Abstract

The controlled delivery of growth factors and cells within biomaterial carriers can enhance and accelerate functional bone formation. The carrier system can be designed with preprogrammed release kinetics to deliver bioactive molecules in a localized, spatiotemporal manner most similar to the natural wound healing process. The carrier can also act as an extracellular matrix-mimicking substrate for promoting osteoprogenitor cellular infiltration and proliferation for integrative tissue repair. This review discusses the role of various regenerative factors involved in bone healing and their appropriate combinations with different delivery systems for augmenting bone regeneration. The general requirements of protein, cell and gene therapy are described, with elaboration on how the selection of materials, configurations and processing affects growth factor and cell delivery and regenerative efficacy in both in vitro and in vivo applications for bone tissue engineering.

Keywords: Bone tissue engineering, controlled delivery, growth factors, cells, scaffolds

1. Introduction

Every year, more than 500,000 bone graft procedures are performed to address bone fractures and other orthopedic-related injuries resulting from a variety of surgical, degenerative and traumatic causes [1, 2]. The current gold standard of treatment is autologous bone, harvested primarily from the patient’s iliac crest or other locations such as the distal femur, proximal tibia, ribs and intramedullary canal [2–4]. Despite its immunocompatibility and excellent osteoconductive properties, autograft bone is of limited supply and presents associated donor-site morbidity [5–7]. Allograft bone from human donors/cadavers or xenograft bone from a non-human are viable alternative treatments. However, risks of disease transmission, infection and host rejection have restricted their use. The application of biological signals and cells to stimulate the host’s natural healing response for functional tissue repair may successfully address the drawbacks of current approaches for bone regeneration.

Direct growth factor and cell delivery has shown great therapeutic potential in preclinical testing and clinical trials, but few have reached commercial success. Bone morphogenetic protein (BMP)-2 and BMP-7, currently regulated by the Food and Drug Administration (FDA), were found to be promising alternatives to autografts in non-union bone defects, open tibial fractures, spinal fusion and accelerated fracture healing [8, 9]. However, currently employed delivery methods experience insufficient local retention and require high amounts of protein to exert a biological effect, especially in larger animal models and humans [10]. Cellular therapy using localized administration of cells to the defect site has been constrained by similar problems. Despite the positive results obtained from clinical applications of cell therapy using autologous or allogeneic bone marrow, plasma and cultured osteoblasts [11, 12], studies show that transplanted cells poorly engraft to local tissue and fail to spread from the injury site, limiting repair and cell viability [13]. Tissue engineering strategies have emerged as promising methods to provide superior regenerative treatment through the combination of biological factors, cells and biomaterial scaffolds.

The controlled delivery of bone regenerative factors can be accomplished via biomaterial carrier systems to facilitate local repair at the defect. The optimal carrier should provide four main functions: 1) site specific delivery of regenerative factors to the defect, 2) local regulation and retention of released factors, 3) enhanced infiltration and proliferation of cells on a three-dimensional substrate and 4) optimized biodegradation for complete tissue regeneration. In addition, the carrier system and its soluble byproducts should also be biocompatible and noncytotoxic as to prevent premature clearance and/or adverse local tissue responses which may lead to delayed wound healing. While there have been many investigations in regards to the material, configuration and processing of carriers, the main challenge lies in balancing the design elements to preserve the essential functions for successful delivery [14]. The carrier must retain proteolytic protection without interfering with the bioactivity and spatiotemporal dosing of encapsulated molecules and biological function of the local microenvironment. This review discusses the role of different bone regenerative factors in bone regeneration and examines the requirements for protein, cell and gene therapy for bone regeneration, with emphasis on the materials and methods for controlled delivery.

2. Bone Regenerative Factors

Bone healing and remodeling is accomplished by a complex, coordinated effort of cells, bioactive factors and extracellular matrix to stimulate the proliferation, differentiation and migration of osteoprogenitor cells [15, 16]. The induction of signaling cascades for tissue repair results from the elevated expression of pro-inflammatory, angiogenic and osteogenic growth factors released by cells in the injury site, many of which have well established roles in embryonic development and skeletal homeostasis [17, 18]. The ability to recapitulate and manipulate those signaling processes on a similar spatiotemporal scale could provide specific control over the regenerative process.

2.1 Growth Factors

Growth factors are soluble signaling molecules that control a wide variety of cellular responses through specific binding of transmembrane receptors on target cells [18]. The ultimate biological response elicited from a growth factor depends on the identity of the growth factor and target cell, cell number, receptor type and other signaling events. Therefore, a critical component in designing a controlled delivery system is selection of the appropriate single or combination of growth factors for maximized tissue repair [19].

2.1.1. Osteogenic Factors

Members of the highly conserved transforming growth factor-β (TGF-β) superfamily play an important role in embryonic development, tissue morphogenesis, cell proliferation and cell differentiation [20]. TGF-βs, activins, growth differentiation factors (GDF), BMPs, and their various isoforms share similar biological activities through their homologous polypeptide structure, which only differs in the C-terminal amino acid sequences [20]. First implicated by Urist in the 1960s for directing osteoblast differentiation, several TGF-β superfamily members have been further linked to the biological processes of bone induction, including mesenchymal cell recruitment, proliferation, and extracellular matrix (ECM) production [21, 22]. Various defect types and animal models have been investigated with TGF-β [23–29] but TGF-β isoforms have only provided limited success for endochondral bone formation in adult non-human primates [20, 30]. BMPs, particularly BMP-2, BMP-4 and BMP-7, are the most extensively studied osteogenic molecules for inducing de novo bone formation in ectopic and orthotopic sites, including critical size defects (CSD) [10, 31–33].

2.1.2. Angiogenic Factors

Vascularization for the transport of oxygen, nutrients, growth and differentiation factors and circulating cells is essential for the formation and homeostasis of bone [34, 35]. The presence of a local microvascular network supports the osteogenic, chondrogenic and mesenchymal stem cells required for bone repair. Angiogenesis is regulated by soluble molecules such as vascular endothelial growth factor (VEGF), platelet-derived growth factor (PDGF), fibroblast growth factor (FGF) and insulin-like growth factor (IGF) [34]. Bone research with angiogenic factors has primarily focused on VEGF’s role in neovascularization and osteogenic recruitment [36]. VEGF delivery was found to increase blood vessel density and stimulate slight bone regeneration in rabbit [37, 38] and rat [39–42] critical size bone defects. Recent studies have shown that the combined delivery of VEGF with osteoinductive growth factors synergistically enhances osteogenesis [43–47].

2.1.3. Inflammatory Factors

Fracture healing can be characterized by the three phases of inflammation, renewal and remodeling. Control of inflammation involves the manipulation of proinflammatory cytokines and growth factors temporally and spatially released following bone injury. Studies have shown that inflammatory molecules including tumor necrosis factor-α, interleukins, interferon-γ and prostaglandins stimulate the migration and differentiation of osteoblasts and osteoclasts. Also, their release activates the secondary signal cascade required for enhanced angiogenesis and bone repair. Incorporation of immunomodulatory and anti-inflammatory agents such as peptide factors [48, 49], selective anticytokine therapies, corticosteroids and nonsteroidal anti-inflammatory drugs into bone tissue engineering strategies provides methods to direct the proregenerative and proresorptive effects of inflammatory signals. An in-depth examination of inflammatory factors for bone regeneration can be found in recent reviews [50, 51].

2.1.4. Systemic Factors

Since bone injuries also involve a systemic physiological response, the therapeutic role of systemic factors such as parathyroid hormone (PTH), growth hormone, steroids, calcitonin and Vitamin D in osteogenesis and angiogenesis have also been considered [52]. Although their mechanisms for directing osteogenic activity are not well understood, studies have shown that periodic exposure of PTH can stimulate bone formation in rats and humans [53–55]. Time-and dose-dependent administration of calcitonin and Vitamin D can also induce limited bone formation [56, 57] and osteoblastic differentiation [58], respectively.

2.2. Cells

Successful bone induction using autologous and allogeneic grafts relies on the presence of undifferentiated stem cells with high osteogenic potential to replace injured end stage differentiated cells. Stem cells are characterized by their abilities to self renew and differentiate into a variety of functional specialized cell types. Most cellular therapy strategies for bone regeneration employ adult stem cells, like mesenchymal stem cells (MSCs), due to their potential to differentiate into cells of a particular lineage. MSCs are culture-adherent, multipotent progenitor cells capable of differentiating into bone, cartilage, fat, tendon, muscle and nerve [59, 60]. They have been isolated from various sources including bone marrow, adipose tissue, muscle tissue, amniotic fluid, human placenta, periosteum, cord blood and even peripheral blood [59, 61–63]. The efficacy and survival of MSCs depend on the methods of isolation and ex vivo expansion and manipulation prior to transplantation.

