Abstract

Background

Two of our long term efforts are to discover compounds with synergistic antifungal activity from metabolites of marine derived microbes and to optimize the production of the interesting compounds produced by microorganisms. In this respect, new applications or mechanisms of already known compounds with a high production yield could be continually identified. Surfactin is a well-known lipopeptide biosurfactant with a broad spectrum of antimicrobial and antiviral activity; however, there is less knowledge on surfactin’s antifungal activity. In this study, we investigated the synergistic antifungal activity of C15-surfactin and the optimization of its production by the response surface method.

Methodology/Principal Findings

Using a synergistic antifungal screening model, we found that the combination of C15-surfactin and ketoconazole (KTC) showed synergistic antifungal effect on Candida albicans SC5314 when the concentrations of C15-surfactin and KTC were 6.25 µg/mL and 0.004 µg/mL, respectively. These concentrations were lower than their own efficient antifungal concentrations, which are >100 µg/mL and 0.016 µg/mL, respectively. The production of C15-surfactin from Bacillus amyloliquefaciens was optimized by the response surface methodology in shaker flask cultivation. The Plackett-Burman design found sucrose, ammonium nitrate and NaH2PO4.2H2O to have significant effects on C15-surfactin production. The optimum values of the tested variables were 21.17 g/L sucrose, 2.50 g/L ammonium nitrate and 11.56 g/L NaH2PO4·2H2O. A production of 134.2 mg/L, which were in agreement with the prediction, was observed in a verification experiment. In comparison to the production of original level (88.6 mg/L), a 1.52-fold increase had been obtained.

Conclusion/Significance

This work first found that C15-surfactin was an efficient synergistic antifungal agent, and demonstrated that response surface methodology was an effective method to improve the production of C15-surfactin.

Introduction

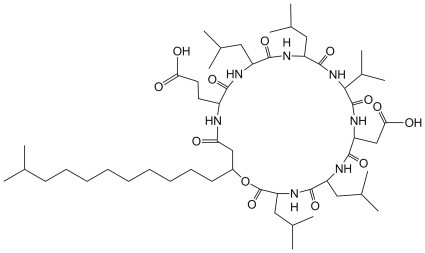

Biosurfactants (e.g., glycolipids, phospholipids, lipoproteins or lipopeptides, polymeric compounds, mycolic acids, and lipopolysaccharides) are a heterogeneous group of secondary metabolites with surface active properties, and described to be synthesized by a variety of bacteria [1], [2]. Surfactin is an important biosurfactant with superior surface activity and belongs to a group of cyclic lipoheptapeptides containing beta-hydroxyl fatty acids and D−/L- amino acid residues [3], [4]. Surfactins are mainly composed of three components: C13-surfactin, C14-surfactin, and C15-surfactin. Of those C15-surfactin has the highest: (1) surface activity, about 1000 times higher than the traditional chemical surfactant sodium dodecyl sulfate (SDS) [5], [6], and (2) hemolytic activity [7], [8]. C15-surfactin also has other activites, including anti-tumor, anti-microbial, and anti-mycoplasma functions [9], [10], [11], [12], [13]. Its amphiphilic structural characteristics contribute to its unique ability to interact with cell membranes and macromolecules such as enzymes and lipopolysaccharides (LPSs). Specifically, C15-surfactin non-competitively inhibits the activity of the alkaline phosphatase due to the chelating action by the free carboxyl groups of the Asp and Glu residues [14]. The binding of C15-surfactin with LPS inhibits the activity of LPS, which leads to the interruption of the LPS induced pathway [15], [16]. These properties demonstrate the commercial importance of C15-surfactin, specifically in the biomedical science and pharmaceutical fields [17], [18].

Yet, even with significant investigations on C15-surfactin, commercial production has been impeded by its high production cost due to low product yield. To address this problem, the discovery of an alternative C15-surfactin producer or improved methods for the efficient production of C15-surfactin is of particular importance. We have constructed a high quality microbial natural product library, from which Bacillus velezensis strain H3, Saccharopolyspora sp. A9 and Streptomyces sp. B3 have been recently identified to be biosurfactant producers [19], [20], [21]. This microbial natural product library has been a rich source for the discovery of C15-surfactin producing strains.

The goal of the current research is to demonstrate an efficient method for the production of C15-surfactin and the novel synergistic antifungal effects of surfactins with ketoconazole against Candida albicans. On the basis of this discovery, the medium composition was optimized to enhance the productivity of C15-surfactin by a novel marine derived Bacillus amyloliquefaciens strain MB199. This was achieved by combining the Plackett-Burman design (PBD), the steepest ascent design, and the central composite rotatable design (CCRD) of response surface methodology (RSM). This study will provide promising results for the development of new antifungal drug combination.

Materials and Methods

Synergistic Antifungal Assay

A synergistic antifungal assay was performed with surfactins according to the previously described method [22]. Briefly, Candida albicans SC5314 cells (∼1×104) were inoculated in a final volume of 80 µL mixture of RPMI 1640 medium, 8% Alamar blue (BioSource International, Camarillo, CA), and 2 µL drugs in each well of flat bottom, 96-well microtiter plates (VWR, West Chester, PA). Candida albicans SC5314 cells was incubated overnight at 35°C, 80% humidity, and 5% CO2. Surfactins and KTC were prepared as stock solutions in DMSO. Growths of fungus cells were affected in the presence and absence of a sub-clinical concentration of 0.004 µg/mL ketoconazole. To determine the percentage of remaining viable cells, the fluorescence was measured at an excitation wavelength (Ex) of 544 nm and an emission wavelength (Em) of 590 nm using an EnVision 2103 multilabel reader (PerkinElmer, USA).

