled to −78 °C under argon atmosphere. The reaction mixture was stirred for 1 hour and anhydrous K2CO3 (2.0 equiv.) was added to the reaction mixture to stir at −78 °C for 1 hour. The reaction mixture warmed to room temperature and stirred for an additional 1.5 h. Upon reaction completion, confirmed by TLC, the organic solution was poured into saturated aqueous sodium bicarbonate and extracted with methylene chloride. After back-extraction of the aqueous layer with methylene chloride and/or ethyl acetate, the organic layers were combined, dried over sodium sulfate, filtered and concentrated in vacuo to give the oxazoline as an oil. The oxazoline was used without further purification for the oxidation of the oxazoline to yield the desired oxazole. DBU (2.0 equiv.) was added (0.1mL/min) to a solution of oxazoline (1.0 equiv.) in methylene chloride (0.1M) at −47 °C under argon. The reaction was stirred for 20 min and BrCCl3 (2.0 equiv.) was added to the reaction mixture (0.1mL/min). The reaction continued to stir at −47 °C for an additional 2 h and then warmed to room temperature to stir an additional 12 h, or until complete by TLC. Upon reaction completion, a work-up was done by extracting with 10% aqueous hydrochloric acid. After back extraction of aqueous layers with large quantities of methylene chloride and/or ethyl acetate, organic layers were combined, dried over sodium sulfate, filtered and concentrated in vacuo. Flash column chromatography using a gradient of ethyl acetate–hexane gave our desired peptidyl-oxazole. Finally, when necessary, reversed-phase HPLC was used for additional purification using a gradient of acetonitrile and deionized water with 0.1% trifluoroacetic acid.

6.14. General amide formation

Boc-protected amino ester (1 equiv.) was dissolved in 50% ammonium hydroxide and 50% methanol (0.05M). The reaction mixture was stirred overnight or until complete by TLC. Upon completion, the solvent was concentrated in vacuo.

6.15. General thioamide formation

Boc-protected amide (1 equiv.) was converted into Boc-protected thioamide using Lawesson’s Reagent (0.8 equiv.) in 0.4M 1,2-dimethoxyethane at room temperature under argon. The mixture was stirred overnight or until complete by TLC. Upon completion, the solvent was concentrated in vacuo. Boc-protected thioamide was purified by flash column chromatography using an ethyl acetate/methylene chloride gradient on silica gel.

6.16. General bromoketal acid formation

Trimethyl orthoformate (3 equiv.) and sulfuric acid (0.25 equiv.) were used to dissolve bromopyruvic acid (1 equiv.) under argon. The mixture is stirred overnight for less than 24 h. Acid work-up was done by extracting with 10% aqueous hydrochloric acid. After back-extraction of aqueous layers with methylene chloride and/or ethyl acetate, the organic layers were combined, dried over sodium sulfate, filtered and concentrated in vacuo.

6.17. General ketone deprotection

Ketones were deprotected using formic acid (0.1M), heated to 60 °C. The reaction was monitored by TLC and usually done within 30 min. Upon completion, the reaction was washed with saturated aqueous sodium bicarbonate. After back extraction of aqueous layers with methylene chloride, organic layers were combined, dried over sodium sulfate, filtered and concentrated in vacuo.

6.18. General thiazole synthesis (modified Hantzsch)

Thiazole synthesis reaction was carried out under argon with anhydrous 1,2-dimethoxyethane. KHCO3 (8 equiv.) was added to the dry flask containing peptidyl thioamide (1.0 equiv.). Anhydrous 1,2-dimethoxyethane (0.15 M) was added to the reaction, and it was stirred at room temperature for 15 min. α-Bromo ketone residue (3.0 equiv.) was added (0.1mL/min) and the reaction mixture was stirred overnight. Upon reaction completion, confirmed by TLC, the organic solution was poured into pre-prime celite with ethyl acetate. The filtrate was concentrated in vacuo to give the thiazoline intermediate as an oil to be used without further purification. Next, pyridine (9.0 equiv.) was added (0.1mL/min) to a solution of thiazoline in 1,2-dimethoxyethane (0.05M) at 0 °C under argon for the dehydration of the thiazoline to yield the desired thiazole. The reaction was stirred for 15 min and then TFAA (4.0 equiv.) was added to the reaction mixture (0.1mL/min). After 3 h, TEA (2.0 equiv.) was added to the reaction mixture (0.1mL/min) and the reaction continued to stir at room temperature for an additional 2–3 h, or until complete by TLC. Upon completion, the reaction was exctracted with 10% aqueous hydrochloric acid. After back-extraction of aqueous layers with methylene chloride and/or ethyl acetate, the organic layers were combined, dried over sodium sulfate, filtered and concentrated in vacuo. Flash column chromatography using a gradient of ethyl acetate/methylene chloride gave our desired peptidyl-thiazole. Finally, when necessary, reversed-phase HPLC was used for additional purification using a gradient of acetonitrile and deionized water with 0.1% trifluoroacetic acid.

6.19. Benzylation procedure

The cyclized peptide was dissolved in 50% tetrahydrofuran and 50% dimethylformamide to make a 0.1 M solution. The 60% NaH was used at 1.1 equiv and dissolved in the 0.1 M solution. Benzyl bromide (2 equiv.) was then added to the reaction. After 2 h, LC/MS indicated the reaction was developing. The reaction was completed in about 5 h and then worked up by washing with deionized water. After that, the organic layer was collected, dried and preliminarily purified by flash column chromatography. Finally, reverse-phase HPLC was used for further purification by using a gradient of acetonitrile and deionized water with 0.1 % trifluoroacetic acid.

6.20. Synthesis of Compound 1 (A-tri-III)

6.20.1. Dipeptide MeO-Phe-Leu-NHBoc

Dipeptide MeO-Phe-Leu-NHBoc was synthesized following the “General solution-phase peptide synthesis” procedure. Utilizing 1.50 g (6.96 mmol) of amine 19 MeO-Phe-NH2·HCl, 1.46 g (6.32 mmol) of acid 18 HO-Leu-NHBoc, 3.95 mL (27.8 mmol) of DIPEA, 2.44 g (7.58 mmol) of TBTU, in 66.0 mL of methylene chloride. The crude reaction was purified by column chromatography (silica gel, EtOAc/Hex) to yield the dipeptide (2.26 g, 87% yield). Rf: 0.6 (EtOAc: Hex 1:1). Physical and spectroscopic data are consistent with those reported in the literature.30

6.20.2. Dipeptide MeO-Phe-Leu-NH2 (20)

Dipeptide MeO-Phe-Leu-NH2 was synthesized following the “General solution-phase amine deprotection”. This dipeptide was taken on to the next reaction without further purification or characterization. (445 mg, 100% yield).

6.20.3. Monomer HO-Val-N3 (21)

Monomer 21 HO-Val-N3 was synthesized utilizing 500 mg (4.27 mmol) of HO-Val-NH2, 2.82 g (8.54 mmol) of triflic anhydride, 2.78 g (42.7 mmol) of sodium azide, 885 mg (6.41 mmol) of potassium carbonate, 10.6 mg (42.5 µmol) of CuSO4·5H2O, in 48 ml of DCM:MeOH:H2O (2:1:1) solvent system. The crude reaction was purified using an aqueous acidic wash to yield the pure monomer (600 mg, 97% yield).

