Abstract

Published emission factors (EFs) often vary significantly, leading to high uncertainties in emission estimations. There are few reliable EFs from field measurements of residential wood combustion in China. In this study, 17 wood fuels and one bamboo were combusted in a typical residential stove in rural China to measure realistic EFs of particulate matter (PM), organic carbon (OC) and elemental carbon (EC), as well as to investigate the influence of fuel properties and combustion conditions on the EFs. Measured EFs of PM, OC, and EC (EFPM, EFOC, and EFEC, respectively) were in the range of 0.38~6.4, 0.024~3.0 and 0.039~3.9 g/kg (dry basis), with means and standard derivation of 2.2±1.2, 0.62±0.64 and 0.83±0.69 g/kg, respectively. Shrubby biomass combustion produced higher EFs than tree woods, and both species had lower EFs than those of indoor crop residue burning (p<0.05). Significant correlations between EFPM, EFOC and EFEC were expected. By using a nine-stage cascade impactor, it was shown that size distributions of PM emitted from tree biomass combustions were unimodal with peaks at a diameter less than 0.4 µm (PM0.4), much finer than the PM from indoor crop residue burning. Approximately 79.4% of the total PM from tree wood combustion was PM with a diameter less than 2.1µm (PM2.1). PM size distributions for shrubby biomasses were slightly different from those for tree fuels. Based on the measured EFs, total emissions of PM, OC, and EC from residential wood combustion in rural China in 2007 were estimated at about 303, 75.7, and 92.0 Gg.

Introduction

Residential wood combustion is of wide concern due to its adverse impacts on air quality and human health, especially in the many developing countries where wood is often used for residential cooking and heating. Particulate matter (PM), one of many pollutants emitted from wood combustion, contains organic carbon (OC) and elemental carbon (EC, sometimes referred to as black carbon1). PM is harmful to human health, and is considered a climate-relevant pollutant. PM, especially fine PM, can penetrate deep into the bronchial and lung areas, leading to respiratory and cardiovascular diseases and increased rates of mortality2–4. Sulfates and OC content in PM generally have a cooling effect on climate because they scatter light, while EC can absorb light resulting in a positive radiative forcing 1, 5. It has been reported that PM emitted from combustion in wood stoves is often characterized by small particle size and high levels of organic pollutants; subsequently, it can cause high levels of free radicals, DNA damage, inflammatory, and oxidative stress response in humans who are exposed to it 6.

An estimated 1324~1615 Tg of wood was used in the residential sector globally in 1995, of which approximately 800~930 Tg was consumed in Asia 7. Accordingly, 670~820 Gg and 400~470 Gg EC were emitted from wood combustion globally and in Asia, respectively 7, contributing an important fraction of the total emissions from all sources. In most developing countries, residential biomass combustion, including wood and crop residues, dominates the total emissions of fine PM, EC and OC. It has been calculated that around 28, 72, and 39 % of the total PM, OC, and EC emissions in China in 2005 were from residential biomass combustion 8.

Emissions of primary PM, OC, and EC are usually calculated based on the total quantities of consumed fuel and emission factors (EFPM, EFOC, and EFEC), defined as PM, OC, and EC emitted per mass of fuel consumed. Unfortunately, data on EFs of these pollutants are scarce in China 9–11 and using the EFs reported for other countries and/or calculated based on EFs of other pollutants in the emission inventories often results in high uncertainties and bias 7–8, 12–15. The measured EFs for biomass burning often varied dramatically due to the differences in fuel properties, like fuel moisture and volatile matter content, and combustion conditions, e.g. fire management, burning temperature, oxygen supply and mixing states in stove chamber 14–24. The impacts of these factors were complicated and sometimes interacted with one another. For example, fuel with high moisture often required additional energy to vaporize the water and hence resulted in low combustion efficiency and high pollutant emissions, while in a stove chamber with limited volume, low moisture fuel may burn too fast resulting in incomplete combustion due to the insufficient air supply 17, 25. To achieve high efficient combustion, adequate air supply and proper mixing status are necessary 26–27. It is accepted that high combustion efficiency leads to relative low emissions of pollutants, and combustion efficiency is usually affected by many factors, like fuel moisture, oxygen supply, and combustion temperature 20–21. In addition, fuel properties and combustion conditions were also reported to influence the size distribution of PM emitted 28–29.

In a previous study, we found that the EFEC for crop residue measured using a traditional cooking stove in China was significantly higher than the EFEC measured in laboratory chambers, and fuel moisture and combustion efficiency were the most important factors affecting the EFPM and EFEC from crop residue burning 15. To provide firsthand field data for firewood combustion in China, EFPM, EFOC, and EFEC were measured for a wide range of wood fuels used in China in a traditional cooking stove. The influences of fuel properties and burning conditions on the EFs were also investigated. Finally, the size distributions of freshly emitted PM were characterized.

Method

Fuels, Stove and Combustion Experiments

Residential wood combustion experiments were conducted in a simulated rural kitchen, which was built to replicate the layout of kitchens found in rural Northern China. The experimental site is located in a remote area outside of Beijing with no residential or traffic sources nearby. One commonly used brick cooking stove was used in this study. This type of stove is currently used by about 175 million residences in rural areas, following a campaign to disseminate fuel-saving stoves (National Improved Stove Program) during the 1980~1990s in rural China. Detailed information about the kitchen and the stove was published in a previous study 15. For residential cooking and heating, residents usually burn a mixture of various wood fuels that are available for them, so it is difficult to accurately estimate the consumption of each type of woods burned in the household. This study investigated 17 types of wood, which represent the main tree species used for bio-energy in China 30. These include Chinese white poplar (Populus tomentosa Carr.), water Chinese fir (Metasequoia glyptostroboides), Chinese pine (Pinus tabulaeformis Carr.), cypress (Cupressus funebris Endl.), elm (Ulmus pumila L.), fir (Cunninghamia lanceolata), larch (Larix gmelini (Rupr.) Rupr.), maple (Acer mono Maxim.), oak (Quercus mongolica), paulowonia tomentosa (P.tomentosa (Thunb.) Steud.), toon (Ailanthus altissima), white birch (Betula platyphylla Suk), willow (Salix babylonica), locust (Robinia pseudoacacia L.), bamboo (Phyllostachys heterocycla(Carr.)), lespedeza(Leapedeza bicolor. Turcz), holly (Buxus megistophylla Lévl) and buxus sinica shrub (Buxus sinica (Rehd. et Wils.) Cheng). The properties of these fuels, including density, moisture, elemental contents (C, H, N, O), proximate analysis results (volatile matter, fixed carbon, and ash content), and high heating values, were measured and provided in the Table 1 and Table 2.

