Abstract

An increase in the marginal discrepancy is seen after cementation with a luting agent and provision of cement space with a die-spacer is the most preferred method to avoid it. Recommended thickness of die-spacer is 25–40 μm. Smaller die-spacer thickness was consistently found at the axio-occlusal line angles as compared to the other surfaces which has been postulated to that the spacer paint tends to flow away from the sharp line angles and cusp tips as a result of increased surface tension. The absence of adequate relief spaces in these areas impedes the flow of cement beyond the occlusal portion of the casting, which would result in incomplete seating because of hydraulic pressure. Fifty stone dies were duplicated from a steel die and were divided into five groups of sample size 10, where the die-spacer was selectively placed. Measurements were taken at four points, 90° apart from each other with the help of optical microscope. Later all the castings were cemented using Glass Inomer cement as a luting agent, under a 10 kg static load and measurements were recorded. Statistical analysis showed samples with no spacer had the maximum pre and post cementation gap while the least discrepancy was seen in group with additional layer of die-spacer painted over the axio-occlusal line angle. The results were highly significant which clearly indicated the superiority of this group over others. Within limitations of the study, it can be said that application of additional layer of die-spacer at the axio-occlusal line angle will help in decreasing the post cementation marginal discrepancy in full cast metal crowns.

Keywords: Marginal discrepancy, Selective placement, Die-spacer, Frictional resistance, Hydrostatic force

Introduction

Importance of marginal integrity and its relation to the oral health and longevity of metal restorations have been proven. An increase in the discrepancy of marginal integrity is seen after cementation [1]. Two phenomena have been mainly attributed to this conundrum. First, while seating frictional resistance between the inner axial surface of the casting and the axial walls of the stone die. Second, it has been postulated that hydrodynamics during cementation of the crown may prevent complete seating of the crown.

Methods have been suggested to avoid this increase in post cementation marginal discrepancy. These include provision of cement space [2, 3], cement escape channels [4], venting [5], seating aid procedures such as vibratory techniques [5], dynamic loading [6] and limiting the amount and site of cement placement [7].

Provision of cement space or relief is the most preferred method. This relief can be provided by subtracting bulk of metal from the inner surface of the crown but these methods weaken the casting and are unreliable [8]. The additive method which involves application of die-spacer or tin foil is favoured. Campbell consistently found smaller die-spacer thickness at the axio-occlusal line angles as compared to the other surfaces [9]. Campagni et al. [10] postulated that the spacer paint tends to flow away from the sharp line angles and cusp tips as a result of increased surface tension. The absence of adequate relief spaces in these areas impedes the flow of cement beyond the occlusal portion of the casting, which would result in incomplete seating because of hydraulic pressure [11]. Thus a technique needs to be developed in order to prevent friction resistance and development of the hydraulic pressure during cementation.

Consequently, this study was undertaken with the aim of evaluating the effect of selective placement of additional die-spacer on the marginal discrepancy, pre and post cementation, in an in vitro environment.

