Abstract

Objectives

The objectives of this study were to determine the psychological fatigue and analyze muscle activity of production workers who are performing processes jobs while standing for prolonged time periods.

Methods

The psychological fatigue experienced by the workers was obtained through questionnaire surveys. Meanwhile, muscle activity has been analyzed using surface electromyography (sEMG) measurement. Lower extremities muscles include: erector spinae, tibialis anterior, and gastrocnemius were concurrently measured for more than five hours of standing. Twenty male production workers in a metal stamping company participated as subjects in this study. The subjects were required to undergo questionnaire surveys and sEMG measurement.

Results

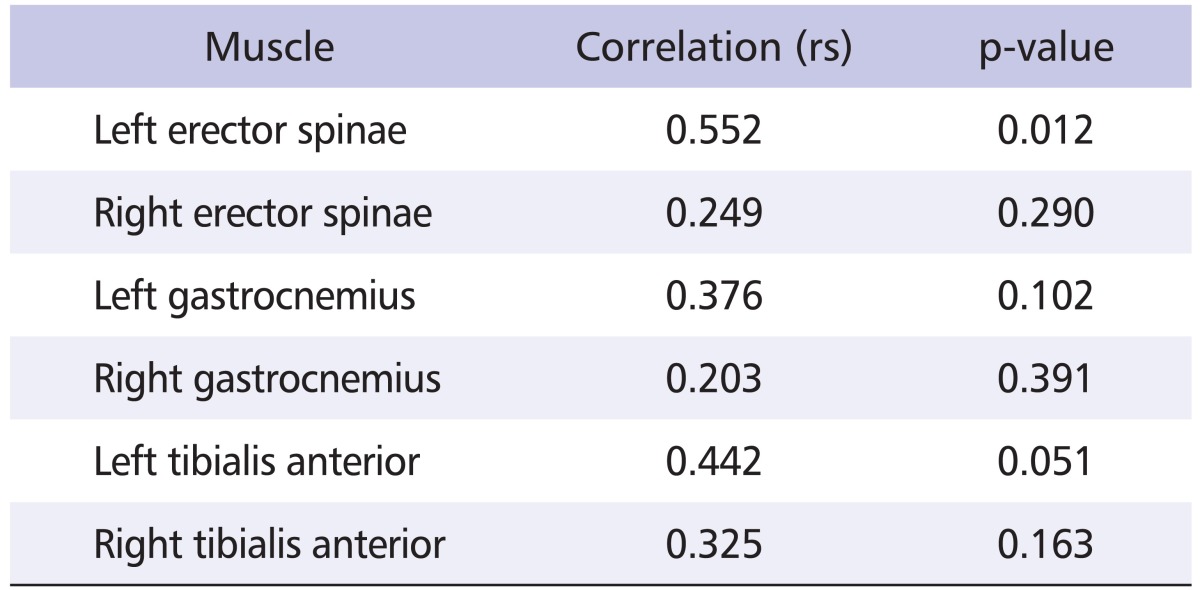

Results of the questionnaire surveys found that all subjects experienced psychological fatigue due to prolonged standing jobs. Similarly, muscle fatigue has been identified through sEMG measurement. Based on the non-parametric statistical test using the Spearman's rank order correlation, the left erector spinae obtained a moderate positive correlation and statistically significant (rs = 0.552, p < 0.05) between the results of questionnaire surveys and sEMG measurement.

Conclusion

Based on this study, the authors concluded that prolonged standing was contributed to psychological fatigue and to muscle fatigue among the production workers.

Keywords: Prolonged standing, Muscle fatigue, Questionnaire survey, Surface electromyography, Metal stamping industry

Introduction

Today, the world population is estimated about 6.9 billion, with 3.1 billion number of workers [1] working in more than 55 major industrial sectors [2]. While providing job opportunities, a large number of workplaces in the industrial sectors may lead to occupational injuries if there is no awareness or concern regarding occupational health and safety. According to United States Bureau of Labour Statistics, in 2008, there were 3.7 million cases of non-fatal occupational injuries and 5,214 cases of fatal occupational injuries among industrial workers in United States [3]. In addition, occupational injuries have an effect on direct medical costs and indirect losses in wages and productivity. As an example the total cost of fatal and non-fatal occupational injuries were estimated at USD 11.5 billion in 2002 in the construction industry alone [4].

In industrial workplaces, several risk factors associated with occupational injuries have been identified, among them is prolonged standing. Usually, many process jobs at workstations require workers to perform in the standing position. Standing is a practical working position when the workers are handling heavy equipment and products, reaching materials and goods, and pushing and pulling excessive loads, because the processes require frequent movements and large degree of freedom. When the processes jobs are not suitable and nearly impossible to perform in the sitting position, the workers have to stand throughout their working hours.

A previous study defined worker exposure to prolonged standing as spending over 50% of total working hours during a full work shift in the standing position [5]. Prolonged standing in the workplace can cause discomfort and muscle fatigue especially in the lower extremities of workers by the end of the workday. Discomfort or subjective fatigue can be linked to psychological fatigue and it has been recognized as a factor in the decline of alertness, mental concentration, and motivation [6]. Usually, the psychological fatigue due to prolonged standing can be assessed subjectively through questionnaire surveys [7], use of the Borg Scale [8], use of the Body Part Symptom Survey form [9], or use of the Visual Analogue Scale [10]. Muscle fatigue on the other hand can be identified technically by observing the changes in amplitude and frequency of electromyogram (EMG) signals over time [11]. When signal amplitude increases and power spectrum shifts to a lower frequency, it indicates that the assessed muscles are in a condition of fatigue [12-14]. As recognized by many research works, surface electromyography (sEMG) is one of the reliable techniques that can be used to evaluate muscle fatigue [9,11,15-23].

Furthermore, an insufficient rest period during periods of standing coupled with improper designs in footwear and of the workstation, not only lead to discomfort and muscle fatigue, but can even cause occupational injuries in the long term. In a worst case scenario, the effects of prolonged standing may result in performance decrement, such as low productivity and efficiency, increased medical costs, and demoralized workers. For example, when a worker is experiencing injuries or discomfort due to prolonged standing, the conditions may bother him or her to perform their job efficiently. In addition, workers who suffered from occupational injuries must be referred to clinical experts for health treatment, which definitely involved a substantial amount of consultancy and medication costs. If the injuries are not recovered from in a short time, the employer has to find someone to replace the injured worker. The employer incurs further costs, searching for and training a new worker for the same position. Additional costs may be incurred if the new employee is incompetent for the position.

The chain of this cause-effect provides a strong argument to justify the studies in prolonged standing is significant to workers, industry owners, and to the national economy as a whole. In recognizing the importance of managing jobs that require prolonged standing, this study was performed. The initial objective of this study was to determine the psychological fatigue experienced by the workers due to performing process jobs that require prolonged standing. Concurrently, this study performed analysis on muscle fatigue in the left and right erector spinae (lower back), left and right tibialis anterior (anterior legs), and left and right gastrocnemius (posterior legs) of workers when they are performing process jobs during prolonged standing.

Materials and Methods

This study has performed 2 major tasks; determine the psychological fatigue experienced by the production workers regarding performing processes jobs in prolonged standing; and measure and analyze the muscle activity of workers performing process jobs in prolonged standing.

Determination of psychological fatigue

Psychological fatigue was determined through questionnaire surveys. In the questionnaire, the workers are required to fill up the personal information addressing employee number, age, gender, working experience, body mass, body height, name of work department, job description, and working schedule. In addition, the questionnaire surveys were performed to investigate the level of psychological fatigue experienced by the workers while performing process jobs with prolonged standing. The question was:

Do you feel any fatigue in the following body parts during working hours?

Please specify the level of fatigue by selecting the provided scales.

