Abstract

Failures of zirconia-based all-ceramic restorations appear to be predominantly chips and fractures in the porcelain veneer, from occlusally induced sliding contact damage. We hypothesized that such failure may be substantially mitigated by controlled grading of the elastic modulus at the ceramic surface. In this study, we fabricated graded structures by infiltrating glass into zirconia plates, resulting in improved aesthetics and diminished modulus at the surfaces. Individual plates were then embedded in epoxy or cemented to dental composites and subjected to single- or multi-cycle sliding contact. Plates of porcelain-veneered zirconia and monolithic zirconia served as controls. Graded zirconia-glass structures exhibited over 3 times better resistance to single-cycle sliding damage than monolithic zirconia and 25 times better than veneered zirconia, and had a fatigue sliding damage resistance comparable with that of monolithic zirconia. These zirconia-glass materials can be engineered in shades from white to yellow, and have potentially better cementation properties than homogeneous zirconia.

Keywords: graded zirconia-glass structures, sliding contact damage, fatigue loading, veneered zirconia restorations, porcelain veneer fracture

Introduction

Metal-ceramic retainers (MCRs) have been the most common choice for aesthetic fixed prostheses over the past 50 years. Long-term clinical studies have revealed that while MCRs are structurally sound, several clinical performance deficiencies persist (Walton, 1999, 2003; Burke and Lucarotti, 2009). The gray metal framework and opaque oxides make it difficult for natural tooth aesthetics to be imitated in situations where space is limited or where lighter shades are needed (Pjetursson et al., 2007). Additionally, the gingival tissues may recede over time; if a metal collar is used, the dark margins can become visible. In either case, the restoration is then easily identified as a false tooth. Finally, dental alloys, especially cast-metal alloys, are subject to corrosion; the effect can range from degradation of appearance to loss of mechanical strength (Lang et al., 1982; Davis, 2003; Prochazkova et al., 2006). The corrosion products can produce a bluish-gray pigmentation of gingiva and oral mucosa and cause local and systemic hypersensitivities, especially in immunologically susceptible individuals (Khamaysi et al., 2006; Valentine-Thon et al., 2006; Venclikova et al., 2006, 2007).

Compared with MCRs, zirconia-based all-ceramic restorations exhibit better biocompatibility and greater aesthetic potential. Zirconia-based all-ceramic restorations are also easier to fabricate than MCRs. Zirconia frameworks are produced by the milling of either fully sintered or partially sintered zirconia blocks, a process that is more rapid and less labor-intensive relative to the lost-wax casting process for metals (Christensen, 2009). Applying an aesthetic veneer over a zirconia framework is no more difficult than applying similar materials over metal. However, clinical research and practice have revealed that zirconia-based all-ceramic restorations fail at a greater rate than MCRs (Sailer et al., 2007b, 2009; Christensen, 2009). The failures of zirconia-based restorations appear to be occlusion-related chips and fractures of the overlay aesthetic veneer, and not fractures of the strong underlying framework (Vult von Steyern et al., 2005; Raigrodski et al., 2006; Sailer et al., 2007a; Tinschert et al., 2008; Ortorp et al., 2009). Therefore, there is a need to develop a contact-damage-resistant all-ceramic restoration that does not compromise the aesthetics of the overlay ceramic.

In this paper, we present a new concept that improves the resistance to occlusal contact damage of ceramic restorations by utilizing a zirconia-glass functionally graded material. A low-modulus glassy surface dissipates surface bending stress, rendering the graded zirconia-glass material superior in flexural capacity relative to monolithic zirconia (Zhang and Ma, 2009). Since glass is used to infiltrate the accessible surfaces of zirconia, a graded zirconia-glass material possesses much-improved aesthetics. The glass-rich intaglio surface (cementation surface) can be acid-etched and silanized to facilitate a resin-cement bond (Zhang and Kim, 2009). With a simple staining technique or the application of a thin overlay ceramic, the graded zirconia-glass material offers an aesthetic option for damage-resistant inlays, onlays, Maryland bridges, crowns, and fixed partial dentures in the posterior regions.

