Highlights

► Reproducibility and stability measurements of organic field effect transistors (OFET). ► Biased stress stability of n-type OFET. ► The role of reproducibility and stability in organic electronic circuit. ► Providing well defined limits for the modelling of circuit design.

Keywords: Reproducibility and stability of OFET, C60, n-Type OFET, Long time measurement

Abstract

A comprehensive study concerning the reproducibility and stability of organic n-type field effect transistors is presented. C60 based OFETs were chosen to investigate the fabrication reproducibility and the long term stability because C60 is a high mobility n-type material. We fabricated 48 transistors and each transistor was measured for 24 h inside the glove box. To test for life time stability – long term measurements up to three months have been undertaken. We report about the fluctuations in the device parameters of all investigated transistors by comparing the transfer characteristics, and on/off ratio for short time and long time measurements. C60 based OFETs showed good reproducibility and stability for short time measurements and a decay for long time measurements.

1. Introduction

In the last two decades intensive research has been devoted to organic electronic devices due to their potential applications and significant advantages, such as flexibility, low cost and large area processing [1–4]. The technological success of organic electronic devices, especially organic field effect transistor (OFET), is closely linked to improve their charge carrier mobility. However, for industrial application the reproducibility and stability of OFETs is also a critical issue along with high charge carrier mobility. Intensive research has been done to find high charge carrier mobility organic semiconductors [5,6], but very little efforts were made to measure and to improve the reproducibility and stability of organic electronic devices. Some endeavours were made to measure and improve the environmental stability of p-type organic semiconductors [7–11]. However, n-type organic semiconductors are still waiting for considerable attention to measure and improve their environmental and stress stability [12]. The stability of p-type OFETs was tested with flowing water [13] while the contacts were protected by hydrophobic films. It was found that OFETs are stable under water even when carrying currents. The stability of OFETs based on spiro-linked [14] compounds showed no significant change in the transistor characteristics up to nine months. Solution processed OFETs [15], had stable electrical characteristics under multiple scans up to 1 h.

Models of devices for circuit design and simulation are mostly so-called hybrid models. This means that they are based on equations which describe the physics of the device as detailed as possible enhanced with some fitting parameters to adjust the “physics” to measurements. This modelling process is however only possible if the device itself is reproducible, within certain upper and lower limits. In modern bulk silicon processes it is a common issue to define upper and lower limits. For the design of a robust circuit this corner parameter sets for the different devices are used, to guarantee that the design meets the desired requirements for all temperatures and process variations. So for a correctly operating circuit design it is necessary that all used devices work within well defined ranges.

Consequently, we focus in this contribution on a comprehensive study concerning the reproducibility and continuous bias stress stability of OFETs to find the upper and lower limits of operation. We choose C60 based OFETs to measure the reproducibility and stability of OFET. C60 is a high mobility n-type material and we are working with this material for a long time [16,17]. The fluctuations in the device parameters of all 48 fabricated transistors were investigated. We compared the transfer characteristics, on/off ratio of all transistors for short time and long time measurements and found that C60 based OFETs show excellent reproducibility and stability.

2. Experimental setup

For the fabrication of C60 based OFETs the 70 nm thick and 0.5 mm wide aluminium gate electrode was evaporated on glass slides by using a shadow mask. Before the evaporation of aluminium, the glass slides were cleaned using acetone, Helmanex glass cleaning solution, de-ionized H2O in an ultrasonic bath and finally dried with a flow of N2. Benzocyclobutene (BCB) was used as a gate dielectric. BCB purchased from Dow Chemicals, was spin coated onto the patterned aluminium glass substrate and cured at 250 °C for 2 h in a vacuum oven. C60, purified by sublimation, was used as received from MER Corp. After curing the BCB, a 250 nm thick film of C60 was grown by hot wall epitaxy at a substrate temperature Tsub = 140 °C, source temperature Ts = 360 °C and wall temperature Twall = 400 °C with a back ground pressure of 10−6 mbar. The top contact electrodes consisting of LiF/Al 0.5 nm and 70 nm thick respectively were evaporated under high vacuum of 10−6 mbar, using a shadow mask. The schematic structure of the samples consisting of four OFETs is shown in Fig. 1. The channel length L and width W in the OFETs were 70 μm and 1.5 mm, respectively. Device transportation from the hot-wall reactor to the glove box for top-contact evaporation was carried out under ambient conditions. More detail about the experimental procedure and fabrication can be found elsewhere [17]. In an analogue way we fabricated twelve samples containing four OFETs, and each transistor was measured for 24 h inside the glove box where the level of oxygen was maintained below 0.5 ppm. We also extend our investigations to long time measurement up to three months. All measurements were carried out at room temperature under N2 atmosphere inside a glove box, to avoid exposure to ambient humidity and oxygen. For applying the gate voltage and measuring the leakage current a Keithley 6487 Pico-Ampere meter with included voltage source has been used whereas the source-drain voltage characteristic has been recorded by a Keithley 2400 voltage source unit. The gate (source-drain)-voltage has been varied from −10 V (0 V) to 40 V (40 V) in steps of 300 mV for each device. By using a computer controlled switch a fully automatic measurement of four transistors was enabled. After a complete characterisation of one OFET the system is switched to the next. In that way 167 × 134 data points have been collected for each OFET within one cycle of measurement. All instruments are controlled by a PC and the acquired data were stored by a Matlab-Program.