Although MSCs have shown great potential in bone research, the plasticity of embryonic stem (ES) cells is highly desired for replacing the various tissue types affected in bone injuries, enabling widespread, more integrative repair. ES cells are pluripotent, therefore capable of differentiating into cell types from all three germ layers. Despite successful bone regeneration with both human and murine ES cells [64–66], safety and ethical concerns [11, 60] have limited their use. Recent studies have shown that differentiated cells can be genetically reprogrammed to regain their stemness for differentiation into other phenotypes not restricted to their tissue type. Induced pluripotent stem cells, human marrow isolated multilineage inducible cells and vascular smooth muscle cells have shown promise for bone tissue engineering applications [67–69].

3. Protein Therapy

3.1 General Requirements of Growth Factor Carriers

Protein therapy involves the targeted transport and sustained release of therapeutic growth factors using biomaterial carriers, the design requirements of which are similar to many drug delivery vehicles. A carrier system specifically for growth factors should provide protected delivery and regulated time- and dose-dependent release of protein at the target site as well as supportive scaffolding for cell migration and proliferation that will lead to the generation of ECM and vascular networks for enhanced tissue integration and repair.

The main challenge in developing delivery systems for bone tissue engineering stems from the fact that there is no ideal vehicle for all applications. While permanent implants have been utilized for growth factor delivery, degradable systems offer certain benefits for full tissue integration and reduced invasiveness. The shape, size and structure of the bone defect will dictate the required mechanical and degradation characteristics and the mode of delivery (prefabricated or injectable). The optimal carrier should metabolically degrade at a rate of a few weeks to months corresponding to the rate of tissue restoration while maintaining release of the appropriate concentration of protein. High surface area to volume ratio and pore interconnectivity are also required for adequate mass transport between the biological environment and space for cellular ingrowth and neovascularization. Additionally, since the kinetics of growth factor delivery are carrier-dependent, the therapeutic efficacy will rely on the chemistry and interaction of the protein, carrier material and local microenvironment. For example, in the case of delivering BMP-2 for bone regeneration, the ideal carrier would provide sustained release over a period of at least three weeks. Following injury, BMP-2 is released locally into the fracture site from the surrounding bone matrix. BMP-2 expression is further upregulated in differentiating osteoprogenitor cells and MSCs and maintained for about 21 days before returning to normal levels during remodeling [53]. A study by Jeon et al. comparing the long and short term delivery of BMP-2 found that release of bioactive protein over 4 weeks resulted in significantly higher ectopic bone formation and calcium deposition after 8 weeks in vivo than burst release of the same protein dose in 3 days [70]. The results suggest that long term BMP-2 delivery is needed to induce a commitment to the bone phenotype and correlates with previous unsuccessful attempts of bolus growth factor therapy in patients [71].

Discussion of prolonging growth factor retention also highlights the importance of maintaining protein bioactivity over extended periods of time. Although the degree to which protein bioactivity is affected by different methods of growth factor incorporation into the scaffold and carrier sterilization is not comprehensively assessed, studies have shown that encapsulated proteins possess greater stability [72] while modifications to the protein itself may reduce its functionality [8, 73]. Current techniques for evaluating protein bioactivity are limited to in vitro studies with cell lines or ex vivo animal studies with radiolabeled protein, both of which do not provide simple, accurate methods for correlating in vivo growth factor release and biological effect. Kempen et al. investigated a promising non-invasive monitoring method to measure growth factor release and bone formation in vivo using nuclear medicine and radiology techniques [74]. Sequential measurements made with single photon emission computed tomography and micro-computed tomography in association with a scintillation probe setup successfully monitored local retention profiles of radioiodinated BMP-2 (125I-BMP-2) and bone formation in ectopic and orthotopic rat models. Additionally, comparison between non-invasive monitoring and ex vivo analysis showed no significant differences in 125I activity and biodistribution after 8 weeks of follow-up. The non-invasive sequential measurement approach may provide superior ways to optimize present and new carrier systems for growth factor delivery.

3.2 Vehicles for Controlled Protein Delivery

Controlled systems have been accomplished using a variety of natural, synthetic and inorganic materials, each with their own advantages and disadvantages. In vivo applications of different growth factor delivery systems are summarized in Table 1.

Table 1.

Selective in vivo applications of inorganic, natural and synthetic carriers for controlled growth factor delivery

| Material | Growth Factor | Carrier | Animal Model | Key Results | Reference |

|---|---|---|---|---|---|

| Titanium | BMP-2 | Heparin/apatite -coated implant | Rat tibial defect | Increased horizontal and vertical bone formation, BMP-2 presence no effect on bone implant contact | [97] |

| β-TCP/collagen | FGF-2 | Injectable composite | Rabbit segmental defect | Complete healing, marrow formation after 12 weeks | [86] |

| CPC | rhBMP-2 | Porous discs | Rabbit subcutaneous implant | Bone formation and vessel ingrowth after 10 weeks, no implant degradation | [92] |

| CPC + GMP | TGF-β1 | Injectable composite | Rabbit femoral defect | Increased bone density and remodeling after 12 weeks, enhanced degradation | [93] |

| Collagen | BMP-2 | Apatite-coated scaffold | Mouse calvarial CSD | Apatite coating prolonged BMP-2 activity, synergistic enhancement of bone formation and mineralization | [126] |

| nHAp/Collagen/PLA | BMP-2 peptide | Composite scaffold | Rat subcutaneous pocket | Dose-dependent ectopic bone formation over 12 weeks, peptide lower osteoinductivity than BMP-2 protein | [125] |

| Gelatin | rhBMP-2 | Hydrogel | Mouse subcutaneous implant | Osteoprogenitor cell recruitment, de novo bone formation higher with sustained release BMP-2 | [178] |

| Fibrin | BMP-2 | Heparin- conjugated hydrogel | Rat subcutaneous pocket | Increased bone formation, ALP activity, calcium deposition compared to controls; complete hydrogel degradation after 8 weeks | [116] |

| Silk Fibroin | BMP-2 | MP | Rat subcutaneous pocket | Bone formation and calcified ECM with only encapsulated BMP-2, osteocalcin present | [152] |

| PLGA | BMP-7 | MP | Osteopenic ovine vertebral defect | Higher compressive modulus and bone volume for slow release BMP-7; no significant results compared to controls | [148] |

| PLLA + PLGA NP | rhBMP-7 | Composite scaffold | Rat subcutaneous pocket | De novo bone formation with mineralized matrix after 3 weeks with sustained rhBMP-7 release | [132] |

| PPF/gelatin + PLGA MP | BMP- 2/VEGF | Composite Scaffold | Rat ectopic/femoral CSD | Woven/lamellar bone formation with BMP-2 delivery only in ectopic site, no significant synergistic VEGF effect | [44] |

| PPF + GMP | BMP- 2/VEGF | Composite Scaffold | Rat cranial CSD | Dual delivery improved defect bridging and healing time, no effect on vessel formation or total bone volume compared to BMP-2 alone | [45] |

| PLDL | rhBMP- 2/rhTGF- β3 | Porous Scaffold | Rat femoral CSD | Incomplete union, but dense mineralized matrix, sufficient integration/mechanical strength compared to controls | [133] |

ALP, alkaline phosphatase; β-TCP, β-tricalcium phosphate; BMP, bone morphogenetic protein; rhBMP, human recombinant BMP; CaP, calcium phosphate; CSD, critical size defect; FGF, fibroblast growth factor; GMP, gelatin microparticle; MP, microparticle; nHAp, nanohydroxyapatite; NP, nanoparticle; PLGA, poly(DL-lactic-co-glycolic acid); PLLA, poly(L-lactic acid); PLDL, poly(L-lactic acid-co-DL-lactic acid); PPF, poly(propylene fumarate); TGF-β, transforming growth factor-β; VEGF, vascular endothelial growth factor

3.2.1 Three-Dimensional Scaffolds

Three-dimensional matrices and porous scaffolds are the most common growth factor delivery systems and have been investigated extensively in both experimental and clinical applications. The development of new carriers for bone regeneration focuses on improving local protein retention and sustained release for enhanced osteoinductivity in vivo. Strategies for growth factor incorporation into scaffolds include either non-covalent (surface adsorption, physical entrapment, affinity binding, ionic complexation) or covalent immobilization on or into the delivery system (chemical conjugation), the selection of which depends on the physicochemical properties and interactions between the growth factor, carrier and defect type [75].