Materials and Methods

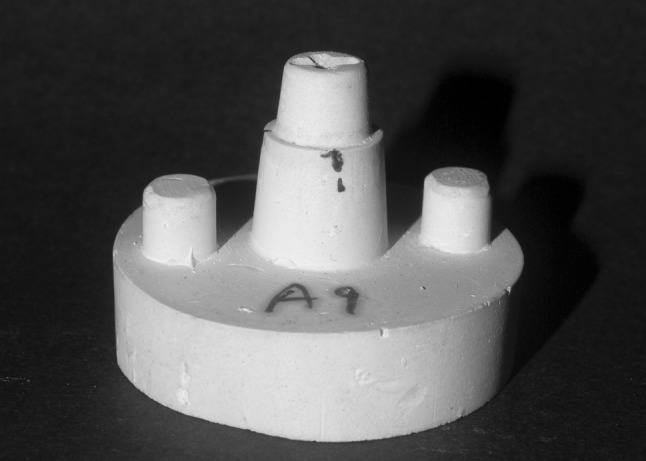

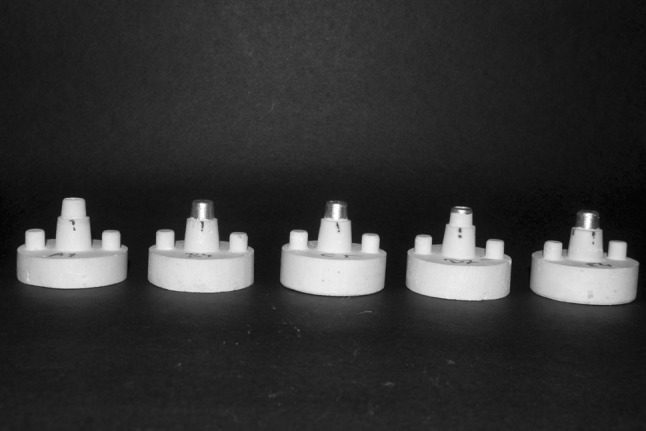

Fifty stone dies (Fig. 1) were duplicated from a steel die (Fig. 2) and were divided into five groups (Fig. 3) of sample size 10 (Table 1). In Group A no die-spacer was applied. In Group B two layers of die-spacer were applied all over and 0.5 mm away from the margin. In Group C two layers of die spacer were applied all over and 0.5 mm away from the margin and an additional single layer of die-spacer was applied on the axio-occlusal line angle. In Group D two layers of die-spacer were applied on the axio-occlusal line angle only. In Group E two layers of die-spacer were applied all over and 0.5 mm away from the margin and an additional layer was applied on the axial surface not involving the axio-occlusal line angle. A single layer of the die-spacer (Durolan, DFS, Germany) was of thickness 13 μm. Hence in areas of two layers the estimated thickness of die-spacer will be 26 μm and in areas of three layers 39 μm, which is still under the acceptable optimal thickness of 25–40 μm.

Table 2.

Comparison of overall pre-cementation and post-cementation marginal discrepancy among various groups

| Group | F value | P value | ||||||

|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | ||||

| Overall pre-cementation marginal discrepancy | Mean (μm) | 56.83 | 39.32 | 27.78 | 33.28 | 43 | 2.57 | <0.05 Significant |

| SD(μm) | ±30.98 | ±19.62 | ±15.62 | ±12.66 | ±24.83 | |||

| Overall post-cementation marginal discrepancy | Mean (μm) | 124.8 | 88 | 55.55 | 92 | 60.07 | 7.51 | <0.0001 Highly significant |

| SD(μm) | ±49.06 | ±22.64 | ±8.28 | ±38.28 | ±24.35 | |||

Fig. 1.

A duplicated stone die

Fig. 2.

Steel die

Fig. 3.

Division of dies in five study groups. Each study group consisted of 10 samples

Table 1.

Description of various groups

| Group | Representation |

|---|---|

| Group A | Control (no die-spacer used) |

| Group B | Double layer of die-spacer all over and 0.5 mm short of margins |

| Group C | Double layer of die-spacer all over and 0.5 mm short of margins with additional single layer on the occluso-axial line angle |

| Group D | A double layer of die-spacer only on the occluso-axial line angle |

| Group E | Double layer of die-spacer all over and 0.5 mm short of margins with additional single layer on the axial surfaces not involving the occluso-axial line angle |

Fifty wax patterns were fabricated with the help of an accurately fitting steel counter die, which was placed on the die stone replica of the master steel die. The dimensions of the counter die was 1 mm larger than the master die, which provided a uniform space for pouring of a low softening temperature wax, thereby providing uniform wax patterns. The patterns were marked according to the group they belonged to and the sample no. they were fabricated on.

In the present study, castings were fabricated using a base metal alloy (Blaze, Ni–Cr alloy, Uni-Globe Dent Inc, Japan) consisting of Ni 28 %, Cr 22 %, Molybdenum 3 %, Silica 4 % and Iron 42 %. Carefully, minimum sand blasting was done with 50 μm A12O3 particles under 30 psi pressure from approximately 5 cm distance [12, 13]. Castings were carefully inspected with magnifying lens and nodules if any were carefully removed. No other adjustments were made on the internal surfaces of the castings, as the adaptation of a casting can be increased by judicious adjustments done by the operator, leading to variables in the result.