Table 1.

Density and elemental analysis of C, H, N, O content (%, dry basis) in tested wood fuels. C, H, and N contents were analyzed by the Analytical Instrumentation Center, Peking University (Elementar Vario MICRO CUBE, German) and O content is calculated by the difference.

| Fuel type | Density, g/cm3 | C, % | N, % | H, % | O,% | |

|---|---|---|---|---|---|---|

| Chinese White Poplar | Populus tomentosa Carr. | 0.463 | 47.75 | 0.08 | 6.15 | 46.03 |

| Elm | Ulmus pumila L. | 0.536 | 46.89 | 0.84 | 5.89 | 46.40 |

| Yellow Locust | Robinia pseudoacacia L. | 1.176 | 45.37 | 1.37 | 6.05 | 47.22 |

| Maple | Acer mono Maxim. | 0.949 | 47.73 | 0.18 | 6.10 | 46.00 |

| Fir | Cunninghamia lanceolata | 0.427 | 49.83 | 0.13 | 6.18 | 43.87 |

| Larch | Larix gmelini (Rupr.) Rupr. | 0.634 | 48.23 | 0.14 | 6.20 | 45.44 |

| Water Chinese fir | Metasequoia glyptostroboides | 0.410 | 49.42 | 0.29 | 6.07 | 44.22 |

| Cypress | Cupressus funebris Endl. | 0.667 | 50.13 | 0.36 | 6.02 | 43.49 |

| Oak | Quercus mongolica | 1.114 | 47.42 | 0.30 | 6.15 | 46.14 |

| Chinese Pine | Pinus tabulaeformis Carr. | 0.443 | 49.10 | 0.18 | 6.32 | 44.41 |

| Willow | Salix babylonica | 0.551 | 47.39 | 0.23 | 6.14 | 46.25 |

| Paulownia tomentosa | P.tomentosa (Thunb.) Steud. | 0.284 | 48.76 | 0.13 | 6.11 | 45.02 |

| Toon | Ailanthus altissima | 0.734 | 47.71 | 0.18 | 6.13 | 45.99 |

| White Birch | Betula platyphylla Suk | 0.798 | 48.33 | 0.21 | 6.20 | 45.28 |

| Lespedeza | Leapedeza bicolor. Turcz | 48.59 | ||||

| Buxus sinica | Buxus sinica Cheng | 48.19 | ||||

| Holly | Buxus megistophylla Lévl | 45.85 | ||||

| Bamboo | Phyllostachys heterocycla | 0.912 | 48.75 | 0.26 | 5.98 | 45.02 |

Table 2.

Moisture, volatile matter, ash, fixed carbon content and HHV of tested fuels. Proximate analysis was conducted by the Analytical Center of Chinese Academy of Agricultural Engineering.

| Fuel type | Moisture, % | ash, % | VM, % | Fixed carbon, % | HHV, MJ/kg |

|---|---|---|---|---|---|

| Chinese White Poplar | 5.32 | 0.90 | 81.69 | 17.41 | 18.35 |

| Elm | 6.52 | 1.50 | 78.56 | 19.94 | 18.27 |

| Yellow Locust | 33.33 | 0.90 | 78.93 | 20.16 | 18.77 |

| Maple | 31.41 | 1.80 | 86.12 | 12.08 | 19.03 |

| Fir | 9.12 | 0.42 | 82.94 | 16.64 | 18.61 |

| Larch | 12.77 | 0.46 | 82.10 | 17.44 | 19.22 |

| Water Chinese fir | 12.83 | 0.71 | 79.91 | 19.38 | 19.49 |

| Cypress | 12.71 | 1.47 | 76.60 | 21.93 | 20.02 |

| Oak | 29.41 | 1.85 | 78.33 | 19.82 | 19.00 |

| Chinese Pine | 9.10 | 0.25 | 84.77 | 14.98 | 18.51 |

| Willow | 9.92 | 1.41 | 82.84 | 15.75 | 16.99 |

| Paulownia tomentosa | 8.69 | 0.30 | 85.03 | 14.67 | 16.00 |

| Toon | 7.17 | 1.49 | 82.94 | 15.57 | 17.28 |

| White Birch | 32.21 | 0.39 | 87.45 | 12.17 | 20.22 |

| Lespedeza | 6.04 | 4.60 | 81.08 | 14.32 | |

| Buxus sinica | 6.96 | 5.84 | 78.36 | 15.80 | |

| Holly | 6.76 | 8.56 | 77.58 | 13.86 | |

| Bamboo | 8.18 | 0.51 | 84.94 | 14.55 | 18.33 |

The combustion experiments were conducted by heating known amounts of water, similar to what has been done in indoor crop residue burning experiments 15. Pre-weighed (~1.0 kg) quantities of wood fuels were cut into small pieces (about 15~20 cm2 × 20~30 cm in length), ignited at the split wood tips and inserted into the stove chamber, to mimic the pattern of residential wood combustion in rural residents’ daily lives. The shrubby biomass was broke into 20~30 cm sections. The associated flue gas entered a mixing chamber (about 4.5 m3) with a built-in fan. There was no further dilution conducted to avoid the alterations in PM mass loading and size distribution 13. Measured smoke temperature and relative humidity were 20–35 °C and 40–60% (TM184, Tenmars), respectively. The sampling period covered the whole burning cycle, including the flaming (obvious fire) and smoldering phases (without obvious fire). The sampling started after the initial ignition and stopped when the measured CO and CO2 concentrations dropped to the background levels. The combustion processes lasted for about 40~60 minutes, and ash in the stove was collected and weighed after combustion. It is recognized that combustion conditions and emissions varied in various burning phases and future study using continuous on-line measurements is suggested. This combustion experiment was repeated three times for each type of fuel.

