Abstract

Aim:

The aim of the study was to compare the frictional resistance of titanium, self-ligating stainless steel, and conventional stainless steel brackets, using stainless steel and titanium molybdenum alloy (TMA) archwires.

Materials and Methods:

We compared the frictional resistance in 0.018 slot and 0.022 slot of the three brackets – titanium, self-ligating stainless steel, and conventional stainless steel – using stainless steel archwires and TMA archwires. An in vitro study of simulated canine retraction was undertaken to evaluate the difference in frictional resistance between titanium, self-ligating stainless steel, and stainless steel brackets, using stainless steel and TMA archwires.

Results and Conclusion:

We compared the frictional resistance of titanium, self-ligating stainless steel, and conventional stainless steel brackets, using stainless steel and TMA archwires, with the help of Instron Universal Testing Machine. One-way analysis of variance (ANOVA), Student's “t” test, and post hoc multiple range test at level of <0.05 showed statistically significant difference in the mean values of all groups. Results demonstrated that the titanium, self-ligating stainless steel, and stainless steel brackets of 0.018-inch and 0.022-inch slot had no significant variations in frictional résistance. The self-ligating bracket with TMA archwires showed relatively less frictional resistance compared with the other groups. The titanium bracket with TMA archwires showed relatively less frictional resistance compared with the stainless steel brackets.

KEY WORDS: Orthodontic brackets, frictional resistance, round arch wires, TMA archwires

The most important orthodontic goal is to achieve creation of the best balance among occlusal relationship, dental and facial esthetics, with stability of result and long-term maintenance.

One of the common clinical challenges in orthodontics is friction, particularly with sliding mechanics. It must be dealt efficiently to provide optimal orthodontic results.

When one moving object contacts another tangentially, friction at the interface resists movement. Orthodontists have long been aware that effects of forces applied by treatment appliances are reduced by friction. Friction is commonly discussed in terms of inhibiting canine retraction, but it is present during most tooth movements. It may be divided into static friction, which is the force required to initiate tooth movement, and kinetic friction or the force that resists motion (Kajdas et al., 1990). The coefficient of static friction is always larger than that of kinetic friction (Jastrzebski, 1959). It is felt that the former is more important in tooth movement, for when a tooth slides along an archwire, tooth movement occurs in a series of short jumps as the archwire and biological resistance strive to upright the root through the alveolar bone, with the static frictional resistance needed to overcome each time the tooth moves a little. In recent years, a variety of new metal alloys have been used in the manufacture of orthodontic archwires. In addition, the straight wire edgewise appliance employing sliding mechanics has become a commonly used appliance.

A common method of translating a tooth orthodontically is by the use of sliding mechanics. Mesiodistal tooth movement is accomplished by guiding a tooth along a continuous archwire with the help of an orthodontic bracket. In sliding mechanics, friction is determined by the type of archwire, type of bracket, and the method of ligation. A new bracket system made from pure titanium has been introduced to the profession in response to the reports about corrosion of stainless steel brackets and sensitivity to nickel that is present in the stainless steel alloy. Titanium has proven to be biocompatible and its benefits have been acknowledged in medical and dental prosthetics. Titanium metal discovered by M. H. Klaproth in 1795 became an important structural metal because of its light weight. Titanium brackets are single-piece cast brackets. The first self-ligating bracket, the Russels attachment, was developed by a New York orthodontic pioneer, Dr. Jacob Stolenzenberg, in the early 1930s. The basic advantages of these self-ligating brackets involve the elimination of certain utilities or materials such as elastomeric modules and the ligature wires. In orthodontics, friction between bracket and archwire is multifactorial. Stoner had mentioned about friction in orthodontic literature as far back as 1960. The friction is due to archwire, angulation of wire to bracket, ligature force, and change in wire shape, surface roughness, and changes in wire and bracket surface. Titanium molybdenum alloy (TMA) or β titanium wire is a new orthodontic alloy with unique properties and an excellent balance of properties suitable for many orthodontic applications. For a given cross section, it can be deflected approximately twice as far as stainless steel wire without permanent deformation. β titanium has a modulus of elasticity less than that of stainless steel and about twice that of nitinol. Distinctive features of this wire include good springback, low force delivery levels, and good formability and weldability. Also, the absence of nickel makes these wires useful in patients allergic to nickel. It is ideal for the situation where force levels less than stainless steel and more than Ni–Ti alloy are required. The objective of this study is to compare frictional resistance in titanium, self-ligating stainless steel, and stainless steel brackets using stainless steel and TMA archwires, with the help of an Instron Universal testing Machine.