Materials & Methods

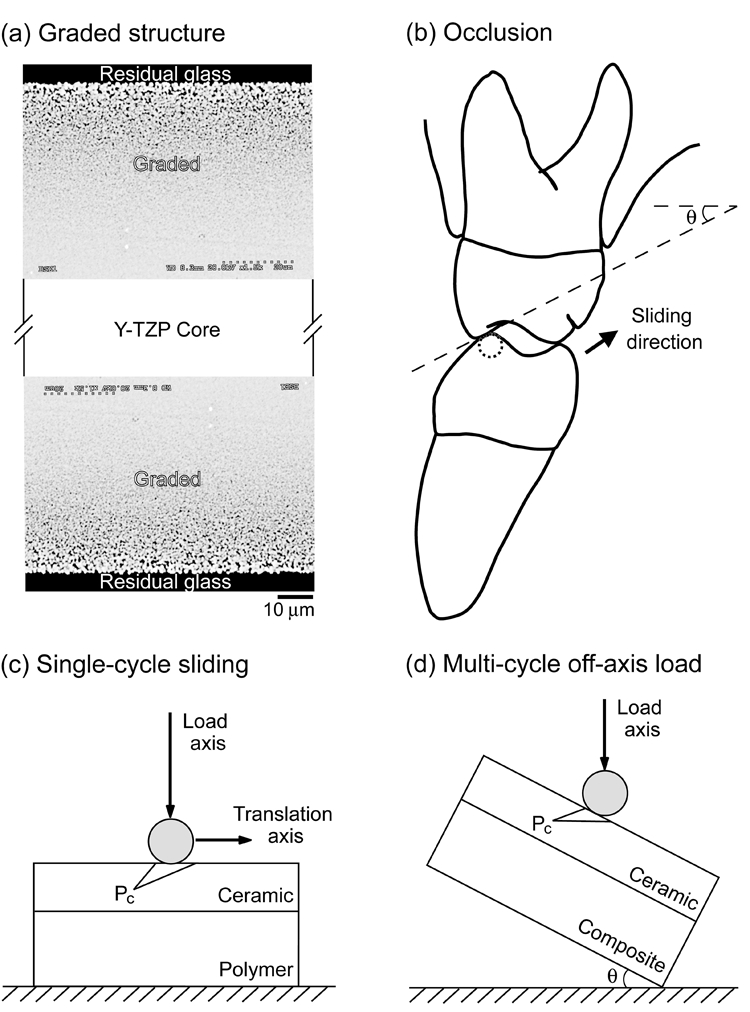

The zirconia material used to produce graded structures was fabricated from a fine yttria-stabilized zirconia powder (TZ-3Y-E grade, Tosoh, Tokyo, Japan). This material has a flexural strength of 1.1 GPa and a coefficient of thermal expansion (CTE) of 10.4 x 10-6°C-1 (Zhang and Ma, 2009), properties comparable with those of commercially available dental zirconias. A slurry of a silicate glass composition with matching CTE (Zhang and Kim, 2009; Zhang and Ma, 2009) was applied to the top and bottom surfaces of heat-treated zirconia plates (1350°C for 1 hr in air). The coated plates were then heated to 1450°C for 2 hrs, producing an infiltrated glass/zirconia/glass (G/Z/G) structure (Fig. 1a). After the plates cooled, we removed the surface excess glass by polishing. Monolithic zirconia controls were sintered at 1450°C for 2 hrs. Heating and cooling rates were 900°C/hr in all cases. G/Z/G and monolithic Y-TZP plates were prepared in 2 dimensions: 12 x 12 x 2.5 and 12 x 12 x 1.5 mm. For comparison purposes, porcelain-veneered zirconia plates 15 mm in diameter and 1.5-mm thick (1 mm porcelain, 0.5-mm zirconia, LAVA, 3M ESPE, St. Paul, MN) were fabricated following manufacturer’s specifications. The top surfaces of the ceramic plates were polished to 1-μm finish.

