Abstract

The aim of this study was to better understand how in vivo oxidation contributes to fatigue damage in total knee arthroplasty (TKA). 119 tibial inserts were consecutively collected after revision surgery. Of the 119 polyethylene retrievals, 29 were gamma sterilized in air (historical), while the remaining 90 were gamma sterilized in nitrogen (conventional). Surface damage assessment and characterization of oxidation were performed on all the retrievals. Delamination was significantly more prevalent and extensive in the longer-term, highly oxidized, historical tibial inserts. Pitting damage, in contrast, appeared to be equally prevalent between both retrieval groups, and was not correlated with in vivo oxidation. Our findings support our hypothesis that in vivo oxidation is a contributing factor to delamination, but not pitting, in TKA. Despite the lower oxidation displayed by conventional retrievals, this study provides strong evidence that delamination secondary to in vivo oxidation may occur during the second decade of implantation.

Keywords: ultra-high molecular weight polyethylene, total knee arthroplasty, in vivo oxidation, pitting, delamination, fatigue

Introduction

Gamma radiation sterilized, ultra-high molecular weight polyethylene components for hip arthroplasty are now recognized to undergo post-irradiation degradation of chemical and physical properties following long-term exposure to the in vivo environment [1–3]. Although many studies have reported on in vivo degradation of polyethylene acetabular liners following the historical practice of gamma irradiation in air, similar trends have also been recently observed in conventional and highly crosslinked polyethylene bearings that were gamma radiation sterilized in an inert environment [1–2, 4–5]. Analysis of both historical and contemporary retrieved acetabular components suggests that implant surfaces with access to oxygenated body fluids, such as the rim, display greater in vivo oxidation than the backside of the liners or protected regions of the bearing surface [1]. On the other hand, because the rim, but not the bearing surface, appears to be more vulnerable to in vivo oxidation, long-term wear studies of the hip have generally shown that clinically wear rates with historical materials tend to decrease over time [6].

The natural history and clinical significance of in vivo oxidation for tibial inserts of total knee arthroplasty (TKA) is much less well understood. In the knee, fatigue wear mechanisms are thought to predominate because of the lower conformity and higher contact stresses between the femoral and tibial components [7–8]. Thus, the consensus is that the delamination and pitting damage often observed in retrieved polyethylene tibial inserts are due to fatigue wear [8–11]. Although factors such as poor consolidation, fusion defects, and implant thickness are known to exacerbate fatigue wear in tibial inserts [7–8, 12–16], post-irradiation oxidation during shelf storage in air was ultimately recognized as probably the most important contributor to premature delamination in gamma radiation air sterilized tibial components [17–23]. On the other hand, pitting damage has also been linked to the presence of bone, bone cement and metal particles, which introduces a third-body wear process [24–27]. Moreover, based on polarized light microscopy studies, it has been suggested that microscopic creep, instead of a fatigue wear mechanism, may also produce pits when third-body particles are forced into the surface of polyethylene bearings [26]. Thus, it remains unknown to what extent in vivo oxidation contributes to delamination and pitting damage in TKA tibial inserts.

We undertook a retrieval study to better understand the relationship, if any, between in vivo oxidation and the wear damage modes of pitting and delamination in TKA. To provide a basis for comparison with conventional gamma-inert sterilized inserts, we also characterized historical bearings that were gamma radiation sterilized in air, a process that was discontinued by major manufacturers in the United States during the 1990s. Since that time, there have also been changes in the fabrication of polyethylene powders (or resins) that form the starting material for medical grade polyethylene. We tested the hypothesis that both historical (gamma air sterilized) and conventional (gamma inert sterilized) tibial inserts undergo pitting and delamination due to in vivo oxidation. To address our global hypothesis, we controlled for variables which might influence the susceptibility of tibial inserts to in vivo oxidation and wear damage, including polyethylene resin, conversion method, and shelf life.

Materials and Methods

In 2000, we initiated a multi-institutional traceable knee implant retrieval program to study in vivo oxidation of polyethylene tibial inserts. Within this knee retrieval program, 119 polyethylene tibial inserts produced by a single manufacturer (Zimmer; Warsaw; IN) were collected at revision surgery from four different medical institutions between December 2000 and October 2008. After retrieval, tibial inserts were expeditiously store in a sub-zero freezer (−80 °C) to minimize ex vivo changes to polyethylene prior to characterization [20]. Relevant clinical information, such as reason for revision, implantation time, side as well as patient gender, age, weight and height, was available. In addition, all these tibial inserts were traced by the manufacturer using the serial numbers obtained from the patients’ operative notes or from inscriptions on the backside of the inserts themselves. Thus, they were confirmed to be either gamma sterilized in air or in an inert atmosphere. Highly crosslinked polyethylene tibial inserts were excluded from this study. Of the 119 retrieved tibial inserts, 29 underwent gamma sterilization in air (historical), and 90 were gamma sterilized in an aluminum foil blister package filled with nitrogen (conventional). The starting polyethylene resin (GUR 415, GUR 1050, or Basell 1900H), the conversion method (ram extrusion, bulk compression molding, or direct compression molding), and the sterilization date were also traced by the manufacturer, so that retrievals could be classified into four categories (Air1&2 and Inert1&2) according to processing conditions (Table 1). Shelf lives could be computed in 74/119 (62%) cases. The revised historical tibial inserts were of both cruciate retaining (CR) and posterior stabilized (PS) designs: Insall-Burstein II (n=12; PS design); Miller-Galante II (n=12; CR design); Miller-Galante I (n=4; CR design); and NexGen Legacy (n=1; PS design). Similarly, gamma inert polyethylene knee bearings were of both CR and PS designs: NexGen Legacy (n=44; PS design); Insall-Burstein II (n=19; PS design); NexGen Legacy Condylar Constrained Knee (n=11; PS Design); Insall-Burstein Constrained Condylar Knee (n=5; PS design); NexGen (n=5; CR design); NexGen Trabecular Metal Monoblock (n=2; CR design); NexGen Legacy Trabecular Metal Monoblock (n=2; PS design); and Miller-Galante II (n=2; CR design). In total, 94 of the 119 retrieved tibial inserts (79%) belonged to the posterior stabilized category, and they had either a polyethylene stabilizing post or spine.

Table 1.

Summary of shelf lives and implantation times (average ± SD) for retrieved historical, gamma sterilized in air, and conventional, gamma sterilized in an inert gas, tibial inserts produced from different polyethylene resins and conversion techniques.

| Retrieval group | Processing Conditions | Shelf Life (y) | In Vivo Duration (y) |

|---|---|---|---|

| Air 1 (n=4) | *DCM 1900H, Gamma Air Sterilized | 0.5 ± 0.2 | 12.0 ± 5.4 |

| Air 2 (n=25) | Extruded GUR 415, Gamma Air Sterilized | 1.1 ± 1.2 | 11.5 ± 3.0 |

| Inert 1 (n=24) | DCM 1900H, Gamma Inert Sterilized | 0.6 ± 1.1 | 2.9 ± 2.9 |

| Inert 2 (n=66) | Molded GUR 1050, Gamma Inert Sterilized | 1.3 ± 1.3 | 3.7 ± 3.0 |

DCM stands for Direct Compression Molded.

