Abstract

The objectives are to compare the airborne asbestos concentrations resulted from mitering of abestos cement roof sheets by a high-speed motor and a hand saw, and to monitor whether other workers near the test sites are vulnerable to the fibers exceeding the occupational exposure limit. Four test cases were carried out and altogether 7 personal and 4 area air samples were collected. The NIOSH method 7400 was employed for the air samplings and analysis. Using the phase contrast microscopy, fiber counting was conducted under Rule A. The study showed that the fiber concentration medians for personal air samples gathered from the two tools were 4.11 fibers/cc (ranged: 1.33-12.41 fibers/cc) and 0.13 fibers/cc (ranged: 0.01-5.00 fibers/cc) respectively. The median for the area samples was 0.59 fibers/cc (ranged: 0.14-3.32 fibers/cc). Comparing each study case, the concentration level caused by the high-speed motor saw was more than twice that of the hand saw. According to the area samples, the workers nearby the test site are at risk from high exposure to asbestos.

Keywords: Asbestos, Cement sheets, Mitering, Construction, Exposure

Introduction

Due to its resulting health hazard [1-3], asbestos has been completely or partially prohibited in many countries. Asbestos-based products are used extensively in several countries because of its usefulness in providing, good insulation and resistance to acid, base, and heat. In addition, it is a good reinforcement for cement and resin. The use of asbestos is particularly common in Asia and Africa [4,5]. The most commonly used asbestos products are friction and construction materials, such as asbestos cement (AC) flat, corrugated sheets, and cement pipes. In some countries, asbestos corrugated-roof sheets are popular because they are cheap, durable and provide good heat insulation [6-8].

Recent studies in four AC roof tile factories in Thailand [9] and one in India [10] indicated that the average fiber concentration levels in these two studies were relatively low at 0.078 (0.19) fibers/cc and 0.04-0.07 fibers/cc respectively, while the asbestos roof-tile removal generated 0.1-0.4 fibers/cc approximately [11]. The low concentration levels can result in a low health-risk impact on the population. Thus, these factors could be the reason for reported cases of asbestos illness in Thailand. One study [12] went as far as indicating negative results for the expected increases in the asbestos-related mortality. Low environmental exposure to asbestos was cited by these studies. As a result, supporters of asbestos use in Thailand have tried to convince authorities that AC roof sheets are of the non-friable asbestos containing material (ACM) type and that the quantity of asbestos fibers generated from the products is very low. In addition, supporters claimed that occupational exposure could be limited easily by engineering-control measures and good practices in the workplace. However, some parts of the AC roof-tile life cycle were ignored, such as mitering and disposal.

In Thailand's rural areas, as in other countries in Asia and Africa, people tend to build their own houses to save the labor cost and most often do the roof mitering work by themselves. This practice endangers their health, the health of their co-workers, and the health of individuals adjacent to a high-level asbestos exposure. The pro-asbestos group, however, believes that the situation does not subject people to health risks from high doses of fiber exposure because the work is normally carried out in the open areas, which dilute the dust concentration to the extent it may no longer cause any harm.

This study aims to show that there are high-level concentrations of airborne asbestos fiber generated during roof-tile mitering by each type of the test tools, a high-speed motor saw with fiber blade and a hand saw.

Case Report

Corrugated roof sheets contain by weight approximately 10% to 15% of asbestos and are usually mitered by a high-speed motor saw and a metal-cutting or wood-cutting saw. Four cases were studied with each performed separately by a worker on different days in various ventilated, open-air locations. In Cases 1-3, the workers employed both types of equipment, while in Case 4, worker used only a high-speed motor saw.

The workers were duly informed of the study's goals, procedures, risks, benefits and of their freedom of choice. They were encouraged to ask questions; those agreeing to participation were continued in the study. The workers were asked to perform mitering by both types of saw, and to cut at the speed and quantity of roof sheets as they would normally. The mitering time was 15 minutes for each saw.