Figure 1.

Graded restorative materials; posterior tooth contact; laboratory loading models. (a) Back-scattered electron image of graded glass/zirconia/glass (G/Z/G) structure in sectional view. Note the light zirconia phase, owing to its high atomic weight relative to that of the glass phase. (b) Schematic of occlusion, showing that posterior tooth-tooth contact can be visualized as a spherical indenter sliding down an inclined flat surface. Experimental setup for (c) single-cycle sliding with a translating sphere, and (d) multi-cycle fatigue loading with a 30° inclination angle. The symbol Pc in (c) and (d) denotes the partial cone cracks.

Previous studies have established that posterior tooth-tooth occlusal contact can be visualized as a spherical indenter sliding down an inclined flat surface (DeLong and Douglas, 1983; Kim et al., 2008; Krejci et al., 1999) (Fig. 1b). We performed sliding contact tests using a ceramic ball-on-flat-surface arrangement to determine the critical normal load for the onset of surface cracks under single-cycle loading and the resistance to fatigue damage under multi-cycle loading. Load was delivered to the top surface of the plates with a hard tungsten carbide (WC) sphere (radius 1.5 mm) in a mouth-motion simulator (Elf 3300, EnduraTEC Division of Bose, Minnetonka, MN, USA) in water. For single-cycle sliding tests, 2.5-mm-thick G/Z/G and Y-TZP plates and 1.5-mm-thick veneered-Y-TZP were individually embedded into two-part epoxy (Leco, St. Joseph, MI, USA) with only the top, polished surface exposed. (Thick G/Z/G and Y-TZP plates used were simply to avoid flexural fracture.) For multi-cycle tests, plates (1.5-mm thick for all specimen groups) were cemented (RelyX Unicem, 3M ESPE) to a dental composite block 4 mm in thickness with lateral dimensions matching those of G/Z/G, Y-TZP, or to veneered zirconia plates, respectively (Z100, 3M ESPE). The composite blocks were incubated in water at 37°C for 1 mo before cementation to allow for any hydroscopic expansion.

Single-cycle sliding tests were conducted in a biaxial mode. The indenter comes into contact with the specimen surface and loads to the prescribed maximum, while the specimen holder translates horizontally at constant velocity v = 2 mm/sec for at least 0.7 mm (Fig. 1c). This produces a steady-state wear track. The range of normal loads (Pn) varied between 30 N and 2000 N, with loading and unloading rates at 2000 N/sec.

We conducted multi-cycle sliding contact tests using an occlusal-like loading profile with the specimen surface tilted at an inclination angle θ = 30° [off-axis loading (Fig. 1d)]. Load (P) was applied in the vertical direction, but with contact−load−slide−liftoff sequence: i.e., the indenter in contact with the specimen, loading to a maximum while sliding down the surface to create a wear facet, unloading, and lifting off from the specimen surface. A maximum fatigue load P = 200 N and a loading frequency f ≈ 2 Hz were selected to simulate restorations subject to occlusion. Fatigue tests were interrupted after a prescribed number of loading cycles, and the specimen was inspected for damage at the top surface by means of a 3D polarized microscope (Model H-160, Edge Scientific Instrument Corporation, Marina del Ray, CA, USA). The specimen was then indexed and re-introduced to the mouth-motion machine for continued testing.

Three specimens were used for each prescribed load level per test per specimen type. We sectioned and polished selected specimens to evaluate the extent of subsurface damage.

