Abstract

The 1,2-diamine moiety is a ubiquitous structural motif present in a wealth of natural products, including non-proteinogenic amino acids and numerous alkaloids, as well as in pharmaceutical agents, chiral ligands and organic reagents. The biological activity associated with many of these systems and their chemical utility in general has ensured that the development of methods for their preparation is of critical importance. While a wide range of strategies for the preparation of 1,2-diamines have been established, the diamination of alkenes offers a particularly direct and efficient means of accessing these systems. The purpose of this review is to provide an overview of all methods of direct alkene diamination, metal-mediated or otherwise.

Keywords: alkene; aminoauration; aminocupration; aminomercuration; aminopalladation; aminothallation; bisnitration; catalysis; cycloguanidination; diaziridinone; bisazidonation; diamination; 1,2-diamine; 1,2-diaminoalkane; 1,2-diazide; dinitrogen tetroxide; dinitrogen trioxide; imidazolination; imidazolidinone; iodane; iodine azide; iodonium; guanidine; hypervalent iodine; nitroamination; nitrogen dioxide; nitrogen oxide; nitrosylation; organocatalysis; pseudonitrosite; sulfamide

1. Introduction

The 1,2-diamine moiety is a ubiquitous structural motif found in a wealth of natural products, including non-proteinogenic amino acids and alkaloids, in pharmaceutical agents, chiral ligands and bases, and organic reagents.1 The biological activity associated with many of these systems and their utility in general has ensured that the development of new methods for their preparation of is of critical importance. While a wide range of strategies for the preparation of 1,2-diamines have been established, the diamination of alkenes offers a particularly direct and efficient means of accessing these systems (Figure 1).

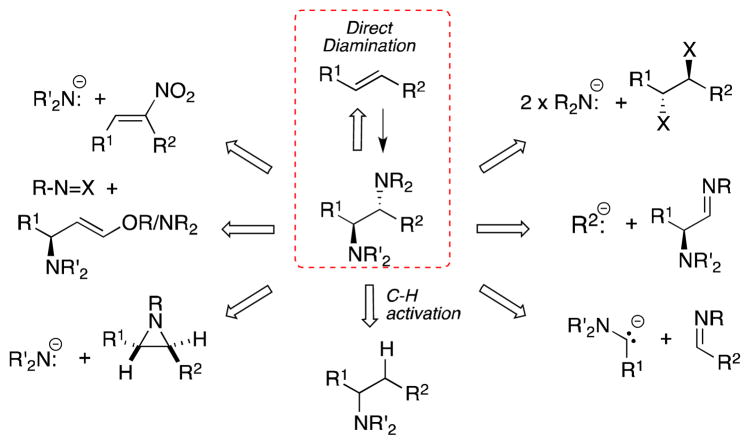

Figure 1.

General synthetic approaches to 1,2-diamines, including direct alkene difunctionalization.

Despite the importance of vicinal diamines, reviews concerning their preparation have, in the past, been rather infrequently published, in marked contrast to their 1,2-diol relatives.2 However, that a recent resurgence of interest in the metal-mediated diamination of alkenes is apparent from the number of reviews dedicated to this specific topic which have appeared over the last decade.3 These articles notwithstanding, the purpose of the current review is to provide an overview of all methods of alkene diamination, metal-mediated or otherwise. In this context, the term “direct alkene diamination” encompasses reactions that lead to the formation of vicinal Csp3-N bonds regardless of the substitution pattern or oxidation state of the nitrogen centers. Transformations in which carbon-nitrogen double bonds are formed, including the formation of α-amino-oximes during the photoaddition of N-nitroso compounds,4 will not be considered. Likewise, reactions in which 1,2-diamines are generated from alkenes with preexisting nitrogen-based substituents, e.g. the hydroamination of vinyl nitro compounds,5 will also not be discussed. Finally, since the hetero-Diels-Alder reaction of azo compounds has recently been reviewed in detail6 and involves 1,4- rather than 1,2-diamination of dienes, this subject will not be considered in the following article.

After an exposition of the occurrence and biological significance of 1,2-diamines, the review itself follows an essentially chronological path. Thus, the reaction of alkenes with binary nitrogen oxides and their surrogates is discussed first, followed by diamination processes that involve generation and addition of the azidyl radical. Methods employing haloamides, halogens, heavy metals and polyvalent iodine reagents then follow in sequence and finally, in the second half of the review, the metal-mediated diamination of alkenes under both stoichiometric and catalytic conditions will be discussed in depth.

2. Importance of 1,2-Diamines

2.1. Naturally Occurring 1,2-Diamines

1,2-Diamino carboxylic acids are widely distributed in the natural world, where they are found in an array of organisms in their both native state and as components of more complex natural products (Figure 2).7 Since they neither occur in proteins, or are coded for in the cellular genetic makeup, these amino acids are classified as non-proteinogenic.8 The simplest members of this group include 2,3-diaminopropionic (L-Dsp, 1) and 2,3-diaminobutanoic (Dap, 2) acid, which in addition to being found as components of non-ribosomal peptide antibiotics such as bleomycin9 and others,10 have also been isolated from an extraterrestrial source. Analysis of the Murchison meteorite has revealed the presence of a number of complex organic molecules, including 1 and 2, which may have participated in prebiotic polycondensation to form peptide nucleic acid material.11

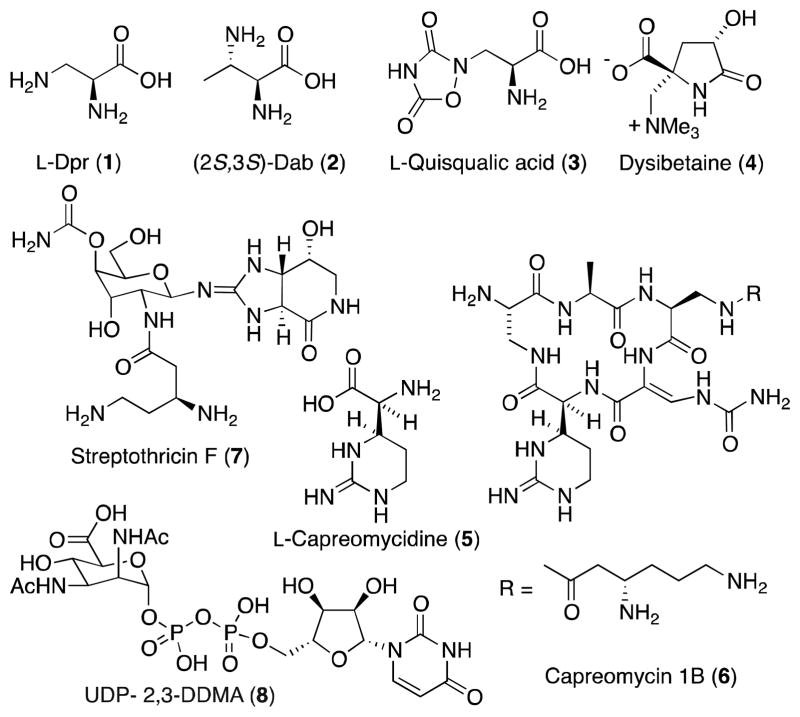

Figure 2.

Naturally occurring, non-proteinogenic 1,2-diamino acids and their derivatives.

Much of the interest in native 1,2-diamino acids and in particular heterocyclic β-substituted alanine derivatives stems from their role as excitatory amino acids (EAA). EAA receptors are widely distributed in the mammalian central nervous system (CNS) and play a role in a range of neural functions and abnormalities, having been implicated in such disorders as Alzheimer’s disease, epilepsy, Parkinsonism and AIDS-related dementia.12 L-Quisqualic acid (3), isolated from the traditional Chinese medicine Shih-chun-tze, is a highly potent agonist of EAA receptors in both mammals and insects. Most recently, 3 was found as a component of the petals of zonal pelargoniums, and shown to act a potent antifeedant against the Japanese beetle, Popilla japonica.13 (-)-Dysibetaine (4), an unusual amino acid isolated from the marine sponge Dysidea herbacea, is also a neuroexcitotoxin, which may bind to the glutamate receptors present in the CNS of mice.14

As previously noted, 1,2-diamino acids are also found as components of non-ribosomal peptides. L-Capreomycidine (5), for example, is a key structural subunit of the tuberculostatic agent capreomycin 1B (6)15 while its β-epimer is found in the muraymycins, a family of uridylpeptide natural products that inhibit the peptidoglycan biosynthesis of Staphylococcus aureus.16,17 Although the broad spectrum antibiotic strephothricin (7) does not contain a capreomycidine residue, this bis-diamine may be biogenetically related to this amino acid.18 Diamino carboxylic acids also play an important role in glycobiology. DiN-acetylated uronic acid residues, for example, are found in the B-band O-antigen of the lipopolysaccharide (LPS) of a number of respiratory pathogens, where they are believed to play an important role in host colonization and maintenance of infection. In this regard, nucleotide sugar UDP-2,3-diacetamido-2,3-dideoxy-D-mannuronic acid (8) is a key building block in the biosynthesis of the LPS of Pseudomonas aeruginosa, an opportunistic pathogen.19

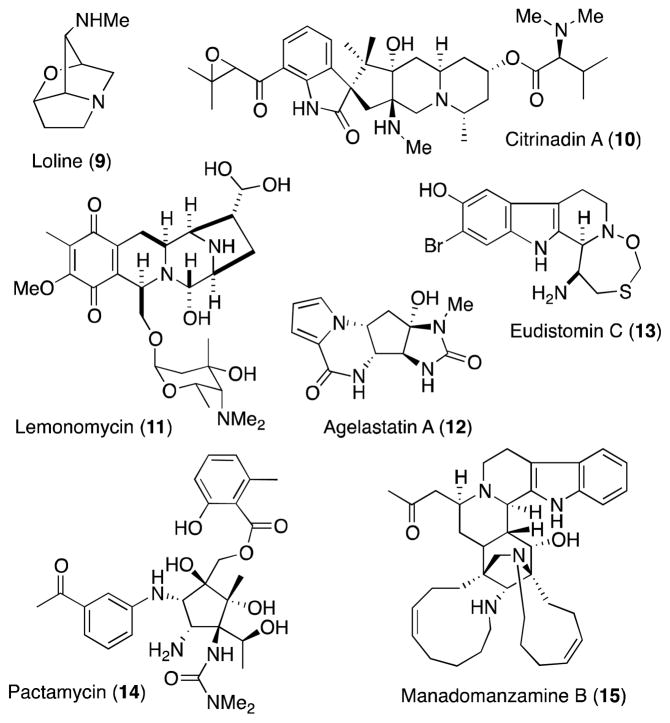

Many alkaloid natural products conspicuously contain the vicinal diamine motif and its presence is often associated with significant biological activity (Figure 3). Structural complexity runs the gamut from relatively simple systems such as the pyrrolizidine alkaloid loline (9),20 which despite it apparent simplicity presents a significant synthetic challenge,21 to the pentacycle citrinadin A (10)22,23 and its structural relatives PF1270 A-C, a group of histamine H3 receptor agonists.24 The 1,2-diamine functionality is also a unifying structural feature of the tetrahydroisoquinoline alkaloid family,25 of which as illustrated by the antibiotic lemonomycin (11),26,27 where it is embedded within the piperazine ring system at the core of all members of this large natural products class. In addition to terrestrial sources, marine organisms have also proven to be a rich source of biologically active 1,2-diamines, including the anti-tuberculosis agent manadomanzamine A (15),28,29 the antineoplastic agent agelastatin A (12)30 and eudistomin-K sulfoxide (13),31 a representative member of the eudistomin family that displays activity against both RNA and DNA viruses.32

Figure 3.

A representative selection of naturally occurring alkaloids that encompass the 1,2-diamine framework.

While a number of the alkaloids represented in Figure 2 have succumbed to total synthesis, most recently pactamycin (14),33,34 others including manadomanzamine A (15), remain unassailed and, a such, offer unique challenges for the development of new diamination methods. Despite the recent progress in diamination methodology, many of these targets present significant challenges to direct alkene amination methods and, as such, are an impetus to the continued investigation of diamine methods that offer enantiocontrol, differential N-protection and, importantly in the context of such complex targets, functional group compatibility.

2.2. 1,2-Diamine Pharmaceutical Agents

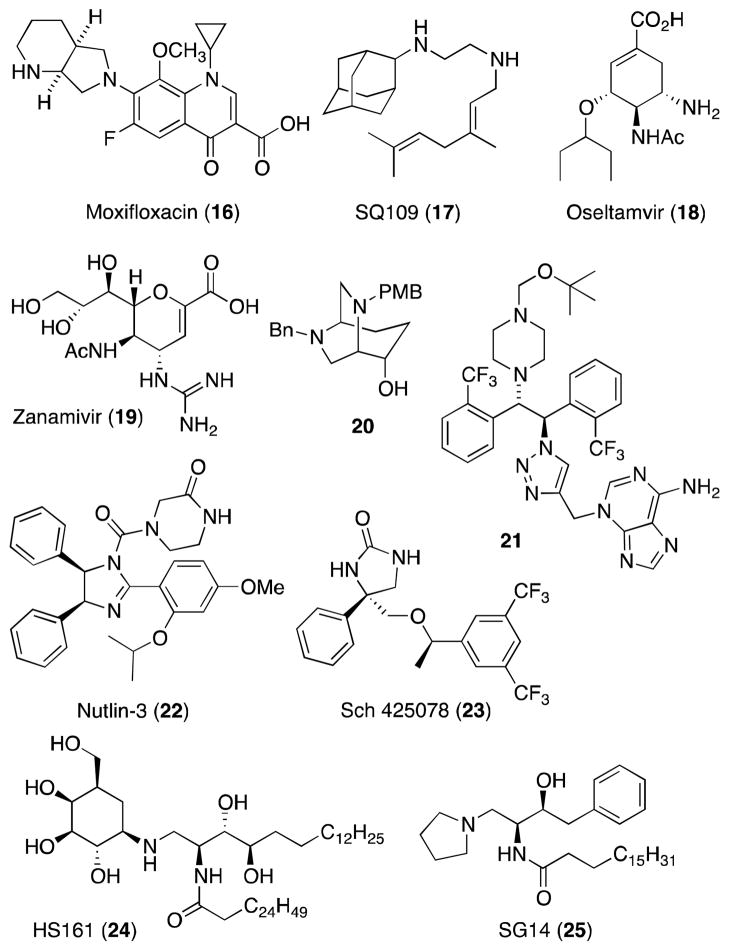

1,2-Diamines are found in wealth of non-natural, synthetic pharmacological tools and therapeutic agents, including several clinically approved drugs (Figure 4).35 For example, the presence of a diamine-based substituent at the 7-position has proven critical in the clinical efficacy of a number of fluoroquinoline antibiotics,36 including the fourth generation agent moxifloxacin (16) where this functionality is encompassed within a conformationally restricted 2,8-diazabicyclo[4.3.0]nonane ring system. Other notable anti-microbials bearing vicinal diamine moieties include the ethambutol analog SQ109 (17),37 which possesses potent activity against multi-drug resistant tuberculosis, and the viral neuraminidase inhibitors oseltamivir (18)38 and zanamivir (19),39 which are employed for the treatment and prophylaxis of influenza virus A and B infections. In further reference to drug development, 1,2-diamines have proven to be valuable scaffolds from which to rapidly build compound libraries: notable discoveries made in this manner include SQ109 (17)37 and stilbene diamine derivative 21, a potent inhibitor of hepatitis C virus RNA replication in the initial stage of infection.40

Figure 4.

Pharmaceutically active, synthetic and semi-synthetic 1,2-diamines.

In addition to anti-infectives, 1,2-diamines are also found within a array of other pharmaceutical agents, including the antiproliferative agent nutlin-3 (22),41 the anti-emetic agent and NK1-antagonist Sch 425078 (23),42 and the 2-substituted 6,8-diazabicyclo[3.2.2]nonane 20, which displays potent affinity for human σ- and δ-receptors, has a cytotoxic potency that exceeds cisplatin, and consequently has potential as an atypical anticancer agent.43

With regard to semi-synthetic pharmaceutical agents, the incorporation of the non-natural vicinal diamine framework into sphingolipids and the associated change in charge of the polar head unit has proven to have a significant impact on the biological profile and metabolic stability of these molecules.44 For example, α-galactosylceramide analog HS161 (24), which lacks a glycosidic linkage and bears an aminocyclitol as a carbohydrate surrogate, is a potent stimulator of invariant natural killer T cells,45 while the 1-amino-1-deoxy sphingoid analog 2546 is a specific inhibitor of human sphingosine kinase, an emerging target for cancer therapeutics.47

2.3. 1,2-Diamines as Tools for Organic Synthesis

The importance of 1,2-diamines extends significantly beyond their role in natural products and pharmaceutical agents since they have also proven to be invaluable scaffolds for the construction of novel metal ligands,48,49 including those that intercalate DNA,50 radiopharmaceuticals and imaging agents.51 Diamines also serve as organocatalysts,5253 chiral reagents and chiral lithium amide bases54 as well as organic receptors.55 In particular, trans-1,2-diaminocyclohexane56 and, to a lesser degree, it 5-membered congener57 have proven to be privileged structures in this regard.

3. Binary Nitrogen Oxides & Related Reagents

3.1. Dinitrogen Tetroxide-Nitrogen Dioxide

The earliest known examples of direct alkene diamination involve the addition reaction of nitrogen dioxide, a process which has been studied for over a hundred years and has played a historically important role in the development of organic synthesis.58,59 Among the various addition products formed in this process, including vicinal nitro-nitrato, nitro-nitrito and nitro-nitro compounds, it is the members of the latter group which are of interest since they are potential precursors of 1,2-diamines.

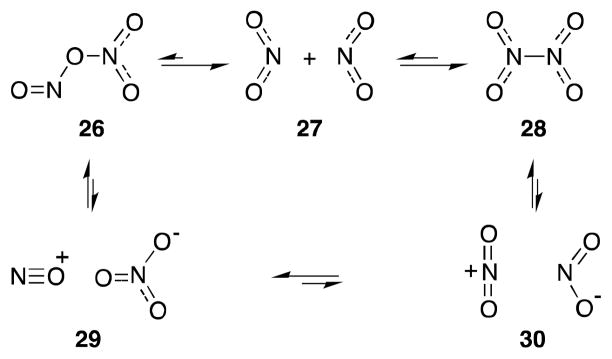

Longevity notwithstanding, the value of alkene dinitration has historically been limited by a number of practical difficulties, not least of which is the instability of the products formed in this process.60 The reaction of nitrogen dioxide with alkenes is also made complex by virtue of the delicate equilibrium that exists between this compound, dinitrogen tetroxide (N2O4; 28)61 and its nitrite isomer 26 (Scheme 1).62 Furthermore, in polar media, both 26 and 28 can undergo heterolytic dissociation to form nitrosonium-nitrate (29) and nitronium-nitrite (30) ion pairs, which can also participate in the addition process.63 As a consequence, reactions of N2O4-NO2 with alkenes are often complex, display significant solvent effects and lead to the formation of numerous products, as exemplified by 2,3-dimethyl-2-butene (31) (Scheme 2).64

Scheme 1.

Dyanamic equilibria of nitrogen dioxide.

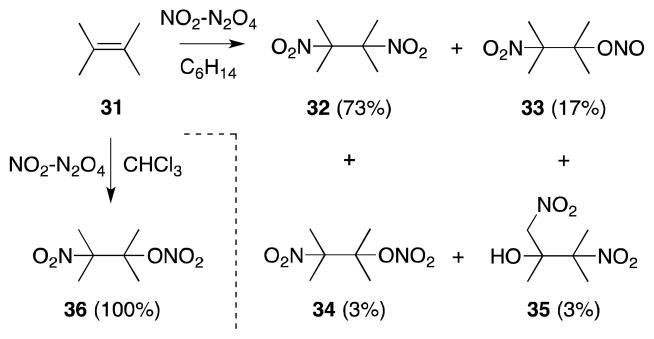

Scheme 2.

Solvent dependancy in the reaction of nitrogen dioxide with 2,3-dimethyl-2-butene.

