Abstract

Objectives:

This in-vitro study investigated the marginal fit of two all-ceramic copings with 2 finish line designs.

Methods:

Forty machined stainless steel molar die models with two different margin designs (chamfer and rounded shoulder) were prepared. A total of 40 standardized copings were fabricated and divided into 4 groups (n=10 for each finish line-coping material). Coping materials tested were IPS e.max Press and Zirkonzahn; luting agent was Variolink II. Marginal fit was evaluated after cementation with a stereomicroscope (Leica MZ16). Two-way analysis of variance and Tukey-HSD test were performed to assess the influence of each finish line design and ceramic type on the marginal fit of 2 all-ceramic copings (α =.05).

Results:

Two-way analysis of variance revealed no statistically significant differences for marginal fit relative to finish lines (P=.362) and ceramic types (P=.065).

Conclusion:

Within the limitations of this study, both types of all-ceramic copings demonstrated that the mean marginal fit was considered acceptable for clinical application (⩽120 μm).

Keywords: Marginal fit, all-ceramic types, finish lines

INTRODUCTION

All ceramic materials are widely used in dentistry for restoring anterior and posterior teeth to provide a metal-free structure and esthetic appearance.1–3

Ceramic crowns/copings can be made from different high-strength ceramic materials, and various manufacturing processes can be used. Today stronger and tougher ceramic materials are available, such as a lithium disilicate-reinforced glass ceramic (IPS e.max Press; Ivoclar Vivadent, Schaan, Liechtenstein) or a partially yttrium-stabilized zirconium oxide ceramic (Zirkonzahn; Zirkonzahn GmbH, Bruneck, Italy). The flexural strength of IPS e.max Press (Ivoclar Vivadent) is in the range of 360–400 MPa,4 whereas that of Zirkonzahn (Zirkonzahn GmbH) ranges from 680 to 1140 MPa.5 IPS e.max Press (Ivoclar Vivadent) was introduced in 2005 as an improved press-ceramic material compared to IPS Empress II (Ivoclar Vivadent). It also consists of a lithium-disilicate pressed glass ceramic, but its physical properties and translucency are improved.6 The heat-pressing technique can be used for the fabrication of copings and is based on the lost-wax principle. Prefabricated ceramic ingots of lithium-disilicate ceramic are heated and then pressed into the lost-wax form of the crown coping.7 The Zirkonzahn system is a direct ceramic machining system that uses a scanning and machining process. The device used in the process, called a Zircograph, has scanning and milling tips. A model of the die of the prepared tooth is made with a resin-based material. During scanning of the model, the other tip of the device mills the partially stabilized zirconia blocks (Zirkonzahn; Zirkonzahn GmbH). The milled specimen is 25% enlarged to compensate for shrinkage after the sintering process at 1400° C.8

All ceramic restorations must ensure requirements for strength and precision of marginal fit for clinical success.9 Marginal fit is one of the most important criteria for the long-term success of all-ceramic crowns. Increased marginal discrepancies expose the luting material to the oral environment, thus leading to cement dissolution and microleakage.10 The cement seal becomes weak, permits the percolation of bacteria, and can cause inflammation of the vital pulp.11 In-vivo studies have provided evidence that a large marginal discrepancy in a fixed restoration correlates with a higher plaque index and reduced periodontal conditions.12–15

Types of finish lines1,17–28 and ceramic manufacturing technique26,29–31 are the factors that have been investigated for all-ceramic crowns. Heavy chamfers and rounded shoulder finish lines have been advocated for all-ceramic crowns, as well.32

The purpose of this in-vitro study was to assess whether different finish lines or ceramic types have an effect on the marginal fit of two all-ceramic copings. The null hypothesis to be tested was: Marginal fit of two all-ceramic copings was not influenced by finish lines or ceramic types.