Results

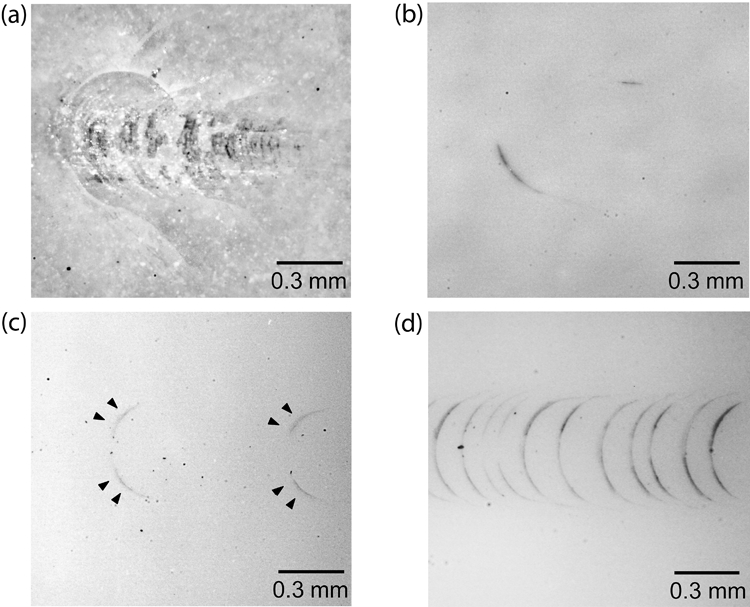

The pertinent features of damage sustained in the surfaces of ceramic plates following the single-cycle sliding test in water are illustrated by optical micrographs (Fig. 2). The sliding direction is from left to right. For porcelain-veneered zirconia, the critical normal load to cause surface cracking in the overlay porcelain was Pn ≈ 80 N. An example of damage in the porcelain surface induced from a translating WC sphere under normal load Pn = 120 N is shown in Fig. 2a. A sequence of incomplete ring cracks (herringbone cracks) formed along the sliding wear track. Some of the ring cracks extended downward to form deep penetrating partial cone cracks (Lawn, 1967; Kim et al., 2007). For graded glass/zirconia surfaces, however, no significant fracture was observed on the wear track following frictional sliding under normal loads up to Pn = 2000 N (Fig. 2b). For monolithic Y-TZP, which is recognized for its excellent wear resistance (Hannink et al., 2000), the critical normal load to initiate surface ring cracking was Pn ≈ 600 N (Fig. 2c). Note that two faint incomplete ring cracks formed along the wear track in this last case. Well-developed herringbone cracks formed during frictional sliding under normal load Pn = 1000 N (Fig. 2d). A previous study revealed that, under these same conditions, the herringbone cracks extended into partial cone cracks, propagating 30 to 40 μm into the bulk of Y-TZP (Kim et al., 2010).

Figure 2.

Surface view of single-cycle sliding damage in (a) porcelain fused to zirconia at Pn = 120 N; (b) graded G/Z/G at Pn = 2000 N; (c,d) monolithic zirconia at Pn = 600 N and 1000 N, respectively. Note two faint incomplete ring cracks indicated by solid arrows in (c). Sliding direction from left to right of micrographs.