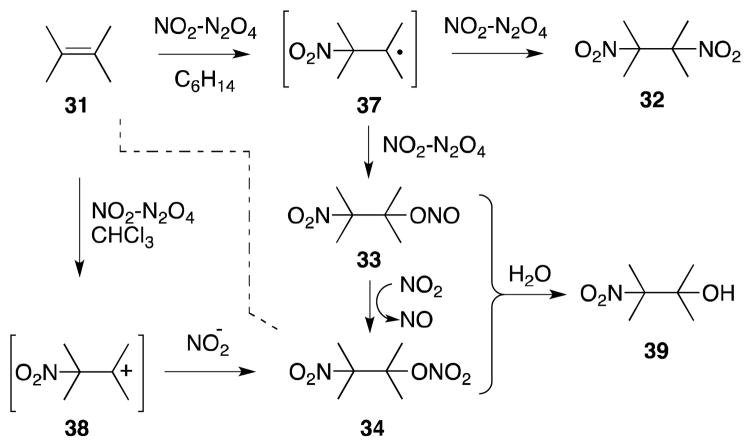

The mechanism of addition of N2O4-NO2 with alkenes has been extensively examined, both kinetically65 and spectroscopically (15N NMR),66 and found to be highly dependent upon the concentration of N2O4-NO2 as well as the nature of the reaction medium (Scheme 3).67 These studies have largely confirmed Schechter’s original proposal of a radical mechanism,68 in which NO2 undergoes addition to the less substituted alkene position to form a β-nitroalkyl radical 37. Trapping of this intermediate with a second molecule of NO2 then forms both dinitro 32 and nitro-nitronite 37 addition products. Oxidation of the latter species also gives rise to nitro-nitrate 34, which in common with 33 can undergo hydrolysis to form nitro alcohol 39. In more polar solvents, such as chloroform, addition can proceed through an ionic mechanism and, in this medium, formation of nitro-nitrato compound 34 becomes favored.

Scheme 3.

Mechanism of nitrogen dioxide-alkene addition.

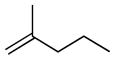

At higher concentrations of NO2, N2O5 may also participate in the initial rate determining step through direct alkene addition to form nitronite product 34 or addition to form β-nitroalkyl radical intermediate 37 and NO2.69 Given the electron deficient nature of NO2 is it not surprising that the rate of addition of this radical is found to be highest with electron rich alkenes (Table 1).

Table 1.

| Substrate | Relative Rateb |

|---|---|

|

|

0.1 |

|

0.6 |

|

|

1.0 |

|

4.5 |

|

16 |

|

21.0 |

Values measured at ambient temperature in CCl4 with a N2O4-NO2 concentration of 0.1 M.

Values are reported relative to allylbenzene.

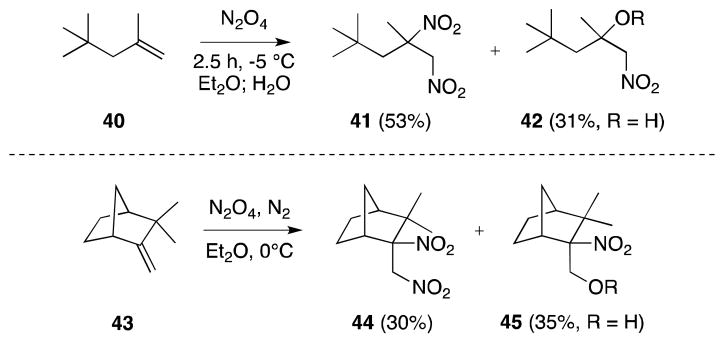

Although, in the case of non-symmetrically substituted alkenes, the regioselectivity of initial NO2 alkene addition is high, non-selective trapping of the resulting β-nitroalkyl radical often leads to the formation of dinitro and β-hydroxy-nitro compounds, which, in the later case, arise from hydrolysis of the first-formed β-nitro-nitrito compounds (R = NO) (Scheme 4). The absence of skeletal rearrangement during the reaction of camphene (43) has been cited as evidence for a lack of an ionic pathway.64b

Scheme 4.

Reaction of 1,2-disubstituted alkenes with N2O4.

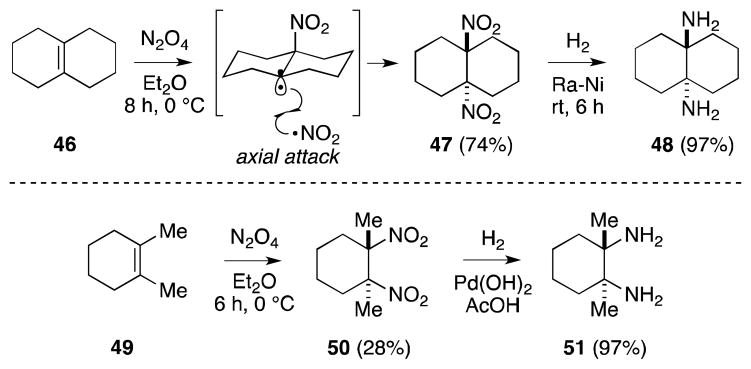

From a practical standpoint, tetrasubstituted alkenes are the most suitable substrates for reaction with N2O4 since yields are generally high and bisnitration is the favored outcome. For example, reaction of Δ9,10-octalin (46) gives rise to the formation of trans-fused decaline 47 (Scheme 5). Jacobsen has also gainfully employed the addition of N2O4 to cyclohexene 49 as a means to access C2-symmetric trans-1,2-diamine 51.70 Reaction of N2O4 in this case generated compound 50 as a single, trans-diastereomer, albeit in relative low yield. Hydrogenation of this vicinal dinitro compound, under medium pressure in the presence of Pd(OH)2, proceeded in high yield to generate diamine 51, which was resolved by way of its mandelate salt. Jacobsen noted that slow addition of alkene to excess N2O4 was requisite for the success of this transformation since it served to avert polymerization between the tertiary radical intermediate and alkene. Müller-Bunz71 and Evans72 have reported closely related routes to diamine 51.

Scheme 5.

Reaction of cyclic tetrasubstituted alkenes with N2O4.

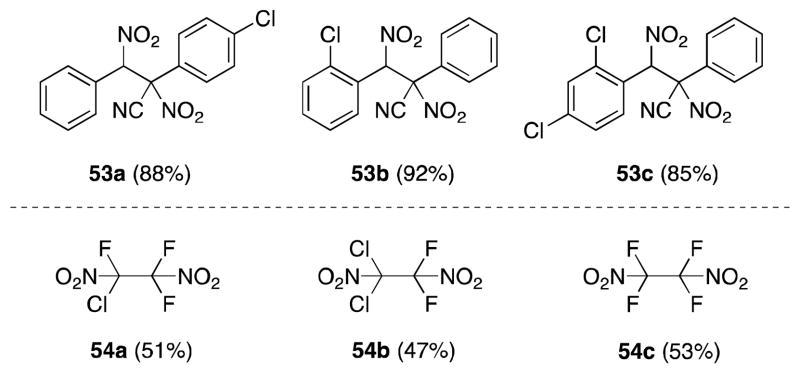

Other highly substituted cyclic alkene substrates which successfully undergo dinitration in the presence of N2O4, include 3-sulfolenes,73 3-phospholene oxides,74 and siliacyclopent-3-enes (Figure 5).75 In these cases, only the products of trans addition were observed.

Figure 5.

Dinitroalkane products resulting from the reaction of N2O4 with cyclic tetrasubstituted alkenes.

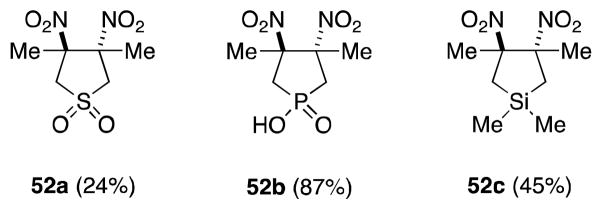

Electron deficient alkenes also undergo dinitration efficiently in the presence of nitrogen dioxide (Figure 6). Notable examples in this regard, include α,β-unsaturated nitriles76 and perhaloalkenes.77

Figure 6.

Dinitroalkane products resulting from the reaction of N2O4 with electron-deficient alkenes.

3.2. Nitric Oxide

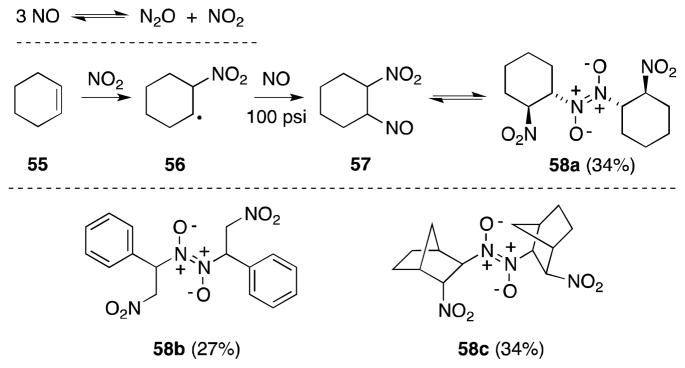

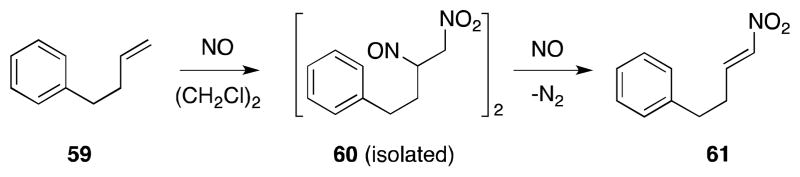

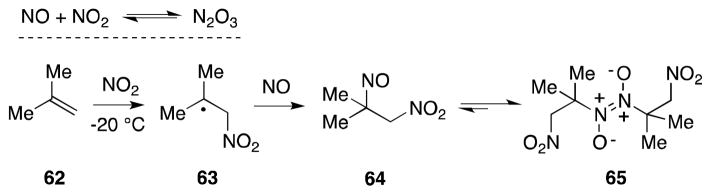

Despite its possession of an unpaired single electron, nitric oxide (NO) in its pure state does not undergo addition to alkyl or aryl-substituted alkenes since this process is thermodynamically unfavorable. While this observation, first confirmed by Brown in 1957,78 holds true for reactions conducted in the absence of higher nitrogen oxides, such as NO2, this common impurity in NO catalyzes the addition process and leads to the formation of β-nitro-nitroso compounds (pseudonitrosites)79 and/or their dimers.80

Capitalizing on the fact that NO undergoes disproportionation to N2O and NO2 at high pressure, Wilkinson (Scheme 6)81 and others82 have successfully conducted the nitronitrosylation of a variety of alkene substrates under medium pressure, including perhaloalkenes.83 In cases where the β-nitro-nitroso addition products are unstable, other secondary processes can take place, including elimination to form nitro alkenes (Scheme 7).84

Scheme 6.

Addition of NO to alkenes is catalyzed by NO2

Scheme 7.

Formation and decomposition of a β-nitro-nitroso-compound.

3.3. Dinitrogen Trioxide

Generated by the combination of NO2 and NO at low temperature, through the aerial oxidation of NO, or by the treatment of metal nitrites with sulfuric acid, dinitrogen trioxide (N2O3) undergoes addition to alkenes to form β-nitro-nitroso compounds (pseudonitrosites) in high yield (Scheme 8).85 From a mechanistic perspective, this transformation has been interpreted as involving a radical process in which NO2 adds to the alkene to generate a β-nitro radical 63, which then traps NO. Despite some early confusion as to whether β-nitroso-nitrite products are also formed in this reaction, Pfab has unequivocally demonstrated that, in the case of 2-methylpropene (62), addition of N2O3 primarily generates 2-methyl-2-nitroso-1-nitropropane (64) and its trans-dimer 65.86

Scheme 8.

Reaction of N2O3 with 2-methylpropene.

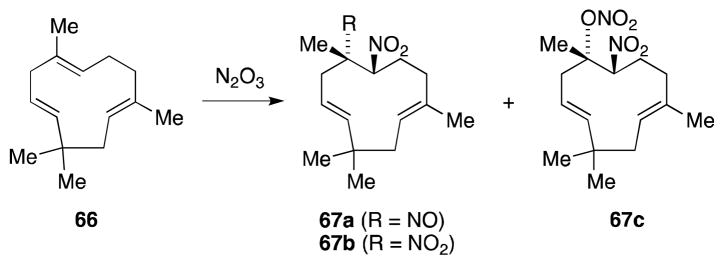

The reaction between alkenes and nitrogen trioxide has historically played an important role in the structural determination studies of terpene natural products since their pseudonitrosite derivatives are often highly crystalline and thus amenable to qualitative and quantitative analysis. Humulene (66), for example, undergoes reaction with N2O3 to yield a mixture of humulene nitrosite (67a), dinitrohumulene (67b) and nitronitratohumulene (67c) (Scheme 9).87

Scheme 9.

Reaction of humulene with N2O3.

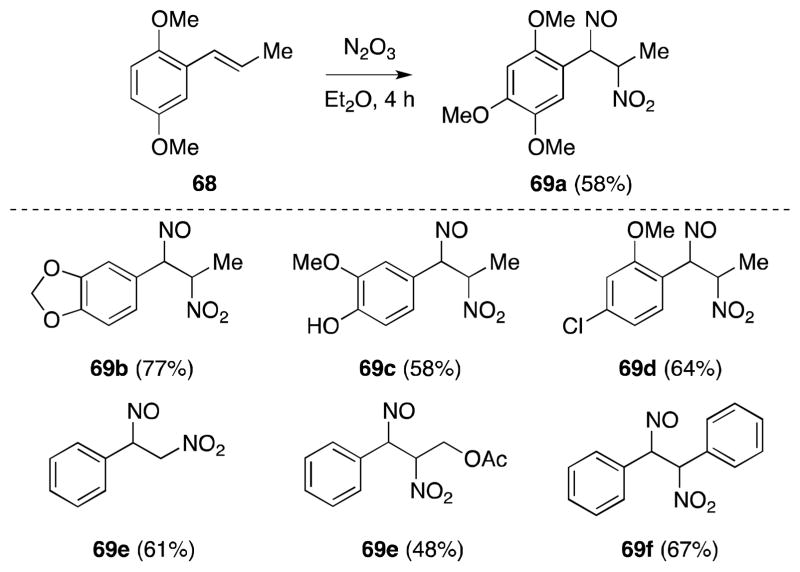

Extensive studies on the reaction of naturally-occurring propenylbenzenes, including asarone,88 isosafrole,89 cinnamyl acetate90 and related substrates91 with N2O3 have been carried out by Bruckner and others (Scheme 10). In these cases, addition occurs efficiently with high regioselectively, although the products are often unstable and, in addition to undergoing dimerization, rapidly tautomerize to the more stable β-nitro-oxime derivatives. That the stereochemical course of this transformation has rarely been determined is a further indication of the reactivity of the primary addition products.

Scheme 10.

Reaction of N2O3 with propenylbenzenes.

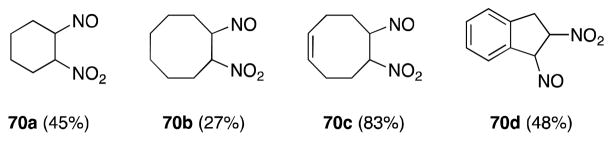

The reaction of dinitrogen trioxide with a range of cyclic alkenes and dienes, including cyclopentadiene,92 cycloctadiene,91,93 and indenes has also been reported (Figure 7).94

Figure 7.

Products of the reaction of N2O3 with cyclic alkenes

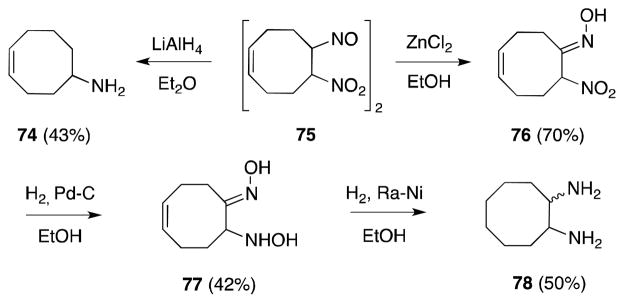

That allyl and vinylsilanes 71 undergo addition, rather than substitution,95 is indicative of a free radical mechanism (Scheme 11). A similar conclusion can be drawn from the regioselectivity observed during the addition of N2O3 to substituted chalcones 72.96

Scheme 11.

Reactions of N2O3 with unsaturated silanes and chalcones.

Despite the extensive body of literature concerning the preparation of pseudonitrosites, conversion of these alkene addition products to the corresponding 1,2-diamines remains a challenging undertaking. In large part, this is due to the propensity with which these systems undergo competitive elimination; e.g. treatment of compound 75 with LiAlH4 leads to the exclusive formation of monoamine 74 (Scheme 12).93 Vicinal diamine 78 can be accessed from 74, albeit indirectly, through a sequence of Lewis acid-mediated isomerization to the corresponding α-nitro-oxime 76 and stepwise hydrogenation.

Scheme 12.

Conversion of pseudonitrosites to the corresponding diamines.

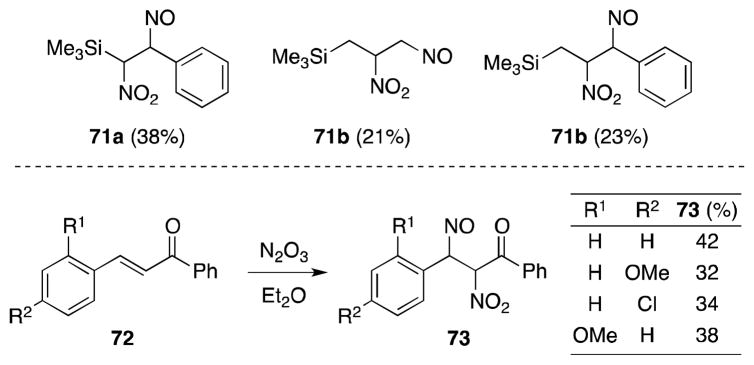

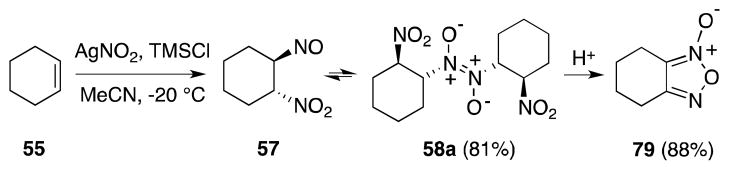

3.4. Silver Nitrate & Trimethylsilyl Chloride

Most recently, Demir and Findik have a reported a convenient method for the generation of dinitrogen trioxide, through the action of AgNO3 on trimethylsilyl chloride (Scheme 13).97 Treatment of alkenes, such as cyclohexene (55) with this reagent in THF or acetonitrile yielded the corresponding β-nitroso-nitrite compounds and their dimers.

Scheme 13.

In-situ generation of N2O3 with AgNO3/TMSCl.

Since the focus of Demir’s study was the preparation of furoxanes (79), the initially formed addition products were directly treated with sulfuric acid to generate the desired heterocycles, presumably by way of the corresponding β-nitro-oximes. Nevertheless, the high yield of pseudonitrite (58a) and the furoxane products, indicate that the addition step in this case is efficient.

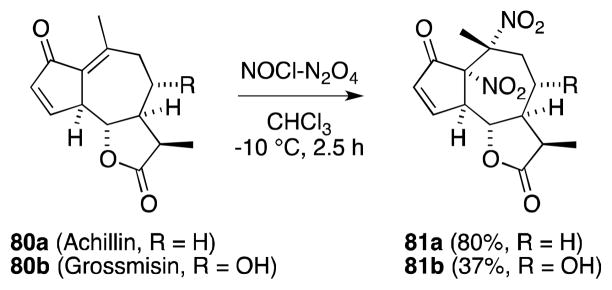

3.5. Nitrosyl Chloride & Dinitrogen Tetroxide

The reaction of nitrosyl chloride with alkenes has been extensively studied and almost exclusively leads to the formation of monomeric and dimeric β-nitroso chlorides. However, attempts by Adekenov and co-workers to nitrosochlorinate the guaianolide achillin (80a) led to the selective formation of cis-1,2-dinitro compound 81a (Scheme 14).98 A similar result was subsequently noted for the closely related terpene grossmisin (80b).99

Scheme 14.

