Abstract

Objective

Spinal manipulation therapy (SMT), an intervention used to treat low back pain, has been demonstrated to affect the stiffness of the spine. To adequately quantify the effects of SMT on stiffness, a device capable of applying specific parameters of manipulation in addition to measuring force-displacement values has been developed previously. Previously developed indentation techniques that quantify stiffness have been modified for novel use in evaluating SMT parameters. The reliability of stiffness measurements performed by the newly adapted device was assessed in this study.

Methods

Seven springs of varying stiffness were each indented 10 times by a Variable Rate Force/Displacement (VRFD) device. Indentations were performed at a rate of 0.5mm/s to a maximal displacement of 4 mm. The stiffness coefficients for a middle portion of the resulting force-displacement graph and the terminal instantaneous stiffness (stiffness at end displacement) were calculated. The intra class correlation and confidence interval were calculated for these stiffness measurements to assess device reliability.

Results

Repeated spring stiffness measures yielded an ICC value of 1.0. The mean stiffness values had narrow 95% confidence intervals ranging from 0.01 N/mm to 0.06 N/mm and small coefficients of variation.

Conclusion

This VRFD device provides highly reliable stiffness measurements in controlled conditions. Although in vivo reliability remains to be established, the results of this study support the use of the VRFD device in future trials investigating the impact of SMT various parameters on spinal stiffness.

Keywords: Manipulation, Spinal, Reproducibility of Results, Elastic Modulus, Chiropractic

INTRODUCTION/BACKGROUND

Low back pain 1 and spinal degeneration 2 are often associated with changes in spinal stiffness. To assess these changes, clinicians most often employ a manual technique where postero-anterior forces are applied to the spine and the resulting tissue response is appreciated. Unfortunately, manual spinal stiffness assessment has been shown to have poor performance. Specifically, prior investigations have demonstrated that clinicians are unable to apply consistent forces 3, perceive changes in the force displacement relationship 4 or judge spinal stiffness 5. As a result, many investigators have designed mechanical devices to increase measurement precision and accuracy when assessing spinal stiffness 6–10.

The mechanical device described in this study has been used previously by Pickar et al. 11–13 to apply rapid forces that simulate spinal manipulation therapy (SMT) in a feline model. Because this device can change the rate at which forces are applied, it may be possible to use the same device to apply lower force rates used in stiffness testing as well as the higher rates used in SMT application. Before using the Variable Rate, Force/Displacement (VRFD) device in an experimental setting to assess spinal stiffness, the device’s reliability should be established with respect to stiffness assessment. Therefore, the objective of this study was to determine the reliability of the VRFD device in a bench-top setting. Given prior technology assessments 6,14, device reliability could be considered to be excellent with intraclass correlation coefficients (ICC) values of 0.8 or higher 15 during replicate tests to determine the stiffness of inanimate objects.

Methods

Variable Rate Force/Displacement Device

VRFD Overview

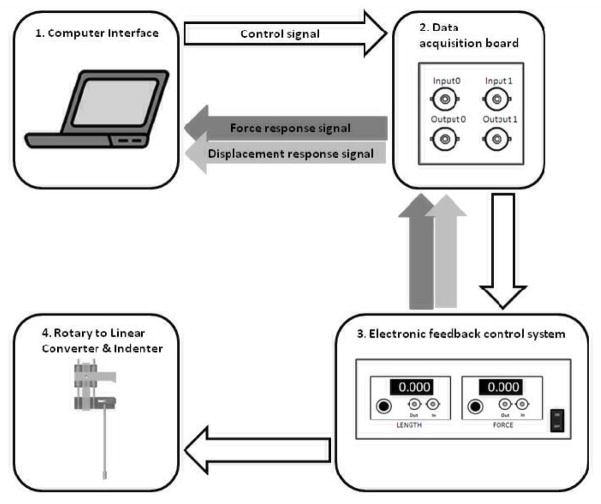

The VRFD device is capable of performing vertebral postero-anterior indentations at high rates of loading to simulate SMT or at low rates to quantify stiffness. The VRFD device is comprised of 5 major components (four are shown in Fig 1): 1) a graphical computer interface, 2) a data acquisition board (USB-6212, National Instruments, Austin Texas) 3) an electronic feedback, motor control system (Aurora Scientific, Dual Mode Lever System, Model 310C, Aurora, ON, Canada) 4) a custom-made indenter connected to the motor via a rotary to linear converter and 5) a custom-made 3D positioning frame. In brief, the computer interface sends a voltage signal whose magnitude represents the desired output of the motor which in turn is controlled by the electronic feedback system. Transducer outputs from the control system provide both feedback control to the motor and output voltage to the computer. These signals represent the amount of displacement and force applied by the indenter respectively. Paired values for applied displacement and force can then be plotted and stiffness derived from the resulting plot.

Figure 1.

Diagram representation of the VRFD device. The voltage control signal is sent through the device and the force and displacement response signals are returned in a continuous loop.