MATERIALS AND METHODS

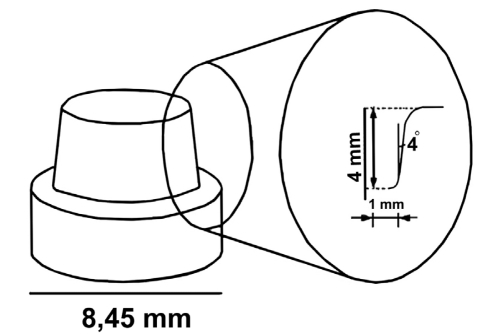

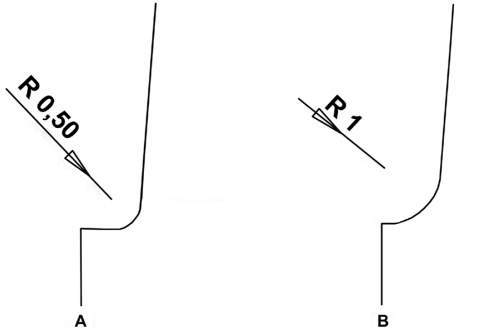

Forty machined stainless steel die models were prepared in a lathe (Tessan, Czech Republic) to simulate full-coverage all-ceramic crown preparations for a mandibular molar. Preparations were standardized with a height of 4 mm and a total convergence angle of 4 degrees (Figure 1). Two finish line designs were prepared: chamfer (C) and shoulder with rounded axiogingival internal line angle (S) (Figure 2).

Figure 1.

Illustration of steel die (mm).

Figure 2.

Finish line designs. A) Rounded shoulder preparation; curvature radius (R) of axiogingival internal line angle is 0,5 mm. B) Chamfer preparation; curvature radius (R) of axiogingival internal line angle is 1,0 mm.

Impression making and fabrication of copings;

Each metal model was duplicated with vinyl polysiloxane impression material (Elite H-D; Zhermack, Rovigo, Italy) and poured in type IV dental stone (Elite Rock; Zhermack) for the fabrication of working dies. The dies of copings for IPS e.max Press (E) (Ivoclar Vivadent) and Zirkonzahn (ZZ) (Zirkonzahn GmbH) were relieved with 3 layers of die spacer (Aqua-Fit; Renfert GmbH, Hilzingen, Germany) applied 0.5 mm short of the margin. A steel template was used to fabricate the all-ceramic core materials in standard conditions. A total of 40 standardized copings (n=20 for each finish line) were fabricated. Twenty E copings were produced by using a heat press technique. Copings were waxed to their proper shape using the steel template and invested with a special type of phosphate-bonded investment material (IPS-PressVEST Speed; Ivoclar Vivadent). After the burn-out of the wax analogue in the conventional pre-heating furnace, ceramic ingot (IPS e.max Press; Ivoclar Vivadent) was plastified at 920º C and pressed under vacuum into the investment mold in the furnace (EP 600; Ivoclar Vivadent).

Copings for ZZ were fabricated using Zirkonzahn T-RIGID (Zirkonzahn GmbH) on the dies with the guidance of the steel template. The copings were fabricated with the copy milling technique using partially sintered zirconium oxide blocks (Zirkonzahn; Zirkonzahn GmbH). The copings were then sintered at in an oven (Keramikofen 1500; Zirkonzahn GmbH) at 1500° C for 8 hours. The specimens were then divided into 4 groups (n=10 for each finish line-coping material), each of which were assigned a code for finish line and coping identification (Table 1).

Table 1.

Specimen groupings.

| Test groups (N=40 copings) | ||

|---|---|---|

| Chamfer (C)(n=20) | Rounded shoulder (S)(n=20) | |

| E-max press (E) (n=20) | EC | ES |

| Zirkonzahn (ZZ) (n=20) | ZZC | ZZS |

n=10 for each group (coping material-margin design).

The same examiner visually assessed the macroscopic fit of all copings on the steel dies before cementation. Copings that had deficiencies at the margins were not included in the study. The intaglio surfaces of the copings were then checked for fit with an aerosol indicator-marking spray (Okklufine Premium; FINO GmbH, Bad Bocklet, Germany). Any discontinuity of spray that indicated fitting surface interferences was eliminated with a small diamond bur (Mani Dia-Burs; Mani Inc, Tochigi-Ken, Japan) under copious water irrigation. Vertical seating of copings was improved by adjusting the intaglio surfaces.