Dinitration of unsaturated terpenes with the reagent combination NOCl/N2O4.

The unanticipated formation of compounds 81a and 81b was ascribed to the presence of N2O4 as an impurity in the NOCl employed in this transformation. N2O4 promotes a radical process and likely involves the formation of a β-nitroalkyl radical, which is trapped to form a nitrosonitrate, which undergoes oxidation 100 to form the observed products. Indeed, reaction of 80a with NOCl spiked with N2O4 led to increased yield and rate over purified NOCl (37 vs. 80%), while treatment with N2O4 alone also generated 81a, albeit in lower yield.

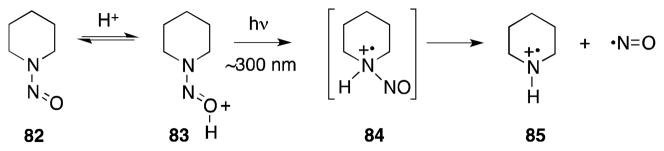

3.6. Photolysis of N-Nitroso Compounds

N-Nitroso compounds undergo photolysis under acidic conditions to generate nitric oxide and the corresponding aminium radical (Scheme 15).4 In the case of N-nitrosopiperidine (NNP; 82) photolysis in acidic aqueous solution (pH 2) generates piperidinium radical 85, which originates from the lowest singlet excited state (84) of the NNP-acid complex 83.101

Scheme 15.

Photolysis of N-nitrosopiperidine (NNP) under acidic conditions.

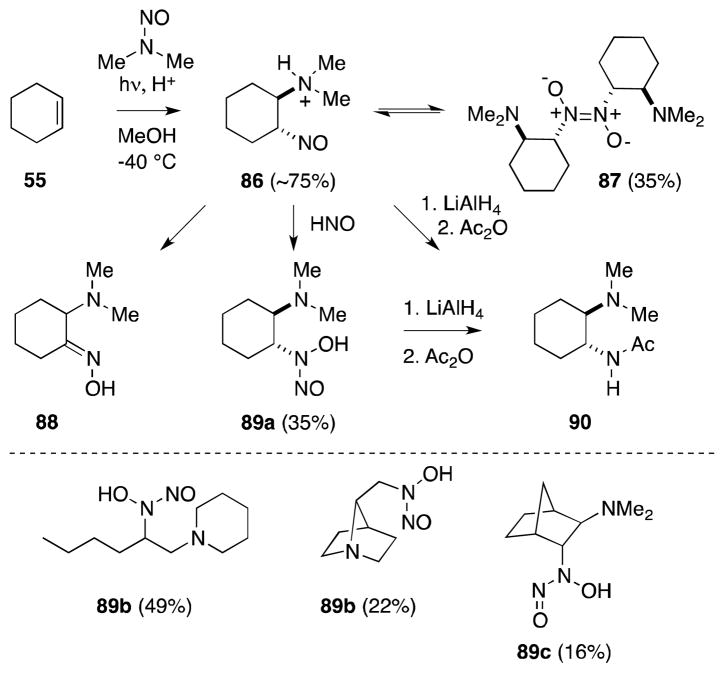

Aminium radicals generated in this manner are electron deficient and undergo a range of chemical reactions, including addition to alkenes (Scheme 16). In the case of cyclohexene (55), photolysis in the presence of an equimolar quantity of N-nitrosodimethylamine generates trans-addition product 86 in high yield.102 Depending on the reaction conditions employed, this compound, to varying degrees, undergoes dimerization to yield 87, rearranges to α-amino-oxime 88, or takes part in a secondary process with the monomer of hyponitrous acid (HNO) to form N-nitrosohydroxylamine 89a. In light of these multiple pathways, yields of this type of process are often impractically low, although Chow has reported conditions, involving extended photolysis and the use of excess nitrosoamine, that favor the formation of N-nitrosohydroxylamines (89a-c).103 In the case of cyclohexane derivative 86, reduction with LiAlH4 generates the corresponding 1,2-diamine, which was acetylated to provide 90.

Scheme 16.

Photoaddition of N-nitrosodimethylamine with cyclohexene and other alkenes.

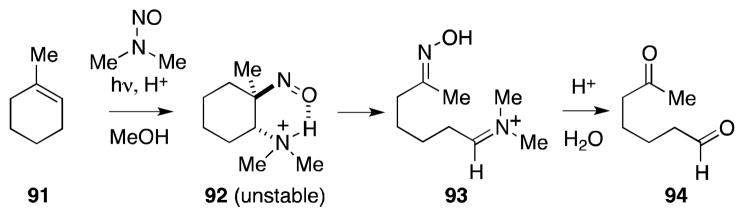

While irreversible tautomerization of the initially formed β-amino-nitroso monomers, such as 86, is observed for most substrates that bear a hydrogen atom at the position alpha to the nitroso group, those systems that lack this feature react to generate the N-nitroso products, as in the case of methylcyclohexene (91) (Scheme 17).104 Unfortunately, while photoaddition with more substituted alkenes is highly regioselective, the addition products generated from these substrates are prone to fragmentation, as in the case of 92 which undergoes fragmentation and hydrolysis to form ketoaldehyde 94.

Scheme 17.

Formation and fragmentation of C-nitroso-β-amines.

3.7. Thermolysis of Tetramethyl-2-tetrazene-Lewis Acid Complexes

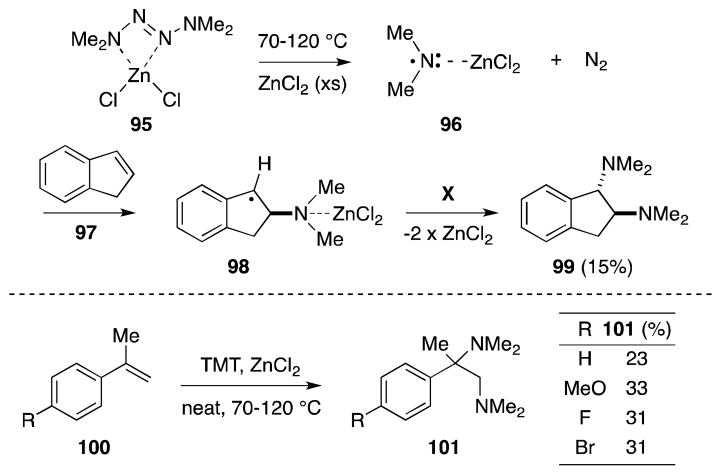

Prepared through the Hg(II)-mediated oxidation of 1,1-dimethylhydrazine,105 tetramethyl-2-tetrazene (TMT) forms 1:1 complexes with a range of Lewis acids, including zinc halides (Scheme 18).106 Taking advantage of the propensity of these compounds to readily undergo thermal decomposition to form dimethylamino radicals, Michejda and co-workers have developed a method for alkene diamination employing the zinc chloride complex 95.107

Scheme 18.

Diamination of styrenes via the thermolysis of the tetramethyl-2-tetrazene-zinc chloride complex.

Heating 95 in the presence of excess ZnCl2 and conjugated alkenes, such as indene (97) or α-methylstyrenes (100), leads to the formation of the corresponding bis(dimethylamino) adducts, albeit in low yield. That the reaction of 97 results in the exclusive formation of the trans addition product 99, was cited as evidence that addition of the two dimethylamino groups proceeds through a stepwise process rather than a concerted one. Detailed Hammett studies also suggest that the dimethylamino radical 96 generated upon the decomposition of 95 is intimately associated with zinc chloride.

3.8. Nitroamidation: Nitronium Salts & the Ritter Reaction

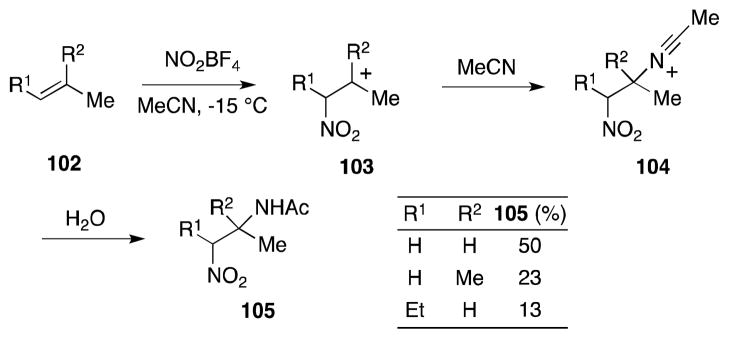

Alkenes undergo reaction with both nitrosonium and nitronium tetrafluoroborate in the presence of nitriles to generate carbocations 103 but whereas the former process leads to the formation N-hydroxyimidazolium salts,108 the reaction of nitronium ions can be employed as a means of diamination. In the presence of nitrile solvents, these intermediates are trapped to form nitrilium ions 104, which undergo hydrolysis to form the products of nitroamidation (Scheme 19). The first report of this type of process was by Scheinbaum, who in 1971, reported that the reaction of simple alkenes 102 with nitronium tetrafluoroborate in acetonitrile generated α-nitro amides 105.109,110

Scheme 19.

Nitroamidation alkenes with nitronium tetrafluoroborate in acetonitrile.

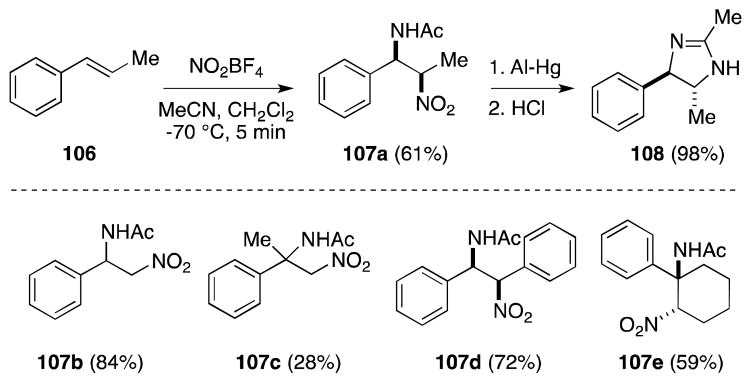

While Scheinbaum’s original report only encompassed three alkenes, Mellor and co-workers have subsequently studied this nitroamidation method in more detail, employing a wider range of substrates and found that, in the case of conjugated alkenes, higher yields can be obtained through use of CH2Cl2 as a co-solvent (Scheme 20).111 In all cases, addition was found to be rapid, highly regioselective and favored the Markovnikov products. That trans-β-methylstyrene (106) undergoes cis addition was confirmed by conversion of 107a to imidazoline 108. Notably, 1-phenylcyclohexene underwent trans addition to yield 107e. Nitroacetamidation of less nucleophilic alkenes, including hex-1-ene, oct-1-ene, cyclohexene, and cyclopentene, was found to be considerably less efficient.

Scheme 20.

Reaction of alkenes with nitronium tetrafluoroborate.

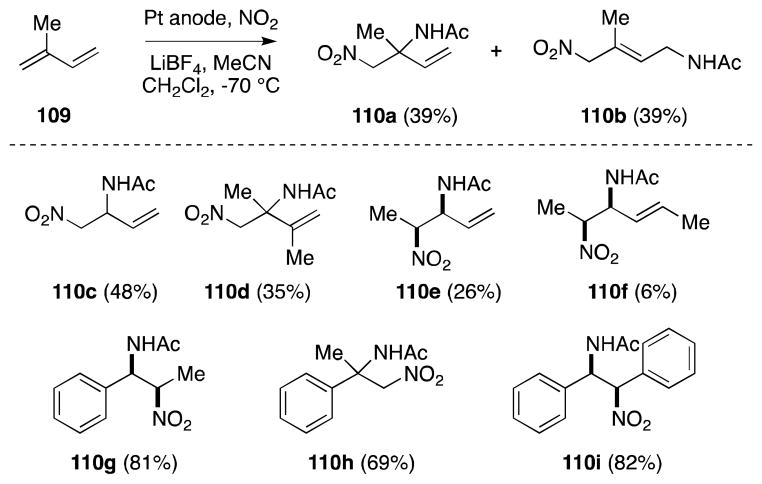

In light of the expense of nitronium tetrafluoroborate and its high moisture sensitivity, Mellor has developed a method for its in-situ electrogeneration from nitrogen dioxide, through anodic oxidation (Scheme 21).112 Yields, in most cases, are higher than those obtained with the non-electrogenerated reagent, an observation which was ascribed to the absence of acidic impurities present during electrolysis.

Scheme 21.

Nitroamidiation of conjugated alkenes with electrochemically generated nitronium tetrafluoroborate.

In this one-pot procedure, electrogeneration of the nitrogen electrophile must precede alkene addition since co-electrolysis failed to provide the nitroacetamide products.

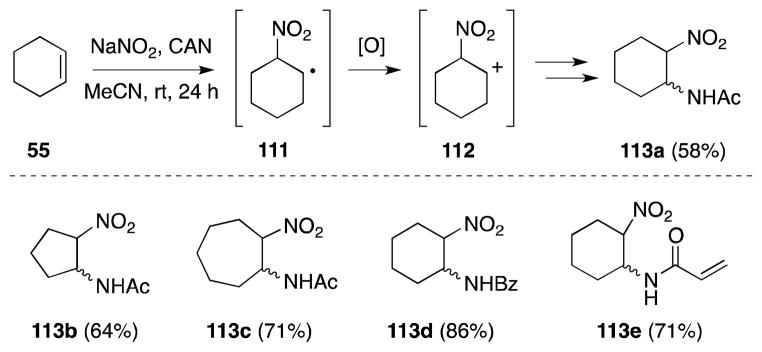

3.9. Ceric Ammonium Nitrate-Sodium Nitrite-Acetonitrile

In an approach that avoids the use of nitronium salts, Vankar and co-workers have developed a nitroamidation method that entails the treatment of alkenes with ceric ammonium nitrate (CAN) and sodium nitrite in nitrile solvents (Scheme 22).113

Scheme 22.

Vankar’s alkene nitroamidation method.

Oxidation of nitrite under these conditions is proposed to generate nitrogen dioxide, which undergoes alkene addition to form a β-nitroalkyl radical 111. A second electron transfer to CAN then generates carbocation 112, which participates in a Ritter reaction to yield the observed products. Notably, use of benzonitrile and acrylonitrile offer access to benzamides (113b) and α,β-unsaturated amides (113e). That this process displays negligible diastereoselectivity in the substrates examined, reflects the intermediacy of the carbocation intermediate.

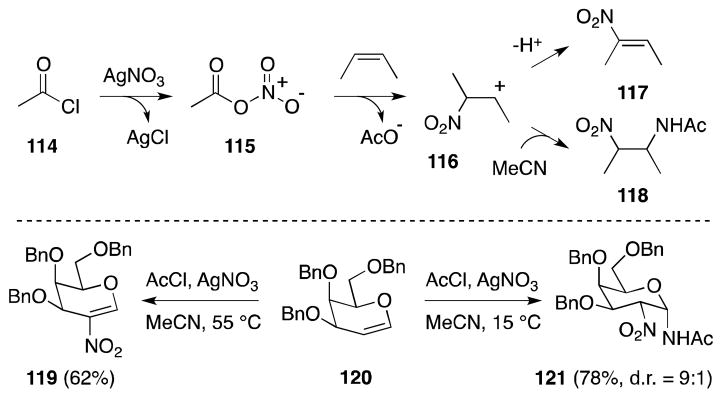

3.10. Acetyl Chloride-Silver Nitrate-Acetonitrile

Vankar has recently developed a reagent system comprising of acetyl chloride, silver nitrate and acetonitrile for the nitration and nitroamidation of glycals and simple alkenes (Scheme 23).114 The acetyl nitrate (115) generated under these conditions is posited to undergo reaction with the substrate to generate a β-nitro carbocationic intermediate 116 whose fate is highly dependent on both the reaction conditions employed and the nature of the substrate itself.115 In the case of tri-O-benzylated galactal 120, reaction at elevated temperature leads to proton loss from the intermediate glycosyl cation and formation of nitroglucal 119. Nitroamidation, on the other hand, is favored at lower temperatures and in the case of 120, leads to the formation of 121 with high diastereoselectivity. Routes to 2-nitro-1-acetamido sugars of this type are of importance in light of the biological significance of 2-amino-β-glycosylamines, which constitute the core structural motif of N-linked glycoproteins.

Scheme 23.

Vankar’s second-generation alkene nitroamidation method and its application to the preparation of 2-nitroglycals and 2-nitro-1-acetamido sugars.

A significant temperature dependence was also observed with E-stilbene (122), which underwent nitroamidation with complete cis selectivity (Scheme 24). Although cyclohexene and 1-methylcyclohexene undergo nitroamidation, the formation of 125a and 126a is accompanied by significant quantities of the elimination products 125b and 126b.

Scheme 24.

Nitroamidation of simple alkenes under Vankar’s conditions.

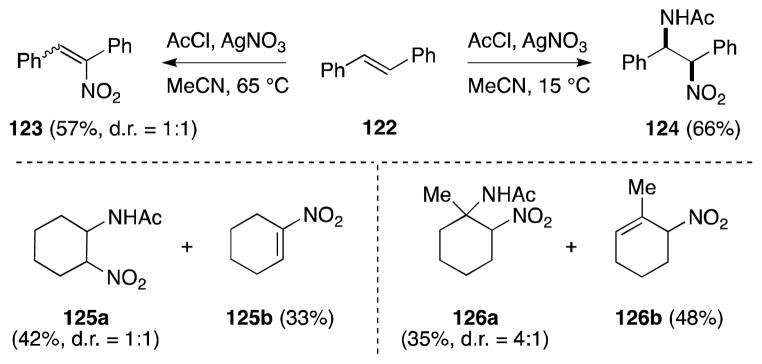

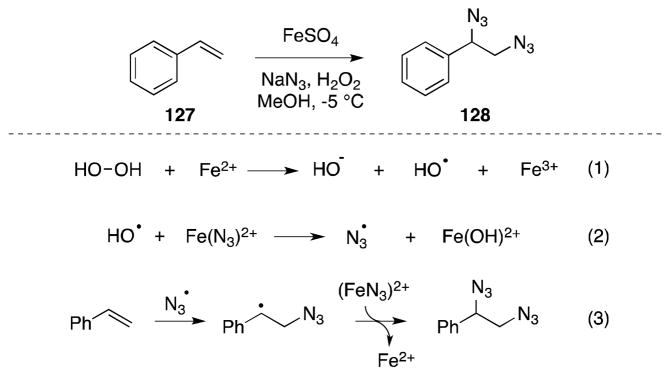

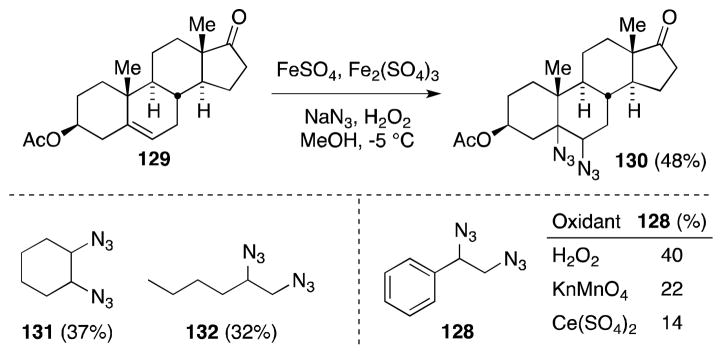

4. Alkene Bisazidonation via Redox

The azide anion (N3−) has a relatively low E0 (ca. −0.6 V)116 and consequently can be oxidized with a range of organic and metal-based oxidizing agents to the corresponding azidyl radical (N3·). This species is sufficiently electrophilic to undergo addition to a range of alkenes117,118 and trapping of the resulting β-azidoalkyl radical with a suitable azide donor, offers a convenient means of alkene diazidonation under mild reaction conditions. This “redox-chain” approach to diamination was first reported by Minisci and co-workers who utilized the reaction between tert-butyl hydroperoxide or hydrogen peroxide, and ferrous sulfate to effect the transformation (Scheme 25).119,120 From a mechanistic standpoint, Minisci has proposed that ferrous sulfate mediates the decomposition of hydroperoxide (1) and the resulting alkoxy radical interacts with an azido Fe(III) complex to generate the azidyl radical (2). Upon alkene addition, azide transfer between an iron(III) azide complex and the β-azido radical then generates the 1,2-diazide and completes the redox cycle.

