Abstract

PURPOSE

The aim of this in-vitro investigation was to describe the effect of reinforcement with different fibers on impact strength of heat polymerized polymethyl methacrylate (PMMA) denture base resin and to analyze the effect of surface treatment of the fibers on the impact strength.

MATERIALS AND METHODS

The specimens were fabricated from the dies formed as per standard ASTM D4812. 2% by weight of glass, polyethylene and polypropylene fibers were incorporated in the PMMA resin. The Izod impact testing was performed on the unnotched specimens and the values obtained were analyzed using appropriate one way ANOVA, followed by unpaired t-test. Fractured ends of the samples were subjected to the SEM analysis.

RESULTS

The polypropylene fibers with plasma treatment showed the highest impact strength (9.229 × 102 J/m) followed by the plasma treated polyethylene fibers (9.096 × 102 J/m), untreated polypropylene fibers (8.697 × 102 J/m), untreated polyethylene fibers (7.580 × 102 J/m), silane treated glass fibers (6.448 × 102 J/m) and untreated glass fibers (5.764 × 102 J/m). Also the surface treatment of all the fibers has shown the significant improvement in impact strength. Findings of the SEM analysis justified the improvement in impact strength after surface treatment.

CONCLUSION

Reinforcement with the fiber is an effective method to increase the impact strength of PMMA denture base resin. The surface treatment of fibers further increases the impact strength significantly.

Keywords: Glass fibers, Polypropylene fibers, Plasma treatment, Silane treatment, Izod impact test

INTRODUCTION

The material most commonly used for the fabrication of complete denture is polymethyl methacrylate (PMMA) denture base resin. This material is not ideal in every respect and it is the combination of virtues rather than one single desirable property that accounts for its popularity and usage. Despite satisfying esthetic demands it is far from ideal in fulfilling the mechanical requirements of prosthesis. A study by Johnston et al.1 showed that 68% of acrylic resin dentures break within a few years after fabrication primarily due to impact failure. Many approaches have been used to strengthen the PMMA denture base resin such as incorporation of metal wire.2,3 The primary problem of using metal wire is poor adhesion between wire and acrylic resin matrix. Alternate polymers do exist like vinyl acrylic, polystyrene and acrylic styrene, but have not been shown to produce dentures of greater accuracy with better performance. 4 Modifications on PMMA by the incorporating a rubber phase in the bead polymer has improved the impact strength but resulted in increased cost.5

The other approach is the reinforcement of PMMA denture base resin with various types of fibers which include glass fiber,6,7 sapphire whiskers fiber,8,9 aramid fiber,8,10 carbon fibers,11,12 nylon fibers13 and polyethylene fiber.5,14,15 However, these fibers break-up the homogeneous matrix of acrylic resin due to poor interface between fiber and resin affecting the mechanical properties. In order to avoid this problem, many studies advocating the surface treatment of fibers have been reported in the literature.6,14 Numerous studies5-15 have been conducted on individual reinforced fibers to improve the strength of the denture base. It seems that very little work has been carried out to compare between individual reinforced fibers to determine which fiber suits best to improve impact strength of denture base.

In view of above observations, a study was considered to find out how the strength of acrylic resin can be improved by using fiber reinforcement and whether surface treatment affect the impregnation of fiber within the resin matrix. Hence, the purpose of this study was to evaluate the effect of reinforcement with untreated and surface treated glass, polyethylene and polypropylene fibers on impact strength of heat polymerized denture base resin.

MATERIALS AND METHODS

The materials used in the study are mentioned in Table 1. According to ASTM D4812 standard16 (standard test method for un-notched cantilever beam impact strength) metal dies with dimensions of 64 mm×13 mm×3 mm were fabricated to prepare the gypsum mold. The specimens were fabricated using standard techniques with mixture of monomer and polymer in ratio of 1:2.4 by weight. The flask was immersed in an acrylizer (Unident, Mumbai, India) at room temperature for curing. The temperature was raised slowly up to 74℃ and held for 2 hours, then raised to 100℃ and was maintained for 1 hour.17 Acrylic specimens were finished and polished. The dimensions and quality of each specimen were verified. A total of 70 specimens were fabricated with 10 specimens for each group (n = 10).