6.20.4. Tripeptide MeO-Phe-Leu-Val-N3

Tripeptide MeO-Phe-Leu-Val-N3 was synthesized following the “General solution-phase peptide synthesis”. Utilizing 444 mg (1.53 mmol) of amine 20 MeO-Phe-Leu-NH2, 200mg (1.39 mmol) of acid 21 HO-Leu-N3, 1.80 mL of DIPEA, 534 mg (1.66 mmol) of TBTU, in 66.0 mL of methylene chloride. The crude reaction was purified by column chromatography (silica gel, EtOAc/Hex) to yield the triipeptide (420 mg, 66% yield). Rf: 0.5 (EtOAc: Hex 1:2); 1H NMR (400 MHz, CDCl3): δ 0.83–0.91 (9 H, m, CH(CH3)2), 1.08 (3 H, d, J 6.6 Hz, CH(CH3)2), 1.47–1.51 (2 H, m, CHCH2(CH3)2), 2.24–2.33 (1 H, m, CH(CH3)2), 3.02–3.20 (2 H, dq, J 86.5, 14.2, 5.5, Hz, CHCH2Ph), 3.72 (3 H, s, OCH3), 3.73 (1 H, d, J 4.1 Hz, αCH), 4.37–4.42 (1 H, m, αCH), 4.90–5.02 (1 H, m, αCH), 6.43 (1 H, d, J 7.7 Hz, NH), 6.62 (1 H, d, J 7.7 Hz, NH), 7.09–7.32 (5 H, m, Ph)

6.20.5. Tripeptide HO-Phe-Leu-Val-N3 (22)

Tripeptide HO-Phe-Leu-Val-N3 was synthesized following the “General solution-phase acid deprotection”. This tripeptide was taken on to the next reaction without further purification or characterization. (382 mg, 94% yield).

6.20.6. Monomer Alkyne-Leu-NHBoc

Monomer Alkyne-Leu-NHBoc was synthesized following “Alkyne formation”. Utilizing 165 mg (0.787 mmol) of 14 Leucinial-NHBoc, 0.353 mL (2.30 mmol) of pTsN3, 0.310 mL (2.30 mmol) of di-methyl (2-oxopropyl) phosphonate, and 317 mg (2.30 mmol) K2CO3 in 3.22 mL of ACN:MeOH (1:1). The crude reaction was purified by column chromatography (silica gel, EtOAc/Hex) to yield the monomer (70.0 mg, 43% yield). Rf: 0.5 (EtOAc: Hex 1:9).

6.20.7. Monomer Alkyne-Leu-NH2 (15)

Monomer 15 Alkyne-Leu-NH2 was synthesized following the “General solution-phase amine deprotection”. This monomer was taken on to the next reaction without further purification or characterization. (83mg, 100% yield).

6.20.8. Dipeptide Alkyne-Leu-Leu-NHBoc

Dipeptide Alkyne-Leu-Leu-NHBoc was synthesized following the “General solution-phase peptide synthesis” procedure. Utilizing 83.0 mg (0.743 mmol) of amine 15 alkyne-Leu-NH2, 204 mg (0.817 mmol) of acid 16 HO-Leu-NHBoc, 1.00 mL (6.53 mmol) of DIPEA, 286 mg (0.896 mmol) of TBTU, in 7.40 mL of methylene chloride. The crude reaction was by column chromatography (silica gel, EtOAc/Hex) to yield the dipeptide (241mg, 74% yield). Rf: 0.6 (EtOAc: Hex 1:4); 1H NMR (400 MHz, CDCl3): δ 0.85–0.90 (12 H, m, CH(CH3)2), 1.37 (9 H, s, OC(CH3)3), 1.45–1.50 (1 H, m, CH2CH(CH3)2), 1.57–1.64 (4 H, m, CHCH2CH), 1.64–1.74 (1 H, m, CH2CH(CH3)2), 2.17 (1 H, s, C≡CH), 3.91–4.02 (1 H, br m, αCH), 4.65–4.78 (1 H, m, αCH), 4.72 (1 H, br s, CHNHCOOtBu), 7.72 (1 H, br d, J 6.19, NH).

6.20.9. Dipeptide Alkyne-Leu-Leu-NH2 (17)

Dipeptide Alkyne-Leu-Leu-NH2 was synthesized following the “General solution-phase amine deprotection”. This dipeptide was taken on to the next reaction without further purification or characterization. (145mg, 100% yield).

6.20.10. Pentapeptide Alkyne-Leu-Leu-Phe-Leu-Val-N3 (23)

Pentapeptide Alkyne-Leu-Leu-Phe-Leu-Val-N3 was synthesized following the “General solution-phase peptide synthesis” procedure. Utilizing 145 mg (0.649 mmol) of amine 17 alkyne-Leu-Leu-NH2, 237 mg (0.591 mmol) of acid 22 HO-Phe-Leu-Val-N3, 0.82 mL (4.73 mmol) of DIPEA, 189 mg (0.591 mmol) of TBTU, 67.0 mg (0.177 mmols) of HATU, and 34.2 mg (0.118 mmol) of DEPBT, in 5 mL of methylene chloride and 2 mL acetonitrile. The crude reaction was purified by column chromatography (silica gel, EtOAc/Hex) to yield the pentapeptide (186 mg, 52% yield). Rf: 0.5 (EtOAc: Hex 1:1); 1H NMR (400 MHz, CD3OD): δ 0.88–0.96 (24 H, m, CH(CH3)2), 1.26–1.36 (1 H, m, CHCH(CH3)2), 1.47–1.65 (6 H, m, CHCH2CH), 1.72–1.83 (1 H, m, CH2CH(CH3)2), 2.05–2.19 (1 H, m, CH2CH(CH3)2), 2.63 (1 H, s, C≡CH), 2.89–316 (2 H, dq, J 80.6, 8.3, 5.6 Hz, CHCH2Ph), 3.55 (1 H, d, J 6.9 Hz, N3CHC=O), 4.32–4.44 (2 H, m, αCH), 4.57–4.70 (2 H, m, αCH), 7.17–7.26 (5 H, m, Ph), 8.01 (1 H, d, J 8.05 Hz, NH), 8.07 (1 H, d, J 7.7 Hz, NH), 8.11 (1 H, d, J 7.8 Hz, NH), 8.21 (1 H, d, J 8.4 Hz, NH). LCMS: m/z calcd for C33H51N7O4 (M+1) = 610.8, found 611.6

6.20.11. Macrocycle Phe-Leu-Val-Triazole-Leu-Leu (1)

Macrocycle Phe-Leu-Val-Triazole-Leu-Leu was synthesized following the “Cu(I)-catalyzed alkyne-azide cycloaddition”. Utilizing 150 mg (0.252 mmol) of linear pentapeptide 23, 389 mg (2.21 mmol) of L-ascorbic acid, 185 mg (2.21 mmol) of NaHCO3, and 18.4 mg (74.2 µmol) CuSO4·5H2O in 35.0 mL MeOH:H2O (1:1). The crude reaction was purified by reverse phase-HPLC to yield the macrocycle (12.3 mg, 7.5% yield). Rf: 0.25 (EtOAc: Hex 1:1); 1H NMR (400 MHz, CD3OD): δ 0.89–1.0 (24 H, m, CH(CH3)2), 1.49–1.54 (2 H, m, CHCH2CH), 1.58–1.63 (2 H, m, CHCH2CH), 1.65–1.69 (1 H, m, CH2CH(CH3)2), 1.75–1.80 (2 H, m, CHCH2CH), 1.98–2.06 (1 H, m, CH2CH(CH3)2), 2.15–2.22 (1 H, m, CH2CH(CH3)2), 3.02–3.16 (2 H, m, CH2Ph), 3.60–3.69 (1 H, m, αCH), 3.80–3.87 (1 H, m, αCH), 4.02–4.09 (1 H, m, αCH), 4.19–4.27 (1 H, m, αCH), 5.18–5.24 (1 H, m, αCH), 7.19–7.32 (5 H, m, Ph), 8.04 (1 H, s, NCH=C). LCMS: m/z calcd for C33H51N7O4 (M+1) = 611.8, found 611.9; HRMS (ESI-TOF): MH+, found 610.4078, requires 610.4075. >95% pure by HPLC.

6.21. Synthesis of Compound 2 (B-tri-III)

6.21.1 . Monomer HO-Val-N3 (32)

Monomer HO-Val-N3 was synthesized utilizing 500 mg (4.27 mmol) of HO-Val-NH2, 2.82 g (8.54 mmol) of triflic anhydride, 2.78 g (42.7 mmol) of sodium azide, 885 mg (6.41 mmol) of potassium carbonate, 10.6 mg (42.5 µmol) of CuSO4·5H2O, in 48.0 ml of DCM:MeOH:H2O (2:1:1) solvent system. The crude reaction was purified using an aqueous acidic wash to yield the pure monomer (600 mg, 97% yield).