Materials and Methods

This study was conducted in the Department of Orthodontics and Dentofacial Orthopedics, Vinayaka Missions Shankarachariyar Dental College, Salem, Tamil Nadu. The in vitro tests were conducted at the Sree Chitra Tirunal Institute for Medical Science and Technology, Thiruvanthapuram Kerala. The basic study was designed to compare the coefficient of kinetic friction of stainless steel, self-ligating stainless steel, and titanium brackets (ORMCO, Columbia, United States), using stainless steel (Ortho-organizers, Carlsbad, CA, United States) and TMA archwires (ORMCO, Columbia, United States). The property investigated was the frictional characteristic using 0.017 × 0.025 and 0.019 × 0.025 rectangular archwires in 0.018 – and 0.022-inch slot, respectively, ligated with elastic modules.

The canine brackets used were coded as follows:

Titanium bracket – 20 nos in each slot (ORMCO; 0.018-inch slot and 0.022-inch slot) [Figure 1].

Self-ligating stainless steel brackets – 20 nos in each slot (ORMCO; 0.018-inch slot and 0.022-inch slot) [Figure 2].

Stainless steel brackets – 20 nos in each slot (ORMCO; 0.018-inch slot and 0.022-inch slot) [Figure 3].

Stainless steel wires 0.017 inch × 0.025 inch and 0.019 inch × 0.025 inch (Ortho-organizers) [Figure 4].

TMA wires 0.017 inch × 0.025 inch and 0.019 inch × 0.025 inch (ORMCO) [Figure 5].

Figure 1.

Self ligating stainless steel brackets

Figure 2.

Stainless steel brackets

Figure 3.

Titanium brackets

Figures 4 and 5.

Stainless steel Arch wires /Titanium molybdenum Arch wires

The evaluation of frictional resistance between brackets and the archwire was carried out as per the protocol described by Tidy.[1] It consisted of a simulated fixed appliance with an archwire in a vertical position. The four premolar brackets on either side were bonded to a rigid Perspex sheet at 8-mm intervals with a 16-mm space for a movable bracket at the center. Both 0.018-inch slot and 0.022-inch slot brackets were set up in this way using in turn archwires of 0.017 × 0.025 inch and 0.019 × 0.025 inch, respectively, for sliding the canine bracket to simulate canine retraction. The archwires used were stainless steel and TMA of 0.017 × 0.025 inch and 0.019 × 0.025, were secured using elastomeric ligatures (Ortho-organizers) [Figure 6]. The movable bracket was fitted with a 10-mm power arm from which weights of 100 g were hung to represent the single equivalent force acting at the center of resistance of the tooth root. The length of the power arm was chosen to represent the distance from the slot to the center of resistance of a typical canine tooth. All the tests were conducted under dry conditions with Instron Universal Testing Machine Model no. 3365 [Figure 7], with a cross head moving downward at a speed of 5 mm / min. The movable bracket was suspended from the load cell of the testing machine, while the Perspex sheet was mounted on the cross head below [Figure 8].

Figure 6.

Elastomeric modules

Figure 7.

Instron machine

Figure 8.

Tidy's protocol

The load cell readings represented the clinical force of retraction that would be applied to the tooth, part of which would be lost in friction, while the remainder was transmitted to the tooth root. The difference between the load cell reading and the load on the power arm thus represented the friction. Brackets of both the sides of the upper arch were mounted on separate Perspex sheets. The 0.017 × 0.025 inch stainless steel and TMA archwires were secured to the 0.018 slot bracket and 0.0.019 × 0.025 inch stainless steel and TMA archwires were secured to the 0.022 slot bracket with elastomeric modules that were done to standardize the ligature force. A trial run was performed on the power arm without any load to check whether the elastomeric module was binding onto the archwire prior to each test. Then, each side was tested with 100 g of weight suspended from the power arm. The load needed to move the canine bracket across the central span was recorded separately as kinetic friction from the graphic plotter. The coefficient of kinetic friction was calculated from this value with the help of the following formula:

![]()

where P is the frictional resistance, F the equivalent force acting at a distance, W the bracket distance, h is 10 mm, and μ is coefficient of friction.