To determine the Minimum inhibitory concentrations (MICs), concentrations of surfactins were diluted by a serial 2-fold dilution method according to a modified protocol from the Clinical and Laboratory Standards Institute (formerly National Committee for Clinical Laboratory Standards) M-38A and M-27A2 methods. The MIC was defined as a concentration of an antimicrobial that prevented 100% of cell growth during 18-hr incubation at 35°C.

To determine whether drug interaction was synergistic, additive, or antagonistic for the combination of surfactins and KTC, fractional inhibitory concentration index (FICI) was used. FICI = (MIC drug A in combination/MIC drug A alone) + (MIC drug B in combination/MIC drug B alone) [22]. The interaction was defined as synergistic if the FICI was <0.50, additive if the FICI was 0.50 to 4.0, and antagonistic if the FICI was >4.0.

Micro-organisms and Culture Medium

Four microbial strains Bacillus sp. MB198, MB245, MB199, and MB200 were isolated from HuangBo Sea, China and shown using mass spectrometry to produce surfactins (data not shown). These strains were screened for the optimum surfactin producer with the fermentation medium as described in the following. The seed culture medium for all Bacillus strains was a Luria Bertani (LB) medium consisting of 5 g/L yeast extract, 10 g/L NaCl, 10 g/L tryptone, and a pH of 7.2. The fermentation medium used for shaker flask cultivation contained 20 g/L carbon source, 2.0 g/L nitrogen source, 3.0 g/L K2HPO4·3H2O, 10 g/L NaH2PO4·2H2O, 0.2 g/L MgSO4·7H2O, 0.002 g/L MnCl2·4H2O, and 0.2 g/L yeast extract. Carbon source and nitrogen source were arranged according to the description of the following section. Two milliliter of seed medium was transferred to a 250 mL Erlenmeyer flask containing 50 mL fermentation medium and incubated at 28°C for 48 h on a rotary shaker (200 rpm).

Selection of Optimum Carbon Source and Nitrogen Source

To optimize the carbon source, glucose, sucrose, galactose, maltose, sucrose, glycerol, mannitol, soluble starch, and dextrin were evaluated. To optimize the nitrogen source, ammonium nitrate, ammonium sulfate, sodium nitrate, soybean flour, peptone, casein acid hydrolysate, urea, and glutamic sodium were evaluated. C15-surfactin (MW1035, Fig. 1) production was calculated by the method described in the section of “Analytical methods”.

Figure 1. The structure of C15-Surfactin.

16S rDNA Sequence Analysis

Genomic DNA of Bacillus sp. was extracted using a TIANamp Bacteria DNA Kit (DP302, Tiangen Biotech (Beijing) Co., LTD., Beijing, China). The PCR method was performed according to the methods described previously [21]. Bacillus strains and calculations of sequence similarity were carried out using CLUSTAL X1 [23]. A phylogenetic tree was constructed using the neighbor-joining method and MEGA 4.0 software [24]. The topology of the phylogenetic tree was evaluated by 1000 bootstrap resampling replicates [25].

Experimental Design and Data Analysis

The most significant parameters affecting C15-surfactin production from Bacillus amyloliquefaciens MB199 were determined using the Plackett-Burman Design (PBD), as noted in Table 1 (Yeast extract is a good source of nitrogen and metals, so the low levels of x2, x7 and x8 could be set as 0). The analysis of C15-surfactin production was carried out in twelve experiments, each of which was performed two times (Table 2). Three dummy variables (x3, x6 and x11) were studied in 12 experiments to calculate the standard error. The final result was expressed as the average value of the two repeated experiments. The variables with confidence levels above 95% were considered to have significant effects on C15-surfactin production and were used for further optimization. Using the trends in the data provided by the results of the PBD, the experiments were adapted by increasing or decreasing the concentrations of each variable following the result of PBD [26]. Finally, a central composite rotatable design was produced with the values of each variable noted with the design matrix (Table 3). The low, middle, and high levels of each variable were designated as −1.68, −1, 0, and 1, 1.68, respectively and a response surface was produced.

Table 1. The Plackett-Burman design for screening variables for C15-surfactin production.

| Factors(g/L) | Code | Lowlevel(−1) | Highlevel(+1) | Coef* | F-value | p-value |

| Sucrose | x 1 | 10 | 30 | −9.98 | 26.10 | 0.0145 |

| NH4NO3 | x 2 | 0 | 4 | 8.07 | 17.06 | 0.0257 |

| K2HPO4·3H2O | x 4 | 0.5 | 6 | 4.98 | 6.49 | 0.0841 |

| NaH2PO4·2H2O | x 5 | 5 | 15 | 8.55 | 19.16 | 0.0221 |

| MgSO4·7H2O | x 7 | 0 | 0.4 | −0.88 | 0.20 | 0.6828 |

| MnCl2·4H2O | x 8 | 0 | 0.004 | 2.48 | 1.62 | 0.2934 |

| Yeast extract | x 9 | 0.05 | 0.35 | −4.61 | 5.57 | 0.0994 |

| Temperature | x 10 | 27 | 30 | 1.72 | 0.78 | 0.4433 |

R2 = 96.25%, R2 (adj) = 86.25%.

Coef: coefficient.