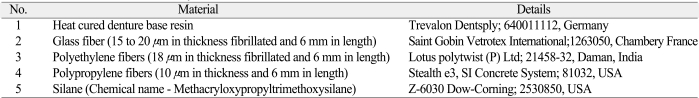

Table 1.

The materials used in the study

The test specimens were grouped as under.

Group A - Control group (Unreinforced specimens)

Group B - Reinforced with glass fibers.

Group C - Reinforced with polyethylene fibers.

Group D - Reinforced with polypropylene fibers.

Group Bt - Reinforced with silane impregnated glass fibers.

Group Ct - Reinforced with plasma treated polyethylene fibers.

Group Dt - Reinforced with plasma treated polypropylene fibers.

For Group B, C, and D specimens, before mixing polymer and monomer, 2% by weight of fibers were soaked in monomer for 10 minutes in a Petri dish for better bonding of fibers with the PMMA resin.18 After the fibers were removed from the monomer, excess liquid was allowed to dry and fibers were mixed thoroughly with the polymer powder. Then the specimens were fabricated as in control group.

In case of Group Bt specimens, 2% by weight of glass fibers were soaked in silane for 5 minutes and allowed to air dry completely before they were dipped in a methacrylate monomer.10,18 In case of Group Ct and Dt specimens, Plasma treatment of polyethylene and polypropylene fibers was carried out in the reactor for enhanced adhesion of the fibers to resin matrix. 2% by weight of the fibers were introduced into the reactor and treated with 100 W power for 3 minutes using a flow of 17× 103 mm3 min-1 of O2 gas as plasma carrier.19 The pressure inside the reactor was 0.5 torr. The fibers were then soaked in monomer for 10 minutes. After the fibers were removed from the monomer, excess monomer was allowed to dry. Then the polymer powder and fibers were mixed thoroughly to disperse the fibers and the specimens were fabricated as in control group.

Each specimen was conditioned in water for 7 days at 37℃ and placed in water at 23℃ for 1 hour prior to testing. Specimens were labeled at each end prior to testing so that fractured pieces could be reunited and examined subsequent to testing.

Impact strength testing could be carried out on un-notched and notched specimens but notching would have cut the superficial fibers in the specimens, therefore testing was carried out on un-notched specimens. Testing was done on Izod impact testing machine (Veekay testlab, Mumbai, Maharashtra, India) with a pendulum of S2 scale in air at 23±2℃. Before testing, pendulum was released to freely swing in the air to record the air resistance (AR) encountered by free-swinging pendulum. Air resistance of 0.6 Joules was recorded. The readings were taken on S2 scale where pointer was stabilized after swing. The specimen was clamped in position precisely (Fig. 1). Pendulum was released and reading indicating energy absorbed (EA) to break the specimens on S2 scale was recorded. All the specimens were tested in the same manner. Fig. 2 shows one fractured specimen from each group.

Fig. 1.

Izod impact testing machine with specimen in position.

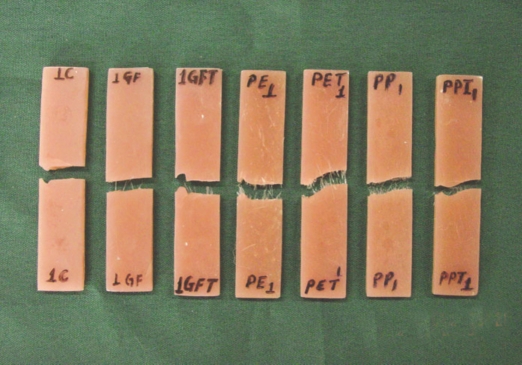

Fig. 2.

Fractured specimens from each group.