Both personal and area air samples were collected using the National Institute for Occupational Safety and Health (NIOSH) method 7400. The SKC Airchek model 224-PCXR4 personal pumps (SKC Inc., Pennsylvania, PA, USA) were used to draw air in at the flow rate of 2 L/minute, passing through the 25 mm cellulose ester membrane filter placed in a cassette equipped with an extension cowl. The pumps were calibrated by the bubble meter (primary standard set) before and after the collection of the samples. The average flow rates of pre- and post-calibration were used for the calculation of air sampling volume. A set of pump and sampler was attached to the worker for personal sampling. For the collection of area samples, the sampling instrument was set at approximately two to three meters away from the mitering point. The quantity of sheets cut simultaneously was recorded. During the test, workers' behaviors and environmental conditions of the surrounding areas were also observed.

For Cases 1-3, the exercise began with a hand saw followed by a high-speed motor saw. Each saw was used continuously for 15 minutes, with a 30-minute break in between. A personal air sampling, which began immediately just before the mitering, was taken for each of the two cuts, lasting about 30 minutes. An area sampling was taken for the entire test for 60 minutes. Placed in a wooden box, the samples were carried back to the laboratory and prepared for the counting by the phase contrast microscopy, equipped with Walton-Beckett Graticule type G-22 counting area of 0.00785 mm2. The sample analysis was in accordance with the NIOSH's counting Rule A, which sets the limit of detection at 7 fibers/mm2.

Case 1 was conducted under the roof in a ventilated area (Fig. 1). Only one sheet at a time was cut using wood-cutting saw and two slowly being cut by a motor saw with the speed of 800 rpm. The worker was aware of the dust and positioned himself up-wind.

Fig. 1.

Hand saw mitering.

Case 2 (Fig. 2) was conducted in a roof-shaded area and without any building nearby. The wind was stagnant for most of the time. Both the metal-cutting and high-speed motor (1,200 rpm) saws were used. One to 2 sheets were cut at a time by the metal-cutting saw and 4 to 5 by the latter. The worker performed the task quickly and was conscious of putting himself at risk from dust exposure.

Fig. 2.

Hand saw and motor saw mitering.

Case 3 (Fig. 3) was tested in an outdoor area where the wind often changed direction. One or more was cut at the same time by a metal-cutting saw and then 3-4 by a high-speed motor (1,200 rpm) saw. Aware of the dust, the worker tried to protect himself by moving up-wind. The wind changed direction dramatically, and the worker was unable to escape the dust.

Fig. 3.

Hand saw and motor saw mitering.

Case 4 was conducted in a ventilated area situated between 2 buildings (Fig. 4). Using only a high-speed motor (1,200 rpm) saw, the worker slowly cut the roof-tile one at a time. The wind changed direction occasionally, but the worker's attempts to stay ahead of the wind were restricted by the site's space limitation.

Fig. 4.

Motor saw mitering.