The readings for 0.018 slot and 0.022 slot using 0.017 × 0.025 inch and 0.019 × 0.025 inch archwires, respectively, for sliding mechanics were taken with three variant brackets (the stainless steel, self-ligating stainless steel, and titanium brackets) using two different archwires, the stainless steel and TMA (β–titanium) archwires, and were averaged.

Codes used for the study

Stainless steel brackets using stainless steel wire – OSB_SS

Stainless steel brackets using TMA wire – OSB_TM

Titanium brackets using stainless steel wire – OTB_SS

Titanium brackets using TMA wire – OTB_TM

Self-ligating stainless steel using stainless steel wire – OSLB_SS

Self-ligating stainless steel using TMA wire – OSLB_TM

Statistical Analysis

Analysis of variance (ANOVA) test was conducted for mean score analysis to compare between three types of brackets and two types of wire combinations. If the P value is greater than 0.05, it means the hypothesis is accepted with higher range frictional resistance. Null hypothesis giving values for different bracket and wire combinations and the post hoc test signified the marginal differences subjecting the variance into three groups. The paired Student's t-test compared mean scores of frictional resistance for titanium self-ligating stainless steel and stainless steel brackets of 0.018-inch and 0.022-inch slots using stainless steel and TMA wires, hence signifying the results to quantify the study. Orthodontic brackets are an important constituent of an orthodontic appliance. The archwires are fitted in the bracket and sliding mechanics require either the bracket or the archwires to slide through the bracket slot. The resulting frictional resistance is an important consideration in appliance design. Of all the different materials tested so far, stainless steel brackets are preferred for their low frictional force values. However, concerns have been expressed about the nickel content in the stainless steel causing hypersensitivity and corrosion in the oral environment. In addition, there are instances where MRI or CT imaging may have been distorted because of the stainless steel alloys. To overcome these difficulties, pure titanium brackets have been made available. These brackets have excellent corrosion resistance and are biocompatible, but have not been subjected to studies related to the frictional resistance force an orthodontist may encounter during sliding mechanics.

To reduce friction clinically, some practitioners prefer the use of round wire or they reduce rectangular wire in the buccal segments to a more rounded cross section. Round wires, of course, eliminate friction caused by active torque. Round wires generally produce less friction than rectangular wire when engaged in brackets out of alignment because of their greater flexibility. Friction as a result of two-point contact is largely independent of wire stiffness or cross section and so is likely to be little affected by the choice of round or rectangular wire.[1] So, for this study, we preferred the rectangular wires.

Very few studies have been conducted and discussed in the literature about corrosion and sensitivity to the nickel present and stainless steel brackets. Titanium has heralded as a material totally compatible in the oral environment and superior in structural integrity compared to stainless steel. The friction-free self-ligating brackets produce reduced friction. Failure or distortion of orthodontic brackets during treatment minimizes control of tooth movement.

The study was designed to compare the frictional properties of stainless steel, titanium, and self-ligating brackets in 0.018 and 0.022 slots, in 0.017 × 0.025 and 0.019 × 0.025 stainless steel and TMA archwires with second-order angulations, ligated with elastic modules to the brackets slot. In this study, Tidy's protocol was followed because it closely approximated the clinical situation.[1] The apparatus consisted of a simulated arch fixed appliance with archwire in a vertical position.

Four premolar pre-adjusted edgewise brackets were bonded to rigid Perspex sheet at 8-mm interval and a space of 16 mm was left at the center of a movable canine bracket. The movable canine bracket was fitted with a 10-mm power arm from which weights of 100 g were hung to represent single equivalent force acting at the center of resistance of the tooth root. All tests were carried out under standard conditions with an Instron Universal Testing Machine, with the cross-head speed at 5 mm / min.

