Executive Summary

Objective

This health technology policy assessment will answer the following questions:

When should in-room air cleaners be used?

How effective are in-room air cleaners?

Are in-room air cleaners that use combined HEPA and UVGI air cleaning technology more effective than those that use HEPA filtration alone?

What is the Plasmacluster ion air purifier in the pandemic influenza preparation plan?

The experience of severe acute respiratory syndrome (SARS) locally, nationally, and internationally underscored the importance of administrative, environmental, and personal protective infection control measures in health care facilities. In the aftermath of the SARS crisis, there was a need for a clearer understanding of Ontario’s capacity to manage suspected or confirmed cases of airborne infectious diseases. In so doing, the Walker Commission thought that more attention should be paid to the potential use of new technologies such as in-room air cleaning units. It recommended that the Medical Advisory Secretariat of the Ontario Ministry of Health and Long-Term Care evaluate the appropriate use and effectiveness of such new technologies.

Accordingly, the Ontario Health Technology Advisory Committee asked the Medical Advisory Secretariat to review the literature on the effectiveness and utility of in-room air cleaners that use high-efficiency particle air (HEPA) filters and ultraviolet germicidal irradiation (UVGI) air cleaning technology.

Additionally, the Ontario Health Technology Advisory Committee prioritized a request from the ministry’s Emergency Management Unit to investigate the possible role of the Plasmacluster ion air purifier manufactured by Sharp Electronics Corporation, in the pandemic influenza preparation plan.

Clinical Need

Airborne transmission of infectious diseases depends in part on the concentration of breathable infectious pathogens (germs) in room air. Infection control is achieved by a combination of administrative, engineering, and personal protection methods. Engineering methods that are usually carried out by the building’s heating, ventilation, and air conditioning (HVAC) system function to prevent the spread of airborne infectious pathogens by diluting (dilution ventilation) and removing (exhaust ventilation) contaminated air from a room, controlling the direction of airflow and the air flow patterns in a building. However, general wear and tear over time may compromise the HVAC system’s effectiveness to maintain adequate indoor air quality. Likewise, economic issues may curtail the completion of necessary renovations to increase its effectiveness. Therefore, when exposure to airborne infectious pathogens is a risk, the use of an in-room air cleaner to reduce the concentration of airborne pathogens and prevent the spread of airborne infectious diseases has been proposed as an alternative to renovating a HVAC system.

Airborne transmission is the spread of infectious pathogens over large distances through the air. Infectious pathogens, which may include fungi, bacteria, and viruses, vary in size and can be dispersed into the air in drops of moisture after coughing or sneezing. Small drops of moisture carrying infectious pathogens are called droplet nuclei. Droplet nuclei are about 1 to 5μm in diameter. This small size in part allows them to remain suspended in the air for several hours and be carried by air currents over considerable distances. Large drops of moisture carrying infectious pathogens are called droplets. Droplets being larger than droplet nuclei, travel shorter distances (about 1 metre) before rapidly falling out of the air to the ground. Because droplet nuclei remain airborne for longer periods than do droplets, they are more amenable to engineering infection control methods than are droplets.

Droplet nuclei are responsible for the airborne transmission of infectious diseases such as tuberculosis, chicken pox (varicella), measles (rubeola), and dessiminated herpes zoster, whereas close contact is required for the direct transmission of infectious diseases transmitted by droplets, such as influenza (the flu) and SARS.

The Technology

In-room air cleaners are supplied as portable or fixed devices. Fixed devices can be attached to either a wall or ceiling and are preferred over portable units because they have a greater degree of reliability (if installed properly) for achieving adequate room air mixing and airflow patterns, which are important for optimal effectiveness.

Through a method of air recirculation, an in-room air cleaner can be used to increase room ventilation rates and if used to exhaust air out of the room it can create a negative-pressure room for airborne infection isolation (AII) when the building’s HVAC system cannot do so. A negative-pressure room is one where clean air flows into the room but contaminated air does not flow out of it. Contaminated room air is pulled into the in-room air cleaner and cleaned by passing through a series of filters, which remove the airborne infectious pathogens. The cleaned air is either recirculated into the room or exhausted outside the building. By filtering contaminated room air and then recirculating the cleaned air into the room, an in-room air cleaner can improve the room’s ventilation. By exhausting the filtered air to the outside the unit can create a negative-pressure room. There are many types of in-room air cleaners. They vary widely in the airflow rates through the unit, the type of air cleaning technology used, and the technical design.

Crucial to maximizing the efficiency of any in-room air cleaner is its strategic placement and set-up within a room, which should be done in consultation with ventilation engineers, infection control experts, and/or industrial hygienists. A poorly positioned air cleaner may disrupt airflow patterns within the room and through the air cleaner, thereby compromising its air cleaning efficiency.

The effectiveness of an in-room air cleaner to remove airborne pathogens from room air depends on several factors, including the airflow rate through the unit’s filter and the airflow patterns in the room. Tested under a variety of conditions, in-room air cleaners, including portable or ceiling mounted units with either a HEPA or a non-HEPA filter, portable units with UVGI lights only, or ceiling mounted units with combined HEPA filtration and UVGI lights, have been estimated to be between 30% and 90%, 99% and 12% and 80% effective, respectively. However, and although their effectiveness is variable, the United States Centers for Disease Control and Prevention has acknowledged in-room air cleaners as alternative technology for increasing room ventilation when this cannot be achieved by the building’s HVAC system with preference given to fixed recirculating systems over portable ones.

Importantly, the use of an in-room air cleaner does not preclude either the need for health care workers and visitors to use personal protective equipment (N95 mask or equivalent) when entering AII rooms or health care facilities from meeting current regulatory requirements for airflow rates (ventilation rates) in buildings and airflow differentials for effective negative-pressure rooms.

The Plasmacluster ion technology, developed in 2000, is an air purification technology. Its manufacturer, Sharp Electronics Corporation, says that it can disable airborne microorganisms through the generation of both positive and negative ions. (1) The functional unit is the hydroxyl, which is a molecule comprised of one oxygen molecule and one hydrogen atom.

Plasmacluster ion air purifier uses a multilayer filter system composed of a prefilter, a carbon filter, an antibacterial filter, and a HEPA filter, combined with an ion generator to purify the air. The ion generator uses an alternating plasma discharge to split water molecules into positively and negatively charged ions. When these ions are emitted into the air, they are surrounded by water molecules and form cluster ions which are attracted to airborne particles. The cluster ion surrounds the airborne particle, and the positive and negative ions react to form hydroxyls. These hydroxyls steal the airborne particle’s hydrogen atom, which creates a hole in the particle’s outer protein membrane, thereby rendering it inactive.

Because influenza is primarily acquired by large droplets and direct and indirect contact with an infectious person, any in-room air cleaner will have little benefit in controlling and preventing its spread. Therefore, there is no role for the Plasmacluster ion air purifier or any other in-room air cleaner in the control of the spread of influenza. Accordingly, for purposes of this review, the Medical Advisory Secretariat presents no further analysis of the Plasmacluster.

Review Strategy

The objective of the systematic review was to determine the effectiveness of in-room air cleaners with built in UVGI lights and HEPA filtration compared with those using HEPA filtration only.

The Medical Advisory Secretariat searched the databases of MEDLINE, EMBASE, Cochrane Database of Systematic Reviews, INAHATA (International Network of Agencies for Health Technology Assessment), Biosis Previews, Bacteriology Abstracts, Web of Science, Dissertation Abstracts, and NIOSHTIC 2.

A meta-analysis was conducted if adequate data was available from 2 or more studies and where statistical and clinical heterogeneity among studies was not an issue. Otherwise, a qualitative review was completed. The GRADE system was used to summarize the quality of the body of evidence comprised of 1 or more studies.

Summary of Findings

There were no existing health technology assessments on air cleaning technology located during the literature review. The literature search yielded 59 citations of which none were retained. One study was retrieved from a reference list of a guidance document from the United States Centers for Disease Control and Prevention, which evaluated an in-room air cleaner with combined UVGI lights and HEPA filtration under 2 conditions: UVGI lights on and UVGI lights off. Experiments were performed using different ventilation rates and using an aerosolized pathogen comprised of Mycobaterium parafortuitum, a surrogate for the bacterium that causes tuberculosis. Effectiveness was measured as equivalent air changes per hour (eACH). This single study formed the body of evidence for our systematic review research question.

Experimental Results

The eACH rate for the HEPA-UVGI in-room air cleaner was statistically significantly greater when the UV lights were on compared with when the UV lights were off. (P < .05). However, subsequent experiments could not attribute this to the UVGI. Consequently, the results are inconclusive and an estimate of effect (benefit) is uncertain.

