Abstract

Objectives:

The aim of this study was to evaluate the effects of different light sources and curing time on the degree of conversion and microhardness of two surfaces within a nanofilled composite resin.

Methods:

Four experimental groups (n=10) were formed in accordance with the light source (quartz-tungsten halogen (QTH – 600mW/cm2), or light-emitting-diode (LED - 800mW/cm2)) and the time of curing (20 s or 40 s). The specimens were prepared with a circular mould (5 mm ∅ and 2 mm thick), according to the respective protocol, and the Knoop microhardness and degree of conversion was measured at the top and the base of the specimens. The degree of conversion was evaluated by the Fourier transform infrared spectrometer (FTIR). The results were analyzed by ANOVA two-way repeated measures and Tukey’s test (α=,05).

Results:

Both the degree of conversion and microhardness were higher at the top than at the bottom of the specimens. The QTH light source presented better values on the degree of conversion evaluation, but this result was not observed in the microhardness evaluation. Although forty seconds of curing promotes an increased level of microhardness, it did not influence the degree of conversion.

Conclusion:

It could be concluded that increasing the time of curing to 40 s promotes an increase in microhardness, but it does not influence the degree of conversion of a nanofilled composite resin. QTH promote better monomeric conversion; however, the microhardness values are similar to LED curing. For all situations tested, the bottom of the specimens presented lower results than the top.

Keywords: Composite resin, degree of conversion, light cure unit, light source

INTRODUCTION

Dental composites have been widely used in dentistry, primarily with direct restorations. The physical properties of these materials can be modulated by different factors, such as composition, light source, and the length of the curing time.1–3

Different factors related to the composition may affect the mechanical properties of the material, such as the type and concentration of the monomer that is used4, or the size, type, and quantity of the filler that is present in the material.5,6 Therefore, nano particles were inserted into composites in order to enhance their mechanical properties and to promote greater esthetic value to the restorations performed with these materials,5,7 as well as to increase packing of fillers and thus to reduce polymerization shrinkage.

Quartz-tungsten halogen (QTH) and light-emitting-diode (LED) are the most popular light sources that are used to cure dental resins. The QTH presents a broad wavelength spectrum, which allows efficient activation of different photo-initiators that are used as an alternative to camphorquinone, the most common initiator among light curing dental resins.8,9

In comparison to QTH devices, LEDs have a superior life span which does not compromise their light intensity after lengthy use. Nevertheless, the LEDs have a narrow wavelength spectrum, which may inadequately cure composite resins that contain alternative initiators (e.g., monoacrylphosphine oxide or TPO-390 nm10 and phenylpropadione, or PPD-410 nm11), due to the different wavelength that these photo-initiators require.8,9

The properties of dental composites can also be influenced by the length of curing time. A longer amount of time can result in the formation of a greater number of polymeric chains, which results in better properties (e.g., microhardness12,13 and compressive strength13).

The optimal properties of a composite resin should be obtained, not only closest to the tip of the light cure unit, but also throughout the entire sample area. Therefore, the aim of this study was to evaluate the effect of two curing units and the times of activation on the degree of conversion and Knoop microhardness in different surfaces of a nanofilled composite resin.

MATERIALS AND METHODS

Degree of Conversion

Specimens (2 mm thick and 5 mm ∅) were made from a circular matrix, using a nanofilled composite resin (Filtek Supreme A2, 3M ESPE, St. Paul, MN, USA) in a single sample. A Mylar strip and a 500-g weight were placed over the mold and left for 20 seconds, allowing better accommodation of the composite. The specimen was light-cured through the strip, avoiding the oxygen inhibition. After the preparation of the samples, the finishing was performed with silicon carbide abrasive papers of decreasing abrasiveness (1200, and 2000-grit).

The specimens were then light cured according to the light source and time of activation, as established in Table 1. The tip of the light cure unit was maintained 2 mm of distance of the composite resin, on the moment of curing. After procedures, specimens were stored dry, at 37°C for 24 h.

Table 1.

Experimental groups (n=10) in accordance with the light source and time of curing tested.

| Group | Light Source | Irradiance (mW/cm2) | Irradiance (mW/cm2) at 2 mm | Time of Curing |

|---|---|---|---|---|

| G1 | QTH (Optilux 501, Sybron Kerr, Danbury, CT, USA) | 600 | 600 | 20 s |

| G2 | QTH (Optilux 501, Sybron Kerr, Danbury, CT, USA) | 600 | 600 | 40 s |

| G3 | LED (Ultralume 5, Ultradent Products Inc., South Jordan, Utah) | 800 | 820 | 20 s |

| G4 | LED (Ultralume 5, Ultradent Products Inc., South Jordan, Utah) | 800 | 820 | 40 s |

The measurements of the degree of conversion were performed with Fourier transform infrared spectroscopy (Spectrum 100 Optica; PerkinElmer, MA, USA) via an instrument that was equipped with an attenuated total reflectance (ATR) device 24 hours after the specimens were prepared. The assay was performed at both the top and the bottom of each specimen.