The average implantation time of the retrieved historical tibial inserts (mean and range: 11.6 years; 4.4 – 17.0 years) was significantly longer than that of the gamma inert sterilized knee retrievals (mean and range: 3.4 years; 0.1 – 12.8 years; p < 0.0001 Wilcoxon test). In contrast, shelf lives prior to implantation for the two cohorts were not significantly different (p = 0.4; Wilcoxon test), with similar mean storage periods: 1.0 year (range: 0.1 – 4.9 years), and 1.0 year (range: 0.0 – 4.6 years) for historical and conventional polyethylene bearings, respectively. Of the 29 TKAs in the historical cohort, 14 (48%) were left knee arthroplasties, and 15 (52%) were performed in female patients. Similarly, of the 90 TKAs in the conventional cohort, 42 (47%) were left knee arthroplasties, and 53 were performed in female individuals (59%). Patients in the historical cohort had a mean age of 58 years (range: 17 – 76 years) at insertion, mean height of 168 cm (range: 150 – 187 cm), and mean weight of 91 kg (range: 48 – 200 kg). Patients who received a conventional tibial insert had a mean age of 63 years (range: 34 – 86 years) at insertion, mean height of 167 cm (range: 149 – 196 cm), and mean weight of 89 kg (range: 51 – 129 kg). Following insertion, patients with historical inserts were slightly more active on average (UCLA score mean and range: 6; 3 – 10) than patients who had conventional tibial inserts (mean and range: 5; 1 – 10). Activity levels before revision surgery were similar (mean and range: 3; 1 – 7; and 3; 1 – 6, respectively). There were no significant differences between historical and conventional cohorts with regard to patient characteristics (p ≥ 0.06), the only exception being the level of activity after insertion (p = 0.03; Wilcoxon test; Power = 65%), which was significantly higher in the historical patient cohort. No significant differences in patient demographics (p ≥ 0.18 or Power < 50%) were found when retrievals were grouped according to processing conditions.

Primary diagnoses were known in 103 of the 119 patients. Overall, osteoarthritis was the most common primary diagnosis in the historical cohort (n=19; 66%), followed by rheumatoid arthritis (n=4; 14%), and a case of post-traumatic arthritis and fracture (n=1; 3%). Similarly, osteoarthritis was the most prevalent condition in the conventional cohort (n=71; 79%, including a patient also with chondrocalcinosis), followed by post-traumatic arthritis (n=6; 7%); rheumatoid arthritis (n=1; 1%); and psoriatic arthritis (n=1; 1%). With regard to reasons for revision, historical tibial inserts were revised due to polyethylene wear (n=9; 31%); aseptic loosening of the implant (n=7; 24%); infection (n=6; 21%); instability (n=4; 14%); knee effusion (n=1; 3%); valgus deformity (n=1; 3%), and patellar failure, n=1 (n=1; 3%). As for conventional knee retrievals, primary revision reasons were aseptic loosening (n=31; 35%); infection (n=24; 27%); instability (n=19; 21%); extensor mechanism disruption (n=3; 3.5%); stiffness (n=3; 3.5%); heterotopic ossification (n=2; 2%); malalignment (n=2; 2%); arthrofibrosis (n=1; 1%); knee effusion (n=1; 1%); malrotation (n=1; 1%); pain (n=1; 1%); periprosthetic fracture (1%); and synovitis (1%). None of the conventional tibial inserts were revised due to polyethylene wear. The incidence of the revision diagnoses was significantly different between the historical and conventional patient cohorts (p=0.0003; Pearson test).

Surface damage assessment

All the retrieved bearings were photo-documented, and examined for surface damage based on the technique previously described by Hood and colleagues [28]. Thus, both plateaus, the backside and the post surfaces, if applicable, were divided into quadrants and scored for the presence and extent of seven damage modes: scratching, abrasion, burnishing, pitting, delamination, surface deformation, and embedded debris. Scratching, abrasion, burnishing and embedded debris were identified as linear features likely produced by plowing of microscopic asperities on the metallic surface, shredding of the polyethylene surface, polished areas due to adhesion of polyethylene onto the metal counterpart, and the inclusion of polymethylmethacrylate (PMMA), bone, or metal fragments in the polyethylene insert, respectively. On the other hand, pitting and delamination were characterized by the presence of small crater-like surface defects, and removal of sheets of polyethylene from the implant surface, respectively.

The presence and extent of each damage mode was scored for every quadrant on a scale of 0 to 3, corresponding to observation of no damage, damage over less than 10%, 10–50%, or more than 50% of the specified region, respectively. For each damage mode, the maximum scores were 24 (3 maximum score × 8 regions) for the articulating surface, 12 (3 maximum score × 4 regions) for the backside surface, and 12 (3 maximum score × 4 regions) for the post region. A total damage score was calculated for each region by adding up the total scores corresponding to each damage mode, and giving maximum total scores of 168 for the articulating surface and identical maximum total scores, 84, for the backside and post. Special attention was also paid to overall delamination and pitting damage scores, which were obtained as the sum of the total delamination and pitting scores of the three regions. Finally, an overall damage score was calculated for every tibial insert by summing the total scores obtained for the articulating, backside and post surfaces.

