Abstract

The Centers for Disease Control (CDC) lists Bacillus anthracis as a category A agent and estimates the cost of an anthrax attack to exceed US$ 26 billion per 100,000 exposed individuals. Concerns regarding anthrax vaccine purity, a requirement for multiple injections, and a limited supply of the protective antigen (PA), underscore the urgent need for an improved vaccine. Therefore, the 83 kDa immunogenic Bacillus anthracis protective antigen was expressed in transgenic tobacco chloroplasts. The PA gene (pag) was cloned into a chloroplast vector along with the psbA regulatory signals to enhance translation. Chloroplast integration of the transgenes was confirmed by PCR and Southern blot analyses. Crude plant extracts contained up to 2.5 mg full length PA/g of fresh leaf tissue and this showed exceptional stability for several months in stored leaves or crude extracts. Maximum levels of expression were observed in mature leaves under continuous illumination. Co-expression of the ORF2 chaperonin from Bacillus thuringiensis did not increase PA accumulation or induce folding into cuboidal crystals in transgenic chloroplasts. Trypsin, chymotrypsin and furin proteolytic cleavage sites present in PA were protected in transgenic chloroplasts because only full length PA 83 was observed without any degradation products. Both CHAPS and SDS detergents extracted PA with equal efficiency and PA was observed in the soluble fraction. Chloroplast-derived PA was functionally active in lysing mouse macrophages when combined with lethal factor (LF). Crude leaf extracts contained up to 25 μg functional PA/ml. With an average yield of 172 mg of PA per plant using an experimental transgenic cultivar grown in a greenhouse, 400 million doses of vaccine (free of contaminants) could be produced per acre, a yield that could be further enhanced 18-fold using a commercial cultivar in the field.

Keywords: Bioterrorism, GM crops, Anthrax vaccine

1. Introduction

Recent occurrences of the inadvertent contamination of the food supply by plant-derived pharmaceutical proteins have resulted in heavy penalties, stricter USDA guidelines and a US government proposal to seize food products tainted with traces of pharmaceutical crops. These incidents underscore the need to produce pharmaceutical proteins in non-food or feed crops. At the same time, the inability of large parts of the human population to afford newly developed human vaccines and therapeutics requires that agricultural scale production be developed for their manufacture. However, this must be achieved in an environmentally friendly manner, without contaminating our food crops. This article describes use of an alternate non-food and non-feed crop to produce recombinant protective antigen (PA) (vaccine antigen) against an agent of bioterrrorism, via chloroplast genetic engineering.

Chloroplasts are ideal for genetic engineering because they offer a number of attractive advantages, including high-level transgene expression [1], multi-gene engineering in a single transformation event [2–4], transgene containment via maternal inheritance [5], lack of gene silencing [2,6], position effect due to site-specific transgene integration [1] and pleiotropic effects [6,7]. Random integration of transgenes via non-homologous recombination results in nuclear transgenic lines with extremely high variability of foreign gene expression and this requires screening of hundreds of independent transformation events. Such a screening is not necessary in chloroplast transgenic lines because of uniform foreign gene expression in chloroplast transgenic lines due to site specific integration of transgenes via homologous recombination of flanking sequences present in chloroplast transformation vectors. Similarly, pleiotrophic effects are often observed when foreign genes are expressed via the nuclear genome. For example, cholera toxin β subunit was expressed in leaves of nuclear transgenic plants, they were unable to grow even with very low levels of CTB expression [8]. However, when CTB was expressed to 410–3300-fold higher levels in transgenic chloroplasts, plants grew normally like the untransformed control [7,9].

Chloroplast genetic engineering is most suitable for hyper-expression of vaccine antigens and production of valuable therapeutic proteins. Since demonstrating expression of human elastin-derived polymers for various biomedical applications [10], we have extended this approach to express vaccines antigens for cholera [7], monoclonal antibody [11] and human therapeutic proteins, including human serum albumin [12], magainin, a broad spectrum topical agent, systemic antibiotic, wound healing stimulant and a potential anticancer agent [13], interferon [14] and insulin-like growth factor [14]. Several other laboratories have expressed other therapeutic proteins, including human somatotropin [15] and interferon-GUS fusion proteins [16] in transgenic chloroplasts.

Tobacco, a non-food and non-feed crop, is easy to manipulate through genetic engineering, and can produce large amounts of biomass. Both nuclear and chloroplast genomes of tobacco have been transformed with ease. Tobacco is a self-pollinating crop and there are no known wild or cultivated relatives in North America. Several studies have demonstrated that transgenes are maternally inherited when introduced into the chloroplast genome of tobacco [1]. Most importantly, harvesting tobacco leaves before the onset of flowering eliminates transgene flow via pollen or seed, thereby preventing contamination of food crops as is required by various regulatory agencies. Tobacco is an excellent biomass producer (in excess of 40 t fresh leaf weight/acre based on multiple mowings per season) and a prolific seed producer (up to one million seeds produced per plant), thus shortening the time in which a product can be scaled up and brought to market. The existence of a large-scale processing infrastructure is yet another advantage for tobacco. Tobacco is also an ideal choice because of the need to explore alternate uses for this crop. Although many tobacco cultivars produce high levels of alkaloids, there are low-alkaloid varieties that can be used for the production of pharmaceutical proteins. Fortunately, alkaloids are easily separated from proteins during purification and any cross contamination can be virtually eliminated. Cramer et al. [17] provide data to support some of the advantages listed above.

Anthrax is a zoonosis, a disease shared by animals and humans. Ruminants such as cattle, sheep, goats, and deer are the most susceptible and commonly affected animals. Animals contract the disease through ingestion of soil-borne Bacillus anthracis spores and may die acutely. Anthrax is endemic to the United States. Most recent outbreaks of anthrax in deer and livestock occurred in September 2001 in the Del Rio, TX, region (USDA, 2002, fact sheet) and in South Dakota. The handling of infected animals or animal products sometimes leads to human infections. The threat of anthrax has increased due to recent bioterrrorism activities.

