Summary

Aims

The aim of this study is to investigate cyclic fatigue resistance of four nickel – titanium rotary (NTR) instruments produced by a new method or traditional grinding processes.

Methods

Four NTR instruments from different brands were selected: group 1. Twisted File produced by a new thermal treatment of nickel – titanium alloy; group 2. Revo S SU; group 3. Mtwo and group 4. BioRaCe BR3 produced by traditional grinding processes. A total of 80 instruments (20 for each group) were tested for cyclic fatigue resistance inside a curved artificial canal with a 60 degree angle of curvature and 5 mm radius of curvature. Time to fracture (TtF) from the start of the test until the moment of file breakage and the length of the fractured tip was recorded for each instrument. Means and standard deviations (SD) of TtF and fragment length were calculated. Data were subjected to one-way analysis of variance (ANOVA).

Results

Group 1 (Twisted File) showed the highest value of TtF means. Cyclic fatigue resistance of Twisted File and Mtwo was significantly higher than group 2 (Revo S SU) and 4 (BioRace BR3), while no significant differences were found between group 1 (Twisted File) and 3 (Mtwo) or group 2 (Revo S SU) and 4 (BioRaCe BR3).

Conclusions

The cyclic fatigue resistance of Twisted File was significantly frigher than instruments produced with traditional grinding process except of Mtwo files.

Keywords: cyclic fatigue, grinding process, nickel-titanium, rotary instruments, twisted file

Introduction

All nickel-titanium rotary (NTR) instrument systems currently on the market are constructed from “Nitinol” an alloy that was applied in endodontics since 1988 (1). Endodontic treatment has benefited from the introduction of NTR root canal instruments (2). This is due to a combination of unique mechanical properties of the alloy, innovative file design, greater tapers and a crown down instrumentation procedure (3). As a result, there are now many systems available commercially, that use NTR instruments of different designs and dimensions, to produce a desirable tapered root canal form, with a low risk of transporting the original canal foramen and facilitate cleaning and shaping procedures (4–7). However, clinicians remain concerned about their breakage in use although the actual prevalence of such breakages has been indicated to be low (about 5%) (8). Several studies have attempted to examine the reasons for fracture of NTR instruments after clinical or simulated use and have shown that fractures can occur as a result of tensional or cyclic fatigue (9–13). Torsional fatigue is the twisting of a metal about its longitudinal axis at one end while the other end is in a fixed position. Cyclic fatigue occurs when a metal is subjected to repeated cycles of tension and compression that causes its structure to break down, ultimately leading to fracture (14).

Cyclic fatigue failure was implicated in more than one-third of those instruments fractured clinically and occurs unexpectedly without any sign of previous permanent deformation (9, 15, 16).

The fracture was due to the alternating tension/compression cycles which instruments are subjected to, when flexed in the region of maximum curvature of the canal (17).

Since the introduction of nickel-titanium alloy to endodontics, there have been many changes in instrument design, but no significant improvements in the raw material properties, or enhancements in the manufacturing processes. Recently, a new manufacturing process was developed by SybronEndo (Orange, CA), to create a NTR instrument called Twisted File (TF). It is produced by twisting the alloy after heat treatment in order to improve super-elasticity and increase cyclic fatigue resistance (18).

The purpose of the present in vitro study was to compare the cyclic fatigue resistance of a nickel – titanium rotary instrument produced by a new method (Twisted File) to three instruments produced by traditional grinding processes.

Materials and methods

Four different NTR instruments from different brands, of identical sizes (.06 taper and 0.25 tip diameter) were selected and evaluated: group 1. Twisted File (SybronEndo, Orange, CA, USA) produced by a new thermal treatment of nickel – titanium alloy; group 2. Revo S SU (MicroMega, Besancon, France); group 3. Mtwo (Sweden-Martina, Padova, Italy) and group 4. BioRaCe BR3, (FKG, La Chaux de Fonds, Switzerland) produced by traditional grinding processes. Twenty NTR files from each manufacturer were tested for cyclic fatigue resistance, resulting in 80 instruments. All instruments had been previously inspected using a measuring microscope for dimensional analysis, and for any signs of visible deformation. None was discarded. Size 06–25 was selected, being the master apical NTR file in many operative sequences. Cyclic fatigue tests were performed by a device as described in previous studies (19, 20).