Elastomeric modules are known to produce higher frictional resistance. However, the force exerted on the bracket wire combination is less variable in elastomeric ligation, compared to stainless steel ligation (Bazokidou 1997).[2] Standardization of ligation force necessitated the use of elastomeric ligatures, as the frictional forces are proportional to the ligational force. Hence, for each TRIAL, new elastomeric modules were used.[3]

The ANOVA and paired Student's t-test were done to evaluate statistically significant differences between the mean coefficients of kinetic friction for different bracket systems. This study shows that the self-ligating stainless steel brackets have the least kinetic friction compared to titanium and stainless steel brackets in 0.018- and 0.022-inch slots. In keeping with several previous studies, we found that both the slots, 0.018 and 0.022, with bracket and ARCH WIRE, Considering the advantages of the self-ligating brackets, showing lesser frictional resistance, they could be used in day-to-day practice.

The result shows that β titanium archwires generated significantly less frictional resistance than the stainless steel wires. On the other hand, the laboratory measurements may be more affected by the other wire properties such as stiffness. The speculation is supported by this study that frictional resistance is delivered when wires are pulled through the bracket slot under resisting 100 g of weight.

The substantial differences in friction between titanium, stainless steel, and self-ligating brackets, using stainless steel and TMA archwires, indicate differences in the coefficient of friction applicable for these materials sliding along the slot. To reduce the friction clinically, some practitioners prefer the use of round wire or they reduce rectangular wire in the buccal segments to a more rounded cross section. Round wires, of course, eliminate friction caused by active torque. Round wires generally produce less friction than rectangular wire when engaged into the brackets that are out of alignment because of their greater flexibility. Friction as a result of two-point contact is largely independent of wire stiffness or cross section and so is likely to be little affected by the choice of round or rectangular wire. It is therefore concluded that after insertion of the archwire, friction with round wire may be initially less than the rectangular wire. However, as the brackets align and any torque becomes passive, the difference will become small. In this respect, the common practice is leaving a rectangular wire in position for a month before sliding forces are used.

It is becoming apparent that stainless steel and elastomeric ligatures will eventually be as outdated like the full banding technique one day. Considering the advantages of the self- ligating brackets, showing lesser frictional resistance, they could be used in day-to-day practice.

Discussion

Orthodontic brackets are an important constituent of an orthodontic appliance. The archwires are fitted in the bracket and sliding mechanics require either the bracket or the archwires to slide through the bracket slot. The resulting frictional resistance is an important consideration in appliance design. Of all the different materials tested so far, stainless steel brackets are preferred for their low frictional force values. However, concerns have been expressed about the nickel content in the stainless steel causing hypersensitivity and corrosion in the oral environment. In addition, there are instances where MRI or CT imaging may have been distorted because of the stainless steel alloys. To overcome these difficulties, pure titanium brackets have been made available. These brackets have excellent corrosion resistance and are biocompatible, but have not been subjected to studies related to the frictional resistance force an orthodontist may encounter during sliding mechanics. Friction is largely independent of wire stiffness or cross section and so is likely to be little affected by the choice of round or rectangular wire.[1] So, for this study, we preferred the rectangular wires. Andreasen and Quevodo (1970)[4] pioneered an in-depth frictional study to evaluate the frictional forces in the 0.022 × 0.028 inches edgewise bracket system. Articolo et al (2000)[5] stated that three mechanical cause of resistance to sliding of a bracket along an arch-wire are classical friction, binding and notching.

Drescher et al (1989)[6] in their study found the following factors to affect friction in tooth-guided arch wire mechanics (in decreasing order): retarding force (biologic resistance), surface roughness of wire, wire size (vertical dimension), and bracket width and elastic properties of the wire. Bednar et al (1991)[7] found that the elastomeric - ligated ceramic brackets demonstrated the greatest friction when compared with other bracket / ligation technique combinations.

David et al[8] states that the opposing frictional forces at the interface of the bracket, archwire, and ligature can influence the sliding arch-guided system generally referred to as sliding mechanics. Dickson et al[9] experimentation demonstrated that the conventional ceramic bracket had highest static frictional characteristics.

