Abstract

Background:

Properties of coated archwires, which have been introduced for esthetic demands during orthodontic treatments, along with the use of tooth-colored brackets, are not clear. The aim of this study is to compare the load-deflection and surface properties of coated superelastic archwires with conventional superelastic archwires in conventional and metal-insert ceramic brackets.

Materials and Methods:

In this experimental study, 3 types of archwires including ultraesthetic polycoated, ultraesthetic epoxyresin coated and conventional (uncoated) superelastic nickel-titanium (NiTi) archwires were used in each of 2 types of brackets including conventional and metal-insert ceramic. To simulate oral environment, all specimens were incubated in artificial saliva using thermocycling model and then were tested in three-bracket bending test machine. Loading and unloading forces, plateau gap and end load deflection point (ELDP) were recorded. Archwires were investigated with a stereomicroscope before and after the experiment. Two-way ANOVA and Tukey tests were used at P<0.05.

Results:

Epoxyresin archwires produced lower forces (19 to 310 gr) compared to polycoated (61 to 359 gr) and NiTi (61 to 415 gr) (P<0.0001). The maximum ELDP (0.43 mm) was observed in epoxyresin archwires (P<0.001). Coatings of some epoxyresin wires were torn and of polycoated wires peeled off. Conventional ceramic bracket produced higher loading forces with polycoated and NiTi archwires and lower unloading forces with all 3 types of archwires compared to metal-insert type (P<0.05).

Conclusion:

Epoxyresin-coated archwire had the lowest force and highest ELDP. Coatings were not durable in these experimental conditions. Conventional ceramic bracket produced higher frictional force compared to metal-insert type.

Keywords: Ceramic bracket, esthetic, mechanical phenomena, orthodontic archwire

INTRODUCTION

In modern society, esthetic aspect of orthodontic appliances is important, particularly due to more adult patients seeking for orthodontic care.[1] Two main groups of materials used in fixed orthodontics are brackets and archwires. In the case of brackets, invention of composite and ceramic brackets solved the problem.[2] Ceramic brackets are available in two types of conventional and metal-insert. The latter produces less frictional force against conventional (uncoated) archwires.[3,4] In terms of archwires, three types of esthetic archwires are introduced. Optiflex, which does not have desirable mechanical properties.[5] Fiber-reinforced composite archwire is still at laboratory level,[6] and coated metallic archwire, which is currently the only available esthetic wire. The materials used in coatings are tooth-colored teflon (polytetrafluoroethylene) or epoxyresin.[7] Disadvantages in durability and surface properties such as tearing and color changing of these coatings in clinical conditions have been reported.[8] kusy[9] stated that these coatings are succumbed to mastication forces and oral enzymes. In a study conducted by Elayyan et al.,[10] loss of these coatings and increased roughness were reported after clinical use. Coatings are also vulnerable to mechanical and thermocycling stresses in vitro.[11,12] On the other hand coating of archwires may influence over their mechanical properties. Husmann et al.,[13] showed that coatings decreased frictional force. Elayyan et al.,[14] found that epoxy resin coated archwires produced lower frictional force compared to uncoated wires of the same nominal sizes.

We did not find studies which had assessed the mechanical properties of coated superelastic wires against esthetic brackets, which seems reasonable to be used along. Three-bracket bending test can be used to investigate mechanical properties of orthodontic wires against brackets. The test allows the investigating load-deflection properties and friction between wire and bracket.[15,16]

The aim of this study is to compare the load-deflection properties of coated superelastic with conventional superelastic archwires when placed within the slot of conventional and metal-insert ceramic brackets. Surface characteristics of archwires were also evaluated.

MATERIALS AND METHODS

In this experimental study, three types of round orthodontic archwire with the size of 0.016-inches including conventional uncoated superelastic nickel-titanium (NiTi), coated ultraesthetic epoxyresin (epoxyresin), and coated ultraesthetic polycoated (polycoated) were tested. All archwires were made by G and H Wire (Greenwood, Ind, USA). Two types of standard maxillary central-incisor ceramic bracket with the slot size of 0.022-inches were used. Both ceramic bracket systems, Reflections and Encore metal-insert, were manufactured by Ortho Technology (Tampa, Fl, USA). All three types of wire were tested in each of the brackets. Sample size calculation formula showed that 12 pieces of each type of wire should be tested in each of 6 experimental groups. A set of three new brackets were used for each 12 tests. Archwire pieces of 30-mm long were cut from the posterior buccal part of archwires. The coating thickness of epoxyresin archwire, according to the manufacturer, was considered as 0.05 mm and of polycoated archwire was measured using a digital caliper (Mitutoyo, Japan) and the mean value of measurements was considered.