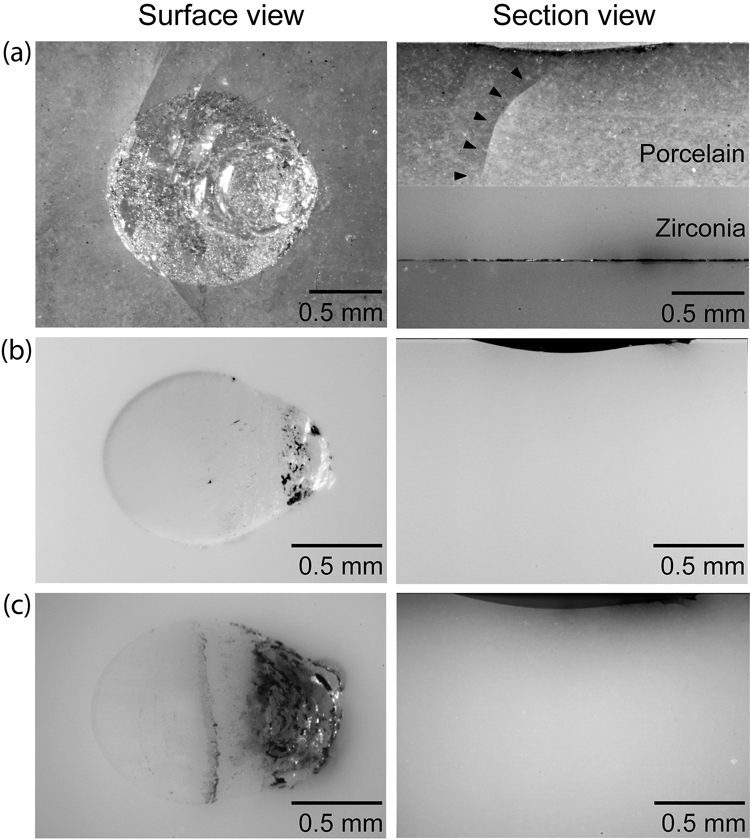

Fatigue sliding contact responses of veneered zirconia, G/Z/G, and monolithic Y-TZP on composites are shown in Fig. 3. For off-axis loading of porcelain-veneered zirconia, a set of herringbone cracks formed at the first contact−load−slide−liftoff cycle at P = 200 N in water. After 100,000 loading cycles, extensive surface wear occurred (surface view), and the partial cone cracks penetrated the entire porcelain veneer, arresting at the veneer/core interface (section view) (Fig. 3a). For off-axis loading of graded G/Z/G and monolithic zirconia, a smooth teardrop-shaped wear track formed (surface view) after 1,000,000 cycles at P = 200 N in water (Figs. 3b, 3c). A section view revealed that a small amount of surface material had been removed due to wear, but no significant cracks were evident (Figs. 3b, 3c).

Figure 3.

Fatigue damage sustained in (a) porcelain fused to zirconia at 200 N 100,000 cycles; (b) graded G/Z/G at 200 N 1,000,000 cycles; and (c) monolithic zirconia at 200 N 1,000,000 cycles. Images are of both surface and sectional views. Note that, in (a), the partial cone crack (indicated by solid arrows in section view) has propagated to the veneer/core interface. Sliding direction from left to right of micrographs.

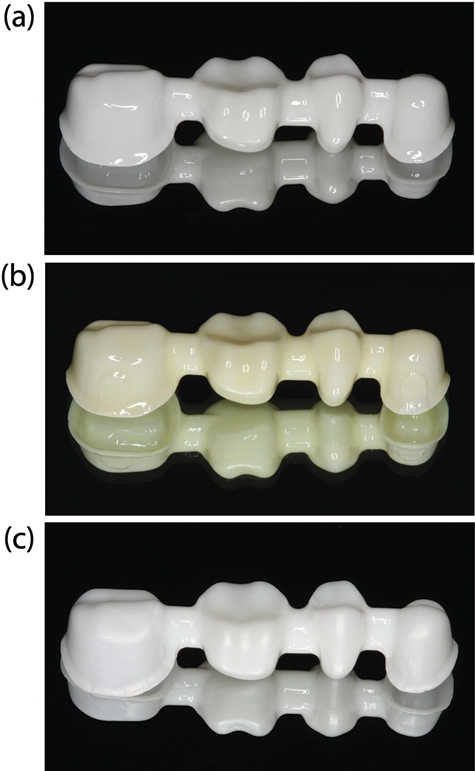

The appearance of the graded G/Z/G frameworks, along with a comparative monolithic Y-TZP framework that has only connector areas infiltrated with white glass shade, is shown in Fig. 4. The G/Z/G frameworks exhibited a glossy appearance and varied in shade between white and light yellow (Figs. 4a, 4b), whereas the Y-TZP framework was white (Fig. 4c). Additionally, the interior of G/Z/G also contained a residual glass layer and a graded glass/zirconia layer, which could potentially facilitate an etching-silane adhesion procedure.

Figure 4.

Digital images showing four-unit graded zirconia-glass (G/Z/G) frameworks with (a) white and (b) light yellow shades; and (c) a four-unit monolithic zirconia framework with only connector areas infiltrated with white glass shade.