Scheme 25.

Ferrous sulfate-mediated diazidonation of alkenes.

Minisci has also reported the use of a Fe(II)/Fe(III) system in the conjunction with a variety of oxidants, including hydrogen peroxide, permanganate,121 and Ce(IV) salts (Scheme 26).122

Scheme 26.

Ferric-Ferrous sulfate-mediated diazidonation of alkenes.

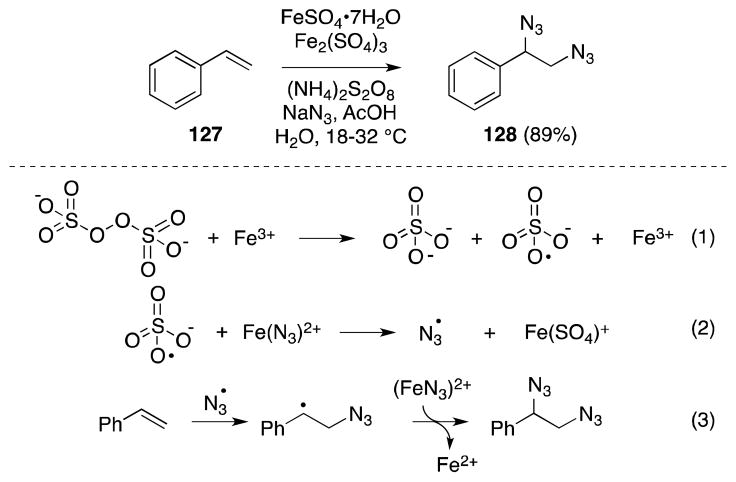

As shown in Scheme 27, the combination of ammonium peroxydisulfate and the Fe(II)/Fe(III) system also been employed for the diazidonation of styrene (127) (Scheme 27).123 In this case, the yield of diazide 128 is significantly improved over that obtained with hydrogen peroxide.

Scheme 27.

Ferric-Ferrous sulfate-mediated diazidonation of alkenes in the presence of ammonium peroxydisulfate.

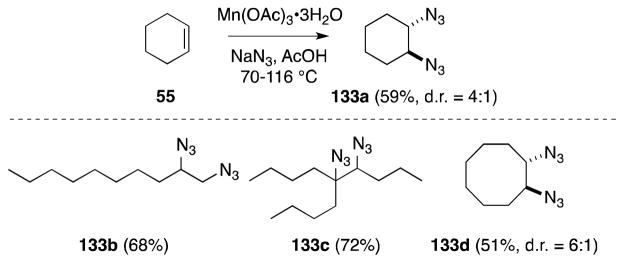

Fristad has reported the use of Mn(III) acetate as a highly effective reagent for alkene diazidonation (Scheme 28).124,125 In this case, treatment of alkenes with Mn(OAc)3 and sodium azide in acetic acid at elevated temperatures leads to the formation of 1,2-diazides 133 in high yield. Efficiency not withstanding, this methodology necessitates a large excess of azide (15 equiv) in order to prevent the formation of monoazidination products, which presumably arise from hydrogen atom transfer to the β-azido radical intermediate. Although the mechanism of this transformation has yet to be fully delineated, the dramatic rate acceleration noted in the presence of alkenes was posited as evidence of a ligand-transfer oxidation, rather than the participation of the azide radical.

Scheme 28.

Mn(III)-mediated diazidonation of alkenes.

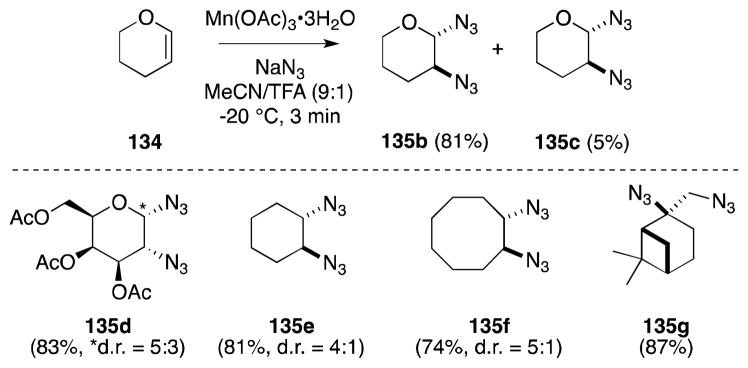

Snider has subsequently reported a modification of Fristad procedure in which replacement of acetic acid with a mixture of acetonitrile and trifluoroacetic acid as the reaction medium leads to significant improvements in yield (Scheme 29).126 That acid sensitive substrates, such as tetrahydropyran (134), are tolerant of these conditions is likely a reflection of the fact that reactions proceed at temperatures as low as −20 °C. Recent application of this methodology include the preparation of 1,2-cyclohexanediamines for oxaliplatin-type complexes127 and the synthesis of imine-based protein labels.128

Scheme 29.

Snider’s Mn(III)-mediated diazidonation of alkenes.

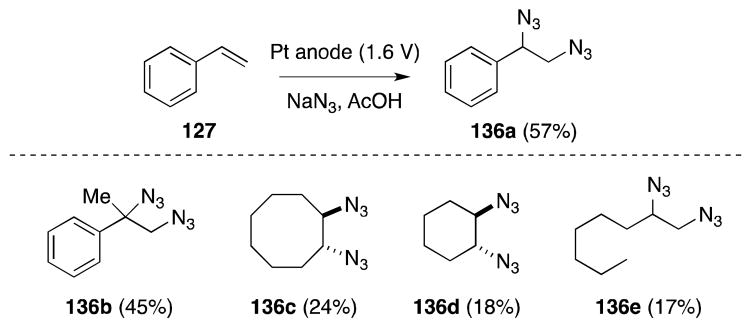

Alkene diazidonation can also be accomplished through electrochemical generation of the azidyl radical. Schäfer has reported that co-electrolysis of solutions of sodium azide in glacial acetic acid and alkenes (1:3, v/v) leads to the formation of 1,2-diazides 136 (Scheme 30).129

Scheme 30.

Alkene diazidonation via azide anion electrolysis.

While this method is reasonably efficient for electron-rich, styrene substrates, the yield for cyclic and acyclic alkenes is less satisfactory.

5. Heavy Metal-Mediated Bisazidonation

5.1. Lead(IV) Acetate-Trimethylsilyl Azide

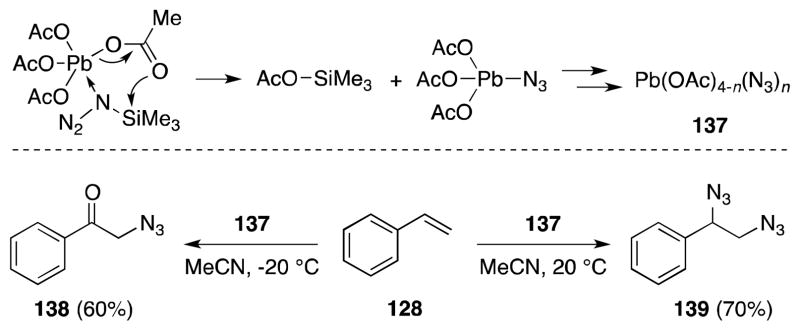

Lead(IV) acetate azide [Pb(OAc)4-n(N3)n] (137) is an effective azide transfer reagent, which is generated by the reaction of lead(IV) acetate and trimethylsilyl azide.130 In light of its thermal instability (decomposition occurs rapidly above −20 °C), this reagent must be generated in situ.131 Zbiral has reported the reaction of this reagent with alkenes to form vic-diazides, albeit in a highly temperature and solvent dependent manner (Scheme 31). In the case of styrene (128), reaction of 137 in acetonitrile at −20 °C leads to the formation of phenacyl azide (138) while reaction at 20 °C generates vic-azide 139 in high yield. In dichloromethane, reaction of 137 and 128 leads to more complex mixtures of products whose composition is dependent on the order of reagent addition.

Scheme 31.

Generation of [Pb(OAc)4-n(N3)n] and its temperature dependent reaction with styrene.

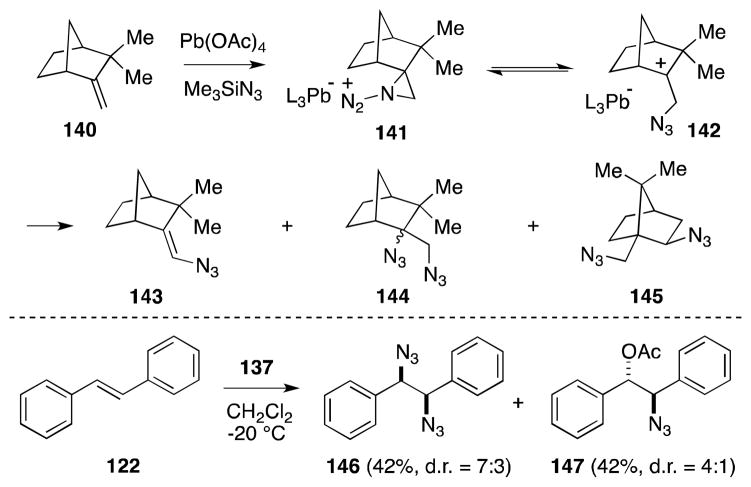

The formation of elimination (143) and rearrangement (145) products during the reaction of camphene (142) and other bridged alkenes with 137, has been cited by Zbiral as persuasive evidence of a “positive” azide-transfer, in which aziridinium ion 141 and carbocation intermediate 142 are involved (Scheme 32).132 Unfortunately, in most substrates, diazidonation is accompanied by the formation of vicinal acetoxy-azido products. Furthermore, acyclic alkenes, such as trans-stilbene (122), undergo diazidonation in a non-stereospecific manner as a result of the cationic intermediate.

Scheme 32.

Reaction of [Pb(OAc)4-n(N3)n] with camphene and E-stilbene.

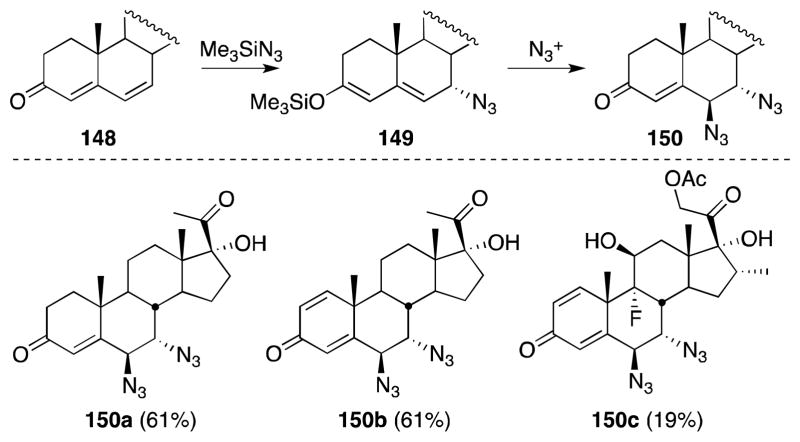

While the usefulness of Zbiral’s reagent with non-cyclic alkenes is limited by the intermediacy of cations, this is not the case with cyclic substrates. Draper has shown that steroidal 4,6-dien-3-ones 148 are suitable substrates for diamination and undergo reaction with 137 to form B-ring vic-diazides 150 with high stereoselectivity (Scheme 33).133 In this case, it is suggested that the lead-mediated azide transfer proceeds through silyl dienol ether 149, which is formed by the Lewis acid-mediated 1,4-addition of trimethylsilyl azide to 148.

Scheme 33.

Reaction of [Pb(OAc)4-n(N3)n] with steroidal 4,6-dien-3-ones.

The behavior of steroidal dienone substrates stands in contrast to that of the analogous trisubstituted Δ6-steroidal alkenes, which, depending on the reaction conditions employed, react with the lead tetraacetate-trimethylsilyl azide reagent to form allylic azides134 or seco keto nitriles.135

5.2. Thallium(III) Acetate-Trimethylsilyl Azide

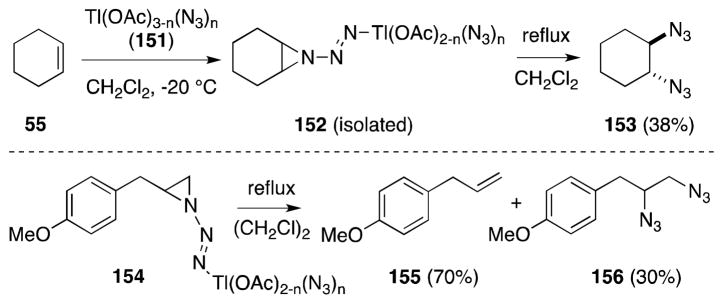

Zbiral has also developed an analogous reagent to 137, generated from thallium(IV) acetate, which also mediates diazidonation, albeit in a less efficient manner (Scheme 34).136 Treatment of thallium(III) acetate with trimethylsilyl azide generates [Tl(OAc)3-n(N3)n] (151), which undergoes reaction with alkenes to generate the corresponding aziridinylazothallium compounds 152 and 154. While only putative intermediates in the analogous lead-mediated transformations, these organothallium compounds are sufficiently stable to permit isolation.

Scheme 34.

Reaction of [Tl(OAc)4-n(N3)n] with cyclohexene and 4-allylanisole.

Thermolysis of 152 and 154 leads to the formation of 1,2-diazido compounds 153 and 156, although, in both cases, the predominant products are the parent alkenes, which were proposed to arise through a cheletropic fragmentation reaction.

6. Heavy Metal-Mediated Diamination

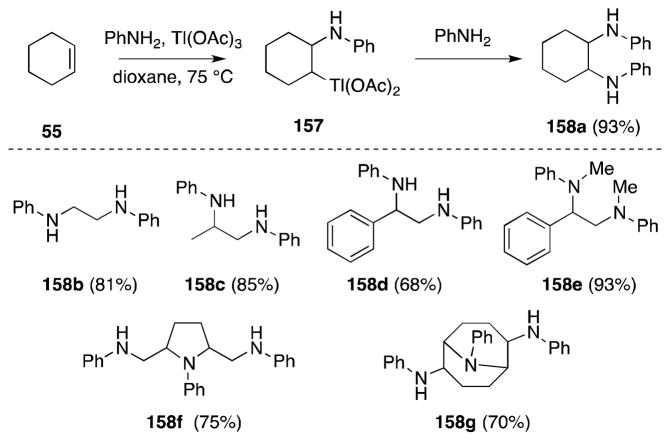

6.1. Thallium Acetate-Amines

Barluenga has reported a method for the preparation of diamines using thallium(III) acetate. Treatment of alkenes with aromatic amines in the presence of this heavy metal salt leads to the efficient formation of the corresponding diamines 158 (Scheme 35).137 While primary and secondary aromatic amines participate in this process, primary aliphatic amines fail to react. This reaction is thought to proceed via aminothallation to generate an organothallium intermediate, 157, which subsequently undergoes substitution. Notably, 1,4-dienes, specifically 1,4-hexadiene and 1,4-cyclooctadiene, undergo double addition to form cyclic and bicyclic products 158f and 158g respectively. The relative stereochemistry of these products was not reported.

Scheme 35.

Addition of aromatic amines to alkenes in the presence of thallium(III) acetate.

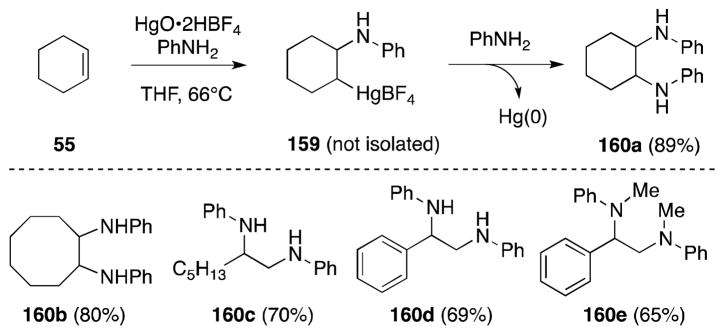

6.2. Mercury Acetate-Amines

Barluenga and co-workers have demonstrated the ability of β-amino alkylmercury(II) salts, formed through alkene aminomercuration, to undergo substitution with a range of nucleophiles, including amines. Initial studies found that treatment of alkenes with the reagent generated from tetrafluoroboric acid and mercury(I) oxide and aromatic or primary amines led to the efficient formation of 1,2-diamines 160 and Hg(0) (Scheme 36).138 The efficiency of this process is highly dependent on the degree to which the C-Hg bond is polarized. For example, the treatment of the β-amino alkylmercury salts of acetate and halides with amines leads only to retromercuration and formation of alkenes.

Scheme 36.

Addition of aromatic amines to alkenes in the presence of mercury(II) tetrafluoroborate.

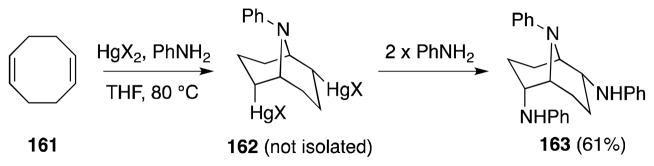

In a more recent mechanistic study, Barluenga has investigated the aminomercuration of 1,4-cyclooctadiene (161) under these conditions as a means of accessing 2,6-disubstituted-9-azabicyclo[3.3.l]nonanes (Scheme 37).139 Treatment of 161 with mercury(II) tetrafluoroborate in the presence of aniline leads directly to the formation of bicyclic triamine 163 as a single diastereomer. The reaction is thought to proceed via intermediate 162.140 The aminomercurials 162 (X = Cl, OAc) generated from mercury(II) chloride or acetate, proved to be less prone to substitution and their transformation to 163 requires more forcing conditions. Reagent notwithstanding, the authors propose that the formation of the observed products proceeds via an aziridinium ion intermediate(s) generated by the internal displacement of the mercury centers in 162.

Scheme 37.

Mercury(II)-mediated bis-diamination of 1,4-cyclooctadiene.

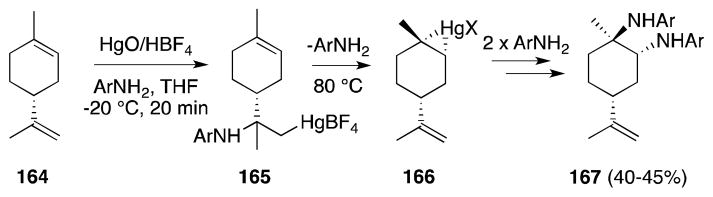

Barluenga has found that (+)-limonene (164) displays unexpected behavior in its diamination reactions with mercury(II) tetrafluoroborate (Scheme 38).141 While reaction of this diene at low temperature proceeded as anticipated, with Markovnikov selectivity at the more accessible exocyclic alkene, heating the resulting aminomercurial (165) at 80 °C leads to the formation of trans-diamine 167 (Ar = Ph, p-ClPh, p-MePh). The formation of this product was attributed to mercurinium ion exchange whereby 165, unable to undergo displacement to form an aziridinium ion, undergoes β-elimination and ion transfer to generate intermediate 166. Stepwise substitution with two equivalents of arylamine then leads to the observed trans-1,2-diamine.

Scheme 38.

Diastereoselective mercury(II)-mediated diamination of (+)-limonene proceeds with unanticipated regioselectivity.