Sampling and Measurement

Sampling work was done throughout the whole burning cycle. Quartz fiber filters (Pall QAT-UP, cut into rounded ones with 25 cm in diameter) were used to collect particulate matter in the flue gas using low-volume pumps (XQC-15E, Tianyue, China) at a flow rate of about 1.0 L/min. Size segregated PM samples were collected using a nine stage cascade impactor (FA-3, Kangjie, China) with glass fiber filters at a flow rate of 28.3 L/min. The cutoff aerodynamic diameters (Da) for each stage were <0.4, 0.4~0.7, 0.7~1.1, 1.1~2.1, 2.1~3.3, 3.3~4.7, 4.7~5.8, 5.8~9.0, and 9.0~10.0 µm, respectively. All filters were baked at 450 °C for 6 hours and equilibrated in a desiccator for 24 hours prior to being weighed. After sampling, particle-loaded filters were folded and packed using aluminum foil. Procedure blanks of PM, OC and EC were also measured using the same protocol, and subtracted from the results.

Gravimetric measurements were conducted using a high precision (0.00001g) digital balance. EC and OC were analyzed using a Sunset EC/OC analyzer (Sunset Lab, USA) 15. The filter was heated in a pure helium at 600, 840, 550 °C for OC detection, and then at 550, 650, 870 °C in an oxygen/helium atmosphere to determine EC. The carbon results were calculated using methane at the end of each analysis cycle, and pryolyzed OC, produced in inert helium when temperature increased, was subtracted from EC results accordingly the initial laser value. CO2 and CO were measured every 2 seconds with an on-line detector equipped with non-dispersive infrared sensor and measurements were recorded automatically. The equipment (GXH-3051, Technical Institute, China) was calibrated using a span gas before each combustion experiment (CO, 1.00%; CO2, 5.00%).

Data Analysis

EFs of PM, OC, and EC were calculated using the carbon mass balance method by assuming that the carbon in the fuel was completely released in the form of CO2, CO, total gaseous hydrocarbons, and carbonaceous carbon in particulate phase 9. In this study, gaseous total hydrocarbon was not measured which may lead to an estimated error of less than 4%, since most of the released gaseous carbon was in the forms of CO2 or CO 13.

Modified combustion efficiency (MCE), defined as CO2/(CO2+CO) ratios (molar basis), and fuel burning rate (R) were calculated to quantitatively describe the combustion conditions. Results of calculated MCE and burning rates for each fuel type were listed in Table 3. Since EFs were lognormal distributed 31, log-transformed EFs were used for comparison and correlation analysis. When other parameters with limited information on frequency distribution were involved, non-parametric tests were applied. Statistical analysis was conducted at a significance level of 0.05. Principal Component Analysis (PCA) was used to investigate the impacts of various factors on EFs of PM, OC and EC from residential wood combustion.

Table 3.

Calculated MCE and burning rates of tested residential wood combustion in the whole burning cycle. Data shown are average and standard derivations of triplicate combustion experiments.

| Fuel type | MCE, % | R, kg/min | OC, g/kg | EC, g/kg | PM, g/kg |

|---|---|---|---|---|---|

| Chinese White Poplar | 94.7±0.9 | 0.055±0.006 | 0.66±0.32 | 0.88±0.49 | 1.8±0.3 |

| Elm | 95.6±0.1 | 0.064±0.005 | 0.79±0.15 | 1.2±0.3 | 2.2±0.2 |

| Yellow Locust | 93.7±0.1 | 0.082±0.011 | 1.9±1.5 | 0.21±0.15 | 1.7±0.6 |

| Maple | 95.7±0.2 | 0.065±0.003 | 0.11±0.01 | 0.056±0.004 | 0.8±0.4 |

| Fir | 96.0±0.3 | 0.051±0.014 | 0.97±0.88 | 0.95±0.20 | 1.7±0.7 |

| Larch | 95.8±0.3 | 0.049±0.000 | 0.14±0.11 | 0.35±0.34 | 0.71±0.36 |

| Water Chinese fir | 96.2±0.0 | 0.071±0.001 | 0.36±0.17 | 0.85±0.45 | 1.8±0.2 |

| Cypress | 93.5±0.8 | 0.052±0.002 | 0.82±0.45 | 0.71±0.39 | 2.0±0.6 |

| Oak | 95.0±0.4 | 0.051±0.008 | 0.54±0.63 | 0.13±0.13 | 1.7±1.0 |

| Chinese Pine | 94.1±0.6 | 0.078±0.010 | 0.60±0.35 | 0.94±0.40 | 1.6±0.3 |

| Willow | 95.1±0.2 | 0.070±0.006 | 0.23±0.10 | 0.47±0.30 | 0.89±0.21 |

| Paulownia tomentosa | 94.8±0.3 | 0.076±0.009 | 0.39±0.12 | 0.94±0.51 | 1.9±0.2 |

| Toon | 95.4±0.3 | 0.071±0.008 | 0.19±0.13 | 0.52±0.41 | 1.0±0.4 |

| White Birch | 93.7±0.7 | 0.064±0.006 | 0.69±0.32 | 0.67±0.61 | 1.9±0.4 |

| Lespedeza | 94.4±0.1 | 0.192±0.052 | 0.21±0.17 | 0.48±0.40 | 3.5±2.5 |

| Buxus sinica | 94.8±0.5 | 0.095±0.006 | 1.2±0.1 | 2.5±1.7 | 4.7±0.6 |

| Holly | 95.8±0.7 | 0.086±0.004 | 0.73±0.28 | 1.6±0.4 | 3.1±0.1 |

| Bamboo | 95.2±0.9 | 0.071±0.021 | 0.13±0.09 | 1.2±0.5 | 2.1±0.5 |

Note: Carbon mass fraction for wood of different types varied due to difference in fuel type and combustion condition. And, adsorption of gaseous organics and systematic error in PM gravimetric measurement may result in the sum percentage larger than 100% in some cases 33.