The study was reviewed by a scientific expert and rated moderate for quality. Further analysis determined that there was some uncertainty in the directness of the outcome measure (eACH); thus, the GRADE level for the quality of the evidence was low indicating that an estimate of effect is very uncertain.

There is uncertainty in the benefits of using in-room air cleaners with combined UVGI lights and HEPA filtration over systems that use HEPA filtration alone. However, there are no known risks to using systems with combined UVGI and HEPA technology compared with those with HEPA alone. There is an increase in the burden of cost including capital costs (cost of the device), operating costs (electricity usage), and maintenance costs (cleaning and replacement of UVGI lights) to using an in-room air cleaner with combined UVGI and HEPA technology compared with those with HEPA alone. Given the uncertainty of the estimate of benefits, an in-room air cleaner with HEPA technology only may be an equally reasonable alternative to using one with combined UVGI and HEPA technology

Conclusions

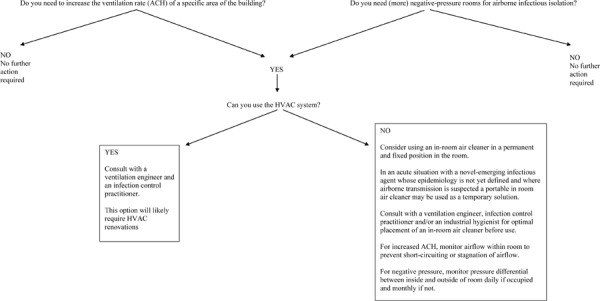

In-room air cleaners may be used to protect health care staff from air borne infectious pathogens such as tuberculosis, chicken pox, measles, and dessiminated herpes zoster. In addition, and although in-room air cleaners are not effective at protecting staff and preventing the spread of droplet-transmitted diseases such as influenza and SARS, they may be deployed in situations with a novel/emerging infectious agent whose epidemiology is not yet defined and where airborne transmission is suspected.

It is preferable that in-room air cleaners be used with a fixed and permanent room placement when ventilation requirements must be improved and the HVAC system cannot be used. However, for acute (temporary) situations where a novel/emerging infectious agent presents whose epidemiology is not yet defined and where airborne transmission is suspected it may be prudent to use the in room air cleaner as a portable device until mode of transmission is confirmed. To maximize effectiveness, consultation with an environmental engineer and infection control expert should be undertaken before using an in-room air cleaner and protocols for maintenance and monitoring of these devices should be in place.

If properly installed and maintained, in room air cleaners with HEPA or combined HEPA and UVGI air cleaning technology are effective in removing airborne pathogens. However, there is only weak evidence available at this time regarding the benefit of using an in-room air cleaner with combined HEPA and UVGI air cleaner technology instead of those with HEPA filter technology only.

Objective

This health technology policy assessment will answer the following questions:

When should in-room air cleaners be used?

How effective are in-room air cleaners?

Are in-room air cleaners that use combined HEPA and UVGI air cleaning technology more effective than those that use HEPA filtration alone?

What is the Plasmacluster ion air purifier in the pandemic influenza preparation plan?

The experience of sever acute respiratory syndrome (SARS) locally, nationally, and internationally underscored the importance of administrative, environmental, and personal protective infection control measures in health care facilities. In the aftermath of the SARS crisis, there was a need for a clearer understanding of Ontario’s capacity to manage suspected or confirmed cases of airborne infectious diseases. This included a review of methods to increase the capacity for airborne isolation within health care facilities in Ontario and to provide health care workers, patients, and visitors to these facilities with safer indoor air quality. In so doing, the Walker commission (2) thought that more attention should be paid to the potential use of new technologies, such as in-room air cleaning units, and subsequently recommended that the Medical Advisory Secretariat of the Ontario Ministry of Health and Long-term Care evaluate the appropriate use and effectiveness of such new technologies.

Therefore, The Ontario Health Technology Advisory Committee asked the Medical Advisory Secretariat to review the effectiveness and utility of in-room air cleaners that use high-efficiency particle air (HEPA) filters and ultraviolet germicidal irradiation (UVGI) air cleaning technology.

Additionally, the Ontario Health Technology Advisory Committee prioritized a request from the ministry’s Emergency Management Unit to investigate the possible role of the Plasmacluster ion air purifier, manufactured by Sharp Electronics Corporation in the pandemic influenza preparation plan.

This health technology policy assessment will answer the following questions:

When should in-room air cleaners be used?

How effective are in-room air cleaners?

Are in-room air cleaners that use combined UVGI lights and HEPA filters more effective than those that use only HEPA filters?

What is the role of the Plasmacluster ion air purifier in the pandemic influenza preparation plan?

Background

Clinical Need

Airborne transmission of infectious diseases depends in part on the concentration of breathable infectious pathogens (germs) in room air. (3) Because of this, infection control measures are needed to decrease the exposure to and risk of illness from such pathogens. Infection control is achieved by a combination of administrative, engineering, and personal protection methods. (3;4) Of these, engineering methods, which are usually carried out by the building’s heating, ventilation, and air conditioning (HVAC) system work to prevent the spread of airborne infectious pathogens by diluting (dilution ventilation) and removing (exhaust ventilation) contaminated air from a room, controlling the direction of airflow and the air flow patterns in a building. (4) However, over time, design (capacity of filters and air ducts), comfort (noise and drafts) issues, and general wear and tear on the HVAC system may limit its ability to maintain adequate indoor air quality. (5) Likewise, financial issues may limit the completion of necessary HVAC system renovations to maintain or increase its effectiveness. Therefore, when exposure to airborne infectious pathogens is a risk and increased ventilation is required, the use of an in-room air cleaner to reduce the concentration of airborne pathogens and prevent the spread of airborne infectious diseases has been proposed as an alternative to renovating the HVAC systems. (3;4;6)

Airborne transmission is the spread of infectious pathogens through the air over large distances. Infectious pathogens, which may include fungi, bacteria, and viruses, vary in size and can be dispersed into the air in drops of moisture after coughing or sneezing. (7). Small drops of moisture carrying infectious pathogens are called droplet nuclei and are about 1 to 5 micrometers (μm) in diameter. This small size in part allows them to remain suspended in the air for several hours and be carried by air currents over considerable distances. Moreover, if inhaled, they are small enough to bypass the protective mechanisms of the respiratory tract and settle in the lung where they may cause infection. (7;8) However, large drops of moisture carrying infectious pathogens are called droplets. Droplets are larger than droplet nuclei; because of this, they travel shorter distances (about 1 metre) before rapidly falling out of the air onto the ground.

Droplet nuclei are responsible for the airborne transmission of infectious diseases like tuberculosis (TB), chicken pox (varicella), measles (rubeola), and dessiminated herpes zoster, whereas direct contact (about 1 metre or less between people) is the primary route of transmission of an infectious diseases spread by droplets, such as influenza (the flu) and SARS.(9) Airborne infection isolation (AII) refers to the isolation of patients infected with diseases spread by droplet nuclei. (4;6;9)

Because droplet nuclei remain airborne for longer periods than do droplets, they are amenable to engineering infection control methods such as air cleaning more so than droplets.

Ventilation

The 3 functions of the general ventilation (HVAC) system of a building are to dilute the concentration of pathogens in room air and remove contaminated room air to the outdoors, control the direction of airflow in a building, and control the airflow patterns with in a room. (4)

Dilution and Removal of Contaminated Air

Two types of general ventilation systems are used to dilute and remove contaminated air: single-pass and recirculating air systems. With a single-pass system, 100% of the air passing through the room is exhausted (removed) to the outside. In a recirculating air system, some of the room air is filtered and recirculated back into the room. (6) With high ventilation rates, the concentration of infectious pathogens in the room air is diluted (decreased). The rate of room ventilation (ventilation rate) is equal to the amount of air moved in and out of a room and is measured as room air changes per hour (ACH). The ACH is the ratio of the volume of air entering the room per hour to the room volume. (6) For example, one room air change occurs when the volume of air entering the room equals the room volume.