0: No fatigue

1: Little fatigue

2: Moderate fatigue

3: Very fatigue

4: Extreme fatigue

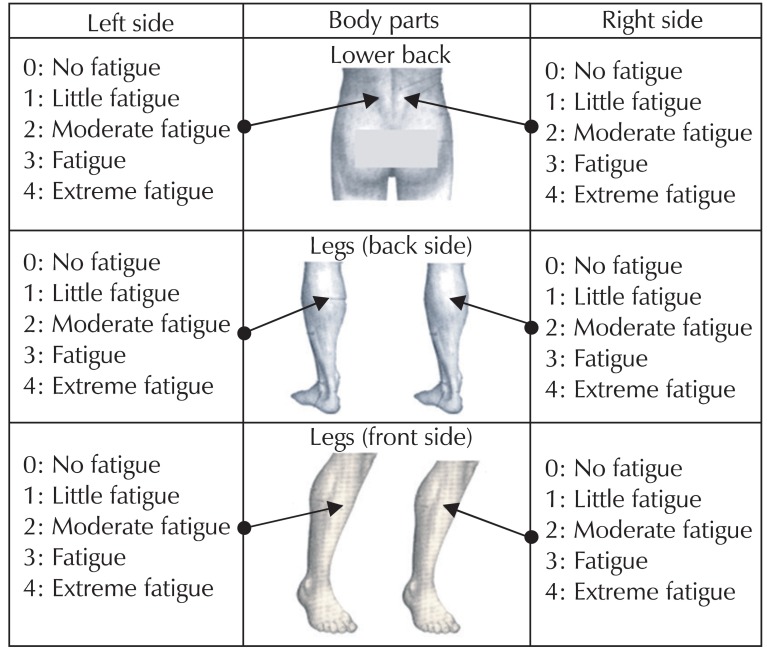

The question is attached with pictures of the lower back, posterior legs, and anterior legs (Fig. 1) to assist the workers to identify the body parts that are fatigued. In addition, answers regarding level of fatigue could be given on a Likert scale from 0 to 4, and was adopted from ISO 20646 [24].

Fig. 1.

Questions on levels of fatigue in the lower back, posterior legs, and anterior legs.

Analysis of workers' muscle activity

The following sections provide the procedures and methods of applying sEMG to determine the muscle fatigue and time-to-fatigue experienced by workers in positions that required prolonged standing.

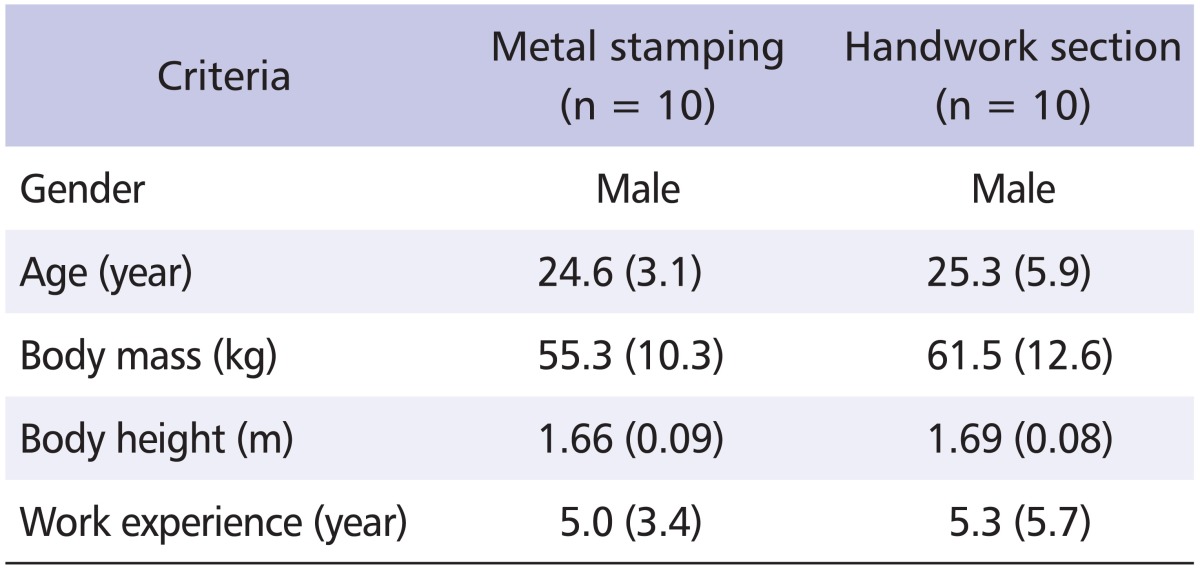

Twenty production workers from a metal stamping industry were recruited as subjects into the study. Among them, ten workers were selected from the metal stamping process lines, and another ten were recruited from the handwork section. The selected subjects represented more than 80% of the total production workers of both departments. The selection of the subject is based on the working position and health condition. To fulfill the basic requirement of this study, only workers who performed processes jobs in prolonged standing and had experienced no injuries for the past 12 months were allowed to participate in the study [14]. All subjects were given a written consent using procedures approved by the Research Ethics Committee of Universiti Teknologi MARA. The demographic of the selected workers enrolled into the study are listed in Table 1.

Table 1.

Demographic of the workers participated in the study

Values are presented as mean (standard deviation).

The sEMG (ME3000P4; MEGA Electronics, Kuopio, Finland) and MegaWin Software (MEGA Electronics) were used to record, store, and analyze all the data regarding the muscle activity of the subjects. The sEMG system is equipped with electrodes to detect the myoelectric signal of a subject, while he is performing jobs in prolonged standing. The electrodes were attached conscientiously to the subject's skin to measure the activity in the 6 muscles: left and right erector spinae, left and right tibialis anterior, and left and right gastrocnemius. In the measurement and analysis of standing jobs, the selected muscles are suggested by the established guidelines [25] and a recent review article [26]. Fig. 2 shows the placement of the sEMG electrodes to measure fatigue in the selected muscles.

Fig. 2.

Surface electrodes (Ag/AgCl) are attached over the erector spinae muscles (lower back), gastrocnemius muscles (posterior legs) and tibialis anterior muscles (anterior legs).

We measured all muscles concurrently for 5 hours and 45 minutes of continuous standing to quantify muscle fatigue in the lower extremities of subjects, as might be encountered over an average workday. To determine the effects of prolonged standing in the muscles at different working periods, the sEMG measurements were conducted for 1 hour and 15 minutes of standing in the beginning of the workday (9:00 a.m. to 10:15 a.m.), 2 hours of standing in the middle of the workday (10:30 a.m. to 12:30 p.m.), and 2 hours and 30 minutes of standing in the end of the workday (2:00 p.m. to 4:30 p.m.) for 3 consecutive workdays from Monday to Wednesday. There was a morning break of 15 minutes and a lunch break of 90 minutes provided during mid-morning and at middle of the workday, respectively.

To ensure that the sEMG protocols were complied with, we attached electrodes on respective muscles and a physiotherapist was consulted before the evaluation was carried out. The setting of the sEMG system during the measurement was based on sEMG for the Non-Invasive Assessment of Muscles [27]. The settings were as follows:

EMG electrodes: Surface electrode Ag/AgCl, 20 mm diameter

Distance between electrodes: 25 mm

Skin preparation: Shaved, clean, gently abraded, and scrubbed with alcohol

Common mode rejection rate: 110 dB

Filter: Band pass filter (85-500 Hz)

Sampling rate: 1,000 Hz

The measurements of muscle activity were conducted based on real-time monitoring. All electrodes were connected to a data logger and the electromyography signals from the data logger are monitored through a lap top screen using a wireless network. Before starting the muscle activity measurement, the personal details of the subject are recorded in the MegaWin software. At the beginning of the measurement, the subject was given sufficient time to familiarize and practice the sEMG system. The subject was informed that he had to perform the process jobs under his own control and should immediately report any feeling of pain or discomfort, so that the sEMG measurement could be terminated. Once all measurement settings were ready, the subject was asked to perform his regular process job.