Impact strength of specimen was calculated by using following formula -

Where,

Corrected readings = (EA - AR) in Joules

W = Test specimen width in meter

Impact strength = J/m

One fractured specimen from each group was selected for SEM analysis. Specimens were cut 3 - 4 mm in length from the fractured end. These cut specimens from each group were mounted on SEM buttons using double sided sticking, and labeled. Mounted specimens were kept in the scanning Electron microscope. All the adjustments for focusing the microscope were done on the computer screen and the microscopic view was observed on the screen. The photographs for each group were stored for comparing the different groups.

RESULTS

The statistical analysis was performed using appropriate tests and statistical software (graphpad quickcals and graphpad prism). The data was interpreted at a confidence interval of 95%. The means and standard deviation are mentioned in Table 2.

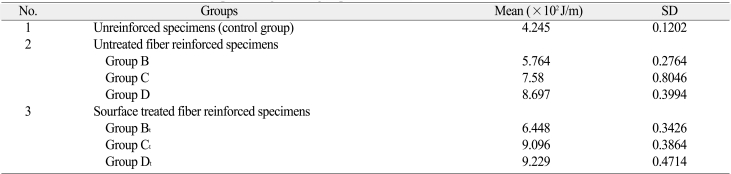

Table 2.

Mean and standard deviation of impact strength of all groups

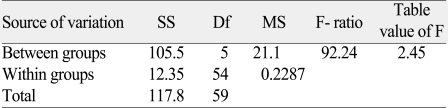

An ANOVA was used to study whether all fibers reinforcement significantly improved impact strength when compared to unreinforced group. The null hypothesis (H0) in the present study being tested by ANOVA is that there is no difference in impact strength of PMMA resin after reinforcement with different fibers. The alternate hypothesis (H1), in case the null hypothesis is rejected, is that there is difference in impact strength of PMMA resins after reinforcement with fibers. The difference caused may be because of the presence of the fibers in the resin matrix.

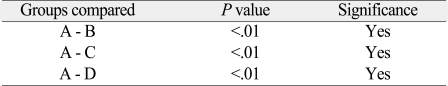

The results of ANOVA test are shown in Table 3. The "F" value obtained was 172.3 whereas the table value of "F" at 0.05 level of confidence was 2.84. This analysis revealed that the results were statistically significant. Though the difference given by one-way ANOVA was significant, this test showed only collective results of all the means therefore Dunnett's post hoc test was applied. Dunnett's post hoc test compared all the reinforcement groups i.e. Group B, C and D with the control i.e. Group A (Table 4). The results revealed that Group B, C and D differed significantly (P<.05) from the control group. This showed that reinforcement with fibers i.e. glass, polyethylene and polypropylene increased the impact strength significantly.

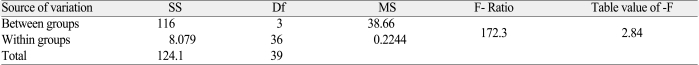

Table 3.

The results of ANOVA test

Table 4.

Dunnett's post hoc test to compare control group with untreated fiber reinforced groups

Since calculated "F" value was more than the value of "F" that was given in the "F" table at difference between the classes and at difference within the classes at 0.05 level of significance, null hypothesis was rejected and alternate hypothesis stating that there was difference in impact strength of PMMA resin after reinforcement with fiber is accepted. This showed that there was improvement in impact strength after fiber reinforcement.

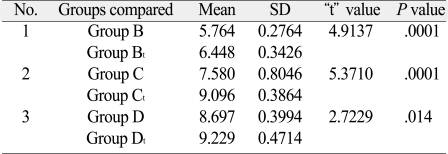

Individual 't' test were performed to compare the mean strength of untreated fiber groups with their respective surface treated fiber groups. The results of 't' test are shown in Table 5. The glass fibers treated with silane compound enhanced the impact resistance significantly compared to the impact resistance given by non-silanized glass fibers (t = 4.9137, df = 18, P=.0001). Plasma treated Polyethylene fibers showed impact resistance significantly higher than the untreated polyethylene fiber (t = 5.3710, df = 18, P=.0001). Plasma treated polypropylene fibers also showed significant difference in the impact resistance compared with the polypropylene fibers of untreated group (t = 2.7229, df = 18, P=.014). This showed that there was increase in the impact strength after surface treatment.

