Abstract

Aim:

To evaluate the effect of water temperature on the marginal fit of bis-acrylic composite provisional crown during resin polymerization.

Materials and Methods:

Precisely machined 10 brass master dies were designed to simulate molar teeth. Five brass dies were selected and precisely machined to simulate all ceramic crown preparation. An acrylic jaw replica was made in which brass dies were arranged equidistant from each other. A custom-made metallic tray was fabricated on the acrylic jaw replica to make polyvinyl siloxane impression matrix. Bis-acrylic composite resin provisional crowns were made using polyvinyl siloxane impression matrix. Provisional crowns were polymerized at room temperature (Group I direct technique, on dental stone cast; Group I indirect technique crowns) and at different water temperatures (Group II direct technique crowns). The vertical marginal gap between all the provisional crown margins and the finish line of brass dies was measured using a Research Stereomicroscope System.

Results:

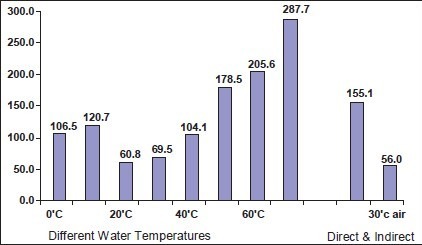

The results were statistically analyzed using one-way analysis of variance (ANOVA) test and Newman–Keul's test. The results showed that crowns polymerized in 20°C and 30°C water had marginal gap approximately three times smaller than those polymerized in 30°C air, due to the reduced polymerization shrinkage.

Conclusion:

This study shows that crowns polymerized in 20°C and 30°C water had mean vertical marginal gap approximately three times smaller than those polymerized in 30°C air. It was approximately closer to that of crowns fabricated by indirect technique. Warmer water also supposedly hastens polymerization.

KEY WORDS: Bis-acrylic composite resin, provisional crown margin, water temperature during polymerization

In clinical situation, it is common to readjust and reline a provisional crown made chair side, until an acceptable marginal fit is obtained. These crowns, when polymerized in air, have poor marginal fit. Polymerizing them at 30°C water temperature improves the marginal fit as laboratory fabricated crowns. This technique helps dentists to obtain better fit of direct provisional crowns in shorter chair time, without the need for relining procedure.

In fixed prosthodontics, the fabrication of provisional restoration is an important milestone, which creates a satisfactory tooth replacement. Accurate fit of provisional crowns at margin is essential to protect the prepared tooth from physical, chemical, bacterial, and thermal insults and also to maintain the health of gingival tissues.

The marginal fit of provisional crown varies with different techniques, materials, and conditions used for fabrication. Provisional crown margin made by indirect technique was considered to be more accurate than that made by the direct technique.[1] The reason for poor marginal fit of provisional crown fabricated by direct technique is distortion as it is removed from the mouth and polymerization shrinkage due to exothermal reaction during resin polymerization.[2]

Ogawa et al.[3] recommended the use of warm water to enhance the polymerization efficiency and reduce any unconverted monomer of polymethyl methacrylate provisional crowns to get a best marginal fit.

Composite resins have gained popularity in the recent years for fabrication of provisional restorations because of decreased polymerization shrinkage and ease of fabrication. Bis-acrylic composite resin has better physical properties when compared to other resins.[4] Hence, in this study, bis-acrylic composite provisional crown was evaluated for the following:

the effect of water temperature on the marginal fit of the provisional crowns, during resin polymerization.

the marginal fit of Bis acrylic composite provisional crown fabricated with different techniques.

Materials and Methods

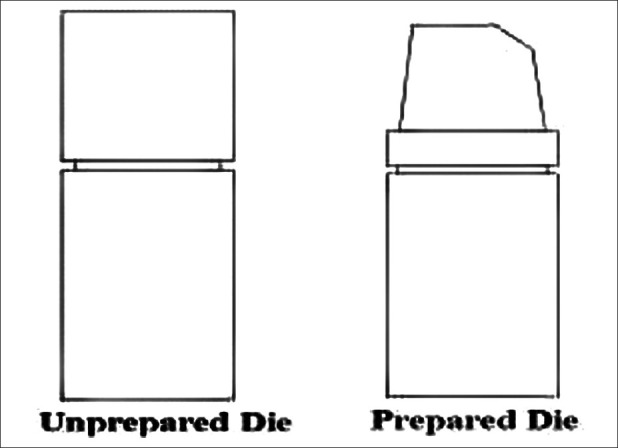

Preparation of master brass metal dies

Precisely machined 10 brass master dies of dimension 8 mm height and 10 mm diameter were designed to simulate molar teeth.[5] This was mounted on a cylindrical base of 20 mm length and 10 mm diameter, as shown in the schematic diagram [Figure 1]. Five brass dies were selected and precisely machined to simulate complete crown preparation. The prepared brass dies were 1.5 mm short of the unprepared dies in occlusal and axial surfaces. The preparation had 5° taper toward the occlusal surface from the finish line.