7. N,N-Dihaloarylsulfonamides & N-Haloarylsulfonamides

7.1. N,N-Dihaloarylsulfonamides-Acetonitrile

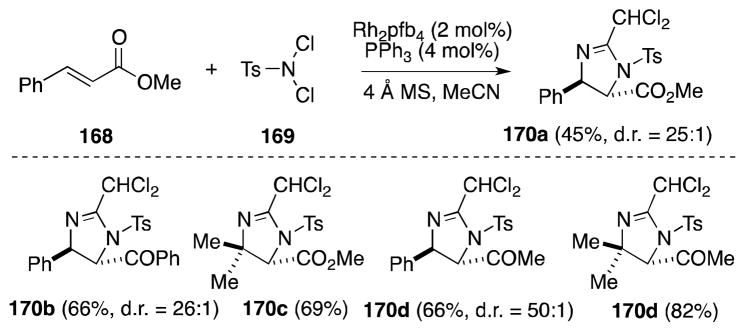

Although a stepwise approach to diamination and thus beyond the purview of this article, the aziridination of alkenes and use of the strained products as substrates for ring-opening via a Ritter reaction is an appealing strategy for the stereocontrolled introduction of vicinal nitrogen functionality.142 In this regard, Li and co-workers, in 2003, first reported a novel method for the indolizidination of α,β-unsaturated carbonyl compounds which is thought to proceed via the Ritter-type reaction of an aziridinium ion intermediate (Scheme 39).143,144 Treatment of α,β-unsaturated ketones and esters, such as methyl cinnamate (168), with N,N-dichloro-p-toluenesulfonamide (TsNCl2, 167), 4 Å molecular sieves, and the complex generated from Rh2pfb4 and Ph3P in acetonitrile was found to generate trans-substituted 2-dichloromethyl-2-imidazolines 170 in moderate to high yield and with excellent diastereoselectivity. The formation of trans imidazolines in this case corresponds to a cis diamination process.

Scheme 39.

Direct imidazolination of α,β-unsaturated ketones and esters with the reagent combination TsNCl2/MeCN/Rh2pfb4·PPh3.

Li has also discovered a number of other catalysts that significantly accelerate the imidazolination process, including Rh2TFA4·PPh3,145 FeCl3·PPh3,146 MnO2,147 and most recently, triphenylphosphine.148 In the case of MnO2 and Rh2TFA4·PPh3, diamination proceeds to generate the trichloromethyl rather than dichloromethyl imidazolines. The copper-catalyzed (CuI·PPh3) addition of N,N-bromo-p-toluenesulfonamide (TsNBr2) to α,β-unsaturated ketones and esters has also been reported.149 In this case, the formation of dichloromethyl imidazolines is favored.

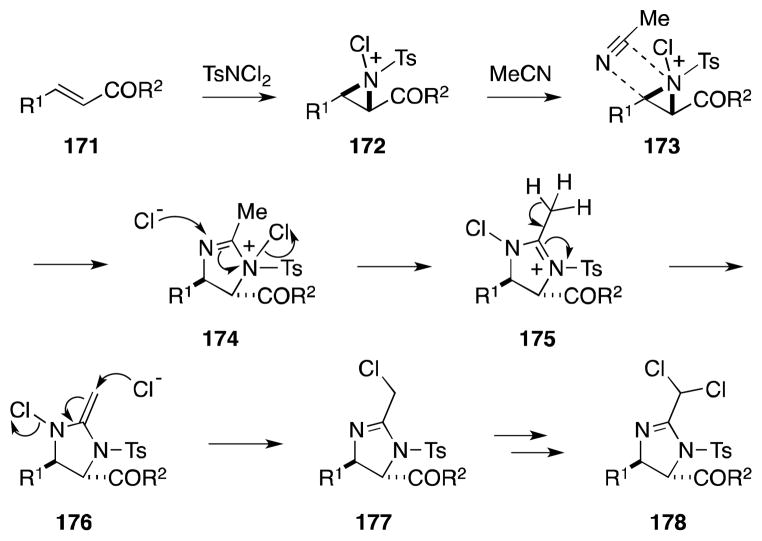

On the basis of their work on the related alkene aminohalogenation reaction,150 Li and co-workers have posited a general mechanistic interpretation of this remarkable transformation (Scheme 40). In a stereospecific process that is accelerated but not dependent upon catalyst additives (vide infra), diamination commences with the formation of N-sulfonyl-N-chloroaziridinium ion 172. In the presence of nitriles, participation of this intermediate in a Ritter-type reaction, involving nucleophilic ring opening at the more substituted or benzylic position, then generates 1N-(tosyl)imidazolium ion 174. Given the overall syn stereochemistry of the diamination process, Li has suggested that this process occurs via a [2+3] mechanism in which 174 is formed directly. Displacement of the 1N-chlorine group in this intermediate then gives rise to 3N-(tosyl)imidazolium ion 175, which undergoes proton loss and a second SN2′-type displacement to form 2-chloromethyl imidazoline 177. 3N-Chlorination of 177 and a repetition of the deprotonation and displacement steps are then proposed to lead to the observed product 178.

Scheme 40.

Proposed mechanism for Li’s alkene syn-imidazolination process.

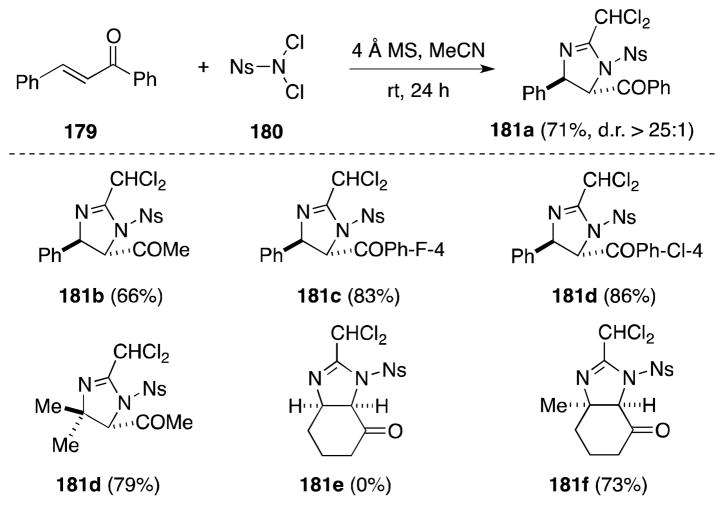

Intriguingly, subsequent studies by Li have revealed that during the addition of TsNCl2 to α,β-unsaturated ketones the need for a catalyst can be obviated simply by raising the reaction temperature to 50 °C.151 Furthermore, in the case of the more reactive reagent N,N-dichloro-2-nitrobenzenesulfomamide (NsNCl2, 180), imidazolination of enones 179 proceeds in the absence of catalyst at room temperature to generate the dichloromethyl adducts (Scheme 41).152 Interestingly, when conducted in the absence of molecular sieves, addition of 180 proceeds at 50 °C to the corresponding trichloromethyl imidazoline products 181.

Scheme 41.

Direct imidazolination of α,β-unsaturated ketones with the reagent combinations NsNCl2/MeCN.

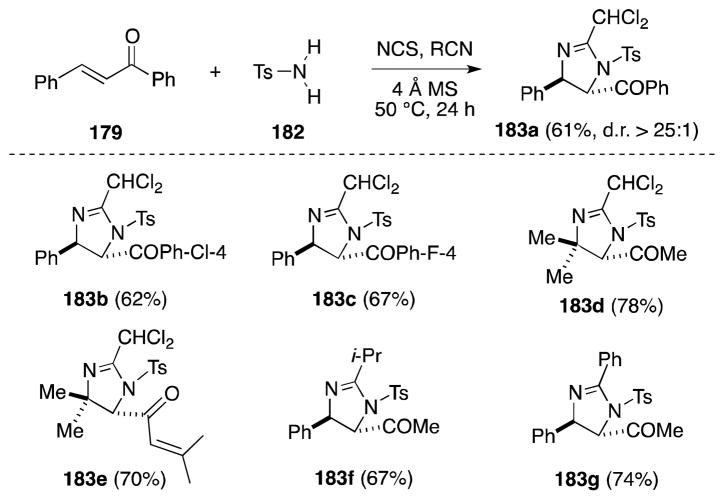

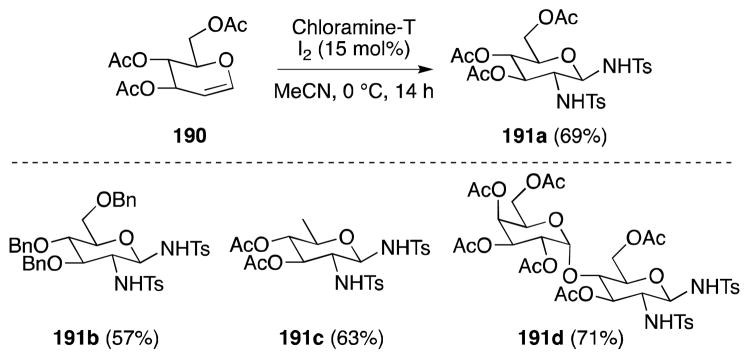

In order to avoid the inconvenience of handling N,N-dichlorosulfonamides 169 and 180, Li has a protocol for the in-situ generation of these unstable reagents. Treatment of enones and dienones with p-toluenesulfonamide (182) and N-chlorosuccinamide (NCS) at 50 °C generates the expected products in comparable yield to the parent reagent (Scheme 42).153 Notably, other nitrile partners, including isobutyronitrile and benzonitrile can be employed and, in the case of benzylideneacetone, leads to the formation of 183f and 183g, respectively. NsCl2 (180) can also be generated in this manner, although in the case of this more electrophilic reagent, esters as well as unsaturated ketones undergo imidazolination.154

Scheme 42.

Direct imidazolination of α,β-unsaturated ketones with the reagent combination TsNCl2/NCS/RCN.

Importantly, Li and co-workers have demonstrated that the imidazoline products 183 can be hydrolyzed to the corresponding open-chain diamines without epimerization at either chiral center (Scheme 43).155 Exposure of these heterocycles to aqueous hydrochloric acid at 70 °C mediates rapid hydrolysis to the differentially protected syn-1,2-diamines 184 in excellent yield. Stannic chloride (SnCl4/THF/H2O) has also been utilized as an effective promoter of imidazoline hydrolysis.149,148

Scheme 43.

Acidic hydrolysis of imidazolines to form differentially protected vicinal diamines.

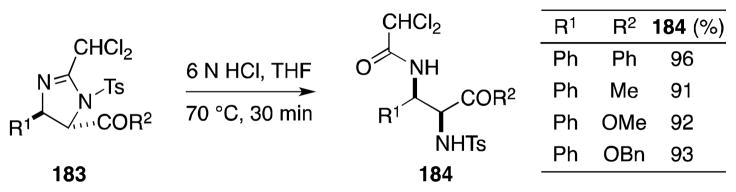

7.2. N-Chlorosaccharin-Acetonitrile-KOEt

An elegant one-pot method for the cis-imidolizidination of alkenes has also been developed by Booker-Milburn and coworkers (Scheme 44).156 In the presence of acetonitrile, alkenes undergo a Ritter-type reaction with the electrophilic chlorinating agent N-chlorosaccharin (NCSacc, 185) to generate a putative nitrilium ion intermediate 187. Capture of 187 by the saccharin anion gives rise to β-chlorosulfonylamidines 188. Treatment of these reactive intermediates with potassium ethoxide then mediates ring-opening of the benzothiazoletrione ring to form an amidine anion 189, which cyclizes to form the corresponding imidazoline systems 186 in low to moderate yield. When isolable, by-products of this process include aziridines and allylic chlorides, which arise from the first-formed chloronium ion intermediate through eliminative ring opening and capture by saccharide, respectively. In common with Li, Booker-Milburn has found that the ring opening of the imidazoline products to differentially protected diamines under acidic conditions presents no difficulties.

Scheme 44.

Imidazolination of alkenes with the reagent combination NCSacc/MeCN/KOEt.

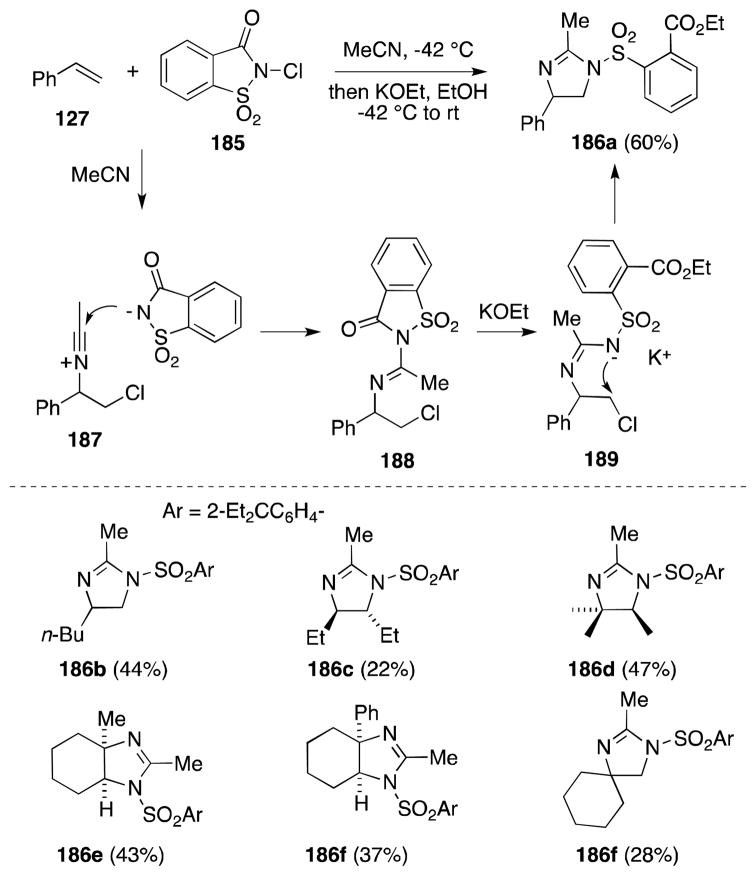

7.3. Chloramine-T-Iodine-Acetonitrile

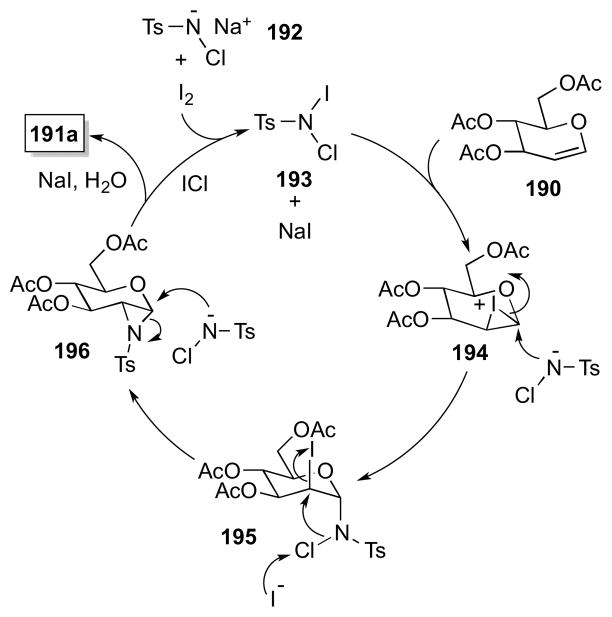

In 2006, Ramesh and Kumar reported the use of chloramine T in a remarkably straightforward, one-pot method for the diamination of glycals (Scheme 45).157,158 Treatment of tri-O-acetyl-D-glucal (190) with 2.3 equivalents of chloramine T in the presence of a catalytic quantity of iodine (15 mol%) leads to the selective formation of β-D-gluco 1,2-disulfonamide 191a in good yield. This mild procedure is successful with a range of mono-, di- and trisaccharide glycals, is compatible with both O-acetate and O-benzyl protecting groups and, in most cases examined, proceeds with complete diastereoselectivity.

Scheme 45.

Iodine catalyzed one-pot diamination of glycals with chloramine-T.

On the basis of their own observations and studies by Komatsu on the iodine-catalyzed aziridination of alkenes using chloramine-T,159 Ramesh and Kumar have proposed a mechanism for the diamination process (Scheme 46). Rapid reaction of chloramine-T (192) with iodine is thought to generate iodine-chloramine-T complex 193, which reacts from the β-face of glycal 190 to form iodonium ion 194. Diaxial ring opening of this species at the anomeric center by chloramine-T then leads to 195, which, with the aid of iodide, undergoes cleavage of the N-Cl bond and ring closure to form glycal aziridine 196 and iodine monochloride (ICl). Ring opening of 196 by a second molecule of chloramine-T then yields 1,2-disulfonamide 191a, after protonation. That stoichiometric quantities of iodine monochloride were found to mediate this transformation in place

Scheme 46.

Proposed mechanism of Ramesh’s one-pot glycal diamination method.

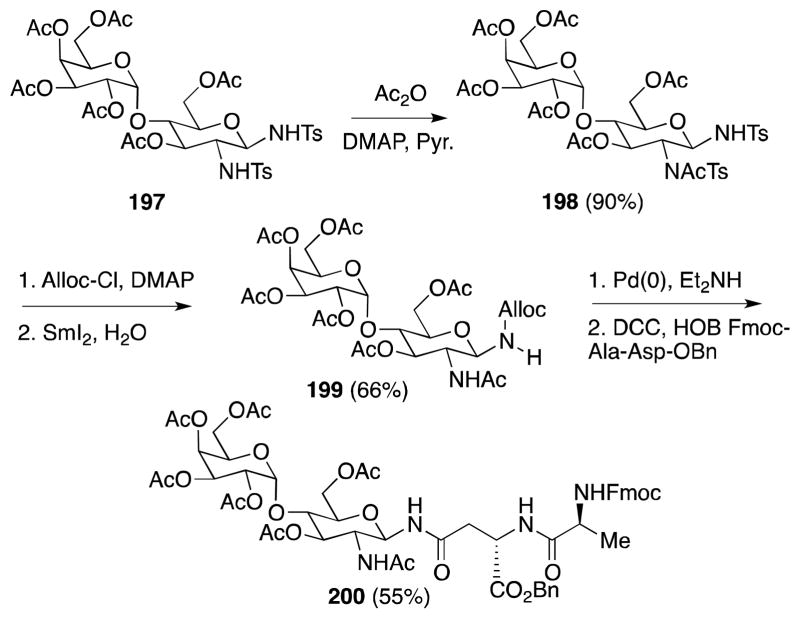

In light of the central structural role that 2-amino-β-glycosylamines play in N-linked glycoproteins, the development of synthetic routes to this glycodomain is a goal considerable importance. In this regard, Ramesh has exploited the differential reactivity of the anomeric and C-2 sulfonamide groups within the glycal addition products to develop a general route to glycosyl amino acids and peptides (Scheme 47). For instance, N-acetylation of 197 proceeds only at the more nucleophilic C-2 position to provide 198 in excellent yield. Conversion of this material to N-Ala-Asp linked glycopeptide 200 was accomplished through a four-step sequence involving protection of the anomeric nitrogen, didetosylation, removal of the Alloc group from 199 and peptide coupling of the liberated anomeric amine.

Scheme 47.

Synthesis of N-Ala-Asp linked glycopeptide X.

8. Iodine Azide & Surrogates

8.1. Iodine Azide

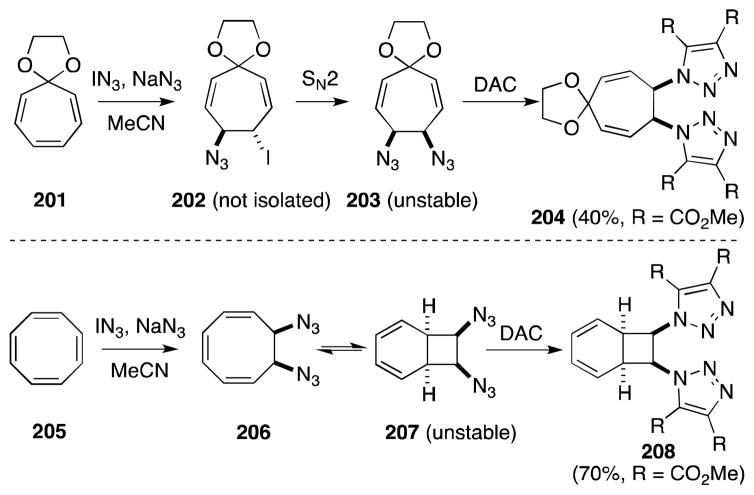

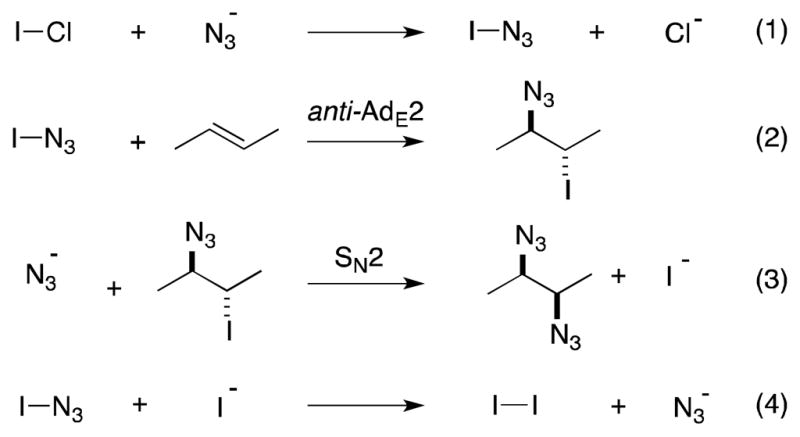

The first reports of pseudohalogen-mediated diazidonation were made by Hassner and involve the use of iodine azide (IN3) prepared by the action of sodium azide on iodine monochloride (ICl) (Scheme 48).160 Although explosive in its pure state, iodine azide can be handled as a 0.25 M solution in polar organic solvents.161 In most cases, reaction with alkenes generates the products of anti-iodo-azidination (2), which are proposed to arise from the ring opening of an iodonium intermediate. In the presence of excess azide anion and with extended reaction times, displacement of the iodide group can take place to yield cis-1,2-diazides (3).162,163,164 In the absence of excess azide, diazides can also form since the iodide generated during displacement reacts with iodine azide to generate iodine and an azide anion (3).165

Scheme 48.