Table 2. The Placket-Burman design variables (in coded levels) with C15-surfactin yield as response.

| Run | Variable levels | Yield of C15-surfactin (mg/L) | ||||||||||

| x 1 | x 2 | x 3 | x 4 | x 5 | x 6 | x 7 | x 8 | x 9 | x 10 | x 11 | ||

| 1 | 1 | −1 | 1 | 1 | 1 | −1 | −1 | −1 | 1 | −1 | 1 | 12.70±0.88 |

| 2 | −1 | 1 | −1 | 1 | 1 | −1 | 1 | 1 | 1 | −1 | −1 | 53.00±0.29 |

| 3 | 1 | −1 | 1 | 1 | −1 | 1 | 1 | 1 | −1 | −1 | −1 | 15.19±0.72 |

| 4 | 1 | 1 | 1 | −1 | −1 | −1 | 1 | −1 | 1 | 1 | −1 | 3.92±0.42 |

| 5 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | 14.55±0.90 |

| 6 | 1 | 1 | −1 | −1 | −1 | 1 | −1 | 1 | 1 | −1 | 1 | 12.73±0.99 |

| 7 | −1 | −1 | 1 | −1 | 1 | 1 | −1 | 1 | 1 | 1 | −1 | 38.27±1.45 |

| 8 | −1 | 1 | 1 | −1 | 1 | 1 | 1 | −1 | −1 | −1 | 1 | 51.72±1.69 |

| 9 | 1 | −1 | −1 | −1 | 1 | −1 | 1 | 1 | −1 | 1 | 1 | 17.88±1.01 |

| 10 | −1 | −1 | −1 | 1 | −1 | 1 | 1 | −1 | 1 | 1 | 1 | 23.22±0.99 |

| 11 | 1 | 1 | −1 | 1 | 1 | 1 | −1 | −1 | −1 | 1 | −1 | 47.93±0.80 |

| 12 | −1 | 1 | 1 | 1 | −1 | −1 | −1 | 1 | −1 | 1 | 1 | 49.31±0.18 |

Table 3. Design and results of CCD.

| Run | Sucrose | NH4NO3 | NaH2PO4·2H2O | Yield of C15-Surfactin (mg/L) | |||

| Code X1 | X1 (g/L) | Code X2 | X2 (g/L) | Code X3 | X3 (g/L) | ||

| 1 | −1 | 17 | 1 | 2.5 | 1 | 14 | 118.08±1.23 |

| 2 | 0 | 20 | 0 | 2.0 | −1.68 | 17 | 45.56±0.42 |

| 3 | 1 | 23 | 1 | 2.5 | 1 | 14 | 130.41±12.94 |

| 4 | 0 | 20 | 0 | 2.0 | 1.68 | 17 | 100.60±1.26 |

| 5 | 0 | 20 | 1.68 | 2.8 | 0 | 10 | 128.96±2.38 |

| 6 | 1 | 23 | 1 | 2.5 | −1 | 6 | 106.70±5.91 |

| 7 | 1 | 23 | −1 | 1.5 | −1 | 6 | 49.84±1.71 |

| 8 | 0 | 20 | −1.68 | 1.2 | 0 | 10 | 96.07±5.94 |

| 9 | −1.68 | 15 | 0 | 2.0 | 0 | 10 | 131.39±0.87 |

| 10 | 1.68 | 25 | 0 | 2.0 | 0 | 10 | 98.41±25.73 |

| 11 | 0 | 20 | 0 | 2.0 | 0 | 10 | 126.27±3.13 |

| 12 | 0 | 20 | 0 | 2.0 | 0 | 10 | 121.33±1.85 |

| 13 | −1 | 17 | 1 | 2.5 | −1 | 6 | 102.68±3.83 |

| 14 | 0 | 20 | 0 | 2.0 | 0 | 10 | 119.36±0.53 |

| 15 | −1 | 17 | −1 | 1.5 | −1 | 6 | 85.18±10.36 |

| 16 | 1 | 23 | −1 | 1.5 | 1 | 14 | 106.23±6.41 |

| 17 | 0 | 20 | 0 | 2.0 | 0 | 10 | 117.49±7.01 |

| 18 | −1 | 17 | −1 | 1.5 | 1 | 14 | 107.49±4.82 |

| 19 | 0 | 20 | 0 | 2.0 | 0 | 10 | 115.14±5.95 |

| 20 | 0 | 20 | 0 | 2.0 | 0 | 10 | 124.47±15.67 |

Statistical Analysis

Design Expert (Version 7.0, Stat-Ease Inc., USA) was used to generate the experimental designs and perform subsequent regression analysis of the experimental data. The quality of the polynomial model equation was judged statistically using analysis of variance (ANOVA) to determine the coefficient of determination, R2. The statistical significance was determined using the F-test and significance of the regression coefficients was determined using the t-test.

Extraction of Surfactins

Isolation and extraction of surfactins were performed according to the previously described method [27] with minor modifications. Briefly, after 48 hours of fermentation 35 mL cell broth was subjected to centrifugation at 8000 rpm for 5 min to remove the bacteria cells. The supernatant was then subjected to an acid precipitation with 6 M HCl by adjusting the pH to 2.0 and refrigerated at 4°C for 24 h. The precipitant was collected by centrifugation at 8000 rpm for 5 min followed by 24 h of lyophilization at −50°C. The lyophilized powder was extracted with 2 mL methanol for 4 h. Then the methanol extract was filtered using a 0.45 µm filter.

Analytical Methods

The methanol extraction of surfactin was analyzed using a HPLC system (Agilent 1100 Series, CA, USA) equipped with an Agilent XDB C18 column (Φ 4.6 mm×15 cm, 5 µm). The mobile phase consisted of 90% methanol and 10% water (0.1% TFA). After loaded with 40 µL filtered methanol extract, and column was eluted at a flow rate of 1 mL/min. The elution was monitored by the UV absorbance at 210 nm. C15-surfactin was identified to be eluted at a retention time of 11.0 min according to LC-MS results.

