Abstract

Despite the increasing utilization of all-ceramic crown systems, their mechanical performance relative to that of metal ceramic restorations (MCR) has yet to be determined. This investigation tested the hypothesis that MCR present higher reliability over two Y-TZP all-ceramic crown systems under mouth-motion fatigue conditions. A CAD-based tooth preparation with the average dimensions of a mandibular first molar was used as a master die to fabricate all restorations. One 0.5-mm Pd-Ag and two Y-TZP system cores were veneered with 1.5 mm porcelain. Crowns were cemented onto aged (60 days in water) composite (Z100, 3M/ESPE) reproductions of the die. Mouth-motion fatigue was performed, and use level probability Weibull curves were determined. Failure modes of all systems included chipping or fracture of the porcelain veneer initiating at the indentation site. Fatigue was an acceleration factor for all-ceramic systems, but not for the MCR system. The latter presented significantly higher reliability under mouth-motion cyclic mechanical testing.

Keywords: all-ceramic, dental ceramic, metal ceramic retainers, fatigue, single-crown

Introduction

Metal ceramic restorations (MCR) are reputed to be the gold standard in dentistry, offering reasonable esthetics (Donovan, 2009) and long-term structural performance, with single-crown porcelain fracture documented clinically at ~ 3% over 20 yrs (Napankangas and Raustia, 2008). Primarily reported are biological complications in MCR, whereas technical complications such as porcelain failure are rarely described (Napankangas and Raustia, 2008).

The patient demand for metal-free and tooth-colored restorations has driven substantial effort to increase the strength and reliability of dental ceramic systems (Raigrodski, 2006). Given its strength and transformation toughening, zirconia may be regarded as the most suitable substructure ceramic for posterior restorations (Raigrodski, 2004). For dental applications, yttrium oxide is usually added (2-3% mol of Y2O3) to the pure zirconia to stabilize the tetragonal phase at room temperature, generating a multiphase material, i.e., partially stabilized zirconia (Piconi and Maccauro, 1999). The utilization of yttria-tetragonal zirconia polycrystals (Y-TZP) in the areas of high tensile stresses of core and fixed partial denture (FPDs) connectors is indicated due to its inherent ability to suppress crack propagation (Studart et al., 2007a). Although Y-TZP substructures show high survival rates, technical complications in FPDs, such as chipping of the veneering porcelain, have resulted in high failure rates (Raigrodski et al., 2006; Sailer et al., 2007a). Such complications have been suggested to arise due to possible variations in materials processing (Coelho et al., 2009; Swain, 2009).

Simulation of occlusal function during laboratory material’s testing becomes essential in predicting long-term performance before clinical usage. Mouth-motion fatigue testing (Rekow and Thompson, 2007; Coelho et al., 2009) has demonstrated success in duplicating and predicting clinical chipping and fracture modes of ceramics (Rekow and Thompson, 2007; Bonfante et al., 2009; Coelho et al., 2009; Silva et al., 2009). Whereas simulation of Y-TZP crowns clinical failure has been shown to be possible in the laboratory, a parallel between laboratory and clinical failure modes in MCR restorations has not been determined to date.

This investigation tested the hypothesis that MCR (Pd-Ag) presents higher reliability than two Y-TZP all-ceramic crown systems under mouth-motion fatigue conditions.

Materials & Methods

We modeled an anatomically correct 3-D prototype of a mandibular first molar full-crown preparation by reducing proximal walls by 1.5 mm and the occlusal surface by 2.0 mm using CAD software (Pro/Engineer Wildfire, PTC, Needham, MA, USA). The CAD file of the prepared tooth was imported to a milling machine to generate plastic models with the dimensions described above. These models were replicated and placed on a dental articulator with a cast of the opposing dentition. Impressions of the prepared, adjacent, and opposing teeth were taken (Aquasil, Dentsply, York, PA, USA) for sample preparation. Alloy (Pd-Ag White Porcelain Alloy, Jensen Industries, North Haven, CT, USA) copings (0.5 mm thick) were fabricated and designated as group MCR (n = 21). Y-TZP core systems were milled in pre-sintered stage, and then fully sintered to achieve 0.5 mm in thickness following manufacturers’ guidelines. The two all-ceramic groups were designated as follows: LAV (n = 21) for LAVA (LAVA, 3M/ESPE, St. Paul, MN, USA) and CER (n = 21) for CERCON (CERCON, Dentsply, York, PA, USA). All groups were hand-layered-veneered with corresponding porcelain for each system (Creation Porcelain, Jensen Industries, North Haven, CT, USA; LAVA Veneer, 3M/ESPE, St. Paul, MN, USA; and Vita Veneer, Dentsply, York, PA, USA, respectively) following the manufacturers’ directions. The standardization of the thickness of the veneering ceramic was accomplished with a silicone index made from an impression of the waxed desired anatomy, which was used to guide porcelain contour and anatomy in all crowns. Final crowns presented appropriate marginal fit (checked by probing and visual inspection) and occlusal morphology.