Characterization of in vivo oxidation

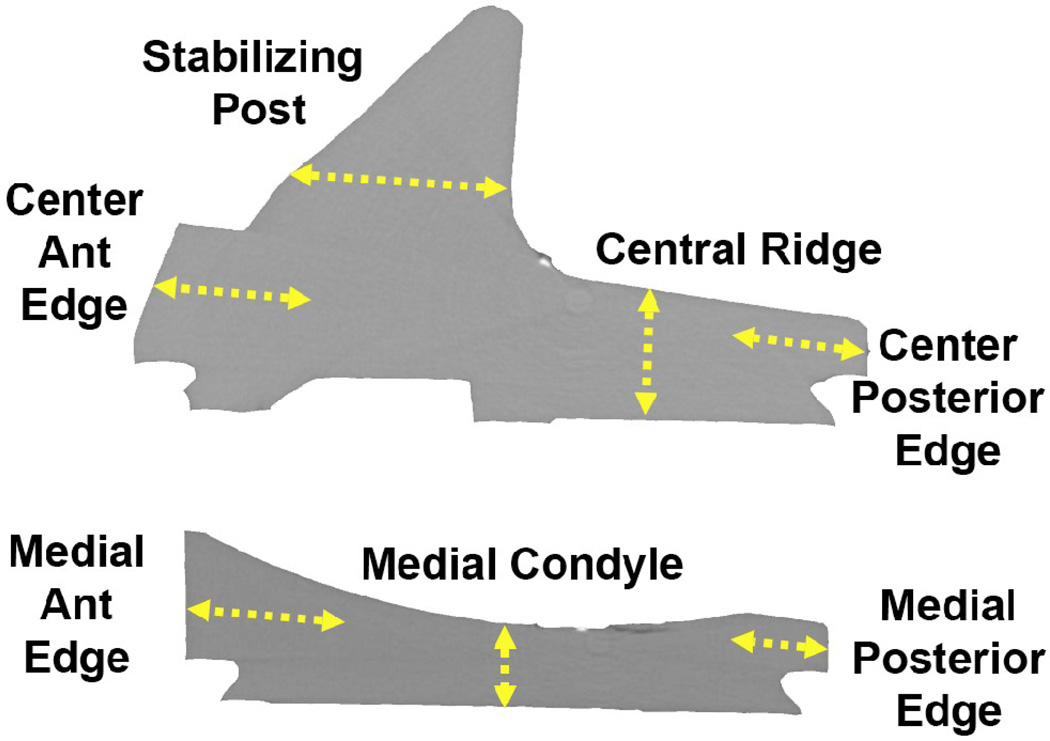

200 microns-thick polyethylene sections were obtained from the sagittal plane of the retrieved tibial inserts using a microtome. Thus, the polyethylene bearings were sectioned through the center at two different locations: medial plateau and intercondylar region. As absorbed lipids into polyethylene are known to interfere with oxidation assessments [29], polyethylene sections were subjected to lipid extraction by immersion in boiling heptane for 6 hours. Afterward, the extracted sections were scanned through the thickness in 0.1 mm depth increments (32 repeat scans per sample location) at different regions of interest using a Fourier Transform Infrared (FTIR) micro-spectrometer (Thermo Fisher Scientific, Waltham, MA). The maximum oxidation index was calculated according to ASTM F2102-01 as the ratio between the area of the carbonyl peak at 1715 cm−1, and the area of the reference band at 1350 cm−1 of the infrared spectrum. Regions of interest included the articular and backside surface of the medial plateau, as well as the anterior and posterior faces of the insert, and the stabilizing post, when applicable (Figure 1). An average maximum oxidation index was calculated for the anterior-posterior faces to simplify subsequent analysis of oxidation results. The evolution of oxidation with implantation time was modeled statistically by an exponential growth model, as reported previously [5].

Figure 1.

Schematic of the regions of interest in sagittal sections obtained from retrieved polyethylene tibial inserts and used for the oxidation analysis.

Hydroperoxides are relevant intermediate products of the oxidation cycle, and represent the oxidation potential for polyethylene, as they eventually convert into the final oxidation products (mainly, carbonyles and esters compounds). To assess the oxidation potential of polyethylene sections, we also measured their hydroperoxide content using FTIR spectroscopy. The sections were exposed for 16 hours to nitric oxide, NO, to convert hydroperoxides into nitrates and nitrites, which are then easily detected by infrared spectroscopy. After NO exposure, polyethylene sections were scanned again with FTIR spectroscopy. A hydroperoxide index was defined as the area of the peak between 1600 and 1670 cm−1 normalized by the area of the reference peak between 1330 and 1396 cm−1. Maximum hydroperoxide indexes were obtained for the same regions of interest previously mentioned in the oxidation analysis section.

Statistical analysis

We evaluated differences between retrieval groups in surface damage and oxidation results by means of Student t-tests or Wilcoxon tests, as appropriate. In addition, Spearman’s correlations served to confirm associations between oxidation results and surface damage scores. Finally, the potential influence of different factors on surface damage found on retrieved polyethylene tibial inserts was examined using general linear models with shelf life, in vivo time, and implant and patient factors as covariates. P < 0.05 was selected as the level of significance for the entire statistical analysis.

Results

Surface damage assessment

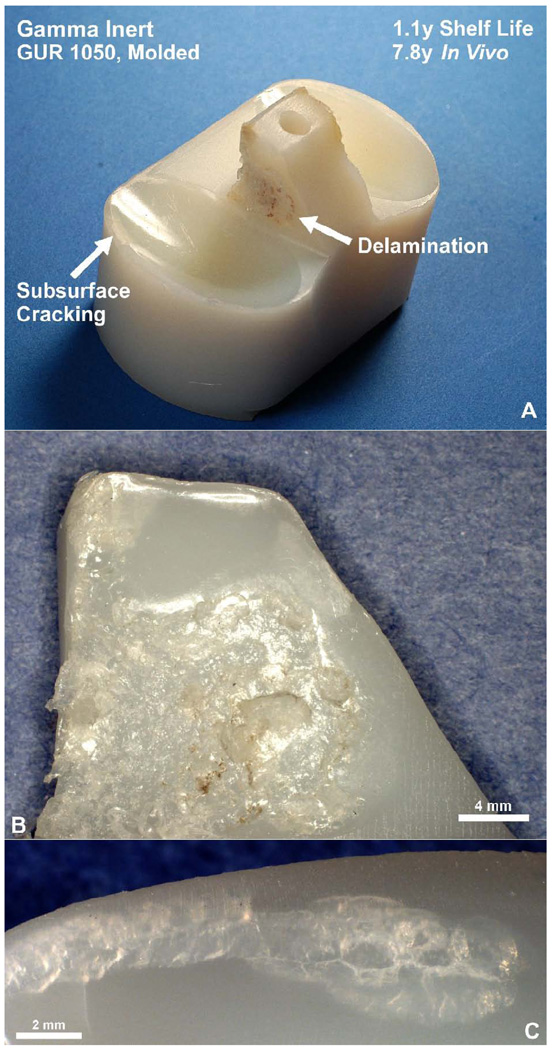

Delamination damage was significantly more prevalent and extensive at the articulating surface and post area of the retrieved historical polyethylene tibial inserts compared to conventional retrievals (p < 0.0001; Wilcoxon test; Table 2). Moreover, delamination became more severe as implantation time increased (p < 0.0001; Linear Model; Figure 2A). Although this damage mode was generally absent in conventional retrievals, seven tibial inserts still presented minor indications of delamination and subsurface cracking at the bearing and post surfaces (Figures 3A–C). No significant difference was detected between the delamination damage scores at the articulating surface among retrievals sterilized by the same technique, but manufactured using different resins and conversion methods (p ≥ 0.79; Wilcoxon test). General linear models corroborated that polyethylene resin, conversion technique and shelf life had no significant influence on delamination damage at the bearing surface (p ≥ 0.65, and p ≥ 0.59 for historical and conventional retrievals, respectively). Delamination was not observed on the backside of either conventional or historical retrievals in this study, the only exception being three historical tibial inserts that were worn through to the tibial tray. Backside damage was essentially burnishing, with pitting, and scratching (often observed as a distinct circular wear pattern in modular total knee replacements).

Table 2.

Overall (bearing, backside and post) damage scores by mode (average ± standard deviation) corresponding to historical and conventional polyethylene tibial insert retrievals.

| Retrieval Group | Scratching | Burnishing | Pitting | Delamination | Abrasion | Embedded Debris | Surface Deformation |

|---|---|---|---|---|---|---|---|

| Air (n=29) | 17 ± 11 | 12 ± 8 | 15 ± 12 | 12 ± 10 | 1 ± 1 | 2 ± 3 | 7 ± 8 |

| Inert (n=90) | 22 ± 10 | 11 ± 11 | 17 ± 9 | 0 ± 1 | 1 ± 1 | 1 ± 1 | 4 ± 4 |

| P Values | P = 0.02* | P = 0.18 | P = 0.31 | P < 0.0001* | P = 0.86 | P < 0.0001* | P = 0.09 |

Asterisks point out significant differences (p<0.05).

