Abstract

A new mechanical neck was developed for a new dummy possessing a complete articulated spine, for low speed rear-end collisions. The new neck consists of seven cervical elements connected by hinge joints. The neck stiffness properties were created by rubber blocks between each pair of vertebrae in combination with simulated muscle elements between the head and T1. The neck was validated against volunteer tests (Δv of 7 km/h) results. Both displacement and acceleration of the head relative to the upper torso for both duration and peak values, were in agreement with the volunteer data.

Neck injuries in rear-end car collisions are increasingly frequent [Ono et al., 1997]. Von Koch (1994) reported that neck injuries account for 50% of all traffic injuries with long term consequences. Rear end collisions account for about 25% of these injuries [Temming, 1998].

Nygren et al. (1985) found that the use of head-restraints decreased the risk of neck injury in a rear-end collision by about 20% on average. Currently, there is an ongoing debate about the possible risk of optimising the stiffness and strength of the seat-back to withstand a high-speed rear impact, which could possibly increase the risk of neck injuries in low-speed rear impacts. The trend toward stronger seat backs raises the need for an improved test method for neck injury risk in low-velocity rear-end impacts.

The most essential component when testing the protective performance of seats and head-restraints is the crash dummy. The best dummy currently available for low speed rear-end collision testing is the Hybrid III supplemented with a RID-neck [Svensson and Lövsund, 1992] or a TRID-neck [Thunnissen et al., 1996]. These two dummy necks improve the head angular response in rear-end collision testing, but some problems still remain with the dummy designs. The Hybrid III has a completely rigid thoracic spine that does not replicate straightening of the spine or the vertical accelerations of the head and T1 that occur in volunteer tests [Scott et al., 1993; Ono and Kanneoka, 1997; Davidsson et al., 1998b]. The RID-neck does not give an adequate head-neck retraction response [Geigl et al., 1995] and the same problem is probably present in the TRID-neck. A new rear impact dummy, BioRID I, using an articulated human-like spinal curvature was presented by Davidsson et al. (1998a). The stiffness of the new dummy spine was designed to correspond with the stiffness of a human at low-speed impacts.

The aim of the present study was to develop and evaluate a new neck concept. This is a part of a new dummy design for testing the influence of seat and car structure design on the head-neck motion during rear-end collisions. The developed neck is a part of the new rear-end impact dummy (BioRID I).

METHODS AND MATERIALS

The aim was to keep the new neck design as simple as possible, but with reasonable biofidelity in terms of head kinematics. The stiffness properties were based on results obtained from a mathematical model of the neck. The mechanical neck was validated against data from volunteer tests. The testing was performed in the same seat and used a similar impact pulse as the volunteer tests. The reproducibility and repeatability of the neck was examined.

The new neck design was based on the design concept of the RID-neck [Svensson and Lövsund, 1992] with vertebral bodies connected by hinge joints, thus restricting the motion to the sagittal plane. All vertebrae are of the same height (17.5 mm) and are made of acetal plastic. The stiffness in the hinge joints connecting the vertebrae to each other is the same for all neck joints. The joint stiffness is progressive as found in the literature [White and Panjabi, 1978]. In the space between each pair of vertebrae, rubber blocks made of shore hardness 40 polyurethane were placed and glued to the inferior vertebra. Added to the RID design are four steel wires, two on the posterior and two on the anterior side of the neck. These wires are attached to the skull base and to T1, and guided through all the vertebrae (C1–C7) (Fig. 1). This new design with wires gave the neck a smaller resistance to retraction motion while retaining a biofidelic resistance to extension/flexion motion. Retraction motion is defined as the horizontal displacement of the head relative to T1 without any angular displacement of the head relative to T1, sometimes referred to as the shear displacement of the head relative to T1. The rubber block could be seen as representing the deeper positioned muscles that connect adjacent vertebrae to each other. The wires represent the superficial muscles that connect the head to the upper torso.

Figure 1.

