Abstract

Objective

To investigate the resistance to sliding (RS) in self-ligating and conventional ligation bracket systems at 5 different second-order bracket angulations by using low-stiffness alignment wires in a 3-bracket experimental model and to verify the performance of the main RS components in both systems when these wires are used.

Methods

Interactive self-ligating brackets with closed and open slides were used for the self-ligating (SL) and conventional ligation (CL) groups, respectively; elastomeric ligatures (1 mm inner diameter) were used in the latter system. The alignment wire used was 0.014 inch heat-activated NiTi (austenitic finish temperature set at 36℃ by the manufacturer). A custom-made testing machine was used to measure frictional resistance. Tests were repeated 5 times at every angulation simulated. All data were analyzed statistically.

Results

The RS increased significantly with increasing angulation in both SL and CL groups (p < 0.0001). However, the RS values were significantly higher at every angulation (p < 0.0001) in the CL group.

Conclusions

Despite the relevance of the binding phenomenon, ligation forces predominantly affect the RS when low-stiffness alignment wires are used.

Keywords: Bracket, Wire

INTRODUCTION

In straight-wire mechanics, the ability of the wire to slide through brackets and tubes is essential for achieving proper dental alignment.1 The resistance to sliding (RS) is the factor opposing to this potential behavior of the wire. Several variables affect the RS at the slot-wire interface, such as: bracket and arch-wire materials,2-6 surface texture,4,7 method and type of ligation,8-10 bracket type,11,12 bracket design,3 wire-slot angulation,13-15 arch-wire size,16 and arch-wire section.17 The overall RS can be expressed as follows:

RS = FR + BI

where FR is classical friction and BI is binding.

FR is proportional to normal force (FN), which acts perpendicularly to the direction of the movement on the contact surface and depends on the coefficient of friction (µ) of a specific material according to the formula: FFR = µFN. The µ is a constant and its value depends on the surface characteristics of the interfacing materials. Binding represents the forces generated when the angulation between the bracket and the wire exceeds the critical contact angle (θc).18 The θc is the first- or second-order angulation at which the archwire (AW) first contacts both opposing edges of the slot. Such angulations are present in different phases of orthodontic treatment, including alignment and leveling, when dental elements are rotated, tipped, or not level.

Burrow19 stated that FR plays an important role in the RS only when the wire is in a passive configuration and that binding dictates the RS once θ > θc. Articolo and Kusy13 investigated the RS as a function of several angulations of 0.021 × 0.02-inch stainless steel (SS), NiTi, and Be-Ti wires to conventional ligation brackets. They noted that increasing the angle between the bracket and the wire increases the influence of binding on the RS. Similarly, Thorstenson and Kusy14,15 compared different self-ligating and conventional ligation brackets by using 0.018 × 0.025-inch SS wires. They demonstrated that once binding occurs, it contributes to the RS until it nullifies any frictional difference in the ligation method. Therefore, there is no difference between self-ligating and conventional ligation brackets in terms of RS, unless the wire is in a passive configuration, which never occurs clinically.19

Pizzoni et al.20 found that self-ligating brackets coupled with an undersized round wire (0.018-inch SS and beta-titanium) caused less friction than conventional ligation brackets. Henao and Kusy21,22 used typodont models to emulate different degrees of malocclusion for studying the frictional values of different wire-bracket combinations. They found that with smaller wires, self-ligating brackets performed better than conventional ligation brackets, but the two bracket types became comparable when larger wires were used. Therefore, the authors22 conclude that the influence of different levels of malocclusion on RS can be minimized by choosing the appropriate wire-bracket combination. In the light of these studies, it would be necessary to evaluate the incidence of binding forces on the RS using typical alignment wires.

The aim of this in vitro study was to investigate the RS in self-ligating and conventional ligation bracket systems at 5 different second-order bracket angulations by using low-stiffness alignment wires in a 3-bracket experimental model and to verify the performance of the main RS components in both systems when these wires are used.