Under ideal air mixing conditions, about 63% of airborne particles are removed in 1 ACH. However, given the variation in air mixing that occurs, a more realistic estimate is between 20% and 60%. (8) The number of air changes per hour will determine how quickly airborne pathogens are removed from the room air. (7) (Table 1) It has been estimated that between 12 and 15 ACH are sufficient to remove airborne pathogens and the cost of additional ACH over and above this exceeds the benefits (Personal communication, clinical expert, November 10, 2005) (7)

Table 1: Air Changes Per Hour and Time Required To Remove 99% or 99.9% of Airborne Particles From Room Air*(9).

| Air Changes | Minutes Required for Removal of Airborne Particles | |

|---|---|---|

| Per Hour | 99% Removal | 99.9% Removal |

| 2 | 138 | 207 |

| 4 | 69 | 104 |

| 6 | 46 | 69 |

| 8 | 35 | 52 |

| 10 | 28 | 41 |

| 12 | 23 | 35 |

| 15 | 18 | 28 |

| 20 | 14 | 21 |

| 50 | 6 | 8 |

From: Centers for Disease Control and Prevention. Guidelines for environmental infection control in health-care facilities: recommendations of CDC and the Healthcare Infection Control Practices Advisory Committee (HICPAC). MMWR Morb Mortal Wkly Rep [serial on the Internet] 2003; 52(RR-10): 1-48 [cited 2005 Sept. 11]. Available at: www.cdc.gov/ncidod/hip/enviro/guide.htm (7)

Recommended ventilation rates vary among different patient care areas of a hospital (9; 10) and between agency standards. (4;6;11;12) For example, The United States American Institute of Architects and Centers for Disease Control and Prevention recommends that aII rooms in existing facilities have at least 6 ACH and those in newly constructed or renovated facilities have a minimum of at least 12, whereas Health Canada states 6 to 9 ACH is adequate. However, the Health Canada recommendation may not reflect current evidence as it references the 1991 Canadian Standards Association Standard, (10) which was revised in 2001 and now supports 12 ACH for AII rooms.

When a room has no general ventilation system, the system cannot provide adequate ACH, or an increase in ventilation effectiveness is needed, in-room air cleaners may be considered to increase room ACH and thus ventilation rates of the room. (4;6)

Because in-room air cleaners recirculate room air, their effectiveness is expressed in equivalent air changes per hour (eACH), which compares airborne particle removal of the recirculated air with particle clearance from exhaust ventilation (HVAC system). (6) Equivalent ACH is determined by calculating the ratio of the airflow rate of the unit measured in cubic units per hour (e.g., cubic feet per minute [cfm]) to the room volume also expressed in cubic units (e.g., cubic feet). (13) For example an in-room air cleaner with a 400 cfm airflow rate through the unit may provide up to 13 equivalent air changes per hour in a hospital room that is 1800 cubic feet. (14) (See example calculation below.) The number of equivalent ACH provided by an in-room air cleaner will largely depend on the relative airflow rate through the device. It has been recommended that such units be designed to achieve at least 12 equivalent ACH and be compatible with the general ventilation system of a building. (6)

Example calculation of equivalent eACH:

Volume of room: 1800 cubic feet (volume = length × width × height of room)

Airflow rate of in-room air cleaner: 400 cfm × 60 minutes = 24,000 cubic feet per hour

eACH = 24,000/1800, or 13

Control of Airflow Direction and Patterns

Airflow Direction

The direction of airflow within a building can be manipulated to prevent the spread of contaminated air to uncontaminated air spaces. When the air pressure in a room is lower than that in the surrounding spaces, the room is said to be under negative pressure, and the room air is prevented from passively leaking out to the surrounding adjacent spaces. (Air always flows into the room but not out of the room.) Exhausting room air at a higher volumetric rate than the rate at which the air is entering the room achieves negative pressure. (6;15)

Negative-pressure rooms are used to isolate patients with confirmed or suspected airborne infections. Health care facility areas, including bronchoscopy suites, sputum induction rooms, selected examination and treatment rooms, autopsy suites, and clinical laboratories, have all been recommended to be in a negative-pressure environment. (6)

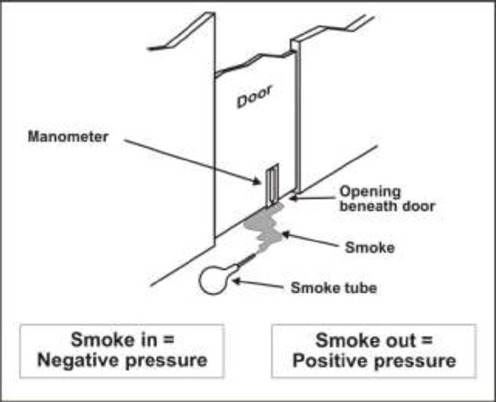

To achieve negative pressure, a pressure differential between the inside and outside of a room of at least 0.01 inches of water gauge (2.5 Pascals) is recommended. (6) Rooms under negative pressure must be monitored to ensure that this pressure differential exists so that air always flows in the intended direction (i.e., into the room for negative-pressure rooms). Monitoring can be undertaken with such methods as chemical aerosols (smoke tubes), differential pressure-sensing devices (manometer) and or physical indicators (flutter strips). (6) Smoke tubes generate smoke, which follows the air currents. If the smoke flows into the room from the corridor, then the room is under negative pressure (Figure 1). (6) When occupied by a patient with a suspected or confirmed airborne infectious disease, the pressure differential of a negative-pressure room should be checked daily using a smoke tube; otherwise, monthly monitoring with a smoke tube is recommended. (6)

Figure 1: Smoke tube testing to determine the direction of airflow.

From: Centers for Disease Control and Prevention. Guidelines for preventing the transmission of Mycobacterium tuberculosis in health-care settings. MMWR Morb Mortal Wkly Rep [serial on the Internet] 2005; 54(RR17): 1-141 [cited 2005 Sept. 11]. Available at: http://www.cdc.gov/mmwr/preview/mmwrhtml/rr5417a1.htm (6)

Air sampling can be used to monitor the cleanliness of the indoor air space. By sampling room air the concentration of airborne contaminants can be determined and the risk of exposure to infectious microorganisms evaluated. Air sampling does not provide absolute assurance that an area is free of biological contamination, because microorganisms may become reaerosolized from surfaces during routine activity. Because of this, surface sampling may also be used to determine areas of contamination.

Airflow Patterns

Airflow patterns refer to the movement of the air within the room. General ventilation should prevent air from stagnating (i.e., not moving) and from short-circuiting, which occurs when air moves directly to the exhaust from the supply without first mixing in the room. (16) Airflow patterns are determined in part by the location of the air supply and exhaust as well as the configuration of the room furniture and movement of people with in the room. In general, air should flow from less contaminated areas (clean spaces) to more contaminated spaces (less clean spaces) (16) Therefore, ideally, clean air entering the room should move first to the areas of the room where the health care workers are likely to be positioned, then to the patient (infectious source), and then to the exhaust (removal area). (6).

Filtration

Mechanical Filtration

Mechanical filtration is the physical removal of particles from air by capturing them in a fibrous net-like structure more commonly called a filter. Mechanical filters may be incorporated into the ducts of the HVAC system or in-room air cleaners. (6; 17)

Filter performance is characterized in terms of its single-pass removal efficiency, which is the fraction of particles captured as air passes once through the filter. (17) The American Society of Heating, Refrigeration and Air-Conditioning Engineers (ASHRAE) standard number 52.2-1999 classifies filter efficiency by how well it removes a particle from the air (particle removal efficiency), expressed as the minimum efficiency reporting value, or MERV. The higher the MERV the more efficient the filter.(18) Sixteen performance ratings covering efficiency in 3 particle size ranges, including 0.3–1.0μm, 1.0–3.0 μm, and 3.0–10.0 μm have been classified (Appendix 1).(18)

ASHRAE standard 52.1-1992 gives parameters for 2 tests used to measure filter efficiency: the dust spot test and the weight arrestance test (Appendix 1). The dust spot test evaluates the ability of a filter to remove large airborne particles. Outdoor air or a defined dust suspension (air suspension of particles of any solid material usually ≤ 100 μm in diameter), is fed into a test duct and captured by a filter, which results in dust spots or stains being left on the filter. The darkness of the stain on the filter is evaluated and based on this an efficiency number is given to the filter. Arrestance is used to describe low and medium-efficiency filters and measures the filter’s ability to capture a mass fraction of coarse test dust. To determine the weight arrestance of a filter, a standardized synthetic dust is fed to the filter and the fraction of the dust that is removed by the filter is weighed.(18) Particles that are about 0.3μm in diameter are the most difficult to capture by mechanical filtration. (17) Disadvantages of mechanical filtration include the possibility of air leaking around the filter (bypassing the filter) and the growth of moulds on the filter surface. (16)

Managing Environmental Infection Control Methods

For optimal effectiveness, environmental infection control methods must be installed, operated, and maintained correctly.

Ongoing maintenance is critical.

The health care facility should develop standard operating procedures for delegating maintenance of and staff training for managing and caring for all types of ventilation and filtration systems responsible for air cleaning.

Emergency power must be available to avoid the disruption of all environmental infection control methods during power failures

Types of Air Cleaning Technology

In-room air cleaners use one or more types of air cleaning technologies. High-efficiency particulate air (HEPA) filters and ultraviolet germicidal irradiation (UVGI) are the 2 most commonly used. Less commonly, ion emission has also been used. Each technology will be described in turn.