Then, the raw signals from the sEMG measurement are interpreted through fast fourier transform using software available in the sEMG system to determine muscle fatigue. A curve was then fitted to the mean power frequency (MPF) values to identify the fatigue in the muscles. Additional analysis from the sEMG measurement is time-to-fatigue. Time-to-fatigue can be explained as the time when the change in the electromyography data became significant [28]. Muscles tend to fatigue with an increase in the duration of standing. The square root of mean squared error (√MSE) was used as a method to identify the variability in the median frequency (Hz). When the median frequency (Hz) exceeded the √MSE value, it represents the time in the job cycle give significant chance for muscle fatigue [28].

The t-test (paired two-sample for means) was used for comparison of time-to-fatigue between the 2 groups of workers. To determine the correlation between psychological fatigue and sEMG measurement, a non-parametric test using the Spearman's rank order correlation (rs) was run.

Data collection in the workplace

As a basic requirement of this study, data collection in the actual workplaces required participation of production workers who performed processes jobs in standing position. In this study, the data collection in the workplace was carried out through questionnaire surveys, and by measurement and analysis of workers' muscle activity. Workers who participated in the questionnaire survey were also invited for sEMG measurement. In other words, both assessments were conducted on the same workers who responded to the questionnaire, and served as subjects for the sEMG measurement.

A metal stamping company situated in Shah Alam, Malaysia was selected to perform the data collection. In the production department of the company, all workers are males and have national citizenship. The workers had 12 hours shifts, with 2 shift periods within each 24 hours period. There were 2 main work departments from which workers were drawn for the study: stamping process lines and handwork section. The stamping process lines produced metal stamped parts for vehicle assembly, while the handwork section performed restoration on the products from the metal stamping process lines. All process jobs in both sections required workers to stand because the nature of jobs are repetitive, require frequent movement, and large degree of freedom. In addition, the workers at the stamping process line are exposed to mechanical vibration due to high impact between a plunger of the stamping machine and die. The cyclic load transfers its vibration to the workers' body through the machine foundation and thus transmits whole-body vibration (WBV).

Results

Results of the psychological fatigue

In the left and right erector spinae muscle (lower back), 8 subjects reported moderate fatigue and 5 subjects complained of being very fatigue. Half of the subjects complained of being very fatigue in the left and right gastrocnemius muscle (posterior legs); while, 2 of the workers were extremely fatigue. In the tibialis anterior muscle (anterior legs), moderate fatigue was prevalent (11 subjects); meanwhile, very fatigue and extreme fatigue were reported by 4 subjects and 1 subject, respectively. All subjects reported fatigue in one or more of the assessed muscles. Based on the results, the complaint of being very fatigue was critically reported in the gastrocnemius muscle (posterior legs).

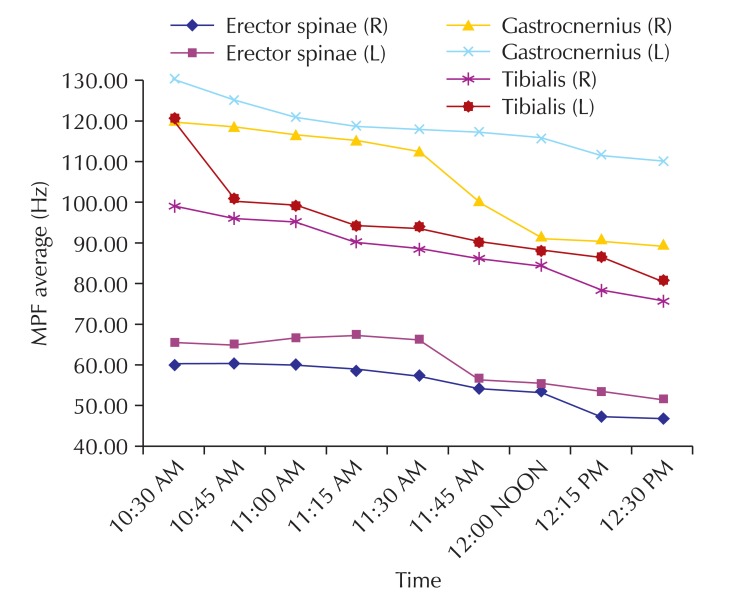

Results of muscle fatigue analysis

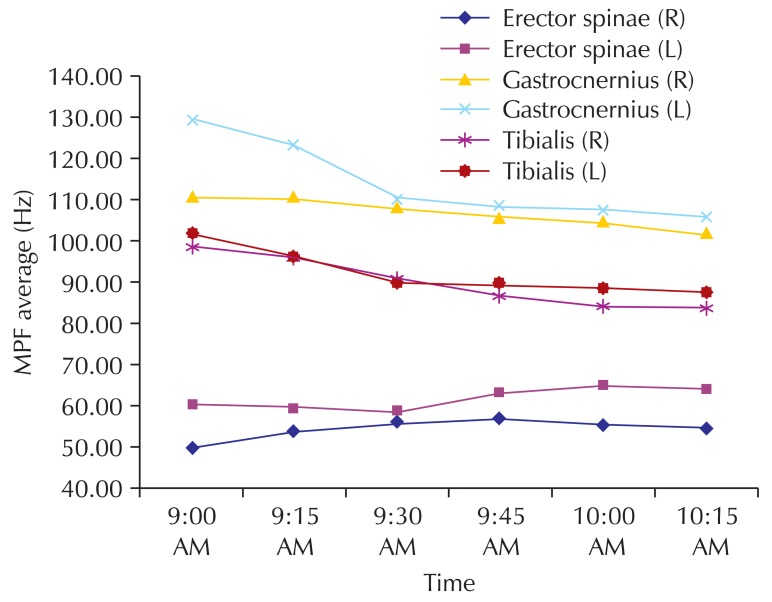

The analysis of muscle fatigue within each working session found that the trend of the MPF average (Hz) in the left erector spinae fluctuated at the beginning of the workday. The MPF average (Hz) in the left erector spinae decreased gradually from 60.40 Hz at 9:00 a.m. to 58.90 Hz at 9:30 a.m., and then increased from 63.45 Hz at 9:45 a.m. to 63.65 Hz at 10:15 a.m.. In contrast, the MPF average (Hz) of the right erector spinae increased marginally from 50.00 Hz at 9:00 a.m. to 56.00 Hz at 9:45 a.m., but it decreased from 57.10 Hz to 54.50 Hz at the last 30 minutes as shown in Fig. 3. Meanwhile, the trend of the MPF average (Hz) for other muscles at all working sessions shows a steady decrement as shown in Figs. 3-5.

Fig. 3.

Trend of the mean power frequency (MPF) average (Hz) for all muscles at the beginning of the workday. R: right, L: left.

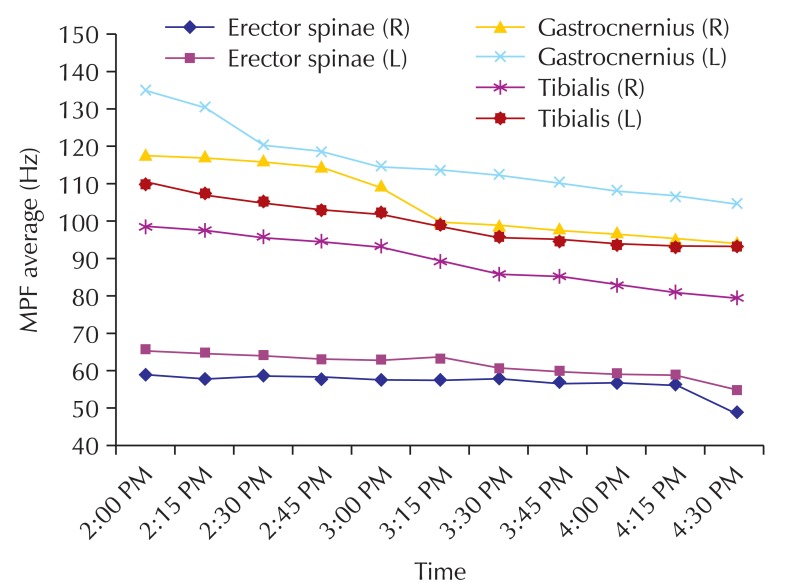

Fig. 5.

