Abstract

Botulinum neurotoxins (BoNTs), composed of a family of seven serotypes (categorized A – G), are the deadliest of known biological toxins. The activity of the metalloprotease, light chain (LC) component of the toxins is responsible for causing the life-threatening paralysis associated with the disease botulism. Herein we report significantly more potent analogs of novel, lead BoNT serotype A LC inhibitor 2,5-bis(4-amidinophenyl)thiophene (Ki = 10.88 μM ± 0.90 μM). Specifically, synthetic modifications involved simultaneously replacing the lead inhibitor’s terminal bis-amidines with secondary amines and the systematic tethering of 4-amino-7-chloroquinoline substituents to provide derivatives with Ki values ranging from 0.302 μM (± 0.03 μM) – 0.889 μM (± 0.11 μM).

Keywords: Bioterrorism, Botulinum neurotoxin, Inhibition

1. Introduction

Botulinum neurotoxins (BoNTs), a family of seven serotypes (categorized A – G), are secreted by Clostridia species botulinum, baratii, and butyricum [1, 2], and are listed among the highest priority of bioterrorism agents [3].

The enzymes are composed of a 100 kDa heavy chain (HC) and a 50 kDa light chain (LC), which are tethered by a reducible disulfide bridge [4, 5]. The HC binds to neuronal receptors and releases the LC into the cell cytosol [5–7]. The LC, a zinc2+ (Zn2+) metalloprotease, cleaves neuron soluble N-ethylmaleimide-sensitive fusion protein attachment protein receptor (SNARE) proteins [6, 7]. This proteolytic activity inhibits the release of acetylcholine into neuromuscular junctions, resulting in the disease state botulism [6, 7]. The BoNT serotype A LC (BoNT/A LC), which is the target enzyme of this study, cleaves SNARE protein synaptosomal associated protein of 25 kDa (SNAP-25) [6, 7], and is known to cause human botulism [8, 9].

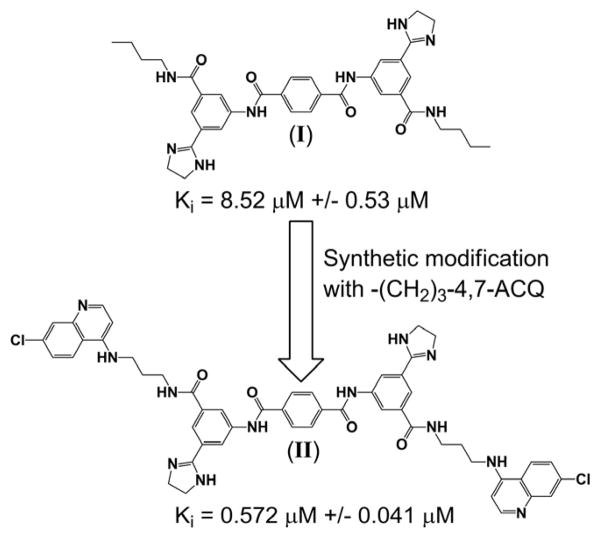

We have previously reported the discovery of a variety of non-Zn2+ chelating BoNT/A LC lead inhibitor chemotypes [10–15], many of which possess terminal di-cationic moieties [11–14]. With respect to di-cationic inhibitors, the synthesis of more potent derivatives of leads possessing bis-amidine and bis-imidazoline functional groups has been described [16–19]. Importantly, the synthetic modification of one of these leads, bis[3-amide-5-(imiazolino)phenyl]terephthalamide-based inhibitor I (Ki = 8.52 ± 0.53 μM) [18] (Figure 1), via the incorporation of terminal -(CH2)3-4,7-ACQ components, resulted in derivative II (Figure 1), which possesses a Ki = 0.572 μM ± 0.041 μM [18]. To the best of our knowledge, II is the most potent, non-hydroxamic acid-based BoNT/A LC inhibitor reported to date.

Figure 1.

Adding -(CH2)3-4,7-ACQ components translated lead BoNT/A LC inhibitor I into nM-range derivatives, II was the most potent of the congeneric series [18].

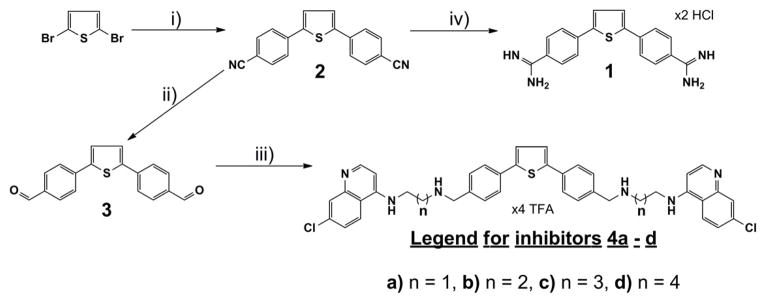

As part of an ongoing research program to discover novel BoNT/A LC inhibitor chemotypes for development, a variety of di-amidine substituted compounds obtained from the National Cancer Institute’s Open Repository were screened. Subsequently, 2,5-bis(4-amidinophenyl)thiophene 1 (NSC 300510) (Scheme 1) was found to provide 78% BoNT/A LC inhibition when tested at 20 μM concentration. Following, 1 was synthesized to ensure purity, and subsequent in vitro testing indicated that it possesses a Ki = 10.88 μM ± 0.90 μM (Table 1).

Scheme 1.