Table 5.

Results of unpaired 't' test between Group - B and Bt, C and Ct, and D and Dt

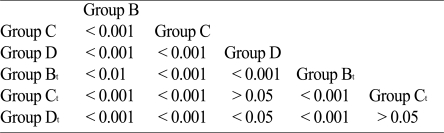

The ANOVA was performed to compare the impact strength of all the fiber reinforced groups i.e. Group B, C, D, Bt, Ct and Dt (Table 6). It is seen that the Group Dt specimens present the highest impact strength followed by Group Ct, D, C, Bt, B.

Table 6.

Results of ANOVA comparing all the untreated and surface treated fiber reinforced groups

Though the result of ANOVA was significant Newman-Keuls post hoc test for multiple comparisons was applied to evaluate the difference of any of the two means (Table 7). The results revealed that all the comparisons were statistically significant except for group D & Ct (P>.05) and group Ct & Dt (P>.05).

Table 7.

Results of Newman-Keuls post hoc test for multiple comparisons.

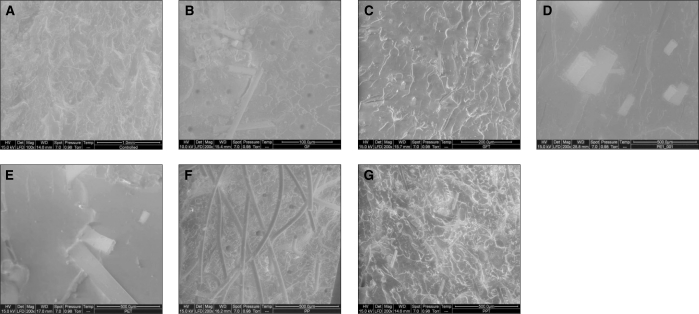

The scanning electron micrographs of surface at the fractured end were taken of representative samples from each group. Following observations were revealed.

Group A: The SEM view of the fractured end of specimen showed rough surface and cracks spread throughout the fractured surface (Fig. 3A).

Group B: The SEM view showed rough surface and cracks of smaller size than Group A. Glass fibers protruding out from the resin matrix and voids formed due to pulled out fibers from the resin matrix were also seen (Fig. 3B).

Group Bt: The SEM view showed rough surface and cracks similar to that in Group B. Glass fibers, which were fractured cohesively at the plane of specimen fracture, and also few protruding fibers were seen. Voids formed due to pulled out of glass fibers from the matrix were less in number as compared to Group B (Fig. 3C).

Group C: The SEM view showed rough surface and cracks same as in above groups. Polyethylene fibers protruding through the fractured end and voids formed due to pulled out polyethylene fibers from the resin matrix were also seen (Fig. 3D).

Group Ct: The SEM view showed similar rough surface and cracks. Polyethylene fibers, which were fractured cohesively, and some protruding fibers were also seen. Voids formed due to pulled out of polyethylene fibers from resin matrix were less as compared to Group C (Fig. 3E).

Group D: The SEM view showed rough surface and cracks similar to that of above reinforcement groups. Polypropylene fibers spread throughout the fractured surface and voids formed due to pulled out fibers were seen. Particles of the acrylate were seen attached to the surface of the fibers (Fig. 3F).

Group Dt: The SEM view showed similar rough surface and cracks. Polypropylene fibers, which were fractured cohesively at the level of specimen fracture, and some protruding fibers were seen. Voids formed due to pulled out of fibers from matrix were less as compared to the Group D (Fig. 3G).

Fig. 3.

SEM view of specimens. A: Group A, B: Group B, C: Group Bt, D: Group C, E: Group Ct, F: Group D, G: Group Dt.