Sixty-three tooth composite (Z100, 3M/ESPE, St. Paul, MN) dies were fabricated from silicon rubber impressions (Aquasil, Dentsply, York, PA, USA) of the machined plastic model. The dies were stored in distilled water at 37°C for 30 days to eliminate any effect of water-uptake dimensional expansion (Huang et al., 2008).

All crowns were cemented (RelyX Unicem, 3M/ESPE, St. Paul, MN, USA) under a 10-N load following manufacturer’s instructions. The cemented crowns were vertically embedded in acrylic resin (Orthoresin, Degudent, Mainz, Germany) poured in a 25-mm-diameter plastic tube, leaving buccal, lingual, and interproximal cervical margins evenly exposed 2 mm above the potting surface (acrylic resin surface).

After cementation, the specimens were equilibrated in distilled water for at least 7 days before mechanical testing. Three crowns of each group underwent single-load-to-fracture (SLF) testing at a cross-head speed of 1 mm/min in a universal testing machine (INSTRON 5666, Canton, MA, USA) with a 6.25-mm-diameter tungsten carbide (WC) ball. Based upon the mean load to failure from SLF, 3 sliding-contact step-stress accelerated life-testing (SSALT) profiles were determined with specimens assigned to each group in the ratio 3:2:1 (mild, moderate, and aggressive, respectively) (Nelson, 1990). Fatigue testing was performed at 2 Hz with an electrodynamic fatigue testing machine (ELF 3300, EnduraTec Division, Bose Corporation, Minnetonka, MN, USA). All specimens were subjected to mouth-motion step-stress sliding contact fatigue until failure or survival (Nelson, 1990). During fatigue, a 6.25-mm-diameter WC indenter under load moved lingually 0.7 mm downward on the incline of the disto-buccal cusp of the mandibular first molar, beginning 0.5 mm lingual to the cusp tip.

Use level probability Weibull curves with a cumulative damage and power law relationship were calculated (Zhao and Elsayed, 2005) (Alta Pro 7, Reliasoft, Tucson, AZ, USA). Reliability (90% two-sided confidence bounds) for completion of a mission of 50,000 cycles at a 200-N load was determined for group comparisons. If the Weibull use level probability calculated β was < 1 for any group, then a Weibull two-parameter probability multi-plot (Unreliability vs. load) and Contour plot (β vs. η) were calculated using final load at failure or survival of specimens.

All specimens were evaluated under polarized light (MZ-APO stereomicroscope, Carl Zeiss MicroImaging, Thornwood, NY, USA) at the completion of each fatigue step for crack initiation/evolution. Criteria for failure involved porcelain veneer fracture with or without core exposure, and bulk fracture (Rekow et al., 2007). Selected samples were gold-sputtered (Emitech K650, Emitech Products Inc., Houston, TX, USA), and fractographic analysis was performed by scanning electron microscopy (SEM) (Hitachi, Model 3500S, Osaka, Japan).

Images of clinical failure and impression replicas of MCR and Y-TZP-supported ceramic systems were utilized for comparison with laboratory failure modes.

Results

The single-load-to-failure SLF mean value (n = 3) for group MCR was 2002 N ± 597 N, for LAV 1220 ± 220 N, and for CER 1140 ± 280 N.

