Abstract

The quality of distinctive artisanal cheeses is closely associated with the territory of production and its traditions. Pedoclimatic characteristics, genetic autochthonous variations, and anthropic components create an environment so specific that it would be extremely difficult to reproduce elsewhere. Pecorino cheese is included in this sector of the market and is widely diffused in Italy (∼62.000t of production in 2010). Pecorino is a common name given to indicate Italian cheeses made exclusively from pure ewes’ milk characterized by a high content of fat matter and it is mainly produced in the middle and south of Italy by traditional procedures from raw or pasteurized milk. The microbiota plays a major role in the development of the organoleptic characteristics of the cheese but it can also be responsible for the accumulation of undesirable substances, such as biogenic amines (BA). Bacterial amino acid decarboxylase activity and BA content have to be investigated within the complex microbial community of raw milk cheese for different cheese technologies. The results emphasize the necessity of controlling the indigenous bacterial population responsible for high production of BA and the use of competitive adjunct cultures could be suggested. Several factors can contribute to the qualitative and quantitative profiles of BA’s in Pecorino cheese such as environmental hygienic conditions, pH, salt concentration, water activity, fat content, pasteurization of milk, decarboxylase microorganisms, starter cultures, temperature and time of ripening, storage, part of the cheese (core, edge), and the presence of cofactor (pyridoxal phosphate, availability of aminases and deaminases). In fact physico-chemical parameters seem to favor biogenic amine-positive microbiota; both of these environmental factors can easily be modulated, in order to control growth of undesirable microorganisms. Generally, the total content of BA’s in Pecorino cheeses can range from about 100–2400 mg/kg, with a prevalence of toxicologically important BA’s, tyramine and histamine. The presence of BA is becoming increasingly important to consumers and cheese-maker alike, due to the potential threats of toxicity to humans and consequent trade implications.

Keywords: Italian ewe cheese, microbial groups, biogenic amines

Introduction

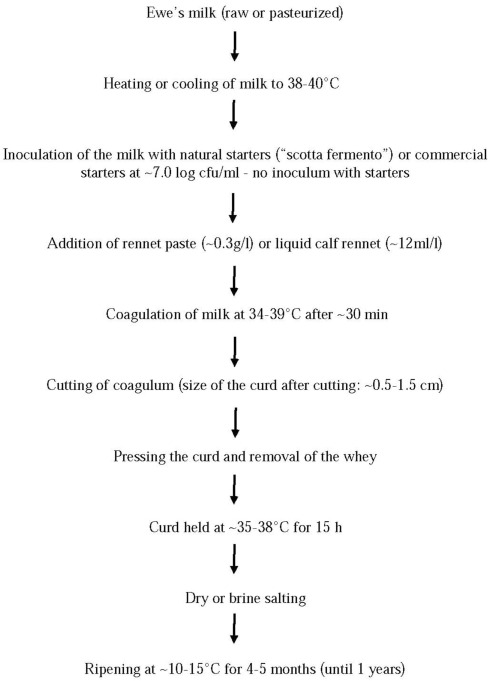

The name Pecorino is commonly given to Italian cheeses made exclusively from pure ewes’ milk and it has in most cases a protected designation of origin or PDO status. Generally this type of cheese is produced in the middle and south of Italy by a traditional procedure, characterized by a different ripening time ranging between 8 and 12 months (Di Cagno et al., 2003). The most popular Pecorino cheeses, such as Pecorino Romano, Fiore Sardo, Canestrato Pugliese, Pecorino Abruzzese, are usually made from raw or pasteurized milk which is inoculated with natural cultures, “scotta fermento,” which is produced by acidifying the “scotta,” the whey obtained from the manufacture of Ricotta (Di Cagno et al., 2003; Figure 1). The natural whey cultures are composed mainly of thermophilic lactic acid bacteria (LAB), such as Streptococcus thermophilus, Lactobacillus delbrueckii subsp. lactis, and Lactobacillus helveticus. The milk is coagulated at 34–39°C adding liquid or powder calf rennet, lamb paste rennet, or pig rennet only for Pecorino di Farindola. After cutting the coagulum, the curds are cooked at 45°C for 5–10 min. The curds removed from the vats are placed in traditional and different molds, pressed manually, and ripened from 4 to 18 months.

Figure 1.

Protocols for the manufacture of some Italian Pecorino cheeses.

However, in spite of these varieties there are many other typologies of Pecorino (Table 1) produced throughout the Italian territory according to local or regional costumes, also characterized by a shorter ripening time (1–2 months), semi-hard consistency, but low flavor and aroma (Caridi et al., 2003).

Table 1.

List of some Italian Pecorino cheeses.

| Production region | Variety |

|---|---|

| Abruzzo | Pecorino Abruzzese, Pecorino di Farindola, Cacio marcetto, Canestrato di Castel del Monte |

| Molise | Pecorino di Capracotta, Pecorino del Sannio |

| Calabria | Pecorino del Monte Poro, Pecorino Calabrese, Pecorino di Vezzano |

| Basilicata | Pecorino del Pollino |

| Campania | Pecorino Bagnolese, Pecorino di Carmasciano, Pecorino di Laticauda, Casu ri pecora, Pecorino Campano |

| Sicily | Pecorino Pepato, Primusali |

| Sardinia | Pecorino di Nule, Pecorino di Osilo |

| Umbria | Pecorino di Norcia, Pecorino Umbro |

| Tuscany | Pecorino Senese, Pecorino di Pistoia, Pecorino del Casentino, Pecorino del Parco di Migliarino-San Rossore, Pecorino Massese, Pecorino Baccellone, Pecorino Pisano, Pecorino di Pienza, Abbucciato Aretino |

| Apulia | Pecorino di Maglie, Pecorino Brindisino |

| Emilia-Romagna | Pecorino del Pastore, Pecorino dell’Appennino Reggiano, Pecorino di Palesio, Pecorino di Vergato |

| Piedmont | Pecorino di Bagnolo |

| Liguria | Pecorino di Malga |

| Marche | Pecorino in Botte |

| Veneto | Pecorino dei Berici, Pecorino Veneto |

| Lazio | Pecorino di Picinisco, Pecorino della Sabina, Pecorino di Amatrice, Pecorino del Viterbese |

For this reason, a differentiation as well as the reduction of the ripening time can positively influence the consumption of these products. In fact the consumer generally prefers sweet flavor which is the result of short ripening (Gobbetti, 2004). More specifically, traditional products can take advantage from variants form specific attributes.

The principal technological features of more representative Pecorino cheeses are shown in Table 2.

Table 2.