Components

A custom graphical interface (LabView 8.6, National Instruments, Austin Texas) enables the operator of the VRFD to program the input voltage signal that will control the magnitude and rate of indenter movement. The waveform constituting the signal is created using customized software (LabView 8.6, National Instruments, Austin Texas) which generates an analog file containing an array of values corresponding to the desired input voltage. The rate at which the data acquisition board will ultimately send the voltage (the rate at which voltage should increase), and the maximum desired voltage, are parameters that determine the number of voltage increments contained in the file and the value of each increment. Files containing unique displacement (voltage) rates and maximum displacement (voltage) magnitudes can be created in advance for conducting indentations of differing parameters. In the current study, a single rate of 0.5 mm/s was used to assess stiffness.

The data acquisition board (Fig 1.2) is powered by, and connects to, a computer through a USB cable. The board sends the input signal for indentation to the electronic feedback control system at a rate of 1 kHz using 16 bit resolution.

The electronic feedback motor control system (Fig 1.3) consists of an electronic feedback interface and a rotary moving coil motor (Fig 2, item A). The electronic feedback interface connects to the data acquisition board and receives the input voltage signal from the computer. This connection can be modified so that the input voltage controls either the displacement or force generated by the motor. In this study, the motor was used in displacement control exclusively. Motor movement is inherently rotational (Fig 2, item B).

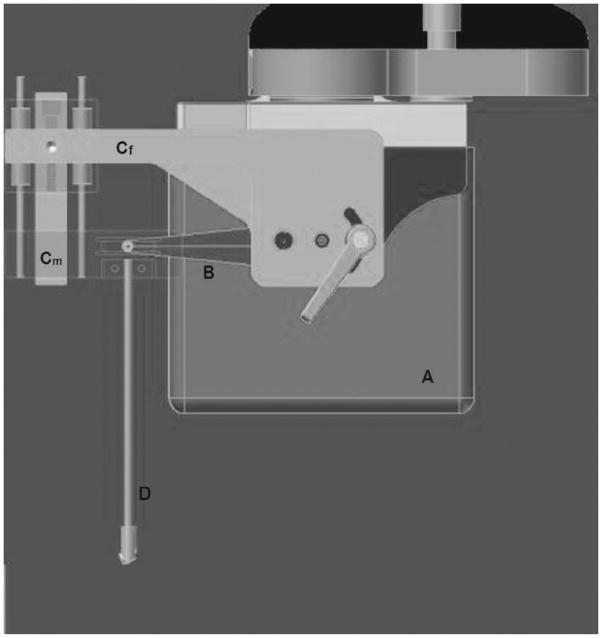

Figure 2.

Schematic representation of the motor (A) and motor arm (B) connected to the rotary to linear converter which is made of a fixed (Cf) and a movable (Cm) component applying displacements through the rod (D).

Because the lever motion is rotary, a component was fabricated to convert rotational motion to linear motion. A portion of this converter (Fig 1. 4 & Fig 2, item Cf) was mounted onto a stationary, rigid positioning frame attached to the motor. The movable portion (Fig 2, item Cm) had an oblong horizontal opening into which a short shaft from the motor’s 8cm lever arm was inserted. The converter’s moveable portion was guided by two rods traveling through linear bearings pressed into the converter’s fixed portion. Actual indentation was performed by a 6 cm long titanium rod fixed in place at the bottom of Cf (Fig 2, item D). The rod was terminated with a 0.5cm thick plastic cap. Consequently, rotary motion of the lever arm created linear motion of the indenter’s tip. Step changes in forces or displacement occur with response times of approximately 8 ms.

Positioning the motor with the attached lever arm, linear converter, and indentation rod (Fig 2) was performed by a custom built 3D frame railing system onto which the motor was mounted. This frame enabled the motor to be positioned along 3 orthogonal axes with a precision of 0.5mm along each axis and 200mm maximum travel.

Calibration

With the rotary to linear converter in place, the maximum force and displacement attainable by the motor was 50.0N and 28.5mm respectively (as determined by the manufacturer). The manufacturer’s calibration values (4.9N/V and 2.85mm/V) were confirmed experimentally by tracing the vertical position of the motor arm at 1V increments then using a digital calliper to measure the distance between tracings. In addition, a linear variable differential transducer (0.1% error, MLT, Honeywell, Intertechnology, Don Mills, Ontario, Canada) was placed on Cm (Fig 2) to confirm that the manufacturer’s conversion factors attained the desired displacement magnitude.