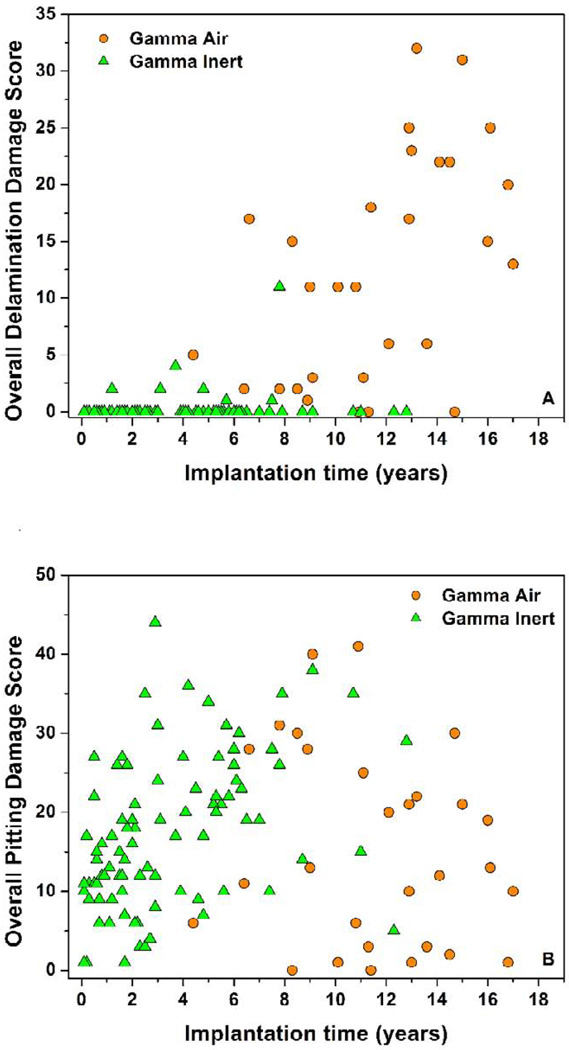

Figure 2.

A–B. Delamination damage was more prevalent in historical (gamma air sterilized) tibial inserts, and it was significantly more severe as implantation time increased (2A). Pitting damage, however, was not associated with sterilization method or implantation time (2B).

Figure 3.

A–C. This Constrained Condylar Knee Tibial Insert was gamma inert sterilized in 1996 and implanted in 1998 (3A). After 8 years in vivo, the patient underwent revision arthroplasty due to infection and secondary loosening, and the retrieved tibial insert exhibited delamination on the medio-lateral surfaces of the post (3B) as well as incipient subsurface cracking on the medial condyle (3C).

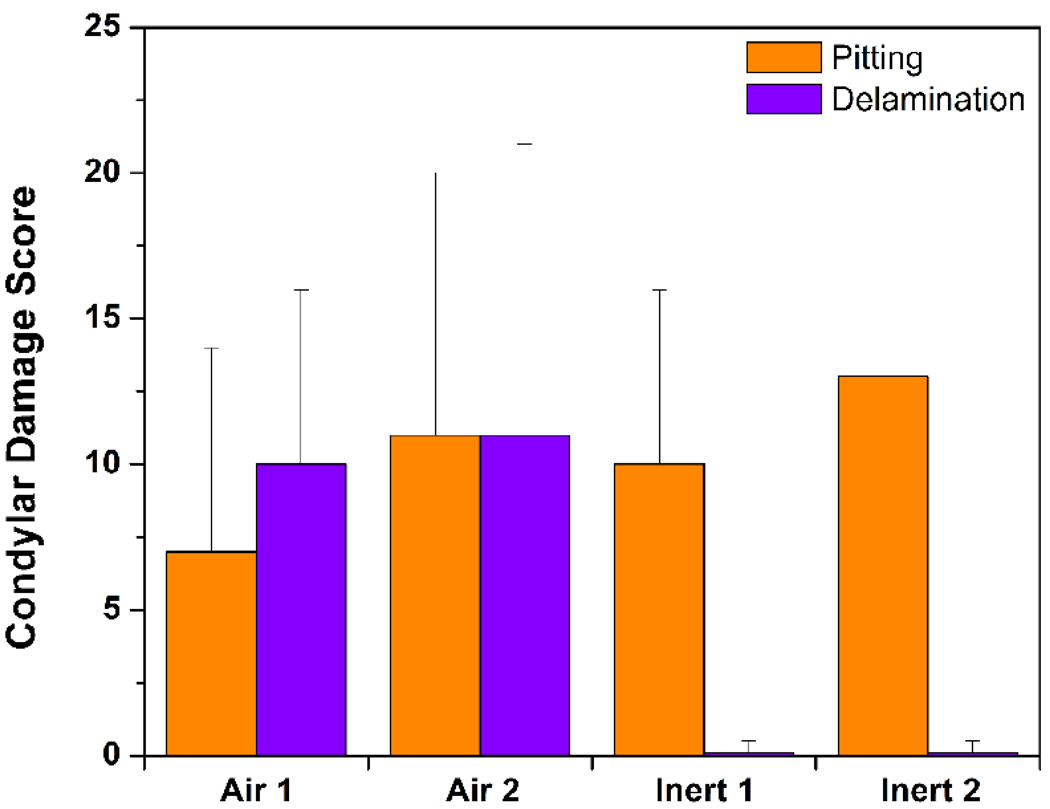

As opposed to delamination, pitting damage was typically present at all regions of both historical and conventional retrievals, and pitting scores were comparable regardless of the sterilization method (p ≥ 0.11; Wilcoxon test). Furthermore, the amount of overall pitting damage was not correlated with in vivo duration (p = 0.38; Figure 2B), and scores as high as 27 were reached even after less than a year of implantation. Pitting damage at the articulating surface was equally prevalent between the two individual historical and conventional retrieval groups regardless of polyethylene resin and conversion method (p ≥ 0.11; Linear Models; Figure 4). Likewise, shelf life had no significant effect on the extent of pitting damage in both historical and conventional tibial inserts (p ≥ 0.21; Linear models).

Figure 4.

Condylar delamination and pitting damage scores in retrieved historical and conventional tibial inserts produced from different polyethylene resins. Delamination and pitting were equally prevalent within retrievals sterilized by the same method regardless of polyethylene resin and conversion technique.

Apart from delamination and pitting, scratching and burnishing were predominant damage modes at all regions in both historical and conventional retrievals. Embedded debris and abrasion had, on the contrary, minor contributions to the overall damage observed in the present retrievals. In this sense, historical tibial inserts had significantly lower scratching scores at the articulating surface than conventional devices (p = 0.03; Wilcoxon test), but significantly higher embedded debris scores at this region (p < 0.0001; Wilcoxon test). Overall burnishing and abrasion scores were similar for both retrieval groups (p = 0.18; and p = 0.86, respectively; Table 2). Multivariate analysis confirmed associations between delamination and pitting damage and embedded debris scores at the articulating surface (rho = 0.32; p = 0.0004; and rho = 0.32; p = 0.0003, respectively).

With regard to the regional prevalence of overall damage, retrieved historical tibial inserts were significantly more damaged at the articulating and post surfaces than conventional retrievals (p=0.003, and p = 0.01, respectively; Table 3). Backside damage scores, however, were comparable between both retrieval groups (p = 0.13). While surface damage at the plateau and post surfaces as well as the overall damage significantly increased with implantation time (p ≤ 0.003; linear models), backside damage appeared to be insensitive to this factor (p = 0.27; linear models). In addition, regional damage scores exhibited by polyethylene retrievals sterilized using the same method but produced from different resins were generally comparable (p ≥ 0.56; Table 4). In this study, insert design and shelf lives prior to insertion did not significantly influence the overall articulating surface damage observed in retrievals sterilized by the same method (p > 0.1; linear models). Finally, patient factors had no significant effect on the damage at the articulating surface and backside of either historical or conventional polyethylene retrievals (p ≥ 0.07; linear models).

Table 3.