Discussion

This study investigated sliding contact damage resistance of a graded zirconia-glass material (G/Z/G) relative to the monolithic Y-TZP control and a commercial porcelain-veneered zirconia system. Our findings demonstrated that the critical normal load for the onset of herringbone cracks in G/Z/G was 2000 N, over 3 times higher than that of monolithic Y-TZP (600 N) and 25 times higher than that of porcelain (80 N). Additionally, G/Z/G had a fatigue sliding damage resistance comparable with that of monolithic zirconia, an order of magnitude better than that of the porcelain-veneered zirconia.

Posterior restorations are subject to sliding contact fatigue under relatively high bite forces. The poor mechanical properties of porcelain (particularly low strength and toughness) combined with residual thermal stresses (induced from mismatch in CTE and thermal diffusivity between the porcelain veneer and zirconia core) (Swain, 2009) make the overlay porcelain susceptible to sliding contact damage, resulting in high incidence of veneer chipping and fracture. In an effort to prevent veneer fracture, some dental labs propose to use monolithic Y-TZP for fixed-prosthesis restorations. Fracture of dental ceramics is associated with crack initiation and propagation. In terms of crack initiation, the normal load to initiate sliding damage in zirconia with a 1.5-mm radius sphere contact is ~600 N, over 7 times higher than that of the overlay porcelain. Additionally, under a nominal chewing force of 200 N, extended fatigue tests (106 cycles) using the same sphere contact showed no crack formation in monolithic Y-TZP. In porcelain-veneered zirconia at 200-N load, herringbone-like partial cone cracks formed in the first sliding cycle and propagated to the veneer/core interface at ~100,000 cycles.

Our findings suggest that monolithic Y-TZP should indeed meet the structural demand for posterior applications. However, Y-TZP has much higher hardness and elastic modulus compared with those of natural enamel, which can cause excessive wear of the opposing dentition. Additionally, zirconia has an unnaturally white opaque appearance. The newly developed G/Z/G material can provide the wear resistance as well as the necessary aesthetics. Guided by analysis, we can design G/Z/G with better strength (Zhang and Ma, 2009) and contact damage resistance than zirconia, while retaining surface physical and optical properties similar to those of porcelain.

The exceptionally high resistance to sliding contact damage of graded zirconia-glass material needs further elaboration. The low-modulus glassy surface effectively dissipates the near-contact stresses and improves the sliding damage resistance of G/Z/G. As a result, G/Z/G possesses three-fold increased resistance to single-cycle sliding relative to monolithic Y-TZP. In the case of multi-cyclic sliding, assuming dominant slow crack growth (SCG) mechanics, the number of cycles to initiate the herringbone cracks for a given load, P, is determined by a fatigue relation, nI = (Pc/P)N/2, where Pc is the critical load for the onset of the herringbone cracks in single-cycle load and N is a velocity exponent for the indented material (Zhang et al., 2005). With experimentally measured values N = 30 and N = 19, and Pc = 600 N and Pc = 2000 N for monolith Y-TZP and G/Z/G in water, the number of cycles for initiating herringbone cracks in Y-TZP and G/Z/G would be 1.4 x 106 and 3.2 x 109, respectively, for a nominal load of 200 N in water. Given the relatively high toughness of Y-TZP, it would take even more cycles to propagate partial cones.

We acknowledge that, in the current study, a residual glass layer (~ 50 microns thick) has been polished away from the surface of the graded structure, creating a flat surface for damage evaluation relative to polished surfaces of monolithic Y-TZP and porcelain-veneered zirconia. In clinical practice, we propose to preserve this thin residual glass layer as a glazed layer. Should a fatigue crack form, it will be contained within the glass-rich layer. Cracks are inhibited from propagating out of a low-modulus and low-toughness glassy layer into the high-modulus and high-toughness zirconia layer (Kim et al., 2006). Additionally, the current tests were done on flat specimens, where G/Z/G demonstrated a superior resistance to sliding contact damage. For closer simulation of the clinical situation, further studies with anatomically correct crowns and fixed partial dentures are necessary.