Spring Piston System

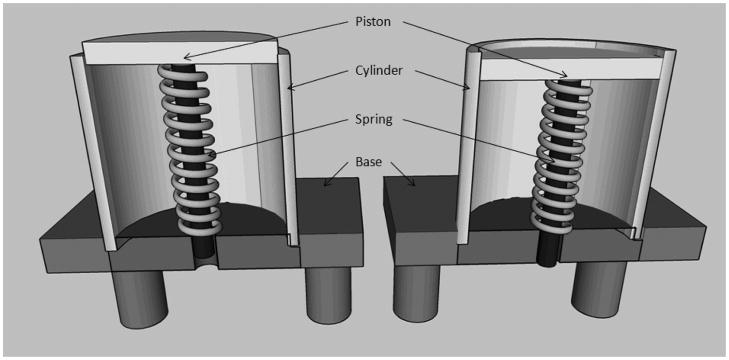

To assess the reliability of the VRFD device, seven compression springs of varying stiffness were used as test media. Springs (A–H) were obtained from Century Spring, Los Angeles California (manufacturer stiffness: 1.19 to 6.68 N/mm; free length: 10.2cm; outer diameter: 2.5cm; wire diameter: 0.3cm). The range of spring stiffness was selected to cover the range of possible stiffness coefficients expected in future experiments 16. Each spring was placed around a piston (Fig 3) and a 1cm thick rubber pad was placed between the indenter and the piston. The pad provided a compliant interface to prevent uncontrolled motor oscillations.

Figure 3.

Spring and piston system.

Repeated Stiffness Testing

The rod (Fig 2. item D) was positioned in line with the center of the spring piston system (Fig 3) and perpendicular to its compressive surface. The piston was initially preloaded by lowering the motor using the positioning frame. A 0.61N preload was determined to be sufficiently high to compensate for the system’s noise (+/− 0.025N of force output) and yet sufficiently low to prevent overloading the motor statically. The preload was also consistent with contact loads expected to be applied during future investigations 16,17.

Following preload application, a 4 mm indentation was performed at 0.5mm/s. In a previous study 7, a relatively fast indentation rate of 2.5mm/s was shown to have diagnostic accuracy but a slower rate of 0.5mm/s was selected to differentiate indentation from the rate at which simulated SMT is to be performed in future experiments (1–3mm/s). Each spring was compressed in this manner 10 times to provide repeated measures for reliability analysis 18. Between each of the 10 compressions, 5–10 seconds were allowed to pass to confirm or reestablish the preload magnitude using the 3D frame.

Analysis & Statistics

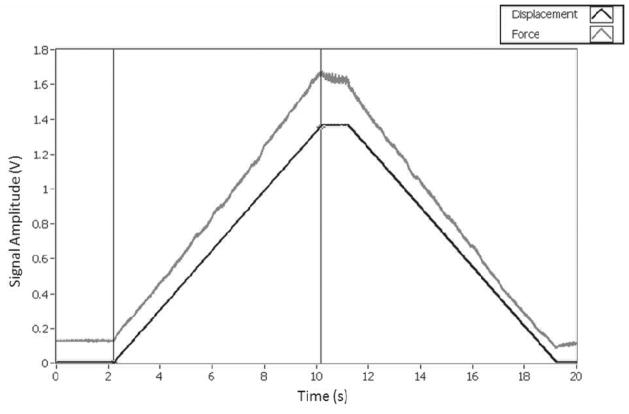

Continuous values for displacement and force during each indentation were recorded at 10 kHz and placed into separate files (Labview 8.6) resulting in 70 files (7 springs × 10 repetitions). For each indentation, the ascending portion of the force-time and displacement-time curves was cropped for the same time interval (Fig 4). Voltages were converted to engineering units using the motor’s calibrated values. Force-displacement (FD) curves were created by plotting displacement on the x-axis and force on the y-axis. The beginning of each FD curve was established as zero spring displacement by subtracting the first value of the displacement signal from all displacement values. Each force and each displacement curve was smoothed by fitting the data to a 5th order polynomial 19.

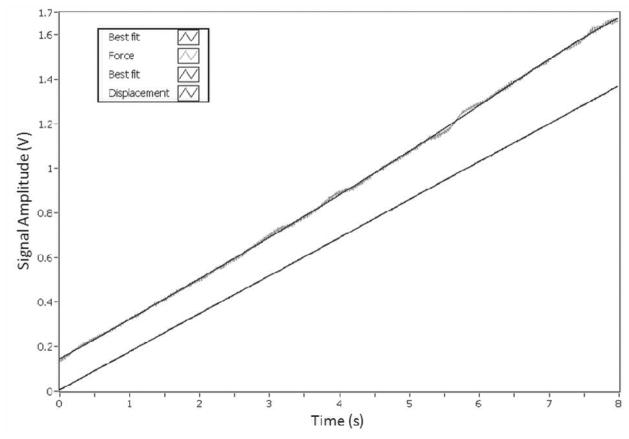

Figure 4.

A voltage time graph demonstrating displacement and force signals collected by the VRFD device. The ascending portion of these plots defined to occur between the point in time where displacement increased from baseline to where displacement reached its first maximal value.