Downing et al[10] evaluated the effect of artificial saliva on the static and kinetic forces of stainless steel and polycrystalline ceramic brackets in combination with stainless, nickel titanium and beta titanium arch wire materials, under a constant ligature force. The stainless steel brackets produced more friction than polycrystalline brackets, but these results were not statistically significant except against beta titanium arch wires. Baker et al[11] investigated on frictional changes in the force values caused by saliva substitution on stainless steel arch wire bracket combination. Their studies clearly shows that when compared to a dry medium less force is required to move teeth in a saliva medium. Stannard et al[12] did a comparative study of friction of wires under dry and wet conditions. They found artificial saliva to increase coefficients of friction for stainless steel, M titanium and nickel-titanium when compared to dry conditions.

Very few studies have been conducted and discussed in the literature about corrosion and sensitivity to the nickel present and stainless steel brackets. Titanium has heralded as a material totally compatible in the oral environment and superior in structural integrity compared to stainless steel. The friction-free self-ligating brackets produce reduced friction. Failure or distortion of orthodontic brackets during treatment minimizes control of tooth movement. The study was designed to compare the frictional properties of stainless steel, titanium, and self-ligating brackets in 0.018 and 0.022 slots, in 0.017 × 0.025 and 0.019 × 0.025 stainless steel and TMA archwires with second-order angulations, ligated with elastic modules to the brackets slot. In this study, Tidy's protocol was followed because it closely approximated the clinical situation.[1] The apparatus consisted of a simulated arch fixed appliance with archwire in a vertical position.

The substantial differences in friction between titanium, stainless steel, self-ligating brackets, using stainless steel and TMA archwire, indicate differences in the coefficient of friction applicable for these materials sliding along the slot. To reduce friction clinically, some practitioners prefer the use of round wire, or they reduce rectangular wire in the buccal segments to a more rounded cross section. Round wires, of course, eliminate friction caused by active torque. Round wires generally produce less friction than rectangular wire when engaged into the brackets that are out of alignment because of their greater flexibility. Friction as a result of two-point contact is largely independent of wire stiffness or cross section, and so is likely to be little affected by the choice of round or rectangular wire. It is therefore concluded that after insertion of the archwire, friction with round wire may be initially less than the rectangular wire. However, as the brackets align and any torque becomes passive, the difference will become small. In this respect, the common practice is leaving a rectangular wire in position for a month before sliding forces are used. It is becoming apparent that stainless steel and elastomeric ligatures will eventually be outdated like the full banding technique one day. Considering the advantages of the self-ligating brackets that they show lesser frictional resistance, they could be used in day-to-day practice.

Results

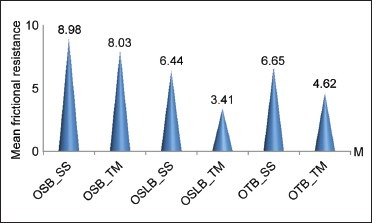

The frictional resistance of 0.022 inch and 0.018 inch slot were measured using instron universal testing machine and recorded [Table 1]. Graph 1 represents six brackets and wire combinations used.

Table 1.

Frictional resistance “P” value recorded from the instron universal testing machine

Graph 1.

Diagrammatic representation of six bracket and wire combinations of 0.018-inch and 0.022-inch slots

Independent samples t-test

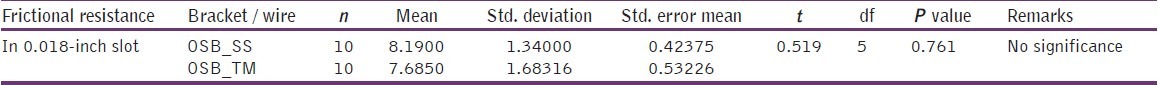

The independent samples t-test procedure is used to compare the mean scores of level of frictional resistance for the titanium, self-ligating stainless steel, and stainless steel brackets of slots 0.018 inch and 0.022 inch. The procedure assumes that the variances of the two groups are equal and it was tested with Levene's test statistics. The results of the analysis are given in Table 2. Null hypothesis – H0: There is no significant difference between the mean scores of stainless steel bracket with stainless steel wire and TMA wire regarding the level of satisfaction.