MATERIALS AND METHODS

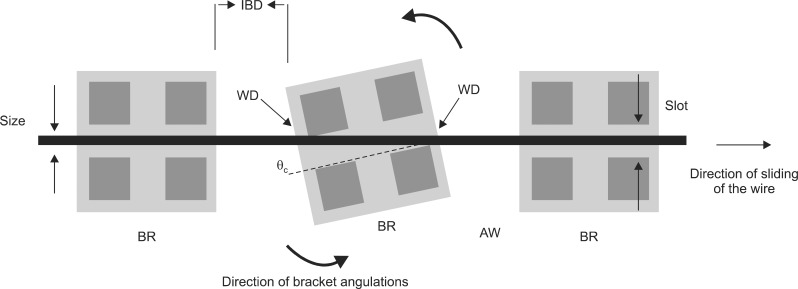

The experimental model of this study is illustrated in Figure 1. One hundred fifty self-ligating brackets (Empower; American Orthodontics, Sheboygan, WI, USA), including 50 lateral incisor, 50 cuspid, and 50 first premolar brackets, were divided into self-ligating (SL) and conventional ligation (CL) groups. They shared the following features: prescription, McLaughlin-Bennet-Trevisi (MBT) system; nominal slot height, 0.022-inch; wire engaging system, active (lateral incisor and canine) and passive (premolar) wires. For the CL group, self-ligating brackets with open slides were surrounded by elastomeric ligatures (1 mm internal diameter; Leone S.p.A., Florence, Italy), which were placed with a needle holder. The ligatures were pre-stretched for 30 seconds, followed by a 2-minute waiting period, to gain a reproducible amount of stress relaxation.

Figure 1.

Experimental model showing brackets (BR), direction of bracket angulations, direction of sliding of the wire, interbracket distance (IBD), 0.014-inch NiTi archwire (AW), wire deflection (WD), and binding angle (θc).

The wires tested in this study were supplied in straight lengths: they were all 0.014-inch heat-activated NiTi wires with nominal austenitic finish temperature stabilization at 36℃.

Experimental apparatus

A SS apparatus (Figure 2) was constructed to hold 3 vertically and horizontally aligned brackets. This support was designed to simulate a dental segment of a lateral incisor, canine and first premolar. The interbracket distance, measured from the center of the brackets, was 14.5 mm, in accordance with Wilkinson et al.23

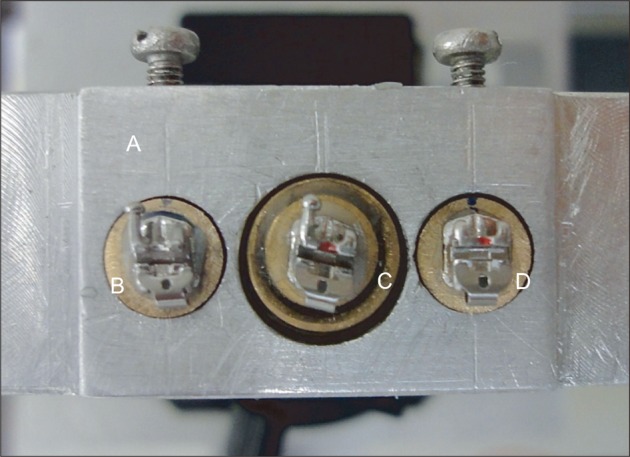

Figure 2.

Frontal view of the experimental model. A, Stainless steel apparatus; B, C, D, first premolar, canine, lateral incisor bracket.

Composite resin (Transbond; 3M Unitek, Monrovia, CA, USA) was used to bond the brackets onto a brass mount in a mounting apparatus (Figure 3) before incorporating them into the 3-bracket apparatus. The bonding procedure described by Matarese et al.24 was used for the outer brass mount-bracket (lateral incisor and first premolar) couples of the mounting apparatus.

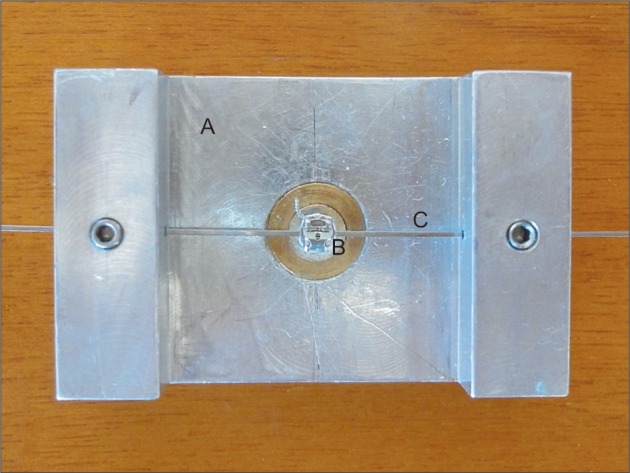

Figure 3.