High-Efficiency Particulate Air Filtration

A HEPA filter uses mechanical filtration to remove airborne particles. A true HEPA filter is standardized at a minimum 99.97% efficiency rating for removing particles greater than or equal to 0.3μm (1/83,000 of an inch) in diameter. This means that for every 10,000 particles that are 0.3μm in diameter, 3 will pass through the filter, and the rest will be trapped by the filter. (6) To be fully effective, a HEPA filtration system must be leak-proof Maintenance costs associated with HEPA filters are higher compared with those for other types of filters, but the use of in-line disposable prefilters can increase the life of the HEPA filter by about 25%. (7) A true HEPA filter efficiency has been tested with a dioctyl phthalate particle test, which challenges the filter using particles that are 0.3 μm in diameter.

The efficiency of a filter will improve as particles accumulate (are loaded) on the filter. However, with loading, the airflow rate of an air cleaner will also decrease, as will the number of eACH the unit can provide. (3)

HEPA filters can be fitted into HVAC ducts or into in-room air cleaners. (6) Rutala et al. (14) found that an in-room air cleaner with a HEPA filter operating at about 400 cubic feet per minute (cfm) could clear 90% of airborne particles greater than or equal to 0.3μm in diameter within 5 to 8 minutes, compared with 12 to 16 minutes for air cleaners without a HEPA filter.

A regularly scheduled maintenance program is required to check for leakage and filter loading. It is suggested that the dioctyl phthalate penetration test should be performed at the initial installation and every time the filter is changed. Likewise, a leakage test using a particle counter should be done every 6 to 12 months on the filter. Trained personnel should always do the filter maintenance, and only while the ventilation system of unit is not operating.

Ultraviolet Germicidal Irradiation

Upper air irradiation with ultraviolet (UV) light was first developed in 1938. (19) Research has shown that under experimental conditions ultraviolet germicidal irradiation (UVGI) is effective in reducing the transmission of tubercle bacilli, the bacteria responsible for TB, as well as reducing the transmission of other airborne infections in hospitals, military housing and classrooms. (4) The CDC cautions that UVGI is not a substitute for HEPA filtration when air from AII rooms is to be recirculated within the building. (6)

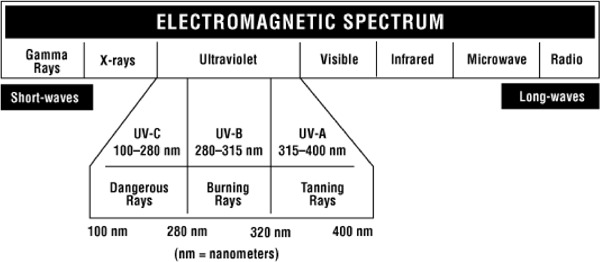

UVGI is a form of radiation encompassing wavelengths from 100 to 400 nm of the electromagnetic spectrum (Figure 2). (15) UV light has been classified into 3 wavelength bands: UV-A (long wavelengths, range 315-400mn); UV-B (midrange wavelengths, range: 280-315 nm); and UV-C (short wavelengths, range: 100-280nm). Most commercially available UV lights used for germicidal purposes are low-pressure mercury vapor lights that emit radiant energy at the UV-C wavelength of 253.7 nm. UVGI damages the deoxyribonucleic (DNA) of microorganisms, destroying their ability to replicate and thereby rendering them noninfections. (8)

Figure 2: Electromagnetic Spectrum.

Reproduced with permission from the Canadian Centre for Occupational Health and Safety. What is ultraviolet radiation [homepage on the Internet]. CCOHS. 2005. [cited Nov. 2005]. Available from: http://www.ccohs.ca/oshanswers/phys_agents/ultravioletradiation.html (20)

There are 3 primary methods of UV air disinfection: duct irradiation, upper-room air irradiation, and in-room air cleaners. (6) With duct irradiation, UVGI lamps are placed within the ducts of the building’s HVAC system that are used to remove air from the room. When air exits the room, it passes by the UV lamps where it gets irradiated (disinfected) and is then either exhausted to the outside or recirculated into the building. With duct irradiation, human exposure to the UVGI can only occur during maintenance of the filters and UV lights in the ducts. To achieve upper-room air irradiation, the UVGI lights are mounted on either the ceiling or the upper wall of a room; contaminated lower air must be moved up toward the lights for disinfection to occur. UVGI lights are also contained in-room air cleaners. The UV lights are contained within the body of the unit, and the number of lights is model specific. The unit’s fan draws contaminated air into the air cleaner and past the UVGI lights for disinfection. (15)

The ability for UVGI to kill pathogens such as bacteria, moulds, and viruses depends on the intensity of the light, the duration of exposure of the pathogen to the UVGI, and the relative humidity of the environment. (6) Different pathogens require different light intensities and durations of exposure. (6) For example, the effective kill dose of UVGI for TB bacilli is reported at 0.01 W-sec/cm2 of ultraviolet-C radiation. Moulds require a higher kill dose than that reported for TB bacilli. Importantly, the rate of the airflow (airflow rate) through the in-room air cleaner will affect the duration of exposure of the pathogen to the UVGI light and therefore the effectiveness of the UVGI to disinfect. The effectiveness of UVGI to kill or inactivate microorganisms has been shown to decline when the relative humidity in a room exceeds 60%. (6)

There are 2 known side effects of human overexposure to UVGI lights using UV-C energy: skin reddening, called erythema, and external eye inflammation, called photokeratitis. (6) UV photokeratitis clears without complications within 24 to 48 hours after exposure. UV-C energy does not penetrate the cornea; therefore, there are no adverse effects on the eye lens or the retina. Threshold limit values for UV-C exposure is 6.0mJ/cm2 during an 8-hour period. (6;21) Exposure above this intensity during an 8-hour period may result in erythema of the skin and photokeratitis. UV exposure is only a concern with upper-room irradiation lamps, but not with in-room air cleaners, unless the UV lamps do not automatically turn off when the cabinet doors are opened.

Ion Generation and Emission

Air ions, which were discovered at the end of the 19th century, are naturally occurring particles that have a positive or negative electrical charge. (22) Research (23) has investigated the physiological benefits of positive and negative air ions, and their role in reducing the concentration of airborne dust and microorganisms in indoor environments. Ion generators that artificially manipulate the ion content in air have been developed and marketed as domestic air cleaners for removing airborne dust and smoke. (24) Ion generator air cleaners can differ by the ion polarity generated such that unipolar generators emit either positive or negative ions, while bipolar generators emit both. Mechanistically, the emission of ions is thought to charge airborne particles similarly, causing them to repel each other and migrate toward and attach themselves to indoor surfaces, thereby being removed from the air. Negative ion generators may produce excessive concentrations of ozone and nitrogen oxides. (25) Likewise, the continuous infusion of unipolar ions into an enclosed environment leads to an electrical charge accumulation on insulating surfaces, which may cause static-related problems, especially at low humidity levels. (23) The Ontario Health Technology Advisory Committee has requested a review of a specific bipolar ion generator (Plasmacluster ion air purifier). Unipolar ion generator air cleaners are beyond the scope of this review.

New Technology Being Reviewed

In-Room Air Cleaners

In-room air cleaners are supplied as portable or fixed units. Fixed units can be attached either to the wall or ceiling of a room, and are preferred over portable units for reasons which will be discussed. In-room air cleaners may be used to increase room ventilation rates in areas where there is no or insufficient ventilation, when an increase in ventilation is needed, or to manipulate the direction of the airflow to create negative-pressure environments. (Not all units can do this.) A fan within the air cleaner pulls room air into the unit, where it then passes through a series of filters that remove particles. The cleaned air can then be recirculated into the room or exhausted to the outside of the building. By filtering contaminated room air and then recirculating the cleaned room air, an in-room air cleaner can increase the number of eACH within the room thereby improving the room’s rate of ventilation. By exhausting the filtered air to the outside of the building, the unit can create a negative-pressure room. There are many types of in-room air cleaners with wide variation in airflow rates through the unit and technical designs. However, at the minimum, each device includes the following features (26):

Intake duct (where air enters the unit)

Prefilter

HEPA filter

Motor/blower assembly (also called the fan)

Control panel with at least an on/off switch, an airflow speed control, a differential pressure gauge and/or a filter change indicator such as an hour metre or timed warning light.