6.21.2 . Monomer Alkyne-Leu-NHBoc

Monomer Alkyne-Leu-NHBoc was synthesized following “Alkyne formation”. Utilizing 310 mg (1.39 mmol) of 24 Leucinial-NHBoc, 0.635 mL (4.18 mmol) of pTsN3, 0.572 mL (4.18 mmol) of di-methyl (2-oxopropyl) phosphonate, and 577 mg (4.18 mmol) of K2CO3, in 5.50 mL of ACN:MeOH (1:1). The crude reaction was purified by column chromatography (silica gel, EtOAc/Hex) to yield the monomer (160 mg, 53% yield). Rf: 0.5 (EtOAc: Hex 1:9).

6.21.3 . Monomer Alkyne-Leu-NH2 (25)

Monomer Alkyne-Leu-NH2 was synthesized following the “General solution-phase amine deprotection”. This monomer was taken on to the next reaction without further purification or characterization. (83.2 mg, 100% yield).

6.21.4. Dipeptide Alkyne-Leu-Leu-N(Me)Boc

Dipeptide Alkyne-Leu-Leu-N(Me)Boc was synthesized following the “General solution-phase peptide synthesis” procedure. Utilizing 83.2 mg (0.748 mmols) of amine 25 alkyne-Leu-NH2, 169 mg (0.689 mmol) of acid 26 HO-Leu-N(Me)Boc, 0.902 mL (5.51 mmol) of DIPEA, 265 mg (0.823 mmol) of TBTU, in 7.05 mL of methylene chloride. The crude reaction was purified by column chromatography (silica gel, EtOAc/Hex) to yield the dipeptide (245 mg, 70% yield). Rf: 0.6 (EtOAc: Hex 1:4); 1H NMR (400 MHz, CDCl3): δ 0.77–0.84 (12 H, m, CH(CH3)2), 1.36 (9 H, s, COOC(CH3)3), 1.37 (2 H, bur m, CH(CH3)2), 1.50–1.66 (4 H, bur m, CHCH2CH), 2.15 (1 H, s, C≡CH), 2.61 (3 H, s, MeNCH), 4.40–4.52 (1 H, br s, αCH), 4.55–4.67 (1 H, q, J 7.3 Hz, αCH).

6.21.5. Dipeptide Alkyne-Leu-Leu-N(Me)H (27)

Dipeptide Alkyne-Leu-Leu-N(Me)H was synthesized following the “General solution-phase amine deprotection”. This dipeptide was taken on to the next reaction without further purification or characterization. (173 mg, 100% yield).

6.21.6. Tripeptide Alkyne-Leu-Leu-N(Me)-Phe-NHBoc

Tripeptide Alkyne-Leu-Leu-N(Me)-Phe-NHBoc was synthesized following the “General solution-phase peptide synthesis”. Utilizing 302 mg (1.13 mmol) of acid 28 HO-Phe-NHBoc, 299 mg (1.25 mmol) of amine 27 Alkyne-Leu-Leu-N(Me)H, 1.54 mL (9.04 mmol) of DIPEA, 362 mg (1.13 mmol) of TBTU, and 128 mg (0.339 mmol) of HATU in 11.0 mL of methylene chloride. The crude reaction was purified by column chromatography (silica gel, EtOAc/Hex) to yield the triipeptide (328 mg, 60% yield). Rf: 0.5 (EtOAc: Hex 1:3); 1H NMR (400 MHz, CDCl3): δ 0.80–0.92 (12 H, m, CH(CH3)2), 1.39 (9 H, s, COOC(CH3)3), 1.48–1.58 (2 H, m, CHCH2CH), 1.63–1.72 (2 H, m, CHCH2CH), 1.81–1.90 (1 H, m, CH2CH(CH2)3), 1.81 (1 H, s, C≡CH), 2.71 (3 H, s, CH3N), 2.84–2.96 (2 H, m, CHCH2Ph), 4.64–4.74 (1 H, m, αCH), 5.05–5.11 (1 H, m, αCH), 5.31–5.51 (1 H, dd, J 50.8, 7.7 Hz, αCH), 5.95 (1 H, d, J 8.17 Hz, NH), 7.23–7.32 (5 H, m, Ph), 7.92 (1 H, d, J 8.4 Hz, NH).

6.21.7. Tripeptide Alkyne-Leu-Leu-N(Me)-Phe-NH2 (29)

Tripeptide Alkyne-Leu-Leu-N(Me)-Phe-NH2 was synthesized following the “General solution-phase amine deprotection”. This tripeptide was taken on to the next reaction without further purification or characterization. (262 mg, 100% yield).

6.21.8. Tetrapeptide Alkyne-Leu-Leu-N(Me)-Phe-Leu-NHBoc

Tripeptide Alkyne-Leu-Leu-N(Me)-Phe-Leu-NHBoc was synthesized following the “General solution-phase peptide synthesis”. Utilizing 262 mg (0.674 mmol) of amine 29 Alkyne-Leu-Leu-N(Me)-Phe-NH2, 152 mg (0.612 mmol) of acid 30 HO-Leu-NHBoc, 0.805 mL (4.89) of DIPEA, 235 mg (0.734 mmol) of TBTU, in 6.70 mL of methylene chloride. The crude reaction was purified by column chromatography (silica gel, EtOAc/Hex) to yield the tetrapeptide (332 mg, 80% yield). Rf: 0.4 (EtOAc: Hex 1:3); 1H NMR (400 MHz, CDCl3): δ 0.86–0.95 (18 H, m, CH(CH3)2), 1.42 (9 H, s, COOC(CH3)3), 1.46–1.56 (2 H, m, CHCH2CH), 1.56–1.68 (2 H, m, CHCH2CH), 1.69–1.80 (1 H, m, CH(CH3)2), 2.84–2.93 (2 H, m, CHCH2Ph), 2.99 (3 H, s, NCH3), 3.04–3.12 (1 H, m, CH(CH3)2), 3.28 (1 H, d, C≡CH), 4.02–4.16 (1 H, m, αCH), 4.59–4.69 (1 H, m, αCH), 4.92 (1 H, m, αCH), 5.09 (1 H, m, αCH), 7.17–7.30 (5 H, m, Ph), 7.94 (1 H, d, J 8.2 Hz, NH), (1 H, d, J 8.13 Hz, NH).

6.21.9. Tetrapeptide Alkyne-Leu-Leu-N(Me)-Phe-Leu-NH2 (31)

Tripeptide Alkyne-Leu-Leu-N(Me)-Phe-Leu-NH2 was synthesized following the “General solution-phase amine deprotection”. This tripeptide was taken on to the next reaction without further purification or characterization. (233 mg, 100% yield).

6.21.10. Pentapeptide Alkyne-Leu-Leu-N(Me)-Phe-Leu-Val-N3 (33)

Pentapeptide Alkyne-Leu-Leu-N(Me)-Phe-Leu-Val-N3 was synthesized following the “General solution-phase peptide synthesis” procedure. Utilizing 326 mg (0.655 mmol) of amine Alkyne-Leu-Leu-N(Me)-Phe-Leu-NH2 (31), 237 mg (0.594 mmol) of acid HO-Val-N3 (32), 0.852 mL (4.75 mmol) of DIPEA, 199 mg (0.623 mmol) of TBTU, and 71.2 mg (0.193) of HATU in 6 mL of methylene chloride. The crude reaction was purified by column chromatography (silica gel, EtOAc/Hex) to yield the pentapeptide (110 mg, 29% yield). Rf: 0.5 (EtOAc: Hex 1:1); 1H NMR (400 MHz, CD3OD): δ 0.88–0.98 (24 H, m, CH(CH3)2), 1.40–1.49 (1 H, m, CH(CH3)2), 1.51–1.61 (6 H, bur m, CHCH2CH), 1.70–1.81 (1 H, m, CH(CH3)2), 2.10–2.14 (1 H, m, CH(CH3)2), 2.64 (1 H, s, C≡CH), 2.91 (2 H, m, CH2Ph), 3.31 (3 H, s, MeNC=O), 3.50–3.57 (1 H, m, αCH), 4.42–4.48 (1 H, m, αCH), 4.60–4.69 (1 H, m, αCH), 4.80–4.89 (1 H, m, αCH), 7.18–7.31 (5 H, m, Ph). LCMS: m/z calcd for C34H53N7O4 (M+1) = 624.9, found 646.5