Results and Discussion

Emission Factors

The measured EFs of PM, OC, and EC for 18 tested wood fuels (dry basis) burned under normal conditions are listed in Table 3. Significant differences (p < 0.05) in EFs of PM, OC, and EC between the tested tree woods (1.5±0.6, 0.62±0.65, and 0.65±0.46 g/kg as means and standard deviations, respectively, n = 42) and shrubs (3.8±1.4, 0.81±0.64, and 1.53±1.10 g/kg, respectively, n = 9) was found. Since there was no significant difference in chemical composition (C, H, N, and O contents) between the tree and shrubby biomasses, and the burning rates of the tree wood fuels (0.065±0.012 kg/min) were significantly lower than those of shrubby biomasses (0.121±0.054 kg/min) (p < 0.05), the relatively higher EFs of shrubby biomass likely resulted from the faster burning which may cause severe oxygen shortage in a stove hearth with limited volume 16, 32. It was also found that the measured EFs for the woods were significantly lower (p < 0.05) than those for crop residues (8.2±4.3, 1.5±0.6, and 1.4±0.7 g/kg for PM, OC, and EC, respectively), which were measured using the same facility under same conditions (p < 0.05) 15. The difference may be partly explained by the higher bulk densities and lower moistures of the crop residues 15, 17.

PM emissions from wood burning in China were reported at 1.17~5.87 g/kg in instant combustion, and 1.51~8.73 g/kg in ultimate combustion 9. In a field measurement on residential wood combustion in rural area, OC, EC, and PM2.5 EFs were 1.14±0.40, 1.49±0.69, and 3.08±0.82 g/kg, respectively 11. It can be seen that these EFs, and also published data for biomass burning in other countries 34–39 were all highly variable depending on fuel types and combustion conditions. It was reported that for the same fuel, EFs of fine PM from cooking stove combustion were significantly lower than those in fireplaces 36–38. Based on the previously published EFs in literature and those measured in this study, EFs of PM, OC, and EC were 2.95±3.04 (0.31~16.3, as range, n=85), 1.10±1.56 (0.02~8.09, n=109), and 0.68±0.64 (0.04~3.77, n=85) g/kg for woodstoves 9,11,14, 37–50 and 7.96±4.32 (1.6~20.2, n=61), 4.80±2.06 (1.09~9.17, n=36), and 0.66±1.23 (0.04~6.58, n=36) for fireplaces, respectively 14, 37–42, 48–50. The differences between them were indeed significant (p < 0.05).

In a previous study, we found that the EFs of PM and EC associated with burning crop residues in stoves were significantly higher than those measured in laboratory chambers. For firewood, however, our data were not higher than those (0.2~1.3, 8.0~27.8, and 7~55 g/kg for EC, OC, and PM, respectively) obtained from an open-burning chamber experiment 50–52. More studies, like those focusing on the evaporation of gaseous organics which were largely emitted in crop residue burning, are needed to explain this phenomenon.

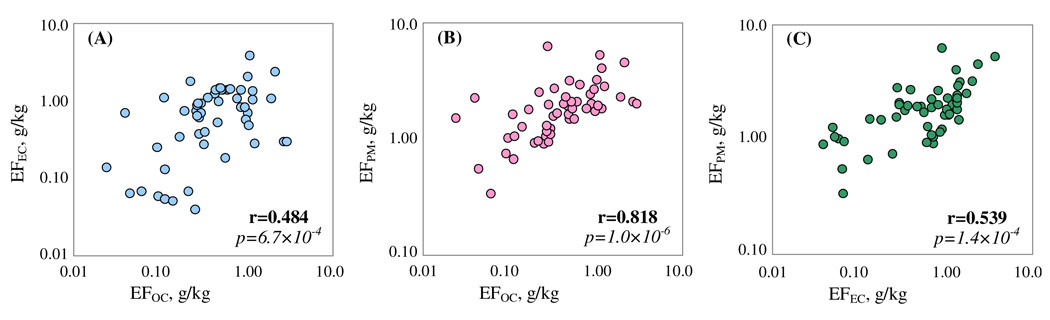

It is reasonable to expect that EFs of PM, OC and EC are significantly correlated (p < 0.05) (Figure 1). Similar correlation has been reported for crop residue and coal combustion15, 53. Although CO is also an incomplete combustion product and is occasionally used as a surrogate for the emissions of PM and other pollutants 18, 34, no significant correlation was found between EFs of CO and PM, EC, or OC in this study (p > 0.05). This complicated relationship between CO and emissions of other pollutants has been mentioned in the literature 11, 18.

Figure 1.

Correlations among EFs of PM, EC, and OC for wood combusted in a residential stove.

The mean ratios of OC/PM and EC/PM were 0.32±0.27 and 0.39±0.26, respectively and there was no significant difference between tested shrubby and tree biomasses (p > 0.05). These ratios were significantly higher (p < 0.05) than those for crop residue burning in the same stove (0.19 ± 0.07 and 0.19 ± 0.07) 15, suggesting that carbon mass fractions in PM from wood combustion were higher than those produced from crop residue burning. Similar results were reported in another study on carbonaceous aerosol emissions from household biofuel combustion 11. Future study is necessary to look into the reason of the phenomenon, for example the difference in fuel ash content.

The mean EC/OC ratio obtained in this study was 1.71±1.19. Li et al., 11 reported an EC/OC ratio at 1.41±0.57 for household wood combustion in China. The value was comparable to our result, and both were found to be higher than those reported in the literature 1, 38–41. CO/CO2 ratios measured in this study (lower in the flaming phase with obvious fire and increased in the smoldering phase without obvious fire) were lower than 10%, indicating the hot flaming domination in the tested wood combustion 11, 54, and hence more EC emitted from the relatively high temperature combustion in the flaming phase. Further studies are necessary to investigate the carbon emission dominated in different phases, like EC emitted in the flaming phase and brown carbon produced mainly in the smoldering phase 24, 55–56.

Individually, most of the investigated factors were not significantly correlated with the measured EFs (p>0.05) in this study, which can be partly explained by the fact that the impacts of these factors were often interacted and relatively greater variation of these factors and measured EFs may prevent from seeing the effect of an individual factor 13. By using PCA (each factor enter individually), four associations were extracted and can explain more than 80% of the total variation. Factor 4 (burning rate and MCE) was the most significant factor identified (p < 0.05) for EFs of OC, EC, and PM (details in the Supporting Information).

