Abstract

The bacterial signaling molecule, cyclic diguanosine monophosphate (c-di-GMP), plays a key role in controlling biofilm formation, organelle formation for motility, cell-cycle differentiation, and pathogenic virulence, among many other functions.(Cotter & Stibitz 2007, Hengge 2009, Romling & Amikam 2006, Schirmer & Jenal 2009, Tamayo et al. 2007) It acts by relaying extracellular signals to internal receptors, including PilZ proteins(Ko et al. 2010) as well as two different classes of riboswitches.(Kulshina et al. 2009, Lee et al. 2010, Smith et al. 2009, Smith et al. 2011, Sudarsan et al. 2008) It has widespread consequences for human health, and current research is actively exploring its molecular mechanisms. The convenient one-flask, gram-scale synthesis of c-di-GMP described here will facilitate these efforts.

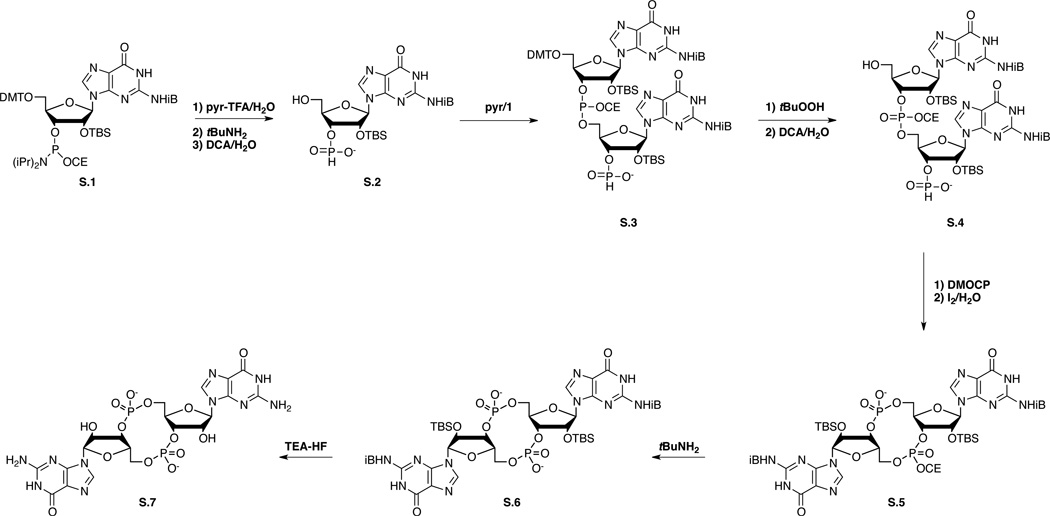

BASIC PROTOCOL: One-Flask, Gram-Scale Synthesis of c-di-GMP

Materials (Reagents and solvents from Sigma-Aldrich, apparatus from Fisher.)

S.1 3'-O-[(diisopropylamino)(2-cyanoethoxy)phosphino]-5'-O-(4,4'-dimethoxytrityl)-2'-O-tert-butyldimethylsilyl-N2-isobutyrylguanosine

Dry acetonitrile

Septa

3 Å Molecular sieves

Pyridinium trifluoroacetate

tert–Butyl amine

Rotary evaporator

Dichloromethane

Dichloroacetic acid (DCA)

Pyridine

16 Gauge double tipped needle

Disposable syringes and needles

5.5 M tert-Butyl hydroperoxide in decane

Sodium bisulfite

95% 5,5-Dimethyl-2-oxo-2-chloro-1,3,2-dioxaphosphinane (DMOCP)

Iodine (I2)

Sodium bicarbonate

Ethyl acetate (EtOAc)

Diethyl ether

Scinterred glass funnels

Potassium hydroxide

Vacuum pump

Methanol

33% Methylamine in anhydrous ethanol

Triethylamine (TEA)

Triethylamine trihydrogen fluoride

HPLC grade acetone

Additional reagents and equipment for analytical high-performance liquid chromatography (HPLC; UNIT 10.5).

