Abstract

Plastic, one of the most preferred materials in today's industrial world is posing serious threat to environment and consumer's health in many direct and indirect ways. Exposure to harmful chemicals during manufacturing, leaching in the stored food items while using plastic packages or chewing of plastic teethers and toys by children are linked with severe adverse health outcomes such as cancers, birth defects, impaired immunity, endocrine disruption, developmental and reproductive effects etc. Promotion of plastics substitutes and safe disposal of plastic waste requires urgent and definitive action to take care of this potential health hazard in future.

Keywords: Polyethylene terephthalate, plastics waste, recycling, plastic industry in India

INTRODUCTION

The advent of fuel based plastics has revolutionized the industrial world and there is no area of manufacturing which is untouched by plastics. Convenience and cost factors have pitch forked plastics as the most preferred material of choice till recently, a rethinking about its impact on environment and sustainability is slowly putting a brake on its continued use. While cheap petroleum fuels from which most plastics are derived was once justified to introduce them in place of traditional materials like glass and metals, this plea cannot hold any more since the cost of non-renewable fossil fuels increased several fold during the last 3 decades.

Research based on plastics proves their injurious nature towards human health in many direct or indirect ways. Phthalates or phthalate esters are esters of phthalic acid mainly used as plasticizers (substances added to plastics to increase their flexibility) in Poly Vinyl Chloride (PVC). PVC is a widely used material, including extensive use in toys and other children's products such as chewy teethers, soft figures and inflatable toys. Di (2-ethylhexyl phthalate (DEHP), dibutyl phthalate (DBP), di-isononylphthalate (DINP), di-isodecyl phthalate (DIDP), benzyl - butyl - phthalate (BBP) and di-n- octyl- phthalate (DNOP) are phthalates mainly used in converting polyvinyl chloride (PVC) from a hard plastic to a flexible plastic. Phthalates migrate into the air, into food and into people including babies in their mother's wombs. Phthalates can be released from soft PVC by surface contact, especially where mechanical pressure is applied e.g. during chewing of a PVC teether). Release of phthalates during manufacture, use and disposal of PVC products, in addition to their use as additives in ink, perfumes etc. has lead to their ubiquitous distribution and abundance in the global environment.[1]

Growing literature links many of the phthalates with a variety of adverse outcomes, including increased adiposity and insulin resistance,[2] decreased anogenital distance in male infants,[3] decreased levels of sex hormones,[4] and other consequences for the human reproductive system, both for females and males,[5] Infants and children may be especially vulnerable to the toxic effects of phthalates given their increased dosage per unit body surface area, immature metabolic system capability and developing endocrine and reproductive system.[6] Legislatures and government agencies in Australia, Canada, the European Union, and the United States have restricted or prohibited the use of phthalates in consumer products Plastics industry generally asserts that Polyethylene terephthalate (PET) bottles are not a source of endocrine disruptors[7] and must be distinguished from phthalate which acts as an additive and is chemically dissimilar. PET is most commonly used to make the clear plastic bottles in which bottled water is sold and as containers for soda beverages, sports drinks, and condiments such as vinegar and salad dressing. PET bottles are also commonly used for the packaging of cosmetic products, such as shampoo, particularly when such products are sold in clear plastic bottles. Indeed, phthalates are not used as substrates or precursors in the manufacture of PET but the available research suggests that the concentration of phthalates in the contents of PET bottles varies as a function of the contents of the bottle, with phthalates leaching into lower pH products such as soda and vinegar more readily than into bottled water. Temperature also appears to influence the leaching both of phthalates and of antimony from PET, with greater leaching at higher temperatures. Lower-pH condiments such as table vinegar and salad dressing may warrant particular attention.[8] The findings suggest that ingesting several servings of salad dressing that had been stored in a warm warehouse for a month might result in a dose of di-(2-ethylhexyl) phthalate (DEHP) on the order of several hundred micrograms, possibly reaching the reference dose limit of 20 μg/kg/day.[9,10]

Besides, playing an increasing role in packaging and consumer products plastics also take up a growing percentage of municipal solid waste streams and pose environmental challenges. Plastics have attracted severe criticism from the environmentalists because of its lack of biodegradability credentials. As widely known, plastic materials take about 100 to 1000 years to degrade when used in landfills besides polluting air and water around. Land availability will pose a challenge in many countries if landfill practice is continued and restrictions are now being put in place to curtail this approach. Besides, extremely thin plastic bags made from less than 20 micron thick films are choking the drains of many cities causing uncontrolled floods during rainy season. Plastics in garbage are estimated to be killing a million creatures in the sea every year. Plastic bags littering has lead to banned use of thin plastic bags by the consumer industry during retail sales of products in many countries.