Cementation of ceramic copings;

Before cementation, all copings were thoroughly cleaned for 15 minutes with distilled water in an ultrasound bath (Whaledent Biosonic JR; Whaledent International, New York, USA). In the E group the ceramic surfaces were etched with 5% hydrofluoric acid (HF) (IPS ceramic etching gel; Ivoclar Vivadent) for 20 seconds, rinsed with water, and dried with air. A layer of silane coupling agent (Monobond-S; Ivoclar Vivadent) was applied to the surfaces and dried again. A thin layer of bonding agent (Heliobond; Ivoclar Vivadent) was applied to the intaglio surface of E copings. Two-component dual polymerizing resin cement (Variolink II translucent; Ivoclar Vivadent) was used for seating the copings on the metal dies. Excess cementation material was removed with a cotton pellet. The cement was light-polymerized for 40 seconds on each side of the coping for a total time of 200 seconds. The light tip of the polymerizing unit (Bluephase; Ivoclar Vivadent) was used without any distance at an intensity of 450 mW/cm2. The interface was covered with a protective gel (Oxyguard; Kuraray, Okayama, Japan) for 3 minutes in order to prevent polymerization inhibition by the oxygen in the air. Finger pressure was also applied during the setting time. This condition was used to reproduce the clinical situation as closely as possible.

For the ZZ copings, single-component priming agent (Metal/Zirconia Primer; Ivoclar Vivadent) was applied both on the surfaces of metal dies and the intaglio surfaces of the ZZ copings. After waiting for 3 minutes, the specimens were dried with air. A silane coupling agent (Monobond S; Ivoclar Vivadent) was applied to the ceramic surfaces for 60 seconds, and dried with air. A thin layer of bonding agent (Heliobond; Ivoclar Vivadent) was applied to the intaglio of the ceramic surfaces, and air-dried again. The cementation procedure was as the same as the E group.

Marginal fit evaluation;

The marginal fit was evaluated by measuring the gap between the edge of the coping and the prepared steel die margin. The measurements were made perpendicular to the steel dies’ axis. For marginal analysis a stereomicroscope (Leica MZ16; Leica Microsystems CMS GmbH, Heerbrugg, Switzerland) combined with a computer system was used to evaluate marginal gaps. The camera (Leica IC3D; Leica Microsystems, Germany) reproduced X46 magnification so that a video image of the marginal gap could be examined using special software (Leica StereoExplorer software; Leica Microsystems). At four different points (midvestibular, -distal, -lingual, -mesial) the distance between the edge of the coping and the prepared steel die margin was measured using image analysis software (Leica StereoExplorer software; Leica Microsystems). Three measurements, made at each of the four positions, for a total of 12 measurements per crown, were performed. The mean of 12 values represented the mean marginal fit value for each coping. A millimeter calibration slide was used during each viewing session at the same magnification and referenced for calibration. All measurements were performed three times by the same investigator.

Statistics;

The means and standard deviations of marginal fit values per group were used for statistical analysis (SPSS 13.00 for Windows; SPSS Inc, Chicago, IL, USA). Statistical inferences among the groups were made using 2-way analysis of variance (ANOVA) and the Tukey honestly significant difference tests (Tukey HSD) (α=.05).

RESULTS

The mean marginal fit values (μm) of groups were as follows: ZZC (119.8 ± 24.69), ZZS (112.6 ± 22.9), EC (105.2 ± 21.33), ES (98.5 ± 26.04). As seen in Table 2, the 2-way ANOVA indicated that there were no significant differences in the mean marginal fit values for both finish lines (P=.362) and ceramic types (P=.065). Although not found statistically significant, E copings revealed better marginal fit than ZZ copings and both ZZ and E copings revealed better marginal fit on shoulder preparations than chamfer preparations. Tukey HSD revealed that there were no significant differences among groups (P=.207).

Table 2.

