Abstract

Space allowance for animals in transit is a consistent concern in many countries that are developing codes of practice and regulations to assure humane treatment of food producing animals. The minimum space allowance requirements for a broad size range of swine in transit has not been well described or scientifically substantiated. A maximal loading pressure recommendation for pigs weighing from 5 to 250 kg was derived by a consultative process involving the swine transportation industry, animal welfare groups, and a literature review. The recommended maximal loading pressure under ideal conditions for swine loaded in groups can be described as a hoerl model y = (37.53)(0.9969)W(W0.5008), where y = loading pressure in kg body weight/m2 and W = average animal body weight in kilograms.

Introduction

Humane care and treatment of food producing animals have become integral to the management and marketing of food products of animal origin. In Canada, concern for farm animal welfare has resulted in the development of a series of Recommended codes of practice for the care and handling of animals. The transportation code is one example (1). The European response to public concern for food animals in transit has been to move rapidly toward regulation. Great Britain passed the most recent Transport Order in 1999 (2), the 4th revision in 10 y (3). Space allowance for animals during transport is a primary determinant of humane transportation, and the establishment of standards for swine is a necessity for the development of codes and regulations.

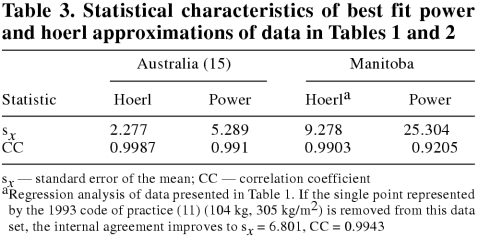

Manitoba is in a period of swine expansion. On April 1, 2001, the breeding sow herd was estimated to be 271 000, a 63% increase since April 1, 1995 (Honey J, Manitoba Agriculture and Food, personal comunication). In the past 6 y, Manitoba has seen a dramatic rise in the number of feeder and slaughter pigs exported to the United States (Figure 1). In the calender year 2000, 1 440 000 isowean (5 kg body weight (BW), 17 to 18 d old) and nursery (25 kg BW) pigs, and over 900 000 slaughter pigs, were exported to the United States (4). This is a fraction of the actual number of pig movements, as accurate data for movement within Manitoba and to other provinces in Canada are not readily available.

Figure 1. Total number of swine exported from Manitoba to the United States by quarter, from the first quarter of 1990 to the last quarter of 2000 (4). No seasonality of exports is apparent. Swine identified as weanlings include both piglets at 17 d of age (4.5 kg) and nursery pigs at around 25 to 30 kg. Slaughter swine include market weight pigs and cull sows and boars.

Age- and site-segregated pork production is a complex process that has been widely adopted in Canada in the last 10 y. The process involves separating the piglets from the sow environment, usually at around 17 d of age, and moving them to an isolated location, thereby preventing the vertical transmission of specific pathogens (5). The term isowean has been recommended to describe this management practice (6). Isowean was previously trademarked by the Pig Improvement Company (PIC; Canada head office, Airdrie, Alberta); however, the PIC has removed all trademark restrictions from the use of the term isowean (6). In Canada, the transition of single location production units to isolated weaning and multisite production requires pigs to be transported more often in their lifetimes and at a young age.

Livestock hauling in Canada is an important and competitive sector of the livestock industry. With the cost of transport being calculated in units of per hundredweight per kilometer, there is a motivation to load the animals as tightly as reasonably possible. The trend toward centralization of slaughter facilities, the international movement of slaughter animals, larger facilities, and fewer of them will continue to provide challenges for the humane transportation of animals, as the average slaughter animal will travel further to slaughter. In western Canada, cull sows and boars are primarily exported to the USA, where facilities are available to slaughter this class of animal.