3.2.1.1 Inorganic Materials

Inorganic materials such as ceramics have long been used as hard bone replacements for the benefits of high compressive strength, biodegradability and osteoconductivity, but lack intrinsic mechanisms for controlled delivery. Although physical adsorption of proteins to material surfaces is the simplest method of growth delivery, the loading and release of functional adsorbed molecules can be non-efficient [75]. Ziegler et al. found that rhBMP-2 and recombinant basic FGF displayed time-dependent decreases in bioactivity after adsorption on different inorganic carriers in vitro [76]. Alkaline phosphatase (ALP) activity and cell proliferation in human primary osteogenic sarcoma cells was attributed to the release of unbound, bioactive protein within the first hour of incubation. Cells receiving protein released from carriers 24 hours after adsorption showed no expression of ALP or other osteogenic activity. Therefore, methods to strengthen the immobilization of growth factors to material surfaces or encapsulation within carriers may prolong osteoinductive activity.

Growth factors like BMP and VEGF can be chemically conjugated to the material surface via its primary amine groups using N-hydroxysuccinimide/N-ethylcarbodiimide, N,N-carbonyldiimidazol and reductive amination chemistry [77, 78] or linker molecules like collagen and heparin [79] for prolonged release. Aminosilane chemistry is a common approach for covalent attachment of growth factors to ceramic surfaces like hydroxyapatite (HAp) [80]. Ehlert et al. achieved a five-to-tenfold increase in BMP-2 immobilization using aminosilane linkers on a nanoporous silica coating [81]. Surface modification provides a different method to enhance growth factor binding by changing the surface chemical composition and topology. Biphosphonate-based precipitation and calcium phosphate coprecipitation techniques have shown potential for bone healing by maintaining protein bioactivity and minimizing burst release [82, 83]. Tsurushima et al. developed a FGF-2 release HAp-ceramic buttons capable of promoting bone formation in a round rat craniotomy parietal defect [84]. High and low doses of FGF-2 were precipitated onto the buttons after immersion in supersaturated calcium phosphate solution. Although the doses of FGF-2 were not optimal, FGF-2 release stimulated in vivo BMP-2, FGF, ALP and osteocalcin activity.

Protein encapsulation can also be performed using composites with ceramics or ceramic derivatives such as calcium phosphate cements (CPC), bioactive glass, HAp and beta tricalcium phosphate (β-TCP) [85, 86]. Ceramic materials provide load bearing [87], retarded delivery [88, 89] and enhanced angiogenic [40, 90] characteristics to natural and synthetic polymeric matrices. CPC composites, in particular, hold great promise in bone tissue engineering applications due to their injectability. CPC can be formulated as an injectable paste that self-sets in vivo which allows for minimally invasive reconstruction of irregular defects without the generation of heat [91]. The delivery of BMP-2 and TGF-β1 in rabbit ectopic, radial and femoral defects from CPC composites have demonstrated an increase in bone formation and remodeling after 8–10 weeks [92–94]. Recent studies with calcium phosphate cement (CPC)/gelatin composite and diopside (CaMgSi2O6) ceramic microspheres show that ceramic microparticle systems can be successfully used as an injectable, biodegradable and osteoinductive delivery vehicles, as demonstrated in Figure 1 [95, 96].

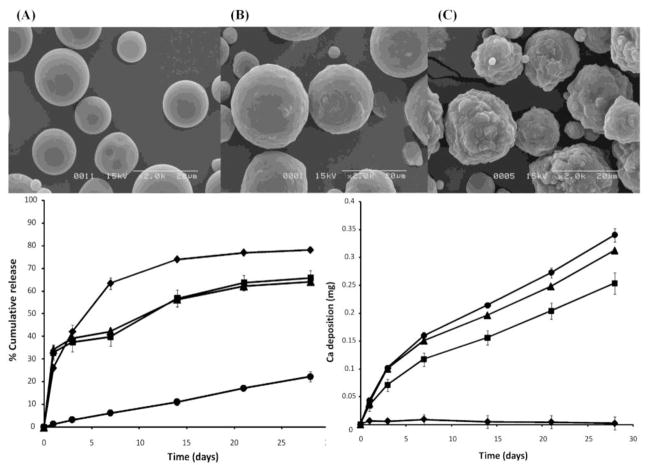

Figure 1.

Scanning electron micrographs of pure gelatin (A), gelatin-10% calcium phosphate (B) and gelatin-40% calcium phosphate microparticle composites (C) and in vitro release (bottom left graph) and mineralization (bottom right graph) characteristics. Composites (■ & ▲) possess bioactive calcifying properties similar to calcium phosphate powder (●) and decreased release rates compared to pure gelatin microparticles (◆). (Reprinted with permission from Leeuwenburgh et al. [95]. Copyright 2010 American Chemical Society.)

Although degradable materials like ceramics are preferred for bone regenerative medicine, tissue engineering principles can be applied to enhance the performance of non-degradable materials. Metals like titanium and stainless steel have been used for many bone applications, but do not possess the clinically desired ability to direct osteoprogenitor function. Common attempts to improve osseointegration and cellular signaling through growth factor delivery involve chemical conjugation with heparin or modification with titanium-binding motifs [97–99]. Surface modification techniques such as plasma spraying, acid-etching, anodic polarization and grit-blasting enhances growth factor binding by changing the surface chemical composition and topology [100–103]. Another surface modification technique is to apply coatings of bioactive polymers and hydrogels that physically entrap molecules against the material surface or within the porous structure to direct osteoinductive cellular function [104–106]. In vivo release profiles of FGF-2 from gelatin microparticles (GMP) embedded in hydroxyapatite-coated titanium nonwoven fabrics (Ti-HAp-GMP) showed less than 15% burst release after one day and more than 60% retention after 7 days in comparison to uncoated Ti and Ti-HAp [107]. Ti-HAp-GMP with bound FGF-2 induced marrow-like bone tissue with mineralization and minor angiogenesis in rabbit skull defects after 6 weeks. Liu et al. achieved ectopic bone formation and ossification in vivo in an ectopic rat model with titanium-alloy discs coated with calcium phosphate and BMP-2 [108]. Osteogenic activity was maintained over 5 weeks with only 60% release of loaded growth factor.

3.2.1.2 Natural Polymers

Polymers of natural origin such as collagen, silk fibroin, hyaluronic acid (HA), starch, fibrin, chitosan and alginate are desirable bone tissue engineering scaffolds due to their biocompatibility, degradability and biomimetic chemical properties. Porous 3D scaffolds, sheets, fibers and other configurations for controlled delivery can be fabricated via freezing, salt-leaching or lyophilization methods. Natural biopolymers provide a signaling ECM-like matrix that facilitates the migration, proliferation and differentiation of osteoprogenitor cells for in vivo manipulation of the regenerative process [109].

As the main protein component of natural ECM, collagen is one of the most investigated natural polymers for tissue engineering scaffolds and its ability for inducing bone formation with delivered growth factors has been well established [110]. Pharmacokinetic and thermodynamic studies show that rhBMP-2 binding to collagen and its isoforms is specific, forming multiple growth factor layers on the collagen surface as a function of proton ion concentration. By modulating the isoelectric point of rhBMP-2 and pH and ionic strength of the carrier solution, increased loading and controlled delivery of BMP-2 for favorable bone induction can be achieved [111, 112]. However, rhBMP-2-soaked collagen sponges, a clinically applied growth factor therapy for bone regeneration, lack sustained release characteristics, exhibiting high burst release and retaining less than 5% protein after a two week time period [113]. Chemical modification of natural polymers with functional groups or linker molecules has displayed improved binding and release. Collagen coupling with perlecan domains, a heparan sulfate proteoglycan, shows equally strong affinity for heparin-binding growth factors such as VEGF, FGF, PDGF and TGF-β as conjugating heparin linker molecules, which have been tested with other biopolymers [114–117]. In a different approach, the growth factor itself can be engineered to increase binding specificity. BMP-2, fused with a collagen binding domain or hexahistidine tag to the N-terminal of the growth factor, shows improved release kinetics and osteogenic activity in vivo when bound to collagen or monoclonal polyhistidine antibody-demineralized bone matrix, respectively [118, 119].