6.21.11. Macrocycle Phe-Leu-Val-Triazole-Leu-Leu-N(Me) (2)

Macrocycle Phe-Leu-Val-Triazole-Leu-Leu-N(Me) was synthesized following the “Cu(I)-catalyzed alkyne-azide cycloaddition”. Utilizing 110 mg (0.176 mmol) of linear pentapeptide (33), 1.75g (8.79 mmol) of L-ascorbic acid, 730 mg (8.79 mmol) of NaHCO3, and 124 mg (0.502 mmol) CuSO4·H2O in 35 mL MeOH:H2O (1:1). The crude reaction was purified by reverse phase-HPLC to yield the macrocycle (8.20 mg, 7% yield). Rf: 0.4 (EtOAc: Hex 1:1) 1H NMR (400 MHz, CD3OD): δ 0.71–0.80 (3 H, m, CH(CH3)2), 0.83–1.12 (18 H, m, CH(CH3)2), 1.19–2.01 (1 H, m, CH(CH3)2), 1.30–1.35 (1 H, m, CH(CH3)2), 1.50–1.57 (2 H, m, CHCH2CH), 1.64–1.68 (2 H, m, CHCH2CH), 1.69–1.73 (2 H, m, CHCH2CH), 1.84–1.88 (1 H, m, CH(CH3)2), 2.52–2.56 (1 H, CH(CH3)2), 2.89–2.95 (2 H, m, CH2Ph), 2.99 (s, 3H, MeNC=O), 3.45–3.50 (1 H, m, αCH), 3.70–3.80 (1 H, m, αCH), 4.90–4.98 (1 H, m, 1 H, m, αCH), 5.01–5.12 (1 H, m, 1 H, m, αCH), 7.15–7.31 (5 H, m, Ph), 7.99 (1 H, d, J 7.7 Hz, O=CNHCH), 8.06 (1 H, s, NCH=C), 8.37 (1 H, d J 8.1 Hz, O=CNHCH). LCMS: m/z calcd for C34H53N7O4 (M+1) = 624.8, found 625.3; HRMS (ESI-TOF): MH+, found 624.4257, C34H53N7O4 requires 624.4232. >95% pure by HPLC.

6.22. Synthesis of Compound 3 (A-Ox-III)

6.22.1. Dipeptide MeO-Ser(Bzl)-Leu-NHBoc

Dipeptide MeO-Ser(Bzl)-Leu-NHBoc was synthesized following the “General solution-phase peptide synthesis” procedure utilizing 756 mg (3.39 mmol) of amine MeO-Ser(Bzl)-NH2 (39), 713 mg (3.08 mmol) of acid HO-Leu-NHBoc (40), 2.10 mL (12.3 mmol) of DIPEA, 1.19 g (3.70 mmol) of TBTU, in 31.0 mL of methylene chloride. This dipeptide was taken on to the next reaction without further purification (1.31 g, 98% yield). Rf: 0.73 (EtOAc: Hex 1:1); 1H NMR (400 MHz, CDCl3): δ 0.85 (6 H, d, J 8.0 Hz, CHCH3), 1.36 (9 H, s, CCH3), 1.41–1.48 (1 H, m, CHCH3), 1.55–1.65 (2 H, m, CH2CH), 3.56 (1 H, d, J 4.0 Hz, CH2O), 3.65 (3 H, s, OCH3), 3.76 (1 H, dd, J 4.0, 7.8 Hz, CH2O), 4.22 (1 H, br s, NH), 4.38 (2 H, m, PhCH2O), 4.66–4.72 (1 H, m, αCH), 5.49 (1 H, d, J 7.8 Hz, αCH), 7.14 – 7.21 (5 H, m, Ph).

6.22.2 Dipeptide MeO-Ser-Leu-NHBoc (41)

Dipeptide MeO-Ser-Leu-NHBoc was synthesized by dissolving 1.31 g (3.01 mmol) of dipeptide MeO-Ser(OBn)-Leu-NHBoc in 30 mL of ethyl alcohol, after purging the reaction vessel several times with hydrogen gas, the reaction was run overnight. Upon completion by TLC, this dipeptide was taken on to the next reaction without further purification or characterization. (902 mg, 89% yield).

6.22.3. Dipeptide MeO-Oxazole-Leu-NHBoc

Dipeptide MeO-Oxazole-Leu-NHBoc was synthesized following the “General oxazole synthesis” procedure utilizing 0.902 g (2.70 mmol) of dipeptide MeO-Ser-Leu-NHBoc, 0.390 mL (2.97 mmol) of DAST, 746 mg (5.40 mmol) of K2CO3, in 40 mL of methylene chloride. The intermediate was oxidized into product by using 0.810 mL of DBU (5.40 mmol), 0.53 mL of CBrCl3 (5.40 mmol), in 14 mL of methylene chloride. This dipeptide was taken on to the next reaction without further purification. (649 mg, 77% yield). Rf: 0.55 (EtOAc: Hex 1:1). Physical and spectroscopic data are consistent with those reported in the literature.48

6.22.4. Dipeptide MeO-Oxazole-Leu-NH2 (42)

Dipeptide MeO-Oxazole-Leu-NH2 was synthesized following the “General solution-phase amine deprotection”. This dipeptide was taken on to the next reaction without further purification or characterization (210 mg, 100% yield).

6.22.5. Dipeptide MeO-Phe-Leu-NHBoc

Dipeptide MeO-Phe-Leu-NHBoc was synthesized following the “General soltuion-phase peptide synthesis” procedure utilizing 850 mg (4.76 mmol) of amine MeO-Phe-NH2 (35), 1.00 g (4.32 mmol) of acid HO-Leu-NHBoc (34), 2.90 mL (17.3 mmol) of DIPEA, 1.66 g (5.18 mmol) of TBTU, in 43.0 mL of methylene chloride. This dipeptide was taken on to the next reaction without further purification (1.64 g, 97% yield). Rf: 0.85 (EtOAc: Hex 1:1). Physical and spectroscopic data are consistent with those reported in the literature.48

6.22.6. Dipeptide HO-Phe-Leu-NHBoc (36)

Dipeptide HO-Leu-D-Leu-NHBoc was synthesized following the “General solution-phase acid deprotection”. This tripeptide was taken on to the next reaction without further purification or characterization (1.40 g, 85% yield).

6.22.7. Tripeptide MeO-Leu-Phe-Leu-NHBoc

Tripeptide MeO-Leu-Phe-Leu-NHBoc was synthesized following the “General solution-phase peptide synthesis” procedure utilizing 757 mg (2.00 mmol) of acid HO-Phe-Leu-NHBoc, 320 mg (2.20 mmol) of amine MeO-Leu-NH2 (37), 1.40 mL (8.00 mmol) of DIPEA, 706 mg (2.40 mmol) of TBTU, in 20 mL of methylene chloride. The crude reaction was purified by column chromatography (silica gel, EtOAc/Hex) to yield the tripeptide (890 mg, 88% yield). Rf: 0.55 (EtOAc: Hex 1:1); Physical and spectroscopic data are consistent with those reported in the literature.49

6.22.8. Tripeptide HO-Leu-Phe-Leu-NHBoc (38)

Dipeptide HO-Leu-D-Leu-NHBoc was synthesized following the “General solution-phase acid deprotection”. This tripeptide was taken on to the next reaction without further purification or characterization (709 mg, 82% yield).