Main characteristics of some Italian Pecorino cheeses (modified by Gobbetti, 2004).

| Italian Pecorino cheeses | Type of milk | Starter | Type of rennet | Cooking (°C) | Salting | Ripening, months | Dimension |

||

|---|---|---|---|---|---|---|---|---|---|

| Weight (kg) | Diameter (cm) | Height (cm) | |||||||

| Canestrato pugliese* | Sheep, raw, whole | None or natural culture in whey or milk | Calf, powder or liquid | No heat treatment or 45 | Dry salting for 4–6 days | 4–12, at 11–14°C | 7–15 | 25–30 | 10–14 |

| Fiore Sardo* | Sheep, raw, whole | Natural whey culture | Lamb or goat, paste | No heat treatment | Saturated brine and/or dry salting | 3–6, at 12–16°C | 1.5–4 | 12–20 | 12–15 |

| Pecorino di Bagnolo | Sheep, raw, whole | None or natural culture in whey or milk | Lamb, paste or calf, liquid | 45–48 | Dry salting for 2–6 days | 6–12, at 15°C | 1.5–2 | 14–16 | 8–10 |

| Pecorino di Farindola | Sheep, raw, whole | None or natural culture in whey or milk | Pig, liquid | No heat treatment | Dry salting for 20–40 days | 2–12, at 14–15°C | 1–3 | 14–22 | 4–8 |

| Pecorino Romano* | Sheep, raw or thermized, whole | Natural culture in “scotta” | Lamb, paste | 45–48 | Dry salting for 30–60 days | 8–12, at 10–14°C | 18–30 | 25–30 | 25–30 |

| Pecorino Sardo* | Sheep, raw or thermized, whole | Natural whey culture | Calf, paste | 40–45 | Saturated brine and/or dry salting | 3–12, at 12–16°C | 1–4 | 15–20 | 6–15 |

| Pecorino Siciliano* | Sheep, raw or thermized, whole | None or natural culture in whey or milk | Lamb, paste | 40–45 | Dry salting for 10–20 days | 4–18, at 12–15°C | 4–15 | 40–45 | 10–18 |

| Pecorino Toscano* | Sheep, thermized, whole | Natural culture in “scotta” | Calf, paste | 40–42 | Saturated brine or dry salting | 1–3 | 15–22 | 7–11 | |

| Pecorino Veneto | Sheep, thermized, whole | Natural culture in “scotta” | Lamb, paste | 40–42 | Dry salting for 12 days | 3–12, at 10–14°C | 2–2.5 | 15–20 | 6–13 |

| Pecorino di Palesio | Sheep, thermized, whole | Natural culture in “scotta” | Lamb, paste or calf, liquid | 40–42 | Dry salting for 10–20 days | 2–12, at 10–15°C | 0.8–2 | 12–14 | 5–8 |

| Pecorino di Norcia | Sheep, raw, whole | None or natural culture in whey or milk | Lamb, paste | 45–50 | Dry salting for 4–6 days | 2–12, at 14–15°C | 3–5 | 15–24 | 8–14 |

| Pecorino di Carmasciano | Sheep, raw, whole | None or natural culture in whey or milk | Lamb or goat, paste | No heat treatment | Dry salting for 10 days | 2–6, at 10°C | 1–2 | 16–20 | 8–10 |

*Protected designation of origin (PDO).

Each unique combination of ingredients and processing parameters leads to a specific type of cheese with unique properties. In fact, the use of raw milk and natural thermophilic starters, cooking of the curd to a high temperature, long ripening, and generally, an ancient tradition are common features to most of Pecorino cheeses.

The particular flavor and typical organoleptic properties of Pecorino cheeses are associated with specific attributes of milk and the natural microbiota responsible for fermentation and ripening processes (Corroler et al., 1998; Beresford et al., 2001). The artisanal cheeses have different and typical microbial population dynamics related to the production technology and geographic area of origin, with a microbiota quite heterogeneous (Poznanski et al., 2004).

The formation of large amounts of biogenic amines (BA) on this kind of cheese during the ripening process is allowed by some conditions, such as the availability of free amino acids produced as an outcome of proteolysis and viability of microorganisms possessing amino acid decarboxylating activity. Many genera of food bacteria are responsible of this characteristic (Suzzi and Gardini, 2003). Lactobacilli are considered producer of histamine, tyramine, and putrescine, whereas enterococci are considered tyramine formers and enterobacteria cadaverine and putrescine producers.

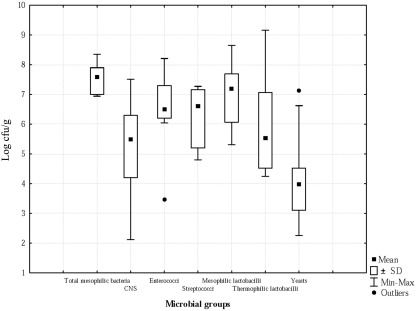

The Microbial Groups of Pecorino

The microbial composition of raw milk of Pecorino cheeses is generally within the limits reported by different authors (Clementi et al., 1994; Ricci et al., 1995; Gobbetti et al., 1997). Total mesophilic bacteria can range from 106 to 107 cfu/g, micrococci and coagulase negative staphylococci are present at 103 to 104 cfu/g, such as Enterobacteriaceae and yeasts. Enterococci, representing a typical microbiota of ewes’ raw milk, are present from 102 to 103 cfu/g. As expected LAB are detected from 102 to 105 cfu/g. A high level of biodiversity characterizes the natural microbiota of traditional Pecorino, in particular the indigenous microorganisms present in milk and coming from the environment during milking and cheesemaking, have a role in the cheese ripening. Figure 2 shows the concentration range among the prevalent microbial groups (Di Cagno et al., 2003; Gardini et al., 2006; Lanciotti et al., 2007; Schirone et al., 2011). Generally high numbers of total mesophilic bacteria have been reported in Pecorino cheeses.

Figure 2.

Principal microbial groups in some Italian Pecorino cheeses.

Lactic acid bacteria

The main groups detected are LAB, lactococci, and enterococci that are associated with streptococci, mesophilic and thermophilic lactobacilli (represented by Lactobacillus paracasei, Lactobacillus plantarum, Lactobacillus pentosus, Lactobacillus rhamnosus, Lactobacillus curvatus), and other microbial groups (Bizzarro et al., 2000; Randazzo et al., 2006; Vernile et al., 2007). In traditional cheeses S. thermophilus has been isolated up to 9 log cfu/g at 1 month of ripening, in particular from Pecorino Sardo (Pisano et al., 2006; Comunian et al., 2010). Recently a strain of S. thermophilus has been found to have a tyrosine decarboxylase gene (tdcA), that appear to be a horizontal gene transfer event from tdcA of L. curvatus (La Gioia et al., 2011).