Frontal view of the mounting apparatus. A, Mounting apparatus; B, single bracket-brass mount couple; C, stainless steel jig (0.016 × 0.022-inch).

The central pit of the 3-bracket apparatus had no bottom on either side, allowing the brass mount, which was soldered to a protractor fixed to a testing machine, to be set on the 3-bracket apparatus. A canine bracket was placed on this brass mount with the top end of the vertical line aligned with the dedicated line engraved on the 3-bracket apparatus to achieve correct mesiodistal positioning. Before bonding the canine bracket, a 0.016 × 0.022-inch SS jig was used so that its largest cross-section (0.022-inch) occupied the entire slot height of the lateral incisor, canine, and first premolar brackets (Figure 4). During the bonding phase, a metal ligature was used to attach the canine bracket to the jig and bring it into contact with the floor of the slot. Through this procedure, the influence of the pre-adjusted bracket prescription on friction was eliminated (all the slots must be parallel); moreover, it also ensured that the bracket position was reproducible in all 3 dimensions.

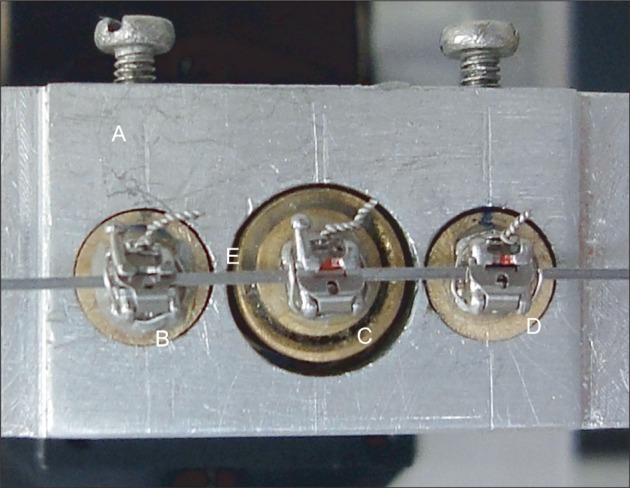

Figure 4.

Stainless steel jig (16 × 22) engaged within all brackets. A, Mounting apparatus; B, C, D, first premolar, canine, lateral incisor bracket; E, 16 × 22 stainless steel jig.

Testing machine

A custom-made testing machine (Figure 5) based on the Instron universal testing machine and built by the Istituto per i Processi Chimico Fisici of the Consiglio Nazionale delle Ricerche (Messina, Italy) was used to measure frictional resistance. It consisted of a static carriage, bearing the 3-bracket apparatus, firmly fixed to a vertical rod through which it acted on a force sensor. The output from the sensor was read by a computer via a special interface and recorded in newtons (N). The alignment wire, which passed through the brackets on the static carriage, was fixed to the end of a moving carriage with 2 stop screws. The moving carriage was driven by a computer-controlled stepper motor at a set speed of 4 mm/minute.