The mechanical neck model with wires guided through the vertebrae and mounted on the BioRID I spine with a Hybrid III head.

The need for wires connected to springs and dampers was determined using a mathematical model of the neck based on the same geometrical properties as the mechanical neck [Linder et al., 1998]. In this study it was found that a velocity dependent component was needed to obtain the same head motion relative to T1 and horizontal acceleration of the head as recorded in the volunteers.

The wires are attached to a spring and damper unit (Fig. 2). The spring and damper unit is activated both in flexion (forward bending) and extension (rearward bending) motions. In the final version, the spring constant was 16.8 kN/m and the damping coefficient was 27 kNs/m. The geometrical properties and the mass of the spring and damper unit made it difficult to place it inside the dummy. The wires are 1.65 meters long, which makes it possible to mount the unit beside the seat for testing. The wires continue below T1 at the sides of the thoracic and lumbar parts of the spine and exit the dummy between the rubber torso and the pelvis of the BioRID I [Davidsson et al. 1998a].

Figure 2.

The spring and damper unit which is connected to the wires.

The neck geometry was based on a drawing of a seated 50th percentile male [Robbins et al, 1983] (Fig. 3). The neck was built with the same number of vertebrae as the human neck and with the lordosis of a seated occupant. It was designed to enable motion in the sagittal plane similar to that of a human.

Figure 3.

Drawing of a seated 50th percentile male with radii of the cervical spine added [Robbins et al, 1983].

The range of motion for the cervical spine was based on the range of motion in volunteers and cadaver tests reported in the literature [Kapandji, 1974; White & Panjabi, 1978] and adjusted to allow realistic retraction-protraction. Motion studies of the cervical spine demonstrate that with retraction of the head (axial extension), a greater range of upper cervical flexion is obtained than by simply flexing the head and neck [McKenzie, 1990]. A total range of motion of 92 degrees in extension and 36 degrees in flexion was chosen. For each cervical joint segment this equals 11.5 degrees in extension and 4.5 degrees in flexion. The length of the radius that gives the best agreement between the curvature of the neck on the drawing of Robbins et al. (1983) and an arc of a circle was found to be 190 mm with a sector of 37 degrees (Fig. 3).

In order to evaluate the design of the neck, a series of sled tests was performed with the new dummy. The tests were carried out on a test set-up consisting of one bullet and one target sled at Chalmers University. The dummies were placed in the same seat and impacted with the same acceleration pulse of the target sled as in the volunteer tests [Davidsson et al., 1998b]. This seat was constructed to have the dynamic yielding characteristics of a modern car seat (Fig. 4). The acceleration data was recorded in a local co-ordinate system and the linear and angular displacement data was presented in a global coordinate system (Fig. 4).

Figure 4.

Schematic drawing of the BioRID I in the test set-up [from Davidsson et al., 1998a].

In the sled tests, the developed neck formed part of a new rear end impact dummy, the BioRID I [Davidsson et al. 1998a]. This dummy has an articulated spine consisting of the same number of vertebrae as a human being and an upper torso with the same mass distribution as a human. Apart from the spine and torso, the dummy was essentially a 50th percentile Hybrid III. The dummy was equipped with two uni-axial accelerometers on the head and one uniaxial accelerometer at the level of T1. The acceleration pulse of the sled was tuned to resemble the pulse achieved in the volunteer test (Fig. 5). A Hybrid III dummy was also tested in the same test set-up and equipped identically to the BioRID I.

Figure 5.

Acceleration pulse of the target sled in the validation tests at Δv 7 km/h.

The validation of the neck was carried out in tests at a Δv of 7 km/h. Comparison with volunteer tests was done for linear horizontal and angular displacement as well as horizontal acceleration of the head relative to the upper torso. This was performed for both peak values and time history. The volunteer test data was presented as a corridor one standard deviation above and below of the average response of 5 male human volunteers.

All tests were filmed with a high speed video camera (Kodak Ektapro RO) recording at 500 frames per second. Dummy output parameters from the tests were displacement and acceleration of head and head angular displacement relative to T1.