Generation, reaction and iodide-mediated disproportionation of iodine azide.

While acyclic 1,2-diazides have a tendency to undergo spontaneous elimination to form vinyl azides,166 Sasaki has demonstrated that medium-sized cyclic alkenes, including tropone ethyleneketal (201), 1-ethoxycarbonyl-1(1H)-azepine and cyclooctatetraene (205), undergo diazidonation successfully (Scheme 49).162 In light of the instability of these products, they were trapped as their respective 1,3-dipolar cycloadducts 204 and 208; treatment with dimethyl acetylenedicarboxylate (DAC) proceeded smoothly. In the case of 208, valence tautomerism of cyclooctatriene 206 generates bicyclo[4.2.0]octatriene 207 which undergoes cycloaddition.

Scheme 49.

Diazidonation of cyclic polyenes with iodine azide-sodium azide.

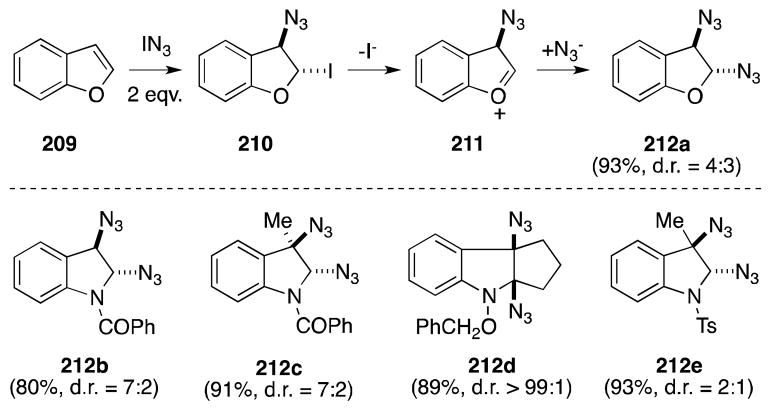

Tamura has also reported the reaction of benzo[b]furans and 1-acyl and 1-tosyl-indoles with IN3 in the presence of sodium azide to generate the corresponding 2,3-diazido-2,3-dihydrobenzo[a]furans and 2,3-diazidoindolines 212 (Scheme 50).167 In all cases, but compound 212d, mixtures of trans and cis stereoisomers were obtained reflecting the likely intermediacy of cationic intermediates, such as 211.162

Scheme 50.

Diazidonation of benzo[b]furans and 1-acyl and 1-tosyl-indoles.

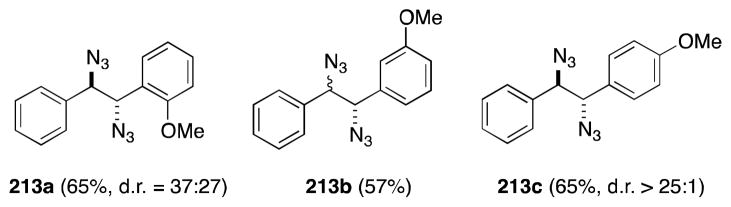

Employing a modification of Hassner’s original conditions,161b Schönenberger has reported the preparation of 1,2-diaryl-1,2-diazidoethanes 213 through the addition of IN3 to E-stilbenes (Scheme 51).168 That in the case of 213c, anti rather syn addition occurs may indicate the intermediacy of a β-azidocarbocation, which would be trapped from the less hindered face.

Scheme 51.

Divergent reactions of 1,3-dienes with bromine and iodine azides.

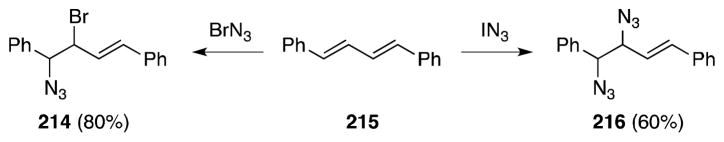

Hassner has reported a single example of the 1,2-diazidonation of a 1,3-diene (Scheme 51).169 In this case, the reaction of E,E-diphenylbutadiene (215) with IN3 generates 1,2-diazide 216 while addition of BrN3 leads only to bromoazide 214; this likely reflects the diminished nucleofugality of the bromide group in comparison with iodide. Exposure of 215 to sodium azide in DMF generates compound 216.

In view of the difficulties associated with the handling of iodine azide, Kirschning and co-workers have developed a stable polymer-bound form of this useful reagent (Scheme 52).170 Sequential treatment of polymer-bound iodide 217 with (diacetoxyiodo)benzene (DIAB) and trimethylsilyl azide generates a resin formulated as bis(azido)iodate salt 219. While most substrates undergo only azido-iodination, prolonged reaction of electron-rich alkenes with this reagent leads to the formation of 1,2-diazides, albeit in low yield and without stereospecificity. In the case of 220, it seems probable that 222 arises from azido-iodide 221, through a non-concerted displacement process.

Scheme 52.

Preparation and reaction of polymer-bound iodine azide.

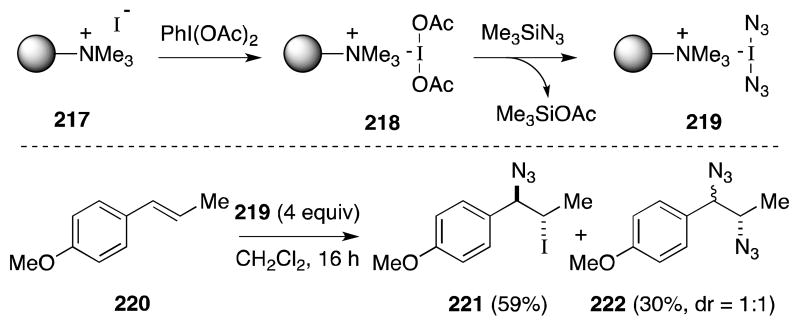

Generated by the reaction of DIAB (223) with Me3SiN3 and tetraethylammonium iodide, bis(azido)iodate salt 225 (Scheme 53),171 the solution phase variant of 219, has also been employed for alkene diazidonation, by Austin and co-workers in their synthesis of the marine natural product dibromophakellstatin (228).172

Scheme 53.

Generation of a solution-phase bis(azido)iodate salt and its use in the synthesis of (±)-dibromophakellstatin.

The key step is this endeavor involves installation of the syn-1,2-diamine functionality present on the piperidinone ring of 228. Treatment of alkene 226 with 225 provided syn-diazide 227b as the major product, albeit in modest yield, while reaction with iodine azide led to the exclusive formation of anti addition product 227a. The authors propose that while both diazides isomers may arise from a common haloazide intermediate, the cis isomer does so via bimolecular nucleophilic displacement. The trans isomer, on the other hand, appears to arise from an azido-iminium ion that undergoes ring opening from the less hindered face.

9. Halogen-Mediated Diamination & Cycloguanidination

9.1. Vicinal Diamination of 1,4-Dihydropyridines

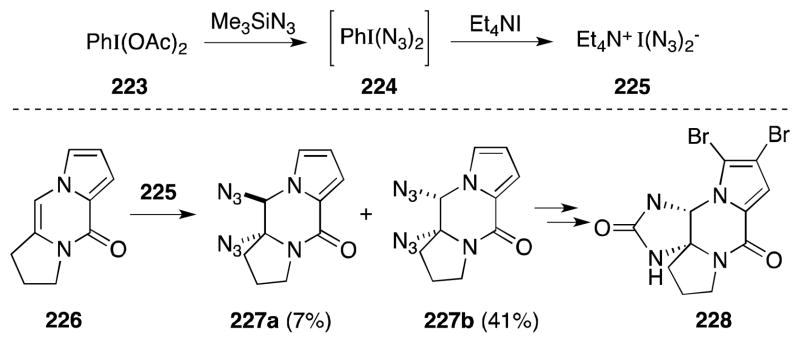

The use of intermolecular alkene aminohalogenation as a means to accomplish the direct diamination of carbon-carbon double bonds is relatively uncommon since the competitive oxidation of alkyl and aryl amines presents a significant setback.173,174 However, in the case of highly reactive alkene partners, such as enamines, this undesirable process can be avoided. In this regard, Lavilla and co-workers have reported a highly effect method for the vicinal diamination of 1,4-dihydropyridines (Scheme 54).175 Treatment of N-alkyl-1,4-dihydropyridine 229 with iodine (3.5 equiv) in the presence of a range of cyclic amines (25 equiv) leads to the formation of the corresponding trans-2,3-diaminotetrahydropyridines 231 in high yield. The stereoselective generation of these products was rationalized in terms of the regioselective formation and trapping of a 3-iodo-3,4-dihydropyridinium ion to form intermediate 230. Internal displacement of the iodide then generates an aziridinium ion which undergoes ring opening at the 1-position with a second equivalent of amine giving rises to the trans-substituted products.

Scheme 54.

Vicinal diamination of 1,4-dihydropyridines in the presence of iodine.

While simple primary amines fail to undergo this reaction, N,N′-dimethylethylenediamine reacts with compound 229 to generate the cis-bicyclic adduct 231d in high yield.

9.2. Halogen-Mediated Cycloguanidination & Related Processes

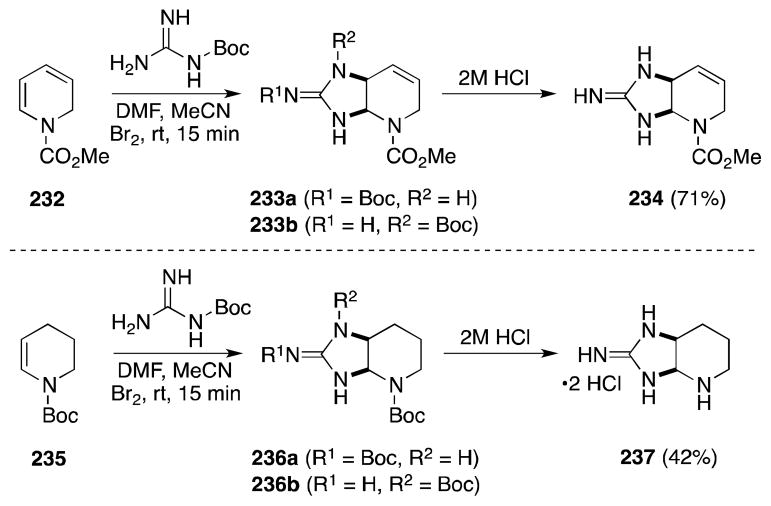

While the direct cycloguanidination of alkenes via transition metal catalysis has recently garnered considerable attention (vide infra), the use of halogens and their synthetic equivalents to effect this transformation with 1,2-dihydropyridines has also met with considerable success. The first reports of this form of alkene diamination were made by Al-Mourabit and co-workers as part of their on-going study of 2-aminoimidazole alkaloid synthesis (Scheme 55). Treatment of carbomethoxydihydropyridine (232) with bromine or NBS in the presence of 3–4 equivalents of Boc-guanidine generated bicycles 233a and 233b, which upon exposure to HCl, where converted to cyclic guanidine 234.176 N-Protected tetrahydropyridines 235177 and 1,2-dihydropyridine imidates178 were also found to undergo this bromine-induced transformation. In both cases, the annulation process likely proceeds in stepwise fashion where bromoamination of the enamine precedes intramolecular ring closure through N-alkylation.

Scheme 55.

Bromine-mediated cycloguanidination of N-acylated dihydropyridines and tetrahydropyridines with Boc-guanidine.

Tepe and co-workers have gainfully employed a closely related aza-annulation in their recent synthesis of the oroidin-type alkaloid (±)-dibromophakellin (240) (Scheme 56).179 Treatment of a mixture of dipyrrolopyrazinone 238 and Boc-guanidine with NBS gave rise to the Boc-protected natural product 239 in low yield.

Scheme 56.

Key alkene cycloguanidination step in Tepe’s synthesis of dibromophakellin.

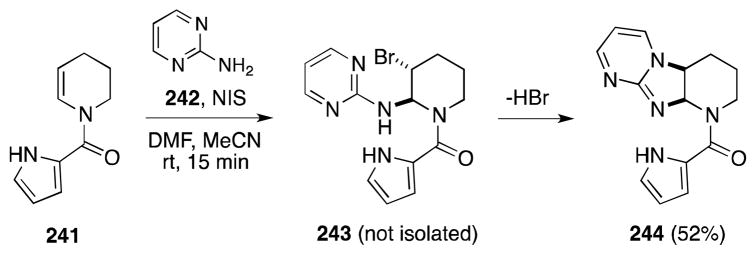

Further studies by Al-Mourabit have revealed that 2-aminopyrimidine (242), which is a stronger nucleophile than Boc-guanidine, can be used in place of this reagent (Scheme 57). For example, treatment of N-acylpyrrole tetrahydropyridine 241 with N-iodosuccinimide (NIS) in the presence of 242 afforded adduct 244 with moderate efficiency.180

Scheme 57.

NIS-mediated cycloguanidination of N-acylated dihydropyridines with 2-aminopyrimidine.

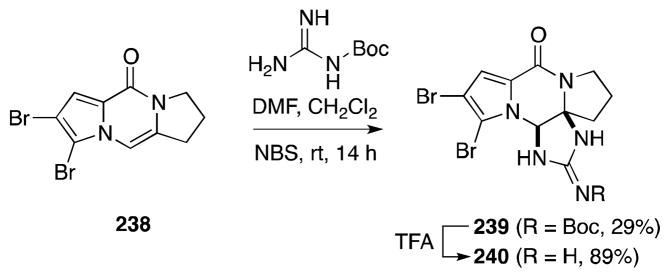

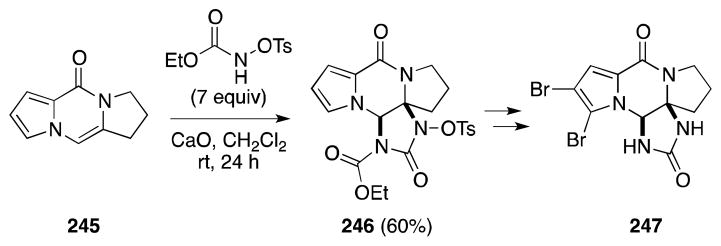

The aza-annulation of dipyrrolopyrazinone 245, albeit without the assistance of halogen reagents, has also been described by Lindel and co-workers in their synthesis of dibromophakellstatin (247) (Scheme 58).181 In this situation, the activated complex generated from ethyl-N-tosyloxycarbamate and calcium oxide is proposed to react with 247 to generate an acyliminium ion that traps excess ethyl-N-tosyloxycarbamate. Subsequent cyclization and loss of ethanol then generates the imidazolidinone ring of the natural product in a single step with reasonable yield.

Scheme 58.

Key alkene cycloguanidination step in Lindel’s synthesis of dibromophakellstatin.

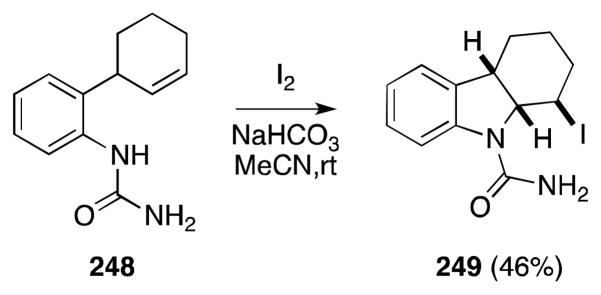

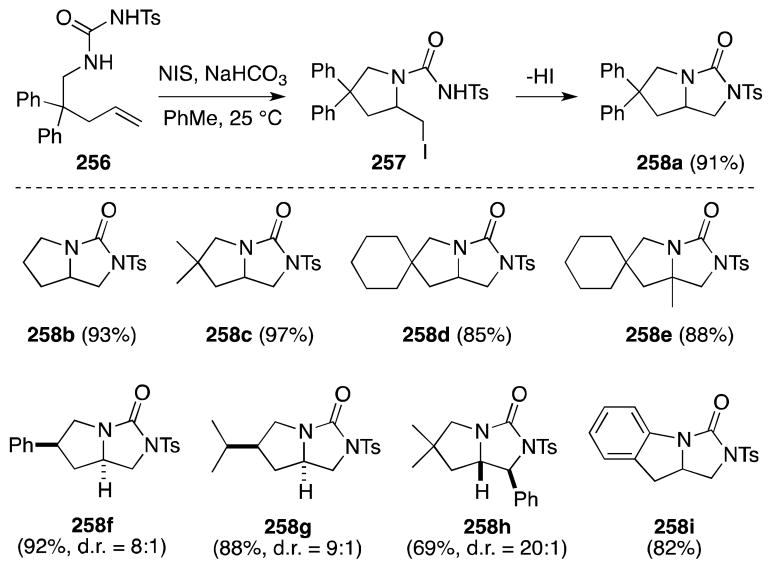

Although the iodonium-induced cyclization of unsaturated carboxamides, sulfonamides and carbamates to form N-heterocycles is well documented,182 the participation of N-ω-alkenyl ureas in this type of cyclization, as exemplified by the conversion of 248 to 249,183 is comparatively rare (Scheme 59). Notwithstanding question of N vs. O selectivity, this is somewhat surprising given that 5-exo-tet cyclization of the iodoamination products in this case potentially offers an entry point to imidazolidin-2-ones, the formal products of alkene diamination. In this regard, Muñiz and Barluenga have successfully employed the iodonium source bis(pyridine)iodonium tetrafluoroborate (IPy2BF4) as a mediator of the direct intramolecular oxidative diamination of δ-alkenyl ureas 250 (Scheme 60).184

Scheme 59.

Illustrative example of the intramolecular iodoamidation of an N-δ-alkenyl urea.

Scheme 60.

Intramolecular oxidative diamination of alkenes with N-sulfonyl ureas in the presence of bis(pyridine)iodonium tetrafluoroborate.

Treatment of N-δ-alkenyl-N′-sulfonyl ureas 250 with IPy2BF4 in toluene at 120 °C was found to selectively generate, in the case of terminal and 1,1-disubstituted alkenes, bicyclic imidazolidin-2-ones 253 in consistently high yield (Scheme 60). A single N-alkyl-N′-sulfonyl guanidine derivative was also found to undergo cyclization to form compound 253g in near quantitative yield. Less successfully, the cyclization of internal alkene substrates, such as 250 (R = Me), gave rise to mixtures of diamination and oxamidation products 252. Notably, the formation of both bicyclic urea 253 (R = Me) and isourea 252 occur in a stereospecifically syn fashion with respect to alkene geometry.

