Abstract

Herein we report the fabrication of protein (bovine serum albumin, BSA) particles which were rendered transiently insoluble using a novel, reductively labile disulfide-based cross-linker. After being cross-linked, the protein particles retain their integrity in aqueous solution and dissolve preferentially under a reducing environment. Our data demonstrates that cleavage of the cross-linker leaves no chemical residue on the reactive amino group. Delivery of a self-replicating RNA was achieved via the transiently insoluble PRINT protein particles. These protein particles can provide new opportunities for drug and gene delivery.

Keywords: Soft lithography, PRINT, protein, cross-linker, disulfide

Delivering promising biological therapeutics to the desired location in the body in a safe and effective fashion is one of the key challenges in medicine. Proteins as the matrices for drug delivery particles have many advantages including bio-degradability, biocompatibility and amenability to surface modification.1 Drug carriers using proteins as matrices for the delivery of small molecule drugs and biological cargos, such as plasmid DNA and siRNA, are being extensively studied.2,3,4 Each of these applications would benefit from having protein-based particles that dissolve slowly in a controlled and desirable manner.5 Herein, we report the synthesis of size- and shape-specific protein micro- and nano-particles using a top-down particle fabrication technique called PRINT. Our approach involves the design and synthesis of a novel“traceless ” cross-linker that renders protein-based particles transiently insoluble in aqueous solutions. We also report the cytoplasmic delivery of a self-replicating RNA via PRINT protein particles stabilized by this novel cross-linker.

Protein particles are often made through costly and complicated processes which include wet-milling, spray-freeze-drying, micro-emulsion, micro-encapsulation, or supercritical fluid methods.6,7,8 Frequently, these procedures result in highly heterogeneous polydispersed spherical or granular particles and do not allow control over particle size or shape.9 PRINT is a platform technology that is an off-shoot of soft lithography that enables the molding of micro- and nano-particles having precisely controlled size, shape, chemical composition and surface functionality.10,11 PRINT has been transitioned to a continuous roll-to-roll fabrication technique that can enable the scale-up of particle production to practical levels for applications in the clinic.

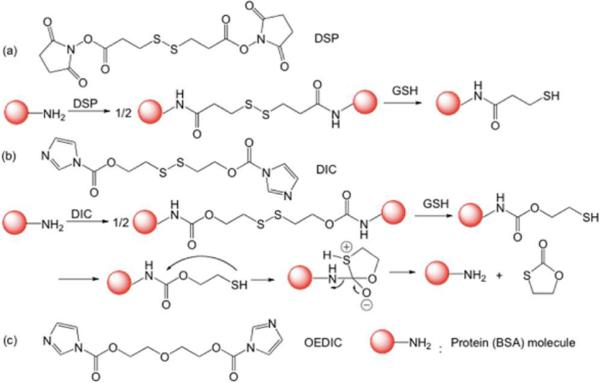

Dry microspheres or nanospheres composed of proteins are usually instantaneously soluble when placed into aqueous solutions.9 A couple of strategies have been reported that maintain the stability of protein-based particles: i) thermal cross-linking, which causes the formation of intermolecular disulfide bridges between free thiol groups;12 ii) the use of non-reversible chemical cross-linkers, such as 1-Ethyl-3-(3-dimethylaminopropyl)carbodiimide (EDC), glutaraldehyde, formaldehyde etc.;7,13 and iii) the use of reversible cross-linkers like Lomant's reagent, dithiobis[succinimidyl propionate] (DSP), which can be cleaved upon exposure to certain biologic conditions.5 Thermal cross-linking involves the thermal denaturation of a given protein at high temperature and cannot be applied to the delivery of fragile cargos. The use of non-reversible chemical cross-linkers introduces permanent cross-linkages between individual protein molecules which limit the release of encapsulated cargos. Reversible cross-linkers can be cleaved upon exposure to certain biologic conditions but leaves a chemical residue —a potential neoepitope—on the protein after cleavage of the disulfide bond (Scheme 1a).14 If the released protein from the particles has molecular pendants attached, it may elicit undesirable immune responses towards foreign antigens, which may induce adverse health effects.15,16 Inspired by the chemistry Wender et al. developed to release drugs in their original state from a pro-drug form,17,18 we designed a “traceless” reversible cross-linker that leaves no pendant chemical residues on the molecule it reacts with after cleavage of the linker. We have applied the use of such transient, traceless chemical cross-linkers to achieve stabilization of protein particles fabricated using the PRINT technology.