The transportation of slaughter-weight pigs has been reviewed recently (7). Welfare of slaughter pigs in transit has been measured by mortality, carcass bruising, serological measurements of physiological stress, and behavioral observations. Overcrowding, higher ambient temperatures, and feeding within 4 h of transport have been associated with increased mortality (7). Pork quality appears to be a relatively insensitive measurement of animal welfare and crowding during transport of slaughter-weight pigs; it does not appear to be dramatically affected by a trip of 2.5 h at densities up to 285 kg BW/m2 (8). In Europe, the maximum recommended floor pressure for transporting market pigs of 90 to 100 kg live weight is 250 kg BW/m2; however, this is often exceeded in commercial transport (9). In a recent survey in Great Britain, there was an increase in mortality when market hogs were transported at a density greater than 238 kg BW/m2 (10). In the pig code (11), the space recommended for market hogs weighing from 95 to 104 kg is 0.34 m2 (279–305 kg BW/m2), when the temperature is below 16°C; 0.38 m2 (250–274 kg BW/m2), when the temperature is from 16 to 23°C; and 0.41 m2 (232–254 kg BW/m2), when the temperature is above 24°C. In addition, there is a recommendation to avoid transporting pigs when the temperature is above 30°C. There is no information in the pig code on the appropriate minimum space allowance in transport for nonmarket weight pigs, such as isowean piglets, young feeder pigs, underweight slaughter pigs, replacement gilts, and cull boars and sows.

Developing a standard

As animals increase in size, their weight increases as a function of their length cubed, while the floor space they require increases as a function of their length squared (12). On a weight per unit area of trailer floor, fewer kilograms of weaned piglets than of slaughter-weight swine can be loaded. When attempting to compare various recommendations of minimal space allowance, it has been shown that conversion of recommended minimum space allowance into maximal pressure points (mass per unit area) and plotting the maximal pressure points vs individual animal weight on a Cartesian chart may allow direct comparison of data from several sources (13). This technique can adjust for the common convention of describing space allowance in a table where a weight range of animals is assigned a minimal space. Briefly, to summarize a tabular recommendation, the maximal floor pressure consistent with the recommendation is the value attained by dividing the top end of the weight range by the minimal allowed space. An equation describing maximal floor pressure consistent with the recommendation can be generated by using curve-fitting software. In preference to tabular descriptions where a fixed area is recommended for a certain weight range, it has been recommended that standards and regulations for minimum space allowance be described as an equation when legislating animal welfare standards on farm (14).

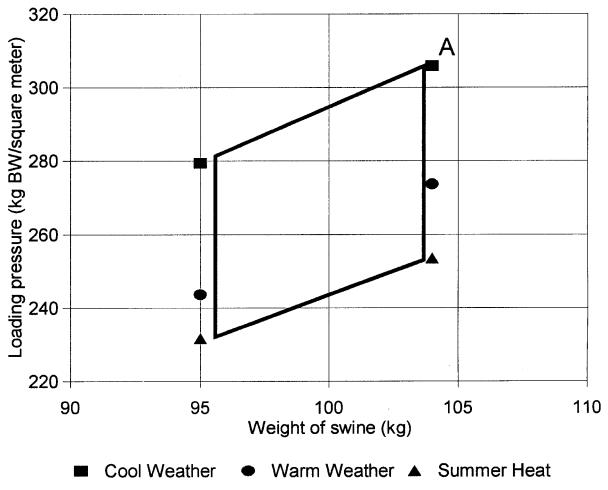

Unlike many minimum space allowance standards for other species, the pig code gives both a weight and a temperature range (11). This recommendation describes an area instead of discrete points on the maximal loading pressure chart (Figure 2).

Figure 2. Graphical representation of the stocking density recommendation contained in the Canadian code of practice for pigs (11). Minimal space per animal is given on on the basis of a weight range and a temperature range. Point A is where a 104-kg animal is allowed 3.7 ft2 when the temperature is below 23°C. All the values within the trapezoid could be considered in agreement with this reference.