The device consists of a main frame to which a mobile plastic support for the hand-piece is connected, and a stainless-steel block containing the artificial canals. The hand-piece was mounted upon a mobile device to allow precise and reproducible placement of each instrument inside an artificial canal. This ensured three-dimensional alignment, and positioning of the instruments to the same depth.

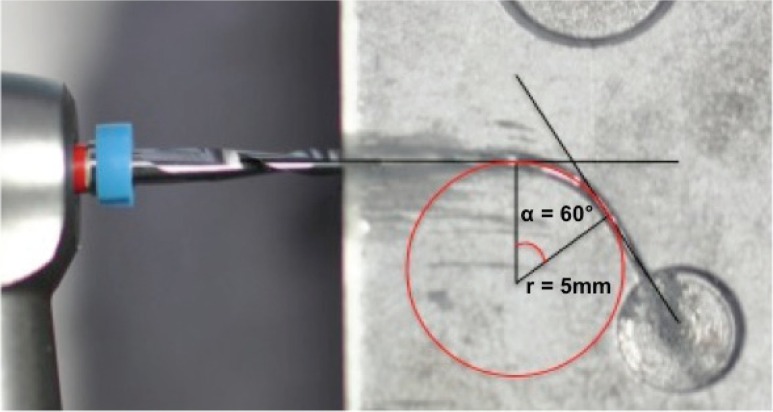

The artificial canal was manufactured reproducing instrument size 25 and taper .06. It provided the instrument with a suitable simulated root canal with a 60 degree angle of curvature and 5 mm radius of curvature (Fig. 1). Radius was measured to the central axis of the curvature. The center of the curvature was 6 mm from the tip of the instrument and the curved segment of the canal was approximately 5 mm in length. Instruments were rotated at a constant speed of 300 rpm using a 6:1 reduction hand-piece (Sirona Dental Systems GmbH, Bensheim, Germany), powered by a torque-controlled motor (VDW Silver, VDW GmbH – Dentsply International Inc., Munich, Germany). Torque was set at 2N/cm. All instruments were rotated until fracture occurred. Time to fracture (TtF) from the start of the test until the moment of file breakage was recorded with a chronometer to an accuracy of 0.1 second. The length of the fractured tip was also recorded for each instrument.

Figure 1.

Mtwo instrument inserted in the stainless-steel artificial canal.

Means and standard deviations (SD) of TtF and fragment length were calculated for each system. Data were subjected to one-way analysis of variance (ANOVA) and Dunn’s multiple comparison post-hoc test to determine significant differences between groups. Significance was set at the 95% confidence level.