Enterococci represent a typical microbiota of ewe’s milk, with Enterococcus faecium and Enterococcus faecalis being the most prevalent ones (Gonzàlez De Llano et al., 1992; Centeno et al., 1995; Giraffa et al., 1997; Martín-Platero et al., 2009). Generally their numbers increase during ripening from 106 to 108 cfu/g in the final product. In the 24-h-old cheese, LAB belonging to Lactococcus lactis are the major components and reached 109 cfu/g, while the enterococci represent 1–10% of the total microbiota (Bizzarro et al., 2000). During ripening, the level of lactococci decrease, while the enterococci maintain a constant number, so that the enterococci may become the most important group. They constitute part of the normal food microbiota and play an important role in manufacture of cheeses typical from mediterranean countries (Ledda et al., 1994; Arizcun et al., 1997; Franz et al., 1999, 2003; Mannu et al., 1999; Gomez et al., 2000; Prodromou et al., 2001; Mannu and Paba, 2002; Foulquié Moreno et al., 2006; Pisano et al., 2007; Ogier and Serror, 2008). In Pecorino cheese enterococci constitute a relevant part of the cheese microbiota (Figure 2). Gelsomino et al. (2002) have demonstrated that enterococci survive and grow in the hidden corners of the milking machine and the bulk tank, thus contaminating the milk directly. From the milk, the enterococci are transferred into the cheese. Regarding BA production, Suzzi et al. (2000) found that great part of enterococci isolated from Semicotto caprino cheese produce tyramine but not histamine in synthetic medium. These data are in agreement with those of Giraffa et al. (1995) and Celano et al. (1992) who found that tyramine was the only BA produced by enterococci in milk.

Non-starter lactic acid bacteria

Non-starter lactic acid bacteria (NSLAB) dominate the microbiota of Pecorino cheeses made from raw milk than in those made from pasteurized milk (Fox, 1998). In the early phase of manufacture NSLAB are present at very low numbers, but they increase throughput ripening and the major part of Pecorino cheeses has >6.0 log cfu/g at the end of the process (Coda et al., 2006). In fact indigenous NSLAB have the unique ability to grow under highly selective conditions prevailing in a cheese ripening and have been shown to contribute to the formation of small peptides and amino acids that are precursors for the flavor components but also for BA formation (Wouters et al., 2002).

Enterobacteriaceae

Enterobacteriaceae are not commonly detected in the final product due to their gradual decrease during cheese ripening (Medina et al., 1991; Hatzikamari et al., 1999; Dahl et al., 2000). However, high numbers of Enterobacteriaceae have been reported in different mediterranean cheeses made from ewes’ and goats’ raw milk after 30 days of ripening (Sánchez-Rey et al., 1993; Freitas et al., 1995, 1996; Freitas and Malcata, 2000; Psoni et al., 2003; Macedo et al., 2004). In Pecorino Abruzzese Enterobacteriaceae can be detected after 15 days of ripening at levels of 103 and 105 cfu/g in spring and summer, respectively, and are still present (102 cfu/g) after 60 days (Chaves-López et al., 2006). According to previous data obtained from Enterobacteriaceae inoculated in UHT milk (Chaves-López et al., 2006), the strains from Pecorino Abruzzese produced high quantities of putrescine but only small or undetectable quantities of cadaverine. Moreover, histamine was produced by all the strains. Many Enterobacteriaceae can produce considerable levels of histamine in fermented foods and particularly Enterobacter cloacae, Enterobacter aerogenes, and Klebsiella oxytoca, as well as Escherichia coli and Morganella morganii (Suzzi and Gardini, 2003). Although these microorganisms are usually present in low numbers in the final product, Enterobacteriaceae can release their decarboxylases in the early steps of cheesemaking (Bover-Cid et al., 2001).

Other microorganisms

In some cases, psychrotrophic microorganisms and Staphylococcus aureus have been reported (Palmas et al., 1999), indicating a possible contamination and a poor hygiene during manufacturing. Generally coagulase negative staphylococci (CNS) are represented by non-pathogenous species, saprophytic, or useful for conferring typical characteristics to the cheese, such as Staphylococcus xylosus (Palmas et al., 1999). The secondary adventitious microbiota belong to the CNS ranging from about 102 to 108 cfu/g and yeasts ranging from about 102 to 107 cfu/g. In Pecorino Crotonese Kluyveromyces lactis and Debaryomyces hansenii strains were found to dominate during the later stages of maturation. Some strains of Yarrowia lipolytica resulted in the highest aminobiogenic potential decarboxylating ornithine, phenylalanine, tyrosine, and lysine (Gardini et al., 2006).

Physico-chemical factors on BA formation

Other extrinsic factors may play an important role in the accumulation of BA in cheese, e.g., pH, salt concentration, water activity, and redox potential (Pinho et al., 2001). In Table 3 the physico-chemical characteristics of Pecorino cheese are reported. The range values for some parameters are very large, indicating important differences during the manufacturing and the ripening conditions of Pecorino cheeses. For example NaCl concentration ranges from 1 to 9%, because some cheeses are salted by immersion in NaCl brine or by application of salt crystals at different times. This parameter could influence water activity, enzyme activity, and microbial dynamics (Fox and Guinee, 1987; Van der Berg and Exterkate, 1993). The NaCl concentration in milk slows down the formation of different amines such as agmatine, spermine, spermidine, putrescine, histamine, tyramine, and tryptamine (Santos et al., 2003).

Table 3.

Range of the gross chemical composition in Italian Pecorino cheeses (modified by Gobbetti, 2004).

| Parameters | |

|---|---|

| Moisture (% w/w) | 30–34 |

| Fat (% w/w) | 27–32 |

| NaCl (% w/w) | 1–9 |

| Protein (% w/w) | 25–32 |

| Ash (%) | 1–3 |

| Soluble N/Total N (%) | 20–28 |

| pH | 5.1–5.5 |

Then, the characteristics of a Pecorino cheese depend on microbiota dynamics. Both starter and secondary microbiota modify the physico-chemical properties of cheese. Each cheese type should be studied particularly, given the high variability in physico-chemical composition. Then, the quality of raw milk, the environmental conditions, and the traditional manufacture play an important role in determining the characteristics of an artisanal Pecorino cheese. Characterizing cheese microbial population may contribute to understand the ecological processes that drive microbial interaction in cheese and their technological relevance. Knowledge of the structure and dynamics of the whole microbial community of cheese would promote better understanding of BA’s formation with respect to microbial growth and metabolism.