Regional surface damage scores (average ± standard deviation) corresponding to retrieved historical and conventional polyethylene tibial inserts. Polyethylene type and conversion technique had no significant effect on the damage scores observed in the present retrievals.

| Retrieval Group | Condylar Damage Score | Post Damage Score | Backside Damage Score | Overall Damage Score |

|---|---|---|---|---|

| Air (n=29) | 46 ± 20 | 17 ± 7 | 15 ± 8 | 67 ± 28 |

| Inert (n=90) | 33 ± 14 | 12 ± 6 | 13 ± 7 | 55 ± 23 |

| P Values | P = 0.003* | P = 0.01* | P = 0.13 | P = 0.02* |

| Air 1 (n=4) | 52 ± 30 | N/A | 15 ± 5 | 67 ± 33 |

| Air 2 (n=25) | 45 ± 18 | 17 ± 7 | 15 ± 8 | 67 ± 28 |

| Inert 1 (n=24) | 32 ± 15 | 11 ± 6 | 9 ± 7 | 49 ± 24 |

| Inert 2 (n=66) | 33 ± 13 | 12 ± 6 | 14 ± 7 | 57 ± 22 |

Asterisks point out significant differences (p<0.05).

Retrieved historical tibial inserts reached significantly higher levels of oxidation than conventional retrievals at all regions (p < 0.0001 in all cases; Wilcoxon test). Oxidation was regional in both retrievals groups. Thus, for historical tibial inserts, the most severe oxidation was observed on the anterior and posterior faces (average and SD: 3.5 ± 1.9). The bearing surface followed the anterior and posterior faces as the second most oxidized region (average and SD: 2.1 ± 1.2), and the oxidation levels at this region were significantly higher than those at the backside (average and SD: 1.0 ± 0.6; p < 0.0001; Paired t test) and comparable to those at the stabilizing post (average and SD: 1.3 ± 0.9; p > 0.05; Paired t test). Although within retrieved conventional tibial inserts oxidation was lower and more homogeneous, the highest oxidation levels could be still detected at the bearing surface (average and SD: 0.4 ± 0.4), followed by the anterior and posterior faces (average and SD: 0.3 ± 0.5) and the post region (average and SD: 0.3 ± 0.3). The backside of the conventional retrievals had significantly lower oxidation than the other regions (average and SD: 0.2 ± 0.2; p ≤ 0.002 in all cases).