Figure 1.

Schematic diagram of unprepared and prepared brass dies

The dies were given shoulder finish line to receive an all-ceramic crown. On one side of the flat occlusal surface, a 30° bevel to the long axis of the die was machined to standardize crown placement. The surfaces of the dies were highly polished. Two lines were drawn parallel to each other on the cylindrical base for all five prepared brass dies.

Preparation of acrylic jaw replica for brass dies

Wax model of an edentulous jaw was constructed using a Fresco mold. Brass dies were arranged in wax jaw replica in arch shape by arranging one brass die in the midline at the incisor region, two in the premolar region, and two in the molar region, equidistant from each other. The wax jaw replica was finished and polished.

The brass dies were removed from wax jaw replica and acrylized using heat-cure acrylic denture base resin (DPI) by compression molding technique. The acrylic jaw replica was recovered, trimmed, finished, and polished. The 10 brass metal dies were checked for the fit in the acrylic jaw replica [Figure 2]. Each brass die was numbered as no. 1, 2, 3, 4, and 5, for both prepared and unprepared brass dies. Four holes of 2 mm diameter were made adjacent to the brass dies in acrylic jaw replica to act as vertical stop.

Figure 2.

Five unprepared and five prepared brass dies and acrylic jaw replica

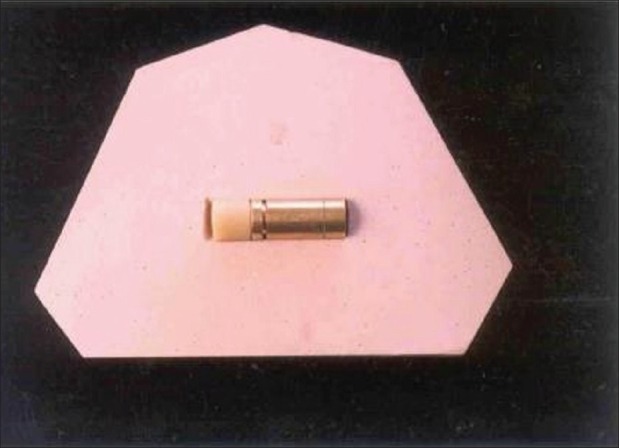

Preparation of custom-made metallic tray for the acrylic jaw replica

A custom-made stainless steel tray [Figure 3] was made on the acrylic jaw replica with five unprepared brass dies, with four vertical stops corresponding to the holes made in acrylic jaw replica. These vertical stops stabilize the tray both in vertical and horizontal directions, ensure uniform flow of impression material, and maintain uniform load during preparation of silicone matrix and fabrication of provisional crowns. Three handles were also made for easy removal and insertion of tray on the acrylic jaw replica.

Figure 3.

Custom-made stainless steel tray

Preparation of silicone putty matrix

The vinyl polysiloxane impression putty [Figure 4] material (3M Express STD) was mixed according to manufacturer's instructions and loaded in the metallic tray. The tray was seated on acrylic jaw with unprepared brass dies with light finger pressure, so that four vertical stops in the tray guide the tray to seat inside the holes made on the acrylic jaw. After the final setting of impression material, the silicone putty matrix was removed and checked for defects and allowed to bench cure for 1 h. Thus, the silicone putty matrix [Figure 4] was made ready for construction of provisional crown.

Figure 4.

Silicone putty matrix for fabrication of provisional crowns

The inner surface of metallic tray with occlusal stops was coated with 3M tray adhesive and allowed to dry for 5 minutes.

Construction of provisional crown

Grouping the provisional crowns

The provisional crowns polymerized in the room temperature with the silicone putty matrix on the brass dies were considered as Group I direct technique provisional crowns [Figure 5].