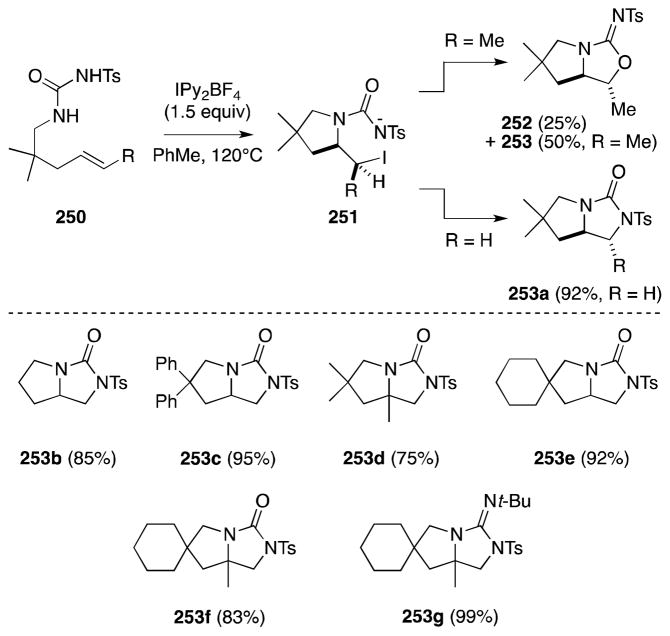

From a mechanistic perspective, Muñiz and Barluenga have proposed that imidazolidinone formation occurs through a sequence of two anti C-N bond-forming steps: (a) formation and ring opening of an iodonium ion giving rise to intermediate 251 and, (b) selective SN2 displacement of the iodide group by the second nitrogen atom to form the products of a cis-diamination. Support for this hypothesis was gained from the deuterium labeling study outlined in Scheme 61.

Scheme 61.

Stereochemical course of N-sulfonyl ureas-alkene diamination reaction.

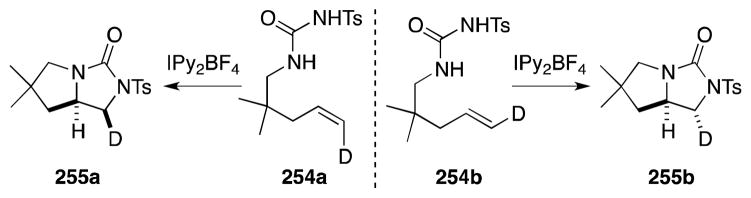

Windenhoefer and Li have recently reported a milder method for the intramolecular oxidative diamination of N-δ-alkenyl-N′sulfonyl ureas (Scheme 62).185, For example, treatment of 256 with iodosuccinimide (NIS; 2 equiv) and sodium bicarbonate (1 equiv) at room temperature gave rise to bicyclic imidiazolidin-2-one 258a in high yield. Notably, the formation of products 258f-h occurs with high diastereolselectivity. In contrast to the findings of Muñiz and Barluenga,184 the NIS-mediated cyclization of internal alkene substrates generates only diamination products, e.g. 258h, although, as before, this transformation proceeds in a stereospecific, syn manner.

Scheme 62.

Intramolecular oxidative diamination of alkenes with N-sulfonyl ureas in the presence of N-iodosuccinimide.

The oxidative cyclization of unsaturated sulfonylureas 256 has also been studied by Michael and co-workers, who employ iodosylbenzene in the presence of Lewis and Brønsted acids to mediate this process.186 Although alkene diamination was observed, the predominant outcome of these reactions proves to be the formation of cyclic isoureas through intramolecular oxamidation.

10. Hypervalent Iodine Reagents

In light of their ready availability, low toxicity and reduced environmental impact, hypervalent iodine reagents have largely replaced heavy metals, such as mercury, lead and thallium, as the reagents of choice for alkene diazidonation and diamination.187

10.1. Aryl-λ3-iodanes

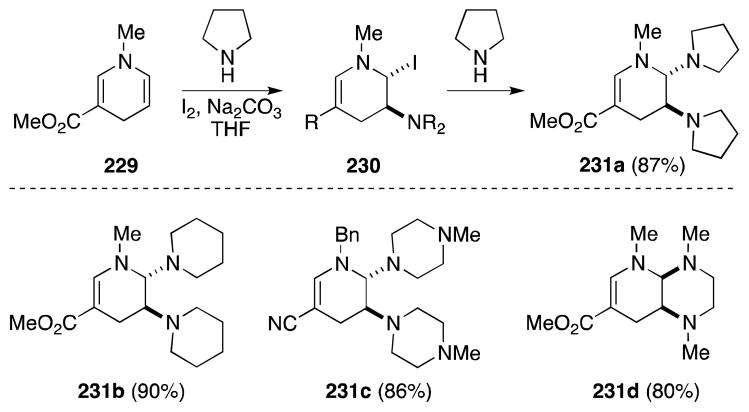

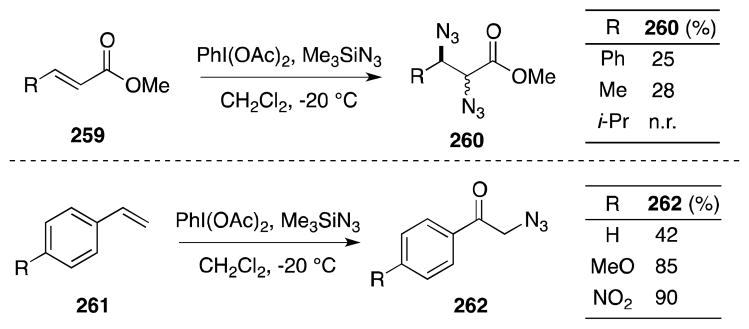

The reaction of alkenes with aryl-λ3-iodanes has proven to be a particular effective and versatile method for the co-introduction of vicinal heteroatoms. However, in the case of alkene diamination use of these reagents is made impractical by the ease with which they oxidize primary and secondary amines. This however is not the case with azide ligands and the use of aryl-λ3-iodanes to effect alkene diazidonation has been reported by a number of groups. In 1972, Zbiral and Ehrenfreund reported that treatment of unsaturated esters 259 with PhI(OAc)2/TMSN3 leads to the formation of vic-diazides 260, albeit in low yield and with very limited substrate scope. (Scheme 63).188 Notably, electron-rich alkenes 261 display a different reactivity mode and are converted to α-azido ketones 262.189

Scheme 63.

Diazidonation of α,β-unsaturated esters with Zbiral’s hypervalent iodine reagent.

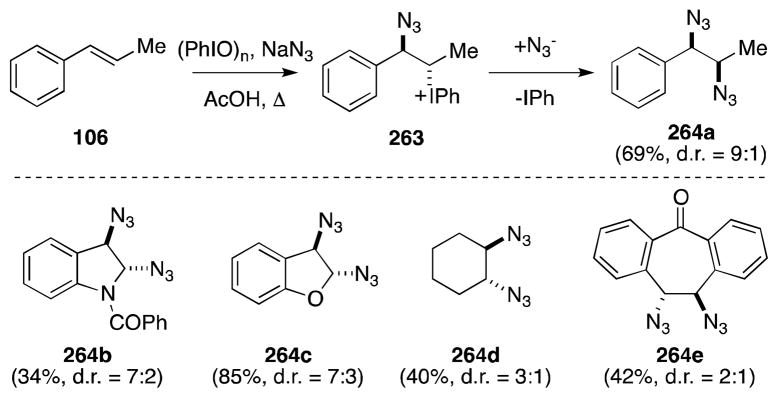

Moriarty and Khosrowshahi have reported a related, but considerable more effective diazidonation reagent generated by the action of sodium azide on iodosylbenzene (Scheme 64).190 A range of alkenes, including benzofuran and N-benzoylindole, undergo reaction to yield diazides 264 with variable diastereoselectivity. Although Moriarty proposed an ionic mechanism, involving the formation and displacement of an iodonium ion intermediate 263, subsequent studies by Magnus (vide infra) suggest that a radical pathway may also exist. That Δ5,6-steroids react with (PhIO)n/NaN3 to form the corresponding 7α-azidosteroids, rather than undergo diazidonation is further evidence of the presence of azide radicals in these reactions.191

Scheme 64.

Synthesis of vicinal diazides using Moriarty’s hypervalent iodine reagent.

Armimoto and co-workers have reported the diazidonation of allylsilanes using a mixture of iodosylbenzene and trimethylsilyl azide (TMSA) (Scheme 65).192 In this case, treatment of (PhIO)n with TMSA at −78 °C for 3 h generates a reagent formulated as 266 or (diazidoiodo)benzene (267). Reaction with allylsilanes then provides the corresponding vicinal diazides 268 in moderate to high yield. Although the diastereoselectivity of this process was not reported, the functional group tolerance is notable. Arimoto has proposed that diazide formation proceeds via a [2+3] cycloaddition to form a triazoline intermediate, which then undergoes ring opening with azide.

Scheme 65.

Diazidonation of allylsilanes with the reagent combination (PhIO)n/TMSN3.

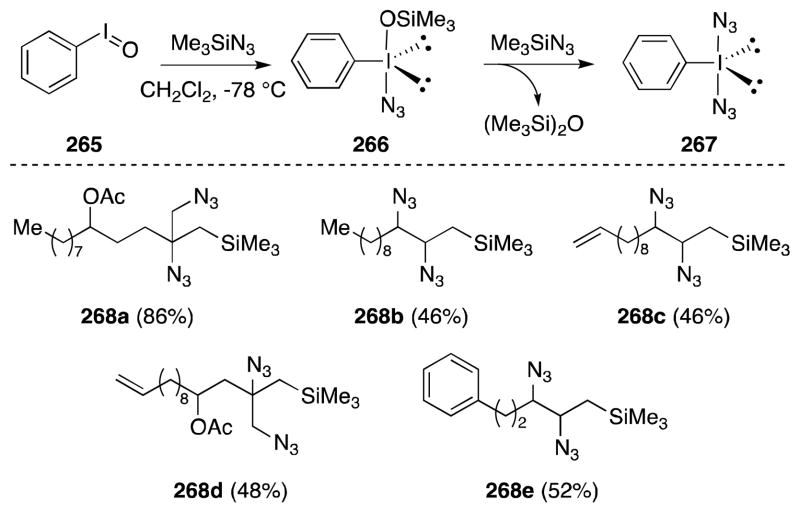

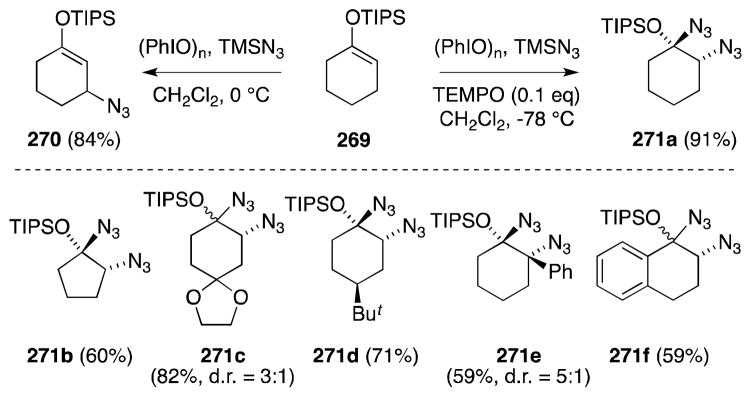

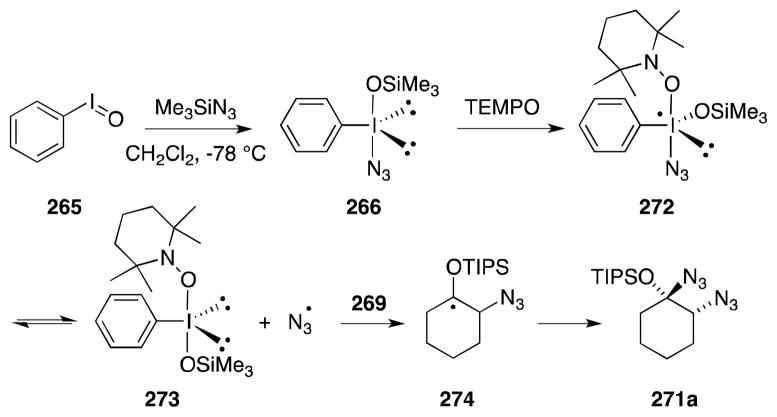

While studying methods for the electrophilic amination of ketones and their derivatives,193 Magnus and co-workers found that treatment of triisopropyl (TIPS) enol ethers, such as 269, with the reagent combination (PhIO)n/TMSN3 led to dramatically differing results depending on the reaction temperature employed (Scheme 66). Reaction of 269 at 0 °C rapidly leads to the formation of β-azidonation product 270, while reduction at −78 °C favors the formation of 271a, the product of α-bis-azidonation.194 It was also found that addition of catalytic quantities of the stable radical TEMPO (2,2,6,6-tetramethylpiperidine-N-oxyl) served to suppress the β-azidonation pathway in favor of α-bis-azidonation. The α-azidonation process has wide substrate scope and, in most cases, proceeds with high stereoselectivity (Scheme 67).

Scheme 66.

Temperature dependent reactivity of TIPS enol ethers with (PhIO)2/Me3SiN3 and substrate scope of bis-azidonation.

Scheme 67.

Proposed mechanism of enol ether bis-azidonation.

The mechanisms of these divergent transformations have been studied in detail and while β-azidonation is thought to involve ionic dehydrogenation at the β-position and capture of the resulting enonium ion by azide, α-azidonation is an azide radical addition process (Scheme 67).195 Magnus has proposed that at low temperature, reaction between 265 and trimethylsilyl azide generates aryl-λ3-iodane 266 which is captured by TEMPO to form iodine(VI) species 272. Homolytic cleavage of 272 generates an azidyl radical, which then participates in the addition process to yield 271a by way of radical intermediate 274.

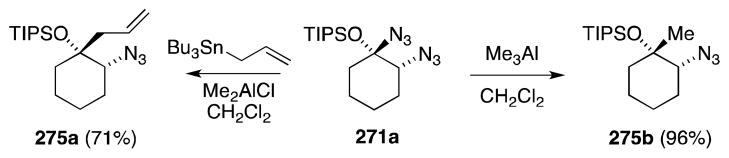

Although unsuitable precursors for the preparation of free 1,2-diamines, the α-bis-azidonation products shown in Scheme 67 undergo, with the aid of aluminum-based Lewis acids, substitution with a range of carbon nucleophiles to provide O-protected 1,2-azidoalcohols 275a and 275b (Scheme 68). Trapping of the intermediate onium ion in the case of bis-azide 271a proceeds with excellent diastereoselectivity.

Scheme 68.

Lewis acid-mediated reaction of bis-azide 271a with carbon nucleophiles.

Magnus has also employed the PhIO/Me3SiN3 reagent combination for the preparation of diamino pyrans (Scheme 69).196 For example, treatment of dihydropyran (276, R = H) provided trans-bis-azide 277a while bis-azidonation of unsaturated carbamate 276 (R = NHCO2Ad) proceeded with complete diastereoselectivity to yield 1,2-diaxial bis-azide 277b.

Scheme 69.

Bis-azidonation of glycals using the reagent combination PhIO/Me3SiN3.

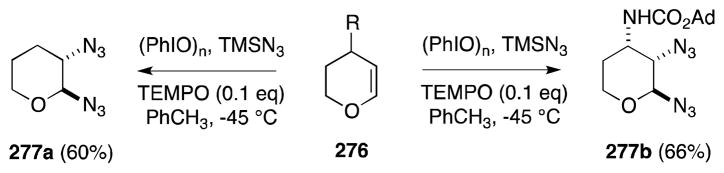

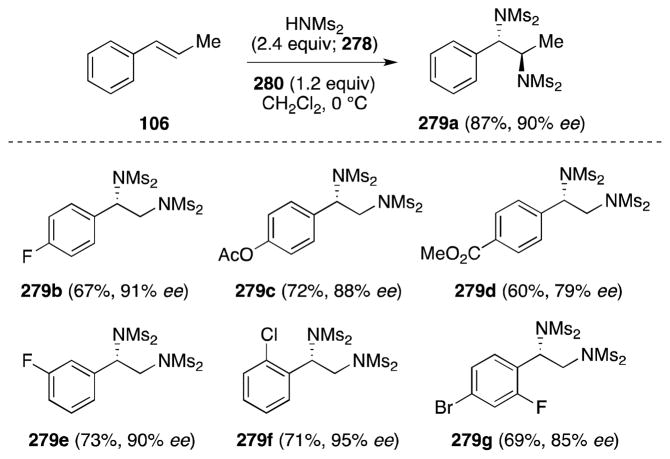

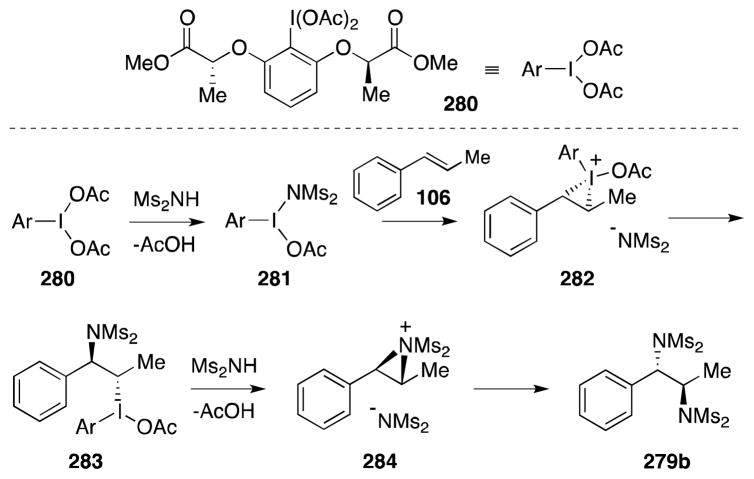

In 2011, Muñiz and co-workers reported a breakthrough method for the iodine(III)-mediated intermolecular enantioselective diamination of styrenes (Scheme 70).197 This method is not only notable in that it is metal-free and practical, requiring only two components, but is the first example of intermolecular, enantioselective alkene diamination. Employing Ishihara’s C2-symmetric chiral iodane 280 (Scheme 71)198 and bismesylide (278) as the nitrogen source, alkenes underwent addition to form diamines 279 with good yields and high asymmetric induction. In all but a few cases, the crystallinity imparted by the bissulfonyl groups facilitates purification of these products to enantiomeric purity by a single recrystallization.

Scheme 70.

Enantioselective, intermolecular diamination of styrenes under metal-free conditions.

Scheme 71.

Structure of Ishihara’s C2-symmetric chiral iodane 280 and proposed mechanism for the enantioselective alkene diamination mediated by this reagent.

Muñiz has proposed a tentative mechanistic rationale for this transformation, in which 279 undergoes ligand exchange with 280 to generate unstable aryl-λ3-iodane 281 (Scheme 71). Reaction between 281 and the alkene then generates anti addition product 283 by way of iodonium ion 282. Ionization and formation of aziridinium ion 284 then precedes ring opening at the benzylic position to yield the observed product. The intermediacy of an aziridinium ion was invoked in order to rationalize the formation of the anti diamine product in the case of trans-β-methylstyrene (106).

As shown in Scheme 72, this methodology has been successfully applied to the preparation of the immunomodulator and veterinary anthelmintic (S)-levamisole (289). Removal of the four methanesulfonyl groups from styrene adduct 286 was accomplished in a four step sequence involving hydride reduction to bis-mono protected 287, N-benzoylation, radical N-desulfonylation under Parson’s conditions199 and acidic hydrolysis. After neutralization of salt 288, the free diamine was converted to target 289 by way of the corresponding mercaptoimidazoline.200

Scheme 72.

Muñiz’s enantioselective synthesis of the anthelmintic (S)-levamisole.

11. Transition Metal-Catalyzed Diamination

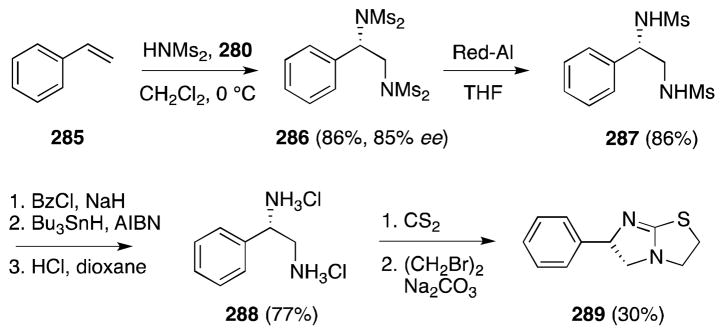

While non-radical, transition metal-mediated alkene diamination processes have been known since the early 1970s it is only in the last decade that the value of this approach has begun to be realized in earnest. Two general mechanistic pathways by which transition metal complexes can mediate alkene diamination can be envisioned (Scheme 73).201

Scheme 73.

