Abstract

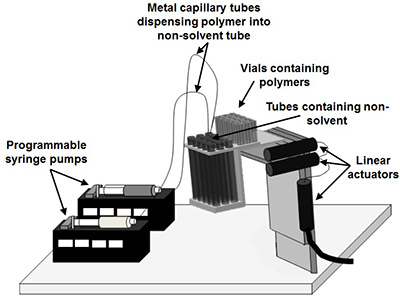

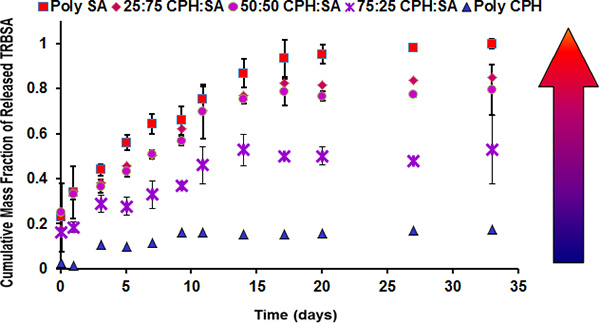

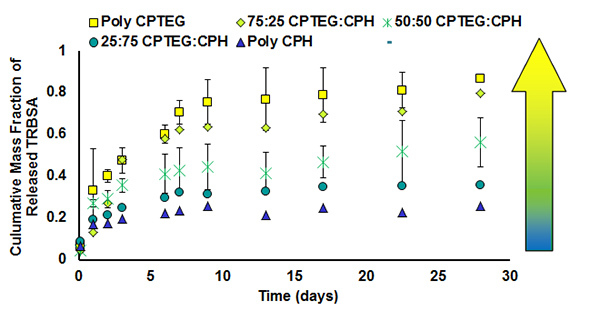

Polyanhydrides are a class of biomaterials with excellent biocompatibility and drug delivery capabilities. While they have been studied extensively with conventional one-sample-at-a-time synthesis techniques, a more recent high-throughput approach has been developed enabling the synthesis and testing of large libraries of polyanhydrides1. This will facilitate more efficient optimization and design process of these biomaterials for drug and vaccine delivery applications. The method in this work describes the combinatorial synthesis of biodegradable polyanhydride film and nanoparticle libraries and the high-throughput detection of protein release from these libraries. In this robotically operated method (Figure 1), linear actuators and syringe pumps are controlled by LabVIEW, which enables a hands-free automated protocol, eliminating user error. Furthermore, this method enables the rapid fabrication of micro-scale polymer libraries, reducing the batch size while resulting in the creation of multivariant polymer systems. This combinatorial approach to polymer synthesis facilitates the synthesis of up to 15 different polymers in an equivalent amount of time it would take to synthesize one polymer conventionally. In addition, the combinatorial polymer library can be fabricated into blank or protein-loaded geometries including films or nanoparticles upon dissolution of the polymer library in a solvent and precipitation into a non-solvent (for nanoparticles) or by vacuum drying (for films). Upon loading a fluorochrome-conjugated protein into the polymer libraries, protein release kinetics can be assessed at high-throughput using a fluorescence-based detection method (Figures 2 and 3) as described previously1. This combinatorial platform has been validated with conventional methods2 and the polyanhydride film and nanoparticle libraries have been characterized with 1H NMR and FTIR. The libraries have been screened for protein release kinetics, stability and antigenicity; in vitro cellular toxicity, cytokine production, surface marker expression, adhesion, proliferation and differentiation; and in vivo biodistribution and mucoadhesion1-11. The combinatorial method developed herein enables high-throughput polymer synthesis and fabrication of protein-loaded nanoparticle and film libraries, which can, in turn, be screened in vitro and in vivo for optimization of biomaterial performance.

Keywords: Bioengineering, Issue 67, combinatorial, high-throughput, polymer synthesis, polyanhydrides, nanoparticle fabrication, release kinetics, protein delivery

Protocol

1. Combinatorial Polymer Library Synthesis (Varying in Polymer Chemistry) - see Figure 1 for Robotic Setup

Dissolve each monomer in the appropriate solvent (concentration = 25 mg/ml) and load each into a 10cc gas tight syringe.

Attach the solvent resistant lure lock capillary tubes to the end of each syringe.

Place the syringes on the syringe pumps (New Era Programmable Syringe Pumps) and lock into position.

Set the linear actuators (Zaber) to the starting position.