PM Size Distribution

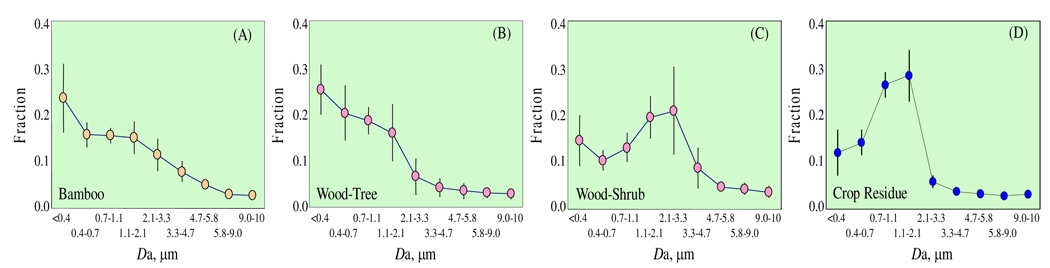

Figure 2 shows size distributions of PM emitted from wood combustion. The fuels tested in this study were classified into three categories of bamboo, tree, and shrubby biomass. For comparison, size distribution of PM from crop residue burning under similar conditions15 is also illustrated. It appears that size distributions of PM from tree, shrubby, and crop residue combustions were different though all of them were unimodal.

Figure 2.

Size distributions of PM from the combustion of bamboo (A), tree fuel (B), shrubby biomass (C), and crop residue (D). The last one in Shen et al., (2010) 15 is shown to compare with those obtained in this study.

PM from 14 tested tree woods of different types had very similar size distributions with peaks (24.3±6.1%) at less than 0.4 µm (PM0.4). In general, PM with diameter less than 2.1 µm (PM2.1) composed up to 79.4±7.0% of the total PM. Domination of fine particles in emissions from firewood combustion has been reported before 6, 42 and it is believed that these fine particles are primarily soot-related 6, 57. The domination of fine particles from tree wood burning is a health concern for those who cook in a kitchen, since fine particles can penetrate deeper into the lungs and are often associated with many toxic compounds 2–4. For shrubby biomass combustion, PM was dominated by those between 2.1 and 3.3 µm (21.0±9.4%), followed by PM at diameter between 1.1 and 2.1 µm (19.6±4.4%). Overall, PM0.4 and PM2.1 fractions were 14.6±5.4% and 57.7±10.8%, respectively, which were very different from those emitted from tree biomass combustion. To the best of our knowledge, size distribution data on PM emissions from shrubby biomass burning are not found in existing literature, likely due to the fact that shrubs are not used as a biomass fuel in developed countries. However, since shrubby biomass contributes to a significant fraction of the overall firewood consumed in developing countries 58, the difference between shrubby and tree biomasses cannot be ignored when characterizing PM emission from firewood combustion.

In this study, MCE was found to be negatively correlated with 3 PM fractions with diameters less than 1.1 µm and positively correlated with all other PM fractions (p < 0.05), which means that under higher MCE, the mass median diameters of emitted PM would be larger. A positively linear relationship between MCE and median diameter was previously reported for fresh forest smoke 22. Meanwhile, moisture affects the size distribution in an opposite direction to MCE. It is negatively correlated with coarse PM and positively correlated with fine PM (p < 0.05), indicating that the median mass diameters of PM from lower moisture wood combustions were larger, and this might be partly explained by the oxygen scarce condition 28. The influence of fuel moisture on median diameters of PM from combustion can be either negative or positive since they can also be affected by many other factors 28–29, 57. It was believed that the influence of moisture is related to the combustion temperature and efficiency, and also the change in the relative humidity of the flue gas and the condensation process. Lower moisture may result in a higher temperature which is favorable for formation of small particles 28, 57; however, wood with too low moisture may burn too fast to result in an oxygen limited atmosphere in the stove with relatively small chamber and only natural air ventilation 17, 25, 53. These, in turn, produce a large number of large particles since lower oxygen levels are expected to promote less intense smoldering conditions producing large particles due to agglomeration and condensation processes 17, 28. Future studies are needed to investigate the factors influencing formation mechanisms of both fine and coarse PM.

Primary Emission off EC, OC, and PM in rural China

Total residential consumption of wood in rural China was 182.17 Tg in 2007 59. Based on the measured EFs, total emissions of PM, OC, and EC from residential wood combustion in rural China were estimated to be 303, 75.7, and 92.0, Gg in 2007. It should be pointed out that, similar to the emissions from many other sources, our estimated emissions are subject to high uncertainty due to uncertainties in both EFs and in the qualities of fuel consumed. One of the sources of uncertainty originates from the difference in the EFs among various woods, which varied dramatically with coefficients of variation of 40~71%. Unfortunately, data on the fractions of various wood fuels consumed in China are unavailable and there is no choice but to average EFs.