The current neck design concept was evaluated by comparing it to an identical neck without the wires and with higher joint stiffnesses. Repeatability was tested by performing three equal tests with one neck and reproducibility was tested by testing three necks.

RESULTS

The sled tests showed that the motion of T1 and the head of the BioRID I agreed well with volunteer data. There was also good agreement for the linear and angular displacement, as well as acceleration of the head, in the co-ordinate system described in figure 4. This was found both in terms of peak values and time. The response of the neck is shown in figure 6 together with the response corridors of the volunteer tests.

Figure 6.

The response of the new neck and the volunteer corridor at Δv 7 km/h. (a) Head x-acceleration, (b) Head z-acceleration, (c) Head relative T1 angular displacement, (d) Head relative T1 x-displacement.

The comparison between the BioRID I and the Hybrid III showed that there was less rotation at the T1 level in the Hybrid III than in the BioRID I (Fig. 7). The response of the new neck was within the corridors of the volunteers for the impact history until 275 ms. Around 250 ms the rebound starts. The focus for the development of the neck has been the initial motion until the rebound. In Fig. 7d it is seen that the amount of horizontal displacement is too high during the rebound. A somewhat higher value of the head x-acceleration is also present in the rebound, Fig. 7a. The angular response of the head of the developed neck and that of the Hybrid III was similar (Fig. 7a). But the rotation at the T1 vertebra differed widely between the new neck and the Hybrid III (Fig 7b). This difference resulted in the different angular response between head and T1 shown in figure 7c.

Figure 7.

The neck response of BioRID I and Hybrid III compared to the volunteer corridor at Δv 7 km/h. (a) Head angular displacement, (b) T1 angular displacement, (c) Head relative T1 angular displacement.

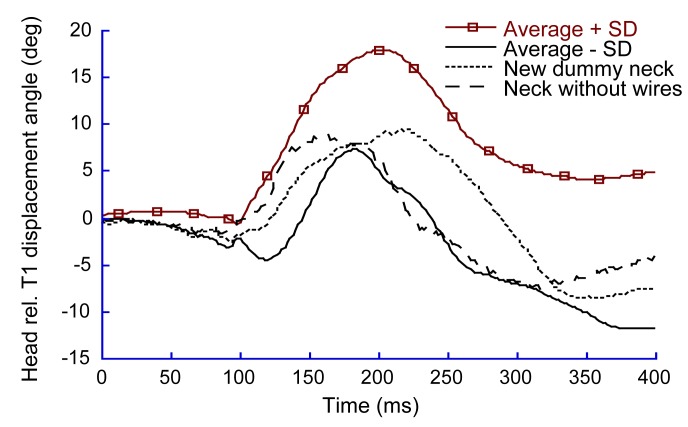

It was found that without the wires the angular response changed significantly. Figure 8 shows the neck response with and without wires producing the same head relative to T1 angular displacement in the corridor of the volunteers. The neck without the wires causes an earlier onset of rearward angular motion and a too swift forward return.

Figure 8.

Effect of the wires on neck angular displacement response of the head relative to the T1.

The maximum retraction of BioRID I, Hybrid III and the mean volunteer is shown in Table 1. This table also includes the time value for the maximum retraction measurement. It was clear that the retraction capability was too small in the Hybrid III where as it was adequate in the BioRID I. Maximum retraction was defined as the difference in horizontal displacement between T1 and head when the head underwent rearward angular motion. The distance was measured in a co-ordinate system fixed in space. Since it was the head relative to T1 motion that is of interest, Figure 7c was used to verify that significant rearward angular head displacement had not occurred before the time of maximum retraction. It was observed that head forward angular displacement was not present before the rearward angular motion began. T1 was under continuous rearward angular motion during the interesting time interval (50–120 ms). Thus, maximum retraction could be measured at maximum forward head angular displacement relative to T1. All maximum retraction values were observed before head restraint contact occurred.