Drying S.1

1. Place 6.31 g (6.5 mmol) of S.1 into a 100 mL pear-shaped flask. Dry the amidite twice by evaporation of 40 mL CH3CN on a rotary evaporator, the last time leaving about 20 mL. Add ten 3 Å molecular sieves, and stopper with a septum. Set aside until needed.

Hydrolysis, β-elimination, and detritylation of 2nd portion of S.1

2. Place another portion of S.1 (4.85 g, 5.0 mmol) into a 500 mL round bottom flask with a stir bar. Add 1.16 g of pyridinium trifluoroacetate (6.0 mmol, 1.2 equiv) and rinse down the sides of the flask with 25 mL of CH3CN. Add 0.18 mL of H2O (10 mmol, 2 equiv) and stir for 1 min. Add 25 mL of tert-BuNH2 and let the solution stir for 10 min. Place the flask on a rotary evaporator and concentrate to a foam. Evaporate twice with 50 mL of CH3CN, each time to give a foam.

tert-BuNH2 has a boiling point of 46 °C so is removed readily.

3. Add 60 mL of CH2Cl2 and mix until the oil is dissolved. Add 0.90 mL of H2O (50 mmol, 10 equiv) and then 60 mL of 6% dichloroacetic acid (DCA, 44 mmol, 8.8 equiv) in CH2Cl2.

Prepare a total of 140 mL of 6% dichloroacetic acid by adding 8.4 mL of dichloroacetic acid to 132 mL of CH2Cl2, because more will be used in step 8. This solution must be used in the same day. Caution: wear gloves, since dichloroacetic acid is very caustic and can remove layers of skin. Upon addition of the acid to the reaction mixture, the solution should turn a deep orange.

4. After 10 min, quench with 7.0 mL pyridine (87 mmol, 2 equiv rel to DCA). Concentrate the solution to about 20 mL and then evaporate three times with 40 mL of dry CH3CN, the last time leaving about 12 mL. Check by HPLC (HPLC conditions are described under Critical Parameters, retention times are given in Table 1.) before the last concentration to be sure detritylation is complete. (If not, concentrate, evaporate several times with ethyl acetate to remove pyridine, and repeat Step 3 with less acid, depending on how much tritylated material was left.) Stopper the flask with a septum.

Upon addition of pyridine, the orange color should immediately disappear.

Table 1.

HPLC retention times for S.1 – S.7

| RP HPLC Retention Time, min |

|

|---|---|

| S.1 | 11.7a |

| S.2 | 5.4a |

| S.3 | 9.2/9.5a |

| S.4 | 7.2a |

| S.5 | 7.3/7.6a |

| S.6 | 6.2a, 9.7b |

| S.7 | 3.2b |

Gradient of 2 to 100% CH3CN and 0.1 M TEAA

Gradient of 2 to 40% CH3CN and 0.1 M TEAA

Linear coupling of S.1 with S.2 and detritylation

5. Transfer the dried S.1 to S.2 through a 16 gauge double-tipped needle by inserting one end of the needle through the septum of the flask with S.1 all the way to the bottom, and the other end through the septum of the flask with S.2 but above the solution. Place a vent needle in the flask with S.2. Place a needle-tipped line from a source of dry nitrogen or argon into the flask with S.1, thereby causing the solution of S.2 to flow into the flask with S.1.

Examples are shown in Sigma-Aldrich technical bulletins (http://www.sigmaaldrich.com/chemistry/chemical-synthesis/learning-center/technical-bulletins.html): AL-134 (Handling Air-Sensitive Reagents) and AL-164 (Handling Pyrophoric Reagents).

It is best to have practiced this transfer ahead of time using only CH3CN. The nitrogen pressure should be such that the solution of S.1 is transferred in less than 1 minute.

6. Immediately inject a 1 mL rinse of dry CH3CN into the flask of S.1, rotate the flask quickly to rinse the sides of the flask, and transfer this rinse through the double-tipped needle to the flask with S.2. Repeat this rinse one more time with 1 mL of fresh CH3CN. Allow the mixture of S.1 and S.2 to stir for 2 min, and then take a sample for HPLC (HPLC conditions are described under Critical Parameters, retention times are given in Table 1) analysis.