Bacillus anthracis is a Gram-positive, nonmotile, aerobic or facultatively anaerobic, spore-forming bacterium. The spores are about 1 μm in size, extremely hardy, resistant to gamma rays, UV light, drying, heat, and many disinfectants [18,19]. Anthrax infects humans through contact with the spores in one of three ways. First, cutaneous anthrax occurs when spores enter the body through a cut or an abrasion on the skin or through the bite of an insect that has recently fed on an infected animal. Second, gastrointestinal anthrax occurs through consumption of contaminated meat products. Third, inhalational anthrax ensues when an animal encounters aerosolized spores that are able to reach lung alveoli [18]. In humans, cutaneous anthrax is the most common form with approximately 2000 cases reported each year worldwide. Gastrointestinal cases are rare and usually occur in small outbreaks. Historically, inhalation anthrax most often occurred in factories that handled animal hides and wool. Nowadays, the threat of biological warfare or terrorism is the principal reason for concern about inhalation anthrax. Prior to 2001, there had been no reports of inhalation anthrax in the US since 1978 [19].

When spores enter the body, macrophages engulf them, migrate to regional lymph nodes and the spores germinate into vegetative bacteria. Spores germinate upon entering an environment rich in glucose, amino acids, and nucleosides, such as in animal and human tissues and blood. Macrophages release the vegetative bacteria and they spread through the blood and lymph until there are up to 108 bacilli per milliliter of blood. The exotoxins are produced from bacteria that lead to symptoms and possible death [18]. The vegetative cells enter the spore state when the nutrients are exhausted or when the organisms are exposed to molecular oxygen in the air [19]. Spores can survive in the lungs or lymph nodes up to 60 days before germination occurs. In animal experiments, it has been seen that once toxin secretion has reached a critical threshold, death will occur, even if the blood is rendered free of Bacillus anthracis through the use of antibiotics. From primate studies, the estimated lethal dose of inhaled anthrax spores sufficient to kill 50% of humans exposed to it (the LD50) is 2500–55,000 spores per treated individual [19].

The Centers for Disease Control (CDC) lists anthrax as a category A disease agent and estimates the cost of an anthrax attack would be US$ 26.2 billion per 100,000 persons exposed [20]. The only vaccine licensed for human use in the US, Biothrax (formerly Anthrax vaccine adsorbed, or AVA), is an aluminum hydroxide-adsorbed, formalin-treated culture supernatant of a toxigenic, nonencapsulated, non-proteolytic strain of Bacillus anthracis [21]. In addition to the immunogenic protective antigen, the vaccine contains trace amounts of edema factor (EF) and lethal factor (LF) that may contribute to the high rate of local reactions at the site of the subcutaneous injection or reported to be toxic causing side-effects [22–24]. However LF alone may enhance vaccine immunogenicity [22]. There is a clear need and urgency for an improved vaccine for anthrax and for improved production methods that allow it to be mass-produced at reasonable cost.

Using chloroplast transformation technology, large quantities of PA could be produced in transgenic plants due to the presence of thousands of copies of transgenes per cell as opposed to only a few copies in nuclear transgenic plants. Transgenic chloroplast technology has been used to hyper-express bacterial proteins—up to 46% of total soluble protein (TSP) from Bacillus genes, the highest ever reported in transgenic plants [2]. Chloroplasts are prokaryotic in nature and express native bacterial genes (like β subunit of cholera toxin) at very high levels (410-fold [7] or 3300-fold [9] higher than nuclear expression). This is in sharp contrast to nuclear expression of pag, that would require extensive codon modifications because of high AT content, unfavorable codons, presence of mRNA destabilizing sequences, and cryptic polyadenylation or splice sites. Chloroplast transformation typically utilizes two flanking sequences that, through homologous recombination, insert transgenes into spacer regions between functional genes of the chloroplast genome, thus targeting transgenes to a known location [1]. The chloroplast genome may be engineered without the use of antibiotic resistance genes as well for the development of edible vaccines [25]. Therefore, pag was expressed in transgenic tobacco chloroplasts in order to obtain large amounts of PA free of contaminants and to facilitate vaccine production to stockpile for times of crisis.

2. Materials and methods

2.1. Construction of chloroplast vectors

The pMS1 plasmid containing pag gene provided by Rakesh Bhatnagar (Centre for Biotechnology, Jawaharlal Nehru University, India) was digested with unique restriction sites BglII and BamHI and cloned into the plasmid p-BlueScript. The psbA 5′-UTR was amplified, introducing two unique restriction sites EcoRV and SalI at 5′-end and NdeI site on the 3′-end. The PCR product was sequenced and cloned into the pCR 2.1 vector. The p-Blue-T7-pag plasmid was digested with NdeI and XbaI to remove the pag gene and it was sub-cloned into pCR 2.1–5′-UTR. The pCR 2.1–5′-UTR-pag vector was digested with EcoRV and XbaI and the 5′-UTR-pag is cloned into chloroplast vector pLD. The final construct was designated pLD-JW1. The pLD-JW1 vector was digested with EcoRV and ligated with the ORF1, 2 promoter and putative chaperonin flanked by EcoRV restriction sites and the resultant construct was designated pLD-JW2.

2.2. Bombardment and selection of transgenic plants

Sterile Nicotiana tabacum cv. Petit Havana tobacco leaves were bombarded using the Bio-Rad PDS-1000/He biolistic device as previously described [26,27]. The bombarded leaves were placed on RMOP medium containing 500 μg/ml spectinomycin for two rounds of selection on plates and subsequently moved to jars of MSO medium containing 500 μg/ml spectinomycin.

2.3. PCR analysis to test stable integration

DNA was extracted from tobacco leaves using Qiagen DNeasy Plant Mini Kit (Qiagen, Valencia, CA). PCR was performed using the Perkin-Elmer Gene Amp PCR System 2400 (Perkin-Elmer, Chicago, IL). PCR reactions contained template DNA, 1× Taq buffer, 0.5 mM dNTPs, 0.2 mM 3P primer, 0.2 mM 3 M primer, 0.05 units/μl Taq polymerase, and 0.5 mM MgCl2. Samples were run for 30 cycles as follows: 95 °C for 1 min, 65 °C for 1 min, and 72 °C for 2 min with a 5 min ramp up at 95 °C and a 72 °C hold for 10 min after all 30 cycles were completed. PCR products were separated on 1% agarose gels.