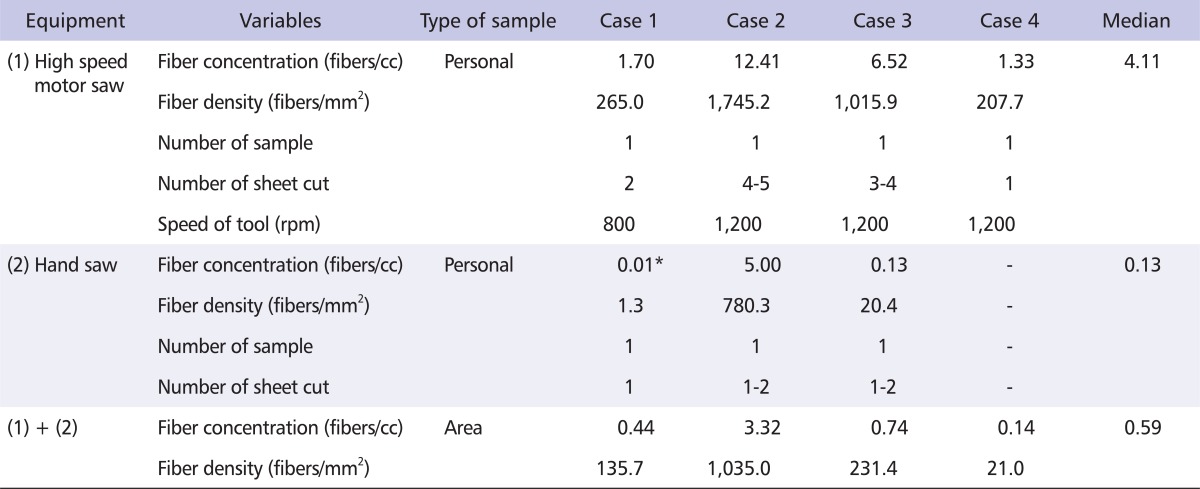

As shown in Table 1, the fiber concentration levels of all personal samples taken for 30 minutes from a high-speed motor saw exceeded the Occupational Safety and Health Administration of the United States (OSHA) 30 minutes excursion standard of 1 fibers/cc, with the median of 4.11 fibers/cc and the range in between 1.33-12.41 fibers/cc. During the tests using hand saws, only one sample, taken from the Case 2, was over the excursion standard, showing the median of 0.13 fibers/cc and the range of 0.01-5.00 fibers/cc. All area samples from the 2 cutting tools showed the median of 0.59 fibers/cc with the range of 0.14-3.32 fibers/cc.

Table 1.

Fiber concentrations obtaining from personal and area samples taken during the mitering

*Lower than the limit of detection.

Discussion

Asbestos can last a long time in the lungs. The OSHA excursion limit has been adopted to help protect workers from exposing themselves, however briefly, from high doses of the harmful fibers. At construction sites, roof-tile cuttings are usually carried out all day long and for big projects can continue for many days and even months. Since the data was collected from a brief, time-limited exercise, the results were compared with the OSHA's excursion limit. Had the test been carried out for eight hours continuously, for example, the fiber concentration levels from the use of a high-speed motor saw could be as high as 4.11 fibers/cc and 0.59 fibers/cc for personal and area samples respectively, far exceeding the time-weighted average standard of 0.1 fibers/cc. As such, the workers and others working nearby would be subjected to the asbestos exposure levels higher than those set by the OSHA limit.

The study shows that the number of sheets cut simultaneously has greater influence on the asbestos fiber-concentration levels than the speed of the saws. More sheets cut together at the same time cause invariably more concentrations. In Case 1, the 800 rpm motor saw, cutting 2 sheets at the same time, generated 1.70 fibers/cc, a level higher than that produced by Case 4, at 1.33 fibers/cc, cutting just only one sheet at the faster 1,200 rpm speed.

The workers' behaviors and practices had an adverse effect on the exposure problem. Among the 4 cases, Case 2's worker faced the greatest exposure risk from working rapidly and from positioning himself closer to the task (Fig. 2). In Cases 3 and 4, each worker tried to minimize the impact by staying up-wind during the cuttings, which were performed at a normal speed. To avoid the dust, Case 4's worker performed the cutting slowly.

In all locations of the study, the environmental conditions and the surroundings' ventilation were good; the speed of air flow at each test site varied. In Case 2, the air movement was stagnant, but was stronger in Cases 3 and 4. Some turbulence was recorded in Case 3. These varied conditions had differential impacts on the asbestos concentration levels, regardless of the saws used and sheet quantity factors. The Case 2 sample showed the highest concentration level.

We can conclude from the study that the environmental conditions, the number of sheets cut simultaneously, the workers' behaviors and the choice of equipment have significant influences on the airborne asbestos concentration levels. Since the mitering duration at construction sites usually lasts much longer than those of the tests, and there is no threshold for asbestos as a cancer causing agent; mitering increases chances of lung cancer not only among construction workers, but also the public at large.

Many studies on occupational lung cancer on construction workers blame asbestos as one of the leading causes of the workers' disease [13,14]. There is a counter-argument that construction materials used in Europe, the United States, and other cold-weathered regions are of the friable ACM type, which is claimed to generate more asbestos concentrations than the non-friable substances, such as the AC sheets that are used extensively in Thailand and in other Asian countries. According to the argument, the AC sheets are safe to use for workers and others living nearby. This study shows that the argument is invalid. The AC sheets release asbestos dust at concentrations harmful not only to the workers, but also to the general public as well.