Exhaust duct (air exits the unit)

In-room air cleaners may use a variety of air cleaning technologies including UVGI lights and HEPA filters, either alone or in combination, as well as ion generation and emission mechanisms. (13)

Effectiveness of In-Room Air Cleaners

The effectiveness of an in-room air cleaner depends on several factors, including the single-pass efficiency of the filter, the airflow rate through the filter, the airflow patterns in the room, and the relative positions of the source of contamination (patient) and the receptor (health care worker that can be infected) to the air cleaner. (3) The effectiveness of several types of in-room air cleaners, including those with HEPA and non-HEPA filters, (3;14;27)UVGI lights,(15) or combined HEPA and UVGI technology, (5;28) has been evaluated under a variety of conditions and found to be variable (Appendix 2). Miller-Leiden (3) reported that the effectiveness of recirculating air from in-room air cleaners with HEPA and non-HEPA filters alone or in combination with HVAC ventilation (2 ACH) ranged from 30% to 90%. Green and Scarpino (15) reported that in room air cleaners with UVGI technology only were effective in inactivating greater than 99% of the concentration of airborne pathogens. Similarly, Kujundzic et al. (28) determined that the effectiveness of a ceiling-mounted in-room air cleaner with combined HEPA and UVGI technology for reducing room air bacteria concentration in a building with an indoor pool ranged from 12% to 76%. Even though the effectiveness varies widely, the CDC (6) has acknowledged in-room air cleaners as alternative technology for increasing room ventilation when this cannot be achieved by the building’s HVAC system; preference is given to fixed re-circulating systems over portable ones.

The configuration of a room as determined by the positioning of furniture and people in the room, and the placement of the air cleaner relative to the contents and layout of the room, can affect room airflow patterns, airflow rate through the air-cleaner, and the effectiveness of the unit. (29) Likewise, the location of the air supply and air exhaust registers can also affect airflow patterns, which has an impact on the air cleaner’s effectiveness. For instance, Miller-Leiden (3) reported that more effective particle removal was achieved when the ventilation exhaust was placed near the source of the contamination (the patient), supporting the CDC’s recommendations that the ventilation exhaust should be located near the more contaminated area of the room.

Because airflow patterns within a room affect the effectiveness of in-room air cleaners, fixed in-room air cleaning systems are preferable to portable ones, because they more reliably achieve adequate room air mixing and airflow patterns if installed properly. (6) Likewise, some fixed systems may also have a higher airflow capacity when compared with portable systems. For these reasons, the HVAC system is the preferred means of room ventilation. The CDC’s hierarchy of ventilation methods for a TB isolation and treatment room supports the concept of using a fixed in-room air cleaner rather than a portable one. Table 2 lists the recommended ventilation methods to achieve dilution ventilation and/or a negative-pressure environment in order of most to least desirable. (4;6)

Table 2: Hierarchy of Recommended Ventilation Methods for Tuberculosis Isolation Rooms and Treatment Rooms*.

| Reducing Concentration of Airborne Tubercle Bacilli |

Achieving Directional Airflow Using Negative Pressure |

|---|---|

|

|

From: Centers for Disease Control and Prevention. Guidelines for preventing the transmission of Mycobacterium tuberculosis in health-care settings. MMWR Morb Mortal Wkly Rep [serial on the Internet] 2005; 54(RR17): 1-141 [cited 2005 Sept. 11]. Available at: http://www.cdc.gov/mmwr/preview/mmwrhtml/rr5417a1.htm (6)

HEPA indicates high-efficiency particulate air.

Whether fixed or portable, the strategic placement and set-up of these units within a room are crucial to maximizing the efficiency of in-room air cleaners and should be done in consultation with a ventilation engineer, infection control expert, and/or an industrial hygienist. A poorly positioned in-room air cleaner risks furniture or people obstructing the airflow through the air cleaner and compromising its efficiency. If the room’s intake air supply is too close to the air cleaner’s intake duct, then inadequate air mixing will occur, which will reduce the effectiveness of the unit. Monitoring of airflow patterns within the room is required for optimal device effectiveness.

Importantly, the use of an in-room air cleaner does not preclude the need for health care workers and visitors to wear personal protective equipment (e.g., N95 mask or equivalent) when entering AII rooms. Nor does it preclude the health care facility meeting regulatory requirements for airflow rates (ACH) for adequate ventilation and airflow differentials for effective negative pressure rooms.

Safety and Performance of In-Room Air Cleaners

ECRI (29) reviewed the safety, performance, human factors design, and cost of in-room air cleaners. Results of this review are summarized below and provide guidance for the selection of in-room air cleaners.

The suggested safety features of an in-room air cleaner include the following:

It should not have any accessible sharp edges or protrusions, its accessible surfaces should not reach temperatures that could damage skin, and it should not allow access to energized or moving parts.

In-room air cleaners that use UVGI lights should not expose people to harmful UV radiation, and UVGI lights should shut off automatically when the access door is opened.

Mechanisms to prevent unauthorized or inadvertent adjustment of controls should be incorporated into the design of the air cleaner.

An in-unit alarm should be programmed to sound if the unit is turned off or unplugged.

The unit should have visible warning signs to prevent the obstruction of the intake or exhaust ducts.

The unit should be equipped with a heavy-duty cord and a hospital-grade plug.

The HEPA filters within the unit should be individually tested and certified as true HEPA filters.

There should be no leaks around filter.

The need for filter changes should be clearly indicated on the unit, and filter maintenance should be easy to perform.

The exhaust blowers should be positioned downstream (after) the HEPA filter to minimize the possibility of exposure to infectious particles.

Portable devices should be physically stable during movement or when stationary and easy to transport otherwise.

Performance issues include the airflow rate through the device and size of the room to be cleaned, the room placement of the device, the air cleaning technology used, and the maintenance needs of the device.

Airflow Rate:

In an evaluation of volumetric airflow rates of in-room air cleaners, ECRI reported that devices with a volumetric airflow greater than or equal to 600 cfm had higher eACH than those with volumetric airflow rates less than or equal to 400 cfm did.

It should be noted that as the HEPA filter becomes dirty (loaded with particulate matter), airflow and subsequently eACH will be reduced. Therefore, choosing an in-room air cleaner with a high volumetric airflow rate will allow a margin of safety for this variable.

Airflow should be verified either by the manufacturer or by an independent third party such as a ventilation consultant or an industrial hygienist. A standard HVAC flow metre may be used to measure airflow.

It has been suggested that the minimum required airflow of an in-room air cleaner be determined by calculating the product of the required airflow for at least 12 eACH and a factor of 1.5 to account for air mixing and the unit efficiency. For example, for a 60 cubic metre room, the desired airflow rate would be 720 cfm to achieve 12 eACH. Therefore, the minimum required airflow for an in-room air cleaner would be 1.5 × 720 or 1080 cfm.

Size:

The appropriate sized unit depends on the size of the room to be serviced. Larger rooms will require devices with larger volumetric airflow rates.

Room Placement:

Poor placement of the unit in a room can reduce its effectiveness. The location of the room air intake and air exhaust areas, and the placement of the in-room air cleaner and the room furniture will affect the room airflow patterns and the effectiveness of the in-room air cleaner.

In-room air cleaners should be placed so that the device’s air intake is unobstructed by furniture and the device’s exhaust can move air as far as possible before being deflected.

Optimally, in-room air cleaners should have a fixed room placement that is determined in consultation with ventilation engineers, infection control practitioners, and/or industrial hygienists.

Air Cleaning Technology:

In an evaluation of in-room air cleaners with UVGI lights, it was reported that some generate ozone when new. Therefore, when UVGI lights are incorporated into in-room air cleaners, the manufacturer should be consulted regarding the possibility that the device will produce ozone when first used.

In-room air cleaners with UVGI lights will consume more power than will those without.

Additional expense will be incurred to maintain UVGI lights in the device.

It has been suggested that adding UVGI technology to an in-room air cleaner with a HEPA filter may be advantageous in 3 ways: the UVGI will sterilize the air that passes by it as well as the inside of the unit; it will serve as a backup air cleaning technology to the HEPA filter should the filter become damaged (leak) or fail; and the UVGI acts to protect the filter maintenance staff from exposure to infectious microorganisms by inactivating microorganisms within the system. Additionally, if the UVGI lights are upstream to (before) the HEPA filter, such that air passes first by the UVGI lights and then to the HEPA filter, this may help to prolong the life of the filter.

Dust build-up on UVGI lights will reduce their effectiveness; therefore, periodic cleaning is required.

UVGI may sterilize the interior surfaces of an in-room air cleaner that are directly exposed to it but not unexposed or shadowed areas. Because of this, the shadowed areas within the cabinetry of the air cleaner may still contain viable infectious pathogens to which maintenance personnel could be exposed. Because of this, when changing filters, proper isolation precautions should be used by maintenance personnel, regardless if UVGI lights are incorporated within the system.

Maintenance:

In-room air cleaners should be used and maintained by people knowledgeable about this technology.

Maintenance, physical plant, or biomedical engineering staff should be instructed in the use of the in-room air cleaner and about infection-control precautions to be used when servicing the device.

Regardless of the use of UVGI, lights within the in-room air cleaner system and any contaminated filters should be treated as infectious material and disposed of according to local institutional policy for the management of biohazardous waste.

The HEPA filter should be adequately sealed within the in-room air cleaner and periodically inspected for damage and particle loading.

Human Factors Design:

The airflow patterns generated by the unit should not create uncomfortable drafts within the room.