The main challenges affecting the use of natural polymers for scaffolds is their batch-to-batch variability, potential immunogenicity, sterilization-induced inactivation and fabrication costs, especially if they are reconstituted from allogeneic or xenogenic sources. Although purification and recombinant technology has streamlined mass production of biopolymers with defined material properties, the degradation rate and the subsequent growth factor release rate are still difficult to control. Collagen, in particular, is relatively unstable and degrades quickly in the physiological environment due to protease activity. Using more robust natural materials [120, 121], improved crosslinking methods [122, 123] or natural composites with inorganic or synthetic material such as HAp/chitosan/poly(L-lactic acid) (PLLA) or collagen/poly(DL-lactic acid) (PLA) [124–126] can provide greater control over the physical properties. Collagen type I vitrigel, a compact collagen scaffold comprised of vitrified type I collagen fibers, demonstrated enhanced mechanical properties and sustained release of BMP-2 in comparison to collagen type I scaffolds in vitro and in vivo [127]. In a mouse calvarial defect, BMP-2-containing vitrigel showed extensive bone formation and 85% BMP-2 retention after 4 weeks, even though vitrigel and BMP-2-loaded normal collagen scaffold controls experienced similar burst release in the first day. Sustained delivery of BMP-2 was attributed to the dense microarchitecture of the vitrigel scaffold, which deters the rapid degradation of the collagen fibers, thus slowing BMP-2 release. Therefore, modifications in the physical structure or processing of natural polymers can improve their controlled release kinetics.

3.2.1.3 Synthetic Polymers

Synthetic polymers offer great versatility for growth factor delivery due to their simple processing and physical, chemical, and mechanical properties, which can be specifically tailored for different applications. Although there are some issues in terms of inflammatory response, bulk degradation and poor clearance of high molecular weight polymers, rational design and formulation of synthetic materials can provide superior characteristics for controlled delivery of functional protein and bone tissue restoration. Poly(α-hydroxy acids), poly(anhydrides), poly(phosphazenes), poly(ethylene glycol) (PEG), poly(ε-caprolactone) (PCL), poly(propylene fumarate) (PPF), polaxamers, polyurethanes and polyphosphate polymers have all been used as scaffolds for bone tissue engineering [128].

In order to create ECM-mimicking scaffolds capable of tissue ingrowth, synthetic materials require processing to generate uniform and well-distributed porous architectures, which tunes the scaffold degradation rate, mechanical strength and degree of growth factor entrapment. Fabrication techniques such as solvent casting, particulate leaching, freeze drying, thermally induced phase separation, melt molding, phase emulsion, in situ polymerization and gas foaming have all been utilized for scaffold construction [129]. Porous scaffolds created from poly(glycolic acid) (PGA), PLA and its copolymer poly(DL-lactic-co-glycolic acid) (PLGA) have been widely investigated for BMP-2 [130, 131], BMP-7 [132] and TGF-β3 [133] delivery. The primary processing method with those scaffolds is salt-leaching or emulsion freeze drying, which may create irregular, nonuniformly distributed pores that decrease transport and mechanical properties. Sustained released can be obtained through careful design of the pore size, shape and interconnectivity [134, 135]. Supercritical carbon dioxide mixing technology has been used to form PLA scaffolds with controlled porosity and incorporate BMP-2 or VEGF simultaneously in one step [136, 137]. The average pore size was 250 μm and porosity was 70%, as determined by microcomputed tomography. In vivo studies with a VEGF-incorporated PLA scaffold showed increased bone volume and ALP activity 28 days post-implantation in a mouse femur segmental model [137]. Hydrophobic polymers like PPF can be favorable substrates for bone formation as well when processed into porous scaffolds or coupled with micro/nanoparticles for growth factor release. Vehof et al. demonstrated that photocrosslinked and salt-leached PPF scaffolds enhanced bone formation in a rabbit subcritical size cranial defect when coated with TGF-β1 [29]. Kempen et al. reported enhanced bioactivity and ectopic osteoinductivity of BMP-2 when it was released from PLGA microsphere-PPF composites than gelatin hydrogels or microsphere/gelatin hydrogels [72]. The in vivo release profile showed an S-shaped curve over 84 days in a rat subcutaneous model.

Since extended release of growth factors has shown to be more beneficial for osteogenic efficacy, synthetic polymer blends and other scaffold configurations such as films, mats and meshes have also been studied to provide additional control over the release kinetics. Electrospinning is a technique which creates fibrous scaffolds and films through electrostatic repulsion of liquid polymer solutions using a high-voltage source. The nano/micron-sized fibers, reminiscent of ECM collagen fibers, are suitable for cell attachment and growth. Their orientation and geometries for growth factor release can be controlled by collecting the extruded fibers on various static or rotating plates. Sahoo et al. demonstrated that at least one week of sustained basic FGF release with both blended electrospun and coaxial electrospun PLGA scaffolds upregulated ECM protein gene expression in bone marrow stromal cells [138]. Electrospun PLGA-HAp composite scaffolds incorporating BMP-2 showed sustained release and complete bone healing in nude mice tibial defects over 6 weeks [139]. Similarly, PCL-PEG electrospun scaffolds displayed core-shell pore size-dependent release of rhBMP-2 in a rat cranial defect for 8 weeks [140]. The advent of computer-aided design strategies such as solid free form fabrication, application solvent technology and fused deposition modeling have provided additional methods for altering carrier morphology. Rapid prototyping technology enables the fabrication of reproducible scaffolds with precisely controlled geometry for complex shapes as well as manipulation of scaffold surface properties and bioactive factor incorporation to direct desired biological activities [141–143].

3.2.2 Encapsulated Growth Factor Carriers

Since growth factors suffer from rapid degradation, encapsulation within a biomaterial vehicle can provide protection from enzymes and increased protein retention at the target site. Additionally, controlled dosing prevents unwanted cytotoxic and inflammatory effects from superphysiological doses as well as ectopic bone formation, problems encountered by direct administration of protein [144]. The release kinetics of particulate carrier systems are ultimately determined by the rate of carrier degradation, loaded amount of protein, protein diffusion, particulate size and if applicable, the particulate crosslinking extent.

Synthetic polymers such as poly(α-hydroxy acids), poly(orthoesters), poly(anhydrides), poly(amino acids) and copolymers of lactic and glycolic acid have been used for encapsulated delivery for their tunable physicochemical properties. Studies have shown that the release profile of rhBMP-2 from PLGA microparticles is affected by the molecular weight, lactic to glycolic acid ratio, end-group functionalization, and dose of incorporated growth factor. In vivo studies have demonstrated that PLGA microparticles prolonged retention and release of rhBMP-2 and rhBMP-7 to sufficiently bridge rat and ovine critical size cranial defects, respectively [145–148]. The release kinetics were affected greater in vitro by the functionalization of acidic moieties to PLGA end groups, which accelerated the degradation of the carrier, resulting in premature release of encapsulated protein and sub-optimal bone formation. Copolymerization of PLGA with other polymers has been examined to prevent inflammatory response and loss of BMP-2 bioactivity. Poly(ethylene glycol) (PEG)-PLGA diblock copolymers and PLGA-HAp composites were found to be more biocompatible without affecting encapsulation efficiencies and rates of release [149, 150].

Natural carrier materials have also been used for delivering bone growth factors due to their protein affinity and mild processing conditions. Gelatin, silk fibroin and glycidyl methacrylated dextran-PEG microspheres have all been used to efficiently deliver functional BMP-2 in vitro and in vivo [151–153]. One problem concerning naturally derived materials is the poor mechanical stability under physiological conditions, resulting in inadequate protein retention. Employing composite materials or chemical crosslinking methods can also provide the necessary physicochemical properties. In vivo studies with chitosan-alginate or chitosan-collagen microparticles showed enhanced bone formation when delivering Nel-like molecule 1 or TGF-β1 in rat defect models, respectively [154, 155]. Chan et al. fabricated injectable collagen microspheres using a modified emulsion and self-assembled reconstitution process that provided dose-dependent growth factor release based on the degree of photochemical crosslinking [156].

There is continuous effort in developing strategies to precisely control carrier degradation and the growth factor release rate though the incorporation of particulate systems into scaffolds and use of sub-micron particles. VEGF-alginate microparticles incorporated into chitosan and uncapped end group PLA scaffolds exhibited lower burst release and prolonged VEGF release in comparison to microparticle-uncoated chitosan scaffolds and microparticles separately [157]. Niu et al. achieved similar retention rates in vitro using porous nanohydroxyapatite/collagen/PLA scaffolds with chitosan microparticles encapsulating a BMP-2 synthetic peptide [124]. A different method that requires no external scaffold involves the fusion of PLGA microspheres into modular 3D scaffolds using dichloromethane vapor. Release studies of IGF-1 and TGF-β1 in the fused microsphere scaffolds show promise in spatially and temporally releasing multiple growth factors for tissue engineering applications [158]. Submicron and nano-sized particles (NP) for controlled delivery hold several advantages over microparticle carriers in terms of surface functionality due to scaling effects in their physicochemical properties [159, 160]. Increased growth factor encapsulation efficiency is achieved through encapsulation of proteins with the particles and grafting of proteins on the surface [161]. For bone tissue engineering applications, although nanoparticles alone can provide sustained and even sequential release in vitro [162, 163], their incorporation into a scaffold or hydrogel matrix can modulate the kinetic properties for improved repair [164, 165]. Chung et al. developed a heparin-functionalized NP/fibrin gel complex for the release of low doses of rhBMP-2 in a rat critical size calvarial defect [165]. In vivo results showed the efficacy of the BMP-2 heparin-NP/gel complex for higher defect closure, bone density and alkaline phosphatase activity over 4 weeks in comparison to controls, demonstrating that NP-based systems can induce bone regeneration with prolonged release of minimal amounts of growth factor. The main consideration with using nanoparticulate systems is that the increased surface-to-volume ratio leads to higher initial burst release.