Trend of the mean power frequency (MPF) average (Hz) for all muscles at the end of the workday. R: right, L: left.

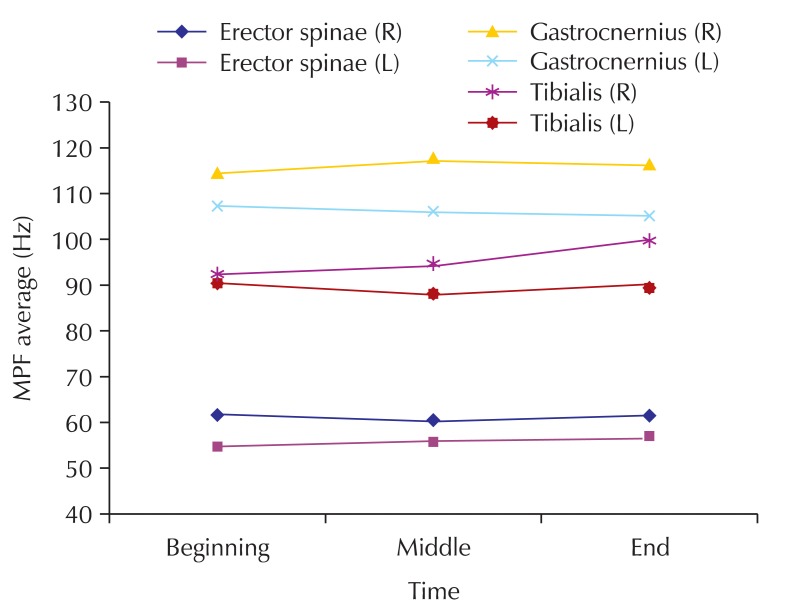

On the other hand, the trend of MPF average (Hz) between working sessions shows an inconsistency, as illustrated in Fig. 6. The MPF average (Hz) of the right gastrocnemius muscle decreased steadily for all working sessions: beginning of the workday, middle of the workday, and end of the workday (Fig. 6). Its MPF average (Hz) decreased from 107.1 Hz (beginning of the workday) to 106 Hz (middle of the workday) and 105.3 Hz at the end of the workday. On the other hand, the MPF average (Hz) for other muscles fluctuated during the 3 working sessions. In addition, it was observed that the MPF average (Hz) in the left muscles was greater than the right muscles for all subjects. For example, the MPF average (Hz) of the left tibialis (92.3 Hz) is higher than the MPF average (Hz) of the right tibialis (90.3 Hz) at the beginning of the workday.

Fig. 6.

Mean power frequency (MPF) average (Hz) for all subjects at all working sessions. R: right, L: left.