Figure 5.

Group I direct technique provisional crowns

The provisional crowns polymerized in the room temperature with stone cast obtained from silicone putty matrix of prepared brass dies were considered as Group I indirect technique provisional crowns [Figure 6].

The provisional crowns polymerized at different water temperature in the Thermostat, along with silicone putty matrix were considered as Group II direct technique 0°C, 10°C, 20°C, 30°C, 40°C, 50°C, 60°C, and 80°C provisional crowns, respectively [Figure 7].

Figure 6.

Group I indirect technique provisional crowns

Figure 7.

Group II direct technique provisional crowns at different water temperatures

Fabrication of group I direct technique provisional crowns

The five unprepared brass dies were removed from the acrylic jaw and replaced with five prepared brass dies. Petrolatum jelly was applied all over the dies and the acrylic jaw. The bis-acrylic composite resin (Tempofit-Duomix, Detax, Ettlingen, Germany) was used for the fabrication of provisional crowns. The bis-acrylic resin [Figure 8], base paste, and catalyst paste were dispensed on the glass slab using a synchronous dispenser (5:1 ratio) and mixed for 20–30 seconds to get a homogenous mix. It was then loaded in the application syringe and the resin dispensed into the silicone putty matrix.

Figure 8.

Bis-acrylic composite resin

The silicone putty matrix along with the resin material was placed over the acrylic jaw having five prepared diesi with constant load. After 2–2.5 minutes from the start of mixing, the matrix was removed from the acrylic jaw when the material reached a firm elastic consistency. The crowns were allowed to polymerize in the room temperature in the silicone putty matrix for 5–6 minutes. The provisional crowns were removed from the putty matrix and trimmed and polished under magnifying lens (Surgitel 275 F, General Scientific Corp,Ann Arbor, USA). The crowns were washed in distilled water and dried with slight air blow and placed over the prepared brass dies.

Fabrication of group I indirect technique provisional crowns

The silicone putty impression was made with five prepared dies in the acrylic jaw. The silicone putty impression was poured with dental stone. The cast was recovered from the silicone matrix and coated with separating media (cold mold seal). A silicone putty matrix was made and the bis-acrylic composite resin was manipulated and dispensed in the silicone putty matrix as mentioned earlier. The matrix was seated over the stone cast, which was having replica of five prepared dies. The crowns were allowed to cure on the stone cast along with putty matrix at room temperature. After 5–6 minutes, the crowns were removed, trimmed, polished, washed, and dried, and placed over the prepared brass dies.

Fabrication of group Ii direct technique provisional crowns

The silicone putty matrix of acrylic jaw with five unprepared dies was made and resin material was held over the acrylic jaw with constant load through fingers. The crowns were allowed to polymerize in the following water temperatures for 5–6 minutes along with silicone putty matrix during resin polymerization in a thermostat [Figure 9] manufactured by Biotech and Scientific Industries, Agra, India:

Figure 9.

Thermostat

0°C water,

10°C water,

20°C water,

30°C water,

40°C water,

50°C water,

60°C water, and

80°C water.

Five crowns for each and every water temperature were fabricated. Then, the crowns were removed, trimmed, polished, washed, and dried as mentioned earlier and seated over the prepared dies.

Load application over the provisional crowns and measuring vertical marginal gap

A spring-loaded seating jig [Figure 10] was used to apply uniform constant load of 3 kg for 15 seconds over the provisional crown seated on the prepared dies. After load application for 15 seconds, the provisional crown along with the brass dies were placed in a Die Positioner [Figure 11], which was made of die stone (Kalabhai, Mumbai, India).

Figure 10.

Spring-loaded seating jig

Figure 11.