The noise created by the unit should allow for conversation at normal volumes. Suggested noise levels should be less than 55dbA (the level of normal conversation) at required airflows for at least 12 equivalent ACH.

The appropriate professionals should evaluate the electrical safety of the unit before it is used.

Technical support from the manufacturer should be available.

Cost Issues

The use of an in-room air cleaner to improve room ventilation rates and/or create negative-pressure rooms may be economically superior to the costs of renovating an HVAC system. Nevertheless, there are costs incurred with using these devices, including capital expenses of purchasing the devices, operational costs, and maintenance costs, which should be evaluated before purchase. Importantly, superior economy does not mean superior effectiveness for reasons previously discussed (in the section headed Technology Being Reviewed).

Some of the ongoing costs associated with in-room air cleaners include these:

Supplying new pre-filters about every 60 days (maintenance cost)

Providing a new HEPA filter about every 2 years, (maintenance cost)

Providing new UVGI lights if applicable about every year (maintenance cost)

Energy (electricity) usage (operational cost)

Plasmacluster Ion Air Filtration

The Emergency Managment Unit of the Ministry of Health requested a review of the possible role of the Plasmacluster ion air purifier in the pandemic influenza preparation measures. A literature search reported 1 published peer-reviewed report describing Plasmacluster ion technology. Other than this, to date, information regarding the Plasmacluster ion technology can only be found on the manufacturer’s Web site. (1)

The Plasmacluster ion technology, developed in 2000, is an air purification technology. Its manufacturer, Sharp Electronics Corporation, says that it can disable airborne microorganisms through the generation of both positive and negative ions. (1) The functional unit is the hydroxyl, which is a molecule comprised of one oxygen molecule and one hydrogen atom.

Plasmacluster ion air purifier uses a multilayer filter system composed of a prefilter, a carbon filter, an antibacterial filter, and a HEPA filter, combined with an ion generator to purify the air. The ion generator uses an alternating plasma discharge to split water molecules into positively and negatively charged ions. The positive ion has one hydrogen atom (H+), and the negative ion has 2 oxygen molecules (O2). When these ions are emitted into the air, they are surrounded by water molecules and form cluster ions. These cluster ions are attracted to airborne particles because of their electrical charge. The cluster ion surrounds the airborne particle, and the positive and negative ions react to form hydroxyls. These hydroxyls steal the airborne particle’s hydrogen atom, which creates a hole in the particle’s outer protein membrane, thereby rendering it inactive. The hydroxyl molecule bonds with the stolen hydrogen atom to form water, which is returned to the air. This process generates a small amount of ozone (< 0.01 parts per million).

Because influenza is primarily acquired by large droplets and direct and indirect contact with an infectious person, any in-room air cleaner will have little benefit in controlling and preventing its spread (Personal communication, clinical infection control expert, August, 2005). Therefore, there is no role for the Plasmacluster ion air purifier or any other in-room air cleaner in the control of the spread of influenza. Accordingly, the Medical Advisory Secretariat did no further analysis of the Plasmacluster ion air purifier in this health technology review.

Regulatory Status

In-room air cleaners do not meet the definition of a medical device as stated in the Canada Food and Drugs Act; therefore, they are exempt from device classification in Canada. (30;31)

Literature Review

Objective

The objective of the systematic review was to determine the effectiveness of in-room air cleaners with combined HEPA filters and UVGI lights compared with those using only HEPA filters.

Questions Asked

What is the benefit of adding UVGI lights to an in-room air cleaner with a HEPA filter?

Are in-room air cleaners that use combined HEPA and UVGI air cleaning technology more effective than those that use HEPA filtration alone?

Methods

Inclusion Criteria:

Basic science/laboratory aerosol-chamber studies

Systematic reviews

Randomized controlled trials (RCTs)

Observational epidemiological studies

Studies that directly compare the effectiveness of portable air cleaners with HEPA and UVGI to those using HEPA filters only

Studies using aerosolized pathogens between 1-5μm in diameter.

Outcome Measures:

Quantification of colony forming units (CFU) and or particle concentration counts of pathogens

Equivalent ACH

Any reported adverse effects of in-room air cleaners

Exclusion Criteria

Studies investigating pollens, dust mites, allergens and other airborne non-infectious particles

Non-comparative studies of portable air cleaners with HEPA filters only

Duplicate publications

Air cleaning for Aspergillus species and or protection of immunocompromised patients

Literature Search Strategy

The detailed search strategy can be found in Appendix 3 and an annotated bibliography of the databases in Appendix 4.

OVID MEDLINE: 1966 to March, week 2, 2005

EMBASE: 1996 to week 12, 2005

Cochrane Database of Systematic Reviews

INAHATA (International Network of Agencies for Health Technology Assessment)

Biosis Previews (Biological Abstracts)

Bacteriology Abstracts

Web of Science

Dissertation Abstracts

NIOSHTIC 2 (National Institute of Occupational Safety and Health)

A meta-analysis was conducted when adequate data was available from 2 or more studies and where statistical and clinical heterogeneity among studies was not an issue. Otherwise, a qualitative review was completed.

GRADE Quality of the Body of Evidence

The GRADE system (32) was used to summarize the overall quality of evidence in the systematic review. This system has 4 grade levels: very low, low, moderate, and high. The criteria for assigning GRADE of evidence is as follows:

Type of evidence (initial GRADE point):

Randomized trial = high GRADE

Observational study = low GRADE level to start

Any other evidence = very low GRADE level to start

Decrease grade if:

Serious limitation to study quality (-1, reduce GRADE level by 1; for example, an initial GRADE point of high will become moderate) or very serious limitation to study quality (-2, reduce GRADE level by 2; for example, an initial GRADE point of high will become low).

Important inconsistency (-1, reduce GRADE level by 1).

Some (-1) or major (-2) uncertainty about directness.

Imprecise or sparse data (-1).

High probability of reporting bias (-1).

Increase GRADE level if:

Strong evidence of association-significant relative risk of > 2 (or < 0.5) based on consistent evidence from 2 or more observation studies, with no plausible confounders (+1, increase GRADE level by 1; for example, if the GRADE level is moderate it will become high. However, a high grade will remain high).

Very strong evidence of association-significant relative risk of > 5 (or < 0.2) based on direct evidence with no major threats to validity (+2, increase GRADE level by 2; for example, if the GRADE level is a low grade it will become a high).

Evidence of a dose response gradient (+1).

All plausible confounders would have reduced the effect (+1).

GRADE scoring definitions:

| High: | Further research is very unlikely to change our confidence in the estimate of effect. |

| Moderate: | Further research is likely to have an important impact on our confidence in the estimate of effect and may change the estimate. |

| Low: | Further research is very likely to have an important impact on our confidence in the estimate of effect and is likely to change the estimate. |

| Very low: | Any estimate of effect is very uncertain. |

Strength of Recommendations

The GRADE system (33) also offers a framework with which to grade the strength of the recommendations that may stem from the body of evidence. The system is predicated on the GRADE level of the body of the evidence (high, moderate, low or very low) and the overall balance between the benefits, risks and burdens of the technology. Briefly, if the benefits clearly outweigh the risks and burdens, then a strong recommendation is made. However, if the benefits are closely balanced with the risks and burdens, or there is uncertainty in the benefits, risks, and burdens, then the recommendation is weak.

Results of Literature Review

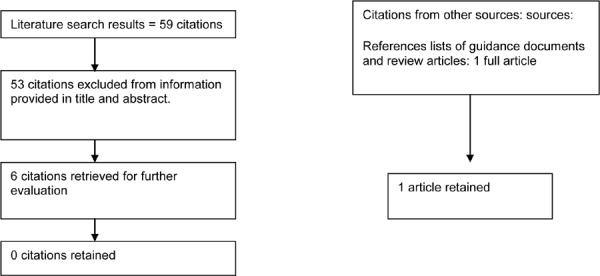

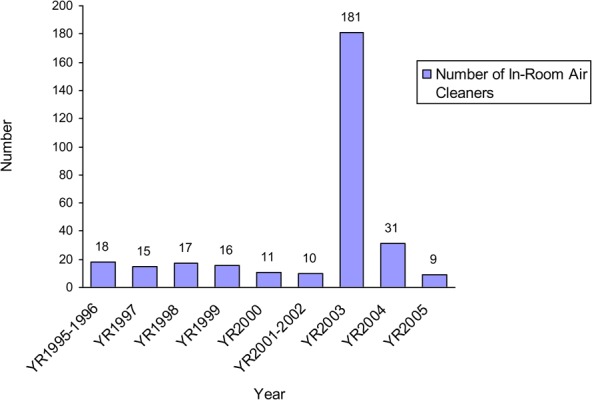

The literature search yielded 59 studies on air cleaning technologies (Figure 3). There were no existing health technology assessments. After reviewing the information in the title and abstract of the 59 citations, 6 were retained, and the full articles were retrieved for further review. After review, all 6 studies were rejected because they did not meet the inclusion criteria of comparing HEPA filtration air cleaners to those with HEPA plus UVGI. One study was retrieved from the reference list of the Guidelines for Preventing the Transmission of Mycobacterium tuberculosis in Health-Care Settings, 2005.(6). This study was retained and included in this review.