Previous research has suggested that there should be a curvilinear mathematical function that accurately describes the relationship between the floor space required in transit and the body weight of the pigs (12,13). Several equations have been proposed, based on body measurements, and have been reviewed recently (7). During the development of the transportation code (1), it became apparent that the loading pressure recommendations for pigs were insufficient because of the small range of weights of animals included in the pig code (11). Since the time that the pig code was written, market hog weights in Canada have increased, with the mean weight of slaughter hogs in Manitoba being 112 kg BW in 2000 (4). Maximum body weight range for which transportation space allowance is given in the pig code is 104 kg (11). Minimum space allowance recommendations for pigs in transit are required for all weights of swine being transported, including weaned piglets, cull animals, and breeding stock.

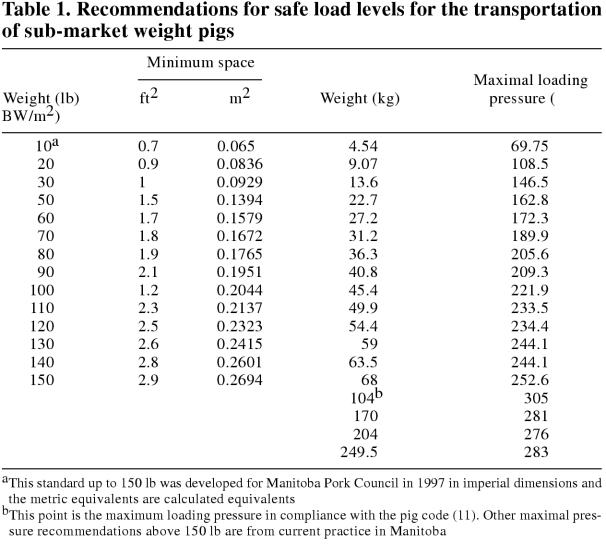

In 1997, the Manitoba Pork Council approached one of us (SB) to develop a recommended loading standard for submarket weight swine, as the pig code (11) made no recommendation on space for pigs less than the 94 kg BW. A table was produced, based on extensive experience in transporting pigs from 4.5 to 68 kg BW in western Canada and the mid western USA (Table 1). This guideline has been used successfully for several years in the local animal transportation industry. At about this time, 2 other minimum space allowance standards for a range of pig weights were published; one from Australia for land transportation (15) and one from Europe for air transportation (16) (Table 2).

Table 1.

Table 2.

Further information related to the safe carrying capacity of trailers for cull sows was collected by direct interview with 2 other commercial swine transporting companies operating in Manitoba. The owner of the 1st company indicated that it was his company's common practice to load 159, 181, and 227 kg BW sows at 240, 249, and 280 kg BW/m2, respectively. The shipping coordinator at the 2nd company indicated that the company's common practice was to load 190 kg BW sows at no more than 273 kg BW/m2, and 240 kg BW sows at no more than 305 kg BW/m2.