Table 1.

Maximum horizontal retraction of the head relative to T1 for the volunteer average, Hybrid III and BioRID I.

| Time (ms) | Maximum retraction (mm) | |

|---|---|---|

| H III | 70 | 7 |

| BioRID I | 100 | 20 |

| Volunteers | 100 | 23 |

Repeatability tests showed less than 4 % difference from the average on any one neck model for the maximum value of any output data. Reproducibility tests showed less than 4 % difference between tests of different necks for maximum output data.

DISCUSSION

The results of this study showed that a combination of elastic stiffness and damping in the muscle substitutes, together with an initial stiffness, was required to obtain the head kinematics found in volunteer tests. Without the wires, the duration of the neck motion was shorter when an acceptable rearward peak angular displacement was reached. A combination of a spring with a linear stiffness of 16.8 kN and a damper with a constant damping coefficient at 27 kNs/m connected in parallel created a response within the corridor of the volunteer tests.

In the design of the new rear-end impact dummy, the focus was on reproducing the kinematics of the head and neck of the volunteers in low-speed impacts. The new neck was validated against volunteer data at Δv 7 km/h and may not be suitable for high-speed rear impacts. The impact response of the human body is velocity dependent and this may require a different dummy design at more severe impact conditions. Moreover, a dummy for high-speed rear-end impacts may have to be instrumented differently to account for other injuries and injury mechanisms than those at low-speed impact.

The amount of head motion relative to T1 has been examined in detail in this study. The angular displacement of the head relative to T1 started in the forward direction before it went in rearward direction (Fig. 7c). This was entirely due to the motion of the T1. The head does not angulate forward before the rearward angular motion starts, which was in accordance with findings in the volunteer tests (Fig. 7c). The amount and the timing of relative forward rotation was similar to that found in other volunteer tests [Siegmund et al., 1997]. For a test of Δv = 8 km/h they found a relative head rotation of 5 degrees at 100 ms.

Designing a dummy neck for an articulated dummy spine with a human like T1 motion (Fig. 7b) differs significantly from the case with a neck mounted on a rigid thoracic spine (like the Hybrid III-dummy). For a similar head motion (angular displacement) the T1 angular motion from the volunteer tests resulted in a completely different neck-bending motion than that of a neck mounted on a rigid thoracic spine (Fig. 7c). The contribution from the T1 angular motion to the neck bending is significant compared to the total amount of the head rearward angular displacement. For this reason it is difficult to compare only the necks of the Hybrid III-dummy and the new BioRID I-dummy [Davidsson et al., 1998a]. A meaningful comparison can only be made between complete dummies.

The new rear-end impact dummy neck was proven to yield a response close to that of volunteers in low velocity rear impacts when used on the first version of the BioRID. A design principle similar to that of the RID or the TRID i.e. without muscle substitute resulted in a less biofidelic motion with a too rapid onset and recoil of head motion. The performens of the neck in the rebound motion will be further developed. There is a significant potential for re-tuning the neck if further validation against other volunteer data sets should indicate that it is desirable. The spring and damper system will be further evaluated and further development of the spring and damper system to integrate these components in the dummy is anticipated.

ACKNOWLEDGEMENTS

This study was supported by the Swedish Vehicle Research Program (NUTEK), Sweden and sponsored and carried out in co-operation with Autoliv Research, Volvo Car Corporation and SAAB Automobile AB. Special thank for valuable help and ideas to Mats Nillius, Per Wilhelmsson and Hans Sjöberg.