Results

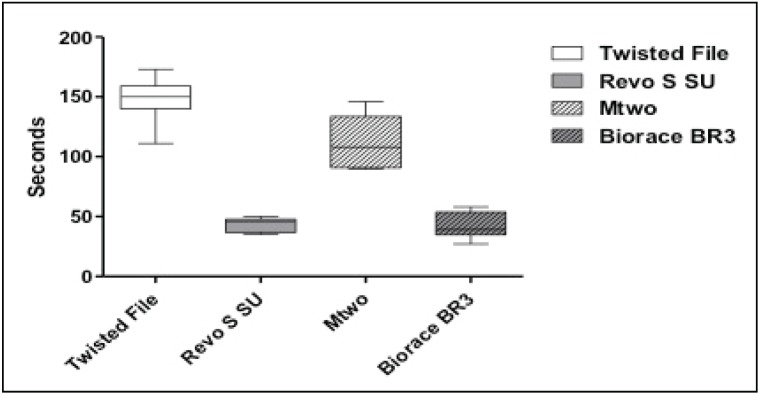

Mean values and standard deviation of Time to Fracture (TtF) and fragment lengths are displayed in Table 1. A higher TtF is due to a higher resistance to cyclic fatigue of the tested instruments. Group 1 (Twisted File) showed the highest value of TtF means. Cyclic fatigue resistance of Twisted File (Group 1) and Mtwo (Group 3) was significantly higher than group 2 (Revo S SU) and 4 (BioRace BR3) (P<0.05). No statistically significant difference was noted between groups 1 (Twisted File) and 3 (Mtwo) or groups 2 (Revo S SU) and 4 (BioRaCe BR3) (P>0.05) (Fig. 2).

Table 1.

Time to Fracture and fragment length (mean and SD) of size 25, taper.06 instruments.

| Instruments | Time to Fracture (TtF) | Fragment length | ||

|---|---|---|---|---|

| Mean (seconds) | SD | Mean (millimeters) | SD | |

| Twisted File | 148.5 | 17.48 | 5.25 | 0.58 |

| Revo S SU | 43.5 | 5.66 | 5.05 | 0.49 |

| Mtwo | 112 | 21.49 | 5.9 | 0.87 |

| Biorace BR3 | 42.9 | 10.97 | 5.8 | 0.95 |

Figure 2.

Column bar plot of Time to Fracture (TtF) for instruments.

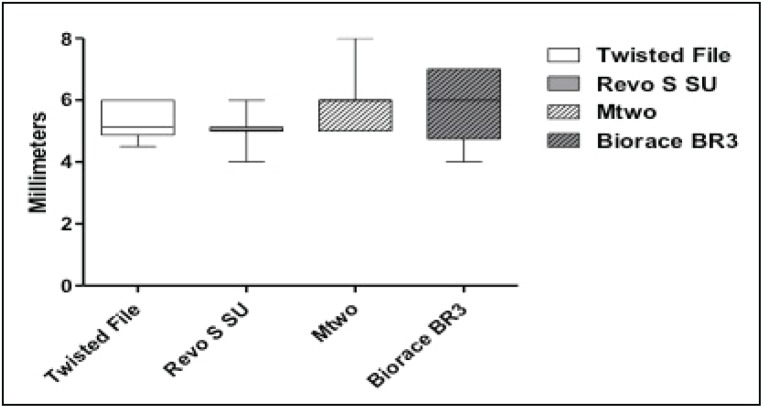

Mean length of the fractured segment was also recorded to evaluate the correct positioning of the tested instrument inside the canal curvature, and whether similar stresses were being induced. No statistically significant difference (P>0.05) was reported in the mean length of the fractured fragments for all of the instruments tested (Fig. 3).

Figure 3.

Column bar plot of fragment length for instruments.

Discussion

File fracture is a major concern during endodontic treatment. Although multiple factors are responsible for instrument separation in use, cyclic fatigue has been shown to be an important cause because the rotary instrument might be used in curved root canals (9, 13, 16). The shorter the radius of curvature, the greater is the chance of fatigue breakage (13, 21). Cyclic fatigue occurs when a metal is subjected to repeated cycles of tension and compression that cause its structure to break down (as a result of concentration of stress at the propagating crack front) and ultimately fracture (21, 22). Among the four instruments tested, Twisted Files were produced by processes of heating and twisting while the other three instruments were produced by traditional grinding methods.

No scientific method was developed to date, which evaluated the resistance to fatigue of NTR instruments (18). Device or methods for fatigue testing didn’t incorporate into international standards for endodontic instruments. The cyclic fatigue testing device used in this study has been utilized in previous studies of cyclic fatigue resistance and has generated the maximum stress at the center of simulated curve (about 6 mm from the tip) (23). No difference (P > 0.05) between fragment lengths of all NiTi files confirmed the correct positioning of the tested instrument inside the canal curvature, and whether similar stresses were being induced.

Although the simulated canal does not duplicate the in vivo situation, it allows the comparative testing of different instruments in a standardized environment (24).