Biogenic Amines in Pecorino Cheeses

The presence of relevant amounts of BA in cheeses has been recently documented for a few types of Pecorino cheeses (Martuscelli et al., 2005; Lanciotti et al., 2007; Del Signore and Di Giacomo, 2008; Mascaro et al., 2010; Mercogliano et al., 2010; Bavazzano et al., 2011; Forzale et al., 2011; Schirone et al., 2011). In these studies the quantitative and qualitative accumulation of such compounds was extremely variable (Table 4). The diamines, putrescine and cadaverine, were found in higher concentrations in Pecorino di Fossa and Pecorino di Farindola. In particular, Mascaro et al. (2010) in Pecorino di Fossa found values of 579.60 and 1302.86 mg/kg for putrescine and cadaverine, respectively; while in samples of Pecorino di Farindola, putrescine ranged from 9.9 to 394 mg/kg and cadaverine from 26.8 to 276.1 mg/kg (Schirone et al., 2011). Tyramine was always present at high concentrations compared with the other amines of the same cheese. Among ten batches of Pecorino di Farindola (Schirone et al., 2011) tyramine resulted to be the BA present in the highest concentration in all cheeses examined, representing in six samples more than 40% of the total amines. A high relationship between tyramine and total BA content in Pecorino di Farindola cheese was found (R2 = 0.9869). High values of this BA have been determined also in Pecorino di Fossa, Pecorino Abruzzese and Pecorino di Migliarino-San Rossore, particularly in the cheese core (1300 mg/kg). The relevant incidence of tyramine in cheese manufactured from raw ewes’ milk has been reported (Roig-Saguès et al., 2002; Martuscelli et al., 2005; Pintado et al., 2008; Ladero et al., 2010).

Table 4.

Levels of Biogenic Amines in Italian Pecorino cheeses at different time of ripening.

| Italian Pecorino cheeses | Biogenic amines (mg/kg) |

References | ||||||

|---|---|---|---|---|---|---|---|---|

| Ethylamine | Putrescine | Cadaverine | 2-phenylethylamine | Tyramine | Histamine | Total biogenic amines | ||

| Pecorino Abruzzese1 | Martuscelli et al. (2005) | |||||||

| Batch A* | 20.0 | 80.0 | 18.0 | 35.0 | 185.0 | 261.0 | 697.0 | |

| Batch B** | 180.0 | 163.0 | 75.0 | 305.0 | 230.0 | 76.0 | 1086.0 | |

| Pecorino2 | Lanciotti et al. (2007) | |||||||

| Milk HPH*** | 14.80 ± 4.46 | 20.3 ± 1.88 | 19.5 ± 5.24 | 62.8 ± 9.08 | 3.35 ± 1.32 | |||

| Thermized milk | 70.92 ± 11.11 | 257.0 ± 11.7 | 155.0 ± 19.2 | 350.0 ± 21.6 | 23.9 ± 1.67 | |||

| Raw milk | 29.3 ± 5.83 | 107.0 ± 6.20 | 63.3 ± 4.74 | 162.0 ± 12.2 | 6.32 ± 0.59 | |||

| Pecorino3 | Del Signore and Di Giacomo (2008) | |||||||

| Ripening 5°C | 2.0−5.80 | 2.20−4.20 | 28.70−51.70 | 7.70−14.20 | ||||

| Ripening 10°C | 8.20 | 6.90 | 43.70 | 23.0 | 114.0 | |||

| Ripening 15°C | 6.00−6.20 | 6.80−7.10 | 29.10−33.10 | 20.20−25.30 | ||||

| Pecorino Carmasciano4 | 90.0 | 120.0 | 136.41 | 65.5 | Mercogliano et al. (2010) | |||

| Formaggio di Fossa5 | 579.60 ± 0.88 | 1302.86 ± 5.02 | 173.0 ± 39.13 | 461.62 ± 11.99 | 24.11 ± 10.06 | 2557.69 ± 39.13 | Mascaro et al. (2010) | |

| Pecorino di Farindola6 | 12.9−601.3 | 9.9−394.0 | 26.8−276.1 | 0−127.1 | 52.3−1171.3 | 0−21.8 | 209−2393 | Schirone et al. (2011) |

| Pecorino Toscano7 | 3.0−84.2 | 7.9−25.6 | 1.3−21.8 | 6.9−122.5 | 0.8−52.6 | Bavazzano et al. (2011) | ||

| Pecorino Del Parco Di Migliarino-San Rossore8 | Forzale et al. (2011) | |||||||

| In the core | 172.95 ± 15.56 | 22.38 ± 20.1 | 1300.05 ± 117.01 | 32.41 ± 2.91 | 1578.72 ± 142.08 | |||

| In the external part | 84.96 ± 9.34 | 30.61 ± 3.37 | 527.85 ± 58.06 | 39.45 ± 5.44 | 721.81 ± 80.51 | |||

1After 60 days of ripening; *whole raw milk without starter culture; **whole thermized milk with starter culture; 2after 21 days of ripening; ***milk high pressure homogenization; 3after 4 months of ripening; 4after 201 days of ripening; 5after 90 days of ripening into pits; 6after 90 days of ripening; 7after 8 months of ripening; 8after 153 days of ripening.

Tyramine-producing bacterial strains are expected to be present in Pecorino especially within the groups of NSLAB, Enterobacteriaceae and enterococci, as indicated in the study of Martuscelli et al. (2005). The high level of tyramine in the Pecorino cheese could be due to the activity of thermoresistant enterococci, usual contaminants of raw milk. However, the heat resistance at more than 65°C of some Lactobacillus species, and in particular of L. paracasei, has been demonstrated (Jordan and Cogan, 1999). There is evidence that LAB are occasionally associated with tyramine formation, although they can also contribute to the accumulation of other BA such as putrescine. On the contrary, Enterobacteriaceae would be associated with cadaverine, putrescine, and histamine formation, mainly when a deterioration process occurs in either raw materials or end products (Marino et al., 2003). It is well known that BA accumulation in cheese can be influenced, firstly by the microbial quality of raw milk, the sanitation procedures adopted, the use of starter cultures, and the condition and time of the ripening process (Novella-Rodríguez et al., 2004; Pinho et al., 2004). The differences detected in BA accumulation could be attributable to the milk used, probably because of the heterogeneity of the cheese typology considered. An analogous heterogeneity in BA content was observed by Novella-Rodríguez et al. (2003) in cheeses from bovine milk. The microbial population of raw milk can influence BA presence in cheese, even when thermal treatment are applied such as for a Pecorino cheese (Lanciotti et al., 2007) or for Pecorino Abruzzese (Martuscelli et al., 2005). It can be hypothesized that the mild thermal treatment applied selects a decarboxylating microbial population, which dominates during cheesemaking and, possibly, during ripening. Similar results have been reported by Marino et al. (2008) showing the highest BA contents in cheese produced using pasteurized milk and natural milk culture; therefore, the thermal treatment of milk seems to be not enough by itself to reduce the counts of decarboxylase-positive bacteria in cheese. However, other authors observed a higher BA accumulation in cheeses obtained from raw milk than in similar products from pasteurized milk (Schneller et al., 1997).