Scheme 1.

(a) Structure of DSP and reaction scheme for protein cross-linking and dissolution; (b) Structure of DIC and reaction scheme for protein cross-linking and dissolution; (c) Structure of OEDIC

Based on our previous efforts,9 a melt-solidification strategy was employed in the fabrication of PRINT protein particles (Figure S1). Lactose and glycerol (for use as plasticizers) are mixed with the protein of choice, in this case BSA, to form the pre-particle material that readily “flows” when heated. Serum albumin was chosen in this study for two reasons: 1) As the most abundant blood plasma protein it is essential for the transport of many physiological molecules and 2) it also has the advantage of being readily available.1 In particular, bovine serum albumin (BSA) was used in this study due to its easy accessibility and cost effectiveness for our proof-of-concept study. The processing temperature used to fabricate protein-based particles in this study can be as low as 60 °C, which avoids the potential degradation of the delicate biological therapeutics we are investigating.

Taking advantage of the PRINT process, a series of BSA particles were fabricated in the size range of 200 nm to several micrometers (Figure S2). In this study, cylindrical particles with both diameter and height as 1 µm were fabricated with a pre-particle composition containing 37.5 wt % of BSA, 37.5 wt% of α-D-lactose and 25.0 wt% of glycerol. In order to determine the final composition after the purification step, particles were analyzed by high-performance liquid chromatography (HPLC) coupled with evaporative light scattering detection (ELSD). The dry particles were found to contain 86.7±1.1 wt% of BSA, 10.2±1.7 wt% of lactose and 3.1±0.7 wt% of glycerol (Table S1). The protein particles, at this stage, are fully soluble when brought into contact with water (Figure S3), which indicated the necessity for a cross-linker to transiently stabilize the albumin particles.

In order to utilize protein-based particles for therapeutic applications, they are usually stabilized with cross-linkers, which can be cleaved under certain physiological stimuli.19 The cytoplasm of cells is known for its high concentration of reduced glutathione (GSH) compared to the extracellular environment (GSH concentration differs by 1000 folds intracellularly and extracellularly).20 In this study, we take advantage of the reducing environment in the cytoplasm of cells by introducing a disulfide-based cross-linker that should trigger the intracellular dissolution of our protein particles. Wender et al. developed a disulfide based pro-drug linker, which contains a carbonate group instead of conventionally used ester linkage, to release the drug in its original state.17 This chemistry has also been applied to develop a fluorogenic probe for thiol detection and a pro-drug for intracellular delivery.21,22,23 Inspired by previous work, we developed a novel cross-linker dithio-bis(ethyl 1 H-imidazole-1-carboxylate) (DIC) for this study. Compared to DSP, DIC has several advantages. Imidazoles were introduced as the leaving groups in DIC to replace the highly reactive NHS as in DSP in order to better control the rate of the cross-linking reaction and the cross-linking density on the particle surface. Furthermore, DIC is a “traceless” reversible cross-linker, which does not leave any molecular pendants after disulfide cleavage (Scheme 1b). As a control, a nondisulfide non-degradable crosslinker, 2,2'-oxybis(ethane-2,1-diyl) bis(1H-imidazole-1-carboxylate) (OEDIC) was also synthesized (Scheme 1c).

To demonstrate the ability of DIC to release the amino group in its original form after cleavage of the disulfide, we utilized tyramine as a model, a small molecule with only one amino group. Two tyramine molecules were reacted with DIC in isopropanol, which completely simulates the cross-linking conditions for protein-based particles (Scheme S2). To prove this unique property of DIC, the commercially available disulfide crosslinker DSP was used as a control in this study. The dimer products were denoted as tyramine-DIC and tyramine-DSP, respectively. Both compounds were treated with 50 mM of dithiothreitol (DTT) in phosphate buffer saline (PBS) to cleave the disulfide bond. Gas chromatography mass spectrum (GC-MS) results indicated that after cleavage of the disulfide bond, tyramine was regenerated from tyramine-DIC. No peak of tyramine was observed with tyramine-DSP (Figure S4). In addition, 1H-NMR and high-resolution mass spectrometry confirmed the structure of tyramine recovered after DTT treatment of tyramine-DIC. (SI)