6.22.9. Pentapeptide MeO-Oxazole-Leu-Leu-Phe-Leu-NHBoc (43)

Pentapeptide MeO-Oxazole-Leu-Leu-Phe-Leu-NHBoc was synthesized following the “General solution-phase peptide synthesis” procedure utilizing 469 mg (0.952 mmol) of acid HO-Leu-Phe-Leu-NHBoc (38), 223 mg (1.05 mmol) of amine MeO-Oxazole-Leu-NH2 (42), 0.700 mL (3.81 mmol) of DIPEA, 366 mg (1.08 mmol) of TBTU, in 11.0 mL of methylene chloride. The crude reaction was purified by column chromatography (silica gel, EtOAc/Hex) to yield the pentapeptide (468 mg, 72% yield). Rf: 0.35 (EtOAc: Hex 1:1); 1H NMR (400 MHz, CDCl3): δ 0.70–0.97 (18 H, m, CHCH3), 1.40 (9 H, s, CCH3), 1.47–1.68 (9 H, m, CHCH3, CH2-CH), 2.98–3.24 (2 H, m, CH2O), 3.84 (3 H, s, OCH3), 4.50–4.78 (2 H, m, αCH), 4.96–5.02 (1 H, m, αCH), 5.17–5.31 (1 H, m, αCH), 7.07–7.28 (5 H, m, Ph), 8.09 (1 H, s, OCH=C).

6.22.10. Macrocycle Phe-Leu-Oxazole-Leu-Leu (3)

Macrocycle Phe-Leu-Oxazole-Leu-Leu was synthesized following the “Macrocyclization procedure” utilizing 349 mg (0.611 mmol) of linear pentapeptide (43), 1.10 mL (6.11 mmol) of DIPEA, 138 mg (0.431 mmol) of TBTU, 141 mg (0.375 mmol) of HATU, and 129 mg (0.432 mmol) of DEPBT, in 9.20 mL methylene chloride and 9.00 mL acetonitrile. The crude reaction was purified by reverse phase-HPLC to yield the macrocycle (1.3 mg, 0.4% yield). Rf: 0.21 (EtOAc: Hex 1:1); 1H NMR (600 MHz, CD3OD): δ 0.69–0.96 (18 H, m, CHCH3), 1.18–1.65 (9 H, m, CHCH3, CH2CH), 2.97–3.27 (2 H, m, CH2O), 3.52–3.77 (2 H, m, αCH), 4.03–4.19 (1 H, m, αCH), 4.38–4.57 (1 H, m, αCH), 6.63 (1 H, br s, NH), 7.03 (1 H, br s, NH), 7.17–7.23 (5 H, m, Ph), 7.79 (1 H, s, OCH=C). LCMS: m/z calcd for C30H43N5O5 (M+1) = 554.6, found 554.3; HRMS (ESI-TOF): MH+, found 554.3313, requires 554.3337. >90% pure by HPLC.

6.23. Synthesis of Compound 4 (B-Ox-III)

6.23.1. Dipeptide MeO-Phe-Leu-NHBoc

Dipeptide MeO-Phe-Leu-NHBoc was synthesized following the “General solution-phase peptide synthesis” procedure. Utilizing 850 mg (4.80 mmol) of amine MeO-Phe-NH2, 1.00 g (4.30 mmol) of acid HO-Leu-NHBoc, 2.90 mL (17.2 mmol) of DIPEA, 1.66 g (5.20 mmol) of TBTU, in 43.2 mL of methylene chloride. The crude reaction was purified by column chromatography (silica gel, EtOAc/Hex) to yield the dipeptide (1.64 g, 97% yield). Rf: 0.3 (EtOAc: Hex 1:3); 1H NMR (400 MHz, CDCl3): δ 0.78–0.84 (6 H, m, CH(CH3)2), 1.33 (9 H, s, C(CH3)3), 1.35–1.40 (1 H, m, CH(CH3)2), 1.45–1.60 (2 H, m, βCH2), 2.90–3.05 (2 H, m, βCH2), 3.59 (3 H, s, OCH3), 4.00–4.10 (1 H, br, αCH), 4.70–4.78 (1 H, m, αCH), 5.25–5.35 (1 H, br, NH), 6.86–6.96 (1 H, d, J 7.8 Hz, NH), 7.00–7.20 (5 H, m, Ph).

6.23.2. Dipeptide HO-Phe-Leu-NHBoc

Dipeptide HO-Phe-Leu-NHBoc was synthesized following the “General solution-phase acid deprotection”. This Dipeptide was taken on to the next reaction without further purification or characterization. (1.35 g, 85% yield).

6.23.3. Tripeptide MeO-Leu-N(Me)-Phe-Leu-NHBoc

Tripeptide MeO-Leu-N(Me)-Phe-Leu-NHBoc was synthesized following the “General solution-phase peptide synthesis” procedure. Utilizing 338 mg (2.10 mmol) of amine MeO-Leu-N(Me)H, 731 mg (1.90 mmol) of acid HO-Phe-Leu-NHBoc, 1.35 mL (5.70 mmol) of DIPEA, 744 mg (2.30 mmol) of TBTU, in 19.3 mL of Methylene Chloride. The crude reaction was purified by column chromatography (silica gel, EtOAc/Hex) to yield the tripeptide (602 mg, 60% yield). Rf: 0.22 (EtOAc: Hex 1:1); 1H NMR (400 MHz, CDCl3): δ 0.84–0.98 (12 H, m, CH(CH3)2), 1.34–1.42 (2 H, m, CH(CH3)2), 1.47 (9 H, s, C(CH3)3), 1.54–1.75 (4 H, m, βCH2), 2.80 (3 H, s, NCH3), 2.94–3.20 (2 H, m, βCH2), 3.68 (3 H, s, OCH3), 4.05–4.15 (1 H, br, NH), 4.76–4.84 (1 H, br, NH), 4.84–4.88 (1 H, m, αCH), 5.10–5.20 (1 H, m, αCH), 5.25–5.32 (1 H, m, αCH), 7.10–7.33 (5 H, m, Ph).

6.23.4. Tripeptide HO-Leu-N(Me)-Phe-Leu-NHBoc

Tripeptide HO-Leu-N(Me)-Phe-Leu-NHBoc was synthesized following the “General solution-phase acid deprotection”. This tripeptide was taken on to the next reaction without further purification or characterization. (470mg, 80% yield).

6.23.5. Dipeptide MeO-Ser(Bzl)-Leu-NHBoc

Dipeptide MeO-Ser(Bzl)-Leu-NHBoc was synthesized following the “General solution-phase peptide synthesis” procedure. Utilizing 756 mg (3.40 mmol) of amine MeO-Ser(Bzl)-NH2, 713 mg (3.10 mmol) of acid HO-Leu-NHBoc, 2.10 mL (12.4 mmol) of DIPEA, 1.19 g (3.70 mmol) of TBTU, in 30.8 mL of methylene chloride. The crude reaction was purified by column chromatography (silica gel, EtOAc/Hex) to yield the dipeptide (1.31 g, 97 % yield). Rf: 0.76 (EtOAc: Hex 1:1); 1H NMR (400 MHz, CDCl3): δ 0.95–0.96 (3 H, d, J 3.5 Hz, CHCH3)2), 0.96–0.97 (3 H, d, J 3.5 Hz, CHCH3)2), 1.43 (9 H, s, C(CH3)2), 1.61–1.63 (1 H, m, CH(CH3)2), 1.63–1.78 (2 H, m, βCH2), 3.66–3.70 (1 H, dd, J 6.9, 1.5 Hz, βCH), 3.75 (3 H, s, OCH3), 3.88–3.92 (1 H, dd, J 7.1, 1.5 Hz, βCH), 4.14–4.21 (1 H, br, αCH), 4.46–4.59 (2 H, CH2OBn), 4.72–4.76 (1 H, m, αCH), 4.84–4.91 (1 H, br, NH), 6.76–6.80 (1 H, br, NH), 7.26–7.40 (5 H, m, Ph).

6.23.6. Dipeptide MeO-Ser-Leu-NHBoc

Dipeptide MeO-Ser-Leu-NHBoc was synthesized by dissolving 1.28 g (3.03 mmol) of dipeptide MeO-Ser(Bzl)-Leu-NHBoc in 30.0 mL EtOH (0.1 M). The reaction mixture was hydrogenated using a catalytic amount of Pd/C and excess H2 for 24 h. The reaction was filtered over Celite to yield pure dipeptide (900 mg, 89% yield). Rf: 0.28 (EtOAc: Hex 1:1).