2.4. Southern blot analysis

Total plant DNA was digested with BglII and run on a 0.8% agarose gel at 50 V for 2 h. The gel was soaked in 0.25 N HCl for 15 min and then rinsed 2× with water. The gel was soaked in transfer buffer (0.4 N NaOH, 1 M NaCl) for 20 min and then transferred overnight to a nitrocellulose membrane. The membrane was rinsed twice in 2× SSC (0.3 M NaCl, 0.03 M sodium citrate), dried on filter paper, and then crosslinked in the GS GeneLinker (Stratagene, La Jolla, CA). The flanking sequence probe was made by digesting pUC-CT vector DNA with BamHI and BglII to generate a 0.81 kb probe [6]. The pag probe was made by digesting pag with NcoI to generate a 0.52 kb probe. The probes were labeled with 32P using the ProbeQuant G-50 Micro Columns (Amersham, Arlington Heights, IL). The probes were hybridized with the membranes using Stratagene QUICK-HYB hybridization solution and protocol (Stratagene, La Jolla, CA).

2.5. Western blot analysis

Approximately 100 mg of leaf tissue was ground in liquid nitrogen with a mortar and pestle and stored at −80 °C for several months. When it was time to extract the proteins, the powder was removed from −80 °C and mixed with a mechanical pestle in 200 μl of plant extraction buffer (0.1% SDS, 100 mM NaCl, 200 mM Tris–HCl pH 8.0, 0.05% Tween 20, 400 mM sucrose, 2 mM PMSF). The plant extract was then centrifuged for 5 min at 10,000 × g to pellet the insoluble plant material. The supernatant containing the extracted protein was transferred to a fresh tube and an aliquot was taken out, combined with sample loading buffer, boiled, and then run on 8% SDS–PAGE gels for 1 h at 80 V, then 2 h at 150 V. Gels were transferred overnight at 10 V to nitrocellulose membrane. The membrane was blocked with PTM (1 × PBS, 0.05% Tween 20, and 3% dry milk). PA was detected with anti-PA monoclonal antibody 14B7. Secondary antibody used was goat anti-mouse IgG conjugated to horseradish peroxidase (American Qualex Antibodies, A106PN).

The stability assay utilized SDS buffer (0.1% SDS, 100 mM NaCl, 10 mM EDTA, 200 mM Tris–HCl pH 8.0, 0.05% Tween 20, 14 mM β-mercaptoethanol, 400 mM sucrose, 2 mM PMSF) and CHAPS buffer (4% CHAPS, 100 mM NaCl, 10 mM EDTA, 200 mM Tris–HCl pH 8.0, 14 mM β-mercaptoethanol, 400 mM sucrose, 2 mM PMSF). Two hundred μl of each buffer was added to 100 mg powdered leaf tissue. For supernatant fractions, the extraction was centrifuged at 10,000× g for 5 min and supernatant was removed. For homogenate, the entire extract was used. The samples were stored at 4 °C and −20 °C for 2 days. The rest of the western protocol was the same as described above.

2.6. Estimation of total soluble protein

The total soluble protein of the leaf samples was estimated using the Bio-Rad Bradford Protein Assay. Leaf samples of transformed and untransformed plants (100 mg) were ground in liquid nitrogen. Plant protein extraction buffer (15 mM Na2CO3, 35 mM NaHCO3, 3 mM NaN3, pH 9.6, 0.1% Tween, 5 mM PMSF) was used to resuspend the ground mixture. The mechanical pestle was used to finely grind the leaf powder and resuspend the proteins in the buffer. The bovine serum albumin (BSA) standard curve was obtained by diluting BSA in plant extraction buffer. Each standard and sample (10 μl) was added in duplicate to microtiter plate wells. Diluted Biorad dye reagent (200 μl) was added to each well. The sample and the dye were thoroughly mixed. The plate was incubated at room temperature for 5–10 min and read on a plate reader at 630 nm.

2.7. ELISA

The PA quantification was done using the enzyme linked immunosorbent assay (ELISA). The standards, test samples and antibody were diluted in coating buffer (15 mM Na2CO3, 35 mM NaHCO3, 3 mM NaN3, pH 9.6). The standards ranging from 50 to 1000 ng were made by diluting purified PA in coating buffer. The leaf samples were collected from plants exposed to regular lighting pattern (16 h light and 8 h dark), 3 day continuous light, and 5 day continuous light. The standards and protein samples (100 μl) were coated to 96-well polyvinyl chloride microtiter plate (Cell-star) for 1 h at 37 °C followed by washing with PBST and water. The background was blocked with fat-free milk in PBS and Tween and incubated for 1 h followed by washing. The primary anti-PA antibody (Immuno Chemicals) diluted (1:1000) in PBST containing milk powder was loaded into wells and incubated for 1 h. The wells were then washed and incubated with 100 μl of anti-mouse IgG-HRP conjugated antibody made in goat (American Qualex) (1: 5000) diluted in PBST containing milk powder. The plate was then incubated for 1 h at 37 °C. After the incubation the plate was washed thrice with PBST and with water. The wells were then loaded with 100 μl of 3,3′,5,5′-tetramethyl benzidine (TMB from American Qualex) substrate and incubated for 10–15 min at room temperature. The reaction was terminated by addition of 50 μl of 2N sulfuric acid per well and the plate was read on a plate reader (Dynex Technologies) at 450 nm.

2.8. Macrophage lysis assays

Approximately 100 mg of powdered leaf tissue was extracted with 200 μl of extraction buffer. For the supernatant fraction, the buffer and tissue were centrifuged for 5 min at 10,000 × g and the supernatant was placed in a new tube. For the homogenate, all of the tissue and the buffer was assayed. RAW264.7 macrophage cells were plated in 96-well plates in 120 μl DMEM medium and grown to 50% confluence. The medium was aspirated and replaced with 100 μl medium containing 250 ng/ml LF. The control plate received medium with no LF to test toxicity of plant material and buffers. In separate 96-well plates, the plant samples were diluted serially two-fold and 40 μl of the dilutions were transferred onto the RAW264.7 cells so the top row had plant extract at 1:14 dilution. MTT (3-[4,5-dimethylthiazol-2-yl]-2,5-diphenyltetrazolium bromide) was added after 5–10 h to assess cell death [28].