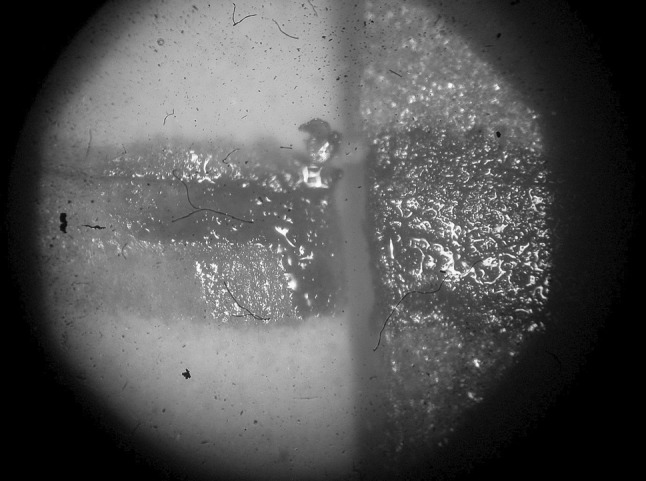

Measurements were taken at four points, 90 ° apart from each other with the help of optical microscope (Fig. 4). A single operator took all measurements and was blinded to the study. Later all the castings were cemented on the same die using Glass inomer cement as a luting agent, under a 10 kg static load. Measurements were again recorded as discussed earlier (Fig. 5).

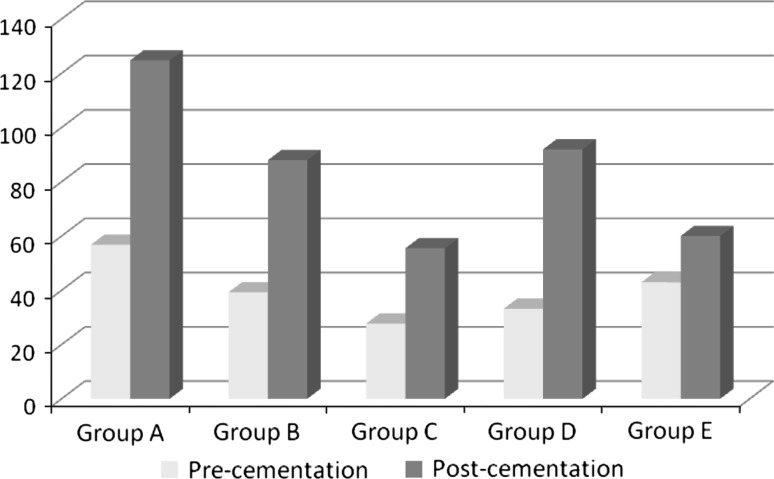

Graph 1.

Bar diagram showing comparison of overall pre and post-cementation marginal discrepancy (n = 10)

Fig. 4.

Microscopic view of marginal discrepancy: pre-cementation

Fig. 5.

Microscopic view of marginal discrepancy: post-cementation

The seating force during cementation also dictates the marginal discrepancy. A static load of 10 kg was used as suggested by Olivera and Satio [12] which allowed sufficient seating pressure and protected the margins of the stone die from any loss.

The recorded data was statistically analyzed and ANOVA was applied for comparison.

Results

The maximum overall pre-cementation mean marginal discrepancy was found in Group A (56.83 μm ± 30.98 SD) and minimum in Group C (27.78 μm ± 15.62 SD). The least Coefficient of Variation (CV) was seen in Group D. According to the ANOVA the “F value” was calculated out to be 2.57 which was statistically significant (< 0.05). In overall comparison among the groups, the Group C showed minimum pre-cementation marginal discrepancy.

Post-cementation marginal discrepancy was again tested at same four points and results were noted. Maximum overall post-cementation mean marginal discrepancy was found in Group A (56.83 μm ± 30.98 SD) and minimum in Group C (55.55 μm ± 8.28 SD). Least CV was seen in Group C. According to the ANOVA the “F value” was calculated out to be 7.51 which was statistically highly significant (P < 0.0001). Consistently at all the four points post cementation maximum mean marginal discrepancy was seen in Group A. Least post cementation mean marginal discrepancy at each point of observation and overall was seen in Group C.

Comparison of coefficient of variation (CV) also reveals that group C showed minimum variation at three point of measurement out of four and in over all comparison Group C had the least coefficient of variation. This again signifies the superiority of Group C over other groups.

An intra-group comparison also reveals that there has been increase in marginal discrepancy post cementation in all the groups.