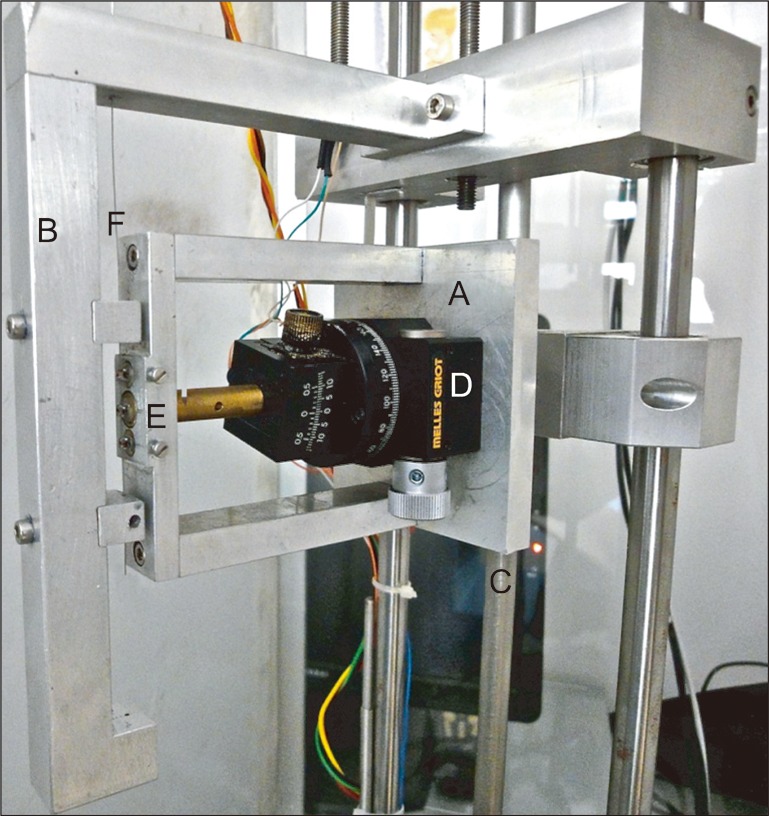

Figure 5.

Lateral view of the testing machine. A, Static carriage; B, moving carriage; C, vertical rod; D, protractor; E, 3-bracket apparatus; F, wire.

A protractor (Figure 5) was mounted on the static carriage, which allowed the central bracket to be rotated along the vertical plane. The protractor was set at the following angulations: 0°, 3°, 7°, 10°, 13°. The testing machine calculated the average sum of the static friction (N) measured at the beginning and the kinetic friction (N) recorded during the test over approximately 100 data points for the first run of the wire through the set of brackets. One test was carried out for each set of brackets and each wire. All tests were repeated 5 times and the wire and brackets were replaced before each test. The testing machine was placed inside a thermostated room, and the tests were carried out at a constant temperature of 35.5℃25 in a dry state (Figure 6).

Figure 6.

Thermostat.

Statistical analysis

Statistical power analysis was performed with the preliminary data obtained from 10 measurements at 7° angulation of the self-ligating and conventional ligation brackets with the following parameters: variance 1, 0.26; variance 2, 3.29; alpha, 0.05; power, 0.8. A sample size of 5 measurements was found to be sufficient to accomplish a power of 0.8.

Data analysis was performed by using statistical software (GraphPad Prism 5 for Windows; GraphPad Software Inc., La Jolla, CA, USA). Before descriptive and inferential statistical analysis, each data set was analyzed by the Shapiro-Wilk normality test (http://dittami.gmxhome.de/shapiro/). Analysis of variance (ANOVA, two-way) and Bonferroni's multiple comparison test were used to compare the RS at each angulation in the SL and CL groups. Student's t-test was also carried out to compare the RS between the two groups at each angulation tested.

RESULTS

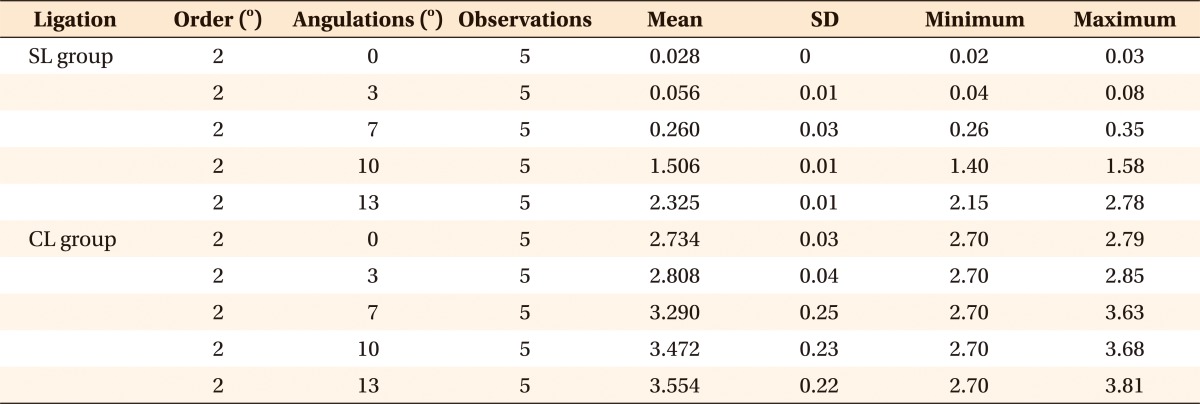

The descriptive statistics of RS at all tested angulations are shown in Table 1. A Student's t-test (Table 2) showed higher RS values in the CL group than in the SL group for every second-order angulation (p < 0.0001). In the SL group (Table 2), RS increased significantly as the angulation increased (p < 0.0001), as revealed by two-way ANOVA. Bonferroni's multiple comparison test showed no significant differences in RS between the 0° and 3° angulations (p > 0.05). However, highly significant differences were found among the 7°, 10°, and 13° angulations (p < 0.0001). A significant difference was also found between the 3° and 7° angulations (p < 0.05).