Figure 3: Summary of the Literature Review.

Study: Evaluating Portable Air Cleaner Removal Efficiencies for Bioaerosols (13)

Table 3: Quality of Evidence of Included Studies According to Study Design.

| Study Design | Level of Evidence |

Number of Eligible Studies |

|---|---|---|

| Systematic review(s) of large RCTs* | 1a | 0 |

| Large RCT | 1b | |

| Large RCT unpublished but reported to an international scientific meeting | 1(g)† | 0 |

| Small RCT | 2 | 0 |

| Small RCT unpublished but reported to an international scientific meeting | 2(g) | 0 |

| Non-RCT with contemporaneous controls | 3a | 1 |

| Non-RCT with historical controls | 3b | 0 |

| Non-RCT presented at international conference | 3(g) | 0 |

| Surveillance (database or register) | 4a | n/a |

| Case series (multisite) | 4b | n/a |

| Case series (single site) | 4c | n/a |

| Retrospective review, modeling | 4d | n/a |

| Case series presented at international conference | 4(g) | n/a |

RCT refers to randomized controlled trial. A large RCT is defined as one that has adequate power to detect differences in the primary outcome.

indicates gray literature.

Objectives

To determine effectiveness expressed as eACH of 3 in room air cleaners (also called portable air cleaners (PAC))

To determine the effectiveness expressed as eACH of an air cleaner with combined UVGI and HEPA technology with and without the use of the UV lights

To determine the effectiveness expressed as eACH of combining an in room air cleaner with an upper-room UVGI system

Methods

In a crossover design study and using a decay experiment methodology, Miller and Hernandez (13) compared the ability of 3 in-room air cleaners – a negative ion generator, an electrostatic precipitator, and a combined HEPA filtration UVGI unit (HEPA-UV) – to reduce the concentration of airborne pathogens in an 89 cubic metre (m3) test chamber, which simulated a hospital patient room. The room air concentration of airborne pathogens was measured after each in-room air cleaner was sequentially placed in the test chamber and turned on. Four experiments were carried out under 0 and 6 ACH room ventilation rates. The airborne pathogens Mycobacterium parafortuitum (M. parafortuitum) and Micrococcus luteus (M. Luteus) and a non-biological aerosol were used to challenge the in-room air cleaners.

Experiment 1: In the first experiment, the HEPA-UV in-room air cleaner was tested to determine its ability to reduce the concentration of an airborne pathogen under 2 conditions: with the HEPA filter in place and the UV lamps on (filter in/lights on) and then with the HEPA filter in place and the UV lamps removed from the device (filter in/lights removed). The experiments were performed under 0 and 6 ACH room ventilation. The M parafortuitum pathogen was used for this experiment.

Experiment 2: In a second experiment, the investigators aimed to determine if there was a change in the internal airflow through the air cleaner when the UV lights were removed from the HEPA-UV device, and which might affect the function of the HEPA filter. The eACH was determined under 3 conditions: HEPA-UV air cleaner with the internal UV lights on (ON); HEPA-UV air cleaner with internal UV lights switched off but left in the unit (OFF/IN); and HEPA-UV air cleaner with the internal UV lights removed from the unit (OUT). Each condition was tested using a non-biological aerosol (phosphate buffer solution particles) to isolate the effect of the airflow through the unit. Experiments were done under 0 and 6 ACH room ventilation.

Experiment 3: In the third experiment, the investigators aimed to determine the effectiveness of the HEPA-UV air cleaner with the UVGI lights functioning and the HEPA filter removed (UVGI only). The HEPA filter was removed, and the UV lights were left in the device and turned on. The author does not describe the methods for this experiment nor the pathogen(s) used.

Experiment 4: In a final experiment, the investigators aimed to determine the effectiveness of combining the HEPA-UV air cleaner with the UV lights functioning with an upper-room UVGI air system functioning at either 100% or 50%. One pathogen (M. parafortuitum) was used for this set of experiments conducted under 0 ACH conditions.

For experiments 1, 3, and 4, the concentration of airborne pathogens in the room was quantified using culture plates and/or direct microscopy. For study 2, an optical particle counter was used. For all studies, the rate at which aerosols were removed from room air was determined using the natural log of a completely mixed room air model, which is a log equation that determined the rate of change of the aerosol concentration with time during the decay period. The eACH for each air cleaner was estimated using a least squares linear regression equation fitted to the decay data of microorganism counts. The eACH rate is useful for determining the rate at which aerosols are removed by methods other than the general ventilation. It also allows the effectiveness of different kinds of air cleaners to be directly compared. Further details of the experimental methods are in Appendix 5.

Results of Experiments

All Experiments: There was no statistically significant difference between the eACH determined using either culturing or direct microscopy. Nor was there a statistically significant difference between the eACH rates of the in-room air cleaner under the different ventilation rates of 0 or 6 ACH.

Experiment 1: There was a statistically significant difference in the eACH rates for the HEPA-UV in-room air cleaner when the HEPA filter was left in the device and the UV lights were also left in and turned on (filter in/lights on) compared when the HEPA filter was left in and the UV lights were removed (filter in/lights removed) (P < .05) (Table 4). The investigators hypothesized that the differences in eACH between conditions (filter in/lights on vs. filter in/lights removed) might be due to a disruption in the internal airflow patterns of the air cleaner when the UV lights were removed, thereby reducing the HEPA filter’s effectiveness and the overall effectiveness of the device. Experiment 2 tested this hypothesis.

Table 4: Equivalent Air Changes Per Hour Rates With M. parafortuitum Across Groups.

| Experiment* | Mean (SE) Equivalent Air Changes Per Hour |

|---|---|

| Filter in/UV lights removed -0 ACH | 2.93 (0.96) |

| Filter in/UV lights in and on -0 ACH | 11.70 (1.20) † |

| Filter in/UV lights removed -6 ACH | 3.76 (2.32) |

| Filter in/UV lights in and on -6 ACH | 10.90 (1.20)‡ |

HEPA represents high-efficiency particulate air; ACH, air changes per hour; UV, ultraviolet.

Significantly different compared with Filter in/UV lights removed condition at 0 eACH. P < .05

Significantly different compared with Filter in/UV lights removed condition HEAP-UV at 6 eACH. P< .05

Experiment 2: There was no statistically significant difference between eACH estimated when the UV lights were left in the air cleaner but turned off (in/off) compared with having the UV lights out (OUT) (Table 5). This did not support the hypothesis that removing the UV lights disrupted the airflow patterns.

Table 5: Equivalent Air Changes per Hour Using Nonbiological Aerosol Across Groups.

| HEPA* Filter In, UV† Lights In and On, Mean (SE) |

HEPA Filter In, UV Lights In and Off, Mean (SE) |

HEPA Filter In, UV lights Out, Mean (SE) |

|---|---|---|

| 7.79 (0.45) | 4.70 (0.33) | 4.70 (0.33) |

| 5.89 (0.34) | 3.97 (0.23) | 3.97 (0.23) |

| 5.48 (0.03) |

HEPA indicates high-efficiency particulate air

UV indicates ultraviolet

Experiment 3: With the HEPA filter removed and the UV lights left in the air cleaner and turned on, the estimated eACH due to the UV lights only was approximately 1.

Experiment 4: The eACH from upper-room UVGI combined with an in-room HEPA-UVGI air cleaner is additive (Table 6).

Table 6: Equivalent Air Changes Per Hour of UVGI Upper-Room Air System plus Portable HEPA-UV Air Cleaner, and for Portable HEPA-UV Air Cleaner and UVGI Systems Only, using M. parafortuitum and 0 Air Changes Per Hour Ventilation.

| Experiment (Comparisons)* | Combined Equivalent eACH (eACH PAC + eACH Upper room UVGI), Mean (SE)* |

Equivalent ACH PAC, Mean (SE) |

Equivalent ACH Upper room UVGI, Mean (SE) |

|---|---|---|---|

| HEPA-UV + UVGI system at 100% | 27.2 (5.6) | 10.7 (3.2) | 16.5 (6.4) |

| HEPA-UV + UVGI system at 50% | 16.9 (5.7) | 9.8 (1.6) | 7.10 (6.0) |

HEPA represents high-efficiency particulate air; UV, ultraviolet; UVGI, ultraviolet germicidal irradiation; eACH, equivalent air changes per hour; PAC, portable air cleaner.