Die Positioner

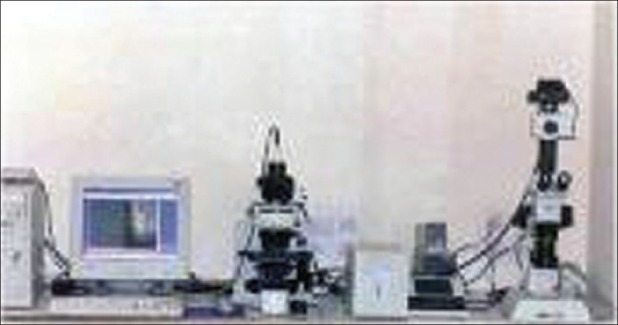

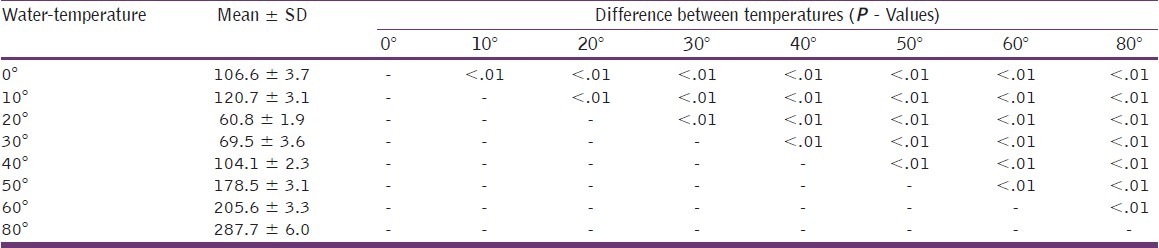

The Die Positioner was kept over the platform of the Stereomicroscope (Olympus, Tokyo, Japan). The two lines drawn parallel to each other on all the five prepared dies guided the position of the die during measurement of vertical marginal gap. Measurement of vertical marginal gap was made on four opposite surfaces of the dies.

The vertical marginal gap between the provisional crown margin and the finish line of brass die was measured by using a computer monitor [Figure 12], which was connected to Research Stereomicroscope System [Figure 13], as shown in the schematic diagram [Figure 14].

Figure 12.

Stereomicroscope connected to computer monitor for marginal measurement

Figure 13.

Stereomicroscope

Figure 14.

Schematic representation of measuring marginal gap

For each and every surface, two vertical marginal gaps were measured. One was from the margin of the crown to the outer finish margin of the die. The second one was from the inner margin of the crown to inner finish margin of the brass die. The average of these two measurements was calculated and tabulated. Hence, 4 measurements for each crown and 20 measurements for each group were tabulated. The values were utilized for statistical analysis.

Results

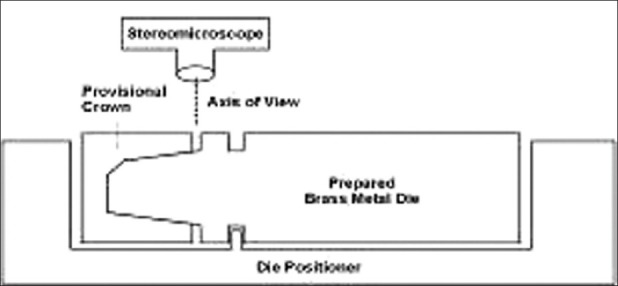

The statistical analysis of the results shows that the mean vertical marginal gap for Group I provisional crowns in direct technique was 155.14 μm and in indirect technique was 55.96 μm [Table 1]. The marginal gap was three times smaller in indirect technique than in direct technique.

Table 1.

Mean vertical marginal gap between Group I direct technique provisional crowns and Group I indirect technique provisional crowns (in μm)

In Group II direct technique provisional crowns, the minimal mean vertical marginal gap observed was at 20°C water temperature, i.e., 60.8 ± 19 mm, followed by at 30°C water temperature, i.e., 69.5 ± 3.6 mm [Table 2].

Table 2.

Comparison of mean vertical marginal gap between Group II direct technique provisional crowns polymerized at different water temperatures (in μm)

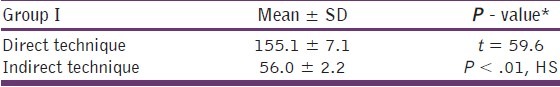

The least marginal gap observed between Group II direct technique provisional crowns and Group I direct technique provisional crowns was 60.8 ± 1.9 mm at 20°C, followed by 69.5 ± 3.6 μm at 30°C water temperature [Table 3]: One-way analysis of variance (ANOVA; F = 9272, P < 0.001) Newman–Keul's range test [least significant difference (LSD) = 4.0, P < 0. 01].

Table 3.

