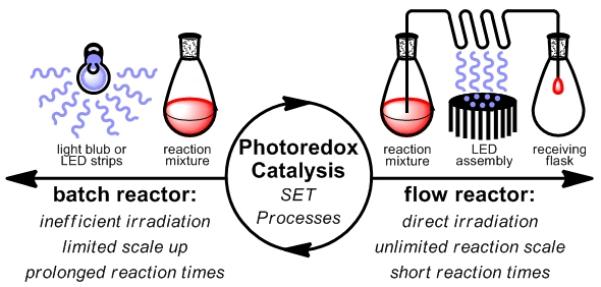

Photoredox catalysts have recently been utilized as powerful tools for synthetic chemists to exploit the energy gained by the absorption of low-energy light within the visible spectrum to initiate a variety of organic transformations.[1] The development of methods based on the single electron transfer properties of photoredox catalysts, particularly in the last several years, has represented a paradigm shift with respect to the way synthetic chemists consider both photochemistry and redox manipulations of organic molecules.[2-4]In addition, the advent of new technologies has enabled chemists to conduct reactions with greater efficiency than ever before. Among these new technologies is the development and wide implementation of flow reactors.[5-6] Conducting transformations in flow has many advantages compared to the more traditional batch reactions, in particular: more predictable reaction scale-up, decreased safety hazards, and improved reproducibility. In addition, for photochemical transformations, the high surface area to volume ratios typical of flow reactors allow for more efficient irradiation of a reaction mixture.[7] Due to this feature, we reasoned that a mesofluidic photochemical flow reactor would be amenable to our group’s ongoing study of visible light induced organic transformations mediated by photoredox catalysts (Figure 1).[8]

Figure 1.

Photoredox Catalysis in Flow: Enabling Increased Efficiency by Reactor Technology.

Our group has studied the utilization of both the oxidative and reductive quenching cycles of photoredox catalysts to initiate synthetically useful manipulations of organic molecules such as intra- and intermolecular radical reactions,[8] formal C-H oxidations,[9] and the halogenation of alcohols.[10] During these studies, it was commonly observed that large scale reactions were often slower than those conducted on smaller scale.[