According to a survey of cancer patients in Thailand, lung cancer was most common among men between 2001-2009 (incidence rates) [15]. A Thai public health study found the country's northern region to have the highest lung cancer incidence rate during 1998-2000. Another study blamed radon [16], air pollutions and home-made cigarettes for age-standardized incidence rate (ASR, 30.7) [17]. However, asbestos exposure from the roof-tile mitering is not considered as a contributing cause of lung cancer among Thais. However in Thailand, corrugated AC roof sheets have been used extensively for sometime.

So far, international efforts to prohibit the use of asbestos have been inadequate and less powerful. The first attempt was made in 1999 by the Collegium Ramazzini, an international academic society specializing in environmental and occupational medicines, which issued a 3-fold rationale calling for the ban of asbestos on the premises [18,19]: "safer substitute materials are readily available, 'controlled' use of asbestos is not possible, and the health risks of asbestos are not acceptable in either the industrialized or the newly industrializing nations." Later, the International Labor Organization has launched several campaigns continuously on asbestos ban. Nevertheless, the use of asbestos has been halted in 44 countries in 2009 [20], and the number increased to 55 in the following year [21].

In Thailand, efforts to restrict the use of asbestos have yet to be successful. False beliefs that effective environment-control measure and its relatively low costs are largely responsible for the lack of progress in limiting its use. Even if factories manage to have an effective workers' exposure control as some have claimed, the exposure problem, as illustrated by this study, does not confine asbestos to the workplace alone. In addition, the asbestos containing materials including AC roof tile wastes disposal have not yet been controlled. Failure to impose the restrictive use of asbestos products would not be beneficial to the public. Lately, nevertheless, some preventive measures have been adopted. To promote the public health risk awareness, the Office of the Consumers Protection Board in 2010 issued a regulation requiring mandatory affixing of warning labels on all asbestos-containing products. In 2011, the government approved a strategic plan calling for a ban on chrysotile, including cement sheets. However, it did not set a time frame for the plan's adoption.

As long as people have easy access to asbestos and benefit from its low cost, it will continue to be used extensively. But, the question is: would it be beneficial to the public as a whole if the people's health is put in jeopardy? There are available many asbestos-free and other substitute products, though at initially higher costs. The manufacturers should be made aware of their social responsibility and encouraged to replace asbestos with health-safe substitute materials. To ensure their well-being, consumers would certainly prefer safer products. In the long run, greater demand will encourage greater production, resulting in greater supply and eventually to lowering production costs. The government can be instrumental in facilitating the mass-market production of asbestos-substitute goods by adopting long awaited national policies and strategic plans.

Acknowledgments

This study was part of the work supported by the Roofing and Accessories Industry Club. The researchers conducted the study independently with no party conferring benefits on the authors and their associated organizations.

Footnotes

No potential conflict of interest relevant to this article was reported.

References

- 1.Bartrip P. Asbestos and health in twentieth century Britain. Motives and outcomes; 14th Interanational Economic History Congress (IEHC); 2006 Aug 21-25; Helsinki, Finland. Helsinki: IEHC; 2006. [Google Scholar]

- 2.AIHA responds to asbestos ban bill [Interent] Troy (MI): Industrial Safety & Hygiene News; 2007. [cited 2007 Nov 27]. Available from: http://connection.ebscohost.com/c/articles/28632662/aiha-responds-asbestos-ban-bill. [Google Scholar]

- 3.LaDou J, Landrigan PJ, Bailar JC, Foa V, Frank A. A call for an international ban on asbestos. CMAJ. 2001;164:489–490. [PMC free article] [PubMed] [Google Scholar]

- 4.Huré P. Respiratory diseases linked to exposure to products such as asbestos: Are preventive measures sufficient? [Internet] Paris (France): National Research and Safety Institute; 2007. [cited 2007 Nov 27]. Available from: http://www.issa.int/pdf/prevention/2hure.pdf. [Google Scholar]