Fig. 1.

Schematic diagram of four OFETs, on one sample.

3. Results and discussion

Usually electronics circuits are comprised of thousands of transistors and the performance of these electronic circuits depends on the response of each single transistors. For the fabrication of electronic circuits based on OFETs, it is necessary to check the reproducibility of OFETs fabrication process. For measuring the reproducibility of OFETs, we made twelve samples containing four OFETs on each sample. In Fig. 2 we present the obtained drain currents (IDS) measured at VDS = VGS = 40 V. We compared the four OFETs fabricated on one sample with all other samples and found some variations in the drain currents (IDS) from sample to sample. We also compared the four OFETs fabricated on the same sample with each other and found good reproducibility in the value of drain currents (IDS) at VDS = VGS = 40 V. The mean value of IDS at VDS = VGS = 40 V was approximately 10−5 A with 10% relative error calculated from all 48 devices. In Fig. 2, the on/off ratio of all devices is also shown. Small fluctuations from sample to sample were observed. The measured mean value of on/off ratio of all OFETs was approximately 105 with 20% relative error. The small variation in the device parameters is attributed to the limitation of our fabrication procedure. The handling of each step of OFET preparation, including cleaning of substrate, BCB spin coating, deposition of C60 and metal evaporation can create small variations in the OFET parameters. The main crucial step of fabrication was to control the exposure of C60 layers to environment/oxygen. For metal evaporation, the sample was transported from HWE to an other laboratory (LIOS Austria) under ambient condition and then again back to our laboratory for long time measurement. The time of transportation between two laboratories always varies from sample to sample, which plays a major role in creating fluctuations in the device parameters. For the fabrication of good OFETs, the rate of metal evaporation should be less than 0.5 Å/s. The relative errors in the device parameters can be reduced by controlling these factors.

Fig. 2.

On each sample four OFET were fabricated, OFET-1 (black star), OFET-2 (red square), OFET-3 (green circle) and OFET-4 (blue pentagon). Fluctuations in the drain current (IDS) at VDS = VGS = 40 V are shown by closed symbols while the fluctuations in on/off ratio are given by opened symbols. (For interpretation of the references to color in this figure legend, the reader is referred to the web version of this article.)

After getting satisfactory results of reproducibility of freshly prepared devices, we checked their stability by applying continuous stress to each device. Each OFET was biased for 24 h continuously and their transfer and out put characteristics was measured. Forty cycles of measurements were completed and each fourth cycle of measurement was recorded within 24 h of continuous stress time. All devices give satisfactory reproducibility and stability during continuous stress of 24 h. The relative error in all measurements during the 24 h stress was approximately 4%. As an example the transfer characteristics as function of time of one OFET are shown in Fig. 3(a). The corresponding out put characteristics are given in Fig. 3(b) plotting all values of IDS obtained in 24 h on top of each other, which result in very narrow band width for the scattering of the data.

Fig. 3.

(a) Transfer characteristics measured for 24 h at VDS = 40 V. (b) Fluctuations in the output characteristics of single OFET, measured for 24 h.