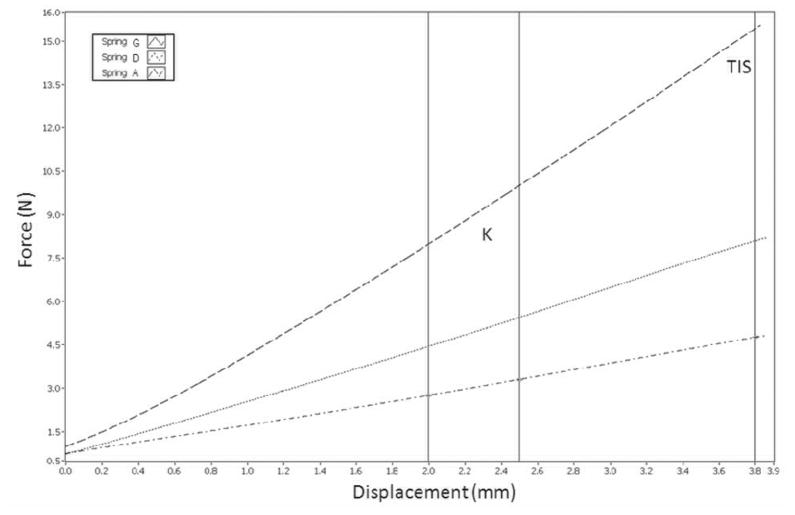

From each smoothed FD curve, a midpoint experimental stiffness coefficient (Ke) was calculated for a 0.5mm interval beginning at the midpoint (2mm total displacement) from the maximum displacement of 4.0mm 19,20. The coefficient Ke was calculated by dividing the change in force by the change in displacement between 2 and 2.5mm. In addition, a terminal instantaneous stiffness coefficient (TIS) was calculated based upon the force developed at 3.8mm displacement (Fig 5). The maximal programmed displacement of 4mm was not selected as the terminal displacement point in order to prevent calculation artefacts (+/− <0.01V) caused when the motor reversed direction and decompressed the spring.

Figure 5.

FD curve analysis. A midpoint interval stiffness coefficient (K) was calculated by dividing the change in force by the change in displacement between 2 and 2.5mm. The terminal instantaneous stiffness (TIS) was also calculated in the same manner at 3.8mm – a common displacement to all trials collected.

The Intraclass Correlation Coefficient (ICC(3,1)) was calculated for Ke and TIS values using a two-way mixed model analysis of variance for the reliability of a single measurement (PASW Statistics 17.0, SPSS, IBM, Chicago, Illinois). The 95% confidence interval and the coefficient of variation for spring stiffness were calculated for each spring to provide an estimate of precision 6,15,21.

Results

Reliability

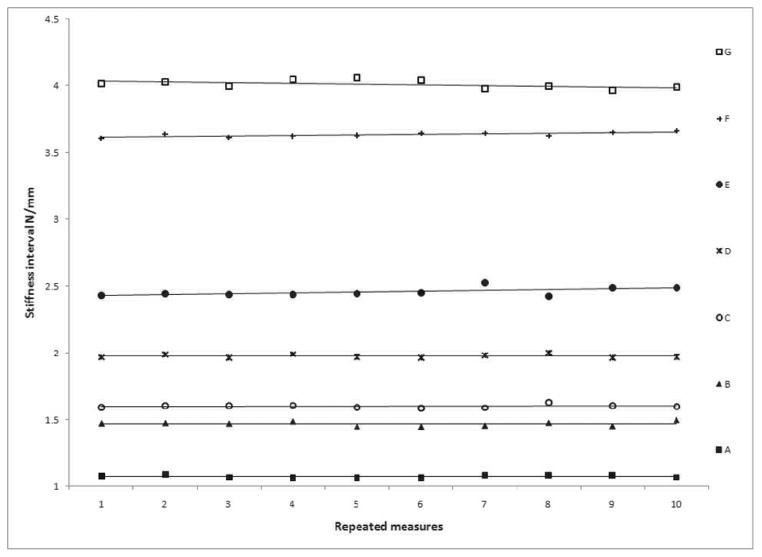

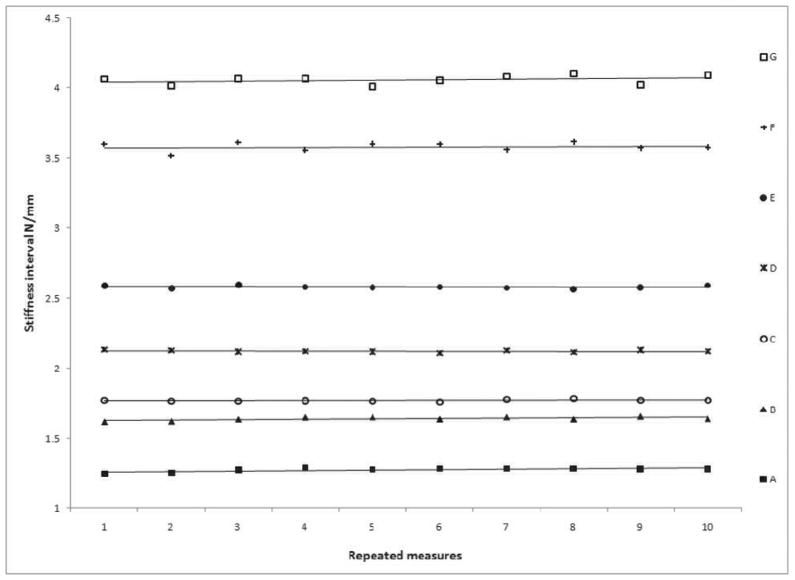

The average ICC(3,1) for both Ke and TIS coefficients was 1.00. These ICC ratings can be considered to be “excellent” 15. Ke and TIS values from 10 repeated indentations for each of seven springs are shown in Figures 6 and 7 respectively. Least squared regression lines were fitted to the repeated stiffness measurements for each spring. All regression line slopes ranged between 0.01N/mm and −0.01N/mm (Fig 6, 7), suggesting there was no change in the stiffness of the springs over time.