Reagents and conditions. i) 4-CN-PhB(OH)2, Pd(OAc)2, DME, Na2CO3(aq), MW, 80°C, 2h; ii) DIBAH, PhMe, 1h, 0°C, Ar; iii) (step 1) NH2-(CH2)n-4,7-ACQ, NaBH4, AcOH, MeOH/CH2Cl2 and (step 2) TFA; iv) (step 1) LHMDS, THF, r.t. and (step 2) HCl/EtOH.

Table 1.

BoNT/A LC inhibition constants for lead 1 and derivatives 4a – d.

| Inhibitor Ki (μM) |

|---|

| 1 10.88 ± 0.90 μM |

| 4a 0.882 ± 0.11 μM |

| 4b 0.302 ± 0.03 μM |

| 4c 0.535 ± 0.60 μM |

| 4d 0.889 ± 0.11 μM |

Interestingly, 1 has previously been shown to possess anti-trypanosomal activity [20, 21], and provided 100 % survival when administered as a single, 320 mg/kg dose during Trypanosoma rhodesiense infection [21]. Additionally, 1 has been analyzed for antineoplastic activity, and based on a dosing regimen of three 100 mg/kg injections (administered on day one, and then every fourth day) was non-toxic to mice [22].

Therefore, based on the possibility of repurposing a biologically relevant chemotype, 1 was chosen as a candidate for synthetic modification to provide derivatives with increased BoNT/A LC inhibitory potencies. Specifically, based on the strategy used to increase the inhibitory potency of lead I (Figure 1) [18], it was hypothesized that systematically tethering terminal 4,7-ACQ motifs to 1 with short methylene chains would also provide significantly more potent derivatives.

2. Chemistry

Initially, we attempted to substitute -(CH2)n-4,7-ACQ components directly onto the terminal amidines of 1. However, as previously encountered when attempting the same amidine substitution with a different BoNT/A LC inhibitor chemotype [18], prohibitive synthesis and/or degradation during purification were encountered. To circumvent these obstacles, an alternative cationic motif, with the terminal amidines of 1 replaced with secondary amines, provided an efficient synthetic route for the generation of a congeneric series to further test our hypothesis for increasing the inhibitory potency of chemotype 1.

The synthesis of 1 and derivatives 4a – d are outlined in Scheme 1. Key intermediate di-nitrile 2 was obtained in 94% yield by coupling 4-cyanophenylboronic acid and 2,5-dibromothiophene under Suzuki conditions. The synthesis of 1, to ensure purity (as it was initially obtained from a chemical repository (vide supra)), was achieved in two-steps by reacting 2 with LHMDS at room temperature, followed by isolation as an HCl salt (97% yield). Di-aldehyde 3 was prepared in 77% yield via the DIBAH-mediated reduction of 2 at 0°C. Following, simultaneous reductive amination of 3 and coupling with NH2-(CH2)n-4,7-ACQ motifs provided targets 4a – d, which were isolated as TFA salts (yields ranged from 24 – 49 %).

3. BoNT/A LC inhibition

Table 1 provides the Ki values for inhibitors 1 and 4a – d when examined in vitro employing a well documented HPLC-based assay for BoNT/A LC inhibition [23–29]. The potencies of the derivatives, in support of our hypothesis, provide further evidence that tethering -(CH2)n-4,7-ACQ components onto the termini of di-cationic lead BoNT/A LC inhibitors (i.e., such as I (Figure 1)) and 1 (Scheme 1 and Table 1) can significantly improve inhibitory potency. Interestingly, as was encountered when tethering 4,7-ACQ components onto the terminal amides of inhibitor chemotype I [18] (Figure 1), trimethylene linkers also afforded the most significant increase in the inhibitory potency of 1. Specifically, tethering -(CH2)3-4,7-ACQ groups onto the secondary amino termini of the 2,5-bis(4-methylaminophenyl)thiophene scaffold (4b, Scheme 1) increased inhibitory potency by approximately (approx.) 36-fold versus 1 (Table 1).

Moreover, as was also previously observed for derivatives of I (Figure 1) [18], decreasing or increasing the methylene tether length above or below that of trimethylenes also resulted in decreased inhibitor 1 derivative potencies. For example, when the tethers were shortened to dimethylenes (4a, Scheme 1), inhibitory potency decreased by approx. 3-fold versus 4b (Table 1). Likewise, when tether lengths were increased to tetramethylenes (4c, Scheme 1), inhibitory potency also decreased, but less dramatically than observed for 4a (Scheme 1) (i.e., an approx. 1.8-fold decrease in potency versus 4b) (Table 1). Finally, derivative 4d (Scheme 1), which possesses pentamethylene tethers, was approx. 3-fold less potent than 4b (Table 1), and with respect to inhibitory potency, is equivalent to 4a (Table 1). Nevertheless, it is noteworthy that regardless of the tether length, 4a – d are all significantly more potent than lead 1 (Table 1).

The data from this study, and the previous study for developing more potent derivatives of inhibitor I (Figure 1) [18], provide further evidence that using trimethylene tethers to link 4,7-ACQ moieties onto the termini of di-cationic BoNT/A LC inhibitors consistently results in derivatives with significantly improved potencies versus dimethylene, tetramethylene, or pentamethylene tethers (Table 1). However, unlike the substitution pattern used to generate more potent derivatives of I (Figure 1), the results from this research indicate that -(CH2)n-4,7-ACQ components may be tethered directly onto the inhibitor’s two cationic substituents to achieve increased potency. For example, II (Figure 1) is approx. 15-fold more potent than I (Figure 1), while 4b is approx. 36-fold more potent than 1 (Table 1) – even though the Ki values of the two leads (i.e., I (Figure 1) and 1 (Table 1)) indicate that their inhibitory potencies are approx. equivalent. Additionally, the Ki values for 4a – d indicate that lower pKa cationic amines may be used to translate μM range, di-amidine substituted leads (such as 1 (Scheme 1)) into nM-range derivatives via an efficient synthetic route (Scheme 1).