Mean difference of vertical marginal gap between Group II direct technique provisional crowns and Group I direct technique provisional crowns

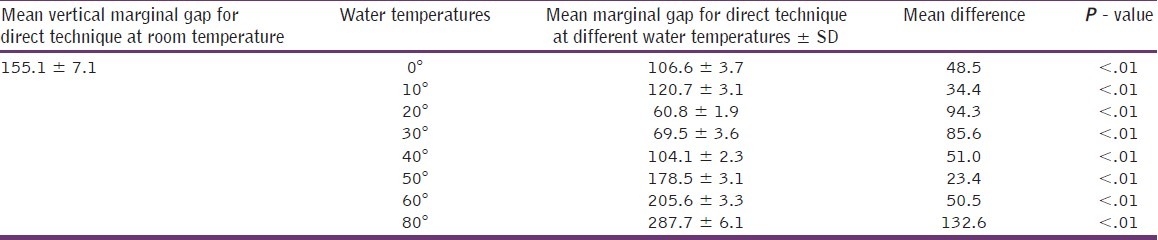

The least marginal gap observed between Group II direct technique and Group I indirect technique provisional crowns was 56.0 ± 2.2 mm in the indirect technique [Table 4]: One-way ANOVA (F = 6137.7, P < 0.001) Newman–Keul's test (P < 0.01).

Table 4.

Mean difference of vertical marginal gap between Group II direct technique provisional crowns and Group I indirect technique provisional crowns

Graph 1 shows the mean vertical marginal gap of Group I and Group II provisional crowns and illustrates that the minimal mean vertical marginal gap observed was at 20°C water temperature, followed by 30°C water temperature, which is comparable to the Group I indirect technique provisional crown.

Graph 1.

Mean vertical marginal gap of provisional crowns polymerized at different water tempertures for direct and indirect technique

Discussion

Temporary coverage of a prepared tooth is an important step in Fixed Prosthodontics.[6] An optimal provisional restoration must satisfy many interrelated factors like biological, mechanical, and esthetic factors, which include marginal accuracy, fracture resistance, tissue compatibility, wear resistance, surface hardness, surface polishability, and color stability. Among these, marginal accuracy of provisional restoration is essential to maintain gingival health and to protect the prepared tooth from physical, chemical, bacterial, and thermal injuries.[7,8]

Many researches reveal that the marginal fit of provisional crown depends on the design of the master die, the amount of resin, the technique used, the brand of resin, type of resin, and the conditions during resin polymerization.[9–11] Although many techniques and materials are available for fabricating provisional restorations, the two main techniques are indirect and direct techniques. The direct technique is done on the actual prepared teeth in mouth and the indirect technique is accomplished on a cast of prepared teeth. The provisional crown margins fabricated by the indirect technique are considered to be more accurate than those fabricated by the direct technique.[12,13]

Direct technique is advantageous comparative to the indirect technique as it requires very less chairside time and cost, by eliminating an additional impression, stone cast, and an ancillary staff.[14] Moreover, this technique of fabrication of provisional crowns can be efficiently performed for all conditions in Fixed Prosthodontics, such as single crown, fixed partial denture, and also for full mouth rehabilitation.

To improve the marginal fit of direct provisional crown, several techniques were introduced like vent and reline, the on/off technique, and method of using silicone putty matrix, which produced different degrees of accuracy at the provisional crown margin.[15]

Another important consideration during direct provisional resinous crown fabrication is heat generated by the exothermic reaction of the resin material during polymerization.[3] Temperature rise can damage the pulp irreversibly. Grajower et al.[2] had recommended silicone matrix for curing direct temporary crowns because it had a high heat absorption capacity and sufficient thermal conductivity for external heat dissipation. Removal of direct provisional restorations after initial resin polymerization allows final polymerization to occur extraorally.[16] This dissipates heat and prevents the unexpected locking of the provisional crown into undercuts.

Moulding et al.[17] reported that removal technique had produced significantly poorer marginal adaptation because of the amount of movement during fabrication.

Few authors recommend placing the provisional restorations in hot water to enhance the polymerization reaction and to reduce the unconverted monomer.[18] Takahiro Ogawa et al. suggest the use of 30°C water temperature to polymerize direct provisional polymethyl methacrylate crowns to get the best marginal fit.[2,4]

Bis-acrylic composites are the material of choice for the fabrication of direct provisional restoration than polymethyl methacrylate as the latter has high exothermic reaction.[19,20] So, the effect of water temperature on the marginal fit of self-cured bis-acrylic composite provisional crown during resin polymerization was considered in this study.