3. Results and discussion

3.1. Chloroplast vectors

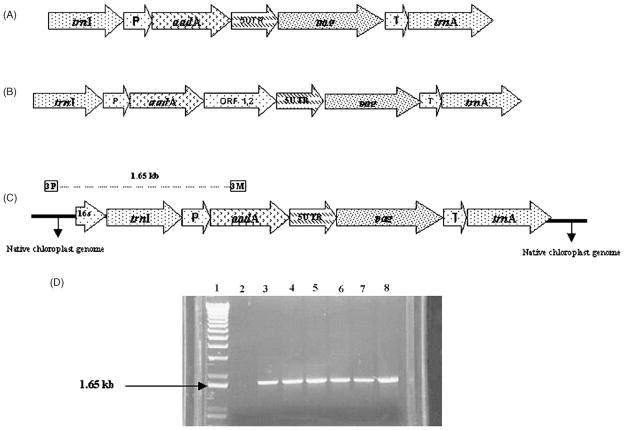

The pLD-JW1 vector (8.3 kb, see Fig. 1A) was constructed to transform tobacco chloroplasts. This construct is based on the vector pLD that was used successfully in previous publications from this laboratory [2,7]. The trnI and trnA chloroplast genes were used as flanking sequences for homologous recombination to insert a pag-containing cassette into the spacer region between the two tRNA genes in the inverted repeat region of the chloroplast genome, as reported previously [10,29]. The pag gene has an ORF of 2315 bp of which 2205 encode for 735 amino acids. The rest of the region encodes the signal peptide, which was not included in the cassette. The constitutive 16 s rRNA promoter, which can be recognized by both the chloroplast encoded RNA polymerase and the nuclear encoded RNA polymerase, was used to drive transcription of the aadA and pag genes. The aadA gene conferring spectinomycin resistance was used for selection of transgenic shoots. The pag gene coding for anthrax protective antigen was regulated by the psbA 5′ and 3′ elements. The 5′-UTR from psbA, including its promoter, was used for transcription enhancement of the pag gene and for translation enhancement as it has several sequences for ribosomal binding sites. It acts as a scaffold for the light regulated proteins involved in ribosomal binding to enhance translation [12] and the 3′-UTR region conferred transcript stability [1].

Fig. 1.

Tobacco constructs and PCR confirmation of chloroplast transgene integration. (A) The pLD-JW1 vector used for chloroplast transformation. The trnI and trnA genes were used as flanking sequences for homologous recombination. The constitutive 16 s rRNA promoter (“P”) was used to regulate transcription. The aadA gene conferring spectinomycin resistance was used for selection of transgenic shoots. The pag gene coding for anthrax protective antigen was regulated by the psbA promoter and 5′-UTR (5UTR) and 3′-UTR (T) elements. (B) The pLD-JW2 construct was made by adding orf1, 2 from B. thuringiensis to the pLD-JW1 vector. (C) Scheme showing PCR with the primers 3P and 3M to investigate chloroplast transgene integration. The 3P primer anneals to the native chloroplast genome and the 3M primer anneals to the aadA gene, generating a 1.65 kb PCR product in chloroplast transgenic lines. (D) Analysis of randomly selected clones. Lane 1: 1 kb plus DNA ladder; lane 2: negative control wild type tobacco plant DNA; lane 3: positive transgenic plant DNA (pLD-5′-UTR/HIS/THR/IFNα2b); lane 4–8: five independent transgenic lines tested.

Since very high expression of the Cry2A2 protein of Bacillus thuringiensis was observed (up to 46% total soluble protein [2]), a second construct was made by adding orf1, 2 from B. thuringiensis to the pLD-JW1 vector, forming the pLD-JW2 vector (see Fig. 1B). The orf1, 2 gene codes for a putative chaperone [30]. Including the orf1, 2 gene was done to test whether the putative chaperone could fold a heterologous Bacillus protein (i.e., PA) into cuboidal crystals or form inclusion bodies, protect PA from proteolytic degradation, and facilitate purification.

3.2. Transgene integration into the chloroplast genome by PCR analysis

Chloroplast transgenic lines were generated by particle bombardment as described previously [26,27]. After bombarding Nicotiana tabacum cv. Petit Havana tobacco leaves with the chloroplast vectors, the leaves were grown on selective medium containing 500 μg/ml spectinomycin. Three different genetic events can produce spectinomycin-resistant tobacco shoots: (1) transgene integration into the chloroplast genome; (2) the nuclear genome; or (3) spontaneous mutants. PCR with two specific primers, 3P and 3M, allowed identification of shoots having the desired chloroplast transgene integration. The 3P primer annealed to the native chloroplast genome and the 3M primer annealed to the aadA gene (see Fig. 1C). Nuclear transformants were eliminated because 3P will not anneal and mutants were ruled out because 3 M will not anneal. At least 50 independent transformation events were observed when ten tobacco leaves were bombarded with two different chloroplast vectors, pLD-JW1 and pLD-JW2, suggesting that there was no inhibitory effect of PA. Among clones tested, in both constructs, all were chloroplast transformants. No spontaneous mutants or nuclear transformants were observed (see Fig. 1D). Because all chloroplast transgenic lines were anticipated to contain similar levels of foreign gene expression [7], only one or two independent lines were characterized further.