Acknowledgments

Discussions with Dean Mersky, Brian Lawn, and Van Thompson are gratefully acknowledged. This research was sponsored by a US NIH/NIDCR grant (1R01 DE017925, P.I. Zhang) and an NSF grant (CMMI-0758530, P.I. Zhang).

References

- Burke FJ, Lucarotti PS. (2009). Ten-year outcome of crowns placed within the General Dental Services in England and Wales. J Dent 37:12-24 [DOI] [PubMed] [Google Scholar]

- Christensen GJ. (2009). Porcelain-fused-to-metal versus zirconia-based ceramic restorations, 2009. J Am Dent Assoc 140:1036-1039 [DOI] [PubMed] [Google Scholar]

- Davis JR, Editor (2003). Handbook of materials for medical devices. Materials Park, OH: ASM International [Google Scholar]

- DeLong R, Douglas WH. (1983). Development of an artificial oral environment for the testing of dental restoratives: bi-axial force and movement control. J Dent Res 62:32-36 [DOI] [PubMed] [Google Scholar]

- Hannink RHJ, Kelly PM, Muddle BC. (2000). Transformation toughening in zirconia-containing ceramics. J Am Ceram Soc 83:461-487 [Google Scholar]

- Khamaysi Z, Bergman R, Weltfriend S. (2006). Positive patch test reactions to allergens of the dental series and the relation to the clinical presentations. Contact Dermatitis 55:216-218 [DOI] [PubMed] [Google Scholar]

- Kim JW, Bhowmick S, Hermann I, Lawn BR. (2006). Transverse fracture of brittle bilayers: relevance to failure of all-ceramic dental crowns. J Biomed Mater Res B Appl Biomater 79:58-65 [DOI] [PubMed] [Google Scholar]

- Kim JW, Kim JH, Thompson VP, Zhang Y. (2007). Sliding contact fatigue damage in layered ceramic structures. J Dent Res 86:1046-1050 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kim JW, Kim JH, Janal MN, Zhang Y. (2008). Damage maps of veneered zirconia under simulated mastication. J Dent Res 87:1127-1132 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kim JW, Liu L, Zhang Y. (2010). Improving the resistance to sliding contact damage of zirconia using elastic gradients. J Biomed Mater Res B Appl Biomater. [Epub ahead of print, June 15, 2010. DOI: 10.1002/jbm.b.31657]. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Krejci I, Albert P, Lutz F. (1999). The influence of antagonist standardization on wear. J Dent Res 78:713-719 [DOI] [PubMed] [Google Scholar]

- Lang BR, Bernier SH, Giday Z, Asgar K. (1982). Tarnish and corrosion of noble metal alloys. J Prosthet Dent 48:245-252 [DOI] [PubMed] [Google Scholar]

- Lawn BR. (1967). Partial cone crack formation in a brittle material loaded with a sliding indenter. Proc R Soc Lond A 299:307-316 [Google Scholar]

- Ortorp A, Kihl ML, Carlsson GE. (2009). A 3-year retrospective and clinical follow-up study of zirconia single crowns performed in a private practice. J Dent 37:731-736 [DOI] [PubMed] [Google Scholar]

- Pjetursson BE, Sailer I, Zwahlen M, Hämmerle CH. (2007). A systematic review of the survival and complication rates of all-ceramic and metal-ceramic reconstructions after an observation period of at least 3 years. Part I: Single crowns. Clin Oral Implants Res 18(Suppl 3):73-85; erratum in Clin Oral Implants Res 19:326-328, 2008 [DOI] [PubMed] [Google Scholar]

- Prochazkova J, Podzimek S, Tomka M, Kucerova H, Mihaljevic M, Hana K, et al. (2006). Metal alloys in the oral cavity as a cause of oral discomfort in sensitive patients. Neuro Endocrinol Lett 27(Suppl 1):53-58 [PubMed] [Google Scholar]