Table 2.

t-Test group statistics

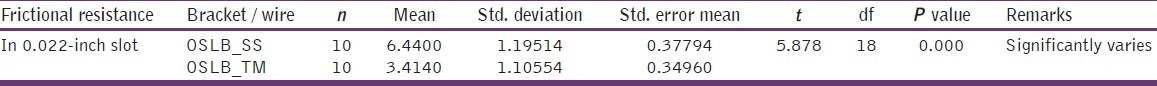

The results of levene's test analysis are given in Table 3. Null hypothesis – H0: There is significant difference between the mean scores of self-ligating stainless steel bracket with stainless steel wire and TMA wire regarding the level of satisfaction.

Table 3.

t-Test group statistics

The independent samples t-test procedure is used to compare mean scores of level of frictional resistance for the titanium, self-ligating stainless steel, and stainless steel brackets of slots 0.018 inch and 0.022 inch. The procedure assumes that the variances of the two groups are equal and it was tested with Levene's test statistics. The results of the analysis are given in Table 4. Null hypothesis – H0: There is significant difference between the mean scores of titanium bracket with stainless steel wire and TMA wire regarding the level of satisfaction. Graphs 2 and 3 represents mean frictional resistance of 0.22 slot and 0.18 slot brackets with displacement respectively.

Table 4.

t-Test group statistics

Graph 2.

0.22 slot brackets with displacement

Graph 3.

0.18 slot brackets with displacement

The table displays the descriptive statistics of the sample size, mean, standard deviation, and standard error. The table also [Tables 5–10] shows the t-statistics, which is calculated as the ratio of the difference between sample means divided by the standard error of the difference. The column “P value” shows the probability value from the t distribution. Since the P value is greater than 0.05, we accept the hypothesis. Hence, there is no significant / there is a significant difference in the mean scores of the two groups with respect to the level of frictional resistance.

Table 5.

t-Test group statistics

Table 10.

t-Test group statistics

Table 6.

t-Test group statistics

Table 7.

t-Test group statistics

Table 8.

t-Test group statistics

Table 9.

t-Test group statistics

Frictional resistance in the groups of 0.022-inch slot ANOVA

The mean score analysis (ANOVA) test procedure [Tables 11–16] is used to compare the mean scores of level of frictional resistance for more than two groups. The procedure assumes that the variances of the groups are equal and it was tested with Levene's test statistics. The significant difference between the mean scores of level of frictional resistance is tested with respect to the various titanium, self-ligating stainless steel, and stainless steel brackets, using stainless steel and TMA archwires.

Table 11.

One-way descriptives

Table 16.

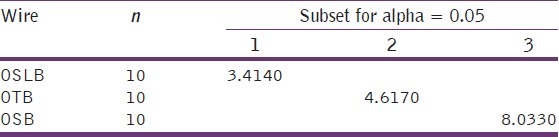

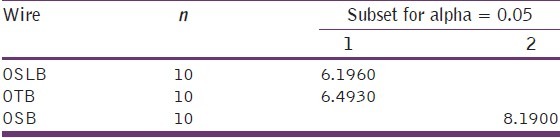

TM_0.022 (Tukey's B)

Table 12.

ANOVA

Table 14.

TM_0.018 (Tukey's B)

Table 15.

SS_0.022 (Tukey's B)

Test for mean scores of level of frictional resistance and six groups of brackets and wire combinations.

The mean scores of level of frictional resistance and six groups of 0.018-inch and 0.022-inch slot brackets were tested with ANOVA test procedures and the results of the analysis are given in Table 11. Null Hypothesis – H0: There is no significant difference between the mean scores of frictional resistance among the six groups regarding the level of coefficient of friction.

Once we have determined that differences exist among the means, post hoc rank tests can determine which means differ. Tukey's tests identified the homogeneous subsets of means that are not different from each other and the results are given in Tables 13–16.

Table 13.

Tukey's B

Post hoc tests homogeneous subsets SS_0.018

We used Tukey's test to identify the homogeneous subsets of means which are not different from each other. Tables 13–16 shows these test analysis. Here the self-ligating stainless steel brackets and titanium brackets come under one group of subset 1 and stainless steel brackets are in subset 2.

Table 16 shows significant difference of frictional resistance among the three groups.