Table 1.

Descriptive statistics of RS (N) recorded in the self-ligating and conventional ligation groups

RS, Resistance to sliding; N, newton; SL, self-ligation; CL, conventional ligation; SD, standard deviation.

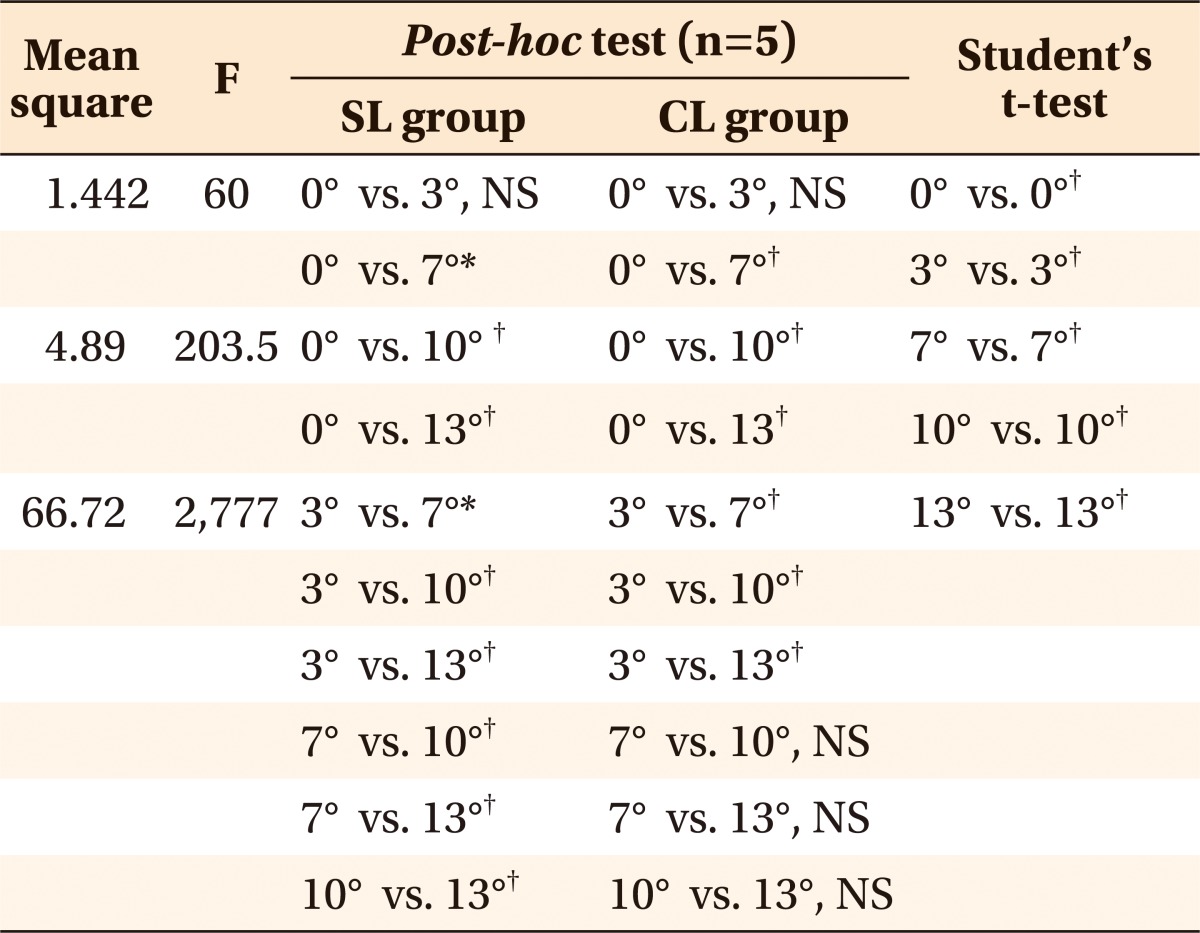

Table 2.

Statistical data obtained by 2-way ANOVA, Bonferroni's post-hoc test, and Student's t-test

ANOVA, Analysis of variance; SL, self-ligation; CL, conventional ligation.