Figure 6.

Mid-point interval (2.0 to 2.5mm of displacement) stiffness coefficients taken from each force displacement curve in order of repeated trial (each letter designates a spring) and linear trend line.

Figure 7.

Terminal Instantaneous Stiffness (at 3.8mm) stiffness coefficients taken from each force displacement curve in order of repeated trial (each letter designates a spring) and linear trend line.

Discussion

In this paper, stiffness data acquired by the VRFD device were assessed for their reliability. Our results show the VRFD device had high ICC values.

Previous Postero-anterior stiffness testing

Postero-anterior (PA) stiffness is most commonly assessed by clinicians using manual techniques. Maher and Adams reported that judgements of stiffness made in this way had poor reliability with ICC values for PA stiffness estimates of the lumbar spine ranging from 0.03 to 0.37 5. Simmonds et al. reported that clinicians are also unable to perceive applied force and resultant displacements accurately 3.

As a response to the poor performance of manual stiffness testing, various mechanical PA stiffness testing devices have been developed. Their performance has been established by measuring the stiffness of beams, cadaveric spines, and live subjects (Table 2). Specifically, Lee and Svensson developed the Spinal Physiotherapy Simulator 22 (SPS) which they reported as having an ICC of 0.88 for stiffness coefficients calculated from the linear portion of the FD curve obtained in asymptomatic subjects. In addition, Lee and Evans developed the Spinal Mobiliser 23 to investigate the effect of tissue mobilisation and relative intervertebral mobility. The Spinal Mobiliser applied loads to the surface of the skin overlying the selected lumbar vertebra and measured displacements of the indenter over the adjacent vertebra. This device was shown to have an ICC of 0.95 for maximal displacements.

Table 2.

Previous devices: force-displacement (FD) curve analysis, reliability and accuracy.

| Study | Device | Subjects | FD curve analysis | Reliability | Accuracy |

|---|---|---|---|---|---|

| Lee and Svensson1990 | SPS | Aluminum alloy beams L3 segment of symptomatic human subjects |

N/A ICC 0.88 |

Within 1% of true value | |

| Lee and Evans 1992 | Spinal Mobiliser | Lumbar segments of asymptomatic human subjects | ICC 0.95 | Maximum error range ± 0.8mm | |

| Latimer et al. 1996 | Portable stiffness device | Beams Lumbar segments of symptomatic human subjects |

Stiffness coefficient | N/A ICC 0.96 |

Maximal error2.5% ± 1.8 N/mm 90% confidence interval |

| Edmontston1998 | SPAM | Lumbar segments of asymptomatic human subjects | Stiffness coefficient from 35–80N interval | ICC 0.98 | ± 1.0N/mm 95% confidence interval |

| Owens 2007 | PAS system | Lumbar segments of symptomatic human subjects | Stiffness coefficient from 55–75N interval | ICC 0.79 | Standard error of measurement 1.62 N/mm |

| Tuttle 2008 | PMAD | Cervical segments of asymptomatic human subjects | Curve shapes | CMD 0.96 | N/A |

Although both the SPS and the Spinal Mobiliser provided highly reliable measurements of PA stiffness, others have commented that the technology is bulky 6 and may be difficult to operate 7. In addition, these devices are not able to perform higher rate indentations 22–24 for dual use in SMT application.

Latimer et al. 6 improved upon these initial devices by developing a smaller, portable device that could be used in clinics to assess symptomatic LBP subjects. This device provided highly reliable measurements (ICC of 0.96) with a 90% confidence interval of 1.8N/mm for the slope of the linear region of the FD curve between 30N and 90N. Similarly, Edmondston and Allison’s group used the Spinal Postero-Anterior Mobilizer (SPAM) to determine the effect of patient position 14, load orientation 25, and mobilizations 10 on lumbar PA stiffness. The SPAM provided an ICC of 0.98 and a 95% confidence interval of 1.0N/mm for the stiffness coefficients calculated from the 35N to 80N section of the slope of the FD curve. These two devices improved on the SPS and the Spinal Mobiliser with their size and portability, but still lacked the ability to perform higher rate indentations 6,14.

Each of these devices offers highly reliable measurements which is a significant improvement over manual assessment techniques. Unfortunately, these devices have been tested on different types of subjects and spinal locations, which make the reliability coefficients difficult to compare.