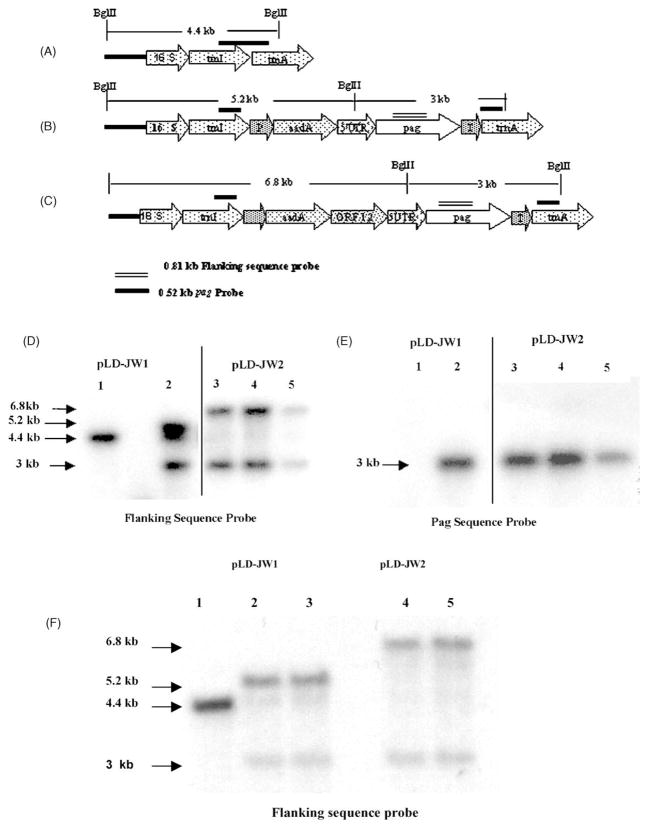

3.3. Chloroplast integration of transgenes and homoplasmy

Southern blots were done to further verify that the trans-genes had been integrated into the chloroplast genome and to determine homoplasmy (containing only transformed chloroplast genomes) or heteroplasmy (containing both transformed and untransformed chloroplast genomes). Total plant DNA was digested with the enzyme BglII which generated a 4.4 kb fragment in wild type, 5.2 and 3 kb fragments in pLD-JW1 transgenic lines, and 6.8 and 3 kb fragments in pLD-JW2 transgenic lines when hybridized with a 0.81 kb probe made from chloroplast flanking sequences (see Fig. 2A–D). The blots were also hybridized with a 0.52 kb probe made from the pag coding sequence (see Fig. 2E). All of the pLD-JW2 plants appeared to be homoplasmic. In the pLD-JW1 plants, the transgenic line appeared to be heteroplasmic, which is not uncommon to find in T0 plants. T0 refers to first generation transgenic lines and T1 refers to second generation lines obtained by germination of seeds from T0. However, germination of seeds from this T0 transgenic line on 500 μg/ml of spectinomycin resulted in T1 plants that were homoplasmic (Fig. 2F).

Fig. 2.

Southern blots to investigate site of transgene integration and determine homoplasmy or heteroplasmy in T0 and T1 generation. Schematic diagram of expected products from digestion of wild type untransformed plant (A); plants transformed with pLD-JW1 (B); or pLD-JW2 (C). (D) Flanking sequence probe showing heteroplasmy in pLD-JW1 line and homoplasmy in pLD-JW2 lines. Lane 1: wild type; lane 2: pLD-JW1; lanes 3–5: pLD-JW2 transgenic lines of T0 generation. (E) pag sequence probe showing presence of pag in transgenic lines of T0 generation. Lane 1: wild type; lane 2: pLD-JW1; lanes 3–5: pLD-JW2 transgenic lines. (F). Flanking sequence probe showing homoplasmy in pLD-JW1 line and pLD-JW2 lines. Lane 1: wild type; lanes 2 and 3: pLD-JW1; lanes 4 and 5: pLD-JW2 transgenic lines of T1 generation.

3.4. PA expression in transgenic chloroplasts

Western blots were performed on transgenic lines containing the two different constructs. Full length 83 kDa polypeptide was detected on blots, confirming PA expression in transgenic lines and absence of unique proteases that cleave PA in plant cells (see Fig. 3A–C). Presence of active furin or trypsin-like proteases would have resulted in a 63 kDa protein due to cleavage at the sequence RKKR (amino acids 164–167). The sequence FFD at residues 312–314 is another site that is highly sensitive to chymotrypsin-like enzymes, and cleavage would have resulted in 47 and 37 kDa fragments. No other cleaved PA products were observed (see full length blots shown), demonstrating stability of chloroplast-derived PA.

Fig. 3.

Western blots demonstrating PA expression of transgenic lines containing the different constructs. (A) Western blot of pLD-JW1 T1 transgenic line. Lane 1: wild type; lane 2: precision plus protein standard; lane 3: 20 ng PA; lane 4: 10 ng PA; lane 5: 5 ng PA; lane 6: 1:10 dilution pLD-JW1 line; lane 7: 1:20 dilution pLD-JW1 line. (B) Western blot of pLD-JW2 T1 transgenic line. Lane 1: wild type; lane 2: precision plus protein standard; lane 3: 20 ng PA; lane 4: 10 ng PA; lane 5: 5 ng PA; lane 6: blank; lane 7: 1:10 dilution pLD-JW2 line 1; lane 8: 1:20 dilution pLD-JW2 line 1; lane 9: 1:10 dilution pLD-JW2 line 2; lane 10: 1:20 dilution pLD-JW2 line 2. (C) Western blot comparing extraction buffers, containing CHAPS and SDS, and both, and measuring stability of extracts at 4 and −20 °C: Sup: supernatant fraction; Hom: homogenate (soluble and insoluble fractions); construct used: pLD-JW2. Lane1: SDS, homogenate −20 °C; lane2: SDS, homogenate, 4 °C; lane3: SDS, supernatant, −20 °C; lane4: SDS, supernatant, 4 °C; lane5: CHAPS, homogenate, −20 °C; lane6: CHAPS, homogenate, 4 °C; lane7: CHAPS, supernatant, −20 °C; lane8: CHAPS, supernatant, 4 °C.

Additional Western blots were done comparing two different detergents in the extraction buffers, CHAPS and SDS, and both were found to extract PA equally well (see Fig. 3C). The supernatant and the homogenate were also found to be comparable in the pLD-JW2 line suggesting that most of the PA is in the soluble fraction and that the chaperone did not fold PA into cuboidal crystals. After storage for 2 days at 4 °C and −20 °C, the PA in plant crude extracts is quite stable (see Fig. 3C). Powdered leaf was stored at −80 °C for several months before performing Western blots or functional assays; this did not result in any noticeable decrease in PA quantity or functionality. This should facilitate long term storage of harvested leaves before extraction of PA for vaccine production. Native PA has been shown to be highly unstable due to proteolysis-sensitive sites, which have been modified to confer better stability [31].