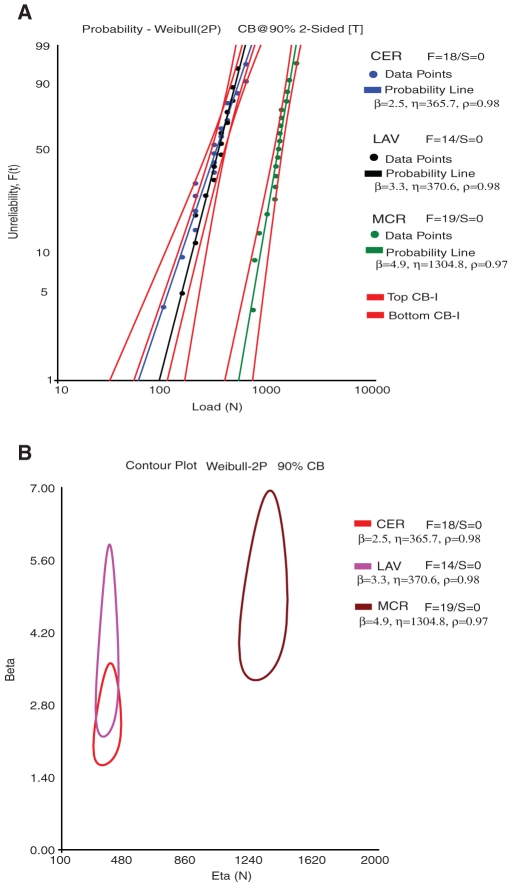

The β values were derived from use level probability Weibull calculation (reliability vs. number of cycles). Considering a use stress of 200 N (Table), group MCR exhibited higher reliability than both CER and LAV for a mission of 50,000 cycles at 200 N. β values (two-sided 90% confidence bounds) of 1.43 (0.76 - 2.69) and 1.72 (0.83 - 3.56) for CER and LAV, respectively, indicated that fatigue was an acceleration factor for both groups. The resulting β of 0.05 (0.03 - 0.08) for MCR indicated that load alone dictated the failure mechanism for this group, and that fatigue damage did not appear to accumulate. Load-at-failure data of all 3 groups were then calculated by a probability Weibull distribution (Weibull 7++, Reliasoft). One instructive graphical method for making this determination involves plotting the data with confidence bounds and seeing whether the bounds overlap or separate at the point of interest. Probability Weibull two-parameter multi-plot (Unreliability vs. load) showed the Weibull modulus for MCR (β = 4.9). CER and LAV presented Weibull moduli β = 2.5 and β = 3.3, respectively (Fig. 1a). MCR presented significantly higher characteristic strength (two-sided 90% confidence bounds), η = 1304.78 (1215.56–1400.55), than CER η = 365.73 (316.94–422.04) and LAV 370.60 (327.36–419.68) (the confidence bounds overlapped for CER and LAV) (Fig. 1a). Another way to determine whether these datasets are significantly different (based upon non-overlap of confidence bounds) is the utilization of a Weibull parameter contour plot (Fig. 1b).

Table.

Calculated Reliability for Full Crowns Given a Mission of 50,000 Cycles at 200 N Load with MCR Showing Significantly Higher Reliability than Both All-ceramic Systems

| Output (50 K cycles @ 200 N) | Cercon | LAVA | MCR |

|---|---|---|---|

| Upper | 0.80 | 0.79 | 1.00 |

| Reliability | 0.66 | 0.64 | 0.99* |

| Lower | 0.44 | 0.43 | 0.99 |

| β | 1.43 (0.76-2.69) | 1.72 (0.83-3.56) | 0.05 (0.03-0.08) |

β is the use level probability Weibull shape factor which, calculated, is < 1 for MCR and > 1 for LAV and CER, indicating that fatigue is an accelerating factor for both of the Y-TZP-supported all-ceramic systems, but not for the MCR.

represents significant higher reliability.

Figure 1.

Probability Weibull (A) and Contour (B) plots for group comparisons. Both plots represent the same Weibull calculation with different data deliverables. Note that characteristic strength (63.2% of the specimens would fail by that load level) for group MCR is significantly higher than for both Y-TZP-supported all-ceramic systems, and the datapoint with probability line is positioned to the right (A) with no overlap of confidence intervals (two-sided 90% confidence bounds).