Cheese is a matrix with a high protein content in which their demolition to free amino acids (or short peptides) is guaranteed by proteases or peptidases produced by microorganisms (including starter cultures), present in milk (especially if not thermally treated), and/or in rennet. Given these activities, the availability of precursors is not a central problem in BA accumulation (Lanciotti et al., 2007). Fernández-García et al. (2000) studied the influence of addition of exogenous proteinases to milk and found that tyramine concentration was significantly (P < 0.05) influenced by this addition.

The high content of BA in many Pecorino cheeses could be due, in part, to proteinases, and peptidases released from rennet used, particularly artisanal lamb rennets, or pig rennet during cheesemaking of Pecorino di Farindola. In fact the traditional lamb paste preparation procedure has a significant impact on rennet composition, as has animal age, precedent diet, or slaughtering condition (Jacob et al., 2011). In artisanal lamb paste production, there is a substantial microbiota, dominated by LAB (Etayo et al., 2006; Gil et al., 2007). The use of artisanal rennets often entails problems concerning curd formation and final characteristics of the cheese. Vincente et al. (2001) reported that the release of free amino acids during ripening is strongly affected by starter added to the cheese, and that this effect varies markedly with the rennet used for cheesemaking. However the level of starter culture does not appears to affect the population of tyrosine decarboxylase microorganisms (Fernández-García et al., 2000). As a consequence of this, the natural whey starter used for Pecorino cheese manufacture and the rennet could affect the quality, the quantities, and variability of BA accumulation.

Conclusion

Pecorino cheeses, ewe’s milk dairy products of many Italian regions, have an important link with their areas of production which confer on them specific microbiological, chemical, and sensorial characteristics (Pirisi et al., 2011). The spread use of raw milk creates a high microbiological biodiversity, such as the use of different traditional rennets contribute to typical aromas and flavors. The presence of high contents of BA in Pecorino cheeses could be related to the enzymatic activity of proteases derived from microorganisms, or from another origin (rennet) that is important from a qualitative point of view, i.e., in relation to the type of amino acids provided to the amino acid decarboxylating microbiota, in particular tyrosine. The bacteriological composition of milk could be critical to define the BA profile in this type of cheese, that is generally produced in little farms. Even though Pecorino cheese is very important from economical point of view in certain Italian areas, studies on BA content and their origin are still scarce. Therefore, large amounts of BA in cheese could indicate unsuitability, from a hygienic point of view, of the milk used for cheesemaking. The need to know in depth and control the indigenous bacterial population responsible for high production of BA and the use of competitive adjunct cultures could be useful to improve the characteristics of Pecorino cheese.

Conflict of Interest Statement

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Acknowledgments

This research line has received funding from Cassa di Risparmio di Teramo (Rapid methods to determine and quantify tyramine content in dairy products of Abruzzo region).

References

- Arizcun C., Barcina Y., Torre P. (1997). Identification and characterization of proteolytic activity of Enterococcus spp. isolated from milk and Roncal and Idiazabal cheese. Int. J. Food Microbiol. 38, 17–24 10.1016/S0168-1605(97)00091-3 [DOI] [PubMed] [Google Scholar]

- Bavazzano P., Boccetti M., Cianti L., Colzi A., Leandri A., Munaò G., Perico A. (2011). Indagine sulla prevalenza delle amine biogene nel Pecorino toscano D.O.P. stagionato. Associazione Italiana Veterinari Igienisti 1, 197–201 [Google Scholar]

- Beresford T. P., Fitzsimons N. A., Brennan N. L., Cogan T. M. (2001). Recent advances in cheese microbiology. Int. Dairy J. 11, 259–274 10.1016/S0958-6946(01)00056-5 [DOI] [Google Scholar]

- Bizzarro R., Tarelli G. T., Giraffa G., Neviani E. (2000). Phenotypic and genotypic characterization of lactic acid bacteria isolated from Pecorino Toscano cheese. Ital. J. Food Sci. 12, 303–316 [Google Scholar]

- Bover-Cid S., Izquierdo-Pulido M., Vidal-Carou C. (2001). Effect of the interaction between a low tyramine-producing Lactobacillus and proteolytic staphylococci on biogenic amine production during ripening and storage of dry sausages. Int. J. Food Microbiol. 65, 113–123 10.1016/S0168-1605(00)00525-0 [DOI] [PubMed] [Google Scholar]

- Caridi A., Micari P., Caparra P., Curari A., Sarullo V. (2003). Ripening and seasonal changes in microbial groups and in physico-chemical properties of the ewes’ cheese Pecorino del Poro. Int. Dairy J. 13, 191–200 10.1016/S0958-6946(02)00157-7 [DOI] [Google Scholar]

- Celano G. V., Cafarchia C., Buja F., Tiecco G. (1992). Ricerca di amine biogene in alcuni formaggi. Ind. Aliment. 31, 764–768 [Google Scholar]

- Centeno J. A., Cepeda A., Rodríguez-Otero J. L. (1995). Identification and preliminary characterization of strains of enterococci and micrococci isolated from Arzúra raw cows’-milk cheese. Nahrung 39, 55–62 10.1002/food.19950390107 [DOI] [Google Scholar]

- Chaves-López C., De Angelis M., Martuscelli M., Serio A., Paparella A., Suzzi G. (2006). Characterization of the Enterobacteriaceae isolated from an artisanal Italian ewe’s cheese (Pecorino Abruzzese). J. Appl. Microbiol. 101, 353–360 10.1111/j.1365-2672.2006.02941.x [DOI] [PubMed] [Google Scholar]

- Clementi F., Cenci Goga B. T., Di Antonio E. (1994). On-farm manufactured Pecorino cheese. Evaluation of the microbiological characteristics of milk and cheese in Umbria (Italy). Latte 19, 575 [Google Scholar]

- Coda R., Brechany E., De Angelis M., De Candia S., Di Cagno R., Gobbetti M. (2006). Comparison of the compositional, microbiological biochemical, and volatile profile characteristics of nine Italian ewes’ milk cheeses. J. Dairy Sci. 89, 4126–4143 10.3168/jds.S0022-0302(06)72458-4 [DOI] [PubMed] [Google Scholar]

- Comunian R., Paba A., Daga E., Dupré I., Scintu M. F. (2010). Traditional and innovative production methods of Fiore Sardo cheese: a comparison of microflora with a PCR-culture technique. Int. J. Dairy Technol. 63, 224–233 10.1111/j.1471-0307.2010.00581.x [DOI] [Google Scholar]

