A smart structure is a system containing multifunctional parts that can perform sensing, control, and actuation; it is a primitive analogue of a biological body. Smart materials are used to construct these smart structures, which can perform both sensing and actuation functions.

The “I.Q.” of smart materials is measured in terms of their “responsiveness” to environmental stimuli and their “agility.” The first criterion requires a large amplitude change, whereas the second assigns faster response materials with higher “I.Q.” Commonly encountered smart materials and structures can be categorized into three different levels: (i) single-phase materials, (ii) composite materials, and (iii) smart structures. Many ferroic materials and those with one or more large anomalies associated with phase-transition phenomena belong to the first category. Functional composites are generally designed to use nonfunctional materials to enhance functional materials or to combine several functional materials to make a multifunctional composite. The third category is an integration of sensors, actuators, and a control system that mimics the biological body in performing many desirable functions, such as synchronization with environmental changes, self-repair of damages, etc. These three levels cover the general definition of smart materials and structures. In this short summary, we will use a few examples to illustrate such systems and to provide some general guidelines for designing “smart” systems.

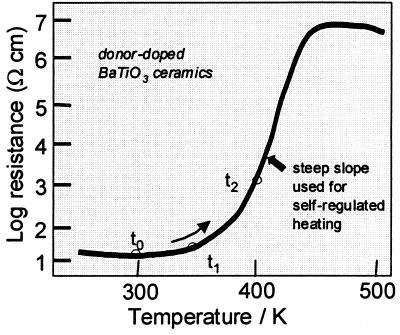

The difference between an ordinary and a “smart” material can be demonstrated through the following positive temperature coefficient (PTC)-resistance materials. A large group of temperature sensors is based on the temperature dependence of the electrical resistivity of conductors. Platinum, for example, is a widely used metal for PTC sensors. The resistance rises constantly with increasing temperature over a wide range from about 20 to 1,500 K. Temperature sensors based on this material show the advantage to be chemically and mechanically robust and to cover a large temperature range with an almost linear characteristic. The change, however, is less than .03 μΩ⋅cm/K. Therefore, the material cannot be used for self-regulated heating purposes. An example of smart PTC materials is donor-doped barium titanate ceramics. In this case, there is a temperature range (from ≈350 to 450 K) in which the resistivity rises by almost six orders of magnitude, as shown in Fig. 1.

Figure 1.

Temperature dependence of resistivity in smart PTC materials.

Resistive heating elements are usually built with materials of intermediate resistivity level. Applying an electrical voltage to these elements causes a current to flow, which generates Joule’s heat in the resistor. If there is a surge of current or a blockage of heat circulation, the resistor frequently overheats and may even cause a fire.

When a smart PTC resistor material is used, it can form a self-protection circuit. The principle can be understood as follows. At the beginning, the PTC heater is at room temperature with low resistance. Closing the switch in the circuit will produce a large current, which causes a fast temperature increase. Because of this rise in temperature, the resistance increases drastically (see Fig. 1); hence, the current will be reduced under a constant voltage source.

Finally, this self-regulation leads to a temperature stabilization at the steepest part of the characteristic curve. This established temperature is quite independent of the ambient temperature and the amount of heat extracted from the heating element. Therefore, a smart self-regulating heating circuit is formed.

Donor-doped BaTiO3 ceramics can be regarded as a typical smart material in which the sensed temperature signal is inherently fed back to the heat generation. A temperature control is achieved with no additional electronics.

Magnetic probe is a good example of a multifunctional composite (1) in which a magnetostrictive material is integrated with a piezoelectric material to produce a large magnetoelectric effect. The magnetostrictive material will produce shape deformation under a magnetic field, and this shape deformation produces a stress on the piezoelectric material which generates electric charge. The so obtained magnetoelectric effect could be two orders of magnitude larger than that of Cr2O3.

Smart structures are an integration of sensors, actuators, and a control system. Apart from the use of better functional materials as sensors and actuators, an important part of a “smarter” structure is to develop an optimized control algorithm that could guide the actuators to perform required functions after sensing changes.