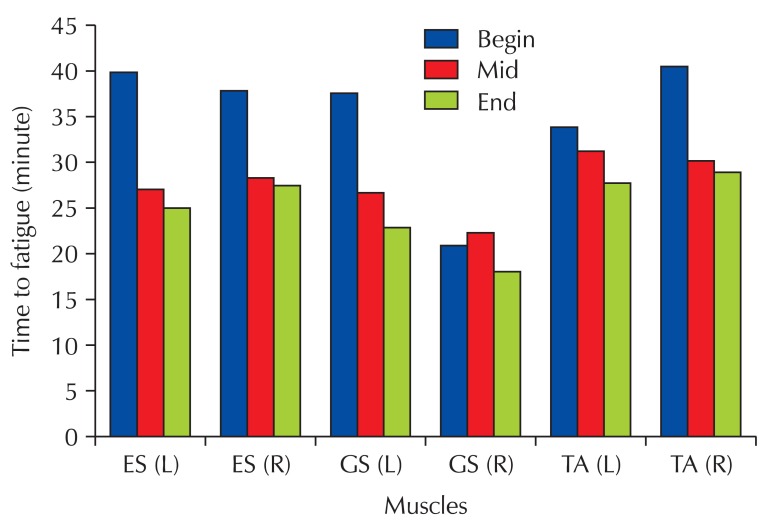

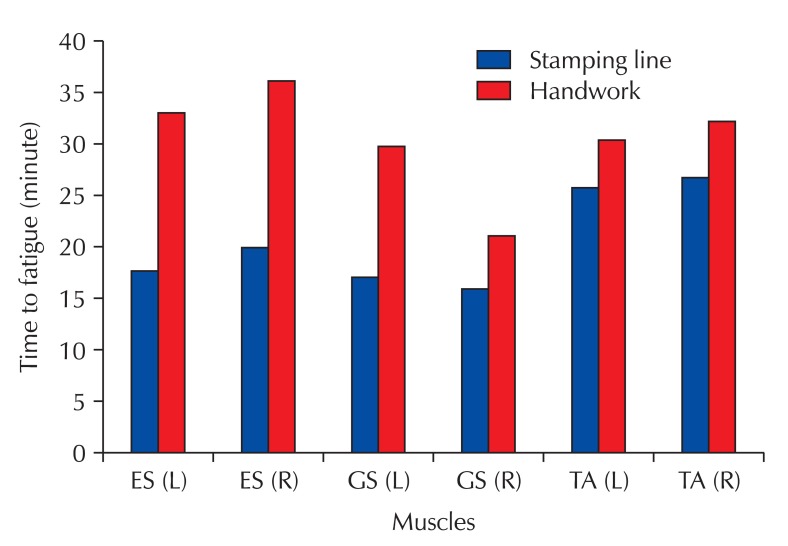

Results of time-to-fatigue analysis

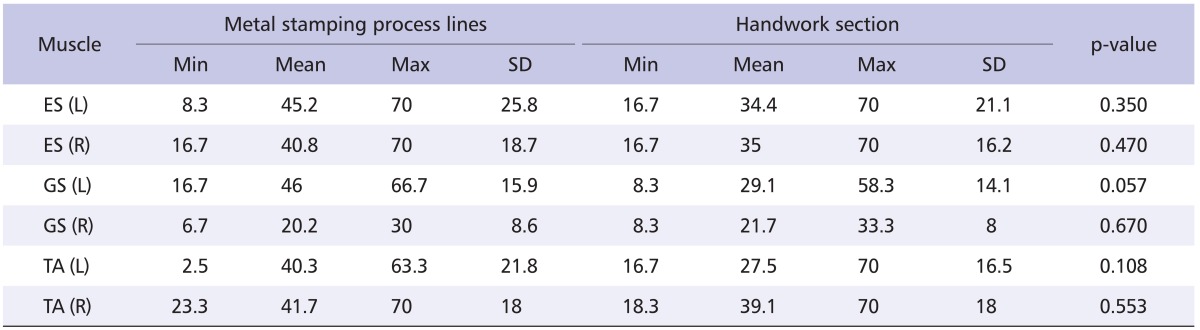

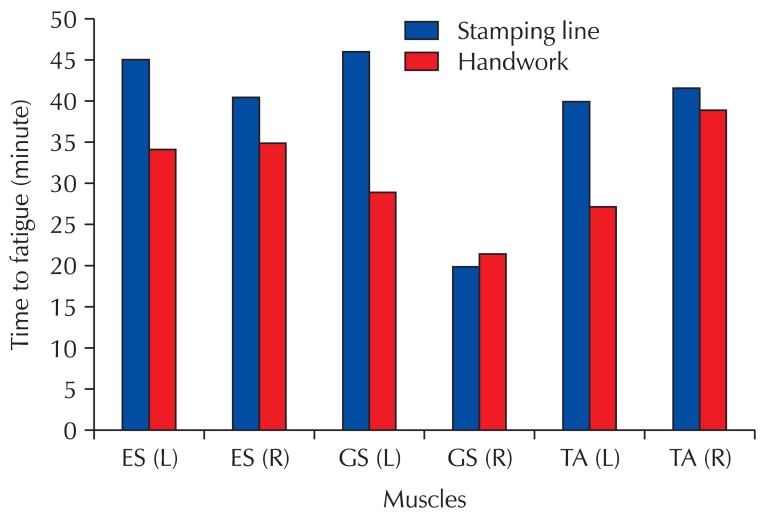

Table 2 tabulates the time-to-fatigue in each muscle for both groups of workers (metal stamping process lines and handwork section) during beginning of the workday. The authors present the results of time-to-fatigue by referring to the mean values. Among workers in the metal stamping process lines, the earliest time-to-fatigue was identified in the right gastrocnemius muscle (20.2 minutes); whereas, the latest time-to-fatigue was noticed in the left gastrocnemius muscle (46 minutes). In the handwork section, the right gastrocnemius muscle obtained the earliest time-to-fatigue (21.7 minutes); meanwhile, the right tibialis anterior muscle recorded the latest time-to-fatigue (39.1 minutes). The 2 groups of workers did not show any significant difference in time-to-fatigue.

Table 2.

Time-to-fatigue (minutes) of all subjects during beginning of the workday

Min: minimum, Max: maximum, SD: standard deviation, L: left, R: right, ES: erector spinae, GS: gastrocnemius, TA: tibialis anterior.

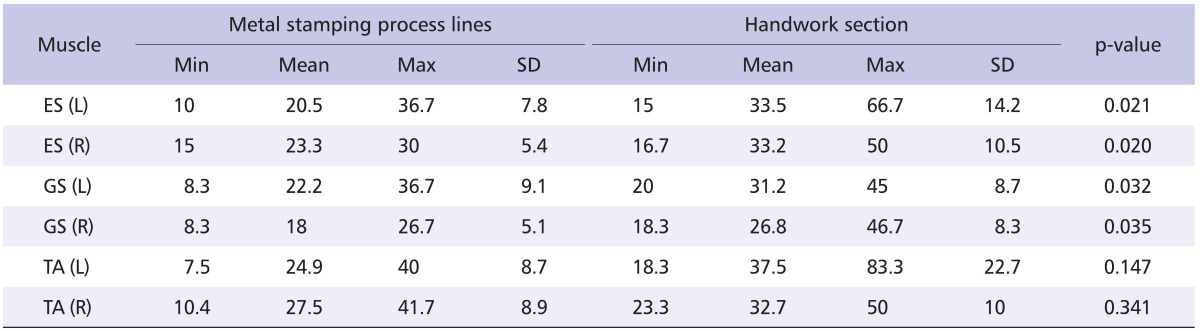

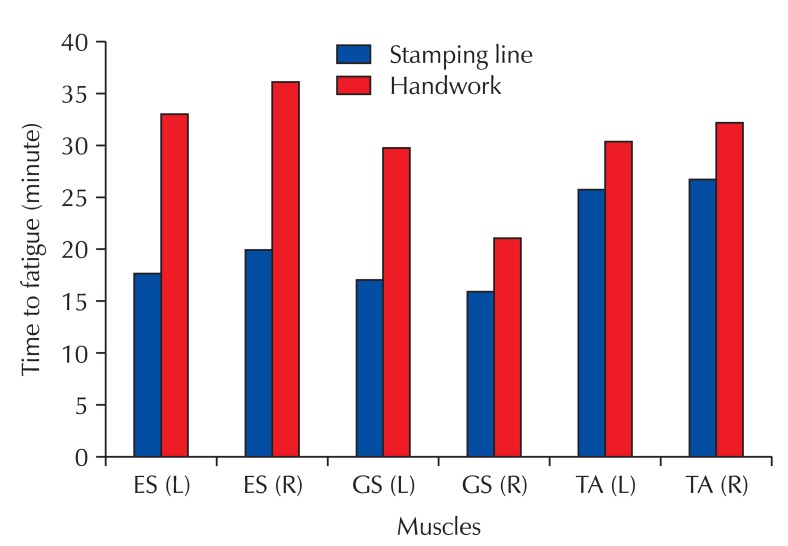

Table 3 presents the time-to-fatigue in each muscle for both groups of workers during middle of the workday. In metal stamping process lines, the earliest time-to-fatigue was identified in the right gastrocnemius muscle (18 minutes); meanwhile, the latest time-to-fatigue was found in the right tibialis anterior muscle (27.5 minutes). Among workers in handwork section, the right gastrocnemius muscle obtained the earliest time-to-fatigue (26.8 minutes); in contrast, the latest time-to-fatigue was observed in the left tibialis anterior muscle (37.5 minutes). As tabulated in Table 3, the 2 groups of workers show significant differences in time-to-fatigue (p < 0.05) in the left and right erector spinae muscle, and the left and right gastrocnemius.

Table 3.

Time-to-fatigue (minutes) of all subjects during middle of the workday

Min: minimum, Max: maximum, SD: standard deviation, L: left, R: right, ES: erector spinae, GS: gastrocnemius, TA: tibialis anterior.

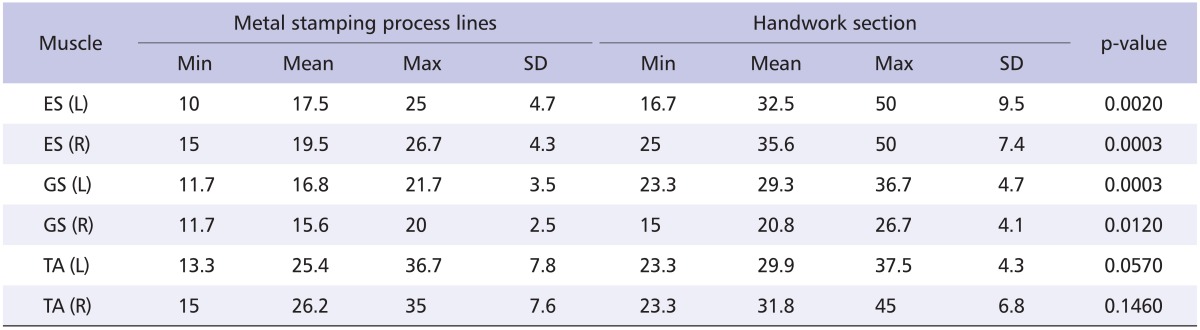

In Table 4, this study outlines the time-to-fatigue in each muscle for both groups of workers during end of the workday. In metal stamping process lines, the earliest time-to-fatigue was identified in the right gastrocnemius muscle (15.6 minutes); meanwhile, the latest time-to-fatigue was observed in the right tibialis anterior muscle (26.2 minutes). Among workers in handwork section, the right gastrocnemius muscle obtained the earliest time-to-fatigue (20.8 minutes); in contrast, the latest time-to-fatigue was observed in the right erector spinae muscle (37.5 minutes). Similar to middle of the workday, the 2 groups of workers show significant differences in time-to-fatigue (p < 0.05) in the left and right erector spinae muscle, and the left and right gastrocnemius (Table 4).

Table 4.

Time-to-fatigue (minutes) of all subjects during end of the workday

Min: minimum, Max: maximum, SD: standard deviation, L: left, R: right, ES: erector spinae, GS: gastrocnemius, TA: tibialis anterior.