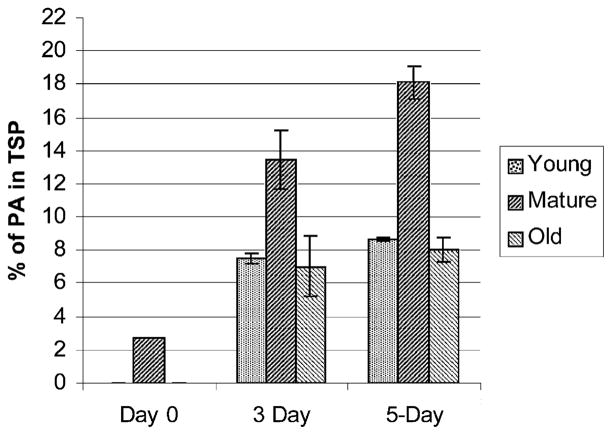

3.5. Quantification of PA in transgenic chloroplasts

Using ELISA, a standard curve was obtained with the purified PA, diluted to different concentrations in coating buffer. To estimate the expression levels of recombinant PA protein, the known concentrations of transgenic plant’s total soluble protein was compared with that of the known concentrations of purified PA antibody complex (standard curve). The PA protein levels of the pLD-JW1and pLD-JW2 homoplasmic transgenic lines of T1 generation under the normal illumination pattern (16 h light and 8 h dark) reached up to 2.7 and 1.7% of total soluble protein, in mature leaves, respectively. The psbA regulatory sequences, including the promoters and UTRs, have been shown to enhance translation and accumulation of foreign proteins under continuous light [12]. Therefore, pLD-JW1 T1 transgenic plants were placed under continuous light exposure (24 h light). Young, mature, and old leaves were collected after 3 and 5 days of continuous illumination. The PA expression patterns of JW1 in terms of percentage of total soluble protein were determined for 3 and 5 days of continuous illumination. The percentage of PA in the total soluble protein of JW1 plants reached a maximum of 18.1 and 13.4% in mature leaves of plants exposed to continuous light for 5 and 3 days, respectively. The maximum PA expression was observed in mature leaves compared to young and old leaves (Fig. 4). The decrease in PA expression in old plants could be due to degradation of the proteins due to senescence. The amount of PA present per plant and the relative yield from young, mature and old leaves were estimated based on the different parameters of the biomass of transgenic plants (Table 1). Under the consistent environmental conditions provided in the plant growth chamber, a total of 172 mg of PA could be obtained from each plant with a maximum of 92.7% contribution from mature leaves, 4.8% from young leaves and 2.3% from old leaves. The large contribution of PA from the mature leaves is due to the high number of chloroplasts in mature leaves and the high copy number of chloroplast genomes (up to 10,000 copies per cell) resulting in very high levels of PA expression in mature leaves (2.56 mg/g fresh weight). The large size of mature leaves and the presence of more mature leaves per plant also add to their contribution.

Fig. 4.

Quantification of PA of JW1 plants of T1 generation using ELISA. Histogram of percentage of PA in total soluble protein in fresh tissue of young, mature, old leaves of plant in 16 h light and 8 h dark (day 0), 3 day continuous illumination and 5 day continuous illumination.

Table 1.

The yield of PA expressed in pLD-JW1 tobacco T1 transgenic line relative to its biomass

| Leaf age | Leaves per plant | Average weight (g)/leaf | PA (mg/g) in fresh leaf | Amount of PA (mg) per leaf | Amount of PA (mg) per age group | Percentage of PA in relation to whole plant |

|---|---|---|---|---|---|---|

| Young | 3.2 | 2.5 | 1.05 | 2.625 | 8.4 | 4.80 |

| Mature | 7.8 | 8 | 2.56 | 20.48 | 159.74 | 92.76 |

| Old | 4.5 | 5 | 0.180 | 0.9 | 4.05 | 2.35 |

| Total amount of recombinant PA per plant | 172.19 | 100 | ||||

Young: small, tender leaves from the top; mature: large, dark leaves from the middle; old: bleached leaves at the bottom.

3.6. PA functionality determined by macrophage lysis

Supernatant and homogenate samples from both T0 constructs, pLD-JW1 and pLD-JW2, were tested. Two different buffers were used to extract proteins—one contained CHAPS detergent and one did not have any detergent. The functionality of the chloroplast-derived PA was determined by its ability to internalize the lethal factor and cause lysis of cultured mouse macrophages. The percentage macrophage viability was determined using the ability of live but not dead cells to reduce a water-soluble yellow dye, MTT (3-[4,5-dimethylthiazol-2-yl]-2,5-diphenyltetrazolium bromide) to an insoluble purple formazan product. The transgenic plants were shown to produce fully functional PA (see Fig. 5A). A comparative assay was done on the supernatant (containing the soluble fraction) and homogenate parts (contains soluble and membrane fractions) of the T0 generation of pLD-JW1, pLD-JW2 and wild type plants. Both the supernatant and homogenate fractions of pLD-JW1 showed similar functional activity, suggesting that most of the PA is present in the soluble fraction. In pLD-JW2, the supernatant showed higher functional activity than the homogenate as evident by the activity at 100-fold greater dilution, where the percentage viability of supernatant sample is much less than the homogenate sample. This could possibly be due to interference of membranes in the lysis assays, which are removed by centrifugation in the supernatant fractions. To check the possible interference of other proteins in the crude plant extract or the components of the extraction buffer, the functional assays were carried out using the supernatant and homogenate of wild type untransformed plants and the extraction buffer; none of these showed any detectable macrophage lysis activity. This clearly shows that there is no toxicity to macrophage cells from the components of plant extracts or the extraction buffer. The activity of purified PA (500 ng/ml) was used as the standard to quantify unknown samples. Having determined that supernatant fractions contain most of the PA, further analysis was done with supernatants on next generation (T1) pLD-JW1 transgenic plants to determine the functionality of the PA in the subsequent generations. To determine the stability of the PA during storage, functional assays were done on the plant supernatant extracts stored at −20 °C for 2 and 7 days. The PA stored for 2 and 7 days showed similar activity, which suggests that there is no degradation of PA upon storage (see Fig. 5B), confirming that chloroplast-derived antigens are quite stable during storage and transportation. The extracts of wild type plants and transgenic plants had no macrophage lysis activity in the absence of LF. Crude plant extracts contained up to 5 μg/ml functional PA, confirming expression of high levels of functional PA in T0 plants (see Fig. 5A). Much higher macrophage lysis activity was observed in supernatant samples from T1 pLD-JW1 transgenic lines, showing they contained approximately 12–25 μg functional PA/ml (see Fig. 5B). The higher activity in T1 compared T0 plants could be due to homoplasmy achieved in T1 generation but not in T0 plants (as shown in Fig. 2F).