4. Conclusions

In summary, we report that tethering -(CH2)n-4,7-ACQ motifs onto the modified cationic components of lead BoNT/A LC inhibitor 2,5-bis(4-amidinophenyl)thiophene (i.e., 1) significantly increases derivative potencies. The data from this study corroborates and further validates a previous report in which a similar strategy was used to translate a bis[3-amide-5-(imidazolino)phenyl]terephthalamide-based BoNT/A LC lead inhibitor into submicromolar-range derivatives [18]. However, in this study, we show that tethering -(CH2)n-4,7-ACQ components directly onto the lead inhibitor chemotype’s terminal di-cationic components provides a more pronounced increase in potency. The implications of this research: such modifications may be made to a variety of our lead, di-cationic BoNT/A LC inhibitors [10–15, 18, 30] to significantly increase derivative potencies. Finally, results from this study preface future syntheses to optimize the elemental composition and rigidity of the tethered components, i.e., beyond that of -(CH2)n-4,7-ACQ motifs.

5. Experimental section

5.1. Chemistry

Melting points were determined using a Boetius PMHK apparatus (Carl Zeiss, Germany) and were not corrected. IR spectra were recorded on a Perkin-Elmer spectrophotometer FTIR 1725X. 1H and 13C NMR spectra were recorded on a Varian Gemini-200 spectrometer (at 200 and 50 MHz, respectively) and a Bruker Ultrashield Advance III spectrometer (at 500 and 125 MHz, respectively) employing indicated solvents (vide infra) using TMS as the internal standard. Chemical shifts are expressed in ppm (δ) values and coupling constants (J) in Hz. ESI–MS (HRMS) spectra of the synthesized compounds were acquired on a Agilent Technologies 1200 Series instrument equipped with a Zorbax Eclipse Plus C18 (100 × 2.1 mm i.d. 1.8 μm) column and DAD detector (190 – 450 nm) in combination with a 6210 Time-of-Flight LC/MS instrument in positive ion mode. The samples were dissolved in pure H2O (HPLC grade). The selected values were as follows: capillary voltage = 4 kV, gas temperature = 350°C, drying gas = 12 L min−1, nebulizer pressure = 45 psig, and fragmentator voltage = 70 V. Lobar LichroPrep Si 60 (40 – 63 μm) or LichroPrep RP-18 columns (Merck, Germany), coupled to a Waters RI 401 detector, were used for preparative column chromatography. Microanalyses were performed using a Vario ELP III (Elementary, Germany). Thin-layer chromatography was performed on pre-coated Merck silica gel 60 F254 and Merck RP-18 F254 plates. Reactions carried out employing microwave (MW) conditions were performed using a Biotage Initiator Eight Robot with an automatic sampler (USA and Sweden). Compounds were analyzed for purity (HPLC) using a Waters 1525 HPLC dual pump system equipped with an Alltech, Select™ degasser system, and dual λ 2487 UV-VIS detector. HPLC analyses were performed using two distinct methods:

Method A

Octadecylsilica was used as the stationary phase (Symmetry C18 analytical column, 4.6 mm – 150 mm, 5 μm, series no. 021336278136 37 (Waters Corporation, Milford, Massachusetts 01757-3696, USA). Compounds were dissolved in 5% formic acid in methanol. Final concentrations (concs.) were 0.1 – 0.5 mg/ml, and injection volumes were 10 μL. Eluent was prepared from the following solvents: 0.2% formic acid in water and methanol. Gradient method runs from 10% to 90% MeOH over 15 min and back to 90% aqueous over 5 min, followed by a 5 min 10% MeOH isocratic period were employed. The analyses were performed at the UV max of the compounds (330 nm) to maximize selectivity. For data processing, Empower software (Waters Corporation, Milford, Massachusetts 01757-3696 U.S.A) was used. All compounds were > 95% pure.

Method B

Octadecylsilica was used as the stationary phase (Nucleosil C18 analytical column, 4 mm – 150 mm, 5 μm, series no. 72923.40 (Macherey-Nagel GmbH & Co. KG, Düren, Germany)). Compounds were dissolved in 5% formic acid in methanol. Final concs. were 0.1–0.5 mg/ml, and the injection volume was 10μL. Eluent was prepared from 0.5% formic acid in water and methanol. Gradient method runs from 10% to 90% MeOH over 15 min and back to 90% aqueous over 5 min, followed by a 5 min 10% MeOH isocratic period, were performed. The analyses were performed at the UV max of the compounds (330 nm) to maximize selectivity. For data processing, Empower software was used. All compounds were > 95% pure.