7. As soon as the HPLC sample is removed, add 2.73 mL of anhydrous 5.5 M tert-butyl hydroperoxide in decane (15 mmol, 3 equiv). Let the solution stir for 30 min and then take an HPLC sample. Once the HPLC sample is removed, place the flask in an ice bath, and add 1.25 g NaHSO3 dissolved in 2.5 mL of H2O. After 5 min of stirring, concentrate to an oil.

The anhydrous tert-butyl hydroperoxide should be kept in a refrigerator, but removed an hour prior to use. The NaHSO3 solution takes some time to dissolve, so prepare it 15 minutes ahead of time, but not earlier.

8. Add 80 mL of CH2Cl2 to the flask and mix until the oil is dissolved. Add 0.90 mL of H2O (50 mmol, 10 equiv) and then 80 mL of 6% dichloroacetic acid (58 mmol, 11.6 equiv) in CH2Cl2.

Use the rest of the 6% dichloroacetic acid prepared in Step 3.

9. After 10 min, quench the reaction with 15 mL of pyridine. Take an HPLC sample, add 35 mL more pyridine, and concentrate to about 20 mL. Add 150 mL pyridine and concentrate to 100 mL. Stopper with a septum.

The orange color for this detritylation is often less intense than in Step 3.

Cyclization of S.4

10. Add 3.40 g of 95% 5,5-dimethyl-2-oxo-2-chloro-1,3,2-dioxaphosphinane, DMOCP (17.5 mmol, 3.5 equiv) and stir for 10 min.

DMOCP is also named 2-chloro-5,5-dimethyl-1,3,2-dioxaphosphorinane 2-oxide.

11. Add 3.2 mL of H2O (175 mmol, 10 equiv rel to DMOCP). Immediately add 1.65 g of I2 (6.5 mmol, 1.3 equiv) and stir for 5 min. Take an HPLC sample, immediately pour the mixture into a 2 L Erlenmeyer containing 700 mL of H2O and 1.0 g NaHSO3, and stir 5 min.

12. Slowly add 20 g of NaHCO3 (20 g, 238 mmol) and stir for five minutes.

The mixture will foam.

13. Add 800 mL of 1:1 EtOAc:Et2O and stir for 5 min. Pour the mixture into a 2L separatory funnel and shake thoroughly. Drain the aqueous layer and pour the organic layer into a 2 L round bottom flask. Extract the aqueous layer again with 200 mL more of 1:1 EtOAc:Et2O. Drain the aqueous layer and pour the second organic layer into the round bottom flask. Concentrate to remove most of the ether, and check by HPLC.

At this point, the flask can be placed in a freezer overnight and the work continued the next day.

β-elimination of S.5

14. Continue concentrating the solution of S.5 to less than 50 mL. Transfer the solution to a 250 mL round bottom flask. Add 20 mL portions of ethyl acetate and evaporate three times to help remove excess pyridine.

15. Add a stir bar and 25 mL of CH3CN. Stir to mix, add 25 mL of tert-BuNH2, and stir for 10 min. Concentrate the solution to dryness. Add 25 mL of CH3CN, scrape the sides of the flask with a spatula, and concentrate to dryness. Repeat two more times. Dissolve the solid in 25 mL of CH3OH and check by HPLC. Filter (using a filter paper) the solution into a 100 mL round bottom flask, removing the stir bar. Concentrate the solution to a foam.

As the β–elimination takes place, the product forms as a white solid. Thorough mixing of this solid upon each addition of CH3CN will help to remove the tert-BuNH2.

16. Add 25 mL of CH2Cl2 to the foam and immediately swirl vigorously until the solid dissolves. Stopper the flask with a septum and let it sit until crystal deposition has slowed. Then refrigerate overnight.

Crystallization should begin anywhere from 1 min to 1 h, and should be nearly complete after 30 min.