6.23.7. Dipeptide MeO-Oxazole-Leu-NHBoc

Dipeptide MeO-Oxazole-Leu-NHBoc was synthesized following the “General oxazole synthesis” procedure. The oxazoline intermediate was synthesized utilizing 900 mg (2.72 mmol) of dipeptide MeO-Ser-Leu-NHBoc, 0.390 mL (2.97 mmol) of DAST, 746 mg (5.40 mmol) of K2CO3 in 40.0 mL of methylene chloride. The resulting oxazoline was oxidized utilizing 0.810 mL (5.40 mmol) of DBU, 0.530 mL (5.40 mmol) of CBrCl3 in 40.0 mL of methylene chloride. The crude reaction was purified by column chromatography (silica gel, EtOAc/Hex) to yield the desired peptidyl-oxazole (649 mg,77 % yield over 2 steps). Rf: 0.5 (EtOAc: Hex 7:13); 1H NMR (400 MHz, CDCl3): δ 0.94–0.96 (3 H, d, J 3.5 Hz, CHCH3), 0.96–0.98 (3 H, d, J 3.5 Hz, CHCH3), 1.43 (9 H, s, C(CH3)3), 1.58–1.64 (1 H, m, CH(CH3)2), 1.64–1.80 (2 H, m, βCH2), 3.93 (3 H, s, OCH3), 4.94–5.04 (1 H, br, αCH), 5.04–5.10 (1 H, br, NH), 8.18 (1 H, s, OCH=C).

6.23.8. Dipeptide MeO-Oxazole-Leu-NH2

Dipeptide MeO-Oxazole-Leu-NH2 was synthesized following the “General solution-phase amine deprotection”. This dipeptide was taken on to the next reaction without further purification or characterization. (212 mg, 100% yield).

6.23.9. Pentapeptide MeO-Oxazole-Leu-Leu-N(Me)-Phe-Leu-NHBoc

Pentapeptide MeO-Oxazole-Leu-Leu-N(Me)-Phe-Leu-NHBoc was synthesized following the “General solution-phase peptide synthesis” procedure. Utilizing 210 mg (0.990 mmol) of amine MeO-Oxazole-Leu-NH2, 470 mg (0.930 mmol) of acid HO-Leu-N(Me)-Phe-Leu-NHBoc, 0.650 mL (3.72 mmol) of DIPEA, 353 mg (1.10 mmol) of TBTU, in 10.0 mL of methylene chloride. The crude reaction was purified by column chromatography (silica gel, EtOAc/Hex) to yield the pentapeptide (281 mg, 43 % yield). Rf: 0.47 (EtOAc: Hex 1:1); 1H NMR (400 MHz, CDCl3): δ 0.80–1.02 (18 H, m, CH(CH3)2), 1.22–1.57 (6 H, m, βCH2), 1.35–1.44 (9 H, m, C(CH3)3), 1.57–1.73 (2 H, m, CH(CH3)2), 1.73–1.94 (1 H, m, CH(CH3)2), 2.69 (3 H, m, NCH3), 2.84–3.23 (2 H, m, βCH2), 3.91 (3 H, m, OCH3), 4.04–4.15 (2 H, br, NH), 4.60–4.70 (1 H, br, NH), 4.78–4.96 (2 H, m, αCH), 5.14–5.28 (1 H, m, αCH), 5.28–5.38 (1 H, m, αCH), 7.08–7.30 (5 H, m, Ph), 8.08–8.20 (1 H, m, OCH=C). LCMS: m/z calcd for C37H57N5O8 (M+1) = 699.88, found 699.8

6.23.10. Macrocycle Phe-Leu-Oxazole-Leu-Leu-N(Me) (4)

Macrocycle Phe-Leu-Oxazole-Leu-Leu-N(Me) (4) was synthesized following the “Macrocyclization procedure”. Utilizing 281 mg (0.400 mmol) of linear pentapeptide, 0.420 mL (2.4 mmol) of DIPEA, 90.0 mg (0.280 mmol) of TBTU, 107 mg (0.280 mmol) HATU, and 83.8 mg (0.280 mmol) of DEPBT in 571 mL Methylene Chloride. The crude reaction was purified by column chromatography (silica gel, EtOAc/Hex) and reverse phase-HPLC to yield the macrocycle (17.3 mg, 6.4% yield). Rf: 0.42 (EtOAc: Hex 1:1) 1H NMR (400 MHz, CDCl3): δ 0.75–0.80 (3 H, d, J 3.5 Hz, CH(CH3)2), 0.84–0.89 (3 H, d, J 3.5Hz, CH(CH3)2), 0.90–1.00 (21 H, bur m, C(CH3)3 & CH(CH3)2), 1.08–1.20 (1 H, m, CH(CH3)2), 1.43–1.50 (2 H, m, CH(CH3)2), 1.50–1.64 (2 H, m, βCH2), 1.65–1.80 (4 H, m, βCH2), 2.56–2.66 (3 H, m, NCH3), 2.98–3.15 (2 H, m, βCH2), 4.15–4.45 (3 H, br, NH & 2αCH), 4.88–4.98 (1 H, br, NH), 4.99–5.10 (2 H, m, αCH Leu-Ox & αCH Phe), 6.93–7.03 (1H, m, Ph), 7.33–7.38 (4 H, m, Ph), 8.15 (1 H, s, OCH=C). LCMS: m/z calcd for C31H45N5O5 (M) = 567.72, found 567.8; HRMS (ESI-TOF): MH+, found 568.3520, C31H45N5O5 requires 568.3493. >90% pure by HPLC.

6.24. Synthesis of Compound 5 (C-Ox-III)

6.24.1 Dipeptide MeO-Lys(Cbz)-Phe-NHBoc

Dipeptide MeO-Lys(Cbz)-Phe-NHBoc was synthesized following the “General solution-phase peptide synthesis” procedure. Utilizing 294 mg (1.00 mmol) of amine MeO-Lys(Cbz)-NH2, 241 mg (0.910 mmol) of acid HO-Phe-NHBoc, 1.30 mL (7.28 mmol) of DIPEA, 235 mg (0.730 mmol) of TBTU, 209 mg (0.550 mmol) of HATU, in 9.00 mL of methylene chloride. The crude reaction was purified by column chromatography (silica gel, EtOAc/Hex) to yield the dipeptide (380 mg, 77% yield). Rf: 0.37 (EtOAc: Hex 1:1) 1H NMR (400 MHz, CDCl3): δ 1.11–1.49 (2 H, m, γCH2 Lys), 1.30–1.36 (9 H, s, C(CH3)3), 1.36–1.64 (2 H, m, δCH2 Lys), 1.51–1.81 (2 H, m, βCH2 Lys), 2.93–3.03 (2 H, m, εCH2 Lys), 3.03–3.16 (2 H, m, βCH2), 3.60–3.65 (3 H, s, OCH3), 4.21–4.35 (1 H, m, αCH), 4.42–4.52 (1 H, m, αCH), 4.85–4.93 (1 H, br, NH), 5.00–5.05 (2 H, s, CH2Ph), 6.39–6.47 (1 H, br, NH), 7.08–7.32 (10H, m, Ph).

6.24.2. Dipeptide MeO-Lys-Cbz-Phe-NH2

Dipeptide MeO-Lys(Cbz)-Phe-NH2 was synthesized following the “General solution-phase amine deprotection”. This dipeptide was taken on to the next reaction without further purification or characterization. (309mg, 100% yield).