Analysis techniques

In addition to difficulties in comparing ICCs derived from different devices and experimental conditions, a standard measure of stiffness has not been adopted to enable comparisons across studies although most have calculated stiffness coefficients from a pre-selected force interval 6,9,10,26. To address this issue, Latimer et al. 27 compared different force interval widths and sections of the FD curve and found that wider sections provided more reliable stiffness coefficients but that higher force intervals provided poor reliability in asymptomatic subjects. In the present study, a displacement interval was deemed preferable because a standard force interval would not have covered the same region of the FD curve due to the range of stiffness coefficients of our springs 26. The testing in this study was performed in displacement-control mode, which further supports the selection of a displacement interval. Disparities in the confidence interval widths occurred between the stiffness coefficient Ke and TIS for each spring, however, there was no trend indicating which of these two stiffness measures was over all more reliable. It should be noted that the plotted FD data from each spring is in most instances linear. Although this data can be modelled with a single stiffness coefficient, complementary techniques to calculate stiffness from plotted data were employed as these techniques (Ke and TIS) have been used previously to evaluate force displacement data in clinical trials 28.

Limitations

This study design did not rule out the possibility of a systematic measurement error present in our collected data. Our use of stiffness measures used previously in clinical studies (Ke and TIS) ruled out the possibility of comparing our spring stiffness values with the manufacturer’s values (Km) which were derived and calculated with unknown methods. Therefore, comparisons between Ke, TIS and Km were not considered valid.

Importantly, the VRFD device is small and has limited force (50N) and displacement (28mm) capabilities compared to the devices reviewed above. As a result, the VRFD would not be capable of generating sufficient load or displacement to test humans at parameters used previously (>100N) 6,23. In its present form, the VRFD device would be inadequate for human experimentation unless the motor was replaced with a more powerful model and the ability to provide a greater linear displacement during the indentation possible.

Even with the mechanical reliability of the VRFD device, it is important to consider that the reliability of stiffness measurements obtained may change when used in an in-vivo setting. In-vivo tissues are known to be more difficult to measure given their rate-dependant properties and may therefore produce less reliable measurements due to their complex and dynamic nature 23,29–31. Furthermore, Kawchuk and Fauvel identified factors that reduce the reliability during in-vivo PA stiffness testing including intra-abdominal pressure changes due to breathing, muscular response, patient position, and indenter repositioning error between trials 19.

Significance

Changes in spinal stiffness have been associated with low back pain 1, spinal degeneration 2 and range of motion 32. Therefore, stiffness assessments may provide insight into relevant changes in spinal properties attributed to disease or therapy. Latimer & al. 1 found an 8% decrease in stiffness coefficients as LBP decreased in patients, however, investigations into the effect of manual therapies aimed at normalizing spinal stiffness have been unable to detect significant changes 10,33. The reliability of the VRFD device is equivalent if not superior to that of previously reported devices. The high reliability 15 of this device suggests that the detection of small changes in stiffness following SMT intervention may be possible.

Conclusion

In a benchtop setting, the VRFD device provides highly reliable stiffness measurements over a range of stiffness coefficients related to future clinical trials. The results of this study support the future use of the VRFD device in trials investigating the impact of SMT and other interventions that may influence spinal stiffness. Protocols to establish the reliability of in vivo measurements using the VRFD device are still necessary; the full characterisation of the accuracy of stiffness measurements using this device is unknown.

Table 1.

Summary statistics: mean stiffness from the midpoint interval and the TIS.

| Spring | Midpoint interval (2.0 to2.5mm) Mean stiffness | Terminal Instantaneous Stiffness (3.8mm) Mean stiffness |

|---|---|---|

| A | 1.08 (1.06–1.10) | 1.28 (1.25–1.31) |

| 0.01% | 0.02% | |

| B | 1.47 (1.44–1.50) | 1.65 (1.62–1.68) |

| 0.02% | 0.01% | |

| C | 1.61 (1.59–1.63) | 1.78 (1.77–1.79) |

| 0.01% | 0.00% | |

| D | 1.99 (1.96–2.02) | 2.13 (2.11–2.15) |

| 0.01% | 0.00% | |

| E | 2.47 (2.41–2.53) | 2.59 (2.57–2.61) |

| 0.04% | 0.00% | |

| F | 3.65 (3.62–3.68) | 3.60 (3.54–3.66) |

| 0.01% | 0.03% | |

| G | 4.03 (3.97–4.09) | 4.07 (4.01–4.13) |

| 0.02% | 0.02% |

Values are shown in newtons per milimeter (95% Confidence Interval).

coefficient of variation is given in % = (σ2/mean stiffness) *100

PRACTICAL APPLICATIONS.

The variable rate force/displacement application system provides highly reliable stiffness measurements in inanimate objects.

Direct comparisons to previous devices are limited by the various mediums tested and analysis techniques used.

This device can perform high loading rates to simulate spinal manipulation therapy.

This device is equipped with smaller components ideal for future investigations in a feline model.

Acknowledgments

Funding source

Support for this project was provided by the National Institutes of Health (U19 AT004137). Support for Greg Kawchuk was provided by the Canada Research Chairs program.

The authors thank Dean Macken and Steven Struckman at the University of Iowa Design and Prototyping Center for the design and construction of the rotary to linear converter and 3-D positioning frame.

Footnotes

No conflicts of interests were reported by the authors.