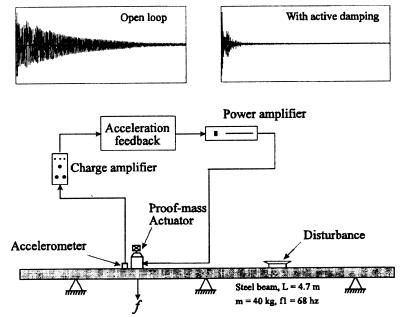

Active damping is one of the most studied areas using smart structures. By using collocated actuator and sensors (i.e., physically located at the same place and energetically conjugated, such as force and displacement), a number of active damping schemes with guaranteed stability have been developed. These schemes are categorized on the basis of feedback type in the control procedure, i.e., velocity, displacement, or acceleration.

Fig. 2 is an illustration of a stiff beam with active damping. The system used an acceleration feedback scheme with an accelerometer as the sensor. The comparison between the open and closed circuit situations is shown in Fig. 2 Upper.

Figure 2.

Impulse response of a stiff beam with active damping control (2).

Another example is a piezoelectric qualitative health monitoring system (3), which is based on impedance measurement on the piezoelectric transducers bonded or embedded in structures. The principle of operation is to excite the structure with the piezoelectric transducer and measure impedance change (>30 kHz). The impedance equation is

|

1 |

When a structure is damaged, the elastic moduli, effective mass, and capacitance change so that the impedance also varies. The technique has been implemented in space structures as shown in Fig. 3.

Figure 3.

A space structure with impedance monitoring unit.

The advantages of the technique are as follows:

• No structure model needed.

• Is nonintrusive.

• Can be used in inaccessible locations.

• Allows on-line health monitoring.

• Very sensitive to small amounts of damage.

• Localized sensing, unaffected by changes in boundary conditions, loading, or operational vibrations.

• Can warn of incipient damage.

Some natural materials are born to be “smart,” such as piezoelectric, electrostrictive, and magnetostrictive materials, but they are far from satisfying the diversified needs of smart structures. Most natural materials also have limited amplitude in response and must be operated in a limited temperature range. One could, however, use chemical and mechanical engineering to create “smarter” materials and to tailor their properties for a particular smart structure design.

One of the main methods used in chemical engineering is to introduce doping elements. Nonstoichiometric doping proved to be effective in creating instabilities in the material to generate large responses, making the material “smarter.” The lead zirconate–lead titanate solid solution (PZT) system is one such successful example. The use of Nb doping can drastically increase the piezoelectric property of PZT. It is also possible to use physical means to create disorder in an ordered system, such as the misoritational poling in single-crystal lead zirconate niobite–lead titanate (PZN-PT) (4). PZN-PT produces a multidomain system with a >90% electromechanical coupling coefficient and a d33 value three times that of PZT. In the engineering of smart composite and smart structures, the design philosophy is to use nonfunctional materials to enhance the ability of functional materials through redirecting the force and to make multifunctional composites by combining the abilities of several functional materials (5, 6).

The field of smart materials and structures is interdisciplinary between science and technology and combines the knowledge of physics, mathematics, chemistry, computer science, and material, electrical, and mechanical engineering. It implements human creativity and innovative ideas to serve human society for such tasks as making a safer car, a more comfortable airplane, a self-repair water pipe, etc. Smart structures can help us to control the environment better and to increase the energy efficiency of devices.

In the future, with the help of miniaturized devices such as electromechanical devices, we expect to see structures that can be smart enough to communicate directly with the human brain. The development of supersensitive noses, ears, and eyes would enable us to smell more scents, hear beyond our frequency range, and see what we cannot normally see, such as the infrared spectrum. There are a lot of demands on smart structures, and the imagination of scientists is unlimited. We can expect to see smarter materials and structures being developed in the near future.

ABBREVIATION

- PTC

positive temperature coefficient

References

- 1.Bracke L P M, van Vliet R G. Int J Electron. 1981;51:255–262. [Google Scholar]

- 2.Preumont A. Vibration Control of Active Structures. Dordrecht, The Netherlands: Kluwer; 1997. [Google Scholar]

- 3.Park G, Kabeya K, Cudney H H, Inman D J. SPIE’s 5th Annual International Symposium on Smart Structures and Materials. 1998. , March 1–5, 1998, San Diego. [Google Scholar]

- 4.Park S E, Shrout T J. Mater Res Innov. 1997;1:20–25. [Google Scholar]

- 5.Newnham R E. MRS Bull. 1997;22(5):20–34. [Google Scholar]

- 6.Cao W, Zhang Q, Cross L E. J Appl Phys. 1992;72:5814–5821. [Google Scholar]