Results and Discussion

Synergistic Antifungal Activity of Surfactins

During the process of high throughput screening for the novel synergic antifungal compound, C14-surfactin and C15-surfactin were found to be most efficient when compared to the crude extract-acid precipitation (Table 4). It showed that C14-surfactin and C15-surfactin had synergistic antifungal activities with KTC against Candida albicans at 12.5 µg/mL and 6.25 µg/mL, respectively (Table 4). Based on these MIC values, the FICIs of C14-surfactin and C15-surfactin were less than 0.4 and 0.3 (all of them were less than 0.5), respectively, so the combination of surfactins and KTC were synergistic.

Table 4. Synergy antifungal screening resulta.

| Samples | Anti-fungal MICs (µg/mL) | Synergistic anti-fungal MICs (µg/mL) |

| Acid Precipitationb | >100 | 50 |

| Lipopeptide Mixturec | 50 | 25 |

| C14-surfactin | >100 | 12.5 |

| C15-surfactin | >100 | 6.25 |

| Cyclosporin A | >64 | 4 |

The MIC of KTC is 0.016 µg/mL. The concentration of KTC in synergy antifungal screening experiment is 0.004 µg/mL, at which KTC does not show antifungal activity.

Acid precipitation was obtained by centrifugation of cell broth at pH 2.0. It contains C13-surfactin, C14-surfactin, C15-surfactin and other kind of compounds.

Lipopeptide mixture is purified fraction from acid precipitation, and is the mixture of C13-surfactin, C14-surfactin, and C15-surfactin.

KTC is a frequently used antifungal drug (MIC = 0.016 µg/mL), which resulted in two drawbacks. One is the appearance of the resistant fungi. The other is the side-effect on human being produced by KTC at an efficient active concentration. So we design this synergy antifungal model to screen compounds which can synergize KTC with 1/4MIC (a concentration found to be no antifungal activity and also less side-effect on the patient). With this method C15-surfactin was identified to be best synergistic antifungal agent for KTC. This result not only proved the efficiency of our synergy screening model, but also highlights the new application of surfactin as a synergistic antifungal agent of KTC.

It has been reported that surfactin has synergistic activity with iturin on its hemolytic activity [28]. However, there is limited knowledge about the antifungal and synergistic antifungal activities of this compound. The results of our study showed a new effect of surfactin when KTC was incorporated. Surfactin has been known to interact with the cell membrane and disturbs the membrane’s stability [29], [30], [31], [32]. Among C13-surfactin, C14-surfactin and C15-surfactin, C15-surfactin was the most effective compound to interact with membranes because the longer fatty acid chain induces a greater interfacial activity of surfactins with the membrane [29]. This performance was helpful to explain our result that C15-surfactin was more active than C14-surfactin.

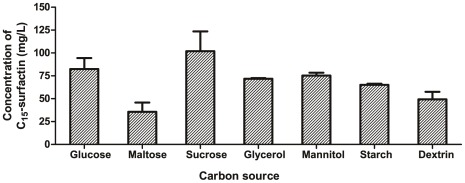

Selection of Optimum Carbon Source, Nitrogen Source

The effect of the carbon source on C15-surfactin production of strain MB199 was given in Fig. 2. The optimum carbon source was found to be sucrose, which enabled MB199 to reach a maximum yield of 102.0 mg/L C15-surfactin.

Figure 2. Effects of carbon source on the production of C15-surfactin from B. amyloliquefaciens MB199.

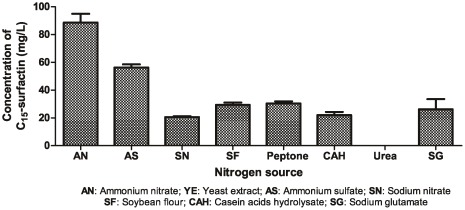

With sucrose as the carbon source, the effect of the nitrogen source on C15-surfactin production for strain MB199 is given in Fig. 3. The maximum yield of surfactin (99.6 mg/L) was produced by the MB199 strain with ammonium nitrate used as the nitrogen source.

Figure 3. Effects of nitrogen source on the production of C15-surfactin from B. amyloliquefaciens MB199 with sucrose as the carbon source.

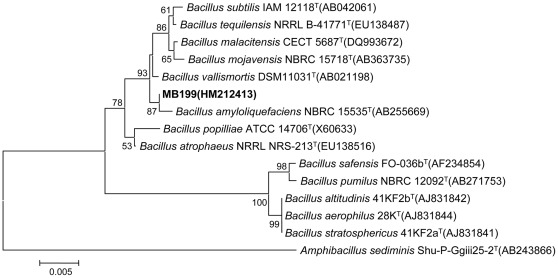

Identification of Surfactin Producing Bacillus sp. MB199

The analysis of the 16S rRNA gene sequence (GeneBank accession no. HM212413) revealed that MB199 was similar to B. amyloliquefaciens NBRC 15535T (similarity, 100%/1472 bps, based on 16S rRNA) (Fig. 4). Through the alignment and cladistic analysis of homologous nucleotide sequences of known Bacillus, phylogenetic relationships could be inferred. The approximate phylogenetic position of the strain is shown in Fig. 4. According to the gene sequence, the strain Bacillus sp. MB199 was identified as a strain of B. amyloliquefaciens, and named B. amyloliquefaciens MB199.

Figure 4. Neighbour-joining phylogenetic tree of B. amyloliquefaciens MB199 constructed by Mega 4.0.