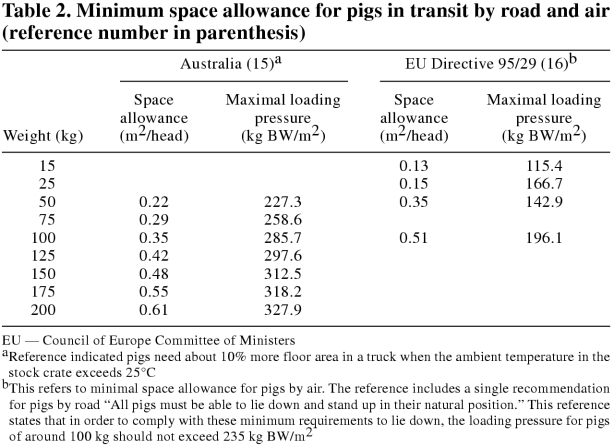

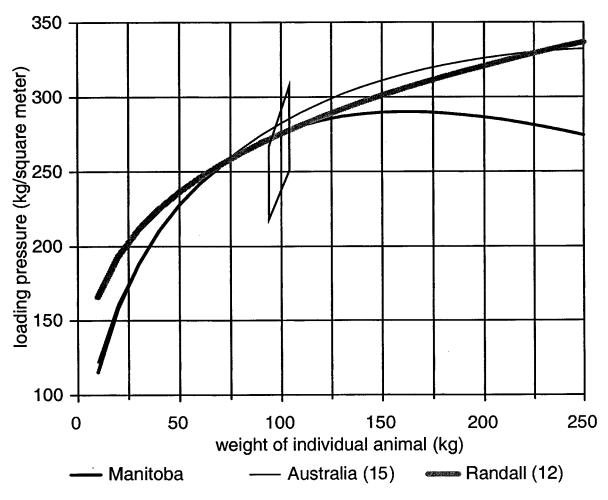

To allow comparison of our data with other published data, the data were plotted on the same loading pressure/animal weight graph (Figure 3). A curvilinear relationship between body mass and maximal floor pressure represented by a power function was to be expected (12,13). From Figure 3, it can be seen that the data from the Canadian source and the Australian code cover substantially different weight ranges, with the Australian code making no recommendation below 50 kg BW. However, where the 2 recommendations overlap in the 50 to 75 kg BW range, there is excellent agreement. The European data were not in agreement with the other standards and did not have good internal agreement. This standard would allow for 25 kg BW pigs to be loaded at a significantly higher loading pressure than 50 kg BW pigs, which is inconsistent with scientific principles related to the changing space requirements of animals as they grow. The data from this source were not considered further.

Figure 3. Scatter plot of tabular data from the 3 sources in Table 1 for Manitoba data and Table 2 for Australian and European data (reference in parentheses). The Manitoba and Australian recommendations are in excellent agreement between 50 and 75 kg body weight (BW) considering that they were arrived at independently. There is some divergence between the recommendations for pigs in excess of 125 kg and the Australian source gives no recommendations below 50 kg. The point marked A is the maximal loading pressure from the pig code where 104 kg BW pigs are loaded at 305 kg BW/m2 (11). The 4 data points from the European reference show poor internal agreement as the (x,y) point (25 kg BW, 167 kg BW/m2) is significantly above the line visualized by connecting the other 3 points.