First, surface of all specimens were scrutinized using a stereomicroscope at a magnification of ×63 (MGC-IO, SN: 110734, Russia) and a photograph was taken of each wire using a digital camera (Moticam, Mod480, Canada). To simulate oral environment, the specimens then, were incubated in Bioxtra artificial saliva (Bio-x Healthcare, Les Isnes, Belgium) at pH of almost 6.7 (pH, Ion Meter, Metrohm, Herisau, Switzerland) and temperature was adjusted at 37°C for 3 weeks. Saliva was changed every day. Thermocycling was performed, after incubation, for 500 cycles (Nemo Co, mashhad, Iran) with a periods of 10 min at each temperature of 5°C and 55°C and an interval of 10 s at room temperature. After incubation and thermocycling treatment, archwires were subjected to three-bracket bending test. To conduct the test, which was similar for both types of bracket, a jig was prepared with two brass rods located at a distance of 14 mm from each other. Two brackets of the same type were bonded on them so that their slots were aligned and leveled in all three planes of space (using a piece of 0.021×0.025-in wire). The jig was fixed on the base of universal testometric testing machine (Testometric Co, Rochdale, UK) which uses WinTest™ software. A third bracket of the same type was located on the central moving rod which was connected to the crosshead of the loading cell adjusted at the mid point of the inter-bracket distance. When the three slots of brackets were along each other, loading cell was fixed in that position. The wires inserted into brackets, using elastomeric ligatures (Ortho Technology, Carlsbad, USA). The central moving rod was headed vertically at a speed of 0.5 mm/min. The wires were deflected 2 mm and then unloaded at the same speed. The loading and unloading forces were registered and load-deflection curves plotted. Loading force at 2-mm deflection (L2), unloading forces at 1.4-mm, 1-mm and 0.6-mm (UL1.4, UL1, UL0.6), force loss between 1.4 to 1 mm of unloading plateau (P.G) and End Load Deflection Point (ELDP) were reported. After testing, the wires were observed again under stereomicroscope and a photograph was taken of each one.

Data were analyzed using SPSS 15.0 for windows (SPSS Inc, Chicago, III). Two-way ANOVA and Tukey's post hoc test were used to identify main effects and the effects of the interactions between three types of archwires and two types of bracket. In the cases with significant interactions, one-way ANOVA was applied. All statistical analysis were undertaken at the P<0.05 level of significance.