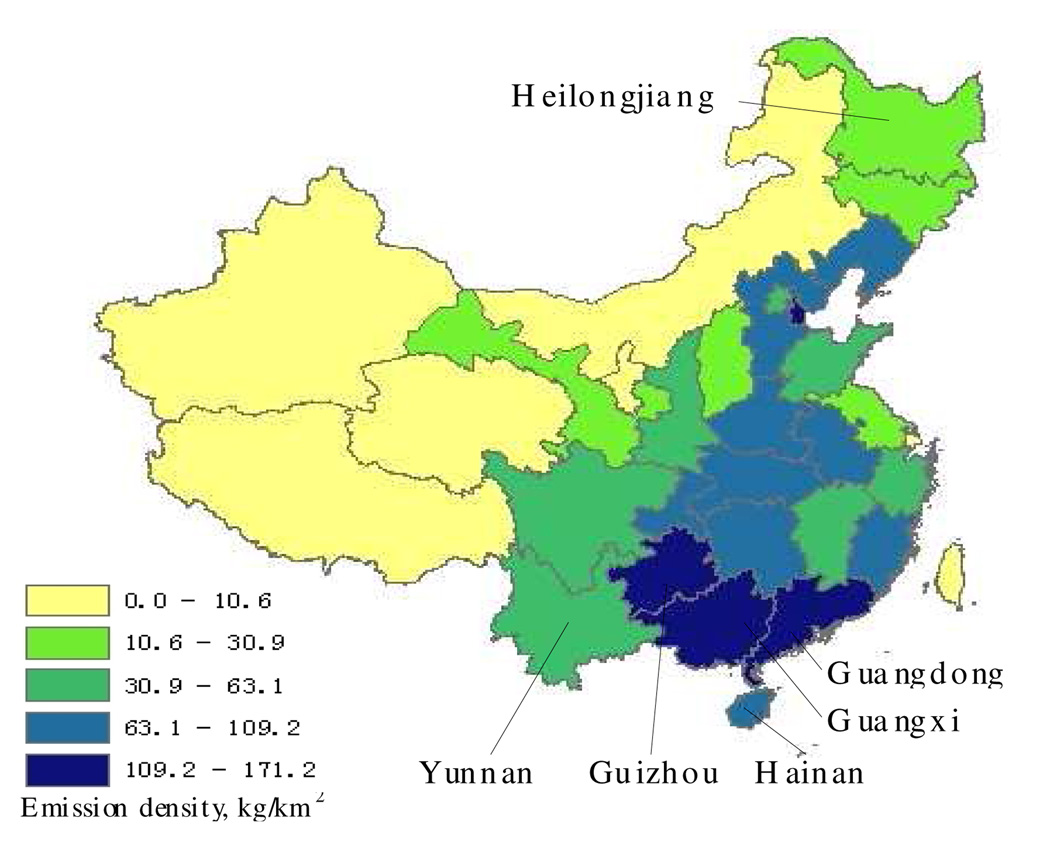

The geographical distribution of PM emissions from rural residential wood combustion in mainland China in 2007 is shown in Figure 3 as emission density. The highest emission densities were found in southern China including Guizhou, Guangxi, and Guangdong. Due to a shortage of fossil fuel and relatively high abundance of biomass fuels, wood was widely used for daily cooking in these areas. And, a large rural population in the regions requires large volume of fuels and subsequently leads to high emissions. Although other southern provinces including Fujian, Hainan, and Yunnan and northeastern provinces such as Heilongjiang are also rich in woods, emission densities of firewood burning were relatively low due to either the domination of fossil fuel or lower population density.

Figure 3.

Emission density of primary PM from residential wood combustion in Mainland China.

Supplementary Material

Acknowledgment

Funding for this study was provided by the National Natural Science Foundation of China (41001343, 41130754, 40703029), Ministry of Environmental Protection (201209018), Beijing Municipal Government (YB20101000101), and NIEHS (P42 ES016465). We thank Zoë Chafe (University of California, Berkeley) and Marcus Trail (Georgia Institute of Technology) for proof reading.

Footnotes

Supporting Information Available

Analysis of influencing factors using PCA are provided in the supporting information, and available free of charge via the Internet at http://pubs.acs.org

References

- 1.Chow JC, Watson JG, Lowenthal DH, Antony Chen L-W, Motallebi N. PM2.5 source profiles for black and organic carbon emission inventories. Atmos. Environ. 2011;45:5407–5414. [Google Scholar]

- 2.Dockery DW, Pope CA, III, Xu X, Spengler JD, Ware JH, Fay ME, Ferris BG, Speizer FE. An association between air pollution and mortality in six U.S. cities. N. Engl. J. Med. 1993;329:1753–1759. doi: 10.1056/NEJM199312093292401. [DOI] [PubMed] [Google Scholar]

- 3.Englert N. Fine particles and human health-a review of epidemiological studies. Toxicol. Lett. 2004;149:235–242. doi: 10.1016/j.toxlet.2003.12.035. [DOI] [PubMed] [Google Scholar]

- 4.Pope CA, III, Ezzati M, Dockey DW. Fine-particulate air pollution and life expectancy in the United States. N. Engl. J. Med. 2009;360:376–386. doi: 10.1056/NEJMsa0805646. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Jacobson MZ. A physically-based treatment of elemental carbon optics: Implications for global direct forcing of aerosols. Geophys. Res. Lett. 2000;27:217–220. [Google Scholar]

- 6.Danielsen PH, Møller P, Jensen KA, Sharma AK, Wallin H, Bossi R, Autrup H, Mølhave L, Ravanat J-L, Briedé JJ, de Kok TM, Loft S. Oxidative stress, DNA damage, and inflammation induced by ambient air and wood smoke particulate matter in human A549 and THP-1 cell lines. Chem. Res. Toxicol. 2011;24:168–184. doi: 10.1021/tx100407m. [DOI] [PubMed] [Google Scholar]

- 7.Venkataraman C, Habib G, Eiguren- Fernandez A, Miguel AH, Friedlander SK. Residential biofuels in South Asia: carbonaceous aerosol emissions and climate impacts. Science. 2005;307:1454–1456. doi: 10.1126/science.1104359. [DOI] [PubMed] [Google Scholar]

- 8.Lei Y, Zhang Q, He KB, Streets DG. Primary anthropogenic aerosol emission trends for China, 1990–2005. Atmos. Chem. Phys. 2011;11:931–954. [Google Scholar]

- 9.Zhang J, Smith KR, Ma Y, Ye S, Jiang F, Qi W, Liu P, Khalil MAK, Rasmussen RA, Thorneloe SA. Greenhouse gases and other airborne pollutants from household stoves in China: a database for emission factors. Atmos. Environ. 2000;34:4537–4549. [Google Scholar]

- 10.Chen YJ, Zhi G, Feng Y, Fu J, Feng J, Sheng G, Simoneit BRT. Measurement of emission factors for primary carbonaceous particles from residential raw-coal combustion in China. Geophys. Res. Lett. 2006;33:L20815. [Google Scholar]

- 11.Li X, Wang S, Duan L, Hao J, Nie Y. Carbonaceous aerosol emissions from household biofuel combustion in China. Environ. Sci. Technol. 2009;43:6076–6081. doi: 10.1021/es803330j. [DOI] [PubMed] [Google Scholar]

- 12.Streets DG, Gupta S, Waldhoff ST, Wang MQ, Bond TC, Yiyun B. Black carbon emissions in China. Atmos. Environ. 2001;35:4281–4296. [Google Scholar]

- 13.Roden CA, Bond TC, Conway S, Pinel ABO. Emission factors and real-time optical properties of particles emitted from traditional wood burning cookstoves. Environ. Sci. Technol. 2006;40:6750–6757. doi: 10.1021/es052080i. [DOI] [PubMed] [Google Scholar]

- 14.McDonald JD, Zielinska B, Fujita EM, Sagebiel JC, Chow JC, Watson JG. Fine particle and gaseous emission rates from residential wood combustion. Environ. Sci. Technol. 2000;34:2080–2091. [Google Scholar]