Discussion

Difference in marginal gap has been seen, and proven microscopically, before and after cementation with a luting agent. Two phenomena have been mainly thought as the reasons behind this post-cementation marginal opening. Resistance to seating leading to marginal discrepancy can be due to non uniform casting distortion, binding causing frictional resistance along the axial wall was much more frequent than in other areas. The degree of binding seemed to correlate directly to the magnitude of post cementation margin opening. Eames et al. [1] have called this as “rebound phenomena” that allows the crown to be forced off the preparation because of internal pressure resulting from discrepancies against dentine and from casting distortion. However, this may not be true in actual clinical situation where a loss of accuracy can be expected during the impression, die making stages, wax pattern fabrication, casting and finishing polishing of the crown.

Hydrodynamics during cementation also play a vital role. The hydrodynamic resistance or the hydrostatic force generated during the cementation of full coverage restorations has caused problems in clinical dentistry. Tjan et al. [13] showed in their study that grooves used with complete crown preparation significantly inhibit the seating of castings, presumably by acting as small hydraulic cylinders during cementation process. These forces have left clinicians with inadequately seated castings resulting in open margins, cement washout, disrupted occlusion and potential clinical failures [4, 12].

The post-cementation marginal openings were generally considerably higher than the arithmetic sum of the film thickness according to ADA Specification no. 8 and the pre-cementation marginal openings. Therefore all logical precautions that minimize the film thickness and marginal opening should be considered [15].

The most important factor in reducing the marginal discrepancy remains provision of cement space. Pascoe demonstrated geometrically that the oversized castings could give a better adapted margin upon cementation than undersized castings. This was thought to be due to casting irregularities which prevented seating and did not allow space for the cement. The geometry demonstrated that any surface of a preparation which is more vertical than the margin will prevent the crown form seating optimally unless additional space is supplied for the cement film [16]. According to Hollenback a minimum of 25 μm relief on axial walls of casting is necessary or the cast crown may fail to seat by approximately 100 μm [17]. Many techniques have been suggested for providing this relief space and they can be broadly categorized as subtractive method and additive method [11].

Subtractive methods involve bulk reduction of metal from internal surface of the casting and include (1) internal carving of wax patterns before casting (2) internal grinding of castings (3) aqua regia etching and (4) electrochemical milling [8]. Such a method of relief is unreliable and undesirable as the advantage of cast crown is reduced by irregular loss of bulk [12].

The additive method involves application of die-spacer onto the stone die or use of tin foil. Die-spacer allow increased space for the cement between the tooth surface and internal surface of the casting, facilitates distribution of cement with minimal friction resistance or filtration along the axial walls; thereby resulting in a better fit [12, 17]. Retention of the final restoration also improves with the use of die-spacer. On a retentive scale, the die-spaced castings proved 25 % more retentive than the unrelieved castings, although contrasting results have also been reported [2, 18–20].

The popularity of this technique has been attributed to its simplicity, convenience and cost effectiveness [20]. Die-spacer consists of metal-oxide powders and adhesives dispensed in an organic liquid such as ketone. This is painted onto the stone die before the fabrication of the wax pattern. An optimal thickness of 25–40 μm is generally specified to facilitate complete seating of the castings and to allow for the film thickness of the cement [10, 21, 22].

Conventionally, the die-spacer is applied evenly all over the die and placed 0.5–1 mm from the die-margin [10, 14, 22].The film thickness of the paint—on die-spacer recorded was found to vary according to the surface area of the die to which it was applied [8]. Campbell consistently found smaller die-spacer thickness at the occluso-axial line angles as compared to the other surfaces [9]. Campagni et al. [10] postulated that the spacer paint tends to flow away from the sharp line angles and cusp tips as a result of increased surface tension. The absence of adequate relief spaces in these areas impedes the flow of cement beyond the occlusal portion of the casting, which would result in incomplete seating because of hydraulic pressure [14].

In this study, of the four points used for measurement at three points, Group A showed maximum mean pre-cementation marginal discrepancy at three points and in over all comparison. This is probably because of the binding of the castings to the axial walls causing friction resistance and incomplete seating as suggested by Hager et al. [11] and Eames et al. [2].

In overall comparison among the groups, the Group C showed minimum pre-cementation marginal discrepancy which is in accordance with the results found Eames et al. [2] and Fusayama et al. [23]. Application of die-spacer causes formation of castings with relief space for the cements, consequently there is no binding or friction resistance.