Results of 2-way ANOVA for marginal fit data.

| df | Sum of Squares | Mean Square | F | P | |

|---|---|---|---|---|---|

| Finish line | 1 | 483.025 | 483.025 | .852 | .362 |

| Ceramic type | 1 | 2059.225 | 2059.225 | 3.633 | .065 |

| Finish line*Ceramic type | 1 | .625 | .625 | .001 | .974 |

DISCUSSION

In this study marginal fit of two all-ceramic copings with two finish line designs was investigated. The results obtained verified the null hypothesis. The findings agreed with the previous studies23,26 which reported that the type of finish line design did not influence the marginal adaptation of all-ceramic copings. In the literature similar to this study, Quintas et al26 investigated in vitro vertical marginal discrepancy of ceramic copings with different ceramic materials, finish lines, and luting agents. Marginal accuracy of Procera, Inceram and Empress 2 copings were evaluated before and after cementation. According to Quintas et al,26 type of margin did not influence the marginal adaptation; ceramic type was the only significant factor tested that influenced vertical marginal discrepancy. However, in this study neither ceramic types nor finish line designs influenced the marginal adaptation of copings. Although the two ceramic systems tested have different microstructures and use different fabrication techniques, manufacturing of both E and ZZ copings involved the use of three layers of die spacer. According to studies,33,34 the three layers of die spacer resulted in 40 μm of internal relief. In addition, for the two types of ceramic copings, internal relief was made according to manufacturer’s instructions.

Although not found statistically significant, E copings showed better marginal fit than ZZ copings. Both E and ZZ copings showed better marginal fit on shoulder preparations than chamfer preparations. This may be due to the differences in fabrication methods. In pressed ceramics, sintering shrinkage during firing may be avoided because it is fabricated by the lost-wax technique. In this technique, the complete contour wax pattern is invested and a ceramic ingot is pressed into the resultant investment mold. The thermal expansion of the investment material is matched to that of the ceramic material. Because the ceramic is pressed directly into the investment to the full extent of the wax pattern, this method is simple and quicker than the ZZ system. In the ZZ system, by comparison, the coping is subjected to distortion and shrinkage during the sintering stage. This may consequently have a negative effect on marginal adaptation. Moreover, the adaptation of zirconia copings may be affected by the milling process and size of milling burs.

In clinical practice, natural teeth show a large variation because of their age and individual structure, thus causing difficulties in getting standardized abutments. Therefore, in this study two types of standardized steel dies were used for the measurement of marginal fit. Komine et al,23 Quintas et al,26 and Iwai et al,35 similar to this study, used machined steel dies in their studies.

In the present study, the adaptation of copings was assessed without porcelain veneering because the copings principally define the overall adaptation of veneered crowns.23,35,36 For marginal analysis, a stereomicroscope combined with a computer system was used to evaluate marginal gaps. Some authors16,29,32,37,38 also used stereomicroscopes in their studies. Bindl et al39 and Naert et al29 measured the distance between the outline of the tooth/die and the coping margin at four points (midvestibular, -mesial, -distal and -lingual) when determining the marginal discrepancy. However, four measurements are not representative of the marginal gap in one specimen. Therefore, in the present study, three measurements were made at each of four positions of a coping, with a total of twelve measurements per coping performed. The measurements were made at the same coordinates. Holden et al40 and Goldin et al41 used the same measurement method in their studies.

There were some limitations in this study. Marginal fit of copings before cementation and internal adaptation of copings were not determined. The seating force applied was finger pressure, which can be reproduced clinically. However, finger pressure is variable and the pressure cannot be standardized.

Moreover, cemented copings were not subjected to thermal cycling. Thermal cycling is one of the important factors that affect the long-term marginal fit of crowns. Factors that affect the marginal and internal adaptation of all ceramic copings require further investigations supported with clinical trials.