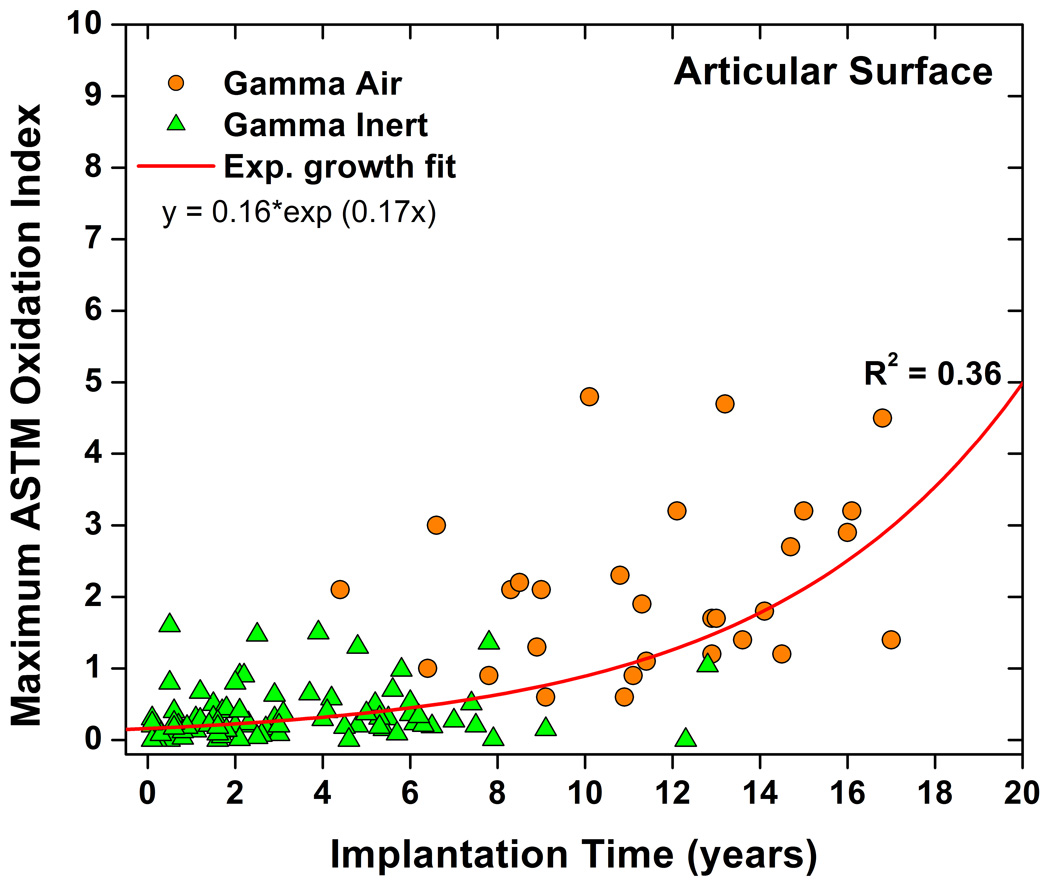

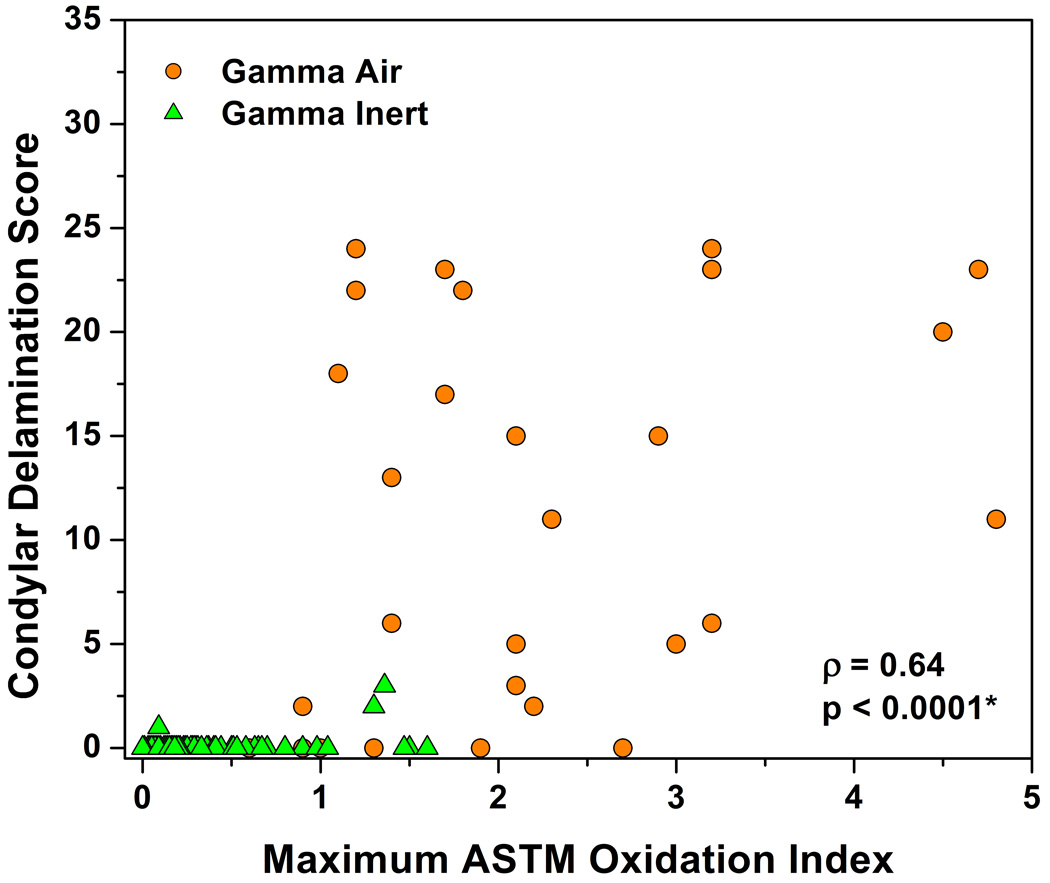

The progression of oxidation with implantation time was best fitted by an exponential relationship, OI = A*exp[B*(in vivo time)], although lower correlation coefficients were obtained for the bearing surface (R2=0.36; Figure 5), and backside (R2=0.31) as compared with the anterior-posterior faces (R2=0.46). General linear models confirmed the significant influence of in vivo duration of the implant on the level of oxidation (p < 0.0001 in all cases). A strong correlation between the oxidation level and delamination damage at the bearing surface of the present polyethylene knee retrievals was confirmed (rho = 0.64, and p<0.0001; Spearman’s; Figure 6). Pitting damage at the articular surface, however, was not correlated with the oxidation level found at this region (rho = − 0.04, and p = 0.64; Spearman’s). Similar correlations between oxidation and delamination damage at the post surface (rho = 0.37, and p = 0.0004; Spearman’s) and backside (rho = 0.24, and p = 0.01; Spearman’s) were observed. Finally, polyethylene resin and conversion technique had no significant effect on the oxidation of retrieved knee bearings sterilized by the same method according to linear models (p ≥ 0.06).

Figure 5.

The progression of in vivo oxidation with implantation time for historical and conventional retrievals followed an exponential growth behavior at all regions, the bearing surface in particular.

Figure 6.

The extent and severity of delamination damage was significantly correlated with oxidation levels in the present polyethylene tibial insert retrievals.

Similar to oxidation results, historical retrievals exhibited significantly higher hydroperoxide levels than conventional inserts at all regions (p ≤ 0.009 in all cases). Regional patterns similar to those found for the oxidation state of historical and conventional retrievals were also observed.

Discussion

The current findings support our hypothesis that in vivo oxidation is associated with delamination damage in total knee arthroplasty. Thus, 90% of the historical polyethylene tibial inserts presented high oxidation levels and evidence of delamination, whereas 92% of the conventional knee retrievals had low oxidation and no evidence of delamination. Moreover, oxidation appears to gradually increase with in vivo duration in both types of gamma sterilized devices. Although conventional retrievals were in situ for much shorter times than historical inserts, and coherently they exhibited lower oxidation, less overall damage, and no delamination in most cases, the expected exponential progression of oxidation might result in more instances of delamination damage during their second decade of implantation [5].Shelf life, in contrast, was not a significant factor in terms of oxidation and damage in this study. This is in agreement with researchers who have also found that time periods between gamma radiation sterilization and insertion shorter than one year were not correlated with mechanical degradation and early fatigue damage of implanted bearings [1–2, 17]. Overall, this study provides evidence that, despite changes in sterilization and packaging practices, conventional, gamma inert sterilized, knee retrievals are susceptible to in vivo oxidation and delamination damage, as were historical inserts[30].

In vivo oxidation appears to not be responsible for pitting, as this damage mode was equally prevalent in retrieved polyethylene inserts regardless of the sterilization method and oxidation level. Pitting damage, as opposed to delamination, seems to not be related to a critical oxidation threshold beyond which polyethylene cannot withstand peak stresses below the implant surface [10, 31–32]. Rather, pitting appears to be related to bone, bone cement, or metal fragments that were embedded in the articular surface and subsequently dislodged during repeated articulation, as suggested by Crowninshield and colleagues, and McDonald and Bloebaum [25–26]. In this sense, Cornwall and coworkers documented two different types of pit morphology in 8 retrieved total knee replacements, which were thought to result from third-body damage, and fatigue crack initiation at polyethylene grain boundaries, respectively [15].

Osteolysis has previously been associated with polyethylene degradation and delamination of gamma air sterilized knee implants [33]. In this study, polyethylene wear and osteolysis motivated revision surgery in 30% of the patients who received a historical polyethylene insert after 11–12 years in vivo. Coherently, high oxidation (close to 3, on average) and severe delamination damage (20, on average) characterized these historical polyethylene devices. Wear of the plastic component and secondary osteolysis, however, was not a significant clinical complication among the conventional polyethylene knee bearings in our study, which were implanted, on average, between three and four years. In any case, the potential progression of in vivo oxidation in conventional tibial inserts during the second decade of implantation could make them susceptible to delamination damage, and it warrants further research on this topic. The clinical significance of pitting and other damage modes in total knee arthroplasty, on the other hand, remains poorly understood, but it should not be underestimated. Although not as catastrophic as the oxidation-induced delamination damage found at the bearing and post surfaces of historical tibial inserts, backside wear is a current clinical concern because of the potential production of sub-cellular sized polyethylene particles that may lead to osteolysis and eventual loosening of the implant [34]. In this regard, thinner knee bearings demonstrated higher backside damage scores according to Taki and colleagues [35], and, in turn, backside damage and the incidence of osteolysis in modular total knee replacements have been associated with variables such as the sterilization method and baseplate surface finish [36].

On the basis of our current data, polyethylene resin and conversion technique have no substantial influence on the resistance of tibial inserts to surface damage and in vivo oxidation. After comparable shelf lives and in vivo durations, the surface damage and oxidation state exhibited by polyethylene produced from the different resins and different conversion methods were similar. There appears to be some controversy in the orthopedic literature in this regard. Previous studies have thus reported both lower oxidation levels and superior damage resistance of polyethylene components molded from 1900H resins as compared with those machined from GUR 415 extruded bars [37–40]. 1900H polyethylene, however, was demonstrated to lose mechanical strength at lower oxidation levels than GUR 415 polyethylene, so the apparent advantage of the former material might be lost as it oxidizes [38]. Recently, no significant difference in the in vitro wear performance was observed between conventional polyethylene components and unirradiated specimens manufactured from various resins and conversion techniques, including 1900H and direct compression molding [41–42].

Patient factors and tibial insert design also appeared to have a marginal impact in the progression of oxidation and damage for the retrieved components in this study. These findings do not necessarily imply that implant design and clinical factors can be disregarded. This study was limited to specific tibial insert designs from a single manufacturer, and the present results may not necessarily extrapolate to devices from other orthopedic manufacturers. Nevertheless, similar oxidation and damage resistance behaviors are anticipated for historical and conventional polyethylene tibial inserts of other designs and manufacturers, as most orthopedic converters followed almost identical sterilization practices. Clinical and radiographic information on range of motion and implant alignment would have proven very useful to confirm retrievals were well functioning devices as well as to assess their potential impact on implant damage. Other factors, such as insert thickness and conformity, or increased activity level, were not controlled in this study, but may also account for elevated wear rates and severe damage in specific cases [7, 16, 43].

In conclusion, this study documents the prevalence and severity of delamination and pitting damage in retrieved historical, gamma air sterilized, and conventional, gamma inert sterilized tibial inserts of a single manufacturer. The present findings support that in vivo oxidation was the primary contributor to delamination damage in gamma sterilized total knee arthroplasty components. In contrast, we found no evidence to suggest that pitting is related to in vivo oxidation. Furthermore, polyethylene resin and conversion technique did not have a substantial effect on the resistance to damage and in vivo oxidation of polyethylene knee implants according to this study. Although the oxidation levels reached by conventional retrievals were comparatively much lower than those of historical tibial inserts, more research is needed to ascertain whether or not delamination damage will occur in conventional tibial inserts as in vivo oxidation progresses during the second decade of implantation.