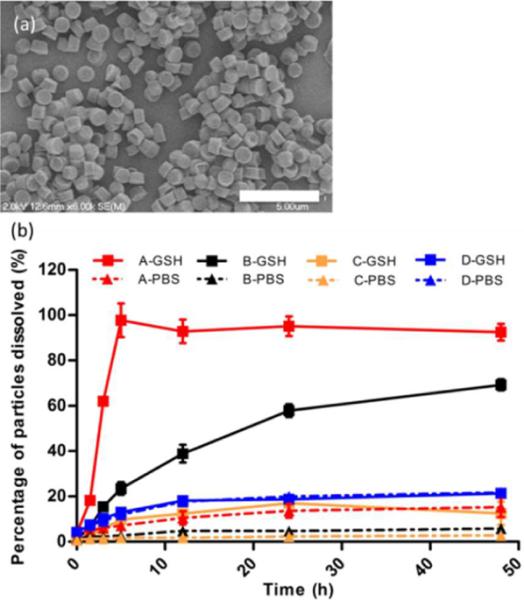

The PRINT albumin particles were cross-linked with DIC and OEDIC at different cross-linker concentrations (based on a constant particle concentration) and a quantitative study of particle dissolution was performed (Figure 1). From these data, it was apparent that the particles cross-linked with the disulfide linker DIC retained their stability in PBS and preferentially dissolved under reducing conditions. The rate of particle dissolution can be effectively modulated by changing the cross-linker concentration.

Figure 1.

(a) SEM image of BSA particles (cross-linked at 4.4 mM of DIC) after incubation with water, scale bar represents 10 μm. (b) Dissolution profile of cross-linked BSA particles in PBS containing 5 mM GSH (GSH, squares with solid lines) and PBS only (PBS, triangles with dotted lines), A, B and C: particles cross-linked at 4.4 mM, 6.6 mM, and 9.9 mM of DIC, respectively; D: particles cross-linked at 4.4 mM of OEDIC. The error bars stand for the standard deviation calculated from triplicates.

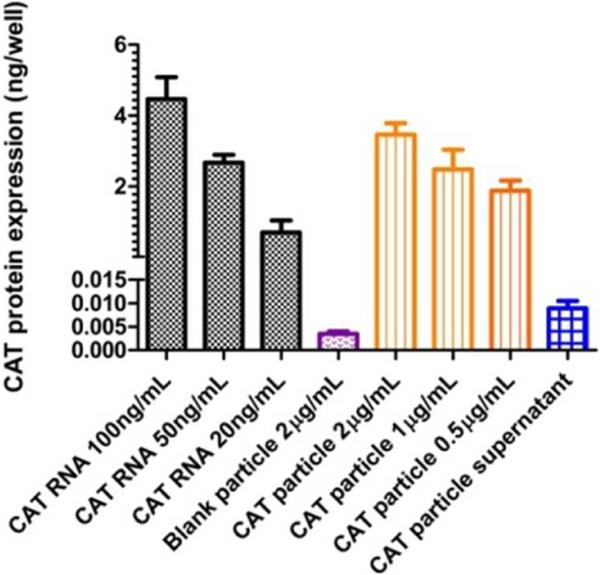

In order to demonstrate the capability of the particles to deliver biological cargos to a reducing cellular compartment, we selected an RNA molecule capable of self-replication and encoding Chloramphenicol Acetyl Transferase (CAT) protein exclusively in the cytoplasm. Successful delivery of this RNA into the cytoplasm of Vero cells would yield expression of CAT protein which can be detected by enzyme-linked immunosorbent assay (ELISA) using antigen-specific antibodies. Particles were fabricated using the PRINT process containing the Replicon RNA cargo (1 wt%), BSA, lactose and glycerol and were stabilized using the DIC cross-linker. The isoelectric point of BSA is 4.75, resulting in cross-linked particles with a negative ζ-potential. Based on the previous studies, cells preferentially internalize positively charged particles.11 TransIT®-mRNA transfection reagent (TransIT) was mixed with BSA particles in order to introduce positive charges to BSA particle surface to enhance cell uptake and endosomal escape (Table S3). As a result of internalization of the particles coated with TransIT into Vero cells, CAT protein was generated (Figure 2). CAT protein production via delivery of PRINT particles was competitively comparable to the same amount of RNA directly transfected by TransIT. As a negative control, blank particles (no RNA encapsulated) did not induce any protein expression. Furthermore, to rule out CAT protein expression induced by complexing of extracellular RNA and TransIT reagents, DIC-crosslinked BSA / RNA particles were incubated in PBS for 4 h at 37 °C, particles were pelleted by centrifugation and the supernatant was dosed to cells with TransIT. Absence of CAT protein expression was observed confirming particle mediated delivery of RNA. Analysis using confocal microscopy was also carried out to visually confirm the generation of CAT protein (Figure S6).