The provisional crown polymerized on the stone cast showed least mean vertical marginal gap because it had supporting form during resin polymerization. The provisional crowns polymerized in the silicone putty matrix in 30°C air had a maximum mean vertical marginal gap that was three times that of the indirect technique. This is because without any supporting form in putty matrix, the amount of distortion and shrinkage of the crown was dependent on the fluidity of the resin during polymerization.[21]

Improved vertical marginal fit of provisional crowns polymerized at 20°C–30°C water temperature was comparable to that of indirect technique, which may be due to two reasons:

The water acted as a supporting medium during polymerization.

Possible compensation of polymerization shrinkage by means of hygroscopic expansion of Bis acrylic composite resin.

Provisional Crowns polymerized at higher water temperatures produced increased vertical marginal gap as,

The heating of some monomers can cause them to vaporize, which reduces the ratio of monomer and allows further dimensional contraction.

Heat activates the chemical reaction between monomer and polymer, and produces more complete polymerization. Such complete polymerization results in greater dimensional contraction.[4,22]

Provisional crowns polymerized at 0°C–10°C water temperatures produced increased vertical marginal gap as they delayed polymerization.

In the clinical situation, it is common to readjust and reline a provisional crown few times until an acceptable marginal fit is obtained. The results of this study show that crowns polymerized in 20°C and 30°C water had mean vertical marginal gap approximately three times smaller than those polymerized in 30°C air. It was approximately closer to that of crowns fabricated by indirect technique. Warmer water also supposedly hastens polymerization. This technique of polymerizing the provisional crown at 20°C–30°C water temperature may help dentists to obtain better fit of direct provisional crown in a shorter chair time, without the need for relining procedure.

Resinous polymerization shrinkage is unavoidable to some extent and physical properties of resin are still not fully understood.[23] Further studies are required to evaluate the strength and hygroscopic expansion of bis-acrylic composite resin at different water temperatures.

Conclusion

Provisional crowns made in direct technique have poor marginal fit. Crowns polymerized in 20°C and 30°C water had mean vertical marginal gap approximately three times smaller than those polymerized in 30°C air. Marginal fit of provisional crowns using direct technique at water temperatures of 20°C and 30°C were comparable to that of indirect technique provisional crowns. Therefore, when the direct technique is used, it is recommended to polymerize bis-acrylic composite resin provisional crowns in 30°C water during resin polymerization.

Acknowledgement

We would like to thank the staff of Bapuji Institute of Engineering and Technology, Davangere, for helping us to carry out this study in their college.

Footnotes

Source of Support: Nil

Conflict of Interest: None declared.

References

- 1.Groten M, Axmann D, Pröbster L, Weber H. Determination of the minimum number of marginal gap measurements required for practical in vitro testing. J Prosthet Dent. 2000;83:40–9. doi: 10.1016/s0022-3913(00)70087-4. [DOI] [PubMed] [Google Scholar]

- 2.Grajower R, Shaharbani S, Kaufman E. Temperature rise in pulp chamber during fabrication of temporary self-curing resin crowns. J Prosthet Dent. 1979;41:535–40. doi: 10.1016/0022-3913(79)90088-x. [DOI] [PubMed] [Google Scholar]

- 3.Ogawa T, Aizawa S, Tanaka M, Matsuya S, Hasegawa A, Koyano K. Effect of water temperature on the fit of provisional crown margins during polymerization. J Prosthet Dent. 1999;82:658–61. doi: 10.1016/s0022-3913(99)70006-5. [DOI] [PubMed] [Google Scholar]

- 4.Tjan AH, Tjan AH, Grant BE. Marginal accuracy of temporary composite crowns. J Prosthet Dent. 1987;58:417–21. doi: 10.1016/0022-3913(87)90266-6. [DOI] [PubMed] [Google Scholar]

- 5.de Araujo PA, Jorgensen KD. Effect of material bulk and undercuts on the accuracy of impression materials. J Prosthet Dent. 1985;54:791–4. doi: 10.1016/0022-3913(85)90472-x. [DOI] [PubMed] [Google Scholar]

- 6.Koumjian JH, Holmes JB. Marginal accuracy of provisional restorative materials. J Prosthet Dent. 1990;63:639–42. doi: 10.1016/0022-3913(90)90320-c. [DOI] [PubMed] [Google Scholar]