The baseline technique, which was traced by the spectrum program, was used to conduct these calculations. The degree of conversion was calculated to consider the intensity of the C═C stretching vibration (peak height) at 1635 cm−1 and, as an internal standard, according to the symmetric ring stretching at 1608 cm−1, as previously described.14

Knoop Microhardness

The microhardness measurements were obtained for the same specimens and regions in which the degree of conversion was analyzed. Three indentations were performed on each surface, at a relative distant of 100 μm, using a microhardness tester (HMV-2T, Shimadzu Corp., Tokyo, Japan), with a load of 50 g and a dwell time of 15 s.

Statistical Analysis

The normality of the data was evaluated according the parameter, using the Kolmogorov-Smirnov and Shapiro-Wilk tests (α=.05), and the analysis of variance (Split-Plot ANOVA two-way) was performed in accordance with Tukey’s test (α=.05).

RESULTS

Degree of Conversion

The results of the degree of conversion are presented in Table 2. The factors “light source” and the sub-parcel “surface” (i.e., top and bottom) were statistical significant. The highest values were obtained when QTH was used, and the top presented better values than the bottom, regardless of the light source. The length of curing time did not promote significant alteration on the degree of conversion.

Table 2.

Means and (standard deviation) of the degree of conversion obtained with the different time of curing and light cure unit tested, on the respective surface analyzed.

| Top | Base | ||

|---|---|---|---|

| G1 (QTH 20s) | 56,29 (3,9)Aa | 48,11 (4,31)Ba | * |

| G2 (QTH 40s) | 53,14 (3,19)Aa | 48,12 (3,83)Ba | |

| G3 (LED 20s) | 50,36 (6,05)Aa | 43,27 (3,82)Ba | |

| G4 (LED 40s) | 45,99 (3,46)Aa | 44,49 (2,12)Ba | |

Different letters represents significant statistical difference.

Means followed by distinct capital letters in the same row, and distinct small letters in the same column, are significantly different at P<.05

represents statistical difference between the light cure units

Microhardness

The results of the Knoop microhardness test are described in Table 3. The statistical analysis showed an significant influence of “exposure time” and the sub-parcel “surface” on the values. Better values were obtained on top surfaces, and the 40-second curing time promoted the highest means of achieving microhardness, independent of the light source used.

Table 3.

Means and (standard deviations) of Knoop microhardness (KHN) in function of the light cure units, time of curing and surfaces studied.

| Top | Base | |

|---|---|---|

| G1 (QTH 20s) | 67,72 (2,59)Ab | 47,54 (3,79)Bb |

| G2 (QTH 40s) | 70,81 (3,63)Aa | 54,54 (3,56)Ba |

| G3 (LED 20s) | 69,14 (3,5)Ab | 49,2 (4,72)Bb |

| G4 (LED 40s) | 72,21 (2,84)Aa | 52,83 (3,29)Ba |

Different letters represents significant statistical difference.

Means followed by distinct capital letters in the same row, and distinct small letters in the same column, are significantly different at P<.05

DISCUSSION

Different situations can influence the properties of dental composites. In the present study, the time of curing (20 s and 40 s) did not influence the degree of conversion and Knoop hardness of the nanofilled composite resin that we evaluated. Two surfaces were analyzed; the top surface, which is closest to the tip of the light unit. This area receives the energy emitted by the device in a direct way, without any attenuation, since there is nothing between the light-curing tip and the resin composite. The other surface is at the bottom of the resin increment, 2 mm below the top, allows the evaluation of differences of various properties within the same specimen.

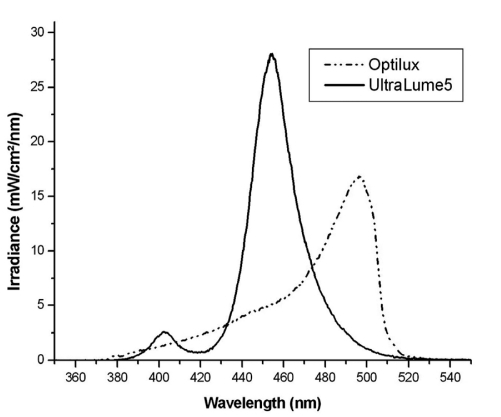

The composite resin used in this study contains camphoroquinone as a photo-initiator. It absorbs the light in a broad wavelength spectrum of 360 to 510 nm, with a absorption peak of approximately 468 nm.15 Figure 1 show the spectral distribution and irradiance of the two light cure units, which were used in this study. It should be noted that they both overlap the required wavelength necessary to achieve the correct curing of the resin composite tested.