- 5.Tossavainen A. Global use of asbestos and the incidence of mesothelioma. Int J Occup Environ Health. 2004;10:22–25. doi: 10.1179/oeh.2004.10.1.22. [DOI] [PubMed] [Google Scholar]

- 6.Virta RL. Asbestos. US Geological Survey. Washington, DC: US Department of the interior; 2007. [Google Scholar]

- 7.Virta RL. Asbestos. US Geological Survey. Washington, DC: US Department of the interior; 2002. [Google Scholar]

- 8.Virta RL. Asbestos. US Geological Survey. Washington, DC: US Department of the interior; 2004. [Google Scholar]

- 9.Phanprasit W, Sujirarat D, Chaikittiporn C. Health risk among asbestos cement sheet manufacturing workers in Thailand. J Med Assoc Thai. 2009;92(Suppl 7):S115–S120. [PubMed] [Google Scholar]

- 10.Ansari FA, Ashquin M, Siddiqui H, Ahmad I. Asbestos fiber counts in work zone area of an asbestos-cement factory. J Sci Ind Res. 2007;66:935–937. [Google Scholar]

- 11.Tangtong C, Phanprasit W. Asbestos exposure monitoring in worker demolished asbestos contained material building and the concentration in environment. J Public Health. 2008;38:198–210. [Google Scholar]

- 12.Ohlson CG, Hogstedt C. Lung cancer among asbestos cement workers. A Swedish cohort study and a review. Br J Ind Med. 1985;42:397–402. doi: 10.1136/oem.42.6.397. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.Bruske-Hohfeld I, Muhner M, Pohlabeln H, Ahrens W, Bom-Audorff U, Kreienbrock L, Kreuzer M, Jahn I, Erich-Wichmann, Juckel KH. Occupational lung cancer risk for men in Germany: Result from a pooled case-control study. Am J Epidemiol. 2000;151:384–395. doi: 10.1093/oxfordjournals.aje.a010218. [DOI] [PubMed] [Google Scholar]

- 14.Jockel KH, Ahrens W, Jahn I, Pohlabeln H, Bolm-Audorff U. Occupational risk factors for lung cancer: a case-control study in West Germany. Int J Epidemiol. 1998;27:549–560. doi: 10.1093/ije/27.4.549. [DOI] [PubMed] [Google Scholar]

- 15.National Cancer Institute of Thailand. Cancer Registry 2001-2009. Bangkok (Thailand): Department of Medical Services, Ministry of Public Health; 2010. [Google Scholar]

- 16.Klinchid J, Chewaskulyoung B, Saeteng S, Lertprasertsuke N, Kasinrerk W, Cressey R. Effect of combined genetic polymorphisms on lung cancer risk in northern Thai women. Cancer Genet Cytogenet. 2009;195:143–149. doi: 10.1016/j.cancergencyto.2009.08.011. [DOI] [PubMed] [Google Scholar]

- 17.Martin N. Lung cancer in Thailand 1998-2000. Vol. IV. Bangkok (Thailand): National Cancer Institute; 2003. p. 41-4-blue. [Google Scholar]

- 18.Maltoni C. Call for an international ban on asbestos. Toxicol Ind Health. 1999;15:529–531. doi: 10.1177/074823379901500601. [DOI] [PubMed] [Google Scholar]

- 19.Landrigan PJ, Nicholson WJ, Suzuki Y, Ladou J. The hazards of chrysotile asbestos: a critical review. Ind Health. 1999;37:271–280. doi: 10.2486/indhealth.37.271. [DOI] [PubMed] [Google Scholar]

- 20.Good practice note; asbestos: occupational and community health issues [Internet] Washington, DC: World Bank Group; 2009. [cited 2009 May 1]. Available from: http://siteresources.worldbank.org/EXTPOPS/Resources/AsbestosGuidanceNoteFinal.pdf. [Google Scholar]

- 21.Current asbestos bans and restrictions [Internet] London (UK): International Ban Asbestos Secretariat; 2011. [cited 2011 Jan 6]. Available from: http://ibasecretariat.org/alpha_ban_list.php. [Google Scholar]