*p < 0.05, †p < 0.0001

In the CL group (Table 2), RS increased significantly as the angulations increased (p < 0.0001) as well. A significant difference (p < 0.0001) in RS was found between the 3° and 7° angulations, but not among the 7°, 10°, and 13° angulations (p > 0.05) or between the 0° and 3° angulations (p > 0.05). In general, the angulation and ligation method affected RS for 21.03% and 71.74% of its total variation, respectively (Table 2).

DISCUSSION

In this study, RS in the CL group was higher than that in the SL group at every tested second-order angulation. This finding is clearly related to the absence of ligation forces in self-ligating brackets. However, in both groups, RS increased with increasing angulation. Considering that the method of ligation is constant in each group in this study, the increase in RS could be totally related to binding forces.

In the SL group, a significant difference in RS was noted between the 3° and 7° angulations, which could be related to the active configuration of the wire. Moreover, the 7° - 10°, 7° - 13°, and 10° - 13° settings showed highly significant differences, indicating that binding increasingly affects RS at greater angulations in this system.

When ligatures were placed (CL group), the only significant difference was observed between the 3° and 7° angulations. This finding could be related to the increase in forces due to the active configuration of the wire. The absence of significant differences among the other tested angulations could be a result of the partial inhibition of binding forces by the ligation forces exerted by the elastomeric ligatures.

In the present study, ligation forces affected the RS even when binding forces increased because of the greater bracket angulations. For example, in the SL group, RS increased to 1.50 and 2.32 N on average at 10° and 13°, respectively (Table 1), but these values were considerably lower than those recorded at the same settings in the CL group (3.47 and 3.55 N, respectively). These results confirm that when low-stiffness wires are used, the sliding mechanics is significantly enhanced.

The reason for contrasting results from previous findings is the difference in the wires tested. In this study, low-stiffness heat-activated NiTi wires were used because they are supposed to be applied during the first stage of treatment when sliding of the wire through the brackets and tubes is desired.

Henao and Kusy22 argued that "frictional values were dictated by a combination of AW size, malocclusion, bracket design, and bending stiffness. The influence exhibited by the height of the AWs underscored the effectiveness of decreasing clearances and AW stiffness," placing more emphasis on binding. Matarese et al.24 argued that for equal deflection, the friction produced by the wire depends on the alloy's stiffness. They demonstrated that, when coupled with SS brackets, the low stiffness of NiTi wires decreases the amount of normal force produced. Liaw et al.26 and Thorstenson and Kusy14 claimed that stiffness affects the rate of binding, which is related to the geometry and elastic modulus of the wire.

In the present study, the same brackets with closed and open slides (with elastomeric ligatures) were used to eliminate the influence of bracket design (e.g., slot height, slot width, and slot depth) in comparing the ligation systems. Every other variable affecting binding should be eliminated before this type of comparison.

To date, there is no scientific evidence demonstrating that self-ligating brackets are more efficient or effective than conventional ligation brackets in treating malocclusions.27 However, this in vitro study model demonstrated that when low-stiffness wires are used, self-ligating brackets show less RS than conventional ligation brackets. Reduction in RS could lead to improved standardization of the forces applied by fixed appliances.

Despite these results, in vitro experimental models cannot exactly emulate in vivo conditions, in which additional environmental variables affect RS (e.g., moisture, force of mastication, host response of the periodontal ligament and alveolar bone28).

Orthodontic movement is a series of short steps rather than a smooth continuous motion,29 causing predominantly static friction as opposed to kinetic friction in opposing tooth movements.30 Although the results of this study are relative to the sum of static and kinetic friction, they can be considered in qualitative comparison between ligation systems. Well-designed randomized controlled clinical trials could provide further clinical evidence regarding the effect of ligation system on RS.

CONCLUSION

The RS increased significantly as the bracket angulations increased in both the self-ligating and conventional ligation bracket systems (p < 0.0001). The RS values recorded in the conventional ligation system were significantly higher than those in the self-ligating system at every tested angulation (p < 0.0001). In the conventional ligation system, no significant differences (p > 0.05) in RS were found in the 7° - 10°, 7° - 13°, and 10° - 13° settings. The reason for this stagnancy could be that the ligation forces inhibited the binding forces.

Footnotes

The authors report no commercial, proprietary, or financial interest in the products or companies described in this article.

