Abstract

As a potential intermediary feedstock, succinic acid takes an important place in bulk chemical productions. For the first time, a method combining Plackett-Burman design (PBD), steepest ascent method (SA), and Box-Behnken design (BBD) was developed to optimize Actinobacillus succinogenes ATCC 55618 fermentation medium. First, glucose, yeast extract, and MgCO3 were identified to be key medium components by PBD. Second, preliminary optimization was run by SA method to access the optimal region of the key medium components. Finally, the responses, that is, the production of succinic acid, were optimized simultaneously by using BBD, and the optimal concentration was located to be 84.6 g L−1 of glucose, 14.5 g L−1 of yeast extract, and 64.7 g L−1 of MgCO3. Verification experiment indicated that the maximal succinic acid production of 52.7 ± 0.8 g L−1 was obtained under the identified optimal conditions. The result agreed with the predicted value well. Compared with that of the basic medium, the production of succinic acid and yield of succinic acid against glucose were enhanced by 67.3% and 111.1%, respectively. The results obtained in this study may be useful for the industrial commercial production of succinic acid.

1. Introduction

Succinic acid is a member of the four-carbon dicarboxylic acid family in tricarboxylic acid cycle (TCA) and has a wide range of applications in the fields of surfactants, green solvents, and pharmaceutical intermediates as an important four-carbon intermediate compound [1]. Succinic acid is classified as the most promising chemical among 12 biobased chemicals by the U.S. Department of Energy [2]. Succinic acid has been conventionally produced from fossil raw materials for more than a century, which can lead to high cost, feedstock exhaustion, and environment pollution [3, 4]. Recent studies suggest that the production of succinic acid by microbe fermentation has the potential to solve the aforementioned problems [5].

As the endproduct of energy metabolism, succinic acid can be produced by many anaerobic microbes, such as Actinobacillus succinogenes, Anaerobiospirillum succiniciproducens, Mannheimia succiniciproducens, and Escherichia coli especially A. succinogenes ATCC 55618, which is a facultative anaerobe isolated from the bovine rumen [6]. It could produce higher concentration succinic acid as a major endproduct than other strains without gene reconstruction and glucose feeding [7]. However, to obtain a high production of succinic acid (i.e., more than 45 g L−1), the fermentation medium compositions were often complicated with the addition of high concentration of glucose and ten kinds of slight vitamins [8–10]. According to the aforementioned reports, about twenty kinds of components were added into the fermentation medium for the succinic acid production, which led to high cost and complex operation. It must be paid attention that the complicated medium is not the assurance of high production of succinic acid [11–13]. So the optimization of fermentation medium of A. succinogenes ATCC 55618 is essential.

Since nine components existed in the fermentation medium (i.e., glucose, yeast extract (YE), corn steep liquor (CSL), KH2PO4, K2HPO4, NaCl, MgCl2, CaCl2, and MgCO3), a great number of experiments should be simultaneously run, and the possible interactions between these components were also needed to be studied. For fermentation medium optimization, Plackett-Burman design (PBD) was a good choice in rapid screening multifactors to find the most significant independent factors [14]. Moreover, to optimize the concentration of the important factors, statistical methods have been done by using response surface methodology (RSM), in which several factors were simultaneously varied [15]. Compared with the one-factor-at-a-time method, statistical experimental design has the advantages of reducing experiment numbers and improving statistical interaction analysis [16–18]. For the reasons above, we proposed the optimization method including the following steps: (1) using a two-level PBD to identify the key medium components and their experimental levels for further optimization, (2) applying the path of steepest ascent (SA) to move rapidly towards the neighborhood of the optimum response, and (3) employing a Box-Behnken design (BBD) to develop mathematical models to estimate the relationships between the response (i.e., the succinic acid production) and the key components.

2. Materials and Methods

2.1. Maintenance and Preculture of A. succinogenes ATCC 55618

The strain of A. succinogenes ATCC 55618, purchased from American Type Culture Collection (ATCC), was maintained in 20% glycerol at −70°C.

The plate was inoculated with the strain maintained at −70°C and incubated at 37°C for 2 days. Preculture medium consisted of the following components (g L−1): tryptone 17; soya peptone 3; glucose 2.5; NaCl 5; K2HPO4 2.5. The culture pH was adjusted to 7.5. For the first preculture, 50 mL of medium was prepared in a 250-mL anaerobic bottle, and a colony from a plate culture was inoculated, and then incubated for 12 hours at 37°C on a rotary shaker at 120 rpm. For the second preculture, 47.5 mL of medium was prepared in a 250-mL anaerobic bottle, inoculated with 2.5 mL of the first preculture broth, and incubated for 12 hours at 37°C on a rotary shaker at 120 rpm.

2.2. Fermentation Process

Basic fermentation medium with an initial pH of 7.0 was composed of (g L−1): glucose 107; yeast extract (YE) 16; corn steep liquor (CSL) 12; KH2PO4 3; K2HPO4 1.5; NaCl 1; MgCl2 0.3; CaCl2 0.3; MgCO3 40. The fermentation medium was inoculated with 2.5 mL of the second preculture broth in 47.5 mL of medium in a 250-mL anaerobic bottle with CO2 as the gas phase. The fermentation was incubated at 37°C on a rotary shaker at 180 rpm. The dynamic profile of the succinic acid biosynthesis of A. succinogenes was monitored during the submerged fermentation process. Three flasks were taken each time for sampling. Each data point was expressed by an average with an error bar (i.e., standard error from three independent samples).

2.3. Plackett-Burman Design (PBD)

The purpose of Plackett-Burman design (PBD) was to identify the key medium components for the succinic acid production. Table 1 shows the PBD used in this study [19]. Two dummy variables, whose levels did not change in the design, were introduced to estimate the population standard error. The first order was used to fit data from PBD as follows:

| (1) |

where Y is the predicted response, β0 and βi are constant coefficients, and xi is the coded independent factors. Analysis for the PBD was carried out as follows.

Table 1.

The Plackett-Burman design experiment design matrixa and experimental results.

| Runs | Variables (g L−1) | OD660 | Succinic acid production (g L−1) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Glucose | YEb | CSLc | K2HPO4 | KH2PO4 | NaCl | MgCl2 | CaCl2 | MgCO3 | |||

| 1 | 80.0 | 15.0 | 15.0 | 1.5 | 3.0 | 1.5 | 0.3 | 0.6 | 40.0 | 7.9 ± 1.6 d | 32.5 ± 1.0 |

| 2 | 50.0 | 15.0 | 15.0 | 1.5 | 3.0 | 1.0 | 0.3 | 0.3 | 60.0 | 4.2 ± 0.4 | 32.2 ± 1.3 |

| 3 | 80.0 | 10.0 | 15.0 | 1.5 | 1.5 | 1.0 | 0.6 | 0.6 | 60.0 | 6.2 ± 0.3 | 51.9 ± 4.8 |

| 4 | 80.0 | 15.0 | 10.0 | 3.0 | 1.5 | 1.0 | 0.3 | 0.6 | 60.0 | 9.3 ± 0.4 | 50.2 ± 3.1 |

| 5 | 50.0 | 10.0 | 10.0 | 3.0 | 3.0 | 1.5 | 0.3 | 0.6 | 60.0 | 2.6 ± 0.6 | 36.2 ± 0.6 |

| 6 | 80.0 | 10.0 | 10.0 | 1.5 | 3.0 | 1.5 | 0.6 | 0.3 | 60.0 | 6.7 ± 0.1 | 50.4 ± 1.5 |

| 7 | 50.0 | 10.0 | 10.0 | 1.5 | 1.5 | 1.0 | 0.3 | 0.3 | 40.0 | 5.9 ± 0.3 | 36.0 ± 0.2 |

| 8 | 50.0 | 15.0 | 15.0 | 3.0 | 1.5 | 1.5 | 0.6 | 0.3 | 60.0 | 2.9 ± 0.5 | 33.2 ± 1.2 |

| 9 | 50.0 | 10.0 | 15.0 | 3.0 | 3.0 | 1.0 | 0.6 | 0.6 | 40.0 | 5.3 ± 0.3 | 35.4 ± 1.2 |

| 10 | 80.0 | 15.0 | 10.0 | 3.0 | 3.0 | 1.0 | 0.6 | 0.3 | 40.0 | 9.1 ± 0.5 | 36.3 ± 0.6 |

| 11 | 50.0 | 15.0 | 10.0 | 1.5 | 1.5 | 1.5 | 0.6 | 0.6 | 40.0 | 10.0 ± 0.6 | 36.5 ± 2.7 |

| 12 | 80.0 | 10.0 | 15.0 | 3.0 | 1.5 | 1.5 | 0.3 | 0.3 | 40.0 | 6.3 ± 0.6 | 38.3 ± 0.7 |

aThe two dummy was not shown in Table 1.

bYE: yeast extract.

cCSL: corn steep liquor.

dStandard error was calculated from three independent samples.

First, the effect of all variables, including dummies, was calculated as follows:

| (2) |

where Evi is the effect of variable i; Rvi(+) and Rvi(−) represent the response parameter (i.e., the succinic acid production) of an assembly in the screening design which contains the high and low levels of variable i, respectively; N is the number of assemblies (in this study, N = 12).

After determining the effect of each variable, the standard deviation (SD) of dummies, which serves as the population standard deviation in the Student's t-test as follows was calculated:

| (3) |

where Ed is the effect of dummy variables; n is the number of dummy variables (in this study, n = 2).

Finally, a Student's t-test was performed to identify the significant t factors as follows:

| (4) |

The variable which has no effect will give a t-value of 0. The larger the absolute value of the t-value, the variable is more significant.

2.4. Steepest Ascent (SA)

The method of steepest ascent (SA) design was used to move rapidly towards the neighborhood of the optimum response. Table 2 shows the SA used in this study. The experiments were adopted to determine a suitable direction by increasing or decreasing the concentrations of variables according to the results of PBD [20].

Table 2.

Experiment design and results of the steepest ascent path.

| Runs | Glucose (g L−1) | Yeast extract (g L−1) | MgCO3 (g L−1) | OD660 | Succinic acid production (g L−1) |

|---|---|---|---|---|---|

| 1 | 80 | 10 | 60 | 6.1 ± 0.2a | 48.4 ± 1.3 |

| 2 | 85 | 7 | 65 | 3.7 ± 0.7 | 41.7 ± 2.6 |

| 3 | 90 | 4 | 70 | 0.6 ± 0.0 | 36.4 ± 2.4 |

| 4 | 95 | 1 | 75 | 0.2 ± 0.0 | 22.1 ± 5.3 |

| 5 | 100 | 0 | 80 | 0.1 ± 0.0 | 4.2 ± 1.1 |

aStandard error was calculated from three independent samples.

2.5. Box-Behnken Design (BBD)

A 15-run Box-Behnken design (BBD) with three center points was employed in this work, and the maximal values of the productions of succinic acid were shown in Table 3.

Table 3.

The Box-Behnken design of RSM for the optimization of succinic acid production by A. succinogenes ATCC 55618.

| Run | Glucose (g L−1) | Yeast extract (g L−1) | MgCO3 (g L−1) | OD660 | Succinic acid production (g L−1) |

|---|---|---|---|---|---|

| 1 | 70 (−1)a | 10 (0) | 50 (−1) | 6.0 ± 0.7c | 38.9 ± 1.3 |

| 2 | 90 (1) | 10 (0) | 50 (−1) | 5.5 ± 0.8 | 40.3 ± 0.7 |

| 3 | 70 (−1) | 10 (0) | 70 (1) | 0.6 ± 0.1 | 43.2 ± 5.5 |

| 4 | 90 (1) | 10 (0) | 70 (1) | 5.7 ± 0.4 | 45.8 ± 0.9 |

| 5 | 70 (−1) | 5 (−1) | 60 (0) | 1.3 ± 0.6 | 37.0 ± 2.5 |

| 6 | 90 (1) | 5 (−1) | 60 (0) | 1.0 ± 0.8 | 38.1 ± 4.0 |

| 7 | 70 (−1) | 15 (1) | 60 (0) | 8.0 ± 0.2 | 45.8 ± 1.3 |

| 8 | 90 (1) | 15 (1) | 60 (0) | 7.8 ± 0.6 | 50.9 ± 0.7 |

| 9 | 80 (0) | 5 (−1) | 50 (−1) | 0.8 ± 0.6 | 35.1 ± 1.7 |

| 10 | 80 (0) | 5 (−1) | 70 (1) | 0.5 ± 0.1 | 34.8 ± 1.1 |

| 11 | 80 (0) | 15 (1) | 50 (−1) | 8.3 ± 0.2 | 41.5 ± 2.6 |

| 12 | 80 (0) | 15 (1) | 70 (1) | 6.2 ± 0.2 | 50.7 ± 0.8 |

| 13b | 80 (0) | 10 (0) | 60 (0) | 6.5 ± 1.0 | 49.6 ± 1.0 |

| 14b | 80 (0) | 10 (0) | 60 (0) | 5.8 ± 0.1 | 50.2 ± 1.5 |

| 15b | 80 (0) | 10 (0) | 60 (0) | 5.9 ± 0.1 | 49.0 ± 3.5 |

aReal values of independent variables and the corresponding coded level.

bRuns 13–15 were three replications.

cFor each trial, the dynamic profile of the succinic acid production was monitored. Multiple flasks were run at the same time, and three flasks were taken at each sampling point. Each data point was expressed by an average with an error bar (i.e., standard error from three independent samples).

To describe the relationships between the succinic acid production and the medium components, a mathematical model was developed by the following second-order polynomial equation to fit data in RSM of BBD:

| (5) |

where Y is the predicted response, β0 is the offset term, βi is the linear effect, βii is the quadratic effect, βij is the interaction effect, and ε is an experimental error. And xi and xj represent the independent variables (medium components) in the form of coded values as follows:

| (6) |

where xi and Xi are the dimensionless and the actual values of independent variable i, X is the actual value of the independent variable i at the central point, and ΔXi is the step change of Xi corresponding to a unit variation of the dimensionless value.

The model of response was expression in terms of code variables and without the statistically insignificant terms (different models are available in BBD of statistical software package Minitab 15, Minitab Inc., State College, PA 16801-3008, USA).

2.6. Data Analysis

Standardized Pareto charts, representing the estimated effects of parameters and parameter interactions on responses, permitted us to check the statistical significance of the PBD. The Student's t-test permitted to check the statistical significance of the regression coefficients. The analysis of variable (ANOVA) was performed on experimental data to evaluate the statistical significance of the model. The models of each response were expressed in terms of code/uncoded variables and without the statistically insignificant terms. A p value less than 5% indicates that model terms are significant, while less than 1% indicates that model terms are highly significant. A p value is a measure of how much evidence one has against the null hypothesis (the null hypothesis of the test read like this: H0: β1 = β2 = ⋯ = βi = 0; H1: at least one β is not zero) and evidence against null hypothesis is more for smaller p value. A p value of 0.05 or less rejects the null hypothesis at the 5% level, that is, only 5% of the probability the supposed statistical model will fail to predict the response. The model adequacies were checked by the determination coefficients (R2), adjusted R2, and predicted R2. The determination coefficient (R2) is a measure of how well the regression equation fits the sample data. While R2 can be made larger simply by adding more predictor variables to the model, an adjusted R2 has been proposed. Adjusted R2 is a modification of R2 that adjusts for the number of explanatory terms in a model. A predicted R2 is used to measure the amount of variation in new data (i.e., other levels among the tested maximal value and minimal value of the factor) explained by the model. It is calculated by systematically removing each observation from the data set, estimating the regression equation, and determining how well the model predicts the removed observation. Predicted R2 is used in regression analysis to indicate how well the model predicts responses for new observations, whereas R2 indicates how well the model fits the data. Predicted R2 can prevent overfitting the model and can be more useful than adjusted R2 for comparing models because it is calculated using observations not included in model estimation. Predicted R2 larger values of predicted R squared suggest models of greater predictive ability. The predicted R2 and the adjusted R2 should be within 0.20 of each other. Otherwise there may be a problem with either the data or the model. The “Minitab 15 (Minitab Inc., State College, PA 16801-3008, USA)” software was employed for the regression analysis and the graphical optimization, respectively.

2.7. Sampling and the Determination of Succinic Acid Production

For sampling, three flasks were taken each time, and cell growth was monitored by measuring the optical density at 660 nm (OD660). At an OD660 of 1.0, A. succinogenes ATCC 55618 has a concentration of 0.626 g dry cell weight (DCW) l−1. For succinic acid determination, 1 mL of methanol and 1 mL of acetonitrile were added to 1 mL of fermentation broth to remove proteins, and the sample was kept at 4°C overnight. After centrifugation at 11,000 rpm for 30 min, the supernatants were diluted and filtrated through a 0.22-μm filter and analyzed by high-performance liquid chromatography (HPLC, Waters) using an Agela Venusil ASB C18 column. The optimized mobile phase was 50 mM KH2PO4 water solution, with the pH adjusted to 3.5 by H3PO4. The column oven temperature was maintained at 40°C, and the flow rate was 1 mL min−1. The detection wave was fixed at 210 nm.

3. Results and Discussion

3.1. Plackett-Burman Design (PBD)

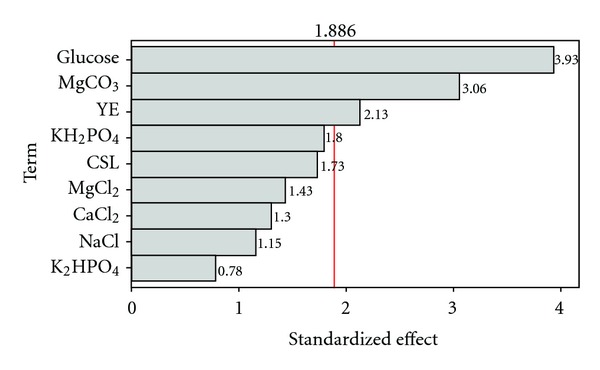

The methodology of Plackett-Burman design (PBD) is a powerful and useful tool in rapidly searching key factors from a multivariable system. PBD does not determine the exact quantity, but it can provide some important information about each factor by relatively few experiments [19]. As shown in Table 1, PBD for 12 trials with two levels of concentrations was undertaken to evaluate the significances of nine medium components. In order to determine the influence of the most important parameters, a standardized Pareto chart (Figure 1) was employed. Analysis of the measured response variables enabled to obtain standardized Pareto charts and response surface plots. A standardized Pareto chart consists of bars with a length proportional to the absolute value of the estimated effects, divided by the standard error. The bars are displayed in order of the size of the effects, with the largest effects on top. The chart includes a vertical line at the critical t-value for an alpha. Some investigations find that the confidence levels greater than 80% (p < 0.2) are acceptable [21]. In this study, the chart includes a vertical line at the critical t-value for α of 0.20. Effects for which the bars are smaller than the critical t-value are considered as not significant and not affecting the response variables. Effects may be positive or negative.

Figure 1.

Pareto chart of standardized effects on the succinic acid production. The chart includes a vertical line (i.e., standardized effect = 1.886) at the critical t-value for α of 0.20. The bars are displayed in order of the size of the effects, and the standardized effect of each term was shown on the top of its corresponding bar.

As shown in Figure 1, for the succinic acid production, the variables glucose, yeast extract, and MgCO3 had a confidence level above 80%. Hence, these were considered to be significant for the succinic acid biosynthesis.

Analyzed by Minitab, a first-order model, was fitted to the results obtained from the twelve experiments as the equation:

| (7) |

where Y is the succinic acid production, and CGlucose, CYE, CCSL, CK2HPO4, CKH2PO4, CNaCl, CMgCl2, CCaCl2, and CMgCO3 are the value of glucose, YE, CSL, K2HPO4, KH2PO4, NaCl, MgCl2, CaCl2, and MgCO3, respectively. The goodness of the regression was checked by the coefficient of determination R2 whose value (R2 = 95.39%) indicates that only 4.61% of the total variation could not be explained by the model, and it was reasonable to use the regression model to analyze the trend in the response. And then, glucose, yeast extract, and MgCO3 were selected for further optimization to obtain a maximum response. According to the coefficients of the glucose (4.18), yeast extract (−2.28) and MgCO3 (3.26), the positive coefficients indicated that the high level of glucose and MgCO3 concentration in PBD was benefit for the succinic acid production. On the contrary, the negative coefficient indicated that the low level of yeast extract concentration was helpful for the succinic acid accumulation. A maximum succinic acid production of 51.9 g L−1 was obtained with 80.0 g L−1 of glucose, 60.0 g L−1 of MgCO3, and 10.0 g L−1 of yeast extract. The corresponding productivity and specific productivity were 1.1 g L−1 h−1 and 13.4 g succinic acid g−1 DCW. However, the OD660 of 6.2 obtained with this medium was not the highest among the 12 conditions.

According to the metabolic pathway of A. succinogenes, succinic acid was an end-product from the substrate of glucose, which implied that succinic acid formation was decided by the supplement of glucose directly [22]. The yield of succinic acid against glucose was improved by the increase of initial glucose concentration, and it would reach the peak value when the initial glucose concentration was 70.0 g L−1 [23].

The culture pH value is one of the key factors in the production of succinic acid [24]. MgCO3 was used as a neutralizing agent and added to the fermentation broth to adjust culture pH. Before optimization, the pH value decreased from 7.5 to 5.7 during the fermentation. Compared with the pH value of basic medium, the initial pH increased up to 8.0 and was followed by slow decline after the optimization. So after MgCO3 was elevated, the extent of system buffering was improved. The final pH value of optimal medium with an initial pH of 7.5 was more close to neutral (about 6.5) during the fermentation, and neutral environment was helpful to accumulate succinic acid. In our previous results, the highest succinic acid production of 48.2 g L−1 was obtained at a culture pH of 7.5 [25]. The pattern of succinic acid production at a culture pH of 7.0 was similar with that obtained at 7.5. When the initial culture pH was adjusted to 6.5 or 8.0, a significant decrease of succinic acid production was observed. So, the effect of medium optimization MgCO3 may be partly from the influence of the pH.

On the other hand, sufficient CO2 supplement in the fermentation broth could strongly influence the metabolic flux of carbon and the activities of phosphoenolpyruvate (PEP) carboxykinase, which were the important committed steps for the biosynthesis of succinic acid [24, 26]; therefore, sufficient CO2 is another key factor influencing succinic acid accumulation. However, in our previous work, there was no significant effect of CO2 partial pressure on the production of succinic acid when gaseous CO2 was used as the sole CO2 donor [27]. As an important CO2 donor in the A. succinogenes fermentation, MgCO3 could react with organic acids in fermentation broth and caused an increase in the dissolved concentrations of HCO3−, CO32−, and CO2. When gaseous CO2 was used with MgCO3, higher amount of MgCO3 was more effective on promoting the succinic acid synthesis. And the maximum succinic acid production of 61.92 g L−1 was obtained at 159.22 mM dissolved CO2 concentration, which was supplied by 40 g L−1 MgCO3 with 100% CO2 gas. This means that the dissolved CO2 concentration was another factor affecting succinic acid synthesis. And during the fermentation process, insoluble MgCO3 caused turbid broth, which made the cells spread uniformly in the broth. This effectively avoids the cell flocculation. All these properties make MgCO3 to be one of the key factors significantly improved the succinic acid production.

At last, yeast extract was also screened to be a key factor because it affected cell growth directly as the nutrient. It contains many trace substances, such as folic acid, pantothenic acid, biotin, and vitamin B1, B2, B6, and B12. This may be the important reason why many kinds of vitamins could be omitted meanwhile the succinic acid could efficiently be accumulated in this work.

To conclude, the variables of glucose, MgCO3, and yeast extract had a confidence level above 80% and hence were considered to significantly influence the succinic acid production. The optimal concentrations of these three key components needed to be further studied as follows.

3.2. Steepest Ascent (SA)

Based on the results above, glucose, yeast extract, and MgCO3 were the three key factors, and the high level of glucose (i.e., 80.0 g L−1) and MgCO3 (i.e., 60.0 g L−1), while the low level of yeast extract (i.e., 10.0 g L−1) was benefit for the succinic acid production of A. succinogenes ATCC 55618. Thus, the path of SA was moved along the path in which glucose and MgCO3 increased, while yeast extract decreased (Table 2). The highest succinic acid production of 48.4 ± 1.3 g L−1 and OD660 of 6.1 was observed under the point of levels, namely, 80.0 g L−1 of glucose, 10.0 g L−1 of yeast extract, and 60.0 g L−1 of MgCO3. The corresponding productivity and specific productivity were 1.0 g L−1 h−1 and 12.4 g succinic acid g−1 DCW. This result suggested that the point was near the optimal point and was chosen for further optimization.

As shown in Table 2, the succinic acid production did not further increase with the increase concentrations of glucose and MgCO3 and the decrease concentration of yeast extract. For glucose, although A. succinogenes could tolerate glucose concentration as high as 150.0 g L−1, the yield of succinic acid would decrease when glucose concentration exceeds 70.0 g L−1 [9, 23]. So when the concentration of glucose increased from 80.0 to 100.0 g L−1, the concentrations of succinic acid could not be further improved. For MgCO3, the culture pH of fermentation broth was increased with the increase of MgCO3 concentration (data not shown), which may make the cells more difficult to adapt. Therefore, the succinic acid production was not enhanced. For yeast extract, it was observed that the absence of yeast extract led to almost no succinic acid accumulation, which indicated that this component was the basic nutrient for the cell growth.

To conclude, the highest succinic acid production was obtained under the condition of 80.0 g L−1 of glucose, 10.0 g L−1 of yeast extract, and 60.0 g L−1 of MgCO3, which suggested that this point was near the optimal point.

3.3. Box-Behnken Design (BBD)

Based on the information above, taking the point (80.0 g L−1 of glucose, 10.0 g L−1 of yeast extract and 60.0 g L−1 of MgCO3) as the central level of BBD, then the three-factors, three-level BBD was employed (Table 3).

Table 4 shows the analysis of variance (ANOVA) for the BBD. The p values ≤0.05 indicate that the model terms are significant. The Lack of fit (LOF) is the variation of the data around the fitted model. LOF is a model fit test that is used to check how well a model fits the data and help to remove insignificant terms from the model. A p-value of LOF 0.614 indicted that the model fits the response well. The “predicted R2” of 0.9696 was in reasonable agreement with the “adjusted R2” of 0.9911, and it might be also said that the model determination coefficient (R2 of 0.9968) was reasonable agreement with the experimental results, indicating that 99.68% of the variability could be revealed by the model.

Table 4.

Analysis of variance (ANOVA) for regression model.

| Source | SSa | DF | MS | F | p |

|---|---|---|---|---|---|

| Model | 481.38 | 9 | 53.49 | 174.13 | <0.001 |

| Linear | 298.58 | 3 | 99.53 | 324.01 | <0.001 |

| Quadratic | 155.85 | 3 | 51.95 | 169.12 | <0.001 |

| Interactions | 26.95 | 3 | 8.98 | 29.24 | 0.001 |

| Residual | 1.54 | 5 | 0.31 | ||

| Lack of fit | 0.82 | 3 | 0.27 | 0.75 | 0.614 |

| Pure error | 0.72 | 2 | 0.36 | ||

| Total SS | 482.91 | 14 | |||

|

| |||||

| R 2 = 0.9968, Radj2 = 0.9911, Rpred2 = 0.9696. | |||||

aSS: sum of squares; DF: degrees of freedom; MS: mean square; R2: determination coefficient; adj R2: adjusted R2; pred R2: predicted R2.

The polynomial model for the succinic acid production was expressed by (8) (in coded value) and (9) (in uncoded value) (Table 5) consider the following:

| (8) |

| (9) |

Table 5.

Regression coefficients and their significance for response surface model.

| Term | Coefficient | Standard error | T (C/S) | p |

|---|---|---|---|---|

| Intercept | 49.563 | 0.32 | 154.89 | <0.001a |

| A—Glucose | 1.274 | 0.20 | 6.50 | 0.001a |

| B—Yeast extract | 5.495 | 0.20 | 28.04 | <0.001a |

| C—MgCO3 | 2.346 | 0.20 | 11.97 | <0.001a |

| AB | 1.008 | 0.29 | 3.64 | 0.015b |

| AC | 0.310 | 0.29 | 1.10 | 0.321 |

| BC | 2.373 | 0.29 | 8.56 | <0.001a |

| A 2 | –2.562 | 0.28 | –8.88 | <0.001a |

| B 2 | –4.084 | 0.28 | –14.16 | <0.001a |

| C 2 | –4.972 | 0.28 | –17.24 | <0.001a |

aSignificant at 1% level.

bSignificant at 5% level.

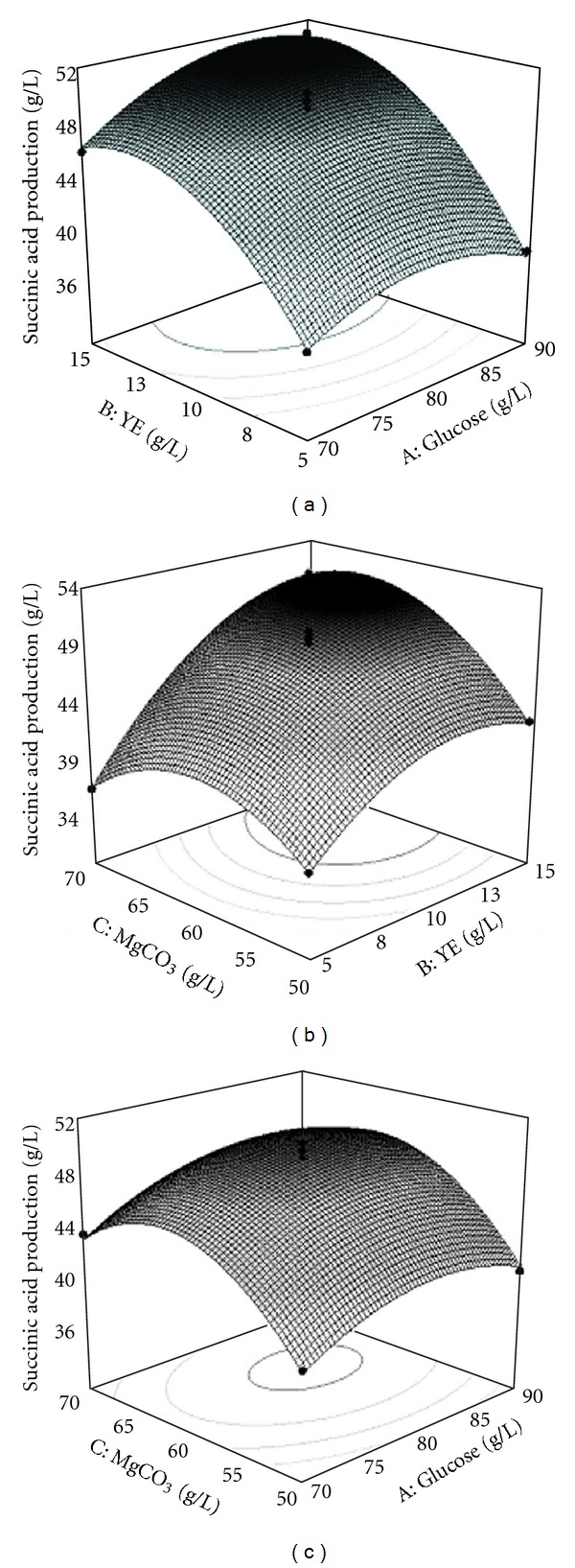

The model reveals that glucose concentration (A), yeast extract concentration (B), and MgCO3 concentration (C) had a significant effect (p < 0.0001) on the succinic acid production (Y). Positive coefficient of A, B, and C indicated a linear effect to increase. However, quadratic term A2, B2, and C2 had the negative effect. The graphs (Figure 2) depict the changes in the parameter modeled as the two factors move along those levels, while the other factor held constant at the central point. According to (9), the highest succinic acid production of 52.3 g L−1 was obtained at 14.0 g L−1 of yeast extract and 64.3 g L−1 of MgCO3, while glucose concentration was held at 80.0 g L−1; the maximal succinic acid production of 50.0 g L−1 could be observed at 82.6 g L−1 of glucose and 62.4 g L−1 of MgCO3, while holding 10.0 g L−1 of yeast extract; under the conditions of 83.9 g L−1 of glucose, 13.6 g L−1 of yeast extract and 60.0 g L−1 of MgCO3 (the factor held constant), the succinic acid production could reach its peak value of 51.8 g L−1. According to (8) and (9), it was predicted that a maximum succinic acid production of 53.0 g L−1 was appeared at 84.6 g L−1 of glucose, 14.5 g L−1 of yeast extract, and 64.7 g L−1 of MgCO3.

Figure 2.

Response surface curve for the succinic acid production by Actinobacillus succinogenes ATCC 55618 showing the combination effects of (a) glucose and yeast extract, (b) yeast extract and MgCO3, and (c) glucose and MgCO3. Other factors are constant at zero levels.

In a word, the best level combination of the three key factors (i.e., glucose, yeast extract, and MgCO3) was predicted by the polynomial model from BBD. Then the reliability of the model and the accuracy of the prediction should be checked by verification experiment.

3.4. Model Verification

The availability of the regression model of the succinic acid production using the calculated optimal medium compositions, namely, 84.6 g L−1 glucose, 14.5 g L−1 yeast extract, and 64.7 g L−1 MgCO3, was validated with triplicate experiments. The mean maximal value of succinic acid production was 52.7 ± 0.8 g L−1, which agreed with the predicted value (53.0 g L−1) well. As a result, the model was considered to be accurate and reliable for predicting the succinic acid production by A. succinogenes. Theoretically, 1.71 mol succinate can be produced per mol glucose (plus CO2), based on the available electrons (i.e., 24 electrons in glucose divided by 14 electrons in succinate = 1.71). In this work, compared with that of basic medium (0.45 mol mol−1 glucose), the yield of succinic acid against glucose was enhanced by 111.1% in optimized medium (0.95 mol mol−1 glucose). However, there is a certain gap between the yield and the theoretical value. This may be because there are some factors other than the medium, which affect the yield of succinic acid but are not investigated in this study.

Other authors have reported that the succinic acid production reached 84 g L−1 in the fermentation of Actinobacillus succinogenes NJ113, in which the medium was with similar components to the basic medium in this work, and the corresponding yield of succinic acid was 1.20 mol mol−1 glucose [28]. Since NJ113 is the strain screened by Jiang et al, this strain may have greater ability to synthesize succinic acid.

To conclude, the best level combination of the three key factors (i.e., 84.6 g L−1 glucose, 14.5 g L−1 yeast extract, and 64.7 g L−1 MgCO3) was obtained by using the statistical experimental design. The succinic acid production reached its peak values of 52.7 ± 0.8 g L−1 under the optimal medium compositions, which agreed with the predicted value (53.0 g L−1) well and was 67.3% higher than that obtained with the basic medium (i.e., 31.5 ± 2.3 g L−1).

4. Conclusion

In this study, a highly efficient optimization method by combining Plackett-Burman design, steepest ascent, and Box-Behnken design was developed. This method was demonstrated to be effective in selecting the significant factors and enhancing succinic acid production in A. succinogenes ATCC 55618 fermentation. Glucose, yeast extract, and MgCO3 were screened to be key factors for the succinic acid production. A maximal succinic acid production of 52.7 ± 0.8 g L−1 was obtained with 84.6 g L−1 glucose, 14.5 g L−1 yeast extract, and 64.7 g L−1 MgCO3. This result agreed with the predicted value well and was 67.3% higher than that obtained with the basic medium.

Author's Contribution

L.-W. Zhu and C.-C. Wang are equally contributed to this work.

Acknowledgments

Financial supports from the National Natural Science Foundation of China (NSFC, Project nos. 20976038 and 21176059), the Key Project of Chinese Ministry of Education (Project No. 210132), Hubei Provincial Natural Science Foundation for Innovative Research Team (Project No. 2008CDA002), Hubei Provincial Natural Science Foundation for Agriculture, Scientific Research Key Project of Hubei Provincial Department of Education (Project No. Z20101401), Discipline Leader Project of Wuhan Municipality (Project No. 200951830553), Key Technology R&D Program of Wuhan Municipality (Project No. 201120822280-2), the Open Project Programs for the Key Laboratory of Fermentation Engineering (Ministry of Education), the National Key Laboratory of Biochemical Engineering (Project No. 2010KF-06), and the State Key Laboratory of Bioreactor Engineering are gratefully acknowledged. Y-J Tang also thanks the Chutian Scholar Program (Hubei Provincial Department of Education, China) (2006) and Program for New Century Excellent Talents in University (NCET-11-0961).

References

- 1.Song H, Lee SY. Production of succinic acid by bacterial fermentation. Enzyme and Microbial Technology. 2006;39(3):352–361. [Google Scholar]

- 2.Werpy T, Petersen G. Top value added chemicals from biomass. Washington, DC, USA, US Department of Energy, 2004, http://www1.eere.energy.gov/biomass/pdfs/35523.pdf.

- 3.Wilke D. Chemicals from biotechnology: molecular plant genetics will challenge the chemical and the fermentation industry. Applied Microbiology and Biotechnology. 1999;52(2):135–145. doi: 10.1007/s002530051500. [DOI] [PubMed] [Google Scholar]

- 4.Bechthold I, Bretz K, Kabasci S, Kopitzky R, Springer A. Succinic acid: a new platform chemical for biobased polymers from renewable resources. Chemical Engineering and Technology. 2008;31(5):647–654. [Google Scholar]

- 5.Willke T, Vorlop KD. Industrial bioconversion of renewable resources as an alternative to conventional chemistry. Applied Microbiology and Biotechnology. 2004;66(2):131–142. doi: 10.1007/s00253-004-1733-0. [DOI] [PubMed] [Google Scholar]

- 6.Guettler MV, Rumler D, Jain MK. Actinobacillus succinogenes sp. nov., a novel succinic-acid-producing strain from the bovine 1umen. International Journal of Systematic Bacteriology. 1999;49(1):207–216. doi: 10.1099/00207713-49-1-207. [DOI] [PubMed] [Google Scholar]

- 7.Jantama K, Haupt MJ, Svoronos SA, et al. Combining metabolic engineering and metabolic evolution to develop nonrecombinant strains of Escherichia coli C that produce succinate and malate. Biotechnology and Bioengineering. 2008;99(5):1140–1153. doi: 10.1002/bit.21694. [DOI] [PubMed] [Google Scholar]

- 8.Guettler MV, Jain MK, Rumler D. Method for making succinic acid, bacterial variants for use in the process, and methods for obtaining variants. US patent 5573931, 1996.

- 9.Guettler MV, Jain MK, Soni BK. Process for making succinic acid, microorganisms for use in the process and methods of obtaining the microorganisms. US patent 5504004, 1996.

- 10.Guettler MV, Jain MK, Soni BK. Process for making succinic acid, microorganisms for use in the process and methods of obtaining the microorganisms. US patent 5723322, 1998.

- 11.Du C, Lin SKC, Koutinas A, Wang R, Webb C. Succinic acid production from wheat using a biorefining strategy. Applied Microbiology and Biotechnology. 2007;76(6):1263–1270. doi: 10.1007/s00253-007-1113-7. [DOI] [PubMed] [Google Scholar]

- 12.Du C, Lin SKC, Koutinas A, Wang R, Dorado P, Webb C. A wheat biorefining strategy based on solid-state fermentation for fermentative production of succinic acid. Bioresource Technology. 2008;99(17):8310–8315. doi: 10.1016/j.biortech.2008.03.019. [DOI] [PubMed] [Google Scholar]

- 13.Corona-González RI, Bories A, González-Álvarez V, Pelayo-Ortiz C. Kinetic study of succinic acid production by Actinobacillus succinogenes ZT-130. Process Biochemistry. 2008;43(10):1047–1053. [Google Scholar]

- 14.Liu RS, Tang YJ. Tuber melanosporum fermentation medium optimization by Plackett-Burman design coupled with Draper-Lin small composite design and desirability function. Bioresource Technology. 2010;101(9):3139–3146. doi: 10.1016/j.biortech.2009.12.022. [DOI] [PubMed] [Google Scholar]

- 15.Myers RH. Response surface methodology—current status and future directions. Journal of Quality Technology. 1999;31(1):30–44. [Google Scholar]

- 16.Deepak V, Kalishwaralal K, Ramkumarpandian S, Babu SV, Senthilkumar SR, Sangiliyandi G. Optimization of media composition for nattokinase production by Bacillus subtilis using response surface methodology. Bioresource Technology. 2008;99(17):8170–8174. doi: 10.1016/j.biortech.2008.03.018. [DOI] [PubMed] [Google Scholar]

- 17.Ren J, Lin WT, Shen YJ, Wang JF, Luo XC, Xie MQ. Optimization of fermentation media for nitrite oxidizing bacteria using sequential statistical design. Bioresource Technology. 2008;99(17):7923–7927. doi: 10.1016/j.biortech.2008.03.027. [DOI] [PubMed] [Google Scholar]

- 18.Li X, Ouyang J, Xu Y, et al. Optimization of culture conditions for production of yeast biomass using bamboo wastewater by response surface methodology. Bioresource Technology. 2009;100(14):3613–3617. doi: 10.1016/j.biortech.2009.03.001. [DOI] [PubMed] [Google Scholar]

- 19.Plackett RL, Burman JP. The design of optimum multifactorial experiments. Biometrika. 1946;33:305–325. [Google Scholar]

- 20.Gheshlaghi R, Scharer JM, Moo-Young M, Douglas PL. Medium optimization for hen egg white lysozyme production by recombinant Aspergillus niger using statistical methods. Biotechnology and Bioengineering. 2005;90(6):754–760. doi: 10.1002/bit.20474. [DOI] [PubMed] [Google Scholar]

- 21.Stowe RA, Mayer RP. Efficient screening of process variables. Industrial and Engineering Chemistry. 1966;58:36–40. [Google Scholar]

- 22.McKinlay JB, Zeikus JG, Vieille C. Insights into Actinobacillus succinogenes fermentative metabolism in a chemically defined growth medium. Applied and Environmental Microbiology. 2005;71(11):6651–6656. doi: 10.1128/AEM.71.11.6651-6656.2005. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.Lin SKC, Du C, Koutinas A, Wang R, Webb C. Substrate and product inhibition kinetics in succinic acid production by Actinobacillus succinogenes. Biochemical Engineering Journal. 2008;41(2):128–135. [Google Scholar]

- 24.Samuelov NS, Lamed R, Lowe S, Zeikus JG. Influence of CO2-HCO3- levels and pH on growth, succinate production, and enzyme activities of Anaerobiospirillum succiniciproducens. Applied and Environmental Microbiology. 1991;57(10):3013–3019. doi: 10.1128/aem.57.10.3013-3019.1991. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 25.Wang CC, Zhu LW, Li HM, Tang YJ. Performance analyses of a neutralizing agent combination strategy for the production of succinic acid by Actinobacillus succinogenes ATCC 55618. Bioprocess and Biosystems Engineering. 2012;35(4):659–664. doi: 10.1007/s00449-011-0644-6. [DOI] [PubMed] [Google Scholar]

- 26.McKinlay JB, Vieille C. 13C-metabolic flux analysis of Actinobacillus succinogenes fermentative metabolism at different NaHCO3 and H2 concentrations. Metabolic Engineering. 2008;10(1):55–68. doi: 10.1016/j.ymben.2007.08.004. [DOI] [PubMed] [Google Scholar]

- 27.Zou W, Zhu LW, Li HM, Tang YJ. Significance of CO2 donor on the production of succinic acid by Actinobacillus succinogenes ATCC 55618. Microbial Cell Factories. 2011;10, article 87 doi: 10.1186/1475-2859-10-87. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 28.Jiang M, Su L, Chen KQ, Cai T, Wang QN. Optimization of the culture condition for the production by anaerobic fermentation of Actinobacillus succinogenes NJ113. Food and Fermentation Industries. 2007;33:1–5. [Google Scholar]