CONCLUSION

Within the limitations of this study, the following conclusions can be derived:

The mean marginal discrepancies found in this study were within the clinically acceptable standard (120 μm) according to McLean and Fraunhofer’s study.42

Finish line designs or ceramic types did not influence the marginal fit of all ceramic copings used in this study (P>.05). Although ceramic type factor was not found statistically significant (P=.065), mean marginal fit values of ZZ copings were higher than E copings. Both ZZ and E copings presented better marginal fit on shoulder preparations than chamfer preparations.

REFERENCES

- 1.Bindl A, Mörmann WH. An up to 5-year clinical evaluation of posterior in-ceram CAD/CAM core crowns. Int J Prosthodont. 2002;15:451–456. [PubMed] [Google Scholar]

- 2.Lehner CR, Schärer P. All-ceramic crowns. Curr Opin Dent. 1992;2:45–52. [PubMed] [Google Scholar]

- 3.Mörmann WH, Bindl A. All-ceramic, chair-side computer-aided design/computer-aided machining restorations. Dent Clin North Am. 2002;46:405–426. doi: 10.1016/s0011-8532(01)00007-6. [DOI] [PubMed] [Google Scholar]

- 4.Tysowsky GW. The science behind lithium disilicate: a metal-free alternative. Dent Today. 2009;28:112–113. [PubMed] [Google Scholar]

- 5.Guazzato M, Albakry M, Ringer SP, Swain MV. Strength, fracture toughness and microstructure of a selection of all-ceramic materials. Part II. Zirconia-based dental ceramics. Dent Mater. 2004;20:449–456. doi: 10.1016/j.dental.2003.05.002. [DOI] [PubMed] [Google Scholar]

- 6.Stappert CF, Att W, Gerds T, Strub JR. Fracture resistance of different partial-coverage ceramic molar restorations: An in vitro investigation. J Am Dent Assoc. 2006;137:514–522. doi: 10.14219/jada.archive.2006.0224. [DOI] [PubMed] [Google Scholar]

- 7.Oh SC, Dong JK, Lüthy H, Schärer P. Strength and microstructure of IPS Empress 2 glass-ceramic after different treatments. Int J Prosthodont. 2000;13:468–472. [PubMed] [Google Scholar]

- 8.Yavuzyilmaz H, Turhan B, Bavbek B, Kurt E. All ceramic systems II (Tam seramik sistemleri II) The Journal of Gazi University Faculty of Dentistry (Gazi Üniversitesi Diş Hekimliği Fakültesi Dergisi) 2005;22:49–60. [Google Scholar]

- 9.Schwartz NL, Whitsett LD, Berry TG, Stewart JL. Unserviceable crowns and fixed partial dentures: life-span and causes for loss of serviceability. J Am Dent Assoc. 1970;81:1395–1401. doi: 10.14219/jada.archive.1970.0398. [DOI] [PubMed] [Google Scholar]

- 10.Jacobs MS, Windeler AS. An investigation of dental luting cement solubility as a function of the marginal gap. J Prosthet Dent. 1991;65:436–442. doi: 10.1016/0022-3913(91)90239-s. [DOI] [PubMed] [Google Scholar]

- 11.Goldman M, Laosonthorn P, White RR. Microleakage--full crowns and the dental pulp. J Endod. 1982;18:473–475. doi: 10.1016/S0099-2399(06)81345-2. [DOI] [PubMed] [Google Scholar]

- 12.Valderhaug J, Birkeland JM. Periodontal conditions in patients 5 years following insertion of fixed protheses. Pocket depth and loss of attachment. J Oral Rehabil. 1976;3:237–243. doi: 10.1111/j.1365-2842.1976.tb00949.x. [DOI] [PubMed] [Google Scholar]

- 13.Valderhaug J, Heloe LA. Oral hygiene in a group of supervised patients with fixed prostheses. J Periodontol. 1977;48:221–224. doi: 10.1902/jop.1977.48.4.221. [DOI] [PubMed] [Google Scholar]

- 14.Janenko C, Smales RJ. Anterior crowns and gingival health. Aust Dent J. 1979;24:225–230. doi: 10.1111/j.1834-7819.1979.tb02929.x. [DOI] [PubMed] [Google Scholar]