Figure 2.

CAT protein generated from Vero cells (2×104 cells per well) measured by ELISA. Black: CAT RNA standards with TransIT, purple: blank particles with TransIT, orange: CAT RNA containing BSA particles with TransIT, 2, 1 and 0.5μg/mL of particles corresponds to 30, 15 and 7.5 ng/mL of RNA (SI), blue: supernatant from particles incubated in PBS for 4 h at 37°C with TransIT. Error bars represent standard deviation calculated from four wells.

In summary, a novel cross-linker strategy was able to effectively render the PRINT protein particles transiently insoluble in aqueous solutions. The cross-linked particles preferentially dissolved under reducing conditions and the rate of particle dissolution can be controlled by adjusting the cross-linker concentration. By coating the RNA-loaded particles with TransIT, CAT protein was expressed via delivery of PRINT particles. These precisely engineered protein particles showed great potential for drug and gene delivery.

Supplementary Material

ACKNOWLEDGMENT

We thank Tammy Shen for help with SEM images in Figure S2. The work is supported in part by National Institutes of Health Director's Pioneer Award (1DP1OD006432) and R01 (R01EB009565), University of North Carolina Cancer Research Fund, the Chancellor's Eminent Professorship of Chemistry at the University of North Carolina at Chapel Hill, and a sponsored research agreement with Liquidia Technologies.

Funding Sources The work is supported in part by National Institutes of Health Director's Pioneer Award (1DP1OD006432) and R01 (R01EB009565), University of North Carolina Cancer Research Fund, the Chancellor's Eminent Professorship of Chemistry at the University of North Carolina at Chapel Hill, and a sponsored research agreement with Liquidia Technologies.

ABBREVIATIONS

- BSA

bovine serum albumin

- DIC

dithio-bis(ethyl 1 H-imidazole-1-carboxylate)

- DSP

dithiobis[succinimidyl propionate]

- OEDIC

2,2'-oxybis(ethane-2,1-diyl) bis(1H-imidazole-1-carboxylate)

Footnotes

Supporting Information Available: Experimental procedures, synthetic schemes, characterization. The fabrication process for protein-based PRINT particles (Figure S1). SEM of protein particles (Figure S2). Particle composition (Table S1). BSA particle dissolution by microscopy image (Figure S3). Synthesis scheme of crosslinker DIC and OEDIC (Scheme S1). Synthesis scheme of tyramine-DIC and tyramine-DSP (Scheme S2). GC-MS characterization of tyramine-DIC and tyramine-DSP after treatment with DTT (Figure S4). Characterization of crosslinked BSA particles (Table S2). Particle dissolution by microscopy image at 5-h time point (Figure S5). Charracterization of cross-linked BSA particles with and without TransIT (Table S3). Confocal image of CAT protein expression (Figure S6). Cytotoxicity of particles coated with TransIT (Figure S7). Study of the depth of cross-linking reaction. This material is available free of charge via the Internet at http://pubs.acs.org.

Author Contributions The manuscript was written through contributions of all authors. / All authors have given approval to the final version of the manuscript. /

REFERENCES

- (1).Kratz F. J. Control. Release. 2008;132:171. doi: 10.1016/j.jconrel.2008.05.010. [DOI] [PubMed] [Google Scholar]

- (2).Hawkins MJ, Soon-Shiong P, Desai N. Adv. Drug Deliv. Rev. 2008;60:876. doi: 10.1016/j.addr.2007.08.044. [DOI] [PubMed] [Google Scholar]

- (3).Rhaese S, von Briesen H, Rübsamen-Waigmann H, Kreuter J, Langer K. J. Control. Release. 2003;92:199. doi: 10.1016/s0168-3659(03)00302-x. [DOI] [PubMed] [Google Scholar]