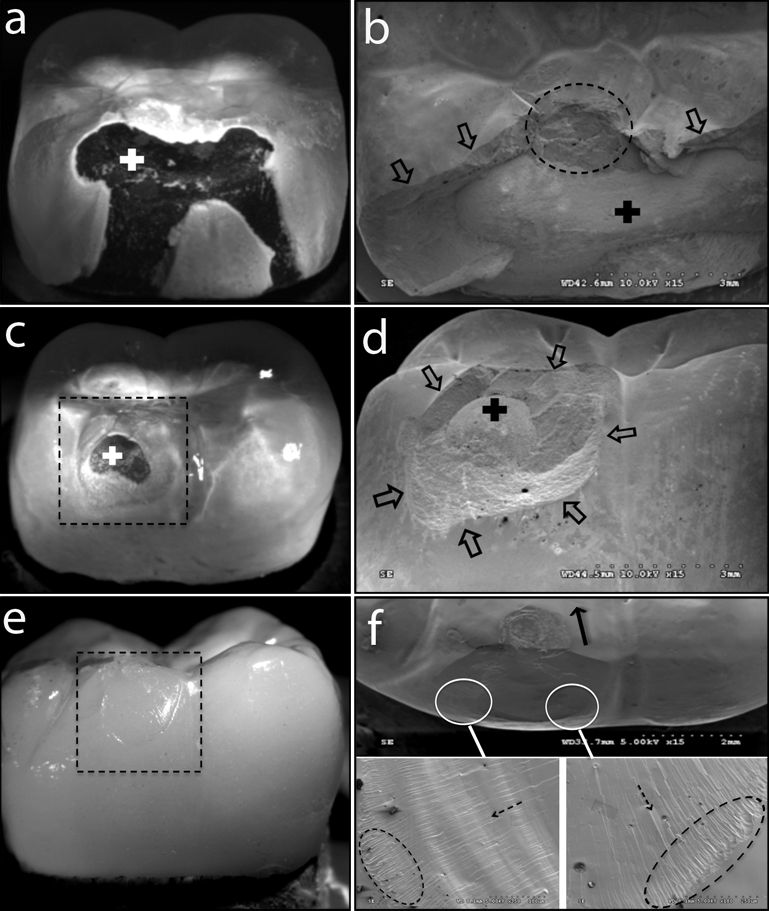

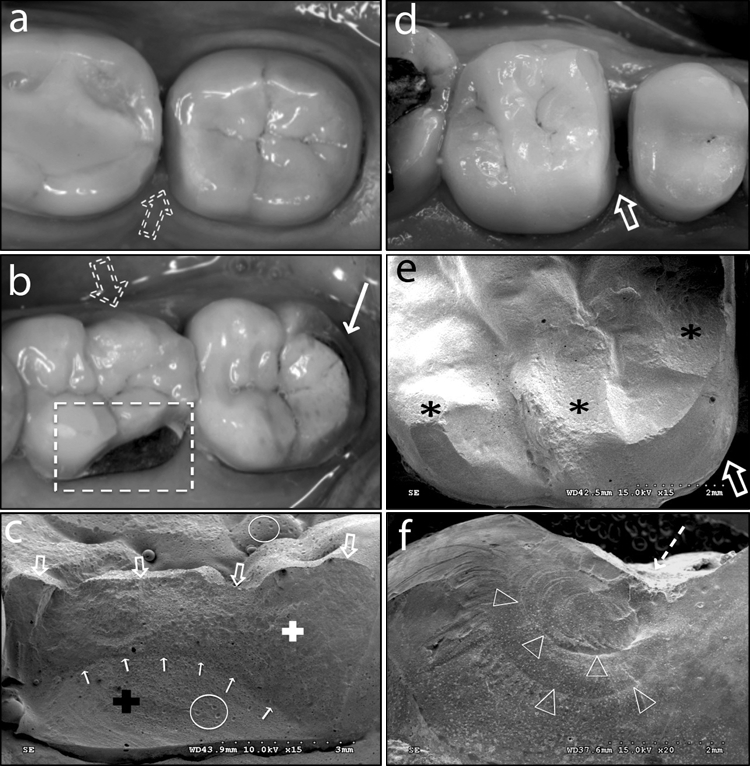

Representative failed specimens of MCR (Figs. 2a-2d) and CER (Figs. 2e, 2f) show the different systems’ fracture modes. All MCR specimens failed, exposing the Pd-Ag coping with different fracture sizes. Y-TZP failures were confined within the porcelain veneer (Fig. 2). Magnified images of the cohesive failed porcelain showed typical markers of crack direction (circled area on Fig. 2f), represented by hackles and twist hackles, indicating crack propagation from the sliding contact area toward the margins of cohesively failed porcelain veneer. To compare failure modes found in the present study with those observed clinically, we selected and documented representative examples from clinical practice. Observations included interproximal cohesive fracture of the veneer ceramic of MCR after 4 mos of service (Fig. 3a), which may be the result of limited core support. The most common failure mode observed clinically for MCR (Figs. 3b, 3c) was veneer fracture, with exposure of the coping, similar to what was observed in laboratory testing failures (Figs. 2a-2d). A clinical cohesive failure of a veneered Y-TZP after 2.5 yrs of service is also presented (Figs. 3d-3f). We have several clinical replicas where the veneered Y-TZP failure mode corresponds to our laboratory findings.

Figure 2.

A series of light-polarized (LP) and SEM images after sliding fatigue testing. Images (a) and (b) are LP and SEM of a sizable fracture of 1 MCR crown after 200,023 cycles at 1300 N of load (mild profile). White (a) and black (b) crosses lie on the exposed PdAg core after the fracture event. Oval segmented black line shows the damage created at the indentation contact area, and arrows delimit the fracture extension. (c) is a representative smaller chip fracture of an MCR crown (dotted box), exposing the PdAg core (white cross). (d) shows the SEM image of the dotted box presented in (c), showing the fracture extension after 95,034 cycles at 1220 N load. Black cross in (d) lies on the core exposed after fracture. Images (e) and (f) are LP and SEM images of a representative fatigue-failed specimen of CER after 49,500 cycles