References

- 1.Dowling PA, Jones WB, Lagerstrom L, Sandham JA. An investigation into the behavioural characteristics of orthodontic elastomeric modules. Br J Orthod. 1998;25:197–202. doi: 10.1093/ortho/25.3.197. [DOI] [PubMed] [Google Scholar]

- 2.Kapila S, Angolkar PV, Duncanson MG, Jr, Nanda RS. Evaluation of friction between edgewise stainless steel brackets and orthodontic wires of four alloys. Am J Orthod Dentofacial Orthop. 1990;98:117–126. doi: 10.1016/0889-5406(90)70005-W. [DOI] [PubMed] [Google Scholar]

- 3.Voudouris JC, Schismenos C, Lackovic K, Kuftinec MM. Self-ligation esthetic brackets with low frictional resistance. Angle Orthod. 2010;80:188–194. doi: 10.2319/110608-565.1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Doshi UH, Bhad-Patil WA. Static frictional force and surface roughness of various bracket and wire combinations. Am J Orthod Dentofacial Orthop. 2011;139:74–79. doi: 10.1016/j.ajodo.2009.02.031. [DOI] [PubMed] [Google Scholar]

- 5.Thorstenson G, Kusy R. Influence of stainless steel inserts on the resistance to sliding of esthetic brackets with second-order angulation in the dry and wet states. Angle Orthod. 2003;73:167–175. doi: 10.1043/0003-3219(2003)73<167:IOSSIO>2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 6.Nishio C, da Motta AF, Elias CN, Mucha JN. In vitro evaluation of frictional forces between archwires and ceramic brackets. Am J Orthod Dentofacial Orthop. 2004;125:56–64. doi: 10.1016/j.ajodo.2003.01.005. [DOI] [PubMed] [Google Scholar]

- 7.Lucchese A, Carinci F, Brunelli G, Monguzzi R. An in vitro study of resistance to corrosion in brazed and laser-welded orthodontic appliances. Eur J Inflamm. 2011;9:67–72. [Google Scholar]

- 8.Hain M, Dhopatkar A, Rock P. The effect of ligation method on friction in sliding mechanics. Am J Orthod Dentofacial Orthop. 2003;123:416–422. doi: 10.1067/mod.2003.14. [DOI] [PubMed] [Google Scholar]

- 9.Khambay B, Millett D, McHugh S. Archwire seating forces produced by different ligation methods and their effect on frictional resistance. Eur J Orthod. 2005;27:302–308. doi: 10.1093/ejo/cji008. [DOI] [PubMed] [Google Scholar]

- 10.Chimenti C, Franchi L, Di Giuseppe MG, Lucci M. Friction of orthodontic elastomeric ligatures with different dimensions. Angle Orthod. 2005;75:421–425. doi: 10.1043/0003-3219(2005)75[421:FOOELW]2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 11.Stefanos S, Secchi AG, Coby G, Tanna N, Mante FK. Friction between various self-ligating brackets and archwire couples during sliding mechanics. Am J Orthod Dentofacial Orthop. 2010;138:463–467. doi: 10.1016/j.ajodo.2008.11.029. [DOI] [PubMed] [Google Scholar]

- 12.Thomas S, Sherriff M, Birnie D. A comparative in vitro study of the frictional characteristics of two types of self-ligating brackets and two types of pre-adjusted edgewise brackets tied with elastomeric ligatures. Eur J Orthod. 1998;20:589–596. doi: 10.1093/ejo/20.5.589. [DOI] [PubMed] [Google Scholar]

- 13.Articolo LC, Kusy RP. Influence of angulation on the resistance to sliding in fixed appliances. Am J Orthod Dentofacial Orthop. 1999;115:39–51. doi: 10.1016/S0889-5406(99)70314-8. [DOI] [PubMed] [Google Scholar]

- 14.Thorstenson GA, Kusy RP. Effect of archwire size and material on the resistance to sliding of self-ligating brackets with second-order angulation in the dry state. Am J Orthod Dentofacial Orthop. 2002;122:295–305. doi: 10.1067/mod.2002.126156. [DOI] [PubMed] [Google Scholar]

- 15.Thorstenson GA, Kusy RP. Comparison of resistance to sliding between different self-ligating brackets with second-order angulation in the dry and saliva states. Am J Orthod Dentofacial Orthop. 2002;121:472–482. doi: 10.1067/mod.2002.121562. [DOI] [PubMed] [Google Scholar]