- 7.Federick DR. The provisional fixed partial denture. J Prosthet Dent. 1975;34:520–6. doi: 10.1016/0022-3913(75)90039-6. [DOI] [PubMed] [Google Scholar]

- 8.Richter WA, Ueno H. Relationship of crown margin placement to gingival inflammation. J Prosthet Dent. 1973;30:156–61. doi: 10.1016/0022-3913(73)90050-4. [DOI] [PubMed] [Google Scholar]

- 9.Hung CM, Weiner S, Dastane A, Vaidyanathan TK. Effects of thermocycling and occlusal force on the margins of provisional acrylic resin crowns. J Prosthet Dent. 1993;69:573–7. doi: 10.1016/0022-3913(93)90284-u. [DOI] [PubMed] [Google Scholar]

- 10.Young HM, Smith CT, Morton D. Comparative in vitro evaluation of two provisional restorative materials. J Prosthet Dent. 2001;85:129–32. doi: 10.1067/mpr.2001.112797. [DOI] [PubMed] [Google Scholar]

- 11.Christensen GJ. Provisional restorations for fixed prosthodontics. J Am Dent Assoc. 1996;127:249–52. doi: 10.14219/jada.archive.1996.0177. [DOI] [PubMed] [Google Scholar]

- 12.Crispin BJ, Watson JF, Caputo AA. The marginal accuracy of treatment restorations: A comparative analysis. J Prosthet Dent. 1980;44:283–90. doi: 10.1016/0022-3913(80)90012-8. [DOI] [PubMed] [Google Scholar]

- 13.Monday JJ, Blais D. Marginal adaptation of provisional acrylic resin crowns. J Prosthet Dent. 1985;54:194–7. doi: 10.1016/0022-3913(85)90285-9. [DOI] [PubMed] [Google Scholar]

- 14.Robinson FB, Hovijitra S. Marginal fit of direct temporary crowns. J Prosthet Dent. 1982;47:390–2. doi: 10.1016/s0022-3913(82)80087-5. [DOI] [PubMed] [Google Scholar]

- 15.Moulding MB, Teplitsky PE. Intrapulpal temperature during direct fabrication of provisional restorations. Int J Prosthodont. 1990;3:299–304. [PubMed] [Google Scholar]

- 16.Castelnuovo J, Tjan AH. Temperature rise in pulpal chamber during fabrication of provisional resinous crowns. J Prosthet Dent. 1997;78:441–6. doi: 10.1016/s0022-3913(97)70057-x. [DOI] [PubMed] [Google Scholar]

- 17.Moulding MB, Loney RW, Ritsco RG. Marginal accuracy of provisional restorations fabricated by different techniques. Int J Prosthodont. 1994;7:468–72. [PubMed] [Google Scholar]

- 18.Ogawa T, Tanaka M, Koyano K. Effect of water temperature during polymerization on strength of autopolymerizing resin. J Prosthet Dent. 2000;84:222–4. doi: 10.1067/mpr.2000.108574. [DOI] [PubMed] [Google Scholar]

- 19.Luthardt RG, Stössel M, Hinz M, Vollandt R. Clinical performance and periodontal outcome of temporary crowns and fixed partial dentures: A randomized clinical trial. J Prosthet Dent. 2000;83:32–9. doi: 10.1016/s0022-3913(00)70086-2. [DOI] [PubMed] [Google Scholar]

- 20.Wang RL, Moore BK, Goodacre CJ, Swartz ML, Andres CJ. A comparison of resins for fabricating provisional fixed restorations. Int J Prosthodont. 1989;2:173–84. [PubMed] [Google Scholar]

- 21.Davidson CL, Feilzer AJ. Polymerization shrinkage and polymerization shrinkage stress in polymer-based restoratives. J Dent. 1997;25:435–40. doi: 10.1016/s0300-5712(96)00063-2. [DOI] [PubMed] [Google Scholar]

- 22.Barghi N, Simmons EW., Jr The marginal integrity of the temporary acrylic resin crown. J Prosthet Dent. 1976;36:274–7. doi: 10.1016/0022-3913(76)90182-7. [DOI] [PubMed] [Google Scholar]

- 23.Tjan AH, Castelnuovo J, Shiotsu G. Marginal fidelity of crowns fabricated from six proprietary provisional materials. J Prosthet Dent. 1997;77:482–5. doi: 10.1016/s0022-3913(97)70140-9. [DOI] [PubMed] [Google Scholar]