- 15.Shen GF, Yang YF, Wang W, Tao S, Zhu C, Min Y, Xue M, Ding J, Wang B, Wang R, Shen H, Li W, Wang X, Russell AG. Emission factors of particulate matter and elemental carbon for crop residues and coals burned in typical household stoves in China. Environ. Sci. Technol. 2010;44:7157–7162. doi: 10.1021/es101313y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Jenkins BM, Jones AD, Turn SQ, Williams RB. Emission factors for polycyclic aromatic hydrocarbons from biomass burning. Environ. Sci. Technol. 1996;30:2462–2469. [Google Scholar]

- 17.Simoneit BRT. Biomass burning- a review of organic tracers for smoke from incomplete combustion. Appl. Geochem. 2002;17:129–162. [Google Scholar]

- 18.Bignal KL, Langridge S, Zhou JL. Release of polycyclic aromatic hydrocarbons, carbon monoxide and particulate matter form biomass combustion in a wood-fired boiler under varying boiler conditions. Atmos. Environ. 2008;42:8863–8871. [Google Scholar]

- 19.Chomanee C, Tekasakul S, Tekasakul P, Furuuchi M, Otani Y. Effects of moisture content and burning period on concentration of smoke particles and particle-bound polycyclic aromatic hydrocarbons from rubber wood combustion. Aerosol Air Qual. Res. 2009;9:404–411. [Google Scholar]

- 20.Dhammapala R, Claiborn C, Corkill J, Gullett B. Particulate emissions from wheat and Kentucky bluegrass stubble burning in eastern Washington and northern Idaho. Atmos. Environ. 2006;40:1007–1015. [Google Scholar]

- 21.McMeeking GR, Kreidenweis SM, Baker S, Carrico CM, Chow JC, Collett JL, Jr, Hao WM, Holden AS, Kirchstetter TW, Malm WC, Moosmüller H, Sullivan AP, Wold CE. Emission of trace gases and aerosols during the open combustion of biomass in the laboratory. J. Geophys. Res. 2009:114. D19210. [Google Scholar]

- 22.Janhäll S, Andreae MO, Pöschl U. Biomass burning aerosol emissions from vegetation fires: particle number and mass emission factors and size distributions. Atmos. Chem. Phys. 2010;10:1427–1439. [Google Scholar]

- 23.Shen G, Wang W, Yang Y, Zhu C, Min Y, Xue M, Ding J, Li W, Wang B, Shen H, Wang R, Wang X, Tao S. Emission factors and particulate matter size distribution of polycyclic aromatic hydrocarbons from residential coal combustions in rural Northern China. Atmos. Environ. 2010;44:5237–5243. doi: 10.1016/j.atmosenv.2010.08.042. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 24.Chen L-WA, Verburg P, Shackelford A, Zhu D, Susfalk R, Chow JC, Watson JG. Moisture effects on carbon and nitrogen emission from burning of wildland biomass. Atmos. Chem. Phys. 2010;10:6617–6625. [Google Scholar]

- 25.Rogge WF, Hildemann LM, Mazurek MA, Cass GR, Simoneit BRT. Sources of fien organic aerosol. 9. pine, oak, and synthetic log combustion in residential fireplaces. Environ. Sci. Technol. 1998;32:13–32. [Google Scholar]

- 26.Lu H, Zhu L, Zhu N. Polycyclic aromatic hydrocarbon emission from straw burning and the influence of combustion parameters. Atmos. Environ .2009;43:4978–4983. [Google Scholar]

- 27.Johansson LS, Leckner B, Gustavsson L, Cooper D, Tullin C, Potter A. Emission characteristics of modern and old-type residential boilers fired with wood logs and wood pellets. Atmos. Environ. 2004;38:4183–4195. [Google Scholar]

- 28.Hays MD, Smith ND, Kinsey J, Dong Y, Kariher P. Polycyclic aromatic hydrocarbon size distributions in aerosols from appliances of residential wood combustion as determined by direct thermal desorption-GC/MS. J. Aerosol. Sci. 2003;34:1061–1084. [Google Scholar]

- 29.Venkataraman C, Joshi P, Sethi V, Kohli S, Ravi MR. Aerosol and carbon monoxide emissions from low temperature combustion in a sawdust packed-bed stove. Aerosol Sci. Technol. 2004;38:50–61. [Google Scholar]

- 30.Gao SW, Ma WY. Tree species as main bio-energy resources in China. Beijing, P.R. China: China Forestry Press; 1990. [Google Scholar]

- 31.Xu S, Liu W, Tao S. Emission of polycyclic aromatic hydrocarbons in China. Environ. Sci. Technol. 2006;40:702–708. doi: 10.1021/es0517062. [DOI] [PubMed] [Google Scholar]

- 32.Zhang Y, Dou H, Chang B, Wei Z, Qiu W, Liu S, Liu W, Tao S. Emission of polycyclic aromatic hydrocarbons form indoor straw burning and emission inventory updating in China. Ann. NY. Acad. Sci. 2008;1140:218–227. doi: 10.1196/annals.1454.006. [DOI] [PubMed] [Google Scholar]

- 33.Fine PM, Cass GR, Simoneit BRT. Chemical characterization of fine particle emissions from fireplace combustion of wood types grown in the Midwestern and western United States. Environ. Eng. Sci. 2004;21:387–409. [Google Scholar]

- 34.Venkataraman CA, Rao GUM. Emission factors of carbon monoxide and size-resolved aerosols from biofuel combustion. Environ. Sci. Technol. 2001;35:2100–2107. doi: 10.1021/es001603d. [DOI] [PubMed] [Google Scholar]

- 35.Johnson M, Edwards R, Alatorre Frenk C, Masera O. In-field greenhouse gas emissions from cookstoves in rural Mexican households. Atmos. Environ. 2008;42:1206–1222. [Google Scholar]

- 36.Gonçalves C, Alves C, Fernandes AP, Monteiro C, Tarelho L, Evtyugina M, Pio C. Organic compounds in PM2.5 emitted from fireplace and woodstove combustion of typical Portuguese wood species. Atmos. Environ. 2011;45:4533–4545. [Google Scholar]

- 37.Alves C, Gonçalves C, Fernandes AP, Tarelho L, Pio C. Fireplace and woodstove fine particle emissions from combustion of western Mediterranean wood types. Atmos. Res. 2011;101:692–700. [Google Scholar]