Numbers at nodes indicate levels of bootstrap support (%) based on a neighbour-joining analysis of 1000 resampled datasets; only values >50% are given. NCBI accession numbers are given in parentheses. Bar, 0.005 nucleotide substitutions per site.

The selection of high amounts of surfactin producing strains is necessary for future mutation or bioengineering studies. Previously, our laboratory has constructed a high quality marine microbial natural product library containing novel microorganisms from marine environments. In this study, B. amyloliquefaciens was discovered to an efficient C15-surfactin producer from four Bacillus species. Actually, a recent report revealed that B. amyloliquefaciens is a producer of both lipopeptide and polyketide antibiotics [33]. These studies proved that B. amyloliquefaciens could be a promising strain used for the C15-surfactin production in the further engineering studies.

Optimization of C15-surfactin Production by PBD

The importance of the eight parameters, namely, sucrose, NH4NO3, K2HPO4·3H2O, NaH2PO4·2H2O, MgSO4·7H2O, MnCl2·4H2O, yeast extract and temperature for C15-surfactin production was investigated by PBD. Table 1 shows the effects of these parameters on the response along with significant levels. Based on the statistical analysis, the parameters that significantly (confidence level >95%) affected the C15-surfactin production were sucrose, NH4NO3, and NaH2PO4·2H2O with coefficients of (−) 9.98, (+) 8.07, and (+) 8.55, respectively. Other factors had no obvious effects and the low confidence levels indicating insignificant influence on the yield of C15-surfactin. With these significant parameters, the R2 was found to be 0.9625, which indicated the model could explain 96.25% of the total variations in the system.

Optimization by the Path of Steepest Ascent Experiment

PBD results indicated that the effect of sucrose was negative, whereas those like NH4NO3 and NaH2PO4·2H2O were positive. Thus, decreasing sucrose concentration and increasing concentrations of NH4NO3 and NaH2PO4·2H2O should result in a higher production of C15-surfactin. For each of these factors, the average values from the PBD experiments were used as initial points for the path of steepest ascent experiments, and the concentrations were either increased or decreased as indicated by the PBD experiments. It showed the maximum production of C15-surfactin (124.18±3.53 mg/L) (Table 5). This was obtained when the parameters were 20 g/L sucrose, 2 g/L NH4NO3 and 10 g/L NaH2PO4·2H2O.

Table 5. Design and results of path of steepest ascent experiment.

| Run | Factor | Yield of C15-surfactin (mg/L) | ||

| X1 (g/L)a | X2 (g/L) | X3 (g/L) | ||

| 1 | 23 | 1.54 | 6.2 | 71.90±11.53 |

| 2 | 20 | 2 | 10 | 124.18±3.53 |

| 3 | 17 | 2.46 | 13.8 | 103.71±1.61 |

| 4 | 14 | 2.92 | 17.6 | 101.75±7.68 |

X1, X2 and X3 represent Sucrose, NH4NO3 and NaH2PO4•2H2O, respectively.

Optimization by Response Surface Methodology

The data shown in Table 3 were analyzed using Design Expert software. The t-test and P-values were used to identify the effect of each factor on C15-surfactin production (Table 6), with a P-value of less than 0.05 indicating significance. Sucrose, NH4NO3 and NaH2PO4·2H2O had significant effects on C15-surfactin yield (P<0.05) and were able to explain 96.11% of the model variability. Therefore, the present prediction model reflected a good degree of correlation between the observed and predicted responses, implying the model was reliable for C15-surfactin production in the present study. The adjusted determination coefficient (R2 = 86.25%) was also satisfactory to confirm the significance of the model. The model can be shown as following:

| (1) |

Where Y is the predicted C15-surfactin yield, X1 is sucrose, X2 is NH4NO3, and X3 is NaH2PO4·2H2O.

Table 6. Regression coefficients and their significance for response surface model.

| Term | Coef | Standard Error | P |

| Intercept | 120.62 | 2.63 | <0.0001 |

| X1 a | −5.54 | 1.75 | 0.0099 |

| X2 | 12.04 | 1.75 | <0.0001 |

| X3 | 15.40 | 1.75 | <0.0001 |

| X1*X1 | −1.64 | 1.70 | 0.3576 |

| X2*X2 | −2.48 | 1.70 | 0.1749 |

| X3*X3 | −16.43 | 1.70 | <0.0001 |

| X1*X2 | 6.62 | 2.28 | 0.0159 |

| X1*X3 | 5.30 | 2.28 | 0.0427 |

| X2*X3 | −4.95 | 2.28 | 0.0554 |

X1, X2 and X3 represent Sucrose, NH4NO3 and NaH2PO4•2H2O, respectively.

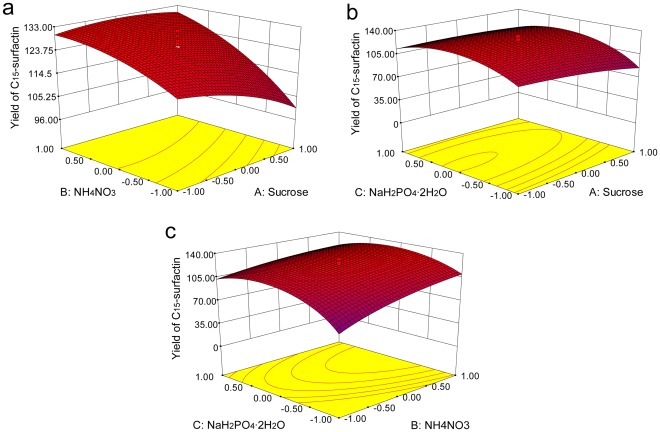

Furthermore, the ANOVA analysis for the response surface quadratic model was presented in Table 7, which reported a statistically significant (P<0.05) regression at a 95% confidence level. To check the fitness of the polynomial model, the significant lack-of-fit was also reported in Table 7, which means there is some variation unaccounted for in the predicted model (the selected model does not well describe the data). In this study, P = 0.0886 indicated that the model was statistically insignificant lack of fit, so it was adequate for the prediction of C15-surfactin yield within the range of variables tested. The 3D response surface graphs provide a more complete representation of the effects of variables on the production of C15-surfactin (Fig. 5).