The authors concluded that more analyses should be performed on the HEPA-UV in-room air cleaning system to understand the discrepancies between the eACH measured when the UV lights where left in the air cleaner and turned on compared to when the UV lights were removed from the air cleaner. They also noted that operating an upper-room UVGI system in conjunction with an in-room HEPA-UVGI air cleaner gives a total eACH that is the sum of the individual eACH of each air cleaning system.

Table 7: GRADE Profile Question: What is the Benefit of Adding Ultraviolet Germicidal Irradiation Air Cleaning Technology to an In-Room Air Clean That Uses a HEPA Filter?

| Quality Assessment | Summary of Findings | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| N (no. of experimental runs) | Effect | |||||||||

| Comparison (study) |

Design | Quality | Consistency | Directness | Other modifying factors | HEPA* only | HEPA + UVGI* | Relative Risk (95% CI) |

Quality | Outcome |

| Outcome: Equivalent Air Changes Per Hour (eACH) | ||||||||||

| (Miller and Hernandez, 2002) | Cross-over laboratory studies† | Some limitations‡ | One study | Some uncertainty§ | None | 6 | 6 | N/A | Low | Important |

| Quality GRADE | High | moderate | low | low | ||||||

HEPA indicates high-efficiency particulate air; UVGI, ultraviolet germicidal irradiation.

Author indicated that air cleaners were evaluated in no particular order.

Scientific expert had some methodological criticisms including that the investigators used glass impingers (AGI-30), whereas it might have been better to use a slit sampler to generate time-related data.

Author converted room airborne pathogen concentration counts to equivalent air changes per hour.

The body of evidence comprised 1 publication with 4 laboratory experiments investigating the value of adding UVGI lights into an in-room air cleaner with a HEPA filter. After consultation with a scientific expert (personal communication, November, 2005), the quality of the experiments were graded as moderate. The body of evidence was further downgraded because of some uncertainty in expressing the outcome as eACH instead of as the concentration of pathogens. The eACH was accepted as a surrogate outcome measure. Therefore the body evidence was given a GRADE level of low. According to GRADE, low quality is defined as “further research is very likely to have an important impact on our confidence in the estimate of effect and is likely to change the estimate.”

Strength of Recommendations

There is uncertainty in the benefit of using an in room air cleaner with combined HEPA and UVGI technology compared with using one with HEPA filtration only. There is/are no known risk(s) to using an in room air cleaner with combined HEPA and UVGI air cleaning technology. There can be an increase in the burden of cost (purchasing, operation, and maintenance costs) to using an in room air cleaner with combined HEPA and UVGI air cleaning technology compared with using a HEPA only model. Given this, the strength of a recommendation to use an in room air cleaner with UVGI lights and HEPA filtration would be rated as weak, meaning alternatives such as an in room air cleaner with a HEPA filter only may be an equally reasonable alternative.

| Comparison | Benefit | Risk | Cost-burden | Quality | Strength |

|---|---|---|---|---|---|

| Air cleaners with HEPA filtration only | Uncertainty in the estimates of benefits | No known risk to using in-room air cleaner with UVGI and HEPA filtration |

Higher - Maintenance of UVGI lights - Purchase of new UVGI lights yearly - Higher energy usage |

Low An estimate of effect is uncertain. |

Weak recommenddation; alternatives may be equally reasonable. |

Cost Profile

The estimated purchase prices of an in-room air cleaner are reported in Table 8.

Table 8: Cost Profile of an In-Room Air Cleaner.

| Specifications | Airflow, Cubic Feet Per Minute |

Maximum Room Volume, Cubic Feet |

Cost (Cdn) |

|---|---|---|---|

| HEPA + UVGI* | ≈500 | Up to 2000 | $4,300-8,500 |

| HEPA + UVGI | 400 | Up to 2000 | $3,000 |

| HEPA only | 465 | Up to 2000 | $3,680 |

HEPA represents high-efficiency particulate air; UVGI, ultraviolet germicidal irradiation.

Existing Guidelines for Use of Technology

Guidelines dealing with environmental infection control from relevant provincial, national and international sources are outlined below.

Provincial Guidelines

For the Public’s Health: A Plan of Action. Final Report of the Ontario Expert Panel of SARS and Infectious Disease Control, April 2004 (2)

No single set of guidelines or standards exists in Ontario on infection control and facility design

There is a need for a uniform set of standards or guidelines for Ontario that should reflect, among other things, design changes essential to effective infection control particularly for emergency rooms in Ontario to ensure adequate and safe holding areas and assessment zones of patients who may pose an infectious disease risk.

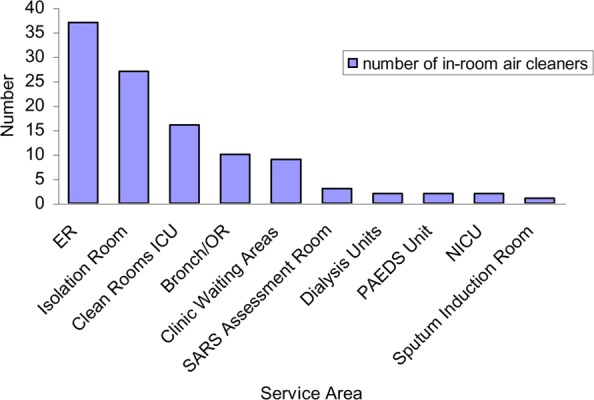

All emergency rooms require a minimum ability to isolate suspected or actual cases of infectious disease. Ranging from separate rooms without special air handling provisions, to negative-pressure rooms with HEPA filtration, to a full negative-pressure isolation rooms with an anteroom and adjacent bath.

All facilities require some baseline capacity to deal with infectious cases. The needs of the facility should be determined based upon a graduated approach to risk.

Recommendation 42: The Ministry should immediately undertake an independent evidence-based needs assessment, reporting back to the Ministry by March 1, 2004 on the supply and distribution of negative-pressure rooms between and within hospitals. The Ministry must ensure that there is a sufficient supply of negative-pressure rooms on a regional basis.

Recommendation 43: The evidence-based needs assessment should be undertaken using standards and guidelines developed through Provincial Communicable Disease Committee. The Ministry should develop and maintain a current inventory of the number and location of all existing negative-pressure and isolation rooms in Ontario.

Recommendation 45: The Ministry, through the Ontario Health Technology Advisory Committee, the Medical Advisory Secretariat, and additional relevant external expertise, should immediately establish a process to evaluate the appropriate use and effectiveness of new technology applicable to isolation precautions, such as portable air filtration units and portable single patient isolation units.

Preventing Respiratory Illnesses Protecting Patients and Staff. (December 2003) Ontario (34) http://www.health.gov.on.ca/english/providers/program/pubhealth/sars/docs/docs3guide_fri_non_acute_031104.pdf (last accessed, November 6, 2005)

All acute care hospitals should have at least one negative-pressure room that meets Health Canada standards as outlined in the Guidelines for Preventing the Transmission of TB in Canadian Facilities. (http://www.phac-aspc.gc.ca/publicat/ccdr-rmtc/96vol22/22s1/, last accessed November 6, 2005)

The negative-pressure room can be used for special procedures that create aerosols in patients with droplet-spread infections. This room may be routinely required to provide patient care for airborne infections.

National Guidelines

Special Requirements for Heating, Ventilation, and Air Conditioning (HVAC) Systems in Health Care Facilities. Z317.2-01 A National Standard of Canada (approved February 2003) Canadian Standards Association (10)

Standard Z317.2-01 states that airborne isolation rooms should have the following:

Inward directional airflow from adjacent spaces to the room

Directional airflow within the room so that clean supply air flows first to parts of the room where workers or visitors are likely to be present, and then flows across the infection source (the patient) to the exhaust.

Nonaspirating diffusers

Low-level exhaust near the head of the patient bed

All air exhausted to the outdoors

HEPA filtration of exhaust in cases where exhaust air is not discharged clear of building openings or where a risk of recirculation exists.

Monitoring and alarm of room pressure

Monitoring of supply and exhaust system function

An exhaust fan supplied by emergency power

As well:

Air may be recirculated within individual infectious isolation rooms if HEP A filtration is used.

Recirculation-type HEPA filters may be used to increase the room air change rate.

Different health care facility service areas require different rates of ventilation (ACH)

Infection Control Guidelines: Health Canada 1999 Routine Practices and Additional Precautions for Preventing the Transmission of Infection in Health Care. (9)

-

Airborne Precautions (does not represent total precautions, but only those recommendations pertaining to engineering methods of infection control):

Negative pressure in relation to surrounding areas

A minimum of 6-9 air exchanges per hour; Health Canada considers 6-9 ACH adequate for patients with TB

Air discharged outside the building and away from intake ducts or through a HEPA filter if recirculated.