5.1.1. 4,4′-Thiene-2,5-diyldibenzenecarboximidamide dihydrochloride (1)

Di-nitrile 2 (vide infra) (2.24 g, 7.82 mmol) was suspended in freshly distilled THF (40 ml) and treated with a solution of lithium bis(trimethylsilyl)amide (LHMDS, 5.24 g, 31.32 mmol) in freshly distilled THF (40 ml). The reaction was stirred for 48 h at r.t., and the mixture was clear and orange in color. The reaction mixture was cooled to 0°C, followed by the addition of HCl-saturated ethanol (100 ml). The mixture was stirred overnight, diluted with ether, and the resulting solid was collected by filtration (3.21 g). The crude product was purified by neutralization with 1N NaOH, and collected by filtration. The di-amidine product (2.50 g, 7.81 mmol) was saturated with 36.7% HCl/EtOH (200 mL). The mixture was stirred for 12 h, diluted with ether, and the resulting solid was collected by filtration. Final product 1 was a yellow amorphous powder. The yield was 2.99 g (97%, mp = 385 – 398°C) [21]. IR (KBr): 3254m, 3074m, 1668s, 1652m, 1605s, 1556w, 1533w, 1517w, 1485m, 1451w, 1415w,1385w, 1286m, 844w, 832w, 800w, 771w, 747w, 704w cm−1. 1H NMR (200 MHz, d6-DMSO): 9.473 (s, 2NH2 = C), 9.250 (s, 2NH2-C), 7.99-7.93 (m, 8H-Ar), 7.882 (s, H-C(3) and H-C(4)). 13C NMR (50 MHz, CD3OD): 164.82, 142.48, 138.04, 129.16, 127.67, 126.80, 125.39. Anal. Calcd. for C18H18Cl2N4S × 0.3H2O: C, 54.14; H, 4.71; N, 14.03; S, 8.03. Found: C, 54.23; H, 4.82; N, 13.35; S, 8.00.

5.1.2. 4,4′-Thiene-2,5-diyldibenzonitrile (2)

A reaction vessel containing a solution of Pd(OAc)2 (20 mg, 0.09 mmol) and PPh3 (94.5 mg, 0.36 mmol) in DME (9 mL) was stirred for10 min under Ar atmosphere. Following, 2,5-dibromothiophene (0.1 mL, 0.89 mmol) and 2M Na2CO3 (1.6 mL, 3.2 mmol) were added. After 5 min, 4-cyanophenylboronic acid (290 mg, 1.97 mmol) was added, and the mixture was stirred for 2 h at 80°C in a MW reactor. The solvent was then removed under reduced pressure, and the reaction mixture was suspended in dichloromethane (DCM), transferred to a separation funnel, and washed well with saturated Na2CO3 solution (2 × 25 mL) containing 1 mL NH3. The organic layer was collected, dried with anh. Na2SO4, and the solvent was filtered. Subsequently, the solvent was removed under reduced pressure and intermediate 2 was isolated using column chromatography (dry-flash, SiO2, eluent DCM), and collected as a pale yellow amorphous powder. The yield was 240 mg (94%, mp = 282 – 284°C) [21]. IR (KBr): 2925w, 2359w, 1535m, 1506m, 1380w, 1207s, 1150s, 1035s, 825s, 781m, 732m, 702m cm−1. 1H NMR (200 MHz, CD3OD): 7.80-7.60 (m, 8H-Ar), 7.50-7.45 (s, H-C(3) and H-C(4)). 13C NMR (50 MHz, CD3OD): 143.31, 137.90, 132.88, 126.36, 125.98, 118.64, 111.19. HPLC purity: method A, RT 15.397 min, area 99.03 %; method B: RT 14.656 min, area 96.58 %.

5.1.3. 4,4′-Thiene-2,5-diyldibenzaldehyde (3)

Di-nitrile 2 (400 mg, 1.50 mmol) was dissolved in dry toluene (50 mL) under Ar atmosphere, and DIBAH (9 mL, 1M in toluene) was added drop-wise. After stirring at 0°C for 1 h, the reaction was quenched with 5% H2SO4 (12 mL), and stirring was continued for 1 h at r.t. The reaction mixture was transferred into a separation funnel as an EA emulsion. The organic layer was separated, and the aqueous layer was extracted with DCM (8 × 50 mL). The combined organic layers were washed with brine (2 × 10 mL) and dried over anh. Na2SO4. After filtration, the solvent was removed under reduced pressure. Resulting intermediate 3, a pale yellow amorphous powder, was sufficiently pure and was used in the next reaction step. The yield was 315 mg (77%, mp = 148 – 152°C) [31]. IR (ATR): 3349w, 3198w, 3069m, 2923m, 2854m, 2764w, 1694s, 1599s, 1568m, 1498w, 1451w, 1423w, 1397w, 1346w, 1310w, 1280m, 1216m, 1167m, 1116w, 838m, 796m, 688w. 1H NMR (500 MHz, DMSO-d6): 10.01 (s, 2H-C=O), 7.96 (s, 8H-Ar), 7.90-7.80 (m, H-C(3) and H-C(4)). 13C NMR (125 MHz, DMSO-d6): 192.27, 142.98, 138.57, 135.24, 130.46, 127.65, 125.73. HRMS: m/z 293.06242 corresponding to molecular formula C18H12O2SH+ (error in ppm: −2.25).