DEALING WITH PLASTIC WASTES

Plastics in the waste stream are dealt with in one of three ways: incineration, burial, or recycling. Incineration, used to dispose about 16% of all municipal wastes in developed countries burn garbage in waste-to-energy facilities that use heat energy to generate steam or electricity. Because plastics are typically derived from petroleum or natural gas, they can generate almost as much energy as fuel oil, although the much higher amount of energy initially required to produce the plastic is lost. Potential hazardous emissions from incinerating plastics include hydrogen chloride, dioxin, cadmium, and fine particulate matter. Even with stricter air pollution standards in place, there is considerable public opposition to incineration.

Land filling plastics is generally a benign practice because plastics are chemically inert. Some additives to plastics do provoke concern as they may migrate from the plastics into the leachate. Plasticizers known as phthalates are hazardous substances and have been found in a number of leachate analyses at various concentrations. A more significant problem for land filling is that plastic wastes now constitute about 10% by weight and about 20% by volume of the municipal waste stream. Since plastics are essentially nondegradable, their volume will not shrink and plastics may eventually consume a disproportionate amount of landfill space.[11]

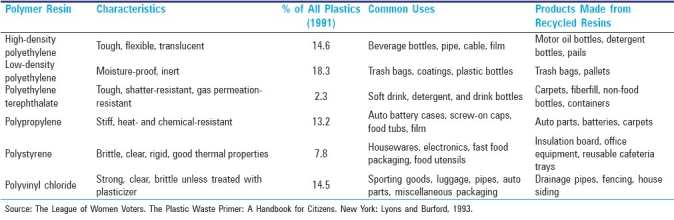

Recycling is a four-part exercise of collecting a mix of plastics at curbside or drop-off centers, sorting the plastics into the six types, reclaiming the plastic by physically or chemically converting them to flakes or pellets, and then processing the flakes or pellets into a final product. One reason plastics are recycled less often than glass or metal is because the sorting step is very labor-intensive and, hence, expensive. However, the cost and accuracy of sorting are crucial elements in making plastics recycling economically viable because each type of plastic has different performance characteristics that make it best suited for specific applications. An innovative method for raising consumer awareness about separation of recyclable wastes from non recyclable is recently introduced in Thailand through “Waste for eggs campaign”. Thirty plastic waste pieces can be exchanged for 5 eggs by local people[12] [Table 1].

Table 1.

Common Plastics and their Uses

REGULATION OF PLASTIC INDUSTRY IN INDIA

The growth of plastic small scale processing and reprocessing industries, as other Small Scale Industries (SSI) in India, began in the decade of eighties with the announcement of the new industrial policy. Policy instruments adopted by the Government to encourage the growth of SSI comprised various incentives such as reservation of certain sectors for SSI, and financial and fiscal incentives.[13] SSI industry of rubber and plastic products, which are declared as reserved products constitute 4.6% of the total number of SSI units, generate 5% of employment in SSI and has 8.4% of investment.[14] Among many advantages, these industries have lower excise duty on the final products and are free from the tiresome procedural formalities. A plastic recycling unit needs to have a power point passed by the local electricity board at the least. Registration with Industrial Development Corporation is not mandatory. Most of these are having less than 5-7 employees and cannot be covered under labor law. Plastic processing and reprocessing industries are also exempted from monitoring by Pollution Control Board.[15]

With regard to safety guidelines for toys in India, Bureau of Indian Standards (BIS) has published three standards which deals with safety aspects of toys related to mechanical and physical properties, flammability requirements and migration of certain elements (limiting heavy metals in toys). None of these standards give limits for phthalates in children's toys and child care articles. The BIS guideline with regard to toy production is self regulatory and not mandatory. Toy manufacturers do not register even for the ISI mark for their products and therefore do not follow even the voluntary standards.[1]

Regulation of plastics waste, particularly manufacture and use of recycled plastics carry bags and containers is being regulated in the country as per “Recycled Plastics Manufacture and Usage Rules”, 1999 and as amended in 2003.[16] This has now been replaced by Plastic Waste (Management and Handling) Rules, 2011.[17] Some of the salient features of the new Rules are:

ban on use of plastic materials in sachets for storing, packing or selling gutkha, tobacco and pan masala,

no food stuffs will be allowed to be packet in recycled plastics or compostable plastics,

recycled carry bags to have specific BIS standards, colour to the prescription by the Bureau of Indian Standards (BIS),

Uniform thickness shall not be less than 40 microns in carry bags etc.

One of the major provisions under the new Rules is the explicit recognition of the rule of waste pickers. The new Rules require the municipal authority to constructively engage agencies or groups working in waste management including these waste pickers. This is the very first time that such a special dispensation has been made.