RESULTS

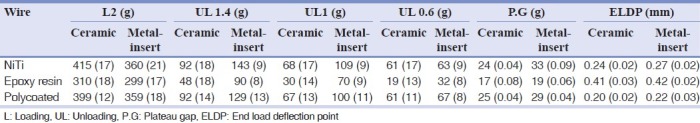

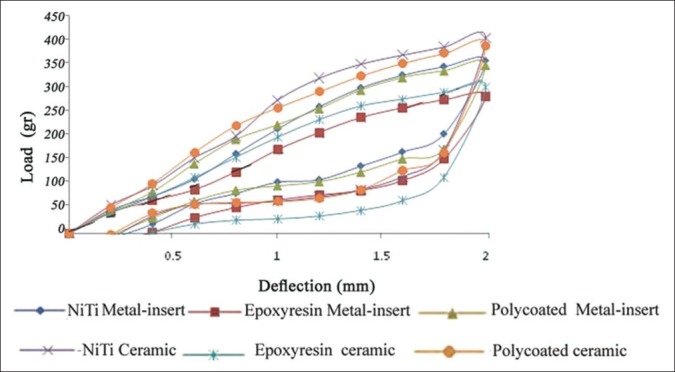

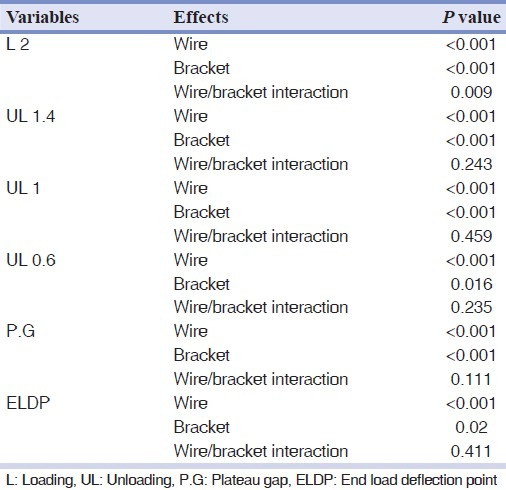

Mean value and standard deviation of measured variables are presented in Table 1, and load-deflection curves are illustrated in [Figure 1]. For the combination of archwire and bracket the results of two-way ANOVA are shown in Table 2. As it can be observed, wire and bracket type effects are significant in all variables (P<0.05). The results of the Tukey test indicated that epoxyresin wire had significantly lower force at all deflections, compared to NiTi and polycoated wires (P<0.001), but forces of NiTi and polycoated wires were not significantly different. Epoxyresin wire had the highest ELDP (0.42 mm) and the lowest was related to polycoated wire (0.20 mm) (P<0.001).

Table 1.

Mean value and standard deviation of measured variables of wires in two types of brackets

Figure 1.

Loading and unloading curves of coated and uncoated wires in conventional and metal-insert ceramic brackets

Table 2.

Results of two-way ANOVA showing P value of main effects (wire type and bracket type) and their interactions

For loading force at 2-mm deflection in which the wire-bracket interaction was significant, the results of one-way ANOVA indicated that the force of NiTi wire, same as of polycoated, in both types of brackets was significantly different (P<0.001), but for epoxyresin wire, the forces at L2 with conventional ceramic bracket (310 gr) and metal-insert type (299 gr) were not significantly different (P=0.069). Unloading forces of ceramic bracket were lower than metal-insert ceramic bracket for all three types of wires (P<0.05).