General mechanistic pathways leading to the transition metal-mediated diamination of alkenes.

In the more classical manner, formation of a metal-alkene π complex precedes insertion, which generates a metal-alkyl species. Reductive elimination of this intermediate or nucleophilic displacement of the metal center then gives rise to the diamination product (eq. 1). Alternatively, metal complexes can undergo a ligand-based cis-addition reaction in which both carbon-nitrogen bonds are simultaneously generated (eq. 2).202 Although of this latter process also forms the basis of the catalytic, osmium(VIII)-mediated dihydroxylation and aminohydroxylation of alkenes and thus firmly established in the canon of organic synthesis,203 the preparation of diamines through this approach has proven to be considerably more challenging.

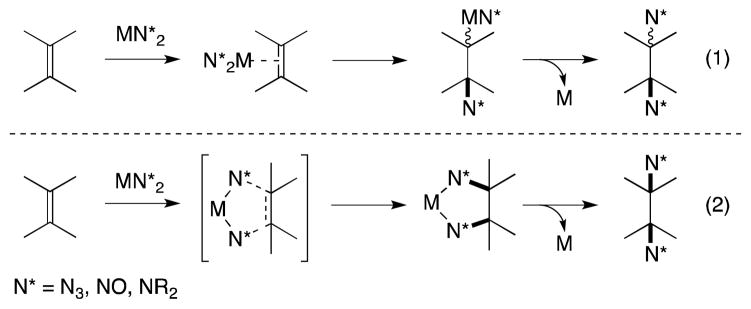

11.1. Metal Nitrosyl Complexes

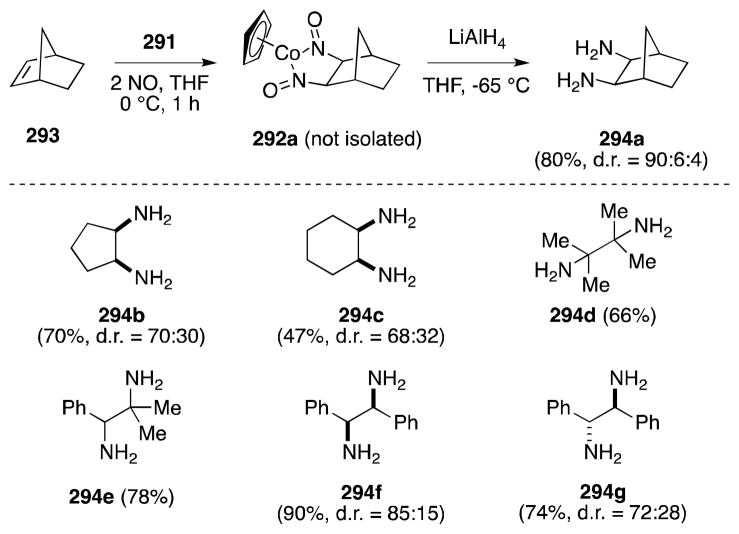

Brunner and Loskot first reported the ligand-based reaction of cobalt nitrosyl complex 291 with bicyclo[2.2.1]hep-2-enes in 1971.204 Generated from the reaction of cyclopentadienylcobalt dicarbonyl (290) and nitric oxide (NO) in hexanes,205 air-stable 291 undergoes addition to strained alkenes to form dinitrosoalkane complexes 292 (Scheme 74). This process is both diastereoselective; only the exo complexes are formed; and regioselective; in the case of dienes, i.e. in the case of 292, addition takes place only at the electron-rich alkene partner. Detailed mechanistic studies conducted by Bergman have subsequently revealed that the addition process proceeds through the intermediacy of CpCo(NO)2, which is generated by the reaction of NO with 291.206

Scheme 74.

Generation of cyclopentadienylnitrosylcobalt dimer and its reaction with strained alkenes.

Brunner’s early observations were subsequently developed by Bergman and co-workers, who employed this transformation as a method for the direct 1,2-diamination of alkenes (Scheme 75).207 In this case, in-situ reduction of the dinitrosoalkane ligands with LiAlH4 generates the corresponding 1,2-diamines 294 in fair to excellent yield. Notably, Bergman found that the reaction of 291 is not restricted to norbornyl systems and indeed undergoes stereospecific addition to a range of di-, tri- and tetra-substituted aliphatic alkenes. Unfortunately, despite the stereospecificity of the initial addition step, epimerization occurs to varying degrees during ligand reduction and mixtures of diamine isomers are obtained.

Scheme 75.

Two-step, one-pot 1,2-diamination of alkenes using cyclopentadienylnitrosylcobalt dimer/NO/LiAlH4.

Taking advantage of the ability of dinitrosyl cobalt complexes to undergo reversible exchange with alkenes and the reactivity of the dinitrosoalkane ligand system itself, Toste and Bergman have more recently employed cobalt nitrosoalkane adducts as vinyl anion equivalents for the C-H functionalization of alkenes208 and dienes.209 With regard to alkene diamination, a remarkable application of their strategy to the preparation of the polycyclic 1,2-diamine 300 is shown in Scheme 76.210

Scheme 76.

Cobalt-mediated [3+2]-annulation of alkenes with α,β-unsaturated ketones.

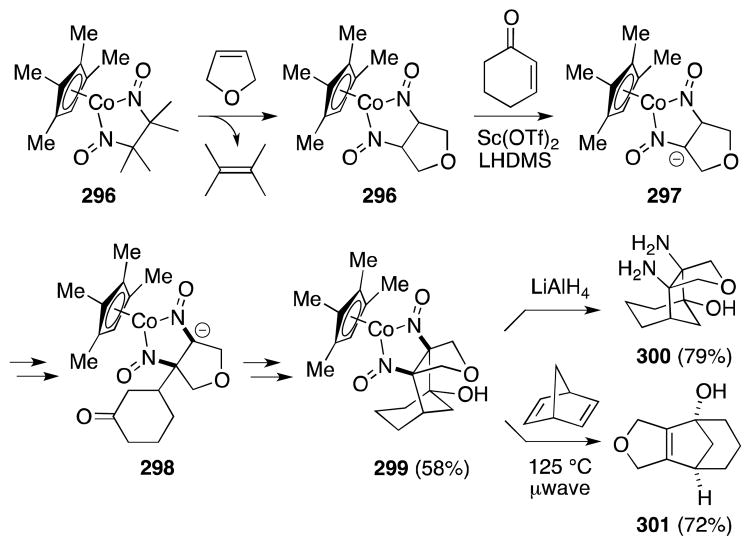

Most recently, Bergman and Toste have reported the first example of ruthenium-mediated alkene bis-nitrosylation (Scheme 77).211 Efficiently generated by the action of nitric oxide on [RuCl2(NO2)2(THF)2] (302), dinitrosyl complex 303 was found to undergo reaction with strained and tetrasubstituted alkenes in the presence of chelating ligands to form six-coordinate dinitrosoalkane complexes 304.

Scheme 77.

Reaction of alkenes with the dinitrosyl complex [RuCl2(NO)2(THF)].

In the case of 1,1-disubstituted and 1,1,2-trisubstituted alkenes addition is accompanied by tautomerization and complexes containing a nitrosoalkane and oxime functional group were isolated. In the case of 1-methylcyclohexene, reaction with 303 leads to the formation of compound 304d.

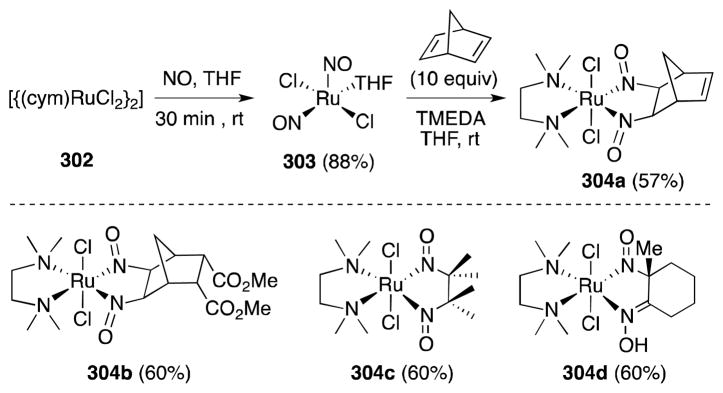

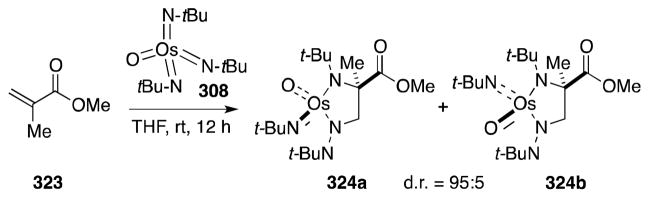

11.2. Imido-osmium(VIII) Reagents

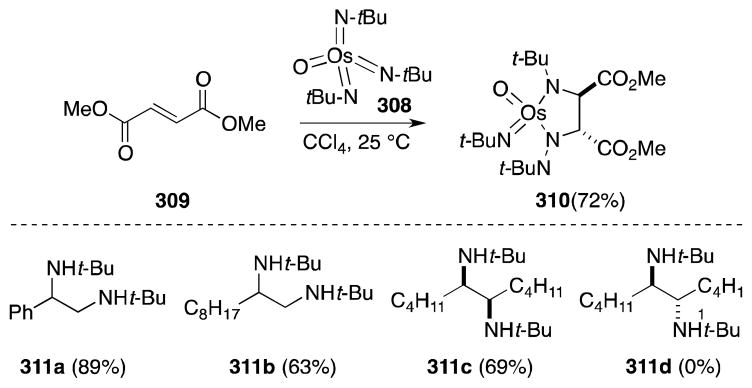

Although first prepared in 1959,212 that imidoosmium(VIII) complexes undergo reaction with alkenes to form 1,2-diamines was not reported until 1977.213 These air and moisture-stable reagents are readily prepared by the condensation of amines, or their equivalents, with osmium tetroxide (305) (Scheme 78).214 In the case of N-trimethylsilyl-tert-butylamine, condensation proceeds to generate a mixture of compounds 306–308, which can be chromatographically separated.

Scheme 78.

Preparation of imido-osmium(VIII) complexes from osmium tetroxide.

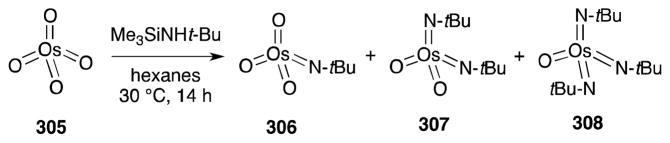

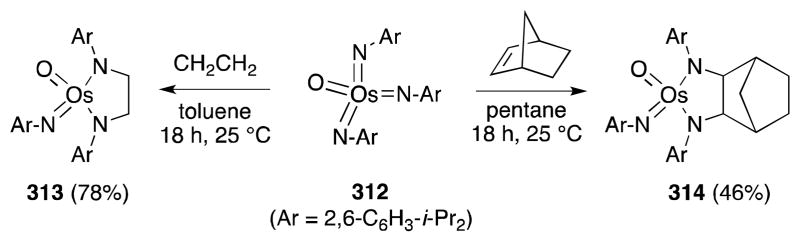

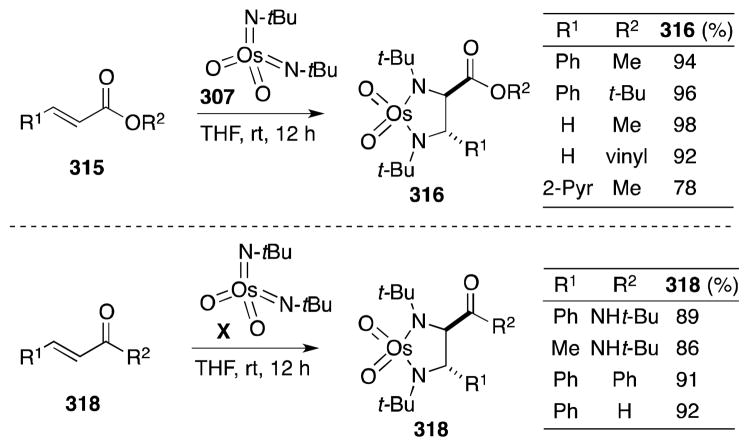

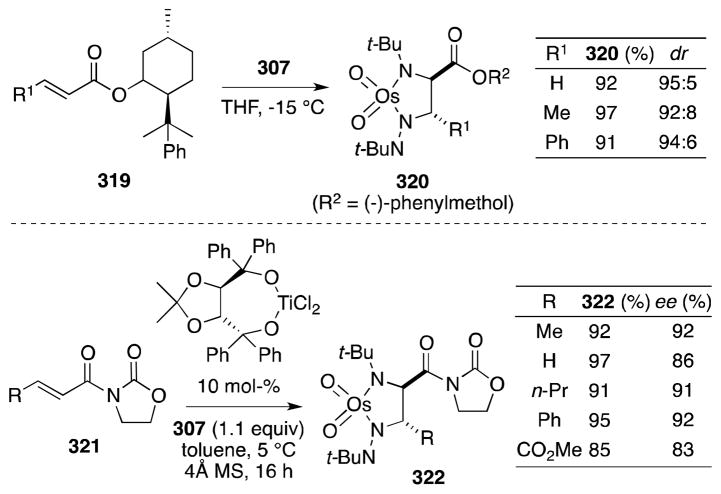

Sharpless and co-workers were first to report the reaction of bis(tert-butylimido)osmium (307) and tris(tert-butylimido)osmium (308) with terminal and trans-disubstituted alkenes (Scheme 79).215 In all cases, addition took place in stereospecific and chemoselective fashion to form diimido complexes. In contrast to osmate(VI) esters, osmaimidazolidines display remarkable stability,216 although can be reduced to the corresponding 1,2-di-tert-butylamines 311 with LiAlH4. Regarding substrate reactivity, cis-disubstituted and trisubstituted alkenes react slowly with 307 and 308 while introduction of electron-withdrawing groups, as in the case of fumarate 309, increases the rate of addition. This reactivity reflects the increased nucleophilicity of the imido complexes in comparison with OsO4.217

Scheme 79.

Stoichiometric diamination of alkenes with oxotris(tert-butylimido)osmium(VIII)/LiAlH4.

The stoichiometric reaction of trisimidoosmium complexes with alkenes has also been studied by Schrock and co-workers, who reported the reaction of aryl imido complex 312 with simple alkenes, including ethylene and norbornene (Scheme 80).218 Despite substantial steric encumbrance at the metal center of 312, formation of the metallaimidazolidines 313 and 314 occurred smoothly at room temperature. To date, this chemistry has not been employed in the preparation of free 1,2-diamines.

Scheme 80.

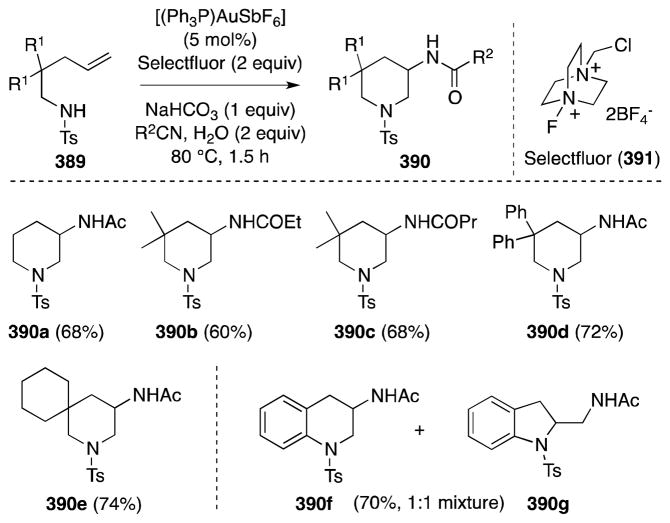

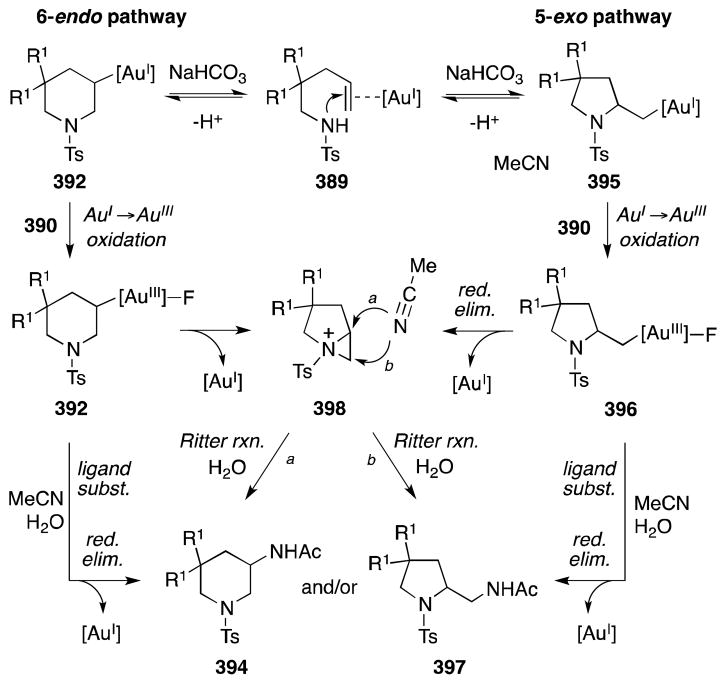

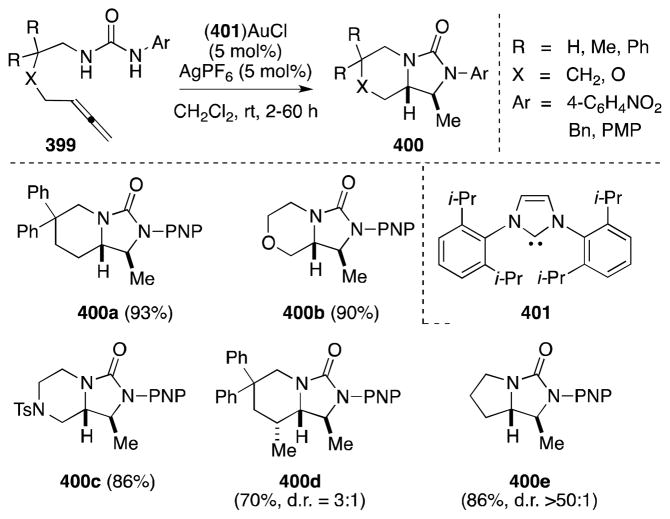

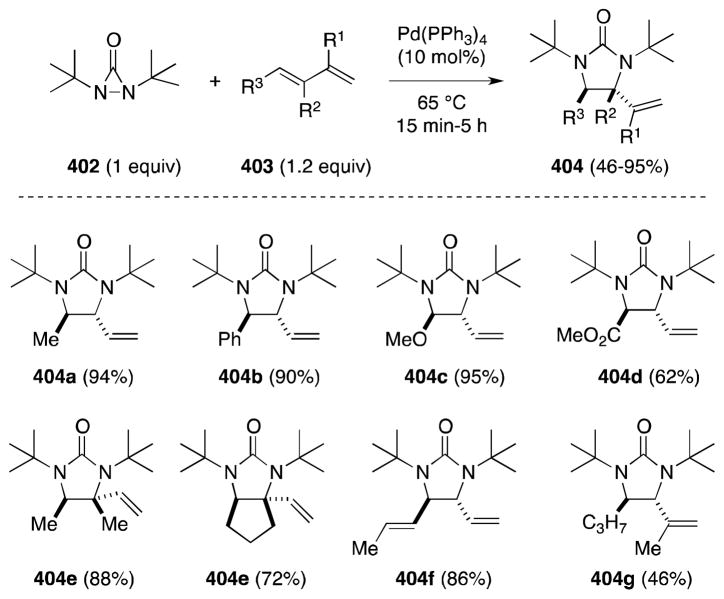

Stoichiometric diamination of alkenes with a sterically encumbered oxotris(arylimido)osmium(VIII) complex.