17. Collect the white crystals in a pre-weighed scinterred glass funnel and wash them three times with no more than 2 mL CH2Cl2 each time, stirring thoroughly. Cover the funnel with filter paper and dry it in a desiccator over KOH overnight. Weigh it and check a sample by HPLC. The melting point should be 191 – 193 °C dec. The NMR should be as follows: 1H NMR (DMSO-d6) 55°C d 8.24 (s, 2H), 5.88 (d, J = 3 Hz, 2H), 4.93 (br, 2H), 4.38 (br, 2H), 4.14 (br, 2H), 4.10 - 4.03 (m, 2H), 3.86 – 3.79 (m, 2H), 2.83 (sep, J = 7 Hz, 2H), 1.22 (s, 22H), 1.06 (d, J = 7 Hz, 6H), 0.91 (d, J = 7 Hz, 6H), 0.84 (s, 18H), 0.14 (s, 6H), 0.07 (s, 6H); 13C NMR (DMSO) 55°C δ (all resonances are singlets) 182.0, 156.4, 149.9, 149.5, 139.5, 122.3, 91.0, 82.4, 77.6, 72.7, 63.3, 52.3, 28.7, 27.4, 20.4, 20.1, 19.4, −2.9, −3.8; 31P NMR (DMSO-d6) 55°C δ −1.87.

S.6 is the tert-butyl ammonium salt.

Final deprotection of S.6

18. Transfer S.6 to a 250 mL round bottom flask. For each 1.00 mmol (1.20 g) of S.6, add 100 mL of CH3NH2 (400 equiv rel to each isobutyryl) in anhydrous ethanol (33% by weight). Add a stir bar, cap with a septum, and stir for 90 min. Check completion of the reaction by HPLC. Concentrate to an oil. Add 4 mL of pyridine and 2 mL of Et3N, swirl to mix, and concentrate to an oil. Repeat this procedure two more times.

Since tert-BuNH2 (bp 46 °C) is more volatile than Et3N (bp 89 °C), the tert-BuNH2 is removed by this process, thereby converting the salt form from tert-BuNH3+ to Et3NH+.

19. Add 4 mL pyridine to the flask, cap with the septum, and insert a vent needle. Place the flask in an oil bath at 50 °C in a hood and stir. For every 1.00 mmol (1.20 g) of S.6, draw up 14 mL Et3N and 8.3 mL Et3N•3HF (75 equiv F− rel to each TBS) into separate syringes and insert them both through the septum of the flask. Add the two reagents simultaneously over about 1 min. Stir the mixture for 1h at 50 °C, occasionally rotating the flask at an angle to dissolve solids on the sides.

Caution! HF is extremely dangerous and can cause severe burns. Wear heavy gloves for this procedure. Do not breathe vapors from the flask or allow any Et3N•3HF to contact your skin. When done, rinse all needles, syringes, septa, etc with aq K2CO3 before discarding. Keep a supply of calcium gluconate gel (available from Lab Safety Supply Inc, Janesville WI) at hand for emergency treatment, should any Et3N•3HF contact your skin.

20. Remove the flask from the oil bath, and start it stirring on a different stir plate. Remove the septum, and for every 1.00 mmol of S.6, add 112 mL HPLC grade acetone in a slow (Acetone added in a steady stream over 1 minute), steady stream. Continue to stir the mixture as the product crystallizes. After 10 min, collect the crystals by filtration in a scinterred glass funnel and wash them 5 times using 5 mL portions of acetone. Stir thoroughly between each wash. If the product is sticky, use a spatula to repeatedly smear it against the sides of the funnel, thereby removing trapped impurities. Cover the funnel with filter paper and dry it in a desiccator over KOH overnight. Weigh it, and check a sample by HPLC. Analyze S.7 by 1H and 31P NMR. The melting point should be 193 – 196 °C dec. The NMR should be as follows: 1H NMR (D2O) 55°C δ 8.03 (s, 2H), 5.81 (s, 2H), 5.07 (br, 2H), 4.80 (br, 2H), 4.07 – 3.96 (m, 2H), 3.13 (q, J = 7 Hz, 12H), 1.22 (t, J = 7 Hz, 18H); 13C NMR (D2O) 55°C δ (all resonances are singlets)159.3 (br), 156.4, 152.1 (br), 139.1, 117.5 (br), 92.8, 83.0, 75.8, 73.0, 65.0, 49.4, 10.8; 31P NMR (D2O) 55°C δ −0.20.