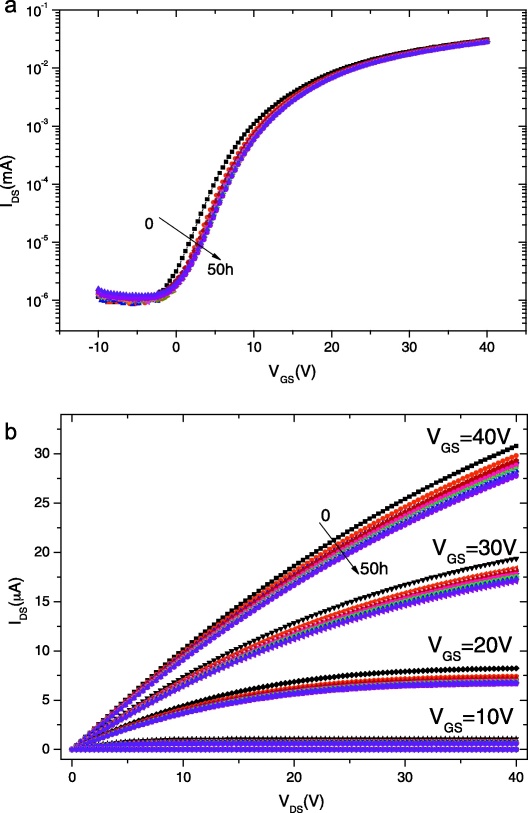

After applying 24 h stress, the same OFETs were stored in the glove box for two weeks. After two week storing in glove box we apply again a continuous stress for 50 h. Sixty cycles of measurements were completed and each fourth cycle of measurement was recorded. The transfer and output characteristics measured for 50 h, two weeks after preparation, are given in Fig. 4. We have not observed any significant change in the drain current during the storage in the glove box and also not during the measurement. The relative change was only 2% during the continuous stress of 50 h.

Fig. 4.

(a) Transfer characteristics measured for 50 h at VDS = 40 V. (b) Output characteristics measured for 50 h, two weeks after preparation.

After applying 50 h continuous stress, the OFET were stored again for two months in a glove box. After two months, we applied again continuous stress for twenty days. Eight hundred cycles of measurements were completed and each fourth cycle of measurement was recorded within twenty days of continuous stress time. We analysed the transfer and output characteristics and observed a degradation of one order of magnitude in the drain currents (IDS). The behaviour of this degradation was exponential and most of the degradation took place in the first two days of measurements. In Fig. 5(a) and (b), the variation in the drain current (IDS) at VDS = VGS = 40 V as well as the on/off ratio during the whole period of three months is shown. The graph clearly shows two different decay rates. From the graph of drain current versus time, it can be concluded that the decay rate during the stress time is faster then the decay rate during the storage time in the glove box. The IDS decays with two different decay rates with respect to storage in glove box and biased stress, while the on/off ratio shows a non exponential behaviour at the end of the life time of OFET. We have observed an interesting behaviour related to threshold voltage. It shifts towards positive gate voltage during the stress, but recovers back to the original value during the storage in the glove box. The explanation of this behaviour requires some more experiments which are still in progress.

Fig. 5.

Variation during three months: (a) drain current (IDS) at VDS = VGS = 40 V and (b) on/off ratio versus time.

4. Aspects for circuit design

To assure proper circuit functionality, in case of circuit design, the device parameter deviation of fabricated transistors of a given technology (organic as well as inorganic) should be as small as possible. Therefore the optimization of the device structure (and performance) to reduce the range of process dispersion is mandatory in the development phase of new technologies on the edge between device development and the start of circuit design within this given new technology. A good and necessary starting point for the device optimization process towards reliable performance in the circuit operation, is the existence of guard bands in the I/V device characteristics as given in Figs. 3(b) and 4(b) for different manufactured geometrically identical devices. Guard bands, in the case of Figs. 3(b) and 4(b) means that there are non-overlapping I/V-curve regions for the different main VGS value steps in the output characteristic, as well as for different main VDS values in the transfer characteristic.

In the early stage of device development, record values of given device parameters (e.g. mobility) is a well known and accepted FOM (figure of merit) to compare and characterize different devices and technologies. In the case of circuit design and the presence of several tens up to thousands or even millions of simultaneously working devices, single record values are of less interest compared to reduced deviation values in the drain-source current at single gate-source voltages of all working devices. This is additional true regarding ageing, therefore stability of the device characteristic over life time within possibly small limits is mandatory important for the acceptance of the devices for circuit applications. The investigated devices show this mandatory stability over life time as depicted in Fig. 5, and therefore they can be used for circuit design.