Following the first set of measurements the castings were luted on to the respective stone dies with Glass Inomer Cement (Type I, GC Corporation). The mixed cement was rapidly coated inside the crown with a brush [7].

The seating force during cementation also dictates the marginal discrepancy. A static load of 10 kg was used as suggested by Olivera and Satio [12] which allowed sufficient seating pressure and protected the margins of the stone die from any loss.

The static load was applied for a period of 5 min. This exceeded the GIC setting time by 30 s (as given by the manufacturer) to ensure complete setting of the luting agent before the load is removed, preventing any chance of rebound.

Post-cementation, consistently at all the four points maximum mean marginal discrepancy was seen in Group A which is in accordance with the result of studies conducted by various authors [2, 11, 13]. This increased discrepancy is seen probably because of friction resistance and development of hydrostatic pressure below the castings in the occlusal area. This was also seen indirectly in form of cement film thickness greatly exceeding the recommended film thickness for most cement.

Least post cementation mean marginal discrepancy at each point of observation and overall was seen in Group C which is in all probability due to extra space provided by additional layer of die-spacer at the axio-occlusal line angle preventing the formation of hydrostatic forces. Hager and Gardner [11] also found improved seating of castings if additional layers are applied over the axio-occlusal line angles but, they found this improvement to be statistically insignificant. In the present study improvement has been found to be statistically highly significant probably due to improvement in casting procedures and luting agents since then.

Comparison of coefficient of variation (CV) also reveals that group C showed minimum variation at three point of measurement out of four and in over all comparison Group C had the least coefficient of variation. This again signifies the superiority of Group C over other groups.

An intra-group comparison also reveals that there has been increase in marginal discrepancy post cementation in all the groups owing to reasons discussed earlier. In Group E this increase in marginal discrepancy is statistically significant while in all other groups it is statistically highly significant.

Thus in a clinical situation, application of additional layer of die-spacer may actually result in decreased marginal discrepancy, provided all other factors are controlled. Method of application of additional layer along with conventional application of die-spacer will prove to be very easy, effective and cost efficient in providing longevity to the cast crown restorations.

Conclusion

Based on the result, within the limitation of the study it can be concluded that there is a definite increase in marginal discrepancy post cementation. Placement of additional single layer of die-spacer on the axio-occlusal line angle is most likely to reduce the pre and post-cementation marginal gap seen. This in all probability is due to better hydrodynamics during cementation as well as prevention of axial binding.

References

- 1.White SN, Kipnis V. Effect of adhesive luting agents on the marginal seating of cast restorations. J Prosthet Dent. 1993;69:28–31. doi: 10.1016/0022-3913(93)90235-G. [DOI] [PubMed] [Google Scholar]

- 2.Eames WB, O’Neal SJ, Monteiro J, Miller C, Roan JD, Jr, Cohen KS. Techniques to improve the seating of castings. J Am Dent Assoc. 1978;96:432–437. doi: 10.14219/jada.archive.1978.0090. [DOI] [PubMed] [Google Scholar]

- 3.Grajower R, Zuberi Y, Lewinstein I. Improving the fit of crowns with die-spacers. J Prosthet Dent. 1989;61:555–563. doi: 10.1016/0022-3913(89)90275-8. [DOI] [PubMed] [Google Scholar]

- 4.Webb EL, Murray HV, Holland GA, Taylor DF. Effects of preparation relief and flow channels on seating full coverage castings during cementation. J Prosthet Dent. 1983;49:777–780. doi: 10.1016/0022-3913(83)90347-5. [DOI] [PubMed] [Google Scholar]

- 5.Nortwick WT, Gettleman L. Effect of internal relief, vibration, and venting on the vertical seating of cemented crowns. J Prosthet Dent. 1981;45(4):395–399. doi: 10.1016/0022-3913(81)90099-8. [DOI] [PubMed] [Google Scholar]

- 6.Gegauff AG, Rosenstiel SF. Reassessment of die-spacer with dynamic loading during cementation. J Prosthet Dent. 1989;61(6):655–658. doi: 10.1016/S0022-3913(89)80036-8. [DOI] [PubMed] [Google Scholar]