Using ring stand clamps, position the end of both capillary tubes into the starting vial/well for monomer deposition.

Initiate the LabVIEW program, which pumps variable volumes of each monomer into each well depending upon the desired copolymer composition. This is achieved in the program by instructing the Z-axis actuator to lower the capillary tubes into the vial/well and then each pump to dispense the desired volume. Next, the program instructs the Z-actuator to return to its home position and the X- and Y- actuators to move to the position of the next vial/well. This is carried out until each well has the desired volume of monomer deposited into it.

Following monomer deposition, the multi-well or multi-vial monomer library is transferred to a pre-heated vacuum oven and incubated under vacuum for the duration of the condensation polymerization reaction. For CPH:SA synthesis the reaction is carried out at 180 °C, 0.3 torr, for 1.5 hr but these reaction conditions will vary between different polymer systems.

2. Combinatorial Blank and Protein-loaded Polymer Nanoparticle and Film Library Fabrication - see Figure 1 for Robotic Setup

The syringe in the first programmable syringe pump is filled with a solvent (blank library) or a solvent with protein dispersed in it (protein-loaded library) while the syringe in the second syringe pump is left empty. Tubes for nanoparticle fabrication in the adjacent sample holder are filled with the non-solvent (ratio of solvent to non-solvent is 1 to 100). For film fabrication an empty multi-well plate is utilized in place of the tubes in the adjacent sample holder.

Using the LabVIEW program, the solvent is deposited into all polymer vials/wells of the library (concentration = 20 mg/ml) and incubated for 1-5 min. An optional sonication step (30 s at 40 Hz) can be introduced to ensure complete polymer dissolution.

Next, by initiating a separate LabVIEW program, the sample is withdrawn into the empty syringe, and deposited into its corresponding tube of non-solvent (nanoparticles) or empty well (films) in the adjacent sample holder.

This process is carried out for each composition of the discrete polymer library.

The nanoparticle or film library is then placed in a vacuum chamber for solvent and non-solvent removal (the nanoparticle library can also be recovered using vacuum filtration).

3. High-throughput Protein Release Kinetics

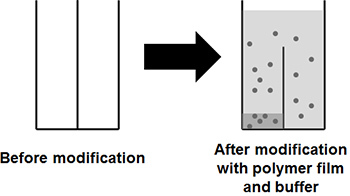

For investigating high-throughput protein release kinetics from a polymer library, a 96 deep-welled (2 ml/well), polypropylene plate is modified such that the top 1/3 of the well wall in neighboring columns (ex: A and B, C and D, E and F, G and H) is removed to adjoin the wells. The protein-loaded films must be fabricated in or the nanoparticles transferred into this plate to perform high-throughput release kinetics studies. Protein-loaded nanoparticle or film samples must only be placed in one well of the adjoining columns (ex: A, C, E, and G). See Figure 4 for details.

Following the transfer of the nanoparticles to the 96 deep-welled release plate, the particles are allowed to settle. PBS buffer (0.1 mM, pH 7.4) is slowly added to each sample well (columns A, C, E and G) and then to each neighboring well (columns B, D, F, and H) until the wells are full and the buffer is free flowing between adjoining wells. For nanoparticles, this process needs to be carried out with extra caution to ensure the particles remain at the bottom of the sample well (columns A, C, E and G) and not transferred into the adjoining release well (columns B, D, F, and H). In some cases, centrifugation is required to localize the nanoparticle samples at the bottom of the sample well (columns A, C, E and G).

Next, the release plate is sealed with a lid and placed at the desired temperature (i.e. 37 °C) under agitation for the duration of the experiment.

At incremental time points (i.e. 0.04, 1, 2, 3, 5, 7, 9, 12, 15, 19, 24, and 30 days) the amount of released fluorochrome-conjugated protein is quantified using a 9,400 Typhoon Flatbed Fluorescent Scanner (GE Healthcare). The release plate is placed on the scanner surface, scanned using the appropriate excitation laser and emission filters, and the fluorescence intensity of the released protein in the release wells (columns B, D, F and H) is quantified (Image Quant). It is suggested that protein standards of known concentrations be included in the well plate for calculating protein quantity and accounting for fluorochrome quenching.