Fig. 5.

Macrophage cytotoxic assays for extracts from transgenic plants. (A) Supernatant and homogenate samples from T0 pLD-JW1 tested (proteins extracted in buffer containing no detergent and MTT added after 10 h): (▼) pLD-JW1 supernatant; (▽) pLD-JW1 homogenate; (■) pLD-JW2 supernatant; (□) pLD-JW2 homogenate; (×) PA 500 ng/ml; (⧗) extraction buffer; (●) control wild type supernatant; (○) control wild type homogenate. (B) Supernatant samples from T1 pLD-JW1 tested (proteins extracted in buffer containing no detergent and MTT added after 5 h): (■) pLD-JW1 (extract stored 2 days); (□) pLD-JW1 (extract stored 7 days); (×) PA 5 μg/ml; (●) control wild type (extract stored 2 days); (○) control wild type (extract stored 7 days); (▲) control wild type no LF (extract stored 2 days); (△) control wild type no LF (extract stored 7 days); (⧗) control pLD-JW1 no LF (extract stored 2 days); (⧖) control pLD-JW1 no LF (extract stored 7 days).

3.7. Potential application of chloroplast-expressed PA

The threat of biological warfare and terrorism is real. The most effective way to prevent or deter use of anthrax as a weapon would be to produce an efficacious and inexpensive vaccine. Plants are an economical and convenient way to produce recombinant proteins, without human or animal pathogen contamination. In an area of one acre about 8000 tobacco plants can be cultivated. At an average yield of 172 mg of PA per plant (Table 1), a total of 1.37 kg PA could be obtained per acre per single cutting of Petit Havana. A total of 4.12 kg of PA could be expected from three cuttings each year. If we assume that there is 50% loss of PA during purification from plant extracts (loss of foreign protein is generally between 30 and 90%), and at 5 μg PA per dose (current vaccine is in a range of 1.75–7 μg PA as per [20]), one could produce about 400 million doses of vaccine per acre of tobacco. This calculation assumes a low yield of tobacco from an experimental cultivar. However, commercial cultivars yield up to 40 t of fresh leaves (40,000 kg in three cuttings as per [15]) as opposed to 2.2 t in Petit Havana; therefore, production could be up to 37.45 kg PA per acre based on current expression levels and 50% loss during purification. An increase of 18.17-fold could be observed in a commercial cultivar compared to the experimental cultivar. Thus a few acres of transgenic tobacco could meet the world’s need for anthrax vaccine. Transgenic plants expressing human therapeutic proteins via the chloroplast genome have been grown already in the field, after obtaining appropriate USDA permit by Chlorogen Inc. Taken together, this study opens the door to large-scale production of an improved vaccine.

In addition, this study should pave the way to develop edible anthrax vaccines to control anthrax outbreaks among wildlife and domestic livestock. There have been recent anthrax outbreaks in deer and livestock in September 2001 in Del Rio, TX, in cattle and horses in Minnesota in June–July 2000, in cattle, horses, and bison in North Dakota in August 2000, and in cattle in Nebraska in January 2001. Currently there is no vaccine considered suitable for protecting wild-life (USDA, 2002, fact sheet).

Acknowledgments

Authors gratefully acknowledge Dr. R. Bhatnagar for providing with pMS1 plasmid containing pag gene, Drs. S.B. Lee and A. Dhingra for their technical help during early stages of this investigation. This investigation was supported in part by the USDA 3611-21000-017-00D and NIH R01 GM 63879 award to H.D.

References

- 1.Daniell H, Khan MS, Alison L. Milestones in chloroplast genetic engineering: an environmentally friendly era in biotechnology. Trends Plant Sci. 2002;7:84–91. doi: 10.1016/s1360-1385(01)02193-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.DeCosa B, Moar W, Lee SB, Miller M, Daniell H. Overexpression of the Bt Cry2Aa2 operon in chloroplasts leads to formation of insecticidal crystals. Nat Biotechnol. 2001;19:71–4. doi: 10.1038/83559. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Ruiz ON, Hussein H, Terry N, Daniell H. Phytoremediation of organomercurial compounds via chloroplast genetic engineering. Plant Physiol. 2003;132:1344–52. doi: 10.1104/pp.103.020958. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Daniell H, Dhingra A. Multigene engineering: dawn of an exciting new era in biotechnology. Curr Opin Biotechnol. 2002;13:136–41. doi: 10.1016/s0958-1669(02)00297-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Daniell H. Molecular strategies for gene containment in transgenic crops. Nat Biotechnol. 2002;20:581–6. doi: 10.1038/nbt0602-581. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Lee SB, Kwon HB, Kwon SJ, Park SC, Jeong MJ, Han SE, et al. Accumulation of trehalose within transgenic chloroplasts confers drought tolerance. Mol Breeding. 2003;11:1–13. [Google Scholar]

- 7.Daniell H, Lee SB, Panchal T, Wiebe PO. Expression of cholera toxin B subunit gene and assembly as functional oligomers in transgenic tobacco chloroplasts. J Mol Biol. 2001;311:1001–9. doi: 10.1006/jmbi.2001.4921. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Mason SH, Haq AT, Clements DJ, Arntzen JC. Edible vaccine protects mice against Eischerichia coli heat-labile enterotoxin (LT): potatoes expressing a synthetic LT-B gene. Vaccine. 1998;16:1336–43. doi: 10.1016/s0264-410x(98)80020-0. [DOI] [PubMed] [Google Scholar]

- 9.Molina A, Herva-Stubbs S, Daniell H, Mingo-Castel AM, Veramendi J. High yield expression of a viral peptide animal vaccine in transgenic tobacco chloroplasts. Plant Biotechnol. 2004;2:141–53. doi: 10.1046/j.1467-7652.2004.00057.x. [DOI] [PubMed] [Google Scholar]