Figure 1.

The light spectrum emitted by the light units that were evaluated. The wavelength of the QTH lamp was between 380 and 515 nm, with the peak of emission at 496 nm. The LED device presents a wavelength between 380 and 510 nm, with the emission peak at 453 nm.

However, the highest mean values were observed with the QTH lamp. The Ultralume 5, used in this study, present a central LED, with four peripheral additional LEDs that emit light in the UV-Vis area (the smaller peak), with maxim light emission at 454 nm (BRANDT 2010). The four additional lights increase the spectrum of wavelength of this light-curing device, however, at distance of 2 mm, these LEDs probably were underused, compromising the optimal performance of the LED device tested.16

The degree of the conversion measurements was lower at the bottoms of the samples than at the top surface. This reduction probably occurred due to the decrease in the irradiance incident on the region. When the light emitted reaches the composite resin, all the specimens is irradiated. The light transmittance through the resin increment is reduced, influencing negatively the degree of conversion of the bottom of the increment. This results are similar to procedures where the indirect restorations compromise the degree of conversion of resin cement, due to the light attenuation through the restoration.17

These results are relevant, since they demonstrate that insufficient curing can compromise the bottom of the sample. Therefore, the region that sometimes is in contact, in direct restorations, with the adhesive layer may be affected. This problem can be aggravated in deep cavities, where a distance of a few millimeters that separate the tip of the light source and the resin increment can drastically reduce the intensity of the light incident at the bottom of resin increment.

The results of the microhardness test were somewhat similar to those of the degree of conversion evaluation. Reflecting the outcome of similar studies12, 8 in each of the situations we noted the top of the sample presents higher results than the bottom. The results are probably due to the reduction in the light intensity on the region, similar the degree of conversion. Polymerization at reduced rate, as bottom of the specimen, may lead to a more linear polymer structure because relatively few growth centers are formed.19,20 At a higher rate of polymerization, as top of the increment, caused by a higher power density, a multitude of growth centers are formed, leading to a more branched and cross-linked polymer structure.19,20

Nevertheless, unlike of the degree of conversion results, the extended time of curing (40 s) influenced the microhardness in a positive way. In observing the results of degree of conversion, demonstrating similar values to 20 s and 40 s, it can be speculated that the extended exposition to light curing could have modulated the polymeric formation, leading to a composite with more crosslink chains, and consequently, higher microhardness. However, further studies should be conducted to evaluate this concern.

The higher curing time probably stimulated the formation of crosslinked chains. Such an outcome resulted in an increased microhardness of the nanofilled composite resin, since this pattern of the polymeric chains promotes better mechanical properties of the material.4,19

In the present study, the curing of the composite resin was performed 2 mm distant of the composite resin. This fact is justified since clinical procedures performed in the posterior teeth require the polymerization performed at 2 mm distant or more in certain circumstances, due to the cuspal presence, and the evaluation of this parameters is important to reveal the behavior of restorative materials in such situations.

In accordance with the obtained results, a period of 40 s to light-cure the composite resin in a direct restoration procedure is suggested. Despite the fact that this protocol does not improve the values in the degree of conversion in the nanofilled dental resin, the microhardness increases and contributes to the achievement of better mechanical properties within this material.

CONCLUSIONS

According to the results, it can be concluded that the QTH lamp promotes better values on the degree of conversion within the nanofilled composite resin than the LED lamp. However, the light cure method that was tested does not differ in terms of the microhardness evaluation.

The extended curing time promotes an increase in microhardness and the results that were obtained at the top of the increment were higher than the bottom in all experimental conditions.

However, the extended time of curing (40 s) does not influence the degree of conversion of the material tested.

REFERENCES

- 1.Bhamra GS, Fleming GJ, Darvell BW. Influence of LED irradiance on flexural properties and Vickers hardness of resin-based composite materials. Dent Mater. 2010;26:148–155. doi: 10.1016/j.dental.2009.09.008. [DOI] [PubMed] [Google Scholar]

- 2.Benetti AR, Asmussen E, Munksgaard EC, Dewaele M, Peutzfeldt A, Leloup G, Devaux J. Softening and elution of monomers in ethanol. Dent Mater. 2009;25:1007–1013. doi: 10.1016/j.dental.2009.01.104. [DOI] [PubMed] [Google Scholar]