at 300 N Load. (f) shows an occlusal SEM view of the indentation area and the arrow indicating the sliding direction toward central fossa. Right and left bottom images in (f) are magnifications of marginal areas (white circles) of porcelain cohesive fracture. Hackle lines (dotted arrows) and a series of twist hackles (oval dotted lines) indicate fracture propagation from indentation contact toward the margins. Note that the Y-TZP core was not exposed.

Figure 3.

Clinical observations. Image (a) represents a cohesive veneer fracture on the mesial aspect of an MCR crown placed on a lower second molar (segmented white arrow) after 4 mos of service. (b) shows typical fractures of MCR molar crowns with metal coping exposure after approximately 13 yrs of function. Note that besides the lingual fracture (segmented white box), a cohesive veneer fracture is also observed on the buccal aspect of the crown (segmented white arrow). Lower second molar in (b) also presents a fracture, with metal coping apparent at the distal portion (white arrow). SEM image (c) of an epoxy resin replica of the fractured area delimited by the white-segmented box in (b) shows: white circles as evidence of bubbles from impression/replica processing; white arrows delimit the occlusal boundaries of fracture; black cross lying on the metal exposed after fracture event; white cross positioned on the cohesively fractured feldspathic ceramic; white open arrows delimiting the junction between the fractured ceramic and the exposed alloy. Image (d) represents a typical cohesive veneer fracture (open white arrow) at the proximal aspect of a Y-TZP-supported all-ceramic upper molar crown after 2.5 yrs in function. The epoxy resin replica of (d) is shown as an SEM image in (e), showing the roughness caused by occlusal adjustments associated with wear facets (black asterisks). SEM proximal view of the fractured site (f) shows arrest lines (white triangles) and their concave portion pointing toward the fracture origin on the occlusal surface (segmented white arrow). Note that the crack initiation is likely associated with the occlusal adjustment area on the mesial aspect of the crown, as shown in the occlusal view in (e).