Correlation between results of questionnaire surveys and sEMG measurement

Based on the non-parametric statistical test using the Spearman's rank order correlation, the left erector spinae obtained a moderate positive correlation and statistically significance (rs = 0.552, p < 0.05) between the results of the questionnaire surveys (psychological fatigue) and sEMG measurement (muscle fatigue). Additionally, a weakly positive correlation was found between psychological fatigue and muscle fatigue assessments for other muscles. Table 5 summarizes the strength and direction, as well as the significance level, of the correlation between the results of questionnaire surveys and sEMG measurement.

Table 5.

Correlation between psychological fatigue assessment and sEMG measurement

sEMG: surface electromyography.

Discussion

Through questionnaire surveys, this study revealed that all workers worked on a 12 hours shift schedule, where workers at the metal stamping process lines worked day shift only; while, workers at the handwork section worked both day and night shifts. Throughout the 12 hours, the workers spent about 80% of the working time in standing position (only sitting during breaks). The long standing period has far exceeded the threshold limit of standing time [9]. Obviously, all workers have to stand because they require frequent movements and large degree of freedom to perform the process jobs. For example, workers at the metal stamping process lines have to reach the workpieces from the pallet and feed the workpieces to the stamping machine synchronize with the machine speed. Thus, the working practice would be practicable if to be performed in standing position. In addition, the stamping machine had insufficient clearance between workers' legs and machine platform; hence, the machine design does not allow workers to perform stamping process in sitting position. The working area was also restricted. In addition, the workers had to perform metal stamping process that was repetitive in nature throughout their working hours.

The handwork section on the other hand is a department, which requires workers to accomplish repair and restoration works on products produced by the metal stamping process. Major activities at the handwork section are grinding and knocking processes using manual methods. Similar to metal stamping process lines, all workers at the handwork section performed the jobs in standing position, because they require a large degree of freedom, especially while performing grinding process on large products. In addition, workers at the handwork section exposed to risk factor associated with extreme working posture. The extreme posture was observed when they have to bend, extend, and flexed their bodies to reach far area of the product that is to be grinded. Continuous exposure to this posture requires workers to apply more effort as compared to being in a neutral position. This working practice is a potential contribution to discomfort, muscle fatigue, and lower back pain [29,30].

As a summary, the working conditions have promoted discomfort and muscle fatigue to the workers because:

The metal stamping process has to perform in standing position throughout 12-hour working hours.

The workstation design and processes jobs have led to extreme working postures.

The processes jobs are repetitive in nature thus limiting ample recovery time.

The jobs require cyclic process and the working area was limited and thus working in static standing posture is practiced.

The stamping machines generated mechanical vibration and the vibration is transferred to workers' body the through standing foundation. Continuous exposure to vibration initiates muscle fatigue and increases the risk of lower back pain [31-34].

Due to the above mentioned working conditions, it was found that fatigue had occurred in the lower extremities, such as the lower back (erector spinae muscle), posterior leg (gastrocnemius muscle), and anterior leg (tibialis anterior muscle) and were critically complained by the workers. The reported fatigue can be linked to performing jobs in standing position [35]. Standing for a long period of time causes static contraction mainly in the back and legs. As static contraction occurs, the function of calf muscle diminishes, thus resulting in discomfort and muscle fatigue. In addition to the static muscle contraction, the posture of the workers was deviated significantly from neutral posture especially when they performed the jobs in bending, extension, forward and side flexion, thus placed more stress in the back.

The analysis of muscle fatigue within each working session found that the trend of the MPF average (Hz) for the muscles shows a steady decrement at all working sessions (except for the erector spinae at the beginning of the workday). As agreed by previous studies, decrement of MPF average (Hz) in the particular muscles is one of the indications of fatigue [36,37]. Meanwhile, the trend in MPF average (Hz) between working sessions shows an inconsistency (Fig. 6). This is due to the breaks (morning break and lunch hour) that were provided to the workers between the working sessions allowed the muscles to recover from the fatigue. The time and foods taken by the workers during the breaks refreshed their energy and slightly diminish the fatigue due to previous work activities.

Through sEMG measurement, it was observed that the right gastrocnemius muscle appeared to experience fatigue earlier than other muscles for all working sessions. In average, the right gastrocnemius muscle suffered from fatigue after 20 minutes of standing. This finding, however, did not agree with a previous study, which identified fatigue occurring after 2 hours of continuous standing [38]. The difference in time-to-fatigue can be justified through the activities of subjects. The subjects involved in this study performed demanding tasks (metal stamping and hand grinding processes), which can accelerate muscle fatigue, meanwhile the subjects in the previous study performed light tasks (small object assembly, currency sorting, and card dealing).

As illustrated in Fig. 7, the beginning of the workday appeared to cause later fatigue for all muscles, except for the right gastrocnemius muscle. In contrast, the end of the workday showed slightly earlier signs of fatigue than the middle of the workday. Additionally, corresponding to Figs. 7, 8, the time-to-fatigue of the right gastrocnemius muscle did not show a homogeneous trend compared to other muscles. In terms of working sessions, it was observed that the right gastrocnemius muscle at the middle of the workday experienced fatigue slightly later than beginning and end of workdays (Fig. 7). In Fig. 8, further analysis found that workers who performed jobs at the metal stamping process lines seemed to suffer fatigue later than those at the handwork section during beginning of the workday. Moreover, the comparison of time-to-fatigue between work departments revealed that the right gastrocnemius muscle of workers at the metal stamping process lines experienced fatigue earlier than handwork section (Fig. 8). Based on these two variations, this study assumed that the position of legs has determined the muscle activity. Through observation carried out by this study, one foot in front and other one at the rear was the most regular position practiced by the workers while performing jobs at their workstations. So, the gastrocnemius muscles (posterior legs) have a flexibility and mobility that are effectively to alleviate the incessant force in the muscle. Another factor is exposure to WBV, which is discussed in the next section.

Fig. 7.

Average of time-to-fatigue in each muscle during all working sessions. L: left, R: right, ES: erector spinae, GS: gastrocnemius, TA: tibialis anterior.

Fig. 8.

Average of time-to-fatigue between metal stamping lines and handwork section during beginning of the workday. L: left, R: right, ES: erector spinae, GS: gastrocnemius, TA: tibialis anterior.

In the case study, workers at the metal stamping process lines were exposed to WBV. The stamping machines, capacities ranging from 300 tons to 1,200 tons generate mechanical vibration due to high and repetitive impact between the machine's plunger and the die. The cyclic load of the machine transfers its vibration to the workers' body through the machine foundation and causing WBV.

Among the 2 work departments, muscles of workers at the metal stamping process lines were observed to experience fatigue later than those at handwork section during beginning of the workday as shown in Fig. 8. In other words, exposure to 1 hour and 15 minutes of WBV induced muscles of workers at the metal stamping process lines to be vigorous. However, the muscles of workers at the metal stamping process lines appeared to experience fatigue rapidly for middle of the workday, and end of the workday as illustrated in Figs. 9, 10 respectively. Based on this situation, long term and continuous exposure to WBV (2 hours and 2.5 hours during middle of the workday and end of the workday respectively) have contributed to fatigue in the muscles.

Fig. 9.

Average of time-to-fatigue between metal stamping lines and handwork section during middle of the workday. L: left, R: right, ES: erector spinae, GS: gastrocnemius, TA: tibialis anterior.

Fig. 10.

Average of time-to-fatigue between metal stamping lines and handwork section during end of the workday. L: left, R: right, ES: erector spinae, GS: gastrocnemius, TA: tibialis anterior.

Furthermore, low frequency of vibration generated by the stamping machine can be another contributor to fatigue. Many studies in occupational health, safety and ergonomics believed that continuous exposure to WBV initiated muscle fatigue and increase the risk of lower back pain [31-34,39,40]. In a radiological study, it was proven that continuous exposure to WBV causes morphological changes in the lumbar spine thus lead to back pain [41]. In addition, over exposure to WBV in daily job activities can lead to various health implications such as damage of central nervous system, insomnia, headache and shakiness, and decreased job proficiency [42].