Table 7. ANOVA of regression model.

| Source | DF1 | Seq SS2 | Adj MS3 | F | P |

| Regression | 9 | 10310.53 | 1145.61 | 27.48 | <0.0001 |

| Pure error | 5 | 88.64 | 17.73 | ||

| Lack of fit | 5 | 328.26 | 65.65 | 3.70 | 0.0886 |

| Total | 19 | 10727.43 |

Determination of coefficient R2 = 0.9611; adjusted determination coefficient Adj R2 = 0.9262.

DF, Degree of freedom;

SS, sum of squares;

MS, mean square.

Figure 5. Response surface plot for C15-surfactin production by B. amyloliquefaciens MB199.

Validation of the Optimized Condition

On the basis of medium optimization, the model predicted the maximum production of surfactin as132.61 mg/L, in the presence of 21.17 g/L sucrose, 2.50 g/L NH4NO3, and 11.56 g/L NaH2PO4·2H2O. To verify the predicted results, a validation experiment was performed in triplicate tests. Under the optimized condition, the observed experimental yield of average C15-surfactin was 134.2 mg/L, which is a 1.52-fold increase as compared to the yield in non-optimized media, suggesting that experimental and predicted values of C15-surfactin yield were in good agreement. This result therefore corroborated the predicted values and the effectiveness of the model, indicating that the optimized medium favors the production of C15-surfactin.

Actually, the pH value of the culture medium also has an effect on surfactin production. Surfactins have emulsification activities, so we use the emulsification index (EU/mL) as a parameter to evaluate the production of surfactins in cell broth. Our previous data showed that the production of surfactin will decrease in a culture medium with a pH less than 5 or larger than 9 [21]. In the present work, a pH of 7.2 was used throughout the optimization experiment. Noteworthy, the data on growth of Bacillus amyloliquefaciens was not measured in the present optimization experiment, so there was no information on the “specific productivity” of C15-surfactin by Bacillus amyloliquefaciens. However, a recent thesis showed that surfactin productivity was cell growth associated for Bacillus subtilis ATCC 21332 [34].

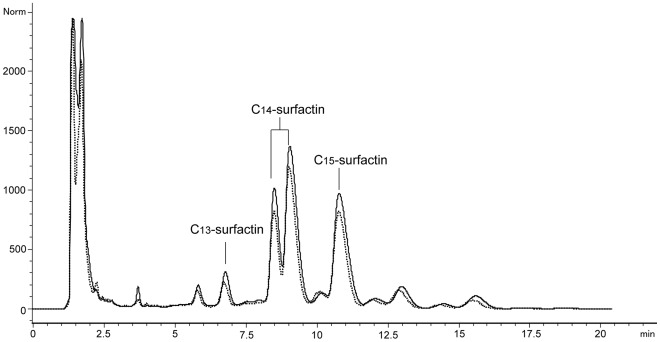

In the literature, a medium containing glucose (10.0 g/L) and ammonium nitrate (4.0 g/L) could lead to the highest quantity of surfactins (439.0 mg/L) by B. subtilis ATCC 21332 [35]. However, C15-surfactin was not clearly reported in these experiments due to the different analysis methods. Our present study focused on C15-surfactin production not only due to its effective biological activities, but also because purification of this compound was relatively easy by using HPLC (Fig. 6). In this respect, the present study was useful for the further investigations of the industrial production of C15-surfactin. Additionally, it has been found that surfactin producing B. subtilis strain S499 could produce a novel lipopeptide fengycin after the optimization of medium composition for the surfactin production [36]. In order to find out how the culture medium components influence the production of the other homologues of C15-surfactin, the HPLC profile of surfactins of B. amyloliquefaciens MB199 was measured. The results showed an increase in the yield of other homologues of C15-surfactin without influencing the diversity of the surfactins produced in the cell broth (Fig. 6).

Figure 6. HPLC profile of surfactin produced by B. amyloliquefaciens MB199.

The elution was monitored at 210 nm at a flow rate of 1 mL/min. The dashed line and the real line represent the HPLC profiles of surfactins produced in optimized and original culture media, respectively.

In conclusion, the present work shows that C15-surfactin as a biomaterial could be utilized as a synergistic antifungal agent with ketoconazole for novel applications in biomedical and pharmaceutical fields. This study also offered a novel marine derived B. amyloliquefaciens strain MB199 which could efficiently produce C15-surfactin in shaker flasks. It showed that sucrose as a soluble carbon source and ammonium nitrate as a nitrogen source gave higher C15-surfactin production. The production of C15-surfactin was found to depend greatly on the key media components that were sucrose, ammonium nitrate, and NaH2PO4·2H2O. Using the RSM, it was possible to model individual and interactive effects of media and efficiently enhance the production of C15-surfactin.

Acknowledgments

The authors are very grateful to Arnold L Demain for critical reading and helpful discussions.

Footnotes

Competing Interests: The authors have declared that no competing interests exist.