Discussion

The majority of in vivo (Larsson et al., 2006; Sailer et al., 2007a,b; Molin and Karlsson, 2008; Tinschert et al., 2008) and in vitro (Studart et al., 2007b; Kohorst et al., 2008) published data on Y-TZP systems have focused on fixed partial dentures. To date, there is one private-practice retrospective short-term evaluation of Y-TZP-supported single crowns (Ortorp et al., 2009), and only one controlled clinical trial (Cehreli et al., 2009), yet with limited numbers of crowns investigated. Comparisons of Y-TZP with MCR tooth-supported crowns are not available.

In a recent comparison regarding the chipping resistance between MCR and Y-TZP, bar-shaped specimens were tested with no difference between groups (Quinn et al., 2010). These authors concluded that clinical differences in chipping between MCR and Y-TZP should exist only if residual stresses or interface flaws may occur. In contrast, the mouth-motion fatigue testing of anatomically correct molar crowns in the present study revealed MCR failures occurring as a function of load and not fatigue. In contrast, both Y-TZP systems’ failures were accelerated by fatigue. Values of β less than 1 indicate that the failure rate is decreasing with time and are commonly associated with failures that occur at a relatively early time due to egregious flaws. Values of β approximately equal to 1 indicate a failure rate that does not vary over time and are associated with failures of a random nature. Values of β greater than 1 indicate that the failure rate is increasing with time and are associated with failures related to mechanical wear-out modes (Abernethy, 2004). The significantly lower reliability found for the Y-TZP systems is a function of lower loads initiating porcelain veneer damage accumulation and failure when compared with MCR crowns.

Differences in thermal conductivity between Y-TZP and metals, the presence of thermal mismatches between core materials and veneer, and cooling rate protocols have been suggested as potential sources of residual stresses within the veneer (Coelho et al., 2009; Swain, 2009). Whereas a layer of compressive stresses has been described as forming in the outer veneer aspect of Y-TZP-based restorations upon cooling, major tensile stresses may develop and become entrapped in an inner layer (Aboushelib et al., 2008; Taskonak et al., 2008). Hence, the combination of tensile stresses from sliding indenter trailing edges and the sliding-contact-fatigue-derived partial cone cracks propagating into the tensile stress layer is likely related to the cohesive failures within the veneer in both Y-TZP crown systems (Kim et al., 2008a,b). Although assessment of residual stresses within the porcelain veneer was not the aim of the present study, our imaging results revealed the consistent presence of twist hackles, especially in the margins of the cohesively failed veneers of Y-TZP crowns. Twist hackles are not only a strong telltale fractographic mark indicating local crack direction, but are also associated with specimens presenting strong thermal or stress gradients (Quinn, 2007). SEMs of chipped MCR samples did not disclose clear fractographic marks, such as hackles, wake, and twist hackles, perhaps because the veneering porcelain has a more coarse inclusion structure or less residual stress.

We compared two Y-TZP systems with MCR, utilizing a testing scenario with a standardized mandibular first molar full-crown preparation. The resemblance of clinical failure modes with the laboratory-tested crowns strongly suggests that sliding contact associated with fatigue in watery media is a powerful tool to predict a material’s reliability and ultimately to validate its potential in a clinical scenario.

The properties of the core, such as modulus of elasticity, hardness, and toughness, are known to be important predictors of reliability in crown-veneered systems (Rekow et al., 2007). Since core failure was not observed in either MCR or Y-TZP systems, we speculate that they were sufficient to withstand fatigue. Hence, the lower reliability observed for both Y-TZP systems resulted almost exclusively from veneering porcelain failure, regardless of the two different systems, each fabricated according to manufacturer’s guidelines.

Studies exploring veneer-core thermal analysis and cooling rate are strongly recommended. Since the role of framework design in offsetting cohesive veneer failures in Y-TZP crowns has been empirically suggested (Marchack et al., 2008), but not systematically tested, investigations on the reliability and failure modes between standard design and different modified-core designs for Y-TZP systems are also warranted.

The hypothesis that MCR presents higher reliability under mouth-motion cyclic loading over two all-ceramic systems was confirmed. Fatigue was an acceleration factor for Y-TZP systems. The reliability and fracture analyses established for MCR and Y-TZP veneer-core systems provide the basis for comparison of other materials combinations prior to clinical evaluation. Although the extrapolation of the present results to clinical performance is limited, the testing method used herein may be utilized for direct comparison between different core/crown configurations for the development of new crown systems.