5.1.4. 4,4′-[Thiene-2,5-diylbis(4,1-phenylenemethyleneammonioethane-2,1-diylimino)]bis(7-chloroquinolinium) tetra(trifluoroacetate) (4a)

A mixture of N-(7-chloroquinolin-4-yl)ethane-1,2-diamine (340 mg, 1.53 mmol), di-aldehyde 3 (150 mg, 0.51 mmol), and anh. AcOH (72 μL, 1.2 mmol) in MeOH/CH2Cl2 (2/1, v/v, 30 mL) was stirred at r.t. for 14 h, followed by the addition of NaBH4 (240 mg, 6.34 mmol) in 40 mg portions over 2 h. After stirring for an additional 6 h at r.t., the solvent was removed under reduced pressure, and the product was isolated using column chromatography (dry-flash, SiO2, gradient EtOAc/MeOH(NH3) 36/1 → 36/3). Fractions containing the product were combined, and the crude product was dissolved in MeOH/CH2Cl2 (1/1, v/v. 15 mL), followed by the addition of TFA (0.6 mL). The solvent and excess of TFA were removed under reduced pressure, and the product was crystallized as a salt from MeOH, and dried at 40°C in a vacuum oven. Final product 4a was a yellow amorphous powder. The yield was 200 mg (34%, mp 242 – 244°C). IR (ATR): 3268w, 3030w, 2822w, 1678s, 1608s, 1569m, 1455m, 1426w, 1381w, 1246w, 1197s, 1132m, 838w, 802m, 721w cm−1. 1H NMR (200 MHz, DMSO-d6): 9.40 (bs, 2H-C(8′)), 8.67 (d, J = 6.8, 2H(2′)), 8.48 (d, J = 9.0, 2H(5′)), 8.02 (d, J = 2.2, H-C(3) and H-C(4)), 7.90-7.50 (m, 2H(6′), 8H-Ar), 6.99 (d, J = 6.8, 2H-C(3′)), 4.30 (s, CH2-Ar), 3.94 (bs, 4H-C(9′), 3.35 (bs, 4H-C(10′). 13C NMR (50 MHz, DMSO-d6): 159.26, 158.63, 158.01, 157.37, 155.07, 143.28, 141.75, 138.36, 137.60, 133.53, 130.86, 130.31, 126.45, 125.29, 124.90, 119.62, 118.99, 115.29, 113.67, 98.36, 49.21, 43.82. HRMS: m/z 703.2172 corresponding to molecular formula C40H36Cl2N6SH+ (error in ppm: −1.54). HPLC purity: method A, RT 6.912, area 98.95%; method B, RT 5.856, area 98.79%. Anal. Calcd. for C40H36Cl2N6S × 4TFA: C, 49.71%; H, 3.48%; N, 7.25%; S, 2.76%. Found: C, 49.56%; H, 3.63%; N, 7.03%; S, 2.52%.

5.1.5. 4,4′-[Thiene-2,5-diylbis(4,1-phenylenemethyleneammoniopropane-3,1-diylimino)]bis(7-chloroquinolinium) tetra(trifluoroacetate) (4b)

Compound 4b was synthesized according to the procedure used to generate 4a using di-aldehyde 3 (75 mg, 0.26 mmol) and N-(7-chloroquinolin-4-yl)propane-1,3-diamine (144 mg, 0.61 mmol), but with a modification to the column chromatography solvent mixture. Specifically, crude product was purified by column chromatography (dry-flash, SiO2 gradient EtOAc/MeOH(NH3) (36/1 → 36/3)), and the product was crystallized from MeOH as a TFA salt. Final product 4b was a yellow amorphous powder. The yield was 150 mg (49%, mp = 165–168°C). IR (ATR): 3612w, 3414w, 3273m, 3070m, 3076m, 2966m, 2816m, 2478w, 2366w, 2331w, 1674s, 1638w, 1613s, 1553m, 1456m, 1422w, 1368w, 1244w, 1199s, 1128s, 900w, 835m, 799m, 721m cm−1. 1H NMR (500 MHz, CD3OD): 8,38-8,35 (m, 2H-C(2′) and 2H-C(8′)), 7,85-7,82 (m, 2H-C(5′)), 7,66 (d, J = 8,25, 2H-C(7) and 2H-C(11)), 7,61 (dd, J=2,02, J=9,07, 2H-C(6′)), 7,50 (d, J=8,30, 2H-C(8) and 2H-C(10)), 7,38 (s, H-C(3) and H-C(4)), 6,87 (d, J=7,20, 2H-C(3′)), 4,25 (s, 2CH2-Ar), 3,70 (t, J=6,85, 2H-C(9′)), 3,22 (t, J=7,82, 2H-C(11′)), 2,24-2,18 (m, 2H-C(10′)). 13C NMR (125 MHz, CD3OD): 157.52, 143.94, 143.75, 141.01, 139.81, 136.38, 131.66, 131.25, 128.72, 126.87, 126.16, 125.82, 120.23, 119.16, 116.82, 99.65, 51.73, 45.42, 41.56, 25.54. HRMS: m/z 731.24576 corresponding to molecular formula C42H40Cl2N6SH+ (error in ppm: −3.74). HPLC purity: method A, RT 7.191 min, area 97.64 %; method B: RT 6.113 min, area 99.08 %. Anal. Calcd. for: C42H40Cl2N6S × 4TFA: C, 50.56%; H, 3.73%; N, 7.07%; S, 2.70%. Found: C, 50.40%; H, 3.85%; N, 6.92%; S, 2.57%.