- Corroler D., Mangin I., Desmasures N., Gueguen M. (1998). An ecological study of lactococci isolated from raw milk in the Camembert cheese registered designation of origin area. Appl. Environ. Microbiol. 64, 4729–4735 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Dahl S., Tavaria F. K., Malcata F. X. (2000). Relationship between flavour and microbiological profiles in Serra da Estrela cheese throughout ripening. Int. Dairy J. 10, 255–262 10.1016/S0958-6946(00)00042-X [DOI] [Google Scholar]

- Del Signore A., Di Giacomo F. (2008). Technological factor influencing the biogenic amine content in sheep cheeses and sensorial analysis (time of ripening, temperature, form size, anti-mould). J. Commodity Sci. Technol. Qual. 47, 229–243 [Google Scholar]

- Di Cagno R., Banks J., Sheehan L., Fox P. F., Brechany E. Y., Corsetti A., Gobbetti M. (2003). Comparison of the microbiological, compositional, biochemical, volatile profile and sensory characteristics of three Italian PDO ewes’ milk cheeses. Int. Dairy J. 13, 961–972 10.1016/S0958-6946(02)00143-7 [DOI] [Google Scholar]

- Etayo I., Perez Elortondo F. J., Gil P. F., Albisu M., Virto M., Conde S., Rodriguez Barron L. J., Nájera A. I., Gómez-Hidalgo M. E., Delgado C., Guerra A., De Renobales M. (2006). Hygienic quality, lipolysis and sensory properties of Spanish protected designation of origin ewe’s milk cheeses manufactured with lamb rennet paste. Lait 86, 415–434 10.1051/lait:2006021 [DOI] [Google Scholar]

- Fernández-García E., Tomillo J., Nuñez M. (2000). Formation of biogenic amines in raw milk Hispánico cheese manufactured with proteinases and different levels of starter culture. J. Food Prot. 63, 1551–1555 [DOI] [PubMed] [Google Scholar]

- Forzale F., Giorgi M., Pedonese F., Nuvoloni R., D’Ascenzi C., Rindi S. (2011). Contenuto di amine biogene nel “Pecorino del parco di Migliarino-San Rossore.” Associazione Italiana Veterinari Igienisti 1, 149–153 [Google Scholar]

- Foulquié Moreno M. R., Sarantinopoulos P., Tsakalidou E., De Vuyst L. (2006). The role and application of enterococci in food and health. Int. J. Food Microbiol. 106, 1–24 10.1016/j.ijfoodmicro.2005.06.026 [DOI] [PubMed] [Google Scholar]

- Fox P. F. (1998). “Developments in biochemistry of cheese ripening,” in Proceedings of Dairy Science and Technology 25th International Dairy Congress, Aarhus, 11–37 [Google Scholar]

- Fox P. F., Guinee T. P. (1987). “Italian cheeses,” in Cheese: Chemistry, Physics and Microbiology, ed. Fox P. F. (London: Elsevier Applied Science; ), 221 [Google Scholar]

- Franz C. M. A. P., Holzapfel W. H., Stiles M. E. (1999). Enterococci at the crossroads of food safety. Int. J. Food Microbiol. 47, 1–24 10.1016/S0168-1605(99)00007-0 [DOI] [PubMed] [Google Scholar]

- Franz C. M. A. P., Stiles M. E., Schleifer K. H., Holzapfel W. H. (2003). Enterococci in foods – a conundrum from food safety. Int. J. Food Microbiol. 88, 105–122 10.1016/S0168-1605(03)00174-0 [DOI] [PubMed] [Google Scholar]

- Freitas A. C., Malcata F. X. (2000). Microbiology and biochemistry of cheeses with appellation d’origine protege’e and manufactured in the Iberian Peninsula from ovine and caprine milks. J. Dairy Sci. 83, 584–602 10.3168/jds.S0022-0302(00)74918-6 [DOI] [PubMed] [Google Scholar]

- Freitas A. C., Pais C., Malcata F. X., Hogg T. A. (1996). Microbiological characterization of Picante da Beira Baixa cheese. J. Food Prot. 59, 155–160 [DOI] [PubMed] [Google Scholar]

- Freitas A. C., Sousa M. J., Malcata F. X. (1995). Effect of ripening time and the combination of ewe and goat milk on the microflora of Picante cheese. Ital. J. Food Sci. 7, 361–377 [Google Scholar]

- Gardini F., Tofalo R., Belletti N., Iucci L., Suzzi G., Torriani S., Guerzoni M. E., Lanciotti R. (2006). Characterization of yeasts involved in the ripening of Pecorino Crotonese cheese. Food Microbiol. 23, 641–648 10.1016/j.fm.2005.12.005 [DOI] [PubMed] [Google Scholar]

- Gelsomino R., Vancanneyt M., Cogan T. M., Condon S., Swings J. (2002). Source of enterococci in a farmhouse raw-milk cheese. Appl. Environ. Microbiol. 68, 3560–3565 10.1128/AEM.68.7.3560-3565.2002 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Gil P. F., Conde S., Albisu M., Perez-Elortondo F. J., Etayo I., Virto M., de Renobales M. (2007). Hygienic quality of ewes’ milk cheeses manufactured with artisan-produced lamb rennet pastes. J. Dairy Res. 74, 329–335 10.1017/S0022029907002440 [DOI] [PubMed] [Google Scholar]

- Giraffa G., Carminati D., Neviani E. (1997). Enterococci isolated from dairy products: a review of risks and potential tech-nological use. J. Food Prot. 60, 732–738 [DOI] [PubMed] [Google Scholar]

- Giraffa G., Pepe G., Locci F., Neviani E., Carminati D. (1995). Haemolytic activity, production of thermonuclease and biogenic amines by dairy enterococci. Ital. J. Food Sci. 7, 339–347 [Google Scholar]

- Gobbetti M. (2004). “Extra-hard varities,” in Cheese Chemistry, Physics and Microbiology, Vol. 2, eds Fox P. F., McSweeney P. L. H., Cogan T. M., Guinee T. P. (London: Academic Press; ), 51–70 [Google Scholar]

- Gobbetti M., Corsetti A., Smacchi E., De Angelis M., Rossi J. (1997). Microbiology and biochemistry of Pecorino Umbro cheese during ripening. Ital. J. Food Sci. 9, 111–126 [Google Scholar]

- Gomez R., Vioque M., Sanchez E., Mata C., Tejada L., Fernandez-Salguero J. (2000). Microbial study of farmhouse ewe cheese during storage in olive oil. Acta Microbiol. Immun. Hung. 47, 53–61 [PubMed] [Google Scholar]

- Gonzàlez De Llano D., Ramos M., Rodríguez A., Montilla A., Juárez M. (1992). Microbiological and physicochemical characteristics of Gamonedo blue cheese during ripening. Int. Dairy J. 2, 121–125 10.1016/0958-6946(92)90005-7 [DOI] [Google Scholar]