Among the four instruments tested, Twisted Files were produced by processes of heating and twisting, while the other three instruments (Revo S SU, Bio Race BR3 and Mtwo) were produced by traditional grinding methods.

Kuhn & Jordan proposed some suggestions to improve the longevity of endodontic files, which include the following: (1) thermal treatments before machining to decrease the work-hardening of the alloy; (2) choosing machining conditions adapted to the NiTi alloy; and (3) electropolishing to reduce the machining damage on the surface. The production method for manufacturing Twisted File instruments would incorporate the first two of these suggestions (25). Hou suggested that new method of manufacturing NiTi instruments by twisting coupled with heat treatment of Twisted File might contribute to the increased phase transformation temperatures and its superior flexibility (26).

Results of this study showed that size 25.06 of Twisted File was more resistant to cyclic fatigue than the other tested size 25.06 NTR instruments in absolute value.

It has been shown that the fatigue life of NTR instruments made from conventional NiTi wire and that are the same size, was not significantly affected by differences in cross-sectional shape and/or design of the cutting flutes (27). Another recent study showed no obvious difference on the fatigue life among ProFile, TYP (triangular configuration), and DS NEYY (square configuration) files, which were made from conventional NiTi wire (28). Moreover, Twisted file and Bio Race BR3 both have an equilateral triangular cross-section, but significant differences were found between TtF of Twisted Files and Bio Race BR3 or Revo S SU in our study (P<0.001) (29). So the improvement in cyclic fatigue resistance for size 25.06 Twisted File would be also related to the manufacturing processes. In fact, heating treatment of Twisted Files transform the austenitic crystalline structure of NiTi alloy into the rhombohedral (R-) phase (30). R-phase shows good super-elasticity and shape memory effect (30); its Young’s modulus typically is lower than that of austenite. Thus, an instrument made up of the R-phase would be more flexible, allowing a greater amount of deformation than austenitic NiTi. (29, 31).

On the other hand, cross-sectional configuration and manufacturing processes may influence flexibility of NTR instruments and have a substantial impact on their fatigue lifetime (32, 33).

Our study showed no statistically significant difference of TtF between Twisted File and Mtwo. Indeed, although produced by the traditional grinding processes, Mtwo instruments showed resistance to cyclic fatigue only slightly lower in absolute value than of new instruments manufactured by thermal methods, such as Twisted File. This is probably due to the lower flexural rigidity for cross-section of Mtwo rather that one of Twisted File. Moreover a significant difference was found between Mtwo and Bio Race BR3 or Revo S SU despite being both made by traditional grinding processes. Instead the comparison of TtF of Bio Race BR3 and Revo S SU showed no significant difference (P>0.05).

The lower resistance to cyclic fatigue of instruments produced by traditional grinding process can be explained by the fact that it has many drawbacks. More precisely, cutting across the grain of the crystalline structure of the nickel-titanium wire limits the overall strength of the instruments, due to the formation of micro-cracks and defects along the surface of the instruments and within the internal structure (29). Kuhn et al. described the crack nucleation stage being facilitated by a high density of surface defects, and then fatigue failure is largely a crack propagation process (34).

For the cyclic fatigue resistance, residual stresses have been considered as an important factor not only after (simulated) clinical uses but also for a brand-new instrument (35, 36). When an instrument is machined (ie, being ground), plastic deformation occurs at the surface of the metal, resulting in residual stresses that remain at the surface (37). Although the exact nature and extent of such residual stress after manufacture are unknown, any internal stresses might act as a negative factor to the martensite substructures (38).

It is important for clinicians to realize that preexisting conditions associated with the manufacturing process might contribute to the propagation of instrument fractures during use (39, 40).

Conclusions

Twisted Files 25.06, produced by thermal and twisted processes, showed the best cyclic fatigue resistance that was significantly better than the other NTR instruments tested produced with the traditional grinding process, except Mtwo files. Additional studies are also necessary to improve correlations between in vitro and in vivo fatigue resistance of NTR instruments.