5.1.6. 4,4′-[thiene-2,5-diylbis(4,1-phenylenemethyleneammoniobutane-4,1-diylimino)]bis(7-chloroquinolinium) tetra(trifluoroacetate) (4c)

Compound 4c was synthesized according to the procedure used to obtain 4b using di-aldehyde 3 (70 mg, 0.23 mmol) and N-(7-chloroquinolin-4-yl)butane-1,4-diamine (180 mg, 0.72 mmol), but with an additional purification step. Specifically, the reaction mixture was initially sub-purified using column chromatography (dry-flash, SiO2 gradient EtOAc/MeOH(NH3) 36/1 → 36/3), and solvent was removed under reduced pressure. Following, the semi-crude product was dissolved in MeOH/CH2Cl2 (1/1, v/v) with TFA added (0.5 mL). After evaporation to dryness, the remaining solid was purified using a second column chromatography procedure: LOBAR, RP-18 column, eluent MeOH/0.1% TFA. Final product 4c was obtained as a yellow amorphous powder. The yield was 70 mg (24%, mp = 154 – 158°C). IR (ATR): 3388w, 3247m, 3034m, 2956m, 2824m, 2366w, 1680s, 1614s, 1561m, 1454m, 1424m, 1365w, 1202s, 1133s, 1016w, 901w, 834m, 800m, 767w, 718m cm−1. 1H NMR (200 MHz, CD3OD): 8.40-8.35 (m, 2H-C(2′) and 2H-C(8′)), 7.86 (d, J = 1.5, 2H-C(5′)), 7.73 (d, J = 8.5, 2H-C(7) and 2H-C(11)), 7.66 (dd, J=2.0, J=9.0, 2×H-C(6′)), 7.53 (d, J = 8.5, 2H-C(8) and 2H-C(10)), 7.44 (s, H-C(3) and H-C(4)), 6.88 (d, J = 7.0, 2H-C(3′)), 4.24 (s, 2CH2-Ar), 3.64 (bs, 2H-C(9′)), 3.15 (bs, 2H-C(12′)), 1.92-1.85 (m, 2H-C(10′), 2H-C(11′)). 13C NMR (125 MHz, CD3OD): 162.65, 157.82, 144.33, 143.97, 141.17, 140.18, 136.72, 131.95, 128.85, 127.19, 126.50, 126.10, 120.48, 117.09, 99.91, 52.07, 48.17, 44.27, 26.28, 24.79. HRMS: m/z 759.27980 corresponding to molecular formula C44H44Cl2N6SH+ (error in ppm: −1.21). Anal. Calcd. for C44H44Cl2N6S × 4 TFA × 2H2O: C, 49.89%; H, 4.19%; N, 6.71%; S, 2.56%. Found: C, 49.74%; H, 4.25%; N, 6.50%; S, 2.33%.

5.1.7. 4,4′-[thiene-2,5-diylbis(4,1-phenylenemethyleneammoniopentane-5,1-diylimino)]bis(7-chloroquinolinium) tetra(trifluoroacetate) (4d)

Compound 4d was synthesized according to the procedure used to obtain 4c using di-aldehyde 3 (70 mg, 0.23 mmol) and N-(7-chloroquinolin-4-yl)pentane-1,5-diamine (190 mg, 0.72 mmol). Note: the additional purification step used to obtain 4c (vide supra) was also used. Final product 4d was obtained as a yellow amorphous powder. The yield was 70 mg (24%, mp = 146 – 149°C). IR (ATR): 3273w, 3033m, 2939m, 2825m, 2360w, 1670s, 1613s, 1454m, 1365w, 1198s, 1128s, 901w, 832w, 798m cm−1. 1H NMR (200 MHz, CD3OD): 8,42-8,28 (m, 2H-C(2′) and 2H-C(8′)), 7,88-7,78 (m, 2H-C(5′)), 7.72 (d, J = 8.0, 2H-C(7) and 2H-C(11)), 7,64 (dd, J =1.8, J = 9.2, 2H-C(6′)), 7,53 (d, J = 8.0, 2H-C(8) and 2H-C(10)), 7,43 (s, H-C(3) and H-C(4)), 6,83 (d, J = 6.8, 2H-C(3′)), 4,22 (s, 2CH2-Ar), 3,57 (t, J = 6.8, 4H-C(9′)), 3,15-3,00 (m, 4H-C(13′)), 1,90-1,70 (m, 4H-C(10′), 4H-C(12′)), 1,53-1,45 (m, 4H-C(11′)). 13C NMR: 157.52, 144.12, 143.68, 140.91, 140.00, 136.45, 131.86, 128.62, 127.02, 126.36, 125.98, 120.30, 116.84, 99.69, 51.84, 44.50, 28.44, 26.73, 24.86. HRMS: m/z 787.31125 corresponding to molecular formula C46H48Cl2N6SH+ (error in ppm: 0.20). HPLC purity: method A: RT 8.071 min, area 97.10 %; method B: RT 6.918 min, area 97.59 %. Anal. Calcd. for: C46H48Cl2N6S × 4 TFA: C, 52.14%; H, 4.21%; N, 6.76%; S, 2.58%. Found: C, 51.98%; H, 4.36%; N, 6.52%; S, 2.42%

5.2. Biology (HPLC-based assay to calculate BoNT/A LC inhibition)

A previously described HPLC in vitro assay was employed to determine inhibitor-mediated BoNT/A LC inhibition kinetics [23–29], with slight modifications [23]. Briefly, the assay utilized an N-terminal acetylated, C-terminal aminated, synthetic peptide identical in sequence to residues 187–203 of SNAP-25. Compounds with intrinsic fluorescence quenching capability do not interfere with the activity measurements of the assay because substrate hydrolysis is determined by HPLC separation of the cleaved product and the intact substrate, followed by measurement of the peak areas. All HPLC separations were conducted on a Shimadzu Prominence Ultra Fast Liquid Chromatography XR system using a Hypersil Gold Javelin c18 guard column (Thermo Fisher Scientific, Waltham, MA, USA) and a Hypersil Gold c18 reverse-phase analytical column (50 × 2.1 mm, 1.9 μm) (Thermo Fisher Scientific, Waltham, MA, USA). Peak areas were measured with LC solution automated integration software (Shimadzu Corporation, Kyoto, Japan) and used to calculate enzyme reaction rates. Assay mixtures consisted of 40 mM HEPES − 0.05% Tween (pH 7.3), recombinant BoNT/A LC (MetaBiologics, Madison, WI, USA), peptide substrate, 0.5 mg/ml Bovine Serum Albumin, 1 mM Dithiothreitol, 50 μM excess zinc, and 20 μM inhibitor. The assays were run at 37°C, quenched via the addition of TFA, and analyzed by reverse-phase HPLC.