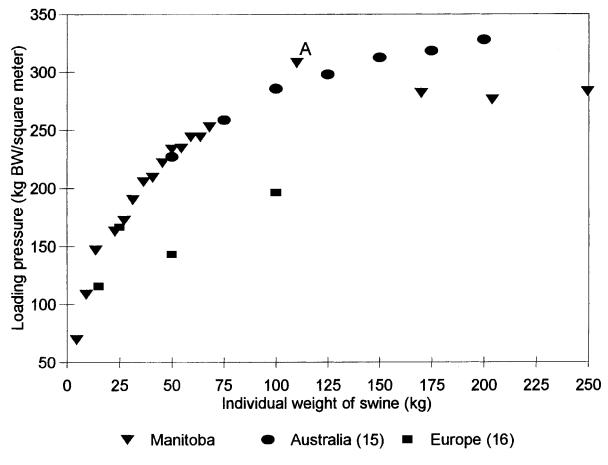

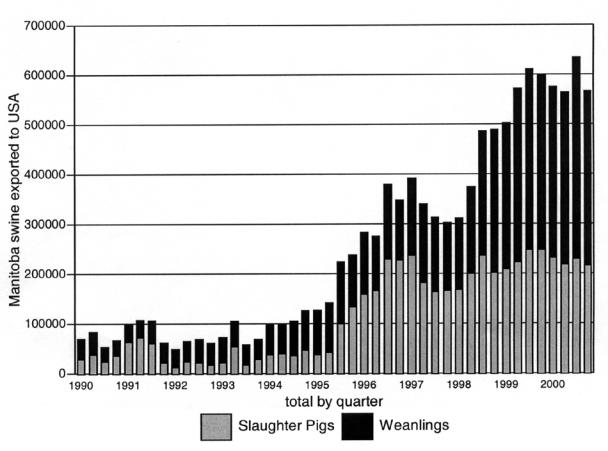

The maximum floor pressure values from the Canadian and Australian data were calculated and analyzed using a curve-fitting program to derive an equation of best fit by linear regression (CurveExpert 1.3; Daniel G. Hyams, Starkville, Mississippi, USA). Previous studies predicted that the function describing the relationship between body mass and the floor space required for swine should be a power formula (12). Power formulas have the format of y = axb, where, in this application, y is the maximal floor pressure in kg BW/m2, x is the weight of the average animal in kg, and a and b are constants. The maximal pressure points calculated from the beef code of practice form a line that conforms extremely well to a power function (13). The Canadian pressure recommendation for maximum stocking density for loose-loaded horses in moderate body condition is described by a power formula (17). The Australian and Canadian swine data, when considered independently and together, provided a better fit with a hoerl function than with a power function (Table 3, Figure 4). Hoerl functions have the format y = a(bx)(xc), where, in this application, y is the maximal floor pressure (kgBW/m2), x is the weight of the average animal (kg), and a, b, and c are space constants. Curve-fitting by linear regression attempts to minimize the difference between data points and the line described by the function. Regression models are divided into families according to their typical behavior. The power and hoerl models are both in the power law family of regression models.

Table 3.

Figure 4. Graphical representation of results of data presented in Tables 1 and 2 subjected to linear regression and the Randall power model (references in parentheses). The Manitoba model is a hoerl equation where y = (37.53)(0.9969)W(W0.5008) and is derived from the data in Table 1 with the point (104 kg, 305 kg BW/m2) excluded. The Australian data most closely fit a hoerl equation where y = (46.81)(0.9985)W(W0.423) is derived from the data in Table 2 and extrapolated down to 5 kg BW. Statistical information on these 2 models is given in Table 3. The Randall formula is a power equation, y = (100)(W0.225), which is a conversion to a pressure based equation of the original area based equation, A = 0.01M0.78, where A is the minimum area in m2 and M is mass in kg BW (13). In all the models depicted graphically, y is the loading pressure in kg BW/m2 and W is the average animal weight in kg. The area within the trapezoid approximates the recommendation from the pig code (11).

Confirmation and consultation

The lines depicted in Figure 4 represent 3 alternative hypotheses of what the approximate maximal loading pressure for swine in transit should be. This information was presented to the Canadian committee then working on a national code of practice for farm animal transport. Experts on this committee from the trucking industry had extensive experience in transporting cattle and pigs. Their consensus opinion was that the power formulae for cattle, where increasing individual animal body weight allowed for loading increased live animal mass per floor are of trailer, was compatible with experiential evidence; however, it was unsafe to load cull sows and boars at additional live animal mass per trailer compartment as you could safely load market hogs under similar conditions. The expert opinion was that cull sows should not be loaded in excess of 300 kg BW/m2 (60 lb BW/ft2) and that due consideration had to be given to the general body condition of the group of sows. If this opinion of maximal loading pressure accurately represents the needs of cull breeding swine, the power model (12) is probably an inappropriate mathematical model to describe the minimum space requirements for cull sows and boars.

In the pig code (11), the 3.7 ft2 given a 104 kg BW market hog is equivalent to a loading pressure of 305 kgBW/m2. When this datum is considered in context with current practices in Manitoba, it appears to be an outlier (Figure 3) and is in excess of other more recent scientific publications (8,9,10). This datum point was excluded from the set of data used in the regression analysis to arrive at the final recommendation.