- 38.Fine PM, Cass GR, Simoneit BRT. Chemical characterization of fine particle emissions from wood stove combustion of prevalent United States tree species. Environ. Eng. Sci. 2004;21:705–721. [Google Scholar]

- 39.Schauer JJ, Kleeman MJ, Cass GR, Simoneit BRT. Measurement of emissions from air pollution sources. 3. C1–C29 organic compounds from fireplace combustion of wood. Environ. Sci. Technol. 2001;35:1716–1728. doi: 10.1021/es001331e. [DOI] [PubMed] [Google Scholar]

- 40.Fine PM, Cass GR, Simoneit BRT. Chemical characterization of fine particle emissions from fireplace combustion of woods grown in the Northeastern United States. Environ. Sci. Technol. 2001;35:2665–2675. doi: 10.1021/es001466k. [DOI] [PubMed] [Google Scholar]

- 41.Fine PM, Cass GR, Simoneit BRT. Chemical characterization of fine particle emissions from fireplace combustion of woods grown in the Southern United States. Environ. Sci. Technol. 2002;36:1442–1451. doi: 10.1021/es0108988. [DOI] [PubMed] [Google Scholar]

- 42.Hedberg E, Kristensson A, Ohlsson M, Johansson C, Johansson P, Swietlicki E, Vesely V, Wideqvist U, Westerholm R. Chemical and physical characterization of emissions from birch wood combustion in a wood stove. Atmos. Environ. 2002;36:4823–4837. [Google Scholar]

- 43.Tissari J, Hytönen K, Lyyränen J, Jokiniemi J. A novel field measurement method for determining fine particle and gas emissions from residential wood combustion. Atmos. Environ. 2007;41:8330–8344. [Google Scholar]

- 44.Tissari J, Lyyränen J, Hytönen K, Sippula O, Tapper U, Frey A, Saarnio K, Pennanen AS, Hillamo R, Salonen RO, Hirvonen M–R, Jokiniemi J. Fine particle and gaseous emissions from normal and smouldering wood combustion in a conventional masonry heater. Atmos. Environ. 2008;42:7862–7873. [Google Scholar]

- 45.Gonçalves C, Alves C, Evtyugina M, Mirante F, Pio C, Caseiro A, Schmidl C, Bauer H, Carvalho F. Characterization of PM10 emissions form woodstove combustion of common woods grown in Portugal. Atmos. Environ. 2010;44:4474–4480. [Google Scholar]

- 46.Lamberg H, Nuutinen K, Tissari J, Russunen J, Yli-Pirilä P, Sippula O, Tapanainen M, Jalava P, Makkonen U, Teinilä K, Saarnio K, Hillamo R, Hirvonen M, Jokiniemi J. Physicochemical characterization of fine particles from small-scale wood combustion. Atmos. Environ. 2011 [Google Scholar]

- 47.Pettersson E, Boman C, Westerholm R, Boström D, Nordin A. Stove performance and emission characteristics in residential wood log and pellet combustion, Part 2: wood stove. Energy & Fuel. 2011;25:315–323. [Google Scholar]

- 48.Gullett BK, Touati A, Hays MD. PCDD/F, PCD, HxCBz, PAH and PM emission factors for fireplace and woodstove combustion in the San Francisco Bay Region. Environ. Sci. Technol. 2003;37:1758–1765. doi: 10.1021/es026373c. [DOI] [PubMed] [Google Scholar]

- 49.Hildemann LM, Markowski GR, Cass GR. Chemical composition of emissions from urban sources of fine organic aerosol. Environ. Sci. Technol. 1991;25:744–759. [Google Scholar]

- 50.Hays MD, Geron CC, Linna KJ, Smith ND. Speciation of gas-phase and fine particle emissions from burning of foliar fuels. Environ. Sci. Technol. 2002;36:2281–2295. doi: 10.1021/es0111683. [DOI] [PubMed] [Google Scholar]

- 51.Lee RG, Coleman P, Jones JL, Jones KC, Lohmann R. Emission factors and importance of PCDD/Fs, PCBs, PCNs, PAHs and PM10 from the domestic burning of coal and wood in the U.K. Environ. Sci. Technol. 2005;39:1436–1447. doi: 10.1021/es048745i. [DOI] [PubMed] [Google Scholar]

- 52.Grandesso E, Gullett B, Touati A, Tabor D. Effect of moisture, charge size and chlorine concentration on PCDD/F emissions from simulated open burning of forest biomass. Environ. Sci. Technol. 2011;45:3887–3894. doi: 10.1021/es103686t. [DOI] [PubMed] [Google Scholar]

- 53.Chen Y, Sheng G, Bi X, Feng Y, Mai B, Fu J. Emission factors for carbonaceous particles and polycyclic aromatic hydrocarbons from residential coal combustion in China. Environ. Sci. Technol. 2005;39:1861–1867. doi: 10.1021/es0493650. [DOI] [PubMed] [Google Scholar]

- 54.Hurst DF, Griffith DWT, Carras JN, Williams DJ, Fraser PJ. Measurements of trace gases emitted by Australian savanna fires during the 1990 dry seasons. J. Atmos. Chem. 1994;18:33–56. [Google Scholar]

- 55.Andreae MO, Gelencser A. Black carbon or brown carbon? The nature of lightabsorbing carbonaceous aerosols. Atmos. Chem. Phys. 2006;6:3131–3148. [Google Scholar]

- 56.Chakrabarty RK, Moosmüller H, Chen LWA, Lewis K, Arnott WP, Mazzoleni C, Dubey MK, Wold CE, Hao WM, Kreidenweis SM. Brown carbon in tar balls from smoldering biomass combustion. Atmos. Chem. Phys. 2010;10:6363–6370. [Google Scholar]

- 57.Purvis CR, McCrillis RC, Kariher PH. Fine particulate matter (PM) and organic speciation of fireplace emissions. Environ. Sci. Technol. 2000;34:1653–1658. [Google Scholar]

- 58.Hu H, Li A. Charactristics of gas release during combustion of main arbor and shrub species in Xiaoxing’ an Mountain. Chin. J. Appl. Ecol. 2008;19:1431–1436. (in Chinese). [PubMed] [Google Scholar]

- 59.National Bureau of Statistics of China. http://www.stats.gov.cn/tjsj/qtsj/hjtjzl/index.htm.

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.