- 10.Guda C, Lee SB, Daniell H. Stable expression of biodegradable protein based polymer in tobacco chloroplasts. Plant Cell Rep. 2000;19:257–62. doi: 10.1007/s002990050008. [DOI] [PubMed] [Google Scholar]

- 11.Daniell H, Dhingra A, San-Milan AF. Chloroplast transformation approach for the production of antibodies, biopharmaceuticals and edible vaccines. Proceedings of the 12th International Congress on Photosynthesis; Brisbane, Australia: CSIRO Publishing; 2001. [Google Scholar]

- 12.Fernandez-San Millan A, Mingo-Castel A, Daniell H. A chloroplast transgenic approach to hyper-express and purify human serum albumin, a protein highly susceptible to proteolytic degradation. Plant Biotechnol J. 2003;1:71–9. doi: 10.1046/j.1467-7652.2003.00008.x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.DeGray G, Kanniah R, Franzine S, John S, Daniell H. Expression of an antimicrobial peptide via the chloroplast genome to control phytopathogenic bacteria and fungi. Plant Physiol. 2001;127:852–62. [PMC free article] [PubMed] [Google Scholar]

- 14.Daniell H. In: Medical molecular farming: expression of antibodies, biopharmaceuticals and edible vaccines via chloroplast genome. Vasil IK, editor. The Netherlands: Kluwer Academic Publishers; 2003. pp. 371–6. [Google Scholar]

- 15.Staub JM, Garcia B, Graves J, Hajdukiewicz PT, Hunter P, Nehra N, et al. High-yield production of a human therapeutic protein in tobacco chloroplasts. Nat Biotechnol. 2000;18:333–8. doi: 10.1038/73796. [DOI] [PubMed] [Google Scholar]

- 16.Leelavathi S, Reddy VS. Chloroplast expression of His-tagged GUS-fusion: a general strategy to overproduce and purify foreign proteins using transplastomic plants as bioreactors. Mol Breeding. 2003;11:49–58. [Google Scholar]

- 17.Cramer CL, Boothe JG, Oishi KK. Transgenic plants for therapeutic proteins: linking upstream and down stream strategies. Curr Topics Microbiol Immunol. 1999;240:95–118. doi: 10.1007/978-3-642-60234-4_5. [DOI] [PubMed] [Google Scholar]

- 18.Dixon T, Meselson M, Guillemin J, Hanna P. Anthrax. N Engl J Med. 1999;341:815–26. doi: 10.1056/NEJM199909093411107. [DOI] [PubMed] [Google Scholar]

- 19.Inglesby T, Henderson D, Bartlett J, Ascher MS, Eitzen E, Friedlander AM, et al. Anthrax as a biological weapon. J Am Med Assoc. 1999;281:1735–45. doi: 10.1001/jama.281.18.1735. [DOI] [PubMed] [Google Scholar]

- 20.Kaufmann AF, Meltzer MI, Schmid GP. The economic impact of a bioterrorist attack: are prevention and postattack intervention programs justifiable? Emerg Infect Dis. 1997;3:83–94. doi: 10.3201/eid0302.970201. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Leppla SH, Robbins JB, Schneerson R, Shiloach J. Development of an improved vaccine for anthrax. J Clin Invest. 2002;110:141–4. doi: 10.1172/JCI16204. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Joellenbeck LM, Zwanziger LL, Durch JS, Strom BL, editors. Is it safe? Does it work? Chapter 7. Washington, DC: National Academy Press; 2002. “Anthrax vaccine manufacture” in the anthrax vaccine; pp. 180–97. [PubMed] [Google Scholar]

- 23.Baillie L. The development of new vaccines against Bacillus anthracis. J Appl Microbiol. 2001;91:609–13. doi: 10.1046/j.1365-2672.2001.01498.x. [DOI] [PubMed] [Google Scholar]

- 24.Ivins B, Fellows P, Pitt L, Estep J, Farchaus J, Friedlander A, et al. Experimental anthrax vaccines: efficacy of adjuvants combined with protective antigen against an aerosol Bacillus anthracis spore challenge in guinea pigs. Vaccine. 1995;13:1779–83. doi: 10.1016/0264-410x(95)00139-r. [DOI] [PubMed] [Google Scholar]

- 25.Daniell H, Muthukumar B, Lee SB. Marker free transgenic plants: engineering the chloroplast genome without the use of antibiotic selection. Curr Genet. 2001;39:109–16. doi: 10.1007/s002940100185. [DOI] [PubMed] [Google Scholar]

- 26.Daniell H. Foreign gene expression in chloroplasts of higher plants mediated by tungsten particle bombardment. Methods Enzymol. 1993;217:536–56. doi: 10.1016/0076-6879(93)17088-m. [DOI] [PubMed] [Google Scholar]

- 27.Daniell H. Transformation and foreign gene expression in plants mediated by microprojectile bombardment. Methods Mol Biol. 1997;62:453–88. doi: 10.1385/0-89603-480-1:463. [DOI] [PubMed] [Google Scholar]

- 28.Gu ML, Leppla SH, Klinman DM. Protection against anthrax toxin by vaccination with a DNA plasmid encoding anthrax protective antigen. Vaccine. 1999;17:340–4. doi: 10.1016/s0264-410x(98)00210-2. [DOI] [PubMed] [Google Scholar]

- 29.Daniell H, Datta R, Varma S, Gray S, Lee SB. Containment of herbicide resistance through genetic engineering of the chloroplast genome. Nat Biotechnol. 1998;16:345–8. doi: 10.1038/nbt0498-345. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 30.Ge B, Bideshi D, Moar WJ, Federici BA. Differential effects of helper proteins encoded by the cry2A and cry11A operons on the formation of Cry2A inclusions in Bacillus thuringiensis. FEMS Microbiol Lett. 1998;165:35–41. doi: 10.1111/j.1574-6968.1998.tb13124.x. [DOI] [PubMed] [Google Scholar]

- 31.Ramirez DM, Leppla SH, Schneerson R, Shiloach J. Production, recovery and immunogenicity of the protective antigen from a recombinant strain of Bacillus anthracis. J Ind Microbiol Biotechnol. 2002;28:232–8. doi: 10.1038/sj/jim/7000239. [DOI] [PubMed] [Google Scholar]