- 15.Silness J. Periodontal conditions in patients treated with dental bridges. 3. The relationship between the location of the crown margin and the periodontal condition. J Periodontal Res. 1970;5:225–229. doi: 10.1111/j.1600-0765.1970.tb00721.x. [DOI] [PubMed] [Google Scholar]

- 16.Smith BG. The effect of the surface roughness of prepared dentin on the retention of castings. J Prosthet Dent. 1970;23:187–198. doi: 10.1016/0022-3913(70)90296-9. [DOI] [PubMed] [Google Scholar]

- 17.Dedmon HW. The relationship between open margins and margin designs on full cast crowns made by commercial dental laboratories. J Prosthet Dent. 1985;53:463–466. doi: 10.1016/0022-3913(85)90625-0. [DOI] [PubMed] [Google Scholar]

- 18.Eames WB, O’Neal SJ, Monteiro J, Miller C, Roan JD, Jr, Cohen KS. Techniques to improve the seating of castings. J Am Dent Assoc. 1978;96:432–437. doi: 10.14219/jada.archive.1978.0090. [DOI] [PubMed] [Google Scholar]

- 19.Gavelis JR, Morency JD, Riley ED, Sozio RB. The effect of various finish line preparations on the marginal seal and occlusal seat of full crown preparations. J Prosthet Dent. 1981;45:138–145. doi: 10.1016/0022-3913(81)90330-9. [DOI] [PubMed] [Google Scholar]

- 20.Grajower R, Lewinstein I. A mathematical treatise on the fit of crown castings. J Prosthet Dent. 1983;49:663–674. doi: 10.1016/0022-3913(83)90393-1. [DOI] [PubMed] [Google Scholar]

- 21.Hunter AJ, Hunter AR. Gingival margins for crowns: a review and discussion. Part II: Discrepancies and configurations. J Prosthet Dent. 1990;64:636–642. doi: 10.1016/0022-3913(90)90286-l. [DOI] [PubMed] [Google Scholar]

- 22.Kay GW, Jablonski DA, Dogon IL. Factors affecting the seating and fit of complete crowns: a computer simulation study. J Prosthet Dent. 1986;55:13–18. doi: 10.1016/0022-3913(86)90062-4. [DOI] [PubMed] [Google Scholar]

- 23.Komine F, Iwai T, Kobayashi K, Matsumura H. Marginal and internal adaptation of zirconium dioxide ceramic copings and crowns with different finish line designs. Dent Mater J. 2007;26:659–664. doi: 10.4012/dmj.26.659. [DOI] [PubMed] [Google Scholar]

- 24.Limkangwalmongkol P, Chiche GJ, Blatz MB. Precision of fit of two margin designs for metal-ceramic crowns. J Prosthodont. 2007;16:233–237. doi: 10.1111/j.1532-849X.2007.00186.x. [DOI] [PubMed] [Google Scholar]

- 25.Pascoe DF. An evaluation of the marginal adaptation of extracoronal restorations during cementation. J Prosthet Dent. 1983;49:657–662. doi: 10.1016/0022-3913(83)90392-x. [DOI] [PubMed] [Google Scholar]

- 26.Quintas AF, Oliveira F, Bottino MA. Vertical marginal discrepancy of ceramic copings with different ceramic materials, finish lines, and luting agents: an in vitro evaluation. J Prosthet Dent. 2004;92:250–257. doi: 10.1016/j.prosdent.2004.06.023. [DOI] [PubMed] [Google Scholar]

- 27.Syu JZ, Byrne G, Laub LW, Land MF. Influence of finish-line geometry on the fit of crowns. Int J Prosthodont. 1993;6:25–30. [PubMed] [Google Scholar]

- 28.Wang CJ, Millstein PL, Nathanson D. Effects of cement, cement space, marginal design, seating aid materials, and seating force on crown cementation. J Prosthet Dent. 1992;67:786–790. doi: 10.1016/0022-3913(92)90583-v. [DOI] [PubMed] [Google Scholar]