Discussion

There is scientific agreement that when loading animals in a group, large individuals of a species can be safely transported at a higher floor pressure than can small individuals. The relationship between average animal weight and safe transportation pressure in weight per unit area is not linear and is increasingly nonlinear at decreasing animal weight. To assure the safety of swine in transit in Canada, there is a need to describe minimum space requirements for a wide range of individual animal weights. One method of describing minimal space allowance for animals loaded in groups is by a mathematical function that graphs maximal recommended floor pressure against average individual animal weight.

The data provided in this study have a closer fit to a hoerl formula than the power formula suggested by Randall (12). The latter has been widely adopted in the development of some national codes of practice, and the Australian code is in close agreement with this standard at swine weights above 100 kg. For swine weighing between 50 and 150 kg, Canadian current practices and the Randall prediction model are in fair agreement (Figure 4). However, for pigs weighing less than 50 kg and more than 150 kg, there is significant divergence, with our (Manitoba) hoerl model providing for considerably more space on a unit live weight basis than the previously suggested power model (12). To be fair, the Randall model is a general scientific prediction based on morphometric measurements of the space requirements for cattle, calves, and swine, and it makes no claim for animals weighing less than 20 kg.

The recommendation presented in this paper is derived largely from current field practice of swine haulers, not from objective scientific principles. It has previously been demonstrated that 100 kg pigs loaded as a group can rest simultaneously in sternal recumbency, if loaded at 250 kg BW/m2 or less (9). This proposed standard recommends a maximum floor pressure of 276 kg BW/m2 for 100 kg pigs which probably allows standing room only for this class and size of pig and would represent overcrowding for trips in excess of 3 h. Market pigs of this size loaded at 281 kg BM/m2 prefer to stand on trips of ≤ 3 h, without evidence of adverse effects (18). In the present study, the truckers perception of the needs of the pigs was the primary determinant of reasonable maximal loading pressure. Animal transporters may be comfortable loading 50 to 150 kg pigs at floor pressure levels that would allow for standing room only, for short trips. The same animal transporters may consistently allow weaned pigs, unthrifty pigs, and cull sows space to lie down, as it is a perceived need of the class of animal.

A possible explanation for the additional space requirements of cull breeding swine in addition to what could be explained by a simple increase in body size, compared with market-weight pigs is that the latter are very uniform in size and body condition and may represent an optimum physiologic state. As breeding swine age, a wide range of mature body size and body condition develops, presenting as a nonuniform load by the time they are transported as cull sows and boars. Cull breeding swine may also have an increase in lameness and a decrease in general ambulatory ability, so that they require more room to get up and down. These physiological realities result in cull animals needing more space on a unit weight basis than do the same animals at the peak of youth, as represented by market weight. Through the consultative process in the development of the transport code (1), individuals directly involved in livestock transportation identified this physiologic requirement of cull sows and boars.

The data presented provide evidence that the maximal loading pressure for the movement of pigs by road increases with body mass to an optimum and that further increases in body size do not translate into less space required on a per unit BW basis. The recommended maximal loading pressure under ideal conditions for swine loaded in groups can be described as a hoerl model with the formula y = (37.53)(09969)W(W0.5008). This maximal loading pressure recommendation is presented as a hypothesis requiring further testing and validation or improvement. Mathematical models are not a substitute for human judgment and experience.

We consider these recommendations of loading pressure to be usable maximums in purpose built equipment with no concurrent risk of heat stress in the pigs. Multideck aluminum punch-out trailers, designed for swine and used in western Canada, have large ventilation holes positioned to assure equal ventilation of all decks. Some “cattle” trailers produced by the same manufacturer have removable decks, to allow for triple decking of swine and double decking of cattle. The pattern of ventilation ports in dual purpose cattle trailers are primarily placed to prevent cattle from getting their feet entrapped in the ports. This pattern may not allow equal ventilation of all decks when hauling swine.

Further research into the space allowance needs of swine in transit by road is required. Animal care committees reviewing research proposals may be required to evaluate whether a certain crowding challenge is likely to be acceptable on humane grounds. The graphical representation given in Figure 4 may be of assistance in making decisions in the absence of complete information. The presentation of minimal space requirement concepts in the form of loading pressure charts is an aid to clarity, avoids internal contradiction within tabular standards, and assists animal handlers in understanding the needs of animals.