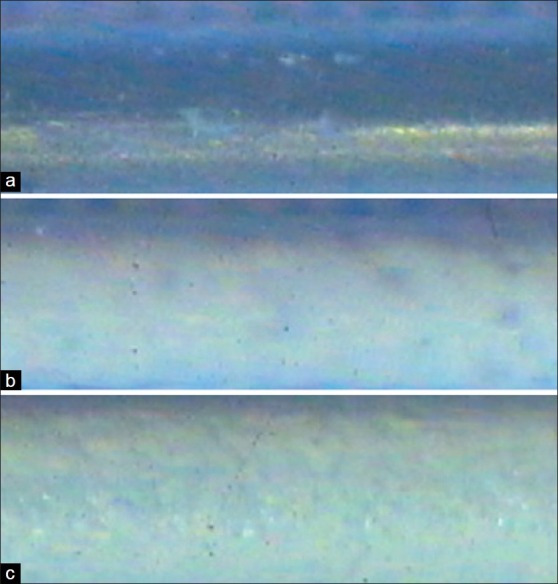

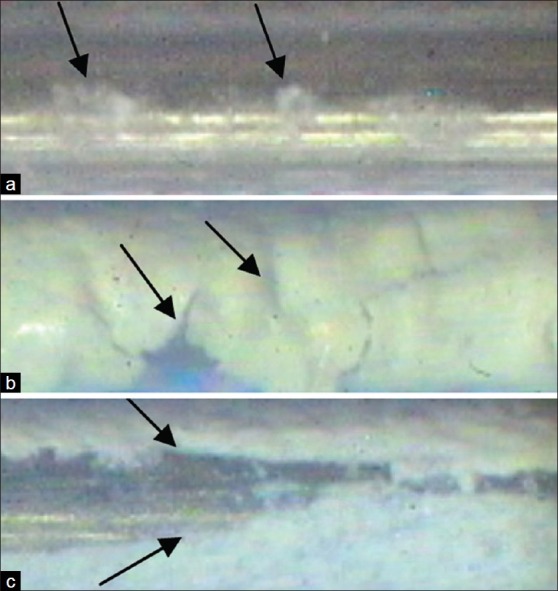

Some scratches were seen on new NiTi wire, probably due to the manufacturing process, and coating of epoxyresin wire presented some roughness. Polycoated wire with 0.02 mm thickness of coating showed more homogenous surface throughout the length compared to epoxyresin archwire; however, the coating did not cover completely all around the wires in some specimens in lingual surfaces [Figures 2a–c]. Following the completion of bending test, a few pieces of NiTi wire had deeper scratches, epoxyresin coating showed shrinkage and tearing while polycoated cover has disappeared and peeled off in some areas. Coating defects were particularly obvious in contact areas with brackets [Figures 3a–c].

Figure 2.

Microscopic images of intact (a) conventional NiTi (b) epoxyresin and (c) polycoated (×63 magnification)

Figure 3.

Microscopic images after investigation stages (a) conventional NiTi (b) epoxyresin and (c) polycoated (×63 magnifications)

DISCUSSION

Plateau phase of unloading curves [Figure 1] of both uncoated and coated superelastic archwires in conventional and metal-insert ceramic brackets confirmed the superelastic property of wires. In a study conducted by Kasuya et al.,[17] with 3-bracket bending test, loading or unloading plateau was not observed while using elastomeric ligatures with uncoated superelastic NiTi archwires. They concluded that the pressure caused by elastomeric ligatures between wire and bracket inhibits the internal changes of wire which would have happened; however, in the present study unloading plateau was seen in all coated and uncoated wires.

Loading curve represents the force required to insert the wire in the bracket on the crowded teeth, therefore, the force is usually measured at the last deflection of loading curve, whereas the unloading curve represents the force delivered to teeth during treatment and usually is measured in several deflection points. In this study the force that was required in loading and produced during unloading of epoxyresin wire was significantly lower than other two types of wire of the same nominal size (P<0.001), almost certainly due to the reduced underneath NiTi alloy to compensate for the coating thickness. It is consistent with the findings of Elayyan et al.[14] They suggested that a larger than 0.016-in of epoxyresin wire should be used to be as efficient as an uncoated 0.016-in wire. It is recommended to use epoxyresin wire in 22-slot bracket. A wire larger than 0.016-in into an 18-slot bracket may cause high frictional force which is not advisable for the first stages of orthodontic treatment in which lower frictional force is desirable. The force of polycoated wire is more similar to NiTi rather than epoxyresin, because the thickness of the coating of polycoated wire is approximately 0.03 mm less than that of epoxyresin wire. Therefore, polycoated wire with similar nominal size of uncoated NiTi wire may be used.

ELDP which represents the deflection at which the force reached zero in unloading phase,[18] was highest in epoxyresin wire (P<0.001). The higher ELDP of a wire, the less capability to align and level the teeth.[15] Therefore, epoxyresin wire must be replaced soon by a wire of larger size or higher force. ELDPs of polycoated and NiTi wires were more satisfying. In clinical conditions, however, the force of mastication may also lead to permanent wire deformation.[19]

In 3-bracket bending test, frictional force between wire and bracket increases the loading force, but decreases the unloading force.[15] NiTi and polycoated wires required higher force in ceramic brackets during loading phase and produced lower force in unloading phase compared to metal-insert ceramic bracket. It indicates a higher frictional force between ceramic bracket and these two types of wire. Force value for epoxyresin wire in two types of bracket during loading phase was not significantly different (P=0.069) which indicates that frictional force of epoxyresin wire against conventional and metal-insert ceramic brackets, during loading phase, was similar. However, during the unloading phase, epoxyresin wire showed similar function to other wires in two types of bracket. According to the report of Cacciafesta et al.,[4] conventional ceramic bracket generated a frictional force higher than that of metal-insert type. Similar results were found for polycoated and NiTi wires in this study with these types of bracket. It should be considered that it is not easy to extrapolate frictional force in clinical conditions from experimental findings. It is possible that factors such as occlusal forces, which make the wires loose and tight in brackets, have more important role in clinic.[20]