- 29.Naert I, Van der Donck A, Beckers L. Precision of fit and clinical evaluation of all-ceramic full restorations followed between 0.5 and 5 years. J Oral Rehabil. 2005;32:51–57. doi: 10.1111/j.1365-2842.2004.01374.x. [DOI] [PubMed] [Google Scholar]

- 30.Sulaiman F, Chai J, Jameson LM, Wozniak WT. A comparison of the marginal fit of In-Ceram, IPS Empress, and Procera crowns. Int J Prosthodont. 1997;10:478–484. [PubMed] [Google Scholar]

- 31.Yeo IS, Yang JH, Lee JB. In vitro marginal fit of three all-ceramic crown systems. J Prosthet Dent. 2003;90:459–464. doi: 10.1016/j.prosdent.2003.08.005. [DOI] [PubMed] [Google Scholar]

- 32.Pera P, Gilodi S, Bassi F, Carossa S. In vitro marginal adaptation of alumina porcelain ceramic crowns. J Prosthet Dent. 1994;72:585–590. doi: 10.1016/0022-3913(94)90289-5. [DOI] [PubMed] [Google Scholar]

- 33.Campagni WV, Preston JD, Reisbick MH. Measurement of paint-on die spacers used for casting relief. J Prosthet Dent. 1982;47:606–611. doi: 10.1016/0022-3913(82)90132-9. [DOI] [PubMed] [Google Scholar]

- 34.Campbell SD. Comparison of conventional paint-on die spacers and those used with the all-ceramic restorations. J Prosthet Dent. 1990;63:151–155. doi: 10.1016/0022-3913(90)90098-w. [DOI] [PubMed] [Google Scholar]

- 35.Iwai T, Komine F, Kobayashi K, Saito A, Matsumura H. Influence of convergence angle and cement space on adaptation of zirconium dioxide ceramic copings. Acta Odontol Scand. 2008;66:214–218. doi: 10.1080/00016350802139833. [DOI] [PubMed] [Google Scholar]

- 36.Beschnidt SM, Strub JR. Evaluation of the marginal accuracy of different all-ceramic crown systems after simulation in the artificial mouth. J Oral Rehabil. 1999;26:582–593. doi: 10.1046/j.1365-2842.1999.00449.x. [DOI] [PubMed] [Google Scholar]

- 37.Rinke S, Hüls A, Jahn L. Marginal accuracy and fracture strength of conventional and copy-milled all-ceramic crowns. Int J Prosthodont. 1995;8:303–310. [PubMed] [Google Scholar]

- 38.Al-Rabab’ah MA, Macfarlane TV, McCord CF. Vertical marginal and internal adaptation of all-ceramic copings made by CAD/CAM technology. Eur J Prosthodont Rest Dent. 2008;16:109–115. [PubMed] [Google Scholar]

- 39.Bindl A, Mörmann WH. Marginal and internal fit of all-ceramic CAD/CAM crown-copings on chamfer preparations. J Oral Rehabil. 2005;32:441–447. doi: 10.1111/j.1365-2842.2005.01446.x. [DOI] [PubMed] [Google Scholar]

- 40.Holden JE, Goldstein GR, Hittelman EL, Clark EA. Comparison of the marginal fit of pressable ceramic to metal ceramic restorations. J Prosthodont. 2009;18:645–648. doi: 10.1111/j.1532-849X.2009.00497.x. [DOI] [PubMed] [Google Scholar]

- 41.Goldin EB, Boyd NW, 3rd, Goldstein GR, Hittelmann EL, Thompson VP. Marginal fit of leucite-glass pressable ceramic restorations and ceramic-pressed-to-metal restorations. J Proshtet Dent. 2005;93:143–147. doi: 10.1016/j.prosdent.2004.10.023. [DOI] [PubMed] [Google Scholar]

- 42.McLean JW, von Fraunhofer JA. The estimation of cement film thickness by an in vivo technique. Br Dent J. 1971;131:107–111. doi: 10.1038/sj.bdj.4802708. [DOI] [PubMed] [Google Scholar]