Publisher's Disclaimer: This is a PDF file of an unedited manuscript that has been accepted for publication. As a service to our customers we are providing this early version of the manuscript. The manuscript will undergo copyediting, typesetting, and review of the resulting proof before it is published in its final citable form. Please note that during the production process errors may be discovered which could affect the content, and all legal disclaimers that apply to the journal pertain.

Contributor Information

Michèle Vaillant, University of Alberta, Edmonton, Alberta.

Joel G. Pickar, Palmer Center for Chiropractic Research, Davenport, Iowa; Dept. Biomedical Engineering, University of Iowa, Iowa City, Iowa.

Gregory N. Kawchuk, University of Alberta, Edmonton, Canada.

References

- 1.Latimer J, Lee M, Adams R, Moran CM. An investigation of the relationship between low back pain and lumbar posteroanterior stiffness. J Manipulative Physiol Ther. 1996;19(9):587–91. [PubMed] [Google Scholar]

- 2.Kawchuk GN, Kaigle AM, Holm SH, Rod Fauvel O, Ekstrom L, Hansson T. The diagnostic performance of vertebral displacement measurements derived from ultrasonic indentation in an in vivo model of degenerative disc disease. Spine. 2001;26(12):1348–55. doi: 10.1097/00007632-200106150-00018. [DOI] [PubMed] [Google Scholar]

- 3.Simmonds M, Kumar S, Lechelt E. Use of a Spinal Model to Quantify the Forces and Motion That Occur During Therapists’ Tests of Spinal Motion. Phys Ther. 1995;75:212–22. doi: 10.1093/ptj/75.3.212. [DOI] [PubMed] [Google Scholar]

- 4.Bjornsdottir SV, Kumar S. Posteroanterior motion test of a lumbar vertebra: accuracy of perception. Disabil Rehabil. 2003;25(4–5):170–8. doi: 10.1080/0963828021000030927. [DOI] [PubMed] [Google Scholar]

- 5.Maher C, Adams R. Reliability of Pain and Stiffness Assessments in Clinical Manual Lumbar Spine Examination. Phys Ther. 1994;74:801. doi: 10.1093/ptj/74.9.801. [DOI] [PubMed] [Google Scholar]

- 6.Latimer J, Goodsel MM, Lee M, Maher CG, Wilkinson BN, Moran CC. Evaluation of a new device for measuring responses to posteroanterior forces in a patient population, Part 1: Reliability testing. Phys Ther. 1996;76(2):158–65. doi: 10.1093/ptj/76.2.158. [DOI] [PubMed] [Google Scholar]

- 7.Kawchuk GN, Liddle TR, Fauvel OR, Johnston C. The accuracy of ultrasonic indentation in detecting simulated bone displacement: a comparison of three techniques. J Manipulative Physiol Ther. 2006;29(2):126–33. doi: 10.1016/j.jmpt.2005.11.015. [DOI] [PubMed] [Google Scholar]

- 8.Tuttle N, Barrett R, Laakso L. Postero-anterior movements of the cervical spine: repeatability of force displacement curves. Man Ther. 2008;13(4):341–8. doi: 10.1016/j.math.2007.03.005. [DOI] [PubMed] [Google Scholar]

- 9.Owens EF, DeVocht JW, Wilder DG, Gudavalli MR, Meeker WC. The reliability of a posterior-to-anterior spinal stiffness measuring system in a population of patients with low back pain. J Manipulative Physiol Ther. 2007;30(2):116–23. doi: 10.1016/j.jmpt.2006.12.006. [DOI] [PubMed] [Google Scholar]

- 10.Allison G, Edmonston S, Kiviniemi K, Lanigan H, Simonsen AV, Walcher S. Influence of standardized mobilization on the posteroanterior stiffness of the lumbar spine in asymptomatic subjects. Physiother Res Int. 2001;6(3):145–56. doi: 10.1002/pri.223. [DOI] [PubMed] [Google Scholar]

- 11.Pickar JG. An in vivo preparation for investigating neural responses to controlled loading of a lumbar vertebra in the anesthetized cat. J Neurosci Methods. 1999;89(2):87–96. doi: 10.1016/s0165-0270(99)00060-6. [DOI] [PubMed] [Google Scholar]

- 12.Pickar JG, Wheeler JD. Response of muscle proprioceptors to spinal manipulative-like loads in the anesthetized cat. J Manipulative Physiol Ther. 2001;24(1):2–11. doi: 10.1067/mmt.2001.112017. [DOI] [PubMed] [Google Scholar]

- 13.Pickar JG, Kang YM. Paraspinal muscle spindle responses to the duration of a spinal manipulation under force control. J Manipulative Physiol Ther. 2006;29(1):22–31. doi: 10.1016/j.jmpt.2005.11.014. [DOI] [PubMed] [Google Scholar]

- 14.Edmondston SJ, Allison GT, Gregg CD, Purden SM, Svansson GR, Watson AE. Effect of position on the posteroanterior stiffness of the lumbar spine. Man Ther. 1998;3(1):21–6. doi: 10.1054/math.1998.0312. [DOI] [PubMed] [Google Scholar]