For Ki value determination, plots of reaction velocity versus substrate conc., at multiple inhibitor concs., were analyzed by global kinetic analysis. Data were fit to a competitive inhibition model and analyzed by nonlinear regression analysis using the program GraphPad Prism, version 5.01 (GraphPad Software, San Diego, CA, USA).

Highlights.

The discovery of a novel BoNT A inhibitor chemotype.

The synthesis of submicromolar-range derivatives of a novel lead inhibitor.

Replacing terminal amidines with secondary amines facilitates syntheses.

Acknowledgments

This research was supported by NATO’s Public Diplomacy Division in the framework of Science for Peace project SfP983638 and by National Institute of Allergy and Infectious Diseases (USA) grant 5-U01AI082051-02.

Furthermore, for J.C.B., in compliance with SAIC-Frederick, Inc. contractual requirements: this project has been funded in whole or in part with federal funds from the National Cancer Institute, National Institutes of Health (USA), under Contract No. HHSN261200800001E.

The content of this publication does not necessarily reflect the views or policies of NATO, the Department of Health and Human Services (USA), or the US Army, nor does the mention of trade names, commercial products, or organizations imply endorsement by NATO, the US Government, or the US Army.

Non-standard abbreviations (footnote)

- BoNT/A LC

Botulinum neurotoxin serotype A light chain

- 4,7-ACQ

4-amino-7-chloroquinoline

Footnotes

Author Contributions

Sina Bavari: group leader, biological testing, sponsor of J.C.B., L.M.G. and J.E.N.

James C. Burnett: compound design and inhibitory potency interpretation.

Vuk Filipovic: compound synthesis and purity analysis.

Laura M. Gomba: biological testing.

Rick Gussio: group leader, compound design and inhibitory potency interpretation, sponsor of J.C.B.

Jon E. Nuss: biological testing.

Igor Opsenica: compound synthesis and purity analysis.

Dejan Opsenica: compound synthesis and purity analysis.

Bogdan A. Solaja: group leader, compound synthesis and purity analysis, sponsor of V.F., I.G., and D.O.

Publisher's Disclaimer: This is a PDF file of an unedited manuscript that has been accepted for publication. As a service to our customers we are providing this early version of the manuscript. The manuscript will undergo copyediting, typesetting, and review of the resulting proof before it is published in its final citable form. Please note that during the production process errors may be discovered which could affect the content, and all legal disclaimers that apply to the journal pertain.

References

- 1.Arnon SS, Schechter R, Inglesby TV, Henderson DA, Bartlett JG, Ascher MS, Eitzen E, Fine AD, Hauer J, Layton M, Lillibridge S, Osterholm MT, O’Toole T, Parker G, Perl TM, Russell PK, Swerdlow DL, Tonat K. JAMA. 2001;285:1059–1070. doi: 10.1001/jama.285.8.1059. [DOI] [PubMed] [Google Scholar]

- 2.Paddle BM. J Appl Toxicol. 2003;23:139–170. doi: 10.1002/jat.903. [DOI] [PubMed] [Google Scholar]

- 3.<http://emergency.cdc.gov/agent/agentlist-category.asp>.

- 4.Lacy DB, Tepp W, Cohen AC, DasGupta BR, Stevens RC. Nat Struct Biol. 1998;5:898–902. doi: 10.1038/2338. [DOI] [PubMed] [Google Scholar]

- 5.Simpson LL. Annu Rev Pharmacol Toxicol. 2004;44:167–193. doi: 10.1146/annurev.pharmtox.44.101802.121554. [DOI] [PubMed] [Google Scholar]

- 6.Willis B, Eubanks LM, Dickerson TJ, Janda KD. Angew Chem Int Ed Engl. 2008;47:8360–8379. doi: 10.1002/anie.200705531. [DOI] [PubMed] [Google Scholar]

- 7.Li B, Peet NP, Butler MM, Burnett JC, Moir DT, Bowlin TL. Molecules. 2010;16:202–220. doi: 10.3390/molecules16010202. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Foran PG, Davletov B, Meunier FA. Trends Mol Med. 2003;9:291–299. doi: 10.1016/s1471-4914(03)00113-8. [DOI] [PubMed] [Google Scholar]

- 9.Foran PG, Mohammed N, Lisk GO, Nagwaney S, Lawrence GW, Johnson E, Smith L, Aoki KR, Dolly JO. J Biol Chem. 2003;278:1363–1371. doi: 10.1074/jbc.M209821200. [DOI] [PubMed] [Google Scholar]