Footnotes

Publisher's Disclaimer: This is a PDF file of an unedited manuscript that has been accepted for publication. As a service to our customers we are providing this early version of the manuscript. The manuscript will undergo copyediting, typesetting, and review of the resulting proof before it is published in its final citable form. Please note that during the production process errors may be discovered which could affect the content, and all legal disclaimers that apply to the journal pertain.

REFERENCES

- 1.Kurtz SM, Hozack WJ, Purtill JJ, Marcolongo M, Kraay MJ, Goldberg VM, Sharkey PF, Parvizi J, Rimnac CM, Edidin AA. 2006 Otto Aufranc Award Paper: significance of in vivo degradation for polyethylene in total hip arthroplasty. Clin Orthop Relat Res. 2006;453:47. doi: 10.1097/01.blo.0000246547.18187.0b. [DOI] [PubMed] [Google Scholar]

- 2.Currier BH, Currier JH, Mayor MB, Lyford KA, Van Citters DW, Collier JP. In vivo oxidation of gamma-barrier-sterilized ultra-high-molecular-weight polyethylene bearings. Journal of Arthroplasty. 2007;22(5):721. doi: 10.1016/j.arth.2006.07.006. [DOI] [PubMed] [Google Scholar]

- 3.Kurtz SM, Rimnac CM, Hozack WJ, Turner J, Marcolongo M, Goldberg VM, Kraay MJ, Edidin AA. In vivo degradation of polyethylene liners after gamma sterilization in air. The Journal of bone and joint surgery. 2005;87(4):815. doi: 10.2106/JBJS.D.02111. [DOI] [PubMed] [Google Scholar]

- 4.Currier BH, Currier JH, Mayor MB, Lyford KA, Collier JP, Van Citters DW. Evaluation of oxidation and fatigue damage of retrieved crossfire polyethylene acetabular cups. Journal of Bone and Joint Surgery-American. 2007;Volume 89A(9):2023. doi: 10.2106/JBJS.F.00336. [DOI] [PubMed] [Google Scholar]

- 5.Medel FJ, Kurtz SM, Hozack WJ, Parvizi J, Purtill JJ, Sharkey PF, MacDonald D, Kraay MJ, Goldberg V, Rimnac CM. Gamma Inert Sterilization: A Solution to Polyethylene Oxidation? Journal of Bone and Joint Surgery-American. 2009;Volume 91A(4):839. doi: 10.2106/JBJS.H.00538. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Medel FJ, Kurtz SM, MacDonald DW, Sha P, Hozack WJ, Sharkey PF, Klein G, Hartzband M, Stulberg B, Garino J, Kraay MJ, Rimnac CM. First-Generation Highly Crosslinked Polyethylenes in THA: Clinical and Material Performance. 55th Annual Meeting of the Orthopeadic Research Society; Las Vegas (NV). 2009. [Google Scholar]

- 7.Fisher J, McEwen HMJ, Barnett PI, Bell CJ, Stewart TD, Stone MH, Ingham E. Wear of polyethylene in artificial knee joints. Current Orthopaedics. 2001;15(6):399. [Google Scholar]

- 8.Lewis G. Polyethylene wear in total hip and knee arthroplasties. Journal of Biomedical Materials Research. 1997;38(1):55. doi: 10.1002/(sici)1097-4636(199721)38:1<55::aid-jbm8>3.0.co;2-g. [DOI] [PubMed] [Google Scholar]

- 9.Kennedy FE, Currier BH, Van Citters DW, Collier JP, Currier JH, Collier JP, Mayor MB. Oxidation of ultra-high molecular weight polyethylene and its influence on contact fatigue and pitting of knee bearings. Tribology Transactions. 2003;46(1):111. [Google Scholar]

- 10.Kennedy FE, Currier JH, Plumet S, Duda JL, Gestwick DP, Collier JP, Currier BH, Dubourg MC. Contact fatigue failure of ultra-high molecular weight polyethylene bearing components of knee prostheses. Journal of Tribology-Transactions of the Asme. 2000;122(1):332. [Google Scholar]

- 11.Currier JH, Duda JL, Sperling DK, Collier JP, Currier BH, Kennedy FE. In vitro simulation of contact fatigue damage found in ultra-high molecular weight polyethylene components of knee prostheses. Proceedings of the Institution of Mechanical Engineers Part H-Journal of Engineering in Medicine. 1998;212(H4):293. doi: 10.1243/0954411981534079. [DOI] [PubMed] [Google Scholar]

- 12.Blunn GW, Joshi AB, Minns RJ, Lidgren L, Lilley P, Ryd L, Engelbrecht E, Walker PS. Wear in retrieved condylar knee arthroplasties - A comparison of wear in different designs of 280 retrieved condylar knee prostheses. Journal of Arthroplasty. 1997;12(3):281. doi: 10.1016/s0883-5403(97)90024-3. [DOI] [PubMed] [Google Scholar]

- 13.Wrona M, Mayor MB, Collier JP, Jensen RE. The Correlation between Fusion Defects and Damage in Tibial Polyethylene Bearings. Clinical Orthopaedics and Related Research. 1994;299:92. [PubMed] [Google Scholar]

- 14.Kilgus DJ, Moreland JR, Finerman GAM, Funahashi TT, Tipton JS. Catastrophic Wear of Tibial Polyethylene Inserts. Clinical Orthopaedics and Related Research. 1991;273:223. [PubMed] [Google Scholar]

- 15.Cornwall GB, Hansson CM, Bowe AJ, Bryant JT. Surface degradation features and microstructural properties of ultra-high molecular weight polyethylene (UHMWPe) Journal of Materials Science-Materials in Medicine. 1997;8(5):303. doi: 10.1023/a:1018564412753. [DOI] [PubMed] [Google Scholar]

- 16.Gupta SK, Chu A, Ranawat AS, Slamin J, Ranawat CS. Review article: Osteolysis after total knee arthroplasty. Journal of Arthroplasty. 2007;22(6):787. doi: 10.1016/j.arth.2007.05.041. [DOI] [PubMed] [Google Scholar]

- 17.McGovern TF, Ammeen DJ, Collier JP, Currier BH, Engh GA. Rapid polyethylene failure of unicondylar tibial components sterilized with gamma irradiation in air and implanted after a long shelf life. Journal of Bone and Joint Surgery-American. 2002;Volume 84A(6):901. doi: 10.2106/00004623-200206000-00002. [DOI] [PubMed] [Google Scholar]

- 18.Bohl JR, Bohl WR, Postak PD, Greenwald AS. The effects of shelf life on clinical outcome for gamma sterilized polyethylene tibial components. Clinical Orthopaedics and Related Research. 1999;(367):28. [PubMed] [Google Scholar]

- 19.Currier BH, Currier JH, Collier JP, Mayor MB, Scott RD. Shelf life and in vivo duration - Impacts on performance of tibial bearings. Clinical Orthopaedics and Related Research. 1997;(342):111. [PubMed] [Google Scholar]

- 20.Rimnac CM, Klein RW, Betts F, Wright TM. Postirradiation Aging of Ultra-High-Molecular-Weight Polyethylene. Journal of Bone and Joint Surgery-American. 1994;Volume 76A(7):1052. doi: 10.2106/00004623-199407000-00014. [DOI] [PubMed] [Google Scholar]