Take great care when handling the acetone filtrate and washes, because they contain excess Et3N•3HF.

COMMENTARY

Background Information

A number of routes for synthesis of c-di-GMP have been reported over the years, starting with van Boom's original phosphate triester approach.(Ross et al. 1990) Since then, various combinations of amidite and H-phosphonate couplings have been employed.(Amiot et al. 2006, Hayakawa et al. 2003, Hyodo & Hayakawa 2004, Hyodo et al. 2006, Kiburu et al. 2008, Yan & Aguilar 2007, Zhang et al. 2004) Until now, these methods have given only small amounts of products. In contrast, the method reported here(Gaffney et al. 2010) gives over 1 g of product and can readily be scaled further. No chromatographic steps are required, and the intermediate S.5 and the final product S.7 are purified by simple crystallizations.

Critical Parameters

The detritylations in steps 3 and 8 are potentially reversible up on quenching and again upon concentration, in spite of the water added to prevent it. The concentrated oils of detritylated S.2 and S.4 should be used immediately, and not stored.

Conditions for the initial amidite coupling between S.1 and S.2 should be as dry as possible.

HPLC is useful for following the course of the synthesis. We used a Waters Atlantis C18 column, 4.6 mm × 50 mm, 3 µm, with a gradient of 2 to 100% CH3CN and 0.1 M TEAA (pH 6.8) for steps 1–17, and 2 to 40% at the end of step 18. However, many steps are time-dependent and the procedure must be continued immediately after taking samples, without waiting to see the results. Note that S.3 and S.5 elute as two peaks, because there are two diastereomers. S.4 appears to elute as a single peak, even though it also has two diastereomers.

The linear dimer is best cyclized and oxidized as soon as it is made. Therefore, steps 1 – 13 should be performed in the same day.

Because of the danger of using Et3N•3HF, HPLC should not be performed to monitor progress of the final desilylation. Once the solids are in solution (there may be two layers), the reaction should be complete in 1 h.

Anticipated Results

The yield for crystallization of S.6 should be around 35% from S.1, and the yield for crystallization of the final product, S.7, should be about 30% from S.1. Both S.6 and S.7 are white powders.

Time Considerations

The entire sequence of reactions can be done in 4 days, with final NMR analysis taking longer. Steps 1 – 13 should be performed all in one day (8 – 10 h) or the yield will suffer. Steps 14 – 16 take a 2nd day (2 – 3 h), and step 17 takes only a few minutes of a 3rd day. Steps 18 – 20 take a 4th day (6 – 8 h).

Figure 1.

Synthesis of c-di-GMP

Acknowledgement

This work was supported by NIH grant GM 79760.

Literature Cited

- Amiot N, Heintz K, Giese B. New approach for the synthesis of c-di-GMP and its analogues. Synthesis. 2006:4230–4236. [Google Scholar]

- Cotter PA, Stibitz S. c-di-GMP-mediated regulation of virulence and biofilm formation. Curr. Opin. Microbiol. 2007;10:17–23. doi: 10.1016/j.mib.2006.12.006. [DOI] [PubMed] [Google Scholar]

- Gaffney BL, Veliath E, Zhao J, Jones RA. One-flask syntheses of c-di-GMP and the [Rp,Rp] and [Rp,Sp] thiophosphate analogues. Org. Lett. 2010;12:3269–3271. doi: 10.1021/ol101236b. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hayakawa Y, Nagata R, Hirata A, Hyodo M, Kawai R. A facile synthesis of cyclic bis(3'–5')diguanylic acid. Tetrahedron. 2003;59:6465–6471. [Google Scholar]

- Hengge R. Principles of c-di-GMP signalling in bacteria. Nat. Rev. Microbiol. 2009;7:263–273. doi: 10.1038/nrmicro2109. [DOI] [PubMed] [Google Scholar]

- Hyodo M, Hayakawa Y. An improved method for synthesizing cyclic bis (3'–5')diguanlic acid (c-di-GMP) Bull. Chem. Soc. Jpn. 2004;77:2089–2093. [Google Scholar]