REFERENCES

- Backaitis SH, Mertz HJ. Hybrid III: The first Human-Like Crash Test Dummy. SAE Inc; USA: 1994. ISBN 1-56091-449-1. [Google Scholar]

- Davidsson J, Linder A, Svensson MY, Flogård A, Håland Y, Jakobsson L, Lövsund P, Wiklund K. BioRID - A New Biofidelic Rear End Impact Dummy. Accepted for IRCOBI. 1998a [Google Scholar]

- Davidsson J, Deutscher C, Hell W, Svensson MY, Linder A, Lövsund P. Human Volunteer Motion in Rear-End Impacts. Accepted for IRCOBI. 1998b [Google Scholar]

- Geigl BC, Steffan H, Dippel C, Muser MH, Waltz F, Svensson MY. Comparison of Head-Neck Kinematics During Rear End Impact Between Standard Hybrid III, RID Neck, Volunteers and PMTO’s. Proc Int. IRCOBI Conf. on the Biomechanics of Impacts; Brunnen, Switzerland. 1995. pp. 261–270. [Google Scholar]

- Koch M, Nygren Å, Tingvall C. Impairment Pattern in Passenger Car Crashes, a Follow-Up of Injuries Resulting in Long Term Consequences. Proc. Int. Technical Conf. on the Enhanced Safety of Vehicles; 1994. pp. 776–782. paper no. 94-S5-O-02. [Google Scholar]

- Kapandji IA. The Physiology of the Joints. Three. Churchill Livingstone; Edinburgh: 1974. ISBN 0 443 01209 1. [Google Scholar]

- Linder A, Jernström C, Svensson MY, Lövsund PA. Mathematical Model of an Improved Neck for a Rear-End Impact Dummy. Manuscript in preparation. 1998 [Google Scholar]

- McKenzie RA. The cervical and thoracic spine, mechanical diagnosis and therapy. Spinal Publications Ltd; New Zeeland: 1990. ISBN 0-9597746-7-X. [Google Scholar]

- Nygren Å, Gustavsson H, Tingvall C. Effects of Different Types of Headrests in Rear-End Collisions. 10th International Conference on Experimental Safety Vehicle; NHTSA, USA. 1985. pp. 85–90. [Google Scholar]

- Ono K, Kanneoka K, Wittek A, Kajser J. Cervical Injury Mechanism Based on the Analysis of Human Cervical Vertebral Motion and Head-Neck Torso Kinematics During Low Speed Rear-End Impacts. Society of Automotive Engineers, Inc; New York: 1997. pp. 339–356. LC 67-22372. [Google Scholar]

- Robbins DH. Antropometric Specifications for Mid-sized Male Dummy. Vol. 2. USA: 1983. 1983. UMTRI-83-53-2. [Google Scholar]

- Scott MW, McConnel WE, Guzman HM, Howard RP, Bomar JB, Smith HL, Benedict JV, Raddin JH, Hatsell CP. Society of Automotive Engineers, Inc; Warrendale, Philadelphia, USA: 1993. Comparison of Human and ATD Head Kinematics During Low-Speed Rearend Impacts. SAE paper no. 930094, SAE/SP-93/945. ISBN 1-56091-330-4, LC 92-63144. [Google Scholar]

- Siegmund GP, King DJ, Lawrence JM, Wheeler JB, Brault JR, Smith TA. Head/Neck Kinematic Response of Human Subjects in Low-Speed Rear-End Collisions. Proc 41st STAPP Car Crash Conf; USA: SAE Inc; 1997. pp. 357–384. [Google Scholar]

- Svensson MY, Lövsund P. A dummy for Rear-End Collisions -Development and Validation of a New Dummy-Neck. Proc. Int. IRCOBI Conf. on the Biomechanics of Impacts; Verona, Italy. 1992. pp. 299–310. [Google Scholar]

- Temming J. Human Factors Data in relation to Whiplash Injuries In Rear-End Collisions of Passengers Cars, SAE paper no. 981191; Warrendale, Philadelphia, USA: Society of Automotive Engineers, Inc; 1998. [Google Scholar]

- Thunnissen JGM, van Ratingen MR, Beusenberg MC, Janssen EG. A Dummy Neck for Low Severity Rear Impacts. Proc. Int. Technical Conf. on the Enhanced Safety of Vehicles; 1996. pp. 1665–1678. paper no. 96-S10-O-12. [Google Scholar]