DISCUSSION

The glass fiber is an inorganic substance. E glass fibers, based on alumina-lime-borosilicate composition are considered the predominant reinforcement for polymer matrix due to their high mechanical properties, low susceptibility to moisture absorption, resistance to chemicals, thermal stability and high melting point.18 The other two fibers used in the study were polyethylene5,14,15 and polypropylene which are the two most common members of olefin family. Olefin fiber is a manufactured fiber in which the fiber forming substance is any long chain synthetic polymer composed of at least 85% by weight of ethylene, propylene or other olefin units.20 These fibers are very lightweight, have high strength and modulus, resistant to deterioration by chemicals, abrasion resistant, resistant to moisture absorption, resilient, and not brittle.20 Polyethylene fibers, because of its natural color and known biocompatibility, have been extensively studied for reinforcement in denture base PMMA resin over the last two decades.21 To date, no studies have been reported in the dental literature using polypropylene fiber for reinforcement in denture base. A polypropylene fiber has natural color and good mechanical properties. Because of its excellent biocompatibility it has been used in general surgery for closure of abdominal wounds and in oral and maxillofacial surgery for reconstruction of orbital floor, where there are multiple fragment fractures.20 The polypropylene reinforced specimens provided good surface finish and polish. American Composite Manufacturers Association suggests polypropylene as one of the reinforcement material for composite resins. Therefore, polypropylene fibers were also used in this study for reinforcement in PMMA.

The reinforcement groups with untreated glass, polyethylene and polypropylene showed statistically significant increase in the impact strength compared to the control group specimens. This might be attributed to the presence of reinforced fibers which carry the load along their length to provide strength and stiffness to the specimen in one direction, resulting in higher absorption of energy compared with un-reinforced specimens.15 Increase in impact strength shown by polyethylene and polypropylene fibers was much higher than that shown by glass fiber. This might be attributed to the inherent brittle property of glass compared to polyethylene and polypropylene fibers, which have more strength and stiffness.22

Findings in this study agree in principle with the findings reported by Smith23 that had shown improvement in mechanical properties after reinforcement by discrete glass fibers in the resin. Vallilttu et al.12, Vallittu and Narva,24 Uzun et al.25, Kim and Watts,26 Karacaer et al.27 are the other authors who are in agreement with the increase in impact strength after reinforcement with glass fibers. Increase in impact strength of polyethylene fiber reinforcement was coinciding with the findings reported by Gutteridge5 who studied different weight percentage of polyethylene fiber in chopped form and found significant improvement in impact strength and also Ladizesky et al.22 who showed improvement in impact strength of polyethylene reinforced group compared to unreinforced group.

Glass fibers, polyethylene fibers and polypropylene fibers are hydrophobic in nature and have low surface energy so their compatibility with PMMA is poor. Untreated fibers could act as inclusion bodies in the acrylic resin mixture and instead of strengthening actually weaken the resin by breaking up the homogenous matrix.6 In order to improve the adhesion between resin and the fibers, surface modification has to be done. Some of the techniques followed are silane treatment of glass fibers,6 plasma treatment of polyethylene fibers using oxygen, Helium or Argon gas,21 chromic acid treatment of polyethylene fibers21 and plasma treatment of polypropylene fibers. The glass fibers used in this study were silane treated and polyethylene and polypropylene fibers used were plasma treated.

Table 5 shows the comparison of Group Bt, Ct, and Dt with Group B, C, and D respectively. There was significant improvement in impact strength after surface treatment of glass fibers which may be attributed to the effect of silane coupling agent, which chemically bonds inorganic glass fibers to the organic resin matrix and may make the mixture more homogenous resulting in strong PMMA resin.6 Improvement in impact strength after silane treatment of glass fiber correlates with that of the findings reported by Solnit6 and Vallittu.28

There was also significant improvement in impact strength of Groups Ct and Dt compared to Groups C and D, which might be because of improved surface energy and surface wettability produced by plasma treatment which etches (micro-etching) the fibers so that they can bond mechanically with the matrix phase.29 Plasma is a partially ionized gas that contains ions, electrons and other neutral species at many different energy levels. Treating a polymer with plasma also introduces the functional group on the surface of fibers thereby making the surface polar, which improves the surface energy of the fibers and its compatibility with other materials.30

Improvement in impact strength after plasma treatment of polyethylene fiber coincide with that of Ladizesky et al.,22 who showed increased in impact strength of PMMA after plasma treatment of fibers but contradicts Gutteridge14 who showed no significant difference between untreated and plasma treated fiber specimen group. Plasma treatment of polypropylene fiber was advocated because of its increased surface energy, wettability and compatibility to other materials after plasma treatment.