Acknowledgments

The authors also acknowledge CAPES, Brazil (Scholarship Process BEX 1359/08-8). The authors are grateful to Carlos A.O. Fernandes, Associate Professor, Department of Operative Dentistry, Federal University of Ceara–UFC, Brazil. The samples utilized in this study were made by Marotta Dental Studio, NY, USA.

Footnotes

This project was supported by NIDCR Grant P01 DE01976.

References

- Abernethy RB. (2004). Reliability & statistical analysis for predicting life, safety, survivability, risk, cost and warranty claims. In: The new Weibull handbook. 5th ed. North Palm Beach, FL, USA: Dr. Robert Abernethy, Publisher [Google Scholar]

- Aboushelib MN, Feilzer AJ, Jager N, Kleverlaan CJ. (2008). Prestresses in bilayered all-ceramic restorations. J Biomed Mater Res B Appl Biomater 87:139-145 [DOI] [PubMed] [Google Scholar]

- Bonfante EA, da Silva NR, Coelho PG, Bayardo-Gonzalez DE, Thompson VP, Bonfante G. (2009). Effect of framework design on crown failure. Eur J Oral Sci 117:194-199 [DOI] [PubMed] [Google Scholar]

- Cehreli MC, Kokat AM, Akca K. (2009). CAD/CAM zirconia vs. slip-cast glass-infiltrated alumina/zirconia all-ceramic crowns: 2-year results of a randomized controlled clinical trial. J Appl Oral Sci 17:49-55 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Coelho PG, Bonfante EA, Silva NR, Rekow ED, Thompson VP. (2009). Laboratory simulation of Y-TZP all-ceramic crown clinical failures. J Dent Res 88:382-386 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Donovan TE. (2009). Porcelain-fused-to-metal (PFM) alternatives. J Esthet Restor Dent 21:4-6 [DOI] [PubMed] [Google Scholar]

- Huang M, Thompson VP, Rekow ED, Soboyejo WO. (2008). Modeling of water absorption induced cracks in resin-based composite supported ceramic layer structures. J Biomed Mater Res B Appl Biomater 84:124-130 [DOI] [PubMed] [Google Scholar]

- Kim JH, Kim JW, Myoung SW, Pines M, Zhang Y. (2008a). Damage maps for layered ceramics under simulated mastication. J Dent Res 87:671-675 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kim JW, Kim JH, Janal MN, Zhang Y. (2008b). Damage maps of veneered zirconia under simulated mastication. J Dent Res 87:1127-1132 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kohorst P, Dittmer MP, Borchers L, Stiesch-Scholz M. (2008). Influence of cyclic fatigue in water on the load-bearing capacity of dental bridges made of zirconia. Acta Biomater 4:1440-1447 [DOI] [PubMed] [Google Scholar]

- Larsson C, Vult von Steyern P, Sunzel B, Nilner K. (2006). All-ceramic two- to five-unit implant-supported reconstructions. A randomized, prospective clinical trial. Swed Dent J 30:45-53 [PubMed] [Google Scholar]

- Marchack BW, Futatsuki Y, Marchack CB, White SN. (2008). Customization of milled zirconia copings for all-ceramic crowns: a clinical report. J Prosthet Dent 99:169-173 [DOI] [PubMed] [Google Scholar]

- Molin MK, Karlsson SL. (2008). Five-year clinical prospective evaluation of zirconia-based Denzir 3-unit FPDs. Int J Prosthodont 2:223-227 [PubMed] [Google Scholar]

- Napankangas R, Raustia A. (2008). Twenty-year follow-up of metal-ceramic single crowns: a retrospective study. Int J Prosthodont 21:307-311 [PubMed] [Google Scholar]

- Nelson W. (1990). Models and data analysis for step and varying stress. In: Accelerated testing: statistical models, test plans, and data analysis. New York: John Wiley & Sons, pp. 493-520 [Google Scholar]

- Ortorp A, Kihl ML, Carlsson GE. (2009). A 3-year retrospective and clinical follow-up study of zirconia single crowns performed in a private practice. J Dent 37:731-736 [DOI] [PubMed] [Google Scholar]