A robust circuit design strategy is an additional important and necessary way to relax the requirement of the single device regarding process stability a bit. Robust circuit design in this case deals not only with the resistance against electromagnetic waves; it also means that the circuit is keeping its functionality over the complete circuit specification. This specification includes e.g. the temperature range, supply voltage variation (Figs. 3 and 4) and technology process global (lot-to-lot) and local (die-to-die) corner, given in Fig. 2.

5. Conclusion

We fabricated twelve samples, containing four OFETs each, in total forty eight OFETs. All fabricated OFETs worked, proving a good reproducibility of the process used to make them. The reproducibility of OFETs within one sample was very satisfactory, the sample to sample parameters showed small fluctuations. During short time (24 h) measurements the devices show excellent stability. In the long time (three months) stability measurements, the devices show a decay in the drain current as well as in the on/off ratio, with different decay rates for time of storage or stress. As a result for circuit design issues these measurements show, that OFETs based on C60 are well suitable for use as a device working simultaneously to realize larger circuit functionalities in terms of a robust design.

Acknowledgements

We gratefully acknowledge Prof. N. S. Sariciftci for the access and support for the experimental facilities in LIOS, Austria. This work was supported by the Austrian Science Foundation (FWF) [Projects: S9706, S9715].

References

- 1.Baude P.F., Ender D.A., Haase M.A., Kelley T.W., Muyres D.V., Theiss S.D. Appl. Phys. Lett. 2003;82:3964. [Google Scholar]

- 2.Sirringhaus H., Tessler N., Friend R.H. Synth. Met. 1999;102:857. [Google Scholar]

- 3.Crone B., Dodabalapur A., Gelperin A., Torsi L., Katz H.E., Lovinger A.J., Bao Z. Appl. Phys. Lett. 2001;78:2229. [Google Scholar]

- 4.Fix W., Ullmann A., Ficker J., Clemens W. Appl. Phys. Lett. 2002;81:1735. [Google Scholar]

- 5.Singh Th.B., Sariciftci N.S., Yang H., Yang L., Plochberger B., Sitter H. Appl. Phys. Lett. 2007;90:213512. [Google Scholar]

- 6.Tatemichi S., Ichikawa M., Koyama T., Taniguchi Y. Appl. Phys. Lett. 2006;89:112108. [Google Scholar]

- 7.Diallo K., Erouel M., Tardy J., André E., Garden J.L. Appl. Phys. Lett. 2007;91:183508. [Google Scholar]

- 8.Deman A.L., Tardy J. Mater. Sci. Eng. C. 2006;26:421. [Google Scholar]

- 9.Suemori K., Uemura S., Yashida M., Hoshino S., Takada N., Kodzasa T., Kamata T. Appl. Phys. Lett. 2007;91:192112. [Google Scholar]

- 10.Rost H., Ficker J., Alonso J.S., Leenders L., McCulloch I. Synth. Met. 2004;145:83. [Google Scholar]

- 11.Suemori K., Uemura S., Yashida M., Hoshino S., Takada N., Kodzasa T., Kamata T. Appl. Phys. Lett. 2008;93:033308. [Google Scholar]

- 12.Jang J., Kim J.W., Park N., Kim J.J. Org. Electron. 2008;9:481. [Google Scholar]

- 13.Someya T., Dodabalapur A., Gelperin A., Katz H.E., Bao Z. Langmuir. 2002;18:5299. [Google Scholar]

- 14.Saragi T.P.I., Fuhrmann-Lieker T., Salbeck J. Synth. Met. 2005;148:267. [Google Scholar]

- 15.Tiwari S.P., Zhang X.-H., Potscavage W.J., Kippelen B. J. Appl. Phys. 2009;106:054504. [Google Scholar]

- 16.Ullah M., Taylor D.M., Schwödiauer R., Sitter H., Bauer S., Sariciftci N.S., Singh Th.B. J. Appl. Phys. 2009;106:114505. [Google Scholar]

- 17.Ullah M., Fishchuk I.I., Kadashchuk A., Stadler P., Pivrikas A., Simbrunner C., Poroshin V.N., Sariciftci N.S., Sitter H. Appl. Phys. Lett. 2010;96:213306. [Google Scholar]