Acknowledgments

“The authors deny any conflicts of interest”

References

- 1.Walia HM, Brantley WA, Gerstein H. An initial investigation of the bending and torsional properties of Nitinol root canal files. J Endod. 1988;14:346–51. doi: 10.1016/s0099-2399(88)80196-1. [DOI] [PubMed] [Google Scholar]

- 2.Parashos P, Gordon I, Messer HH. Factors influencing defects of rotary nickel–titanium endodontic instruments after clinical use. J of Endod. 2004;30:722–5. doi: 10.1097/01.don.0000129963.42882.c9. [DOI] [PubMed] [Google Scholar]

- 3.Kazemi RB, Stenman E, Spångberg LS. A comparison of stainless steel and nickel-titanium H-type instruments of identical design: torsional and bending tests. Oral Surg Oral Med Oral Pathol Oral Radiol Endod. 2000;90:500–6. doi: 10.1067/moe.2000.108959. [DOI] [PubMed] [Google Scholar]

- 4.Schafer E, Schulz-Bongert U, Tulus G. Comparison of hand stainless steel and nickel titanium rotary instrumentation: a clinical study. J Endod. 2004;30:432–5. doi: 10.1097/00004770-200406000-00014. [DOI] [PubMed] [Google Scholar]

- 5.Chen JL, Messer HH. A comparison of stainless steel hand and rotary nickel-titanium instrumentation using a silicone impression technique. Aust Dent J. 2002;47:12–20. doi: 10.1111/j.1834-7819.2002.tb00297.x. [DOI] [PubMed] [Google Scholar]

- 6.Garip Y, Gunday M. The use of computed tomography when comparing nickel-titanium and stainless steel files during preparation of simulated curved canals. Int Endod J. 2001;34:452–457. doi: 10.1046/j.1365-2591.2001.00416.x. [DOI] [PubMed] [Google Scholar]

- 7.Xu X, Eng M, Zheng Y, Eng D. Comparative study of torsional and bending properties for six models of nickel-titanium root canal instruments with different cross-sections. J Endod. 2006;32:372–375. doi: 10.1016/j.joen.2005.08.012. [DOI] [PubMed] [Google Scholar]

- 8.Cheung GS, Darvell BW. Fatigue testing of a NiTi rotary instrument. Part 1: Strain-life relationship. Int Endod J. 2007;40:612–618. doi: 10.1111/j.1365-2591.2007.01262.x. [DOI] [PubMed] [Google Scholar]

- 9.Sattapan B, Nervo GJ, Palamara JEA, Messer HH. Defects in rotary nickel–titanium files after clinical use. J Endod. 2000;26:161–5. doi: 10.1097/00004770-200003000-00008. [DOI] [PubMed] [Google Scholar]

- 10.Spanaki-Voreadi AP, Kerezoudis NP, Zinelis Failure mechanism of ProTaper nickel–titanium rotary instruments during clinical use: fractographic analysis. Int Endod J. 2006;39:171–178. doi: 10.1111/j.1365-2591.2006.01065.x. [DOI] [PubMed] [Google Scholar]

- 11.Zelada G, Varela P, Martın B, Bahıllo JG, Magan F, Ahn S. The effect of rotational speed and the curvature of root canals on the breakage of rotary endodontic instruments. J of Endod. 2002;28:540–542. doi: 10.1097/00004770-200207000-00014. [DOI] [PubMed] [Google Scholar]

- 12.Yared G. In vitro study of the torsional properties of new and used ProFile nickel titanium rotary files. J Endod. 2004;30:410–2. doi: 10.1097/00004770-200406000-00008. [DOI] [PubMed] [Google Scholar]

- 13.Pruett JP, Clement DJ, Carnes DL., Jr Cyclic fatigue testing of nickel-titanium endodontic instruments. J Endod. 1997;23:77–85. doi: 10.1016/S0099-2399(97)80250-6. [DOI] [PubMed] [Google Scholar]

- 14.Hibbeler RC. Mechanics of materials. 3rded. Upper Saddle River, NJ: Prentice Hall; 1997. [Google Scholar]