This study proposes several solutions as control measures to minimize muscle fatigue associated with prolonged standing. Standing with intermittent sitting is the best solution to minimize discomfort and muscle fatigue associated with prolonged standing tasks. Sitting is a much less strenuous posture than standing, mostly because it requires fewer muscles to be contracted to stabilize the body. In addition, when the processes jobs are performed in sitting position, the loading on the upper limbs will be uniformly distributed through the seat pan [43], hence reduces the loading on the lower limbs. However, sitting in long periods of time is also not good for the health. Alternate the standing and sitting positions using sit-stand stool enable the workers to perform the jobs in sitting as well as standing position. Moreover, the sit-stand stool is equipped with a foot rest to provide comfort to the workers' legs. Also, it can be rotated 360 degrees so that the workers can reach the materials without twisting their body and consequently enlarge the degree of freedom to do the jobs. Besides, comfort shoe design, adequate work rest, and applying anti-fatigue mat could be alternative solutions to minimize the risk of discomfort and muscle fatigue associated with prolonged standing.

By using the approach of engineering controls, application of anti-fatigue mat on the standing surface of workstation can absorb pressure in the workers' feet due to hard standing floor [44,45]. Alternatively, providing a soft shoe-insole can reduce fatigue in the feet due to body mass and workload while performing processes jobs in prolonged standing [46]. In cases where engineering controls are impossible to be implemented, administrative controls such as providing micro breaks in the working hours can be applied to minimize muscle fatigue due to prolonged standing. It has been proven that providing breaks in the working hours can minimize risk of leg swelling due to prolonged standing [7].

The initial objective of this study was to determine the psychological fatigue experienced by production workers regarding performing process jobs in a position of prolonged standing. This study concluded that all workers experienced fatigue in the lower back (erector spinae muscle), posterior legs (gastrocnemius muscle), and anterior legs (tibialis anterior muscle).

The second objective of this study was to analyze workers' muscle activity while performing processes jobs in prolonged standing. Through sEMG measurement, this study identified that all muscles suffered from fatigue. Apparently, the right gastrocnemius muscle of the workers at the handwork section experienced fatigue after 20 minutes of standing. Meanwhile, the muscles of workers at the metal stamping process lines suffered from fatigue quickly at the middle and end of the workdays. Statistical analysis found that there is a positive association between results of psychological fatigue and muscle fatigue assessments; hence this study confirmed that prolonged standing was the contributor to muscle fatigue among the production workers.

Fig. 4.

Trend of the mean power frequency (MPF) average (Hz) for all muscles at the middle of the workday. R: right, L: left.

Acknowledgments

The authors would like to acknowledge the Ministry of Higher Education of Malaysia, the Universiti Teknikal Malaysia Melaka (UTeM), the Ministry of Science, Technology and Innovation (MOSTI) of Malaysia for funding this research under e-Science Research Grant, the Faculty of Mechanical Engineering of Universiti Teknologi MARA and Research Management Institute (RMI) of Universiti Teknologi MARA for providing facilities and assistance in conducting this study. Special thank also goes to Miyazu (M) Sdn. Bhd. for the permission and opportunity to facilitate a fruitful case study.

Footnotes

No potential conflict of interest relevant to this article was reported.

References

- 1.Labor force (most recent) by country [Internet] Sydney (Australia): Nation Master; 2011. [cited 2011 Mar 9]. Available from: http://www.nationmaster.com/graph/lab_lab_for-labor-force. [Google Scholar]

- 2.All industries [Internet] Boston (MA): Harvard Business School; 2011. [cited 2011 Mar 9]. Available from: http://hbswk.hbs.edu/industries/ [Google Scholar]

- 3.Injuries, illness, and fatalities [Internet] Washington, DC: US Bureau of Labor Statistics; 2011. [cited 2011 Mar 9]. Available from: http://www.bls.gov/iif/oshcfoi1.htm. [Google Scholar]

- 4.Waehrer GM, Dongb XS, Millera T, Haileb E, Menb Y. Costs of occupational injuries in construction in the United States. Accid Anal Prev. 2007;39:1258–1266. doi: 10.1016/j.aap.2007.03.012. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Tomei F, Baccolo TP, Tomao E, Palmi S, Rosati MV. Chronic venous disorders and occupation. Am J Ind Med. 1999;36:653–665. doi: 10.1002/(sici)1097-0274(199912)36:6<653::aid-ajim8>3.0.co;2-p. [DOI] [PubMed] [Google Scholar]

- 6.Simonson E, Weiser PC. Psychological aspects and physiological correlates of work and fatigue. 1st ed. Springfield (IL): Thomas; Springfield; 1976. [Google Scholar]

- 7.Van Dieën JH, Oude Vrielink HH. Evaluation of work-rest schedules with respect to the effects of postural workload in standing work. Ergonomics. 1998;41:1832–1844. doi: 10.1080/001401398186009. [DOI] [PubMed] [Google Scholar]

- 8.Miedema MC, Douwes M, Dul J. Recommended maximum holding times for prevention of discomfort of static standing postures. Int J Ind Ergon. 1997;19:9–18. [Google Scholar]

- 9.Ahmada N, Taha Z, Eu PL. Energetic requirement, muscle fatigue, and musculoskeletal risk of prolonged standing on female Malaysian operators in the electronic industries: influence of age. Eng e-Trans (University of Malaya) 2006;1:47–58. [Google Scholar]

- 10.Lafond D, Champagne A, Descarreaux M, Dubois JD, Prado JM, Duarte M. Postural control during prolonged standing in persons with chronic low back pain. Gait Posture. 2009;29:421–427. doi: 10.1016/j.gaitpost.2008.10.064. [DOI] [PubMed] [Google Scholar]

- 11.Hamberg-van Reenen HH, Visser B, van der Beek AJ, Blatter BM, van Dieën JH, van Mechelen W. The effect of a resistance-training program on muscle strength, physical workload, muscle fatigue and musculoskeletal discomfort: an experiment. Appl Ergon. 2009;40:396–403. doi: 10.1016/j.apergo.2008.11.010. [DOI] [PubMed] [Google Scholar]

- 12.Luttmann A, Jäger M, Laurig W. Electromyographical indication of muscular fatigue in occupational field studies. Int J Ind Ergon. 2000;25:645–660. [Google Scholar]

- 13.Hostens I, Ramon H. Assessment of muscle fatigue in low level monotonous task performance during car driving. J Electromyogr Kinesiol. 2005;15:266–274. doi: 10.1016/j.jelekin.2004.08.002. [DOI] [PubMed] [Google Scholar]

- 14.Yassierli . Muscle fatigue during isometric and dynamic efforts in shoulder abduction and torso extension: age effects and alternative electromyographic measures [dissertation] Blacksburg (VA): Virginia Polytechnic Institute and State University; 2005. [Google Scholar]

- 15.Balasubramanian V, Adalarasu K, Regulapati R. Comparing dynamic and stationary standing postures in an assembly task. Int J Ind Ergon. 2009;39:649–654. [Google Scholar]

- 16.Dedering A, Németh G, Harms-Ringdahl K. Correlation between electromyographic spectral changes and subjective assessmment of lumbar muscle fatigue in subjects without pain from the lower back. Clin Biomech (Bristol, Avon) 1999;14:103–111. doi: 10.1016/s0268-0033(98)00053-9. [DOI] [PubMed] [Google Scholar]

- 17.Dedering A, Roos af Hjelmsäter M, Elfving B, Harms-Ringdahl K, Németh G. Between-days reliability of subjective and objective assessments of back extensor muscle fatigue in subjects without lower-back pain. J Electromyogr Kinesiol. 2000;10:151–158. doi: 10.1016/s1050-6411(00)00009-2. [DOI] [PubMed] [Google Scholar]