When all the fiber reinforcement groups were compared (Table 6), Group Dt showed highest mean impact strength values followed by Group Ct, D, C, Bt and Group B. Impact strength values of plasma treated polypropylene, plasma treated polyethylene and untreated polypropylene groups were approximately double to that of unreinforced control group. Thus these fibers can be effectively used to reinforce denture base to minimize denture fracture.

From the literature it appears that reinforcement is optimized when fibers are laid down in a strategic fashion, running parallel to the surface of denture base. In this way their contribution to reinforcement is maximized, as fibers at right angle to the surface produce no beneficial effect. However, technical difficulties of ensuring that fibers were aligned correctly might overweigh the possible advantage, by complicating the technique to such an extent that it becomes impractical.5 This study has showed that a significant effect is produced by random orientation of fibers in the specimens. Presumably, some fibers are oriented to produce beneficial effect and others are of little or no benefit. The ease and simplicity of their inclusion would make this technique more acceptable for widespread use, avoiding the necessity of interruption of packing procedures and time consuming placement of oriented fibers or woven filaments.

Any increase in fiber incorporation beyond 3% by weight will affect the flow of the dough. 4% by weight of fibers represents a large volume of material to be wetted by monomer during mixing and may produce dry friable dough.5 This will provide no beneficial effect on strength. For this reason a standard 2% by weight of each type of fiber was added to each specimen in this study.

The SEM of unreinforced specimens showed larger cracks for causing the specimen fracture compared to all the fiber reinforced groups where cracks were small. This might be because of presence of fibers preventing the crack propagation and change in direction of cracks resulting in smaller cracks between the fibers. This can be correlated to the increased impact strength of fiber-reinforced specimens compared to the unreinforced specimens where there is unobstructed crack propagation.

The voids formed due to pulled out fibers from the resin matrix were less in the surface treated glass polyethylene and polypropylene fibers compared to their respective untreated fiber counterparts. This might be because of better adaptation of fibers to the resin matrix after surface treatment. Untreated fiber specimens showed more of the protruding fibers compared to surface treated group where fibers fractured cohesively at the fractured interface of the specimen which might be due to improved adhesion between fiber and resin matrix after surface treatment increasing adhesive strength between fiber and resin matrix above the cohesive strength of fibers.

The particles of acrylate on the surface of the untreated polypropylene fibers compared to the smooth surface of other untreated fibers might be because of better adaptation of untreated polypropylene fibers to the resin compared to the other untreated fibers. This finding can be correlated to the high impact strength of untreated polypropylene fiber reinforced group compared to the other untreated groups.

In the study, each individual reinforced group has produced improved impact strength than the control. This technique can be clinically used for construction of complete dentures and distal extension partial dentures, especially in cases like patients with poor neuromuscular control. It is advisable to reinforce the denture with polypropylene or polyethylene fiber because of its superior impact resistance capability. Further work is clearly required to investigate the effect of fibers on oral mucosa, whether or not they project from the resin following wear and how various cleaning and polishing procedures affect the surface.

CONCLUSION

Impact strength is an important property of denture base resin and fiber reinforcement is an effective and economical method to increase fracture resistance of denture bases. The present study showed that reinforcement with 2% by weight of glass, polyethylene and polypropylene fibers substantially increased the impact strength of PMMA resin and the surface treatment of the fibers further increased the impact strength significantly. Reinforcement with plasma treated polypropylene fiber showed the highest impact strength, hence can be used clinically to reinforce the denture bases to minimize the denture fracture. The random orientation of the fibers is technically easier and can be followed in the dental laboratory routinely.