- Hatzikamari M., Litopoulou-Tzanetaki E., Tzanetakis N. (1999). Microbiological characteristics of Anevato: a traditional Greek cheese. J. Appl. Microbiol. 87, 595–601 10.1046/j.1365-2672.1999.00857.x [DOI] [PubMed] [Google Scholar]

- Jacob M., Jaros D., Rohm H. (2011). Recent advances in milk clotting enzymes. Int. J. Dairy Technol. 64, 14–33 10.1111/j.1471-0307.2010.00633.x [DOI] [Google Scholar]

- Jordan K. N., Cogan T. M. (1999). Heat resistance of Lactobacillus spp. isolated from Cheddar cheese. Lett. Appl. Microbiol. 29, 136–140 10.1046/j.1365-2672.1999.00607.x [DOI] [PubMed] [Google Scholar]

- La Gioia F., Rizzotti L., Rossi F., Gardini F., Tabanelli G., Torriani S. (2011). Identification of a tyrosine decarboxylase gene (tdcA) in Streptococcus thermophilus 1TT45 and analysis of its expression and tyramine production in milk. Appl. Environ. Microbiol. 77, 1140–1144 10.1128/AEM.01928-10 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ladero V., Martínez N., Martín M. C., Fernández M., Alvarez M. A. (2010). qPCR for quantitative detection tyramine-producing bacteria in dairy products. Food Res. Int. 43, 289–295 10.1016/j.foodres.2009.10.007 [DOI] [Google Scholar]

- Lanciotti R., Patrignani F., Iucci L., Guerzoni M. E., Suzzi G., Belletti N., Gardini F. (2007). Effects of milk high pressure homogenization on biogenic amine accumulation during ripening of ovine and bovine Italian cheeses. Food Chem. 104, 693–701 10.1016/j.foodchem.2006.12.017 [DOI] [Google Scholar]

- Ledda A., Scintu M. F., Pirisi A., Sanna S., Mannu L. (1994). Caratterizzazione tecnologica di ceppi di lattococchi e di enterococchi per la produzione di formaggio pecorino Fiore Sardo. Scienza e Tecnica Lattiero Casearia 45, 443–456 [Google Scholar]

- Macedo A. C., Tavares T. G., Malcata F. X. (2004). Influence of native lactic acid bacteria on the microbiological, biochemical and sensory profiles of Serra da Estrela cheese. Food Microbiol. 21, 233–240 10.1016/S0740-0020(03)00064-9 [DOI] [Google Scholar]

- Mannu L., Paba A. (2002). Genetic diversity of lactococci and enterococci isolated from home-made Pecorino Sardo ewes’ milk cheese. J. Appl. Microbiol. 92, 55–62 10.1046/j.1365-2672.92.5s1.8.x [DOI] [PubMed] [Google Scholar]

- Mannu L., Paba A., Pes M., Floris R., Scintu M. F., Morelli L. (1999). Strain typing among enterococci isolated from home-made Pecorino Sardo cheese. FEMS Microbiol. Lett. 170, 25–30 10.1111/j.1574-6968.1999.tb13351.x [DOI] [PubMed] [Google Scholar]

- Marino M., Maifreni M., Bartolomei I., Rondinini G. (2008). Evaluation of aminoacid decarboxylative microbiota throughout the ripening of an Italian PDO cheese produced using different manufacturing practices. J. Appl. Microbiol. 105, 540–549 10.1111/j.1365-2672.2008.03793.x [DOI] [PubMed] [Google Scholar]

- Marino M., Maifreni M., Rondinini G. (2003). Microbiological characterization of artisanal Montasio cheese: analysis of its indigenous lactic acid bacteria. FEMS Microbiol. Lett. 229, 133–140 10.1016/S0378-1097(03)00816-4 [DOI] [PubMed] [Google Scholar]

- Martín-Platero A. M., Valdivia E., Maqueda M., Martínez-Bueno M. (2009). Characterization and safety evaluation of enterococci isolated from Spanish goats’ milk cheeses. Food Microbiol. 132, 24–32 10.1016/j.ijfoodmicro.2009.03.010 [DOI] [PubMed] [Google Scholar]

- Martuscelli M., Gardini F., Torriani S., Mastrocola D., Serio A., Chaves-Lopez C., Schirone M., Suzzi G. (2005). Production of biogenic amines during the ripening of Pecorino Abruzzese cheese. Int. Dairy J. 15, 571–578 10.1016/j.idairyj.2004.11.008 [DOI] [Google Scholar]

- Mascaro N., Stocchi R., Ricciutelli M., Cammertoni N., Renzi F., Cecchini S., Loschi A. R., Rea S. (2010). Biogenic amine content and chemical and physical features of italian formaggio di Fossa. Associazione Italiana Veterinari Igienisti 8, 49–53 [Google Scholar]

- Medina M., Fernández del Pozo B. M., Rodríguez-Marín A., Gaya P., Nuñez M. (1991). Effect of lactic starter inoculation on chemical, microbiological, rheological and sensory characteristics of La Serena cheese. J. Dairy Res. 58, 355–361 10.1017/S0022029900029939 [DOI] [Google Scholar]

- Mercogliano R., De Felice A., Chirollo C., Cortesi M. L. (2010). Production of vasoactive amines during the ripening of Pecorino Carmasciano cheese. Vet. Res. Commun. 34, S175–S178 10.1007/s11259-010-9394-1 [DOI] [PubMed] [Google Scholar]

- Novella-Rodríguez S., Veciana-Nogués M. T., Izquierdo-Pulido M., Vidal-Carou M. C. (2003). Distribution of biogenic amines and polyamines in cheese. J. Food Sci. 68, 750–756 10.1111/j.1365-2621.2003.tb08236.x [DOI] [Google Scholar]

- Novella-Rodríguez S., Veciana-Nogue M. T., Artur Roig-Sagues X., Antonio A. X., Trujillo-Mesa J. A. T., Carmen M., Vidal-Carou M. C. (2004). Evaluation of biogenic amines and microbial counts throughout the ripening of goat cheeses from pasteurized and raw milk. J. Dairy Res. 71, 245–252 10.1017/S0022029904000147 [DOI] [PubMed] [Google Scholar]

- Ogier J. C., Serror P. (2008). Safety assessment of dairy microorganisms – the Enterococcus genus. Int. J. Food Microbiol. 126, 291–301 10.1016/j.ijfoodmicro.2007.08.017 [DOI] [PubMed] [Google Scholar]

- Palmas F., Cosentino S., Fadda M. E., Deplano M., Mascia V. (1999). Microbial characteristics of Pecorino processed cheese spreads. Lait 79, 607–713 10.1051/lait:1999650 [DOI] [Google Scholar]