- (4).Abbasi S, Paul A, Prakash S. Cell Biochem. Biophys. 2011;61:277. doi: 10.1007/s12013-011-9201-9. [DOI] [PubMed] [Google Scholar]

- (5).Yu M, Ng BC, Rome LH, Tolbert SH, Monbouquette HG. Nano. Lett. 2008;8:3510. doi: 10.1021/nl080536z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- (6).Maa YF, Nguyen PA, Sweeney T, Shire SJ, Hsu CC. Pharm. Res. 1999;16:249. doi: 10.1023/a:1018828425184. [DOI] [PubMed] [Google Scholar]

- (7).Arshady R. J. Control. Release. 1990;14:111. [Google Scholar]

- (8).Carrasquillo KG, Carro JCA, Alejandro A, Toro DD, Griebenow K. J. Pharm. Pharmacol. 2001;53:115. doi: 10.1211/0022357011775091. [DOI] [PubMed] [Google Scholar]

- (9).Kelly JY, DeSimone JM. J. Am. Chem. Soc. 2008;130:5438. doi: 10.1021/ja8014428. [DOI] [PubMed] [Google Scholar]

- (10).Wang J, Tian S, Petros RA, Napier ME, Desimone JM. J. Am. Chem. Soc. 2010;132:11306. doi: 10.1021/ja1043177. [DOI] [PMC free article] [PubMed] [Google Scholar]

- (11).Gratton SEA, Ropp PA, Pohlhaus PD, Luft JC, Madden VJ, Napier ME, DeSimone JM. Proc. Natl. Acad. Sci. USA. 2008;105:11613. doi: 10.1073/pnas.0801763105. [DOI] [PMC free article] [PubMed] [Google Scholar]

- (12).Chatterjee J, Haik Y, Chen C-J. Colloid Polym. Sci. 2001;279:1073. [Google Scholar]

- (13).Patil GV. Drug Dev. Res. 2003;58:219. [Google Scholar]

- (14).Johnson RP, Craig SW. J Biol Chem. 2000;275:95. doi: 10.1074/jbc.275.1.95. [DOI] [PubMed] [Google Scholar]

- (15).Jenkins N. Cytotechnology. 2007;53:121. doi: 10.1007/s10616-007-9075-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- (16).Zhang W, Czupryn MJ. Biotechnol. Prog. 2002;18:509. doi: 10.1021/bp025511z. [DOI] [PubMed] [Google Scholar]

- (17).Dubikovskaya EA, Thorne SH, Pillow TH, Contag CH, Wender PA. Proc. Natl. Acad. Sci. USA. 2008;105:12128. doi: 10.1073/pnas.0805374105. [DOI] [PMC free article] [PubMed] [Google Scholar]

- (18).Jones LR, Goun EA, Shinde R, Rothbard JB, Contag CH, Wender PA. J. Am. Chem. Soc. 2006;128:6526. doi: 10.1021/ja0586283. [DOI] [PubMed] [Google Scholar]

- (19).Yan M, Du J, Gu Z, Liang M, Hu Y, Zhang W, Priceman S, Wu L, Zhou ZH, Liu Z, Segura T, Tang Y, Lu Y. Nat. Nanotechnol. 2010;5:48. doi: 10.1038/nnano.2009.341. [DOI] [PubMed] [Google Scholar]

- (20).Saito G, Swanson JA, Lee K-D. Adv. Drug Deliv. Rev. 2003;55:199. doi: 10.1016/s0169-409x(02)00179-5. [DOI] [PubMed] [Google Scholar]

- (21).Namanja HA, Emmert D, Davis DA, Campos C, Miller DS, Hrycyna CA, Chmielewski J. J. Am. Chem. Soc. 2012;134:2976. doi: 10.1021/ja206867t. [DOI] [PMC free article] [PubMed] [Google Scholar]

- (22).Pires MM, Chmielewski J. Org. Lett. 2008;5:837. doi: 10.1021/ol702769n. [DOI] [PubMed] [Google Scholar]

- (23).Li C, Wu T, Hong C, Zhang G, Liu S. Angew. Chem. Int. Ed. 2012;51:455. doi: 10.1002/anie.201105735. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.