Municipal or Government authorities and NGOs may play crucial role in recognizing and legitimizing both plastic waste recovery and trading activities and equipping them with state of art designs of waste management technology and system. Developing safe and low cost technology for which SSIs need institutional and scientific support and making mandatory of guidelines related to safety, process and product standards in consultation with plastic associations are one of the few ways. The Municipal authority under new rules is hold responsible for setting up, operationalization and coordination of the waste management system and for performing the associated functions, This will include ensuring safe collection, storage, segregation, transportation, processing and disposal of plastic waste, no damage to the environment during this process, setting up of the collection centers for plastic waste involving manufacturers, its channelization to recyclers, to create awareness among all stakeholders about their responsibilities, and to ensure that open burning of plastic waste is not permitted.

In India, as part of corporate social responsibility Tamil Nadu Pollution Control Board (TNPCB) is facilitating the disposal of non reusable plastic waste (carry bags, plastic cups, etc) generated in urban local bodies by co-processing at the cement kilns.[18] Reliance Industries (RIL) in partnership with Gujarat Engineering Research Institute (GERI) constructed a 900 meter road stretch using 5% plastic waste. Non recyclable plastic waste used in construction of tar road reduced construction cost and improved road life.[19]

CONCLUSIONS

Plastic Waste Management both in India and abroad has assumed huge significance. Innovative approaches for use of plastic substitutes under conditions of common use merits further research.

In line with the principle of ‘extended producer's responsibility’ the new rules for the first time in India has underlined the role of municipal bodies in not only ensuring safe collection and disposal of plastic wastes but also in engaging agencies or groups working in waste management including waste pickers.

Footnotes

Source of Support: Nil

Conflict of Interest: None declared

REFERENCES

- 1.Johnson S, Saikia N, Sahu R. Centre for Science and Environment. New Delhi: Phthalate in toys. Laboratory Study. [Google Scholar]

- 2.Grun F, Blumberg B. Endocrine disruptors as obesogens. Mol Cell Endocrinol. 2009;304:19–29. doi: 10.1016/j.mce.2009.02.018. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Swan SS, Main KM, Liu F, Stewart SL, Kruse RL, Calafat AM, et al. Decrease in anogenital distance among male infants with prenatal phthalate exposure. Environ Health Perspect. 2005;113:1056–61. doi: 10.1289/ehp.8100. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Pan G, Hanaoka T, Yoshimura M, Zhang S, Wang P, Tsukino H, et al. Decreased serum free testosterone in workers exposed to high levels of di-n-butyl phthalate (DBP) and di-2-ethylhexyl phthalate (DEHP): a cross-sectional study in China. Environ Health Perspect. 2006;114:1643–8. doi: 10.1289/ehp.9016. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Hauser R, Calafat AM. Phthalates and human health. Occup Environ Med. 2005;62:806–18. doi: 10.1136/oem.2004.017590. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Sathyanarayana S. Phthalates and children's health. Curr Probl Pediatr Adolesc Health Care. 2008;38:34–49. doi: 10.1016/j.cppeds.2007.11.001. [DOI] [PubMed] [Google Scholar]

- 7.American Chemistry Council. Phthalates Information Center. 2009. [last accessed on 2009 Nov 15]. Available from: http://www.americanchemistry.com/s_phthalate/

- 8.Sax L. Polyethylene terephthalate may yield endocrine disruptors. Environ Health Perspect. 2010;118:445–8. doi: 10.1289/ehp.0901253. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Farhoodi M, Emam-Djomeh Z, Ehsani MR, Oromiehie A. Effect of environmental conditions on the migration of di (2-ethylhexyl) phthalate from PET bottles into yogurt drinks: influence of time, temperature, and food stimulant. Arabian J Sci Eng. 2008;33:279–87. [Google Scholar]

- 10.Edition of the Drinking Water Standards and Health Advisories. Washington, DC: U.S. EPA; 2006. [last accessed on 2009 Nov 16]. U.S. EPA (Environmental Protection Agency) Available from: http://www.epa.gov/waterscience/criteria/drinking/dwstandards.pdf . [Google Scholar]

- 11. [accessed in 2011]. Available from: http://www.cpcb.nic.in/Highlights/2007/139-144.pdf .

- 12. [accessed in 2011]. Available from: http://www.csrthailand.net/en/news/detail/243 .

- 13.Balasubramaniya MH. Reservation Policy for Small Scale Industry: How it Delivered the goods? Economic and Political Weekly. 1995 [Google Scholar]

- 14.Pain GC. A Manual on Occupational Health in Small Scale Industries of India, Calcutta: All India Institute of Hygiene and Public Health. 1990 [Google Scholar]

- 15.Shah ER. Plastic Recycling in Bangalore- India. Urban Waste Expertise Program. 1997 [Google Scholar]

- 16. [accessed in 2011]. Available from: http://www.cpcb.nic.in/Highlights/2007/139-144.pdf .

- 17. [accessed in 2011]. Available from: http://www.pib.nic.in/newsite/erelease.aspx?relid=69649 .

- 18. [accessed in 2011]. Available from: http://www.cleanairinitiative.org/portal/node/6350 .

- 19.Reliance Industries Limited. Annual report 2010-11. :41. [Google Scholar]