- Pinho O., Ferreira I. M. P. L. V. O., Mendes E., Oliveira B. M., Ferreira M. (2001). Effect of temperature on evolution of free amino acid and biogenic amine contents during storage of Azeitao cheese. Food Chem. 75, 287–291 10.1016/S0308-8146(01)00109-1 [DOI] [Google Scholar]

- Pinho O., Pintado A. I. E., Gomes A. M. P., Pintado M. M. E., Malcata F. X., Ferreira I. M. P. L. V. O. (2004). Interrelationships among microbiological physico-chemical, and biochemical properties of Terrincho cheese, with emphasis on biogenic amines. J. Food Prot. 67, 2779–2785 [DOI] [PubMed] [Google Scholar]

- Pintado A. I. E., Pinho O., Ferreira I. M. P. L. V. O., Pintado M. M. E., Gomes A. M. P., Malcata F. X. (2008). Microbiological, biochemical and biogenic amine profiles of Terrincho cheese manufactured in several dairy farms. Int. Dairy J. 18, 631–640 10.1016/j.idairyj.2007.11.021 [DOI] [Google Scholar]

- Pirisi A., Comunian R., Urgeghe P. P., Scintu M. F. (2011). Sheep’s and goat’s dairy products in Italy: technological, chemical, microbiological, and sensory aspects. Small Rum. Res. 101, 102–112 10.1016/j.smallrumres.2011.09.030 [DOI] [Google Scholar]

- Pisano M. B., Fadda M. E., Deplano M., Corda A., Casula M., Cosentino S. (2007). Characterization of Fiore Sardo cheese manufactured with the addition of autochthonous cultures. J. Dairy Res. 74, 255–261 10.1017/S0022029907002464 [DOI] [PubMed] [Google Scholar]

- Pisano M. B., Fadda M. E., Deplano M., Corda A., Cosentino S. (2006). Microbiological and chemical characterization of Fiore Sardo, a traditional Sardinian cheese made from ewe’s milk. Int. J. Dairy Technol. 59, 171–179 10.1111/j.1471-0307.2006.00260.x [DOI] [Google Scholar]

- Poznanski E., Cavazza A., Cappa F., Cocconcelli P. S. (2004). Indigenous raw milk microbiota influences the bacterial developent in trditional cheese from alpine natural park. Int. J. Food Microbiol. 92, 141–151 10.1016/j.ijfoodmicro.2003.09.006 [DOI] [PubMed] [Google Scholar]

- Prodromou K., Thasitou P., Haritonidou E., Tzanetakis N., Litopoulou-Tzanetaki E. (2001). Microbiology of “Orinotyri,” a ewe’s milk cheese from the Greek mountains. Food Microbiol. 18, 319–328 10.1006/fmic.2001.0403 [DOI] [Google Scholar]

- Psoni L., Tzanetakis N., Litopoulou-Tzanetaki E. (2003). Microbiological characteristics of Batzos, a traditional Greek cheese from raw goat’s milk. Food Microbiol. 20, 575–582 10.1016/S0740-0020(02)00153-3 [DOI] [Google Scholar]

- Randazzo C. L., Vaughan E. E., Caggia C. (2006). Artisanal and experimental Pecorino Siciliano cheese: microbial dynamics during manufacture assessed by culturing and PCR-DGGE analyses. Int. J. Food Microbiol. 109, 1–8 10.1016/j.ijfoodmicro.2005.11.002 [DOI] [PubMed] [Google Scholar]

- Ricci C., Bucchianico R., D’Angelo M. G., Trivillino R., Torriani S., Dellaglio F. (1995). Production of Pecorino d’Abruzzo cheese: characteristics of finished product and aspects of the ripening process. Latte 20, 268–274 [Google Scholar]

- Roig-Saguès A. X., Molina A. P., Hernandez-Herrero M. M. (2002). Histamine and tyramine-forming microorganisms in Spanish traditional cheeses. Eur. Food Res. Technol. 215, 96–100 10.1007/s00217-002-0521-2 [DOI] [Google Scholar]

- Sánchez-Rey R., Poullet B., Cáceres P., Larriba G. (1993). Microbiological quality and incidence of some pathogenic microorganisms in La Serena cheese throughout ripening. J. Food Prot. 56, 879–881 [DOI] [PubMed] [Google Scholar]

- Santos W. C., Souza M. R., Cerqueira M. M. O. P., Glória M. B. A. (2003). Bioactive amines formation in milk by Lactococcus in the presence or not of rennet and NaCl at 20 and 32°C. Food Chem. 81, 595–606 10.1016/S0308-8146(02)00502-2 [DOI] [Google Scholar]

- Schirone M., Tofalo R., Mazzone G., Corsetti A., Suzzi G. (2011). Biogenic amine content and microbiological profile of Pecorino di Farindola cheese. Food Microbiol. 28, 128–136 10.1016/j.fm.2010.09.005 [DOI] [PubMed] [Google Scholar]

- Schneller R., Good P., Jenny M. (1997). Influence of pasteurized milk, raw milk and different ripening cultures on biogenic amine concentrations in semi-soft cheeses during ripening. Z. Lebensm. Unters. Forsch. 204, 265–272 10.1007/s002170050075 [DOI] [Google Scholar]

- Suzzi G., Caruso M., Gardini F., Lombardi A., Vannini L., Guerzoni M. E., Andrighetto C., Lanorte M. T. (2000). A survey of enterococci isolated from an artisanal Italian goat’s cheese (semicotto caprino). J. Appl. Microbiol. 89, 267–274 10.1046/j.1365-2672.2000.01120.x [DOI] [PubMed] [Google Scholar]

- Suzzi G., Gardini F. (2003). Biogenic amines in dry fermented sausages: a review. Int. J. Food Microbiol. 88, 41–54 10.1016/S0168-1605(03)00080-1 [DOI] [PubMed] [Google Scholar]

- Van der Berg G., Exterkate F. A. (1993). Technological parameters involved in cheese ripening. Int. Dairy J. 3, 485. 10.1016/0958-6946(93)90028-X [DOI] [Google Scholar]

- Vernile A., Beresford T. P., Spano G., Massa S., Fox P. F. (2007). Chemical studies of Pecorino Siciliano cheese throughout ripening. Milchwissenschaft 62, 280–284 [Google Scholar]

- Vincente M. S., Ibánez F. C., Barcina Y., Barron L. J. R. (2001). Casein breakdown during ripening of Idiazabal cheese: influence of starter and rennet type. J. Sci. Food Agric. 81, 210–215 [DOI] [Google Scholar]

- Wouters J. T. M., Ayad E. H. E., Hugenholtz J., Smit G. (2002). Microbes from raw milk for fermented dairy products. Int. Dairy J. 12, 91–99 10.1016/S0958-6946(01)00151-0 [DOI] [Google Scholar]