- 7.Ishikiriama A, Oliveira JDF, Vieira DF, Mondelli J. Influence of some factors on the fit of cemented crowns. J Prosthet Dent. 1981;45(4):400–404. doi: 10.1016/0022-3913(81)90100-1. [DOI] [PubMed] [Google Scholar]

- 8.Hollenback GM. A practical contribution to the standardization of casting technique. J Am Dent Assoc. 1928;10:5. [Google Scholar]

- 9.Oliva RA, Lowe JA, Ozaki MM. Film thickness measurements of a paint-on die-spacer. J Prosthet Dent. 1988;60(2):180–184. doi: 10.1016/0022-3913(88)90312-5. [DOI] [PubMed] [Google Scholar]

- 10.Campagni WD, Preston JD, Reisbick MH. Measurement of paint-on die-spacers used for casting relief. J Prosthet Dent. 1982;47:606–611. doi: 10.1016/0022-3913(82)90132-9. [DOI] [PubMed] [Google Scholar]

- 11.Hager TS, Gardner FM, Edge MJ. The effect of selective die-spacer placement techniques on seatability of casting. J Prosthodont. 1993;2(1):56–60. doi: 10.1111/j.1532-849X.1993.tb00382.x. [DOI] [PubMed] [Google Scholar]

- 12.Olivera AB, Saito T. The effect of die-spacer on retention and fitting of complete cast crowns. J Prosthodont. 2006;15(4):243–249. doi: 10.1111/j.1532-849X.2006.00113.x. [DOI] [PubMed] [Google Scholar]

- 13.Tjan AHL, Sarkissian R, Miller GD. Effect of multiple axial grooves on the marginal adaptation of full cast-gold crowns. J Prosthet Dent. 1981;46:399. doi: 10.1016/0022-3913(81)90445-5. [DOI] [PubMed] [Google Scholar]

- 14.Wilson PR, Goodkind RJ, Delong R, Sakaguchi R. Deformation of crowns during cementation. J Prosthet Dent. 1990;64:601–609. doi: 10.1016/0022-3913(90)90136-Z. [DOI] [PubMed] [Google Scholar]

- 15.White SN, Kipnis V. Effect of adhesive luting agents on the marginal seating of cast restorations. J Prosthet Dent. 1993;69:28–31. doi: 10.1016/0022-3913(93)90235-G. [DOI] [PubMed] [Google Scholar]

- 16.Pascoe DF. Analysis of the geometry of finishing lines for full crown restorations. J Prosthet Dent. 1978;40:157. doi: 10.1016/0022-3913(78)90008-2. [DOI] [PubMed] [Google Scholar]

- 17.Pilo R, Cardash HS, Bharav H, Helft M. Incomplete seating of cemented crowns: a literature review. J Prosthet Dent. 1988;59(4):429. doi: 10.1016/0022-3913(88)90037-6. [DOI] [PubMed] [Google Scholar]

- 18.Passon C, Lambert RH, Lambert RL, Newman S. The effect of multiple layers of die-spacer on crown retention. Oper Dent. 1992;17:42–49. [PubMed] [Google Scholar]

- 19.Hemnbreee JH, Cooper EW. Effect of die-relief on retention of cast crowns and inlays. Oper Dent. 1979;4:104–107. [PubMed] [Google Scholar]

- 20.Carter SM, Wilson PR. The effect of die-spacing on post cementation crown elevation and retention. Aust Dent J. 1997;42(3):192–198. doi: 10.1111/j.1834-7819.1997.tb00121.x. [DOI] [PubMed] [Google Scholar]

- 21.Donovan T, Wright W, Campagni WV. Use of paint-on die-spacers in preparations with grooves. J Prosthet Dent. 1984;52(3):384–388. doi: 10.1016/0022-3913(84)90450-5. [DOI] [PubMed] [Google Scholar]

- 22.Bottino MA, Valandro LF, Buso L. The influence of cervical finish line, internal relief and cement type on cervical adaptation of metal crowns. Quintessence Int. 2007;38(7):E425–E432. [PubMed] [Google Scholar]

- 23.Fusayam T, Ide K, Hosaoda H. Relief of resistance of cement of full cast crowns. J Prosthet Dent. 1964;14:95–106. doi: 10.1016/0022-3913(64)90124-6. [DOI] [Google Scholar]