Conclusion

Thus, the aim of the study was to compare the frictional resistance of titanium, self-ligating stainless steel, and conventional stainless steel brackets using stainless steel and TMA archwires, with the help of Instron Universal Testing Machine, One-way ANOVA, Student's “t” test, and post hoc multiple range test at level of <0.05 showed statistically significant difference in the mean values of all the groups. Results demonstrated the following:

The titanium, self-ligating stainless steel, and stainless steel brackets of 0.018-inch and 0.022-inch slots had no significant variations in frictional resistance.

The self-ligating bracket with TMA archwires showed relatively less frictional resistance compared with the other groups.

The titanium bracket with TMA archwires showed relatively less frictional resistance compared with the stainless steel brackets.[13]

Footnotes

Source of Support: Nil

Conflict of Interest: None declared.

References

- 1.Tidy DC. Frictional forces in fixed appliances. Am J Orthod Dentofacial Orthop. 1989;96:249–54. doi: 10.1016/0889-5406(89)90462-9. [DOI] [PubMed] [Google Scholar]

- 2.Bazakidou E, Nanda RS, Duncanson MG, Jr, Sinha P. Evaluation of frictional resistance in esthetic brackets. Am J Orthod Dentofacial Orthop. 1997;112:138–44. doi: 10.1016/s0889-5406(97)70238-5. [DOI] [PubMed] [Google Scholar]

- 3.Frank CA, Nikolai RJ. A comparative study of frictional resistances between orthodontic bracket and archwire. Am J Orthod Dentofacial Orthop. 1980;78:593–609. doi: 10.1016/0002-9416(80)90199-2. [DOI] [PubMed] [Google Scholar]

- 4.Andreasen GF, Qucvodo FR. Evaluation of fictional forces in the 0.022 X 0.028 Edgewisc bracket in vitro. J Biomech. 1970;3:151–60. doi: 10.1016/0021-9290(70)90002-3. [DOI] [PubMed] [Google Scholar]

- 5.Articolo LC, Kusy K, Saunders CR, Kusy RP. Influence of ceramic and stainless steel brackets on the notching of arch wires during clinical treatment. Eur J Orthod. 2000;22:409–25. doi: 10.1093/ejo/22.4.409. [DOI] [PubMed] [Google Scholar]

- 6.Drescher D, Bourauel C, Schumacher HA. Frictional forces between bracket and archwire. Am J Orthod Dentofacial Orthop. 1989;96:397–404. doi: 10.1016/0889-5406(89)90324-7. [DOI] [PubMed] [Google Scholar]

- 7.Bednar JR, Gruendeman GW, Sandrik JL. A comparative study of frictional forces between orthodontic brackets and arch wires. Am J Orthod Dentofacial Orthop. 1991;100:513–22. doi: 10.1016/0889-5406(91)70091-A. [DOI] [PubMed] [Google Scholar]

- 8.De Franco DJ, Spiller RE, Jr, von Fraunhofer JA. Frictional resistance using Teflon coated ligatures with various bracket arch wire combinations. Angle Orthod. 1995;1:63–73. doi: 10.1043/0003-3219(1995)065<0063:FRUTLW>2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 9.Dickson J, Jones S. Frictional characteristics of a modified ceramic bracket. J Clin Orthod. 1996;30:516–8. [PubMed] [Google Scholar]

- 10.Downing A, Mc Cabe J, Gordon PH. The effect of artificial saliva on the frictional forces between orthodontic brackets and arch wires. Br J Orhtod. 1995;22:41–6. doi: 10.1179/bjo.22.1.41. [DOI] [PubMed] [Google Scholar]

- 11.Baker KL, Nieberg LG, Weimer AD, Hanna M. Frictional changes in force values caused by saliva substitution. Am J Orthod Dentofacial Orthop. 1987;91:316–20. doi: 10.1016/0889-5406(87)90173-9. [DOI] [PubMed] [Google Scholar]

- 12.Stannard JG, Gau JM, Hanna MA. Comparative friction of orthodontic wires under dry and wet conditions. Am J Orthod Dentofacial Orthop. 1986;89:485–91. doi: 10.1016/0002-9416(86)90006-0. [DOI] [PubMed] [Google Scholar]

- 13.Omana HM, Moore RN, Michael DB. Frictional properties of metal and ceramic brackets. J Clin Orthod. 1992;26:425–32. [PubMed] [Google Scholar]