References

- 1.Johnston EP, Nicholls JI, Smith DE. Flexure fatigue of 10 commonly used denture base resins. J Prosthet Dent. 1981;46:478–483. doi: 10.1016/0022-3913(81)90232-8. [DOI] [PubMed] [Google Scholar]

- 2.Ruffino AR. Effect of steel strengtheners on fracture resistance of the acrylic resin complete denture base. J Prosthet Dent. 1985;54:75–78. doi: 10.1016/s0022-3913(85)80074-3. [DOI] [PubMed] [Google Scholar]

- 3.Vallittu PK, Lassila VP. Effect of metal strengthener's surface roughness on fracture resistance of acrylic denture base material. J Oral Rehabil. 1992;19:385–391. doi: 10.1111/j.1365-2842.1992.tb01580.x. [DOI] [PubMed] [Google Scholar]

- 4.Smith DC. Recent developments and prospects in dental polymers. J Prosthet Dent. 1962;12:1066–1078. [Google Scholar]

- 5.Gutteridge DL. The effect of including ultra-high-modulus polyethylene fibre on the impact strength of acrylic resin. Br Dent J. 1988;164:177–180. doi: 10.1038/sj.bdj.4806395. [DOI] [PubMed] [Google Scholar]

- 6.Solnit GS. The effect of methyl methacrylate reinforcement with silane-treated and untreated glass fibers. J Prosthet Dent. 1991;66:310–314. doi: 10.1016/0022-3913(91)90255-u. [DOI] [PubMed] [Google Scholar]

- 7.Vallittu PK. Glass fiber reinforcement in repaired acrylic resin removable dentures: preliminary results of a clinical study. Quintessence Int. 1997;28:39–44. [PubMed] [Google Scholar]

- 8.Berrong JM, Weed RM, Young JM. Fracture resistance of Kevlar-reinforced poly(methyl methacrylate) resin: a preliminary study. Int J Prosthodont. 1990;3:391–395. [PubMed] [Google Scholar]

- 9.Goldberg AJ, Burstone CJ. The use of continuous fiber reinforcement in dentistry. Dent Mater. 1992;8:197–202. doi: 10.1016/0109-5641(92)90083-o. [DOI] [PubMed] [Google Scholar]

- 10.Vallittu PK, Lassila VP, Lappalainen R. Acrylic resin-fiber composite-Part I: The effect of fiber concentration on fracture resistance. J Prosthet Dent. 1994;71:607–612. doi: 10.1016/0022-3913(94)90446-4. [DOI] [PubMed] [Google Scholar]

- 11.DeBoer J, Vermilyea SG, Brady RE. The effect of carbon fiber orientation on the fatigue resistance and bending properties of two denture resins. J Prosthet Dent. 1984;51:119–121. doi: 10.1016/s0022-3913(84)80117-1. [DOI] [PubMed] [Google Scholar]

- 12.Vallittu PK, Vojtkova H, Lassila VP. Impact strength of denture polymethyl methacrylate reinforced with continuous glass fibers or metal wire. Acta Odontol Scand. 1995;53:392–396. doi: 10.3109/00016359509006007. [DOI] [PubMed] [Google Scholar]

- 13.Matthews E, Smith DC. Nylon as a denture base material. Br Dent J. 1955;98:231–237. [Google Scholar]

- 14.Gutteridge DL. Reinforcement of poly (methyl methacrylate) with ultra high modulus polyethylene fibers. J Dent. 1992;20:50–54. doi: 10.1016/0300-5712(92)90012-2. [DOI] [PubMed] [Google Scholar]

- 15.Ladizesky NH, Pang MK, Chow TW, Ward IM. Acrylic resins reinforced with woven highly drawn linear polyethylene fibres. 3. Mechanical properties and further aspects of denture construction. Aust Dent J. 1993;38:28–38. doi: 10.1111/j.1834-7819.1993.tb05448.x. [DOI] [PubMed] [Google Scholar]

- 16.ASTM international. Designation: D 4812-99, Standard test method for un-notched cantilever beam impact resistance of plastics (test method under jurisdiction of ASTM committee on plastics D-20) Annual Book of ASTM Standard. 1999 Mar;14:02 [Google Scholar]