The harsh processing conditions and low loading efficiencies of particulate systems have led to the development of lipid-based vehicles for growth factor delivery. Lipid-based carriers are well-established for gene and drug therapy for their abilities of injectable, targeted delivery, biocompatibility and ease of fabrication. The efficacy of loading and dosing depends on the composition and interaction of the drug, liposome and accompanying shells/matrices [166–168]. In a study by Haidar et al., single administration of hybrid core-shell nanoparticles consisting of cationic liposome core and self-assembling layer-by-layer anionic alginate and cationic chitosan for slow release of rhBMP-7 induced bone formation in a rabbit distraction osteogenesis model [169]. Another group obtained sustained release of bioactive BMP-2 over 2 weeks using a lipid-based microtubule system that modulated release through hydrolysis of the microtubule ends [170]. Both studies demonstrate that lipid-based carriers have potential as injectable carriers for localized delivery; however, further investigations are required to assess if growth factor release can be sustained for a physiologically relevant timeframe for full bone regeneration.

3.2.3. Hydrogels

Controlled delivery of growth factors to a bone defect can also be achieved with the release from a hydrophilic hydrogel network, which is dependent on the physicochemical properties of the polymer structure and bioactive factor, type and density of crosslinker and target release kinetics. Drug loading for hydrogels is achieved via physical entrapment, either with drug absorption post-fabrication or in situ encapsulation, with ligands with specific affinity for the active agent or with tethering of metabolically cleavable linker molecules [171]. Both synthetic and natural materials have been used as hydrogel carriers of osteoinductive factors including gelatin [172], alginate [122, 173], fibrin [116], hyaluronic acid [174] and PEG-based polymers [175]. All provide a tissue-compatible substrate for cell attachment and growth while delivering functional proteins in a predictable and controlled manner over time.

For many hydrogel systems, biomolecule release occurs through the diffusion of molecules as a function of porosity, degradation or the swelling of the hydrogel network. Hydrogel permeability and swelling can be precisely controlled by using ionic, physical (UV radiation, thermal) and covalent crosslinking (glutaraldehyde, carbodiimide, acrylate/thiol chemistry) methods. Stable HA and alginate gels have been fabricated in a mild and efficient manner using photocrosslinking techniques. Patterson et al. fabricated slow, intermediate and fast-release glycidyl-methacrylated HA (HA-GMA) hydrogels by modulating the degree of interchain crosslinks with increasing concentrations of HA-GMA or adding 1-vinyl-2-pyrrolidinone as a co-monomer [176]. The release rate of BMP-2 directly correlated with the hydrolysis of the ester linkages of the crosslinks, which was confirmed by gel permeation chromatography analysis. Growth factor release from chemically crosslinked gelatin has shown similar kinetics for BMP-2 in vivo. Studies in a rabbit segmental defect and mouse subcutaneous implantation model suggest that there is an optimum hydrogel water content and crosslinking density for synchronized delivery and bone formation [177, 178].

The main challenge with diffusion- and swelling-dependent release mechanisms is that increased crosslinking extent reduces cytocompatibility and effective control over small biomolecules and proteins. Additionally, the release kinetics are influenced by the mode and rate of hydrogel degradation, hydrogel-protein interaction and inclusion of multiple phases (polymers or particulate carriers) or cleavable sequences within the network. Therefore, chemically-controlled growth factor delivery may be a better mechanism in order to provide reproducible release profiles from hydrogels [171]. A variety of chemically-dependent release systems have been developed with PEG-based hydrogels due to their biocompatibility, hydrophilicity and versatility in tailoring their physicochemical properties. Introducing hydrolytically or enzymatically cleavable functional units along to the PEG backbone can impart specific degradation characteristics for protein delivery. Copolymerization of PEG with PLA, PGA or chemical intermediaries with end-capped acrylate or sebacic acid acrylate groups can produce crosslinkable and degradable hydrogels with labile ester bonds [179–182]. The delivery of BMP-2 with oligo(poly(ethylene glycol) fumarate) (OPF), a copolymer of PEG and fumaric acid, and PEG-PLA has been examined in vitro [183] and in vivo for bone and soft tissue formation [184, 185]. BMP-2 efficacy for bone remodeling and healing can be synergistically enhanced by incorporating proteolytic peptides susceptible to matrix metalloproteinases or plasmin [186, 187] or providing topographical or peptide cues to stimulate specific cellular responses [188–190].

3.2.4 Stimulus Responsive Polymers

The success of sustained growth factor release at therapeutic concentrations for controlling cellular function and tissue regeneration has been demonstrated in aforementioned studies. However, few systems have addressed the cooperative biological signaling events of cells as a function of the changes in their dynamic microenvironment. Incorporating stimulus-responsive elements into growth factor delivery vehicles is one biomimetic strategy to obtain specific growth factor release triggered by selective physical, biochemical and external stimuli [191].

Temperature and pH-sensitive polymers are among the most widely investigated physical stimulus-responsive materials and can be combined to form dual-responsive delivery systems. Poly(N-isopropylacrylamide) (PNiPAAm) [192–194], poly(organophosphazenes) [195], PEG-based di/tri block copolymers [196], PCL [197] and their derivatives as well as biomimetic materials like chitosan, dextran and elastin-like peptides [198, 199] undergo a reversible phase transition at the lower critical solution temperature, which can be exploited for drug delivery in physiological conditions. Release of molecules from pH-dependent carriers like poly(acrylic acid) relies on the reversible volumetric swelling and deswelling of acidic and basic pendant groups. Kim et al. developed a pH-and thermosensitive hydrogel for BMP-2 delivery by adding pH-sensitive sulfamethazine oligomers (SMO) end groups to thermosensitive block copolymer made of poly(ε-caprolactone-co-lactic acid) (PCLA) and PEG units [200]. SMO-PCLA-PEG-PCLA-SMO hydrogels displayed functional BMP-2 activity over a narrow pH and temperature range, leading to elevated ALP activity and mineralization over 7 weeks in vivo. Although the release kinetics and local BMP-2 concentration were not measured, the study demonstrates that carrier systems can be designed for controlled release in specific environmental conditions; conversely, environmentally triggered systems also can be manipulated to improve growth factor retention during long term storage.

Biochemically triggered release of growth factors can be achieved through incorporation of cleavable peptides for enzymatic degradation. Matrix metalloproteinase (MMP) peptide crosslinkers confer proteolytic sensitivity to synthetic and natural hydrogels for synchronized tissue remodeling and hydrogel degradation [201–203]. MMP-sensitive PEG and HA hydrogels with BMP-2 delivery both showed improved bone regeneration in rat calvarial defects [186, 202]. Alternatively, enzyme-cleavable peptides can be used to attach proteins and prodrugs for delayed release and activation in response to cell infiltration [204, 205].

Although drug delivery in response to magnetic, ultrasound, irradiation and electric stimuli has shown promise, the delivery of growth factors and proteins via external triggers for bone tissue engineering remains limited to experimental trials. Magnetic biohybrid scaffolds formulated from collagen-based scaffolds dip-coated in aqueous ferrofluid particles or crosslinked with magnetite nanoparticles have been investigated as novel delivery vehicles. Growth factor loading is accomplished through absorption onto the particle surface and guided into the scaffold with an externally applied magnetic field [206, 207]. The primary strength of the approach is the ability to control reloading and spatiotemporal release of different proteins from an external source after implantation in vivo, allowing for creation of desired growth factor gradients and long term sustained release. Additionally, preliminary in vitro studies suggest that the magnetic scaffolds and their degradation byproducts are biocompatible. However, the influence of the magnetization on osteogenic differentiation as well as magnetization stability for the duration of the tissue repair process has not been thoroughly examined.