Footnotes

Acknowledgments

This work was made possible by Manitoba Agriculture and Food and peer support from staff of the Veterinary Services Branch. D. Heatherington of D&D Livestock provided guidance and encouragement in the early development of this model. Dr. Wayne Clayton, Canadian Food Inspection Agency, Brandon, Manitoba kindly provided additional data on space allowance for cull sows. CVJ

Address correspondence and reprint requests to Dr. Terry Whiting.

This paper was peer reviewed.

References

- 1.Canadian Agri-Food Research Council, Recommended Code of Practice for the Care and Handling of Farm Animals — Transportation. Ottawa: CARC Secretariat, 2001. Also available online: http://www.carc-crac.ca/english/codes_of_practice/transport_code.htm.

- 2.The Stationary Office. The Welfare of Animals (Transport) (Amendment) Order 1999. Statutory Instrument 1999 No. 1622. Norwich, England: The Stationary Office, 1999.

- 3.Penny RHC, Guise JG. Animal welfare in the United Kingdom. Swine Health Prod 2000;8:87–89.

- 4.Honey J. Manitoba Livestock Industry Profiles 2000. Winnipeg: Manitoba Agriculture and Food, 2000.

- 5.Harris DL. Multi-Site Pig Production. Ames: Iowa State Univ Press, 2000.

- 6.Harris DL, Turney-Harris I. One site and multi-site rearing systems: standardized nomenclature and alphanumeric notation. Proc 7th Annu Swine Dis Conf Swine Pract. Ames: Iowa State Univ Press, 1999:135–147.

- 7.Warriss PD. The welfare of slaughter pigs during transport. Anim Welfare 1998;7:365–381.

- 8.Gade PB, Christensen L. Effect of different stocking densities during transport on welfare and meat quality in Danish slaughter pigs. Meat Sci 1998;48:237–247. [DOI] [PubMed]

- 9.Warriss PD. Choosing appropriate space allowances for slaughter pigs transported by road: A review. Vet Rec 1998;142:449–454. [DOI] [PubMed]

- 10.Riches HL, Guise HJ, Penny RHC, Jones TA. A national survey of transportation conditions for pigs. Pig J 1996;38:8–18.

- 11.Canadian Agri-Food Research Council. Recommended code of practice for the care and handling of farm animals — Pigs. Ottawa: CARC Secretariat, 1993.

- 12.Randall JM. Environmental parameters necessary to define comfort for pigs, cattle and sheep in livestock transporters. Anim Prod 1993;57:299–307.

- 13.Whiting TL. Comparison of minimal space allowance standards for transportation of cattle by road from 8 authorities. Can Vet J 2000;41:855–860. [PMC free article] [PubMed]

- 14.Spoolder HAM, Edwards SA, Corning S. Legislative methods for specifying stocking density and consequences for the welfare of finishing pigs. Livestk Prod Sci 2000;64:167–173.

- 15.Standing Committee on Agriculture and Resource Management. SCARM Report No. 63 Collingwood, Victoria, Australia: CSIRO Publ, 1997.

- 16.Council of Europe Committee of Ministers, Chapter VI of Council Directive 95/29/EC of 29 June 1995 amending Directive 91/628/EEC concerning the protection of animals during transport F-67075. Strasbourg: Council of Europe Publ, 1995.

- 17.Whiting T. Maximum loading density of loose horses. Can J Anim Sci 1999;79:115–118.

- 18.Guise HJ, Riches HL, Hunter EJ, Jones TA, Warriss PD, Kettlewell PJ. The effect of stocking density on carcass quality and welfare of slaughter pigs. I. Carcass Measurements. Meat Sci 1998;50: 439–446. [DOI] [PubMed]