- 16.Frank CA, Nikolai RJ. A comparative study of frictional resistances between orthodontic bracket and arch wire. Am J Orthod. 1980;78:593–609. doi: 10.1016/0002-9416(80)90199-2. [DOI] [PubMed] [Google Scholar]

- 17.Drescher D, Bourauel C, Schumacher HA. Frictional forces between bracket and arch wire. Am J Orthod Dentofacial Orthop. 1989;96:397–404. doi: 10.1016/0889-5406(89)90324-7. [DOI] [PubMed] [Google Scholar]

- 18.Kusy RP. Ongoing innovations in biomechanics and materials for the new millennium. Angle Orthod. 2000;70:366–376. doi: 10.1043/0003-3219(2000)070<0366:OIIBAM>2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 19.Burrow SJ. Friction and resistance to sliding in orthodontics: a critical review. Am J Orthod Dentofacial Orthop. 2009;135:442–447. doi: 10.1016/j.ajodo.2008.09.023. [DOI] [PubMed] [Google Scholar]

- 20.Pizzoni L, Ravnholt G, Melsen B. Frictional forces related to self-ligating brackets. Eur J Orthod. 1998;20:283–291. doi: 10.1093/ejo/20.3.283. [DOI] [PubMed] [Google Scholar]

- 21.Henao SP, Kusy RP. Evaluation of the frictional resistance of conventional and self-ligating bracket designs using standardized archwires and dental typodonts. Angle Orthod. 2004;74:202–211. doi: 10.1043/0003-3219(2004)074<0202:EOTFRO>2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 22.Henao SP, Kusy RP. Frictional evaluations of dental typodont models using four self-ligating designs and a conventional design. Angle Orthod. 2005;75:75–85. doi: 10.1043/0003-3219(2005)075<0075:FEODTM>2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 23.Wilkinson PD, Dysart PS, Hood JA, Herbison GP. Load-deflection characteristics of superelastic nickel-titanium orthodontic wires. Am J Orthod Dentofacial Orthop. 2002;121:483–495. doi: 10.1067/mod.2002.121819. [DOI] [PubMed] [Google Scholar]

- 24.Matarese G, Nucera R, Militi A, Mazza M, Portelli M, Festa F, et al. Evaluation of frictional forces during dental alignment: an experimental model with 3 nonleveled brackets. Am J Orthod Dentofacial Orthop. 2008;133:708–715. doi: 10.1016/j.ajodo.2006.06.021. [DOI] [PubMed] [Google Scholar]

- 25.Moore RJ, Watts JT, Hood JA, Burritt DJ. Intra-oral temperature variation over 24 hours. Eur J Orthod. 1999;21:249–261. doi: 10.1093/ejo/21.3.249. [DOI] [PubMed] [Google Scholar]

- 26.Liaw YC, Su YY, Lai YL, Lee SY. Stiffness and frictional resistance of a superelastic nickel-titanium orthodontic wire with low-stress hysteresis. Am J Orthod Dentofacial Orthop. 2007;131:578.e12–578.e18. doi: 10.1016/j.ajodo.2006.08.015. [DOI] [PubMed] [Google Scholar]

- 27.Marshall SD, Currier GF, Hatch NE, Huang GJ, Nah HD, Owens SE, et al. Ask us. Self-ligating bracket claims. Am J Orthod Dentofacial Orthop. 2010;138:128–131. doi: 10.1016/j.ajodo.2010.04.019. [DOI] [PubMed] [Google Scholar]

- 28.Aversa R, Apicella D, Perillo L, Sorrentino R, Zarone F, Ferrari M, et al. Non-linear elastic three-dimensional finite element analysis on the effect of endocrown material rigidity on alveolar bone remodeling process. Dent Mater. 2009;25:678–690. doi: 10.1016/j.dental.2008.10.015. [DOI] [PubMed] [Google Scholar]

- 29.Moore MM, Harrington E, Rock WP. Factors affecting friction in the pre-adjusted appliance. Eur J Orthod. 2004;26:579–583. doi: 10.1093/ejo/26.6.579. [DOI] [PubMed] [Google Scholar]

- 30.Kim TK, Kim KD, Baek SH. Comparison of frictional forces during the initial leveling stage in various combinations of self-ligating brackets and archwires with a custom-designed typodont system. Am J Orthod Dentofacial Orthop. 2008;133:187.e15–187.e24. doi: 10.1016/j.ajodo.2007.08.013. [DOI] [PubMed] [Google Scholar]