- Raigrodski AJ, Chiche GJ, Potiket N, Hochstedler JL, Mohamed SE, Billiot S, et al. (2006). The efficacy of posterior three-unit zirconium-oxide-based ceramic fixed partial dental prostheses: a prospective clinical pilot study. J Prosthet Dent 96:237-244 [DOI] [PubMed] [Google Scholar]

- Sailer I, Feher A, Filser F, Gauckler LJ, Luthy H, Hämmerle CH. (2007a). Five-year clinical results of zirconia frameworks for posterior fixed partial dentures. Int J Prosthodont 20:383-388 [PubMed] [Google Scholar]

- Sailer I, Pjetursson BE, Zwahlén M, Hämmerle CH. (2007b). A systematic review of the survival and complication rates of all-ceramic and metal-ceramic reconstructions after an observation period of at least 3 years. Part II: Fixed dental prostheses. Clin Oral Implants Res 18(Suppl 3):86-96; erratum in Clin Oral Implants Res 19:326-328, 2008 [DOI] [PubMed] [Google Scholar]

- Sailer I, Gottnerb J, Kanelb S, Hämmerle CH. (2009). Randomized controlled clinical trial of zirconia-ceramic and metal-ceramic posterior fixed dental prostheses: a 3-year follow-up. Int J Prosthodont 22:553-560 [PubMed] [Google Scholar]

- Swain MV. (2009). Unstable cracking (chipping) of veneering porcelain on all-ceramic dental crowns and fixed partial dentures. Acta Biomater 5:1668-1677 [DOI] [PubMed] [Google Scholar]

- Tinschert J, Schulze KA, Natt G, Latzke P, Heussen N, Spiekermann H. (2008). Clinical behavior of zirconia-based fixed partial dentures made of DC-Zirkon: 3-year results. Int J Prosthodont 21:217-222 [PubMed] [Google Scholar]

- Valentine-Thon E, Muller K, Guzzi G, Kreisel S, Ohnsorge P, Sandkamp M. (2006). LTT-MELISA is clinically relevant for detecting and monitoring metal sensitivity. Neuro Endocrinol Lett 27(Suppl 1):17-24 [PubMed] [Google Scholar]

- Venclikova Z, Benada O, Bartova J, Joska L, Mrklas L, Prochazkova J, et al. (2006). In vivo effects of dental casting alloys. Neuro Endocrinol Lett 27(Suppl 1):61-68 [PubMed] [Google Scholar]

- Venclikova Z, Benada O, Bartova J, Joska L, Mrklas L. (2007). Metallic pigmentation of human teeth and gingiva: morphological and immunological aspects. Dent Mater J 26:96-104 [PubMed] [Google Scholar]

- Vult von Steyern P, Carlson P, Nilner K. (2005). All-ceramic fixed partial dentures designed according to the DC-Zirkon technique. A 2-year clinical study. J Oral Rehabil 32:180-187 [DOI] [PubMed] [Google Scholar]

- Walton TR. (1999). A 10-year longitudinal study of fixed prosthodontics: clinical characteristics and outcome of single-unit metal-ceramic crowns. Int J Prosthodont 12:519-526 [PubMed] [Google Scholar]

- Walton TR. (2003). An up to 15-year longitudinal study of 515 metal-ceramic FPDs: Part 2. Modes of failure and influence of various clinical characteristics. Int J Prosthodont 16:177-182 [PubMed] [Google Scholar]

- Zhang Y, Kim JW. (2009). Graded structures for damage resistant and aesthetic all-ceramic restorations. Dent Mater 25:781-790 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zhang Y, Ma L. (2009). Optimization of ceramic strength using elastic gradients. Acta Mater 57:2721-2729 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zhang Y, Bhowmick S, Lawn BR. (2005). Competing fracture modes in brittle materials subject to concentrated cyclic loading in liquid environments: monoliths. J Mater Res 20:2021-2029 [DOI] [PMC free article] [PubMed] [Google Scholar]