3.2.5 Multifunctional Delivery Platforms

Biomimetic strategies capable of orchestrating the appropriate time, concentration and spatial profiles of growth factors and other signaling molecules with target cells and ECM may enhance and accelerate effective tissue repair. Although the multitude of signaling mechanisms of the wound healing response is not fully elucidated, the current understanding suggests that the delivery of single proteins inadequately stimulates endogenous repair mechanisms. Numerous studies in both humans and murine fracture models show that expression of various bioactive factors at the site of injury is tightly regulated during the fracture healing and subsequent remodeling periods [15]. The immediate injury response (hours to 3 days) is marked by the release of pro-inflammatory cytokines and growth factors such interleukin (IL)-1, IL-6, TNF-α, FGF, PDGF and TGF-β1 from the systemic circulation and inflammatory cells, initiating the signaling events for matrix deposition and progenitor cell recruitment. Secretion of other growth factors including BMPs, GDFs, IGFs, TGF-βs and angiogenic molecules from MSC and osteoprogenitor populations occurs in the later phases of fracture healing (5–21 days) and returns to normal levels during remodeling. Although certain growth factors like GDF-5 and GDF-10 or VEGF may not play a direct regulatory role in osteogenesis like BMPs (as earlier described), they aid in cartilage mineralization during endochondral bone formation and induction of new vessels, respectively. Reviews by Dimitriou et al. and Tsiridis et al. provide further detail into the temporal expression of the growth factors involved in fracture healing [53, 208].

Therefore, local administration of multiple growth factors with the proper spatiotemporal kinetics may enhance functional tissue restoration with lower doses of loaded protein. Designing carriers capable of pre-programmed release of multiple factors as well as regulating cell activity remains a challenge. Key growth factors and their appropriate combinations and dosing for promoting specific regenerative responses remain unclear [209]. Controlled multiple growth factor delivery and its effects on tissue regeneration remains a strong area of research in tissue engineering.

3.2.5.1 Simultaneous and Sequential Delivery

One strategy for multiple growth factor release involves simultaneous delivery of two growth factors locally to a defect. Since individual growth factors possess different functions depending on the target tissue, the appropriate combination of growth factors may act cooperatively to regulate complete tissue formation. Richardson et al. reported the first dual delivery system consisting of a PDGF-encapsulated PLGA microsphere and VEGF-incorporated PLGA scaffold composite for angiogenesis [210]. Dual delivery of PDGF and VEGF demonstrated enhanced blood vessel density and maturation in comparison to bolus administration of VEGF or PDGF alone in a subcutaneous pocket model. The synergistic effects of dual growth factor delivery have been further examined in vitro and in vivo with other particulate scaffold composites for numerous tissue engineering applications including bone (BMP-2 with VEGF, TGFβ-3 or IGF-1) [45, 211–213] and cartilage formation (IGF-1 and TGFβ-1) [214]. Embedding multiple growth factors in charged polyelectrolyte films on scaffolds or beads using layer-by-layer technology can also provide controlled release via hydrolytic degradation of the multilayer coat [215, 216]. Using another technique, Choi et al. achieved dual release of BMP-2 and dexamethasone from PLGA-core/alginate-shell microcapsules fabricated with coaxial electro-dropping [217]. The temporal release of each component in the injectable system was regulated based on their location (shell or core) within the capsule.

Studies have shown that sequential and spatiotemporal release may lead to improved tissue regeneration by providing physiologically relevant release profiles and spatial gradients that mimic the natural healing response. Various composite systems have been developed to recapitulate the early expression of angiogenic factors and subsequent upregulation of osteogenic factors of bone healing in vivo by releasing VEGF and BMP-2 at different rates; however, enhanced bone formation has only been achieved in ectopic, but not orthotopic models. Initial BMP-2 and VEGF release studies by Patel et al. and Young et al. using GMP-loaded PPF scaffolds found that bone formation in a rat calvarial CSD was BMP-2 dose-dependent [45, 218]. There were significant beneficial effects of VEGF on bone regeneration in the presence of BMP-2 at 4 weeks, but not 12 weeks, as seen in Figure 2. In a separate study by Kempen et al., suboptimal bone formation was found in a rat femoral defect with sequential release of VEGF and BMP-2 from PLGA microsphere-loaded PPF scaffold-gelatin hydrogel composites over 8 weeks [44]. The lack of long term VEGF impact suggests that VEGF action occurs in the early stages of healing and may be inhibited by the large initial burst effect of the system or inherent vascularity of the model. In contrast, current understanding of the angiogenesis as a part of fracture healing indicates that VEGF acts in the late stages of healing prior to remodeling, while PDGF and angiopoietin (1–2) are upregulated immediately after injury [53, 208]. Manipulating VEGF release to achieve the appropriate temporal expression or in conjunction to early release of other angiogenic molecules may improve the synergistic effects of VEGF-BMP-2 for augmenting bone regeneration for extended periods of time.

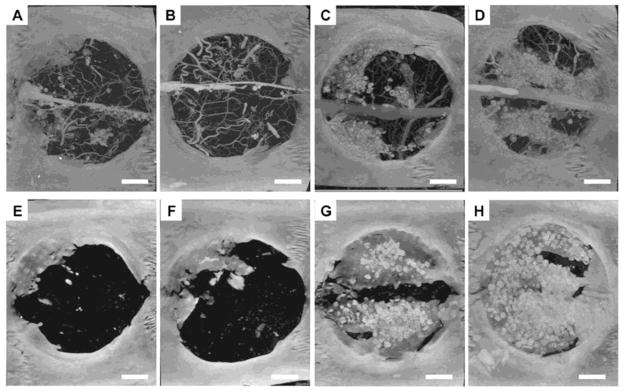

Figure 2.

Microcomputed tomography images of bone regeneration in rat calvarial critical size defect at 4 (top row) and 12 (bottom row) weeks with no growth factor delivery (Panels A & E), VEGF delivery only (Panels B & F), BMP-2 delivery only (Panels C & G) and VEGF/BMP-2 dual delivery (Panels D & H). Bone formation with dual delivery is higher at 4 weeks and comparable at 12 weeks to BMP-2 delivery alone. Scale bar represents 200 μm. (Reprinted with permission from Patel et al. [45])

Sequential release of BMP-2 and BMP-7 has also been investigated with nanocapsules of PLGA and poly(3-hydroxybutyrate-co-3-hydroxyvalerate) and PLGA scaffolds loaded with poly(4-vinyl pyridine)/alginic acid polyelectrolyte microspheres [164, 219]. For both studies, suppressed proliferation of rat MSCs occurred with early release of BMP-2 and later release of BMP-7, indicating increased osteogenic activity, but ALP activity varied. The differing results indicate that the correct growth factor combinations, animal models and carrier properties greatly affect osteogenic differentiation and should be considered when designing delivery systems.

3.2.5.2 Spatially Controlled Delivery

Another factor to account for is the spatial presentation of growth factors to mimic the natural concentration gradients in living systems. Spatially controlled growth factor delivery provides topological cues for cell infiltration and differentiation. A promising approach for osteochondral defects was developed by creating linear gradients of rhBMP-2 and rhIGF-1-incorporated silk fibroin microspheres immobilized in a 3D porous silk scaffold [220]. To prepare single growth factor gradient scaffolds, a gradient maker concurrently eluted silk solution with decreasing volumes of a separate growth factor-loaded microparticle solution into a cylindrical glass mold. Sodium chloride particles were added with the solution mixtures and leached to create porous scaffolds. Reverse gradients were created by adding a different growth factor-loaded microparticles in the silk solution and following the same experimental protocol. Simultaneous release of encapsulated rhBMP-2 and rhIGF-1 promoted osteogenic and chondrogenic differentiation of hMSCs over 5 weeks along the gradients. Multilayered scaffolds are a unique platform that enables multiple growth factor delivery through incorporation of different phases into scaffolds for differential release kinetics. However, multilayered scaffolds can also employ spatially controlled release of bioactive factors to engineer interfacial tissues for orthopedic applications. For example, the cartilage-bone interface between the hyaline cartilage layer and underlying bone consists of separate zones with distinctive ECM composition and mechanical properties [221]. Holland et al. developed a bilayered OPF hydrogel with a bottom bone-forming layer and a top cartilage-forming that incorporated TGF-β1 and IGF-1 to mimic the structure of rabbit osteochondral defects [222]. Although no synergistic effects for cartilage formation was observed from the growth factor combination in vivo, TGF-β1 and IGF-1 were released at different rates only to the cartilage-forming layer. Analogously, bilayered OPF hydrogels developed by Guo et al. demonstrated enhanced chondrogenic differentiation of encapsulated rabbit MSCs in vitro with delivery of TGF-β1 or TGF-β3 in the chondrogenic layer and co-culture with pre-differentiated osteogenic cells in the lower bone-forming layer [223, 224].