- Hyodo M, Sato Y, Hayakawa Y. Synthesis of cyclic bis(3'–5')diguanylic acid (c-di-GMP) analogs. Tetrahedron. 2006;62:3089–3094. [Google Scholar]

- Kiburu I, Shurer A, Yan L, Sintim HO. A simple solid-phase synthesis of the ubiquitous bacterial signaling molecule, c-di-GMP and analogues. Mol. BioSyst. 2008;4:518–520. doi: 10.1039/b719423d. [DOI] [PubMed] [Google Scholar]

- Ko J, Ryu K-S, Kim H, Shin J-S, Lee J-O, Cheong C, Choi B-S. Structure of PP4397 reveals the molecular basis for different c-di-GMP binding modes by Pilz domain proteins. J. Mol. Biol. 2010;398:97–110. doi: 10.1016/j.jmb.2010.03.007. [DOI] [PubMed] [Google Scholar]

- Kulshina N, Baird NJ, Ferré-D’Amaré AR. Recognition of the bacterial second messenger cyclic diguanylate by its cognate riboswitch. Nat. Struct. Mol. Biol. 2009;16:1212–1217. doi: 10.1038/nsmb.1701. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lee ER, Baker JL, Weinberg Z, Sudarsan N, Breaker RR. An allosteric self-splicing ribozyme triggered by a bacterial second messenger. Science (Wash.) 2010;329:845–848. doi: 10.1126/science.1190713. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Romling U, Amikam D. Cyclic di-GMP as a second messenger. Curr. Opin. Microbiol. 2006;9:218–228. doi: 10.1016/j.mib.2006.02.010. [DOI] [PubMed] [Google Scholar]

- Ross P, Mayer R, Weinhouse H, Amikam D, Huggirat Y, Benziman M, de Vroom E, Fidder A, Paus Pd, Sliedregt LAJM, van der Marel GA, van Boom JH. The cyclic diguanylic acid regulatory system of cellulose synthesis in Acetobacter xylinum. J. Biol. Chem. 1990;265:18933–18943. [PubMed] [Google Scholar]

- Schirmer T, Jenal U. Structural and mechanistic determinants of c-di-GMP signalling. Nat Rev Micro. 2009;7:724–735. doi: 10.1038/nrmicro2203. [DOI] [PubMed] [Google Scholar]

- Smith KD, Lipchock SV, Ames TD, Wang J, Breaker RR, Strobel SA. Structural basis of ligand binding by a c-di-GMP riboswitch. Nat. Struct. Mol. Biol. 2009;16:1218–1223. doi: 10.1038/nsmb.1702. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Smith KD, Shanahan CA, Moore EL, Simon AC, Strobel SA. Structural basis of differential ligand recognition by two classes of bis-(3′–5′)-cyclic dimeric guanosine monophosphate-binding riboswitches. Proc. Natl. Acad. Sci. USA. 2011;108:7757–7762. doi: 10.1073/pnas.1018857108. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sudarsan N, Lee ER, Weinberg Z, Moy RH, Kim JN, Link KH, Breaker RR. Riboswitches in eubacteria sense the second messenger cyclic di-GMP. Science (Wash.) 2008;321:411–413. doi: 10.1126/science.1159519. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Tamayo R, Pratt JT, Camilli A. Roles of cyclic diguanylate in the regulation of bacterial pathogenesis. Annu. Rev. Microbiol. 2007;61:131–148. doi: 10.1146/annurev.micro.61.080706.093426. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Yan H, Aguilar AL. Synthesis of 3',5'-cyclic diguanylic acid (cdiGMP) using 1-(4-chlorophenyl)-4-ethoxypiperidin-4-yl as a protecting group for 2'-hydroxy functions of ribonucleosides. Nucleosides Nucleotides Nucl. Acids. 2007;26:189–204. doi: 10.1080/15257770601112762. [DOI] [PubMed] [Google Scholar]

- Zhang Z, Gaffney BL, Jones RA. c-di-GMP displays a monovalent metal ion-dependent polymorphism. J. Am. Chem. Soc. 2004;126:16700–16701. doi: 10.1021/ja0449832. [DOI] [PubMed] [Google Scholar]