- 17.Anusavice KJ Philips' science of dental materials. 11th ed. St. Louis: Elsevier; 2003. pp. 733–734. [Google Scholar]

- 18.John J, Gangadhar SA, Shah I. Flexural strength of heat-polymerized polymethyl methacrylate denture resin reinforced with glass, aramid, or nylon fibers. J Prosthet Dent. 2001;86:424–427. doi: 10.1067/mpr.2001.118564. [DOI] [PubMed] [Google Scholar]

- 19.Ladizesky NH, Chow TW. The effect of interface adhesion, water immersion and anatomical notches on the mechanical properties of denture base resins reinforced with continuous high performance polyethylene fibres. Aust Dent J. 1992;37:277–289. doi: 10.1111/j.1834-7819.1992.tb04744.x. [DOI] [PubMed] [Google Scholar]

- 20.Paula E Silva E, Rosa EL, Barbosa SV. Tissue reactions of polypropylene mesh used in maxillofacial trauma. Braz Dent J. 2001;12(2):121–125. [PubMed] [Google Scholar]

- 21.Braden M, Davy KW, Parker S, Ladizesky NH, Ward IM. Denture base poly(methyl methacrylate) reinforced with ultrathin modulus polyethylene fibers. Br Dent J. 1988;164:109–113. doi: 10.1038/sj.bdj.4806373. [DOI] [PubMed] [Google Scholar]

- 22.Ladizesky NH, Cheng YY, Chow TW, Ward IM. Acrylic resin reinforced with chopped high performance polyethylene fiber--properties and denture construction. Dent Mater. 1993;9:128–135. doi: 10.1016/0109-5641(93)90089-9. [DOI] [PubMed] [Google Scholar]

- 23.Smith DC. The non-metallic denture base-recent developments. Dent Pract. 1957;8:73–80. [Google Scholar]

- 24.Vallittu PK, Narva K. Impact strength of a modified continuous glass fiber-poly(methyl methacrylate) Int J Prosthodont. 1997;10:142–148. [PubMed] [Google Scholar]

- 25.Uzun G, Hersek N, Tinçer T. Effect of five woven fiber reinforcements on the impact and transverse strength of a denture base resin. J Prosthet Dent. 1999;81:616–620. doi: 10.1016/s0022-3913(99)70218-0. [DOI] [PubMed] [Google Scholar]

- 26.Kim SH, Watts DC. The effect of reinforcement with woven E-glass fibers on the impact strength of complete dentures fabricated with high-impact acrylic resin. J Prosthet Dent. 2004;91:274–280. doi: 10.1016/j.prosdent.2003.12.023. [DOI] [PubMed] [Google Scholar]

- 27.Karacaer O, Polat TN, Tezvergil A, Lassila LV, Vallittu PK. The effect of length and concentration of glass fibers on the mechanical properties of an injection- and a compression-molded denture base polymer. J Prosthet Dent. 2003;90:385–393. doi: 10.1016/S0022391303005183. [DOI] [PubMed] [Google Scholar]

- 28.Vallittu PK. Comparison of two different silane compounds used for improving adhesion between fibres and acrylic denture base material. J Oral Rehabil. 1993;20:533–539. doi: 10.1111/j.1365-2842.1993.tb01640.x. [DOI] [PubMed] [Google Scholar]

- 29.Clarke DA, Ladizesky NH, Chow TW. Acrylic resins reinforced with highly drawn linear polyethylene woven fibres. 1. Construction of upper denture bases. Aust Dent J. 1992;37:394–399. doi: 10.1111/j.1834-7819.1992.tb00766.x. [DOI] [PubMed] [Google Scholar]

- 30.Ramos V, Jr, Runyan DA, Christensen LC. The effect of plasma-treated polyethylene fiber on the fracture strength of polymethyl methacrylate. J Prosthet Dent. 1996;76:94–96. doi: 10.1016/s0022-3913(96)90348-0. [DOI] [PubMed] [Google Scholar]