4. Representative Results

Upon fabrication of the polymer library, characterization has been carried out with 1H NMR, GPC, and FTIR to validate this combinatorial method1,7,8,11. Molecular weights range from 10,000-20,000 g/mol, polydispersity index ranges from 1.5-3.0, and chemical composition has been shown to be accurate and in agreement with conventional methods of polyanhydride synthesis12-15. Similarly, SEM images of the nanoparticles libraries showed similar surface morphology, size, and size distribution as that of conventionally fabricated nanoparticles2. Protein release kinetics from polyanhydride nanoparticles or films is carried out in a modified well plate as described previously1. The results revealed an approximate zero order release with or without a burst dependent upon protein loading and polymer chemistry (Figures 2 and 3) 1,12,14,16.

Figure 1. Combinatorial polymer film and nanoparticle fabrication apparatus.

Figure 1. Combinatorial polymer film and nanoparticle fabrication apparatus.

Figure 2. High-throughput release of Texas Red bovine serum albumin (TRBSA) from a CPH:SA polymer nanoparticle library. SA-rich polymer chemistries release encapsulated TRBSA the most rapidly, whereas CPH-rich polymer chemistries release the slowest. Error bars represent standard deviation and n=4. Reprinted with permission from Petersen et. al.1. Copyright 2010 American Chemical Society.

Figure 2. High-throughput release of Texas Red bovine serum albumin (TRBSA) from a CPH:SA polymer nanoparticle library. SA-rich polymer chemistries release encapsulated TRBSA the most rapidly, whereas CPH-rich polymer chemistries release the slowest. Error bars represent standard deviation and n=4. Reprinted with permission from Petersen et. al.1. Copyright 2010 American Chemical Society.

Figure 3. High-throughput release of Texas Red bovine serum albumin (TRBSA) from a CPTEG:CPH polymer film library. CPTEG-rich polymer chemistries release encapsulated TRBSA the most rapidly, whereas CPH-rich polymer chemistries release the slowest. Error bars represent standard deviation and n=3.

Figure 3. High-throughput release of Texas Red bovine serum albumin (TRBSA) from a CPTEG:CPH polymer film library. CPTEG-rich polymer chemistries release encapsulated TRBSA the most rapidly, whereas CPH-rich polymer chemistries release the slowest. Error bars represent standard deviation and n=3.

Figure 4. Image showing two neighboring wells "before" and "after" modification in the 96 deep-welled polypropylene plate. The "after" modification image on the right also depicts the addition of a polymer film (bottom of left well) with an encapsulated fluorescent molecule being released between the two wells into a buffer solution. The released fluorescent molecule is then detected in the right well.

Figure 4. Image showing two neighboring wells "before" and "after" modification in the 96 deep-welled polypropylene plate. The "after" modification image on the right also depicts the addition of a polymer film (bottom of left well) with an encapsulated fluorescent molecule being released between the two wells into a buffer solution. The released fluorescent molecule is then detected in the right well.

Discussion

Knowledge of the necessary synthesis conditions and the glass transition temperatures (Tgs) of the polymers being synthesized are essential for library fabrication. If the Tgs are below room temperature, the nanoparticle fabrication step may need to be carried out in a controlled temperature environment below the Tg of the polymers. Additionally, caution should be taken to ensure that all equipment that comes in contact with high temperatures and the solvents must be fit to handle those conditions. Several of the parameters of this protocol can be adjusted (i.e., temperature, vacuum, incubation times, solvents, non-solvents, polymer concentration, solvent to non-solvent ratios, etc.) to accommodate different polymer systems for synthesis or particle/film fabrication. In some cases, nanoparticles are not stable in solvents for long time periods (sufficient for solvent removal by vacuum drying) so two alternate solvent removal methods can be used. 1) The particles can be slowly centrifuged, the supernatant solvent decanted, and the remaining particles dried or 2) the particles can be separated by vacuum filtration and then dried. Following fabrication of blank or protein-loaded nanoparticles/films, high-throughput characterization or testing can be conducted to screen the biomaterials for protein, cellular, or host interactions. This high-throughput methodology enables the rapid optimization of biomaterial performance for the desired application.

Disclosures

No conflicts of interest declared.

Acknowledgments

The authors acknowledge the ONR-MURI Award (NN00014-06-1-1176) and the U.S. Army Medical Research and Materiel Command (Grant No. W81XWH-10-1-0806) for financial support. This material is based upon work supported by the National Science Foundation under Grant No. EEC 0552584 and 0851519.