- 15.Peng B, Shen Y, Cheung GSP, Xia TJ. Defects in ProTaper S1 instruments after clinical use: longitudinal examination. Int Endod J. 2005;38:550–557. doi: 10.1111/j.1365-2591.2005.00991.x. [DOI] [PubMed] [Google Scholar]

- 16.Shen Y, Cheung GS, Bian Z, Peng B. Comparison of defects in ProFile and ProTaper systems after clinical use. J Endod. 2006;32:61–65. doi: 10.1016/j.joen.2005.10.017. [DOI] [PubMed] [Google Scholar]

- 17.Gambarini G. Cyclic fatigue of nickel-titanium rotary instruments after clinical use with low-and high-torque endodontic motors. J Endod. 2001;27:772–774. doi: 10.1097/00004770-200112000-00015. [DOI] [PubMed] [Google Scholar]

- 18.Testarelli L, Grande NM, Plotino G, Lendini M, Pongione G, Paolis GD, Rizzo F, Milana V, Gambarini G. Cyclic fatigue of different nickel-titanium rotary instruments: a comparative study. Open Dent J. 2009;16:55–58. doi: 10.2174/1874210600903010055. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Plotino G, Grande NM, Sorci E, Malagnino VA, Somma F. A comparison of cyclic fatigue between used and new Mtwo Ni-Ti rotary instruments. Int Endod J. 2006;39:716–723. doi: 10.1111/j.1365-2591.2006.01142.x. [DOI] [PubMed] [Google Scholar]

- 20.Grande NM, Plotino G, Pecci R, Bedini R, Malagnino VA, Somma F. Cyclic fatigue resistance and three-dimensional analysis of instruments from two nickel-titanium rotary systems. Int Endod J. 2006;39:755–763. doi: 10.1111/j.1365-2591.2006.01143.x. [DOI] [PubMed] [Google Scholar]

- 21.Cheung GSP. Instrument fracture: mechanisms, removal of fragments, and clinical outcomes. Endod Topics. 2009;16:1–26. [Google Scholar]

- 22.Kuhn G, Tavernier B, Jordan L. Influence of structure on nickel-titanium endodontic instruments failure. J Endod. 2001;27:516–20. doi: 10.1097/00004770-200108000-00005. [DOI] [PubMed] [Google Scholar]

- 23.Gambarini G, Grande NM, Plotino G, Somma F, Garala M, De Luca M, Testarelli L. Fatigue resistance of engine-driven rotary nickel-titanium instruments produced by new manufacturing methods. J Endod. 2008;34:1003–5. doi: 10.1016/j.joen.2008.05.007. [DOI] [PubMed] [Google Scholar]

- 24.Larsen CM, Watanabe I, Glickman GN, He J. Cyclic fatigue analysis of a new generation of nickel titanium rotary instruments. J Endod. 2009;35:401–403. doi: 10.1016/j.joen.2008.12.010. [DOI] [PubMed] [Google Scholar]

- 25.Kuhn G, Jordan L. Fatigue and mechanical properties of nickel-titanium endodontic instruments. J Endod. 2002;28:716–20. doi: 10.1097/00004770-200210000-00009. [DOI] [PubMed] [Google Scholar]

- 26.Hou X, Yahata Y, Hayashi Y, Ebihara A, Hanawa T, Suda H. Phase transformation behaviour and bending property of twisted nickel-titanium endodontic instruments. Int Endod J. 2011;44:253–8. doi: 10.1111/j.1365-2591.2010.01818.x. [DOI] [PubMed] [Google Scholar]

- 27.Cheung GS, Darvell BW. Low-cycle fatigue of NiTi rotary instruments of various cross-sectional shapes. Int Endod J. 2007;40:626–32. doi: 10.1111/j.1365-2591.2007.01257.x. [DOI] [PubMed] [Google Scholar]