- 10.Burnett JC, Opsenica D, Sriraghavan K, Panchal RG, Ruthel G, Hermone AR, Nguyen TL, Kenny TA, Lane DJ, McGrath CF, Schmidt JJ, Vennerstrom JL, Gussio R, Solaja BA, Bavari S. J Med Chem. 2007;50:2127–2136. doi: 10.1021/jm061446e. [DOI] [PubMed] [Google Scholar]

- 11.Burnett JC, Ruthel G, Stegmann CM, Panchal RG, Nguyen TL, Hermone AR, Stafford RG, Lane DJ, Kenny TA, McGrath CF, Wipf P, Stahl AM, Schmidt JJ, Gussio R, Brunger AT, Bavari S. J Biol Chem. 2007;282:5004–5014. doi: 10.1074/jbc.M608166200. [DOI] [PubMed] [Google Scholar]

- 12.Burnett JC, Schmidt JJ, Stafford RG, Panchal RG, Nguyen TL, Hermone AR, Vennerstrom JL, McGrath CF, Lane DJ, Sausville EA, Zaharevitz DW, Gussio R, Bavari S. Biochem Biophys Res Commun. 2003;310:84–93. doi: 10.1016/j.bbrc.2003.08.112. [DOI] [PubMed] [Google Scholar]

- 13.Hermone AR, Burnett JC, Nuss JE, Tressler LE, Nguyen TL, Solaja BA, Vennerstrom JL, Schmidt JJ, Wipf P, Bavari S, Gussio R. ChemMedChem. 2008;3:1905–1912. doi: 10.1002/cmdc.200800241. [DOI] [PubMed] [Google Scholar]

- 14.Opsenica I, Burnett JC, Gussio R, Opsenica D, Todorovic N, Lanteri CA, Sciotti RJ, Gettayacamin M, Basilico N, Taramelli D, Nuss JE, Wanner L, Panchal RG, Solaja BA, Bavari S. J Med Chem. 2011;54:1157–1169. doi: 10.1021/jm100938u. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Solaja BA, Opsenica D, Smith KS, Milhous WK, Terzic N, Opsenica I, Burnett JC, Nuss J, Gussio R, Bavari S. J Med Chem. 2008;51:4388–4391. doi: 10.1021/jm800737y. [DOI] [PubMed] [Google Scholar]

- 16.Burnett JC, Wang C, Nuss JE, Nguyen TL, Hermone AR, Schmidt JJ, Gussio R, Wipf P, Bavari S. Bioorg Med Chem Lett. 2009;19:5811–5813. doi: 10.1016/j.bmcl.2009.01.111. [DOI] [PubMed] [Google Scholar]

- 17.Li B, Pai R, Cardinale SC, Butler MM, Peet NP, Moir DT, Bavari S, Bowlin TL. J Med Chem. 2010;53:2264–2276. doi: 10.1021/jm901852f. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Nuss JE, Dong Y, Wanner LM, Ruthel G, Wipf P, Gussio R, Vennerstrom JL, Bavari S, Burnett JC. ACS Med Chem Lett. 2010;1:301–305. doi: 10.1021/ml100056v. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Wang WJC, Petronijevic F, Burnett JC, Nuss JE, Bavari S, Gussio R, Wipf P. Heterocycles. 2009;79:487 – 520. [Google Scholar]

- 20.Brendle JJ, Outlaw A, Kumar A, Boykin DW, Patrick DA, Tidwell RR, Werbovetz KA. Antimicrob Agents Chemother. 2002;46:797–807. doi: 10.1128/AAC.46.3.797-807.2002. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Das BP, Boykin DW. J Med Chem. 1977;20:1219–1221. doi: 10.1021/jm00219a023. [DOI] [PubMed] [Google Scholar]

- 22.http://pubchem.ncbi.nlm.nih.gov/assay/assay.cgi?reqid=3081123459703717442&q=r&version=1.1.

- 23.Nuss JE, Wanner LM, Tressler LE, Bavari S. J Biomol Screen. 2010;15:928–936. doi: 10.1177/1087057110374996. [DOI] [PubMed] [Google Scholar]

- 24.Schmidt JJ, Bostian KA. J Protein Chem. 1995;14:703–708. doi: 10.1007/BF01886909. [DOI] [PubMed] [Google Scholar]

- 25.Schmidt JJ, Bostian KA. J Protein Chem. 1997;16:19–26. doi: 10.1023/a:1026386710428. [DOI] [PubMed] [Google Scholar]

- 26.Schmidt JJ, Stafford RG. FEBS Lett. 2002;532:423–426. doi: 10.1016/s0014-5793(02)03738-9. [DOI] [PubMed] [Google Scholar]

- 27.Schmidt JJ, Stafford RG. Appl Environ Microbiol. 2003;69:297–303. doi: 10.1128/AEM.69.1.297-303.2003. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 28.Schmidt JJ, Stafford RG, Bostian KA. FEBS Lett. 1998;435:61–64. doi: 10.1016/s0014-5793(98)01041-2. [DOI] [PubMed] [Google Scholar]

- 29.Schmidt JJ, Stafford RG, Millard CB. Anal Biochem. 2001;296:130–137. doi: 10.1006/abio.2001.5236. [DOI] [PubMed] [Google Scholar]

- 30.Burnett JC, Li B, Pai R, Cardinale SC, Butler MM, Peet NP, Moir D, Bavari S, Bowlin T. Open Access Bioinformatics. 2010;2010:11–18. doi: 10.2147/OAB.S7251. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Fomina L, Garcia A, Fomine S, Tienkopatchev MA, Ogawa T. Polym J. 1997;29:626 – 629. [Google Scholar]