References

- Petersen LK, Sackett CK, Narasimhan B. A novel, high-throughput method to study in vitro protein release from polymer nanospheres. J. Comb. Chem. 2010;12:51–56. doi: 10.1021/cc900116c. [DOI] [PubMed] [Google Scholar]

- Petersen LK. Activation of innate immune responses in a pathogen-mimicking manner by amphiphilic polyanhydride nanoparticle adjuvants. Biomaterials. 2011;32:6815–6822. doi: 10.1016/j.biomaterials.2011.05.063. [DOI] [PubMed] [Google Scholar]

- Vogel BM, Cabral JT, Eidelman N, Narasimhan B, Mallapragada SK. Parallel synthesis and high-throughput dissolution testing of biodegradable polyanhydride copolymers. J. Comb. Chem. 2005;7:921–928. doi: 10.1021/cc050077p. [DOI] [PubMed] [Google Scholar]

- Petersen LK. High-throughput evaluation of in vivo biodistribution of polyanhydride nanoparticles. Adv. Healthcare Mater. 2012. Forthcoming.

- Petersen LK, Narasimhan B. Combinatorial design of biomaterials for drug delivery: opportunities and challenges. Expert Opin. Drug Deliv. 2008;5:837–846. doi: 10.1517/17425247.5.8.837. [DOI] [PubMed] [Google Scholar]

- Petersen LK, Oh J, Sakaguchi DS, Mallapragada SK, Narasimhan B. Amphiphilic polyanhydride films promote neural stem cell adhesion and differentiation. Tissue Eng. 2011;17:2533–2541. doi: 10.1089/ten.TEA.2011.0095. [DOI] [PubMed] [Google Scholar]

- Petersen LK, Sackett CK, Narasimhan B. High-throughput analysis of protein stability in polyanhydride nanoparticles. Acta Biomater. 2010;6:3873–3881. doi: 10.1016/j.actbio.2010.04.004. [DOI] [PubMed] [Google Scholar]

- Petersen LK, Xue L, Wannemuehler MJ, Rajan K, Narasimhan B. The simultaneous effect of polymer chemistry and device geometry on the in vitro activation of murine dendritic cells. Biomaterials. 2009;30:5131–5142. doi: 10.1016/j.biomaterials.2009.05.069. [DOI] [PubMed] [Google Scholar]

- Thorstenson JB, Petersen LK, Narasimhan B. Combinatorial/high-throughput methods for the determination of polyanhydride phase behavior. J. Comb. Chem. 2009;11:820–828. doi: 10.1021/cc900039k. [DOI] [PubMed] [Google Scholar]

- Xue L, Petersen L, Broderick S, Narasimhan B, Rajan K. Identifying factors controlling protein release from combinatorial biomaterial libraries via hybrid data mining methods. ACS Comb. Sci. 2011;13:50–58. doi: 10.1021/co100019d. [DOI] [PubMed] [Google Scholar]

- Adler AF. High-throughput cell-based screening of biodegradable polyanhydride libraries. Comb. Chem. High Through. Screen. 2009;12:634–645. doi: 10.2174/138620709788923764. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Determan AS, Trewyn BG, Lin VS, Nilsen-Hamilton M, Narasimhan B. Encapsulation, stabilization, and release of BSA-FITC from polyanhydride microspheres. J. Control. Release. 2004;100:97–109. doi: 10.1016/j.jconrel.2004.08.006. [DOI] [PubMed] [Google Scholar]

- Determan AS, Wilson JH, Kipper MJ, Wannemuehler MJ, Narasimhan B. Protein stability in the presence of polymer degradation products: consequences for controlled release formulations. Biomaterials. 2006;27:3312–3320. doi: 10.1016/j.biomaterials.2006.01.054. [DOI] [PubMed] [Google Scholar]

- Torres MP, Determan AS, Anderson GL, Mallapragada SK, Narasimhan B. Amphiphilic polyanhydrides for protein stabilization and release. Biomaterials. 2007;28:108–116. doi: 10.1016/j.biomaterials.2006.08.047. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Torres MP, Vogel BM, Narasimhan B, Mallapragada SK. Synthesis and characterization of novel polyanhydrides with tailored erosion mechanisms. J. Biomed. Mater. Res. A. 2006;76:102–110. doi: 10.1002/jbm.a.30510. [DOI] [PubMed] [Google Scholar]

- Carrillo-Conde B. Encapsulation into amphiphilic polyanhydride microparticles stabilizes Yersinia pestis antigens. Acta Biomater. 2010;6:3110–3119. doi: 10.1016/j.actbio.2010.01.040. [DOI] [PubMed] [Google Scholar]