- 18.Anton D, Shibley LD, Fethke NB, Hess J, Cook TM, Rosecrance J. The effect of overhead drilling position on shoulder moment and electromyography. Ergonomics. 2001;44:489–501. doi: 10.1080/00140130120079. [DOI] [PubMed] [Google Scholar]

- 19.Farina D, Gazzoni M, Merletti R. Assessment of low back pain muscle fatigue by surface EMG signal analysis: methodological aspects. J Electromyogr Kinesiol. 2003;13:319–332. doi: 10.1016/s1050-6411(03)00040-3. [DOI] [PubMed] [Google Scholar]

- 20.Aström C, Lindkvist M, Burström L, Sundelin G, Karlsson JS. Changes in EMG activity in the upper trapezius muscle due to local vibration exposure. J Electromyogr Kinesiol. 2009;19:407–415. doi: 10.1016/j.jelekin.2007.11.003. [DOI] [PubMed] [Google Scholar]

- 21.Mesin L, Merletti R, Rainoldi A. Surface EMG: the issue of electrode location. J Electromyogr Kinesiol. 2009;19:719–726. doi: 10.1016/j.jelekin.2008.07.006. [DOI] [PubMed] [Google Scholar]

- 22.Larivière C, Gagnon D, Gravel D, Bertrand Arsenault A. The assessment of back muscle capacity using intermittent static contractions. Part I - Validity and reliability of electromyographic indices of fatigue. J Electromyogr Kinesiol. 2008;18:1006–1019. doi: 10.1016/j.jelekin.2007.03.012. [DOI] [PubMed] [Google Scholar]

- 23.Nelson-Wong E, Callaghan JP. Changes in muscle activation patterns and subjective low back pain ratings during prolonged standing in response to an exercise intervention. J Electromyogr Kinesiol. 2010;20:1125–1133. doi: 10.1016/j.jelekin.2010.07.007. [DOI] [PubMed] [Google Scholar]

- 24.International Organization for Standardization. Ergonomic procedures for the improvement of local muscular workloads. Geneva (Switzerland): ISO; 2004. ISO 20646. [Google Scholar]

- 25.Soderberg GL. Selected topics in surface electromyography for use in the occupational setting: expert perspectives. Washington, DC: US Department of Health and Human Services, US National Institute for Occupational Safety and Health; 1992. [Google Scholar]

- 26.Murley GS, Landorf KB, Menz HB, Bird AR. Effect of foot posture, foot orthoses and footwear on lower limb muscle activity during walking and running: A systematic review. Gait Posture. 2009;29:172–187. doi: 10.1016/j.gaitpost.2008.08.015. [DOI] [PubMed] [Google Scholar]

- 27.Hermens HJ, Freriks B, Disselhorst-Klug C, Rau G. Development of recommendations for SEMG sensors and sensor placement procedures. J Electromyogr Kinesiol. 2000;10:361–374. doi: 10.1016/s1050-6411(00)00027-4. [DOI] [PubMed] [Google Scholar]

- 28.Kirst MA. Effects of tool weight on fatigue and performance during short cycle overhead work operations. Blacksburg (VA): Virginia Polytechnic Institute and State University; 1999. [Google Scholar]

- 29.Haslegrave CM. What do we mean by a 'working posture'? Ergonomics. 1994;37:781–799. doi: 10.1080/00140139408963688. [DOI] [PubMed] [Google Scholar]

- 30.Li G, Haslegrave CM, Corlett EN. Factors affecting posture for machine sewing tasks. Appl Ergon. 1995;26:35–46. doi: 10.1016/0003-6870(94)00005-j. [DOI] [PubMed] [Google Scholar]

- 31.Fritz M, Fischer S, Bröde P. Vibration induced low back disorders-comparison of the vibration evaluation according to ISO 2631 with a force-related evaluation. Appl Ergon. 2005;36:481–488. doi: 10.1016/j.apergo.2005.01.008. [DOI] [PubMed] [Google Scholar]

- 32.Okunribido OO, Shimbles SJ, Magnusson M, Pope M. City bus driving and low back pain: a study of the exposures to posture demands, manual materials handling and whole-body vibration. Appl Ergon. 2007;38:29–38. doi: 10.1016/j.apergo.2006.01.006. [DOI] [PubMed] [Google Scholar]

- 33.Bovenzi M, Pinto I, Stacchini N. Low back pain in port machinery operators. J Sound Vib. 2002;253:3–20. [Google Scholar]

- 34.Wilder D, Magnusson ML, Fenwick J, Pope M. The effect of posture and seat suspension design on discomfort and back muscle fatigue during simulated truck driving. Appl Ergon. 1994;25:66–76. doi: 10.1016/0003-6870(94)90067-1. [DOI] [PubMed] [Google Scholar]

- 35.Krijnen RMA, de Boer EM, Adèr HJ, Bruynzeel DP. Diurnal volume changes of the lower legs in healthy males with a profession that requires standing. Skin Res Technol. 1998;4:18–23. doi: 10.1111/j.1600-0846.1998.tb00080.x. [DOI] [PubMed] [Google Scholar]

- 36.Ament W, Bonga GJ, Hof AL, Verkerke GJ. Electromyogram median power frequency in dynamic exercise at medium exercise intensities. Eur J Appl Physiol Occup Physiol. 1996;74:180–186. doi: 10.1007/BF00376511. [DOI] [PubMed] [Google Scholar]

- 37.Srinivasan J, Balasubramanian V. Low back pain and muscle fatigue due to road cycling-an sEMG study. J Bodyw and Mov Ther. 2007;11:260–266. [Google Scholar]

- 38.Gregory DE, Callaghan JP. Prolonged standing as a precursor for the development of low back discomfort: An investigation of possible mechanisms. Gait Posture. 2008;28:86–92. doi: 10.1016/j.gaitpost.2007.10.005. [DOI] [PubMed] [Google Scholar]

- 39.Zimmermann CL, Cook TM, Goel VK. Effects of seated posture on erector spinae EMG activity during whole body vibration. Ergonomics. 1993;36:667–675. doi: 10.1080/00140139308967928. [DOI] [PubMed] [Google Scholar]

- 40.Kittusamy NK, Buchholz B. Whole-body vibration and postural stress among operators of construction equipment: a literature review. J Safety Res. 2004;35:255–261. doi: 10.1016/j.jsr.2004.03.014. [DOI] [PubMed] [Google Scholar]

- 41.Dupuis H, Zerlett G. Whole-body vibration and disorders of the spine. Int Arch Occup Environ Health. 1987;59:323–336. doi: 10.1007/BF00405276. [DOI] [PubMed] [Google Scholar]

- 42.Ministry of Human Resource of Malaysia. Guidelines on Occupational Vibration. Kuala Lumpur (Malaysia): Department of Occupational Safety and Health; 2003. [Google Scholar]

- 43.Kroemer KH, Kroemer HB, Kroemer-Elbert KE. Ergonomics- how to design for ease and efficiency. Englewood Cliffs (NJ): Prentice Hall International Inc.; 1994. [Google Scholar]

- 44.Zander JE, King PM, Ezenwa BN. Influence of flooring conditions on lower leg volume following prolonged standing. Int J Ind Ergon. 2004;34:279–288. [Google Scholar]

- 45.King PM. A comparison of the effects of floor mats and shoe in-soles on standing fatigue. Appl Ergon. 2002;33:477–484. doi: 10.1016/s0003-6870(02)00027-3. [DOI] [PubMed] [Google Scholar]

- 46.Chiu MC, Wang MJ. Professional footwear evaluation for clinical nurses. Appl Ergon. 2007;38:133–141. doi: 10.1016/j.apergo.2006.03.012. [DOI] [PubMed] [Google Scholar]