3.2.5.3 Platelet-Rich Plasma

An alternative, yet controversial approach for delivering effective combinations of growth factors for tissue is the use of platelet-rich plasma (PRP), an autologous plasma product enriched with growth factor and protein reservoir units like PDGF, VEGF, IGF and TGF-β. PRP preparation involves platelet activation with commercially available bovine thrombin or more immunocompatible substances like calcium chloride, thrombin receptor activator peptide-6 or sodium citrate, as discussed in other reviews [225]. PRP shows promise for bone tissue repair via controlled delivery from hydrogels and scaffolds in conjunction with cells or BMP or as a carrier material for other growth factors and proteins [226–230]. However, the full range of PRP’s benefits is unknown and has shown variable results in clinical settings and experimental studies. Kretlow et al. demonstrated that the inclusion of rat PRP to uncultured bone marrow mononuclear cells within a fibrin glue-scaffold hybrid construct had no effect on cell differentiation or bone formation in a rat calvarial CSD [231]. Although the use of fibrin glue may have influenced PRP function, successful bone regeneration was ultimately dependent on the presence of cells and scaffold material.

4. Cell Therapy

Cellular regenerative strategies offer a different means to recapitulate the bone healing process by providing cell populations that directly participate in the assembly of new tissue and secrete trophic factors to regulate local cellular activity for augmented repair. Biomaterial carriers for controlled delivery of cells function similarly to those for growth factor delivery, in which they act as targeted carriers for delivery as well as supportive ECM-like substrates for cell adhesion, migration and growth. Additional criteria for cell delivery technologies include carrier permeability, biocompatibility and biodegradability to maintain the viability of cells during administration and for the duration of the regenerative process [14]. MSCs, the main source of cells for bone tissue engineering applications, are exempt from most of the ethical and supply concerns with other cell types, making them ideal for cell therapy. Additionally, MSCs possess the ability to differentiate down the osteogenic lineage with high proliferative potential in vitro. There are four primary approaches for engineering MSC-based cell delivery systems with enhanced osteoinductive capacity: 1) delivery of cells within an injectable or prefabricated scaffolds 2) pre-culture/co-delivery of cells with osteoinductive growth factors or co-culture with other cell types, 3) delivery of cellular or acellular bioreactor cultured scaffolds and 4) delivery of genetically modified cells for expression of osteogenic genes. Experimental results for the different approaches of cell delivery systems in vivo are shown in Table 2.

Table 2.

In vivo applications of cell therapy for bone tissue engineering

| Mode of Delivery | Cell type | Animal model | Key Results | Reference |

|---|---|---|---|---|

| CaP-coated titanium scaffold | RMBC | Rat subcutaneous pocket | Supported RBMC attachment and proliferation; no ectopic bone formation | [288] |

| Gelatin/alginate scaffold | rBMSC | Mouse subcutaneous implant | Observed cell attachment and neovascularization; suppression of differentiation markers despite predifferentiation | [232] |

| CPC/alginate scaffold | rBMSC | Rat calvarial CSD | Scaffold directed osteogenic differentiation of cells, bony tissue observed after 6 weeks | [236] |

| MPEG/PCL hydrogel | rBMSC | Rat subcutaneous implant | Dexamethasone dose-dependent differentiation and bone formation; little cell migration from center to periphery | [197] |

| PEG-MMP hydrogel | rBMSC/BMP-2 | Rat calvarial CSD | Bone formation greater in scaffold-BMP-2 groups; undifferentiated rBMSCs had no/inhibitory effect on osteoinduction | [186] |

| ECM-titanium mesh (acellular) | rBMSC | Rat subcutaneous implant | Tissue response of pregenerated ECM-Ti similar to plain Ti; no bone formation, but some vascularization observed | [256] |

| ECM-HAp microparticles (acellular) | Rat calvarial osteoblast and dermal fibroblast | Rat calvarial defect | Compared to HAp control, greater integrated bone formation; no complete bridging or difference between types of cell-generated ECM | [289] |

| Cell transplantation | BMP-2/VEGF expressing mouse MSC | Mouse tibial defect | Augmented bone healing, neoangiogenesis and bone strength with dual expressing cells | [265] |

| Collagen disks | BMP-4/VEGF expressing MDSC | Rat intramuscular pocket/calvarial CSD | Cartilage mineralization, capillary ingrowth in ectopic site; increased bone formation, enhanced angiogenesis with less dual expressing cells compared to BMP4 or VEGF alone | [47] |

| PLGA scaffolds | Runx2/Osterix expressing ADSC | Nude mouse subcutaneous implantation | Extensive mineralization and bone formation with individual or dual genes after 6 weeks | [263] |

| Gelfoam | Ex vivo VEGF- transfected fibroblast | Rabbit tibial defect | Accelerated complete bridging, higher vessel density compared to controls | [266] |

ADSC, adipose-derived stem cell; BMP, bone morphogenetic protein; CaP, calcium phosphate; CPC, calcium phosphate cement; CSD, critical size defect; ECM, extracellular matrix; HAp, hydroxyapatite; MDSC, muscle-derived stem cell; MMP, matrix metalloproteinase; MPEG, methoxy poly(ethylene glycol); PCL, poly(ε-caprolactone); PEG, poly(ethylene glycol); PLGA, poly(lactic-co-glycolic acid); rMBC, rat marrow bone cell; rBMSC, rat bone marrow stromal/mesenchymal stem cell; Ti, titanium; VEGF, vascular endothelial growth factor

4.1 Cell-laden Scaffolds

The simplest method for cell delivery utilizes scaffolds to provide the appropriate physical and chemical properties for controlling the cell response without co-administration of exogenous growth factors. A variety of cell-compatible scaffolds have been formulated with natural and synthetic materials [224, 232, 233]. However, injectable ceramic-based composites consisting of CPC and cytocompatible hydrogels may have better potential as effective bone regenerative systems by possessing osteoconductive characteristics for seeded MSCs with the added benefit of injectability for simple cell encapsulation and delivery [234]. Ceramic composite scaffolds consisting of CPC and cytocompatible hydrogels have demonstrated favorable osteoconductive characteristics for seeded MSCs with the added benefit of injectability for simple cell encapsulation and delivery. In one study, rat MSCs cultured on CPC-chitosan composites showed a several-fold increase in ALP activity in comparison to FDA-regulated CPC scaffolds and tissue culture plastic in vitro, indicating lineage-specific differentiation towards the osteogenic phenotype [235]. Another study showed that direct deposition of injectable CPC-alginate solutions formed degradable fibrous scaffolds capable of stimulating porosity-dependent differentiation of MSCs [236]. In vivo implantation of the porous composite scaffolds within a rat critical size calvarial defect showed near complete closing of the defect over 6 weeks. Other injectable materials like thermoresponsive PNiPAAm or microsphere formulations also show some potential for directing MSC differentiation, without possessing any intrinsic osteoinductivity. Klouda et al. demonstrated that PNiPAAm-based constructs were capable of mineralizing in vitro, which may provide osteogenic cues for encapsulated cells [237].