- 3.Dewaele M, Asmussen E, Peutzfeldt A, Munksgaard EC, Benetti AR, Finne G, Leloup G, Devaux J. Influence of curing protocol on selected properties of light-curing polymers: degree of conversion, volume contraction, elastic modulus, and glass transition temperature. Dent Mater. 2009;25:1576–1584. doi: 10.1016/j.dental.2009.08.001. [DOI] [PubMed] [Google Scholar]

- 4.Asmussen E, Peutzfeldt A. Influence of selected components on crosslink density in polymer structures. Eur J Oral Sci. 2001;109:282–285. doi: 10.1034/j.1600-0722.2001.00057.x. [DOI] [PubMed] [Google Scholar]

- 5.Beun S, Glorieux T, Devaux J, Vreven J, Leloup G. Characterization of nanofilled compared to universal and micro-filled composites. Dent Mater. 2007;23:51–59. doi: 10.1016/j.dental.2005.12.003. [DOI] [PubMed] [Google Scholar]

- 6.Lu H, Lee YK, Oguri M, Powers JM. Properties of a dental resin composite with a spherical inorganic filler. Oper Dent. 2006;31:734–740. doi: 10.2341/05-154. [DOI] [PubMed] [Google Scholar]

- 7.Mitra SB, Wu D, Holmes BN. An application of nanotechnology in advanced dental materials. J Am Dent Assoc. 2003;134:1382–1390. doi: 10.14219/jada.archive.2003.0054. [DOI] [PubMed] [Google Scholar]

- 8.Jimenez-Planas A, Martin J, Abalos C, Llamas R. Developments in polymerization lamps. Quintessence Int. 2008;39:e74–84. [PubMed] [Google Scholar]

- 9.Strydom C. Dental curing lights--maintenance of visible light curing units. SADJ. 2002;57:227–233. [PubMed] [Google Scholar]

- 10.Cadenaro M, Antoniolli F, Codan B, Agee K, Tay FR, Dorigo Ede S, Pashley DH, Breschi L. Influence of different initiators on the degree of conversion of experimental adhesive blends in relation to their hydrophilicity and solvent content. Dent Mater. 2010;26:288–294. doi: 10.1016/j.dental.2009.11.078. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Park YJ, Chae KH, Rawls HR. Development of a new photoinitiation system for dental light-cure composite resins. Dent Mater. 1999;15:120–127. doi: 10.1016/s0109-5641(99)00021-4. [DOI] [PubMed] [Google Scholar]

- 12.Voltarelli FR, Dos Santos-Daroz CB, Alves MC, Peris AR, Marchi GM. Effectiveness of resin composite polymerization when cured at different depths and with different curing lights. Gen Dent. 2009;57:314–319. [PubMed] [Google Scholar]

- 13.Alpoz AR, Ertugrul F, Cogulu D, Ak AT, Tanoglu M, Kaya E. Effects of light curing method and exposure time on mechanical properties of resin based dental materials. Eur J Dent. 2008;2:37–42. [PMC free article] [PubMed] [Google Scholar]

- 14.Rueggeberg FA, Hashinger DT, Fairhurst CW. Calibration of FTIR conversion analysis of contemporary dental resin composites. Dent Mater. 1990;6:241–249. doi: 10.1016/S0109-5641(05)80005-3. [DOI] [PubMed] [Google Scholar]

- 15.Ilie N, Hickel R. Can CQ be completely replaced by alternative initiators in dental adhesives? Dent Mater J. 2008;27:221–228. doi: 10.4012/dmj.27.221. [DOI] [PubMed] [Google Scholar]

- 16.Feng L, Carvalho R, Suh BI. Insufficient cure under the condition of high irradiance and short irradiation time. Dent Mater. 2009;25:283–289. doi: 10.1016/j.dental.2008.07.007. [DOI] [PubMed] [Google Scholar]

- 17.Tezvergil-Mutluay A, Lassila LV, Vallittu PK. Degree of conversion of dual-cure luting resins light-polymerized through various materials. Acta Odontol Scand. 2007;65:201–205. doi: 10.1080/00016350701311632. [DOI] [PubMed] [Google Scholar]

- 18.Zhu S, Platt JA. Curing efficiency of three different curing lights at different distances for a hybrid composite. Am J Dent. 2009;22:381–386. [PubMed] [Google Scholar]

- 19.Asmussen E, Peutzfeldt A. Influence of pulse-delay curing on softening of polymer structures. J Dent Res. 2001;80:1570–1573. doi: 10.1177/00220345010800061801. [DOI] [PubMed] [Google Scholar]

- 20.Asmussen E, Peutzfeldt A. Two-step curing: influence on conversion and softening of a dental polymer. Dent Mater. 2003;19:466–470. doi: 10.1016/s0109-5641(02)00091-x. [DOI] [PubMed] [Google Scholar]