Funding: This work was supported in part by grants from National Natural Science Foundation of China (30973665, 30901849, 30873129, 30911120483, 30911120484, 81011120046, 81102356, 31100075, 81102369, 81102362, 31170095, and 31000004), the CAS Pillar Program (XDA04074000) and the Ministry of Science and Technology of China (2007DFB31620, 2011ZX11102). L. Z. is an Awardee for National Distinguished Young Scholar Program in China. The funders had no role in study design, data collection and analysis, decision to publish, or preparation of the manuscript.

References

- 1.Christofi N, Ivshina IB. Microbial surfactants and their use in field studies of soil remediation. J Appl Microbiol. 2002;93:915–929. doi: 10.1046/j.1365-2672.2002.01774.x. [DOI] [PubMed] [Google Scholar]

- 2.Kiran GS, Thomas TA, Selvin J. Production of a new glycolipid biosurfactant from marine Nocardiopsis lucentensis MSA04 in solid-state cultivation. Colloids Surf B Biointerfaces. 2010;78:8–16. doi: 10.1016/j.colsurfb.2010.01.028. [DOI] [PubMed] [Google Scholar]

- 3.Haddad NIA, Liu XY, Yang SZ, Mu BZ. Surfactin isoforms from Bacillus subtilus HSO121: separation and characterization. Protein Pept Lett. 2008;15:265–269. doi: 10.2174/092986608783744225. [DOI] [PubMed] [Google Scholar]

- 4.Tang JS, Gao H, Hong K, Yu Y, Jiang MM, et al. Complete assignments of 1H and 13C NMR spectral data of nine surfactin isomers. Magn Reson Chem. 2007;45:792–796. doi: 10.1002/mrc.2048. [DOI] [PubMed] [Google Scholar]

- 5.Yoneda T, Tsuzuki T, Ogata E, Fusyo Y. Surfactin sodium salt: an excellent bio-surfactant for cosmetics. J Cosmet Sci. 2001;52:153–154. [PubMed] [Google Scholar]

- 6.Razafindralambo H, Thonart P, Paquot M. Dynamic and equilibrium surface tensions of surfactin aqueous solutions. J Surfactants Deterg. 2004;7:41–46. [Google Scholar]

- 7.Deleu M, Bouffioux O, Razafindralambo H, Paquot M, Hbid C, et al. Interaction of surfactin with membranes: A computational approach. Langmuir. 2003;19:3377–3385. [Google Scholar]

- 8.Kracht M, Rokos H, Ozel M, Kowall M, Pauli G, et al. Antiviral and hemolytic activities of surfactin isoforms and their methyl ester derivatives. J Antibiot. 1999;52:613–619. doi: 10.7164/antibiotics.52.613. [DOI] [PubMed] [Google Scholar]

- 9.Cao XH, Liao ZY, Wang CL, Cai P, Yang WY, et al. Purification and antitumour activity of a lipopeptide biosurfactant produced by Bacillus natto TK-1. Biotechnol Appl Biochem. 2009;52:97–106. doi: 10.1042/BA20070227. [DOI] [PubMed] [Google Scholar]

- 10.Cao XH, Liao ZY, Wang CL, Yang WY, Lu MF. Evaluation of a lipopeptide biosurfactant from Bacillus natto Tk-1 as a potential source of anti-adhesive, antimicrobial and antitumor activities. Braz J Microbiol. 2009;40:373–379. doi: 10.1590/S1517-838220090002000030. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Cao X, Wang AH, Jiao RZ, Wang CL, Mao DZ, et al. Surfactin induces apoptosis and G(2)/M arrest in human breast cancer MCF-7 cells through cell cycle factor regulation. Cell Biochem Biophys. 2009;55:163–171. doi: 10.1007/s12013-009-9065-4. [DOI] [PubMed] [Google Scholar]

- 12.Cao XH, Wang AH, Wang CL, Mao DZ, Lu MF, et al. Surfactin induces apoptosis in human breast cancer MCF-7 cells through a ROS/JNK-mediated mitochondrial/caspase pathway. Chem-Biol Interact. 2010;183:357–362. doi: 10.1016/j.cbi.2009.11.027. [DOI] [PubMed] [Google Scholar]

- 13.Kim SY, Kim JY, Kim SH, Bae HJ, Yi H, et al. Surfactin from Bacillus subtilis displays anti-proliferative effect via apoptosis induction, cell cycle arrest and survival signaling suppression. FEBS Lett. 2007;581:865–871. doi: 10.1016/j.febslet.2007.01.059. [DOI] [PubMed] [Google Scholar]

- 14.Bortolato M, Besson F, Roux B. Inhibition of alkaline phosphatase by surfactin, a natural chelating lipopeptide from Bacillus subtilis. Biotechnol Lett. 1997;19:433–435. [Google Scholar]

- 15.Hwang YH, Park BK, Lim JH, Kim MS, Park SC, et al. Lipopolysaccharide-binding and neutralizing activities of surfactin C in experimental models of septic shock. Eur J Pharmacol. 2007;556:166–171. doi: 10.1016/j.ejphar.2006.10.031. [DOI] [PubMed] [Google Scholar]

- 16.Takahashi T, Ohno O, Ikeda Y, Sawa R, Homma Y, et al. Inhibition of lipopolysaccharide activity by a bacterial cyclic lipopeptide surfactin. J Antibiot. 2006;59:35–43. doi: 10.1038/ja.2006.6. [DOI] [PubMed] [Google Scholar]

- 17.Seydlova G, Svobodova J. Review of surfactin chemical properties and the potential biomedical applications. Cent Eur J Med. 2008;3:123–133. [Google Scholar]