4.2 Co-delivery of Cells with Bioactive Factors

To enhance their osteogenic efficacy, MSCs can be chemically or physically manipulated in vitro to stimulate their differentiation towards a specific lineage prior to scaffold delivery. Most commonly, osteogenic medium with dexamethasone, β-glycerol phosphate and ascorbic acid has been used to enhance osteoblastic differentiation of MSCs ex vivo/in vitro. MSC culture medium can also be supplemented with growth factors like BMPs and TGF-βs for controlling their bone-forming activity. The main problem is that MSC proliferation is greatly hindered by their early induction down the osteogenic lineage, reducing the number of viable cells for delivery. Also, the BMP and TGF-β half life is short, requiring large amounts to maintain the differentiated MSC phenotype. Co-delivery of growth factors and MSCs in various controlled delivery vehicles has been widely investigated, as discussed in earlier sections. Incorporation of growth factors is used to stimulate transplanted cell activity and differentiation as well as recruit undifferentiated osteoprogenitor cells into the carrier. Reciprocally, the cells deposit bone-like matrix to induce bone formation and defect closure. Numerous studies have shown that growth factor and MSC co-delivery possesses regenerative potential in vitro and in vivo [174, 186, 202]; however, it is unclear if the synergistic effects for enhancing bone formation are significant. Recent studies using fluorescent carboxyfluoresceine-diacetate-succinimidyl-ester-labeled MSCs have shown that post-transplant survival after 7 days is very low, suggesting that improved delivery techniques and further understanding is needed for optimal cell efficacy [238]. Co-culture of MSCs with other cell types such as endothelial cells (EC) may address the drawbacks of growth factor-mediated cell differentiation. Cross-talk between different cell types, especially MSCs, osteoblasts and ECs, is vital to the formation of new bone as well as the success of tissue engineered cell constructs due to the need for an adequate blood supply [239]. Additionally, MSC and EC interaction leads to local release of VEGF and osteogenic proteins like BMP-2, respectively, which promote osteoblastic differentiation and angiogenesis. Numerous studies have shown the positive effect of EC co-culture on vascularization of cell-laden scaffolds in vitro and in vivo [240, 241]. Cell proliferation and microvessel-like networks were enhanced in the constructs compared to single cell cultures. Furthermore, MSCs in co-culture experienced higher expression levels of osteocalcin and ALP and higher release of VEGF and BMP-2 in vitro. However, similar to dual VEGF/BMP-2 growth factor delivery, there are mixed results in the beneficial effects of co-culture-induced vascularization on bone formation in vivo. In studies by Sun et al. and Tao et al., MSC/EC co-delivery into rat intramuscular pockets showed significant differences in bone formation and mineralization compared to empty, MSC only and EC only scaffolds [240, 242]. Similar results for improved osteogenesis due to increased vascularity were found in a rabbit segmental defect model [243]. After 12 weeks, porous β-TCP scaffolds consisting of MSCs and MSC-induced ECs achieved complete vascularization. By 16 weeks, full bony union was also complete and 3-point bending tests showed that the mechanical properties of the new bone almost matched that of the original. Koob et al. did not observe the same trends in regenerating mice CSD over 6 weeks with a combination of MSC/HUVEC and processed bovine cancellous bone [244]. Despite significant differences in vascularity, no significant differences were found in bone formation between co-culture and control groups. Further investigation into other cell types such as osteoblasts instead of MSCs [245–248] or different EC sources [249, 250] may provide new understanding of the physical and biochemical aspects of angiogenic and osteogenic cell-cell communication in order to improve co-culture therapy.

4.3 Dynamic Culture of MSCs

Alternatively, cells may be cultured within a dynamic 3D environment in order to mimic the natural transport and biomechanical conditions in vivo. Bioreactors such as spinner flasks, rotating flasks and flow perfusion systems provide engineered fluid stresses for stimulating bone differentiation and mineralization of MSCs [251, 252]. In particular, flow perfusion bioreactor systems better control the shear stresses and uniform transport of nutrients to cell-seeded scaffolds, leading to higher seeding efficiencies, cell attachment and expression of osteogenic markers such as osteopontin, osteocalcin, bone sialoprotein and collagen 1α1 [251, 253]. Even without osteogenic supplements present in the culture medium, flow perfusion culture of rat MSCs on titanium fiber meshes showed increased calcium deposition, osteopontin expression and ALP activity compared to static culture, demonstrating that mechanical stimulation greatly influences the osteoblastic phenotype [254]. A novel bioreactor strategy involves the generation of bioactive ECM coatings on biologically inert scaffolds for the presentation of biological signaling cues for bone regeneration. The mineralized matrix deposited by osteoblasts in vivo plays a large role in mediating bone formation. The native ECM consists of a complex arrangement of collagen, glycoproteins and a variety of osteoinductive factors for promoting cell attachment and matrix mineralization, which cannot be easily replicated in vitro through scaffold, cell or growth factor delivery alone. Initial studies utilizing a combinatorial approach showed that culturing rat MSCs under engineered culture conditions in a flow perfusion bioreactor promoted formation of bone-like ECM coating on titanium meshes. Increased MSC osteogenic differentiation was attributed to the cell-synthesized ECM coating, which rendered the titanium mesh osteoinductive. The pregenerated ECM/titanium scaffolds expressed higher calcium content and ALP activity in comparison to plain titanium mesh in the absence of dexamethasone, which support the bone-forming capabilities of the ECM [255]. However, in vitro generated ECM/titanium constructs showed no observed osteoinductive properties in vivo, due to either the non-degradability of the scaffold, quality of the ECM coating or lack of seeded MSCs to facilitate cell-matrix interaction [256]. Studies on the osteoinductivity of cell-generated ECM coatings on biodegradable materials such as PCL, β-TCP and HAp have shown promise in vitro [257–260]. Acellular pregenerated ECM/HAp microparticles demonstrated cooperative effects for improved, but incomplete bone formation in rat calvarial defect against collagen and HAp controls. This suggests that cell-synthesized coatings may provide synergistic effects to bioactive materials [261].

4.4 Stem Cell-based Gene Therapy

Another method of cell therapy involves the genetic manipulation of cells in vitro to improve their differentiation potential and osteoinductive effect in vivo through the secretion of osteogenic factors. The cells act as an engineered protein factory and overexpress osteogenic genes such as BMP-2, VEGF and LIM mineralization protein-1 and transcription factors, Osterix and Runx2, individually or combinatorially [32, 262, 263]. Transduced MSCs derived from bone marrow, fat and muscle cells have all shown bone forming abilities in numerous studies [47, 264–266], without apparent differences in efficacy between the cell types [267]. In vitro studies have suggested that stem cell-based gene therapy has superior osteogenic potential over exogenous growth factor delivery. Meinel et al. found that adenovirus-BMP-2 transduced hMSCs expressed higher levels of osteogenic proteins than BMP-2 delivery following the same temporal profile [268]. A potential problem of stem cell-based gene therapy is the overexpression of growth factors, leading to unwanted ectopic or heterotrophic bone formation. Incorporating inducible promoters with osteogenic genes provides an ON-OFF pharmacologically-modulated system for regulating therapeutic transgene expression. Tetracycline (Tet) and rapamycin regulatable systems for controlling gene expression will be discussed in the next section.

5. Gene Therapy

Gene therapy offers an alternative means to achieve controlled delivery of protein for bone regeneration through the transfer of nucleic acids to somatic cells for sustained therapeutic expression of osteoinductive factors. The advantage of this approach over protein therapy is that appropriate concentrations of functional growth factors are produced stably at the site of interest to regulate cell activity. There are two main gene therapy strategies for bone repair. As discussed earlier, stem-cell based gene therapy involves the delivery of ex vivo genetically engineered cell populations that act as the carrier for therapeutic genes. A more straightforward approach is to use direct gene therapy, in which therapeutic genes are delivered directly in vivo via viral or nonviral vectors. The efficiency of direct gene therapy for bone repair has been demonstrated with different vectors in various animal models [269]. Table 3 describes select in vivo studies of gene therapy for bone tissue engineering.

Table 3.

In vivo applications of gene delivery vectors for bone tissue engineering

| Mode of Delivery | Gene | Animal Model | Key Results | Reference |

|---|---|---|---|---|

| Adenovirus/silk scaffolds | BMP-7 + rBMSC | Mouse calvarial defect | Bone deposits within pores, enhanced expression of osteogenic markers; no effect with transduced BMSC | [283] |

| Adenovirus/gelatin sponge | BMP-2 | Rat calvarial CSD | Two-fold increase in bone area and volume fraction compared to AdBMP-2 alone | [281] |

| Adenovirus | VEGF-A | Rat femoral defect | Accelerated bone healing and increased, but unorganized vessel formation | [42] |

| Adeno-associated virus | BMP-2 | Rat intramuscular injection | Local gene transduction, mature bone formation with AAV- BMP-2 delivery compared to controls | [270] |

| Moloney leukemia virus | LMP-1 | Rat femoral defect | Increased bony union and mineral deposition without heterotopic bone formation compared to BMP-4 delivery | [262] |

| Murine leukemia virus | Cox-2 | Rat femoral defect | Complete fracture healing in 21 days with persistent Cox-2 expression; no ectopic bone formation observed | [290] |

| Plasmid GAM | VEGF | Rabbit radial CSD | Enhanced bone and vessel formation after 12 weeks; response leveled off with higher VEGF concentrations | [37] |

| Cassette vector/electroporation | BMP- 2/BMP-7 | Rat intramuscular injection | Compared to controls, calcified, bone-like tissue after 10 days with dual delivery | [274] |

| Nucleofected hMSCs | hBMP- 2/hBMP-9 | Mouse intramuscular injection | Mature bone formation with transient expression of transgenes, hBMP-9 higher osteoinductivity than hBMP-2 | [275] |

| Plasmid/sonoporation | rhBMP-9 | Mouse intramuscular injection | Moderate ectopic bone formation over 5 weeks, less comparable to electroporation in same model | [276] |

Ad, adenovirus; AAV, adeno-associated virus; BMP, bone morphogenetic protein; Cox-2, cyclooxygenase-2; CSD, critical size defect; GAM, gene-activated matrix; hBMP, human BMP; hMSC, human mesenchymal stem cell; LMP-1, LIM mineralization protein-1; rhBMP, human recombinant BMP; VEGF, vascular endothelial growth factor