- 15.Portney LG, Watkins MP, editors. Foundations of clinical research. Prentice Hall; 2008. [Google Scholar]

- 16.Ianuzzi A, Pickar JG, Khalsa PS. Determination of torque-limits for human and cat lumbar spine specimens during displacement-controlled physiological motions. Spine J. 2009;9(1):77–86. doi: 10.1016/j.spinee.2007.07.391. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.Pickar JG, Sung PS, Kang YM, Ge W. Response of lumbar paraspinal muscles spindles is greater to spinal manipulative loading compared with slower loading under length control. The spine J. 2007;7(5):583–95. doi: 10.1016/j.spinee.2006.10.006. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Kawchuk G, Herzog W. A new technique of tissue stiffness (compliance) assessment: its reliability, accuracy and comparison with an existing method. J Manipulative Physiol Ther. 1996;19(1):13–8. [PubMed] [Google Scholar]

- 19.Kawchuk GN, Fauvel OR. Sources of variation in spinal indentation testing: indentation site relocation, intraabdominal pressure, subject movement, muscular response, and stiffness estimation. J Manipulative Physiol Ther. 2001;24(2):84–91. doi: 10.1067/mmt.2001.112566. [DOI] [PubMed] [Google Scholar]

- 20.Petty NJ, Maher C, Latimer J, Lee M. Manual examination of accessory movements--seeking R1. Man Ther. 2002;7(1):39–43. doi: 10.1054/math.2001.0431. [DOI] [PubMed] [Google Scholar]

- 21.Kawchuk GN, Fauvel OR, Dmowski J. Ultrasonic indentation: a procedure for the noninvasive quantification of force-displacement properties of the lumbar spine. J Manipulative Physiol Ther. 2001;24(3):149–56. [PubMed] [Google Scholar]

- 22.Lee M, Svensson N. Measurement of stiffness during simulated spinal physiotherapy. Clin Phys Physiol Meas. 1990;11(3):201–7. doi: 10.1088/0143-0815/11/3/002. [DOI] [PubMed] [Google Scholar]

- 23.Lee R, Evans J. Load-displacement-time characteristics of the spine under posteroanterior mobilisation. Australian Journal of Physiotherapy. 1992;38:115–23. doi: 10.1016/S0004-9514(14)60556-0. [DOI] [PubMed] [Google Scholar]

- 24.Lee M, Steven GP, Crosbie J, Higgs RJ. Variations in posteroanterior stiffness in the thoracolumbar spine: preliminary observations and proposed mechanisms. Phys Ther. 1998;78(12):1277–87. doi: 10.1093/ptj/78.12.1277. [DOI] [PubMed] [Google Scholar]

- 25.Allison GT, Edmondston SJ, Roe CP, Reid SE, Toy DA, Lundgren HE. Influence of load orientation on the posteroanterior stiffness of the lumbar spine. J Manipulative Physiol Ther. 1998;21(8):534–8. [PubMed] [Google Scholar]

- 26.Shirley D, Lee M, Ellis E. The relationship between submaximal activity of the lumbar extensor muscles and lumbar posteroanterior stiffness. Physical Therapy. 1999;79(3):278–85. [PubMed] [Google Scholar]

- 27.Latimer J, Lee M, Adams RD. The effects of high and low loading forces on measured values of lumbar stiffness. J Manipulative Physiol Ther. 1998;21(3):157–63. [PubMed] [Google Scholar]

- 28.Stanton T, Kawchuk G. The effect of abdominal stabilization contractions on posteroanterior spinal stiffness. Spine. 2008;33(6):694–701. doi: 10.1097/BRS.0b013e318166e034. [DOI] [PubMed] [Google Scholar]

- 29.Nicholson L, Maher C, Adams R, Phan-Thien N. Stiffness properties of the human lumbar spine: a lumped parameter model. Clin Biomech. 2001;16(4):285–92. doi: 10.1016/s0268-0033(00)00117-0. [DOI] [PubMed] [Google Scholar]

- 30.Nordin M, Frankel V. Biomechanics of tendons and ligaments. In: Butler J, editor. Book, Section. Baltimore: Lippincott Williams & Wilkins; 2001. p. 103. [Google Scholar]

- 31.Little J, Khalsa P. Human lumbar spine creep during cyclic and static flexion: creep rate, biomechanics, and facet joint capsule strain. Ann Biomed Eng. 2005;33(3):391–401. doi: 10.1007/s10439-005-1742-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 32.Sran MM, Khan KM, Zhu Q, Oxland TR. Posteroanterior stiffness predicts sagittal plane midthoracic range of motion and three-dimensional flexibility in cadaveric spine segments. Clin Biomech (Bristol. 2005;20(8):806–12. doi: 10.1016/j.clinbiomech.2005.04.009. [DOI] [PubMed] [Google Scholar]

- 33.Tuttle N, Barrett R, Laakso L. Posteroanterior movements in tender and less tender locations of the cervical spine. Man Ther. 2009;14(1):28–35. doi: 10.1016/j.math.2007.09.003. [DOI] [PubMed] [Google Scholar]