- 18.Singh P, Cameotra SS. Potential applications of microbial surfactants in biomedical sciences. Trends Biotechnol. 2004;22:142–146. doi: 10.1016/j.tibtech.2004.01.010. [DOI] [PubMed] [Google Scholar]

- 19.Khopade A, Ren B, Liu XY, Mahadik K, Zhang L, et al. Production and characterization of biosurfactant from marine Streptomyces species B3. J Colloid Interface Sci. 2012;367:311–318. doi: 10.1016/j.jcis.2011.11.009. [DOI] [PubMed] [Google Scholar]

- 20.Chakraborty S, Khopade A, Ren B, Wang J, Liu XY, et al. Characterization and stability studies on surfactant, detergent and oxidant stable α-amylase from marine haloalkaliphilic Saccharopolyspora sp. A9. J Mol Catal B: Enzym. 2011;68:52–58. [Google Scholar]

- 21.Liu X, Ren B, Chen M, Wang H, Kokare CR, et al. Production and characterization of a group of bioemulsifiers from the marine Bacillus velezensis strain H3. Appl Microbiol Biotechnol. 2010;87:1881–1893. doi: 10.1007/s00253-010-2653-9. [DOI] [PubMed] [Google Scholar]

- 22.Zhang LX, Yan KZ, Zhang Y, Huang R, Bian J, et al. High-throughput synergy screening identifies microbial metabolites as combination agents for the treatment of fungal infections. P Natl Acad Sci USA. 2007;104:4606–4611. doi: 10.1073/pnas.0609370104. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.Thompson JD, Gibson TJ, Plewniak F, Jeanmougin F, Higgins DG. The CLUSTAL_X windows interface: flexible strategies for multiple sequence alignment aided by quality analysis tools. Nucleic Acids Res. 1997;25:4876–4882. doi: 10.1093/nar/25.24.4876. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 24.Kim J, Rohlf FJ, Sokal RR. The accuracy of phylogenetic estimation using the Neighbor-Joining method. Evolution. 1993;47:471–486. doi: 10.1111/j.1558-5646.1993.tb02107.x. [DOI] [PubMed] [Google Scholar]

- 25.Felsenstein J. Confidence limits on phylogenies: an approach using the bootstrap. Evolution. 1985;39:783–789. doi: 10.1111/j.1558-5646.1985.tb00420.x. [DOI] [PubMed] [Google Scholar]

- 26.Gheshlaghi R, Scharer JM, Moo-Young M, Douglas PL. Medium optimization for hen egg white lysozyme production by recombinant Aspergillus niger using statistical methods. Biotechnol Bioeng. 2005;90:754–760. doi: 10.1002/bit.20474. [DOI] [PubMed] [Google Scholar]

- 27.Liu XY, Yang SZ, Mu BZ. Isolation and characterization of a C12-lipopeptide produced by Bacillus subtilis HSO121. J Pept Sci. 2008;14:864–875. doi: 10.1002/psc.1017. [DOI] [PubMed] [Google Scholar]

- 28.Maget-Dana R, Thimon L, Peypoux F, Ptak M. Surfactin/iturin A interactions may explain the synergistic effect of surfactin on the biological properties of iturin A. Biochimie. 1992;74:1047–1051. doi: 10.1016/0300-9084(92)90002-v. [DOI] [PubMed] [Google Scholar]

- 29.Eeman M, Berquand A, Dufrene YF, Paquot M, Dufour S, et al. Penetration of surfactin into phospholipid monolayers: Nanoscale interfacial organization. Langmuir. 2006;22:11337–11345. doi: 10.1021/la061969p. [DOI] [PubMed] [Google Scholar]

- 30.Maget-Dana R, Ptak M. Interactions of surfactin with membrane models. Biophys J. 1995;68:1937–1943. doi: 10.1016/S0006-3495(95)80370-X. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Grau A, Gomez Fernandez JC, Peypoux F, Ortiz A. A study on the interactions of surfactin with phospholipid vesicles. Biochim Biophys Acta. 1999;1418:307–319. doi: 10.1016/s0005-2736(99)00039-5. [DOI] [PubMed] [Google Scholar]

- 32.Carrillo C, Teruel JA, Aranda FJ, Ortiz A. Molecular mechanism of membrane permeabilization by the peptide antibiotic surfactin. Biochim Biophys Acta. 2003;1611:91–97. doi: 10.1016/s0005-2736(03)00029-4. [DOI] [PubMed] [Google Scholar]

- 33.Chen XH, Koumoutsi A, Scholz R, Schneider K, Vater J, et al. Genome analysis of Bacillus amyloliquefaciens FZB42 reveals its potential for biocontrol of plant pathogens. J Biotechnol. 2009;140:27–37. doi: 10.1016/j.jbiotec.2008.10.011. [DOI] [PubMed] [Google Scholar]

- 34.Keenan B. Matieland: Stellenbosch University; 2011. Bacterial production of antimicrobial biosurfactants by Bacillus subtilis.158 [Google Scholar]

- 35.Fonseca RR, Silva AJR, De Franca FP, Cardoso VL, Servulo EFC. Optimizing carbon/nitrogen ratio for biosurfactant production by a Bacillus subtilis strain. Appl Biochem Biotechnol. 2007;137:471–486. doi: 10.1007/s12010-007-9073-z. [DOI] [PubMed] [Google Scholar]

- 36.Jacques P, Hbid C, Destain J, Razafindralambo H, Paquot M, et al. Optimization of biosurfactant lipopeptide production from Bacillus subtilis S499 by Plackett-Burman design. Appl Biochem Biotechnol. 1999;77–9:223–233. [Google Scholar]