6.24.3. Tripeptide MeO-Lys(Cbz)-Phe-D-Phe-N(Me)Boc

Tripeptide MeO-Lys(Cbz)-Phe-D-Phe-N(Me)Boc was synthesized following the “General solution-phase peptide synthesis” procedure. Utilizing 309 mg (0.700 mmol) of amine MeO-Lys(Cbz)-Phe-NH2, 215 mg (0.770 mmol) of acid HO-D-Phe-N(Me)Boc, 0.980 mL (4.9 mmol) of DIPEA, 180 mg (0.560 mmol) of TBTU, 133 mg (0.350 mmol) of HATU, in 7.00 mL of methylene chloride. The crude reaction was purified by column chromatography (silica gel, EtOAc/Hex) to yield the tripeptide (454 mg, 93% yield). Rf: 0.38 (EtOAc: Hex 7:13); 1H NMR (400 MHz, CDCl3): δ 1.10–1.22 (2 H, m, γCH2 Lys), 1.22–1.30 (9 H, s, C(CH3)3), 1.35–1.48 (2 H, m, δCH2 Lys), 1.51–1.83 (2 H, m, βCH2 Lys), 2.51–2.73 (3H, s, NCH3), 2.82–3.02 (2 H, m, βCH2), 3.02–3.15 (2 H, m, CH2ε Lys), 3.16–3.34 (2 H, m, βCH2), 3.59–3.70 (3 H, s, OCH3), 4.34–4.46 (1 H, br, αCH), 4.47–4.68 (2 H, m, 2αCH), 4.98–5.08 (2 H, s, CH2Ph), 6.22–6.61 (2 H, br-m, NH), 6.98–7.34 (15H, m, Ph).

6.24.4. Tripeptide HO-Lys(Cbz)-Phe-D-Phe-N(Me)Boc

Tripeptide HO-Lys(Cbz)-Phe-D-Phe-N(Me)Boc was synthesized following the “General solution-phase acid deprotection”. This tripeptide was taken on to the next reaction without further purification or characterization. (448mg, 100% yield).

6.24.5. Dipeptide MeO-Ser(Bzl)-Leu-NHBoc

Dipeptide MeO-Ser(Bzl)-Leu-NHBoc was synthesized following the “General solution-phase peptide synthesis” procedure. Utilizing 383 mg (1.83 mmol) of amine MeO-Ser(Bzl)-NH2, 414 mg (1.66 mmol) of acid HO-Leu-NHBoc, 1.20 mL (6.64 mmol) of DIPEA, 588 mg (1.83 mmol) of TBTU, in 17.0 mL of methylene chloride. The crude reaction was purified by column chromatography (silica gel, EtOAc/Hex) to yield the dipeptide (701 mg, 100 % yield). Rf: 0.76 (EtOAc: Hex 1:1). 1H NMR (400 MHz, CDCl3): δ 0.95–0.96 (3 H, d, J 3.5 Hz, CHCH3), 0.96–0.97 (3 H, d, J 3.5 Hz, CHCH3), 1.42–1.46 (9 H, s, C(CH3)3), 1.61–1.63 (1 H, m, CH(CH3)2), 1.63–1.78 (2 H, m, βCH2), 3.66–3.70 (1 H, dd, J 7.2, 1.5 Hz, βCH Ser), 3.73–3.76 (3 H, s, OCH3), 3.88–3.92 (1 H, dd, J 7.9 1.5 Hz, βCH), 4.14–4.21 (1 H, br, αCH), 4.46–4.59 (2 H, m, CH2OBn), 4.72–4.76 (1 H, m, αCH), 4.84–4.91 (1 H, br, NH), 6.76–6.80 (1 H, br, NH), 7.26–7.40 (5 H, m, Ph).

6.24.6. Dipeptide MeO-Ser-Leu-NHBoc

Dipeptide MeO-Ser-Leu-NHBoc was synthesized by dissolving 701 mg (1.66 mmol) of dipeptide MeO-Ser(Bzl)-Leu-NHBoc in 4.00 mL EtOH (0.48 M). The reaction mixture was hydrogenated using a catalytic amount of Pd/C and excess H2 for 24 h. The reaction was filtered over Celite to yield pure dipeptide (521 mg, 95 % yield). Rf: 0.28 (EtOAc: Hex 1:1).

6.24.7. Dipeptide MeO-Oxazole-Leu-NHBoc

Dipeptide MeO-Oxazole-Leu-NHBoc was synthesized following the “General oxazole synthesis” procedure. The oxazoline intermediate was synthesized utilizing 421 mg (1.27 mmol) of dipeptide MeO-Ser-Leu-NHBoc, 0.170 mL (1.40 mmol) of DAST, 351 mg (2.54 mmol) of K2CO3 in 12.7 mL of methylene chloride. The resulting oxazoline was oxidized utilizing 0.380 mL (2.54 mmol) of DBU, 0.250 mL (2.54 mmol) of CBrCl3 in 12.7 mL of methylene chloride. The crude reaction was purified by column chromatography (silica gel, EtOAc/Hex) to yield the desired peptidyl-oxazole (298 mg, 76% yield over 2 steps). Rf: 0.5 (EtOAc: Hex 7:13); 1H NMR (400 MHz, CDCl3): δ 0.94–0.96 (3 H, d, J 3.5 Hz, CHCH3), 0.96–0.98 (3 H, d, J 3.5 Hz, CHCH3), 1.42–1.46 (9 H, s, C(CH3)3), 1.58–1.64 (1 H, m, CH(CH3)2), 1.64–1.80 (2 H, m, βCH2), 3.93 (3 H, s, OCH3), 4.94–5.04 (1 H, br, αCH), 5.04–5.10 (1 H, br, NH), 8.18 (1 H, s, OCH=C).

6.24.8. Dipeptide MeO-Oxazole-Leu-NH2

Dipeptide MeO-Oxazole-Leu-NH2 was synthesized following the “General solution-phase amine deprotection”. This dipeptide was taken on to the next reaction without further purification or characterization. (202 mg, 100% yield).

6.24.9. Pentapeptide MeO-Oxazole-Leu-Lys(Cbz)-Phe-D-Phe-N(Me)Boc

Pentapeptide MeO-Oxazole-Leu-Lys(Cbz)-Phe-D-Phe-N(Me)Boc was synthesized following the “General solution-phase peptide synthesis” procedure. Utilizing 152 mg (0.720 mmol) of amine MeO-Oxazole-Leu-NH2, 447 mg (0.650 mmol) of acid HO-Lys(Cbz)-Phe-D-Phe-N(Me)Boc, 0.910 mL (5.2 mmol) of DIPEA, 167 mg (0.520 mmol) of TBTU, 148 mg (0.390 mmol) of HATU in 7.00 mL of methylene chloride. The crude reaction was purified by column chromatography (silica gel, EtOAc/Hex) to yield the pentapeptide (274 mg, 48% yield). Rf: 0.2 (EtOAc: Hex 1:1) 1H NMR (400 MHz, CDCl3): δ 0.78–0.92 (6 H, m, CH(CH3)2), 1.10–1.31 (2 H, m, γCH2 Lys), 1.23–1.27 (9 H, s, C(CH3)3), 1.33–1.48 (2 H, m, δCH2 Lys), 1.48–1.60 (2 H, m, βCH2 Lys), 1.64–1.87 (3 H, m, CH(CH3)2, CH2β Leu), 2.35 (3H, m, NCH3), 2.85–3.05 (2 H, m, βCH2), 3.05–3.19 (2 H, m, εCH2 Lys), 3.19–3.32 (2 H, m, βCH2), 3.75 (3 H, s, OCH3), 4.21–4.43 (1 H, br, αCH), 4.33–4.55 (1 H, br, αCH), 4.46–4.70 (1 H, m, αCH), 4.95–5.06 (2 H, m, CH2Ph), 5.06–5.26 (2 H, m, αCH, NH), 6.28–6.78 (2 H, m, NH), 6.91–7.44 (15H, m, Ph), 8.09 (1 H, s, OCH=C). LCMS: m/z calcd for C48H62N6O10 (M) = 883.04, found 883