- 21.Bell CJ, Walker PS, Abeysundera MR, Simmons JMH, King PM, Blunn GW. Effect of oxidation on delamination of ultrahigh-molecular-weight polyethylene tibial components. Journal of Arthroplasty. 1998;13(3):280. doi: 10.1016/s0883-5403(98)90173-5. [DOI] [PubMed] [Google Scholar]

- 22.White SE, Paxson RD, Tanner MG, Whiteside LA. Effects of sterilization on wear in total knee arthroplasty. Clinical Orthopaedics and Related Research. 1996;(331):164. doi: 10.1097/00003086-199610000-00023. [DOI] [PubMed] [Google Scholar]

- 23.Collier JP, Sperling DK, Currier JH, Sutula LC, Saum KA, Mayor MB. Impact of gamma sterilization on clinical performance of polyethylene in the knee. Journal of Arthroplasty. 1996;11(4):377. doi: 10.1016/s0883-5403(96)80026-x. [DOI] [PubMed] [Google Scholar]

- 24.Affatato S, Bersaglia G, Foltran I, Taddei P, Fini G, Toni A. The performance of gamma-and EtO-sterilised UHWMPE acetabular cups tested under severe simulator conditions. Part 1: role of the third-body wear process. Biomaterials. 2002;23(24):4839. doi: 10.1016/s0142-9612(02)00238-7. [DOI] [PubMed] [Google Scholar]

- 25.Crowninshield RD, Wimmer MA, Jacobs JJ, Rosenberg AG. Clinical performance of contemporary tibial polyethylene components. Journal of Arthroplasty. 2006;21(5):754. doi: 10.1016/j.arth.2005.10.012. [DOI] [PubMed] [Google Scholar]

- 26.Mcdonald MD, Bloebaum RD. Distinguishing Wear and Creep in Clinically Retrieved Polyethylene Inserts. Journal of Biomedical Materials Research. 1995;29(1):1. doi: 10.1002/jbm.820290102. [DOI] [PubMed] [Google Scholar]

- 27.McKellop HA. The lexicon of polyethylene wear in artificial joints. Biomaterials. 2007;28(34):5049. doi: 10.1016/j.biomaterials.2007.07.040. [DOI] [PubMed] [Google Scholar]

- 28.Hood RW, Wright TM, Burstein AH. Retrieval Analysis of Total Knee Prostheses - a Method and Its Application to 48 Total Condylar Prostheses. Journal of Biomedical Materials Research. 1983;17(5):829. doi: 10.1002/jbm.820170510. [DOI] [PubMed] [Google Scholar]

- 29.Shen FW, Yu YJ, Mckellop H. Potential errors in FTIR measurement of oxidation in ultrahigh molecular weight polyethylene implants. J Biomed Mater Res. 1999;48(3):203. doi: 10.1002/(sici)1097-4636(1999)48:3<203::aid-jbm1>3.0.co;2-r. [DOI] [PubMed] [Google Scholar]

- 30.Medel FJ, Rimnac CM, Kurtz SM. On the assessment of oxidative and microstructural changes after in vivo degradation of historical UHMWPE knee components by means of vibrational spectroscopies and nanoindentation. Journal of Biomedical Materials Research Part A. 2009;89A(2):530. doi: 10.1002/jbm.a.31992. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Brown TD, Bartel DL, W IWSE. What design factors influence wear behavior at the bearing surfaces in total joint replacements? Journal of the American Academy of Orthopaedic Surgeons. 2008;16:S101. doi: 10.5435/00124635-200800001-00020. [DOI] [PubMed] [Google Scholar]

- 32.McGloughlin TM, Kavanagh AG. Wear of ultra-high molecular weight polyethylene (UHMWPE) in total knee prostheses: a review of key influences. Proceedings of the Institution of Mechanical Engineers Part H-Journal of Engineering in Medicine. 2000;214(H4):349. doi: 10.1243/0954411001535390. [DOI] [PubMed] [Google Scholar]

- 33.Casey D, Cottrell J, DiCarlo E, Windsor R, Wright T. PFC knee replacement - Osteolytic failures from extreme polyethylene degradation. Clinical Orthopaedics and Related Research. 2007;(464):157. doi: 10.1097/BLO.0b013e3181591c62. [DOI] [PubMed] [Google Scholar]

- 34.Wasielewski RC. The causes of insert backside wear in total knee arthroplasty. Clinical Orthopaedics and Related Research. 2002;(404):232. doi: 10.1097/00003086-200211000-00037. [DOI] [PubMed] [Google Scholar]

- 35.Taki N, Goldberg VM, Kraay MJ, Rimnac CM. Backside wear of Miller-Galante I and Insall-Burstein II tibial inserts. Clinical Orthopaedics and Related Research. 2004;428:198. doi: 10.1097/01.blo.0000148571.34835.ce. [DOI] [PubMed] [Google Scholar]

- 36.Collier MB, Engh CA, McAuley JP, Ginn SD, Engh GA. Osteolysis after total knee arthroplasty: Influence of tibial baseplate surface finish and sterilization of polyethylene insert - Findings at five to ten years postoperatively. Journal of Bone and Joint Surgery-American. 2005;Volume 87A(12):2702. doi: 10.2106/JBJS.E.00074. [DOI] [PubMed] [Google Scholar]

- 37.Berzins A, Jacobs JJ, Berger R, Ed C, Natarajan R, Andriacchi T, Galante JO. Surface damage in machined ram-extruded and net-shape molded retrieved polyethylene tibial inserts of total knee replacements. Journal of Bone and Joint Surgery-American. 2002;Volume 84A(9):1534. doi: 10.2106/00004623-200209000-00005. [DOI] [PubMed] [Google Scholar]

- 38.Currier BH, Currier JH, Collier JP, Mayor MB. Effect of fabrication method and resin type on performance of tibial bearings. Journal of Biomedical Materials Research. 2000;53(2):143. doi: 10.1002/(sici)1097-4636(2000)53:2<143::aid-jbm3>3.0.co;2-5. [DOI] [PubMed] [Google Scholar]

- 39.Ritter MA. Direct compression molded polyethylene for total hip and knee replacements. Clinical Orthopaedics and Related Research. 2001;393:94. doi: 10.1097/00003086-200112000-00011. [DOI] [PubMed] [Google Scholar]

- 40.Won CH, Rohatgi S, Kraay MJ, Goldberg VM, Rimnac CM. Effect of resin type and manufacturing method on wear of polyethylene tibial components. Clinical Orthopaedics and Related Research. 2000;376:161. doi: 10.1097/00003086-200007000-00023. [DOI] [PubMed] [Google Scholar]

- 41.Gul RM, McGarry FJ, Bragdon CR, Muratoglu OK, Harris WH. Effect of consolidation on adhesive and abrasive wear of ultra high molecular weight polyethylene. Biomaterials. 2003;24(19):3193. doi: 10.1016/s0142-9612(03)00165-0. [DOI] [PubMed] [Google Scholar]

- 42.Lancin P, Essner A, Yau SS, Wang AG. Wear performance of 1900 direct compression molded, 1020 direct compression molded, and 1020 sheet compression molded UHMWPE under knee simulator testing. Wear. 2007;263:1030. [Google Scholar]

- 43.Bartel DL, Bicknell VL, Wright TM. The Effect of Conformity, Thickness, and Material on Stresses in Ultrahigh Molecular-Weight Components for Total Joint Replacement. Journal of Bone and Joint Surgery-American. 1986;Volume 68A(7):1041. [PubMed] [Google Scholar]