- Piconi C, Maccauro G. (1999). Zirconia as a ceramic biomaterial. Biomaterials 20:1-25 [DOI] [PubMed] [Google Scholar]

- Quinn GD. (2007). Fractography of ceramics and glasses. A NIST recommended practice guide. Special Publication 960-16 Washington/DC: National Institute of Standards and Technology; http://www.nist.gov/public_affairs/practiceguides/SP960-161.pdf (URL accessed 04/26/2010). [Google Scholar]

- Quinn JB, Sundar V, Parry EE, Quinn GD. (2010). Comparison of edge chipping resistance of PFM and veneered zirconia specimens. Dent Mater 26:13-20 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Raigrodski AJ. (2004). Contemporary all-ceramic fixed partial dentures: a review. Dent Clin North Am 48:531-544 [DOI] [PubMed] [Google Scholar]

- Raigrodski AJ. (2006). Materials for all-ceramic restorations. J Esthet Restor Dent 18:117-118 [DOI] [PubMed] [Google Scholar]

- Raigrodski AJ, Chiche GJ, Potiket N, Hochstedler JL, Mohamed SE, Billiot S, et al. (2006). The efficacy of posterior three-unit zirconium-oxide-based ceramic fixed partial dental prostheses: a prospective clinical pilot study. J Prosthet Dent 96:237-244 [DOI] [PubMed] [Google Scholar]

- Rekow D, Thompson VP. (2007). Engineering long term clinical success of advanced ceramic prostheses. J Mater Sci Mater Med 18:47-56 [DOI] [PubMed] [Google Scholar]

- Rekow D, Zhang Y, Thompson V. (2007). Can material properties predict survival of all-ceramic posterior crowns? Compend Contin Educ Dent 28:362-368 [PubMed] [Google Scholar]

- Sailer I, Feher A, Filser F, Gauckler LJ, Luthy H, Hämmerle CH. (2007a). Five-year clinical results of zirconia frameworks for posterior fixed partial dentures. Int J Prosthodont 20:383-388 [PubMed] [Google Scholar]

- Sailer I, Pjetursson BE, Zwahlén M, Hämmerle CH. (2007b). A systematic review of the survival and complication rates of all-ceramic and metal-ceramic reconstructions after an observation period of at least 3 years. Part II: Fixed dental prostheses. Clin Oral Implants Res 18(Suppl 3):86-96; erratum in Clin Oral Implants Res 19:326-328, 2008 [DOI] [PubMed] [Google Scholar]

- Silva NR, Coelho PG, Fernandes CA, Navarro JM, Dias RA, Thompson VP. (2009). Reliability of one-piece ceramic implant. J Biomed Mater Res B Appl Biomater 88:419-426 [DOI] [PubMed] [Google Scholar]

- Studart AR, Filser F, Kocher P, Lüthy H, Gauckler LJ. (2007a). Mechanical and fracture behavior of veneer-framework composites for all-ceramic dental bridges. Dent Mater 23:115-123 [DOI] [PubMed] [Google Scholar]

- Studart AR, Filser F, Kocher P, Lüthy H, Gauckler LJ. (2007b). Cyclic fatigue in water of veneer-framework composites for all-ceramic dental bridges. Dent Mater 23:177-185 [DOI] [PubMed] [Google Scholar]

- Swain MV. (2009). Unstable cracking (chipping) of veneering porcelain on all-ceramic dental crowns and fixed partial dentures. Acta Biomater 5:1668-1677 [DOI] [PubMed] [Google Scholar]

- Taskonak B, Borges GA, Mecholsky JJ, Jr, Anusavice KJ, Moore BK, Yan J. (2008). The effects of viscoelastic parameters on residual stress development in a zirconia/glass bilayer dental ceramic. Dent Mater 24:1149-1155 [DOI] [PubMed] [Google Scholar]

- Tinschert J, Schulze KA, Natt G, Latzke P, Heussen N, Spiekermann H. (2008). Clinical behavior of zirconia-based fixed partial dentures made of DC-Zirkon: 3-year results. Int J Prosthodont 21:217-222 [PubMed] [Google Scholar]

- Zhao W, Elsayed E. (2005). A general accelerated life model for step-stress testing. IEEE Trans Reliabil 37:1059-1069 [Google Scholar]