6.24.10. Macrocycle Phe-D-Phe-N(Me)-Oxazole-Leu-Lys(Cbz) (5)

Macrocycle Phe-D-Phe-N(Me)-Oxazole-Leu-Lys(Cbz) (5) was synthesized following the “Macrocyclization procedure”. Utilizing 238 mg (0.310 mmol) of linear pentapeptide, 0.430 mL (2.48 mmol) of DIPEA, 80.0 mg (0.250 mmol) of TBTU, 95.0 mg (0.250 mmol) HATU, and 75.0 mg (0.250 mmol) of DEPBT in 44.3 mL methylene chloride. The crude reaction was purified by column chromatography (silica gel, EtOAc/Hex) and reverse phase-HPLC to yield the macrocycle (19.8 mg, 8.5% yield). Rf: 0.18 (EtOAc: Hex 1:1); 1H NMR (400 MHz, CDCl3): δ 0.82–0.88 (3 H, d, J 15.7 Hz, CH(CH3)2), 0.89–0.94 (3 H, d, J 15.7 Hz, CH(CH3)2), 1.03–1.19 (2 H, br, γCH2 Lys), 1.33–1.58 (2 H, m, δCH2 Lys), 1.58–1.70 (2 H, m, βCH2 Lys), 1.86–2.03 (2 H, m, βCH2), 2.17–2.33 (1 H, m, CH(CH3)2), 2.62–2.67 (3H, s, NCH3), 2.82–3.21 (2 H, m, βCH2), 3.01–3.11 (2 H, m, εCH2 Lys), 3.35–3.44 (1 H, dd, J 8.85, 2.92 Hz, CHaHbβ Phe), 3.46–3.56 (1 H, br, αCH), 4.58–4.65 (1 H, dd, J 8.85, 2.94 Hz, βCHaHb Phe), 4.65–4.78 (2 H, m, 2αCH), 5.01–5.06 (2 H, m, CH2Ph), 5.14–5.24 (1 H, m, αCH), 6.76–6.93 (3 H, m, NH), 7.07–7.33 (15H, m, Ph), 8.00–8.08 (1 H, s, OCH=C). LCMS: m/z calcd for C42H50N6O7 (M) = 750.88, found 751; HRMS (ESI-TOF): MH+, found 751.3821, C42H50N6O7 requires 751.3814. >95% pure by HPLC.

6.25. Synthesis of Compound 6 (D-Ox-III)

6.25.1. Dipeptide NH2-(2R,3R)/(2S,3S)-β-OH-Phe-D-Phe-O-Resin

A mixture of NH2-D-Phe-O-Resin (2.00 g, 1.44 mmol), (2R,3R)/(2S,3S)-racemic Fmoc-β-OH-Phe-OH (1.74 g, 4.32 mmol), HOBt (661 mg, 4.32 mmol) and DIC (1.34 mL, 8.64 mmol) were stirred at room temperature for 3 h following the “General solid-phase peptide synthesis” procedure. Completion of the coupling reaction was verified by a negative ninhydrin test. The reaction mixture was then drained to leave the amine-protected resin-bound dipeptide. Deprotection of amine was performed following the “General solid-phase amine deprotection” procedure. A positive ninhydrin test served to verify Fmoc removal and gave the title compound.

6.25.2. Tripeptide Boc-Leu-(2R,3R)/(2S,3S)-β-OH-Phe-D-Phe-OH

A mixture of NH2-(2R,3R)/(2S,3S)-β-OH-D-Phe-O-Resin (1.44 mmol), Boc-Leu-OH residue (1.00 g, 4.32 mmol), HOBt (661 mg, 4.32 mmol) and DIC (1.34 mL, 8.64 mmol) were stirred at room temperature for 3 h following the “General solid-phase peptide synthesis” procedure. Completion of the coupling reaction was verified by a negative ninhydrin test. The reaction mixture was then drained and dried in vacuo overnight to leave the amine-protected resin-bound tripeptide. The tripeptide was cleaved from the resin following the “Cleavage of linear peptide from solid support” procedure. A resin slurry of Boc-Leu-(2R,3R)/(2S,3S)-β-OH-Phe-D-Phe-O-Resin (2.50 g), 2,2,2-trifluoroethanol (12.5 mL) and of methylene chloride (12.5) was stirred for 24 h, after which it was filtered, washed with additional methylene chloride, and dried in vacuo for 24 h. (596 mg, 76% yield).

6.25.3. Dipeptide MeO-Ser(Bzl)-D-Leu-NHBoc

A mixture of amine MeO-Ser(Bzl)-NH2 (709 mg, 3.39 mmol), acid HO-D-Leu-NHBoc (767 mg, 3.08 mmol), DIPEA (4.30 mL, 2.46 mmol), TBTU (1.19 g, 3.94 mmol) in methylene chloride (30.8 mL) was stirred at room temperature under an argon atmosphere for 2.5 h following the “General solution-phase peptide synthesis” procedure. The crude reaction was purified by column chromatography (20% EtOAc/Hex) to yield the title compound (1.24 g, 96% yield). Rf: 0.78 (50% EtOAc/Hex); 1H NMR (200 MHz, CDCl3): δ 0.9–0.95 (6 H, m, CH(CH3)2), 1.43 (9 H, s, C(CH3)3), 1.63–1.73 (2 H, m, CHCH2CH), 3.65–3.70 (1 H, dd, J 2.8, 8.9 Hz, OCHaHb), 3.73 (3 H, s, OCH3), 3.86–3.91 (1 H, dd, J 3.0, 9.0 Hz, OCHaHb), 4.18–4.26 (1 H, br, αCH), 4.45–4.54 (2 H, q, J 11.9 Hz, CH2Ph), 4.70–4.75 (1 H, m, αCH), 4.95–5.07 (1 H, br, NH), 7.01 (1 H, br, NH), 7.23–7.36 (5 H, m, Ph).

6.25.4. Dipeptide MeO-Ser-D-Leu-NHBoc

A mixture of dipeptide MeO-Ser(Bzl)-D-Leu-NHBoc (1.24 g, 2.94 mmol) and a catalytic amount of Pd/C in ethanol (29.4 mL) was stirred under a hydrogen atmosphere for 24 h. Upon completion, confirmed by TLC, the reaction mixture was filtered over Celite to yield the title compound (839 mg, 86% yield). Rf: 0.44 (50% EtOAc/Hex); Physical and spectroscopic data are consistent with those reported in the literature.50

6.25.5. Dipeptide MeO-Oxazole-D-Leu-NHBoc

Dipeptide MeO-Oxazole-D-Leu-NHBoc was synthesized following the “General oxazole synthesis” procedure. The oxazoline intermediate was synthesized utilizing dipeptide MeO-Ser-D-Leu-NHBoc (819 mg, 2.46 mmol), DAST (357 µL, 2.71 mmol), K2CO3 (664 mg, 4.92 mmol) in methylene chloride (24.6 mL). The resulting oxazoline was oxidized utilizing DBU (746 µL, 4.92 mmol), CBrCl3 (489 µL, 4.92 mmol) in methylene chloride (12.3 mL). The crude reaction was purified by column chromatography (40% EtOAc/Hex) to yield the desired title compound (516 mg, 70% yield over 2 steps). Rf: 0.80 (50% EtOAc/Hex); 1H NMR (200 MHz, CDCl3): δ 0.86 (3 H, d, J 1.6 Hz, CHCH3), 0.87 (3 H, d, J 1.8 Hz, CHCH3), 1.35 (9 H, s, C(CH3)3), 1.53–1.61 (1 H, m, CH(CH3)2), 1.63–1.71 (2 H, m, CHCH2CH), 3.83 (3 H, s, OCH3), 4.87–4.95 (1 H, br, αCH), 5.08–5.14 (1 H, br, NH), 8.11 (1 H, s, CCHO).

6.25.6. Dipeptide MeO-Oxazole-D-Leu-NH2

A mixture of peptidyl MeO-Oxazole-D-Leu-NHBoc (516 mg, 1.65 mmol) in TFA (3.30 mL) and methylene chloride (13.2 mL) was stirred at room temperature under open atmosphere for 30 min following the “General solution-phase amine deprotection.” Reaction completion was confirmed by TLC and the mixture was concentrated in vacuo with several washes with methylene chloride. This dipeptide was taken on to the next reaction without further purification or characterization. (350 mg, quantitative yield).

6.25.7. Pentapeptide MeO-Oxazole-D-Leu-D-Phe-(2R,3R)/(2S,3S)-β-OH-Leu-NHBoc