Plateau gap (P.G), which indicates the loss of force in a measured distance of unloading plateau, have been applied in several studies[15,18,21] to investigate the stability of plateau force. P.G in this study indicated that ceramic brackets with coated and uncoated wires produce unloading plateau with less gradient. There are some limitations if P.G is considered as the only factor to determine force stability, therefore, the percentage of force loss should also be considered.[18]

Coating of wires was not durable under the conditions of the present study. It supports the findings of Banderia et al.,[12] who thermocycled coated wires for 3000 cycles in distilled water. In this study, despite the lower cycles, wire coating was damaged more. It could be due to incubating the wires in artificial saliva before thermocycling. Under these experimental circumstances, coating loss of polycoated was more than epoxyresin wires. The coating of Epoxyresin is thicker than that of polycoated and may have higher bond strength with underlying metal. Shrinkage, peeling off, and tearing of coatings could be a site for plaque accumulation and entrapment of bracket.[11] Kim and Jhonson[22] noted that coating decreases corrosion, and coated archwires can be used for patients allergic to nickel, when coatings are sustained. However, according to the present study and other clinical studies,[8–10] the coatings are not durable.

CONCLUSIONS

Coated ultraesthetic epoxyresin wire produced lower forces compared to coated ultraesthetic polycoated and conventional (uncoated) NiTi wires of the same nominal size.

The amount of ELDP of conventional NiTi was more than that of polycoated, and epoxyresin archwire was more than that of both.

Ceramic brackets produced higher frictional force than metal-insert ceramic brackets against polycoated and conventional NiTi wires, but the frictional forces of epoxyresin wire against the two types of bracket during loading were not significantly different.

Unloading plateau gradient of all types of wire in ceramic bracket was lower than that of metal-insert ceramic bracket.

Coating of polycoated wire was damaged more than epoxyresin wires in these experimental processes.

Footnotes

Source of Support: This report is based on a thesis which was submitted to the School of Dentistry, Isfahan University of Medical Sciences, Isfahan, Iran, in partial fulfillment of the requirements for the M.Sc degree in orthodontics (#389336). The study was approved by the Medical Ethics and Research Office at the Isfahan University of Medical Sciences and financially supported by this University.

Conflict of Interest: None declared.

REFERENCES

- 1.Baccetti T, Franchi L, Camporesi M. Forces in the presence of ceramic versus stainless steel brackets with unconventional vs conventional ligatures. Angle Orthod. 2008;78:120–4. doi: 10.2319/011107-11.1. [DOI] [PubMed] [Google Scholar]

- 2.Russell JS. Aesthetic orthodontic brackets. J Orthod. 2005;32:146–63. doi: 10.1179/146531205225021024. [DOI] [PubMed] [Google Scholar]

- 3.Dickson J, Jones S. Frictional characteristics of a modified ceramic bracket. J Clin Orthod. 1996;30:516–8. [PubMed] [Google Scholar]

- 4.Cacciafesta V, Sfondrini MF, Scribante A, Klersy C, Auricchio F. Evaluation of friction of conventional and metal-insert ceramic brackets in various bracket-archwire combinations. Am J Orthod Dentofacial Orthop. 2003;124:403–9. doi: 10.1016/s0889-5406(03)00501-8. [DOI] [PubMed] [Google Scholar]

- 5.Lim KF, Lew KK, Toh SL. Bending stiffness of two aesthetic orthodontic archwires: An in vitro comparative study. Clin Mater. 1994;16:63–71. doi: 10.1016/0267-6605(94)90099-x. [DOI] [PubMed] [Google Scholar]

- 6.Kusy RP. Orthodontic biomaterials: From the past to the present. Angle Orthod. 2002;72:501–2. doi: 10.1043/0003-3219(2002)072<0501:OBFTPT>2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 7.Imai T, Watari F, Yamagata S, Kobayashi M, Nagayama K, Nakamura S. Effects of water immersion on mechanical properties of new esthetic orthodontic wire. Am J Orthod Dentofacial Orthop. 1999;116:533–8. doi: 10.1016/s0889-5406(99)70185-x. [DOI] [PubMed] [Google Scholar]

- 8.Postlethwaite KM. Advances in fixed appliance design and use: 1.Brackets and archwires. (280).Dent Update. 1992;19:276–8. [PubMed] [Google Scholar]

- 9.Kusy RP. A review of contemporary archwires: Their properties and characteristics. Angle Orthod. 1997;67:197–207. doi: 10.1043/0003-3219(1997)067<0197:AROCAT>2.3.CO;2. [DOI] [PubMed] [Google Scholar]

- 10.Elayyan F, Silikas N, Bearn D. Ex vivo surface and mechanical properties of coated orthodontic archwires. Eur J Orthod. 2008;30:661–7. doi: 10.1093/ejo/cjn057. [DOI] [PubMed] [Google Scholar]

- 11.Neumann P, Bourauel C, Jager A. Corrosion and permanent fracture resistance of coated and conventional orthodontic wires. J Mater Sci Mater Med. 2002;13:141–7. doi: 10.1023/a:1013831011241. [DOI] [PubMed] [Google Scholar]

- 12.Bandeira AM, Dos Santos MP, Pulitini G, Elias CN, da Costa MF. Influence of thermal or chemical degradation on the frictional force of an experimental coated NiTi wire. Angle Orthod. 2011;81:484–9. doi: 10.2319/042810-232.1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.Husmann P, Bourauel C, Wessinger M, Jager A. The frictional behavior of coated guiding archwires. J Orofac Orthop. 2002;63:199–211. doi: 10.1007/s00056-002-0009-5. [DOI] [PubMed] [Google Scholar]

- 14.Elayyan F, Silikas N, Bearn D. Mechanical properties of coated superelastic archwires in conventional and self-ligating orthodontic brackets. Am J Orthod Dentofacial Orthop. 2010;137:213–7. doi: 10.1016/j.ajodo.2008.01.026. [DOI] [PubMed] [Google Scholar]

- 15.Segner D, Ibe D. Properties of superelastic wires and their relevance to orthodontic treatment. Eur J Orthod. 1995;17:395–402. doi: 10.1093/ejo/17.5.395. [DOI] [PubMed] [Google Scholar]

- 16.Santoro M, Nicolay OF, Cangialosi TJ. Pseudoelasticity and thermoelasticity of nickel-titanium alloys: A clinically oriented review.Part II: Deactivation forces. Am J Orthod Dentofacial Orthop. 2001;119:594–603. doi: 10.1067/mod.2001.112447. [DOI] [PubMed] [Google Scholar]

- 17.Kasuya S, Nagasaka S, Hanyuda A, Ishimura S, Hirashita A. The effect of ligation on the load deflection characteristics of nickel titanium orthodontic wire. Eur J Orthod. 2007;29:578–82. doi: 10.1093/ejo/cjm068. [DOI] [PubMed] [Google Scholar]

- 18.Wilkinson PD, Dysart PS, Hood JA, Herbison GP. Load-deflection characteristics of superelastic nickel-titanium orthodontic wires. Am J Orthod Dentofacial Orthop. 2002;121:483–95. doi: 10.1067/mod.2002.121819. [DOI] [PubMed] [Google Scholar]

- 19.Drescher D, Bourauel C, Schumacher HA. Frictional forces between bracket and arch wire. Am J Orthod Dentofacial Orthop. 1989;96:397–404. doi: 10.1016/0889-5406(89)90324-7. [DOI] [PubMed] [Google Scholar]

- 20.Kusy RP, Whitley JQ. Influence of archwire and bracket dimensions on sliding mechanics: Derivations and determinations of the critical contact angles for binding. Eur J Orthod. 1999;21:199–208. doi: 10.1093/ejo/21.2.199. [DOI] [PubMed] [Google Scholar]

- 21.Nakano H, Satoh K, Norris R, Jin T, Kamegai T, Ishikawa F, et al. Mechanical properties of several nickel-titanium alloy wires in three-point bending tests. Am J Orthod Dentofacial Orthop. 1999;115:390–5. doi: 10.1016/s0889-5406(99)70257-x. [DOI] [PubMed] [Google Scholar]

- 22.Kim H, Johnson JW. Corrosion of stainless steel, nickel-titanium, coated nickel-titanium, and titanium orthodontic wires. Angle Orthod. 1999;69:39–44. doi: 10.1043/0003-3219(1999)069<0039:COSSNT>2.3.CO;2. [DOI] [PubMed] [Google Scholar]