- 28.Shen Y, Qian W, Abtin H, Gao Y, Haapasalo M. Fatigue testing of controlled memory wire nickel-titanium rotary instruments. J Endod. 2011;37:997–1001. doi: 10.1016/j.joen.2011.03.023. [DOI] [PubMed] [Google Scholar]

- 29.Park SY, Cheung GS, Yum J, Hur B, Park JK, Kim HC. Dynamic torsional resistance of nickel-titanium rotary instruments. J Endod. 2010;36:1200–4. doi: 10.1016/j.joen.2010.02.016. [DOI] [PubMed] [Google Scholar]

- 30.Kim HC, Yum J, Hur B, Cheung GS. Cyclic fatigue and fracture characteristics of ground and twisted nickel-titanium rotary files. J Endod. 2010;36:147–152. doi: 10.1016/j.joen.2009.09.037. [DOI] [PubMed] [Google Scholar]

- 31.Miyai K, Ebihara A, Hayashi Y, Doi H, Suda H, Yoneyama T. Influence of phase transformation on the torsional and bending properties of nickel-titanium rotary endodontic instruments. Int Endod J. 2006;39:119–26. doi: 10.1111/j.1365-2591.2006.01055.x. [DOI] [PubMed] [Google Scholar]

- 32.Viana AC, Chaves Craveiro de Melo M, Guiomar de Azevedo Bahia M, Lopes Buono VT. Relationship between flexibility and physical, chemical, and geometric characteristics of rotary nickel-titanium instruments. Oral Surg Oral Med Oral Pathol Oral Radiol Endod. 2010;110:527–33. doi: 10.1016/j.tripleo.2010.05.006. [DOI] [PubMed] [Google Scholar]

- 33.Zhang EW, Cheung GS, Zheng YF. A mathematical model for describing the mechanical behaviour of root canal instruments. Int Endod J. 2011;44:72–6. doi: 10.1111/j.1365-2591.2010.01801.x. [DOI] [PubMed] [Google Scholar]

- 34.Kuhn G, Tavernier B, Jordan L. Influence of structure on nickel-titanium endodontic instruments failure. J Endod. 2001;27:516–20. doi: 10.1097/00004770-200108000-00005. [DOI] [PubMed] [Google Scholar]

- 35.Kim HC, Cheung GS, Lee CJ, Kim BM, Park JK, Kang SI. Comparison of forces generated during root canal shaping and residual stresses of three nickel-titanium rotary files by using a three-dimensional finite-element analysis. J Endod. 2008;34:743–7. doi: 10.1016/j.joen.2008.03.015. [DOI] [PubMed] [Google Scholar]

- 36.Kim HC, Kim HJ, Lee CJ, Kim BM, Park JK, Versluis A. Mechanical response of nickel-titanium instruments with different cross-sectional designs during shaping of simulated curved canals. Int Endod J. 2009;42:593–602. doi: 10.1111/j.1365-2591.2009.01553.x. [DOI] [PubMed] [Google Scholar]

- 37.Shaw MC. Surface integrity. In: Crookall JR, Shaw MC, Suh NP, editors. Metal cutting principles. 2nd edn. New York: Oxford University Press; 2005. pp. 432–5. [Google Scholar]

- 38.Liu Y, Van Humbeeck J, Stalmans R, Delaey L. Some aspects of the properties of NiTi shape memory alloy. J Alloys Compd. 1997;247:115–21. [Google Scholar]

- 39.Alapati SB, Brantley WA, Svec TA, Powers JM, Mitchell J. Scanning electron microscope observation of new and used nickel-titanium rotary files. J Endod. 2003;29:667–9. doi: 10.1097/00004770-200310000-00014. [DOI] [PubMed] [Google Scholar]

- 40.Alapati SB, Brantley WA, Svec TA, Powers JM, Nusstein JM, Daehn GS. SEM observations of nickel-titanium rotary endodontic instruments that fractured during clinical use. J Endod. 2005;31:40–3. doi: 10.1097/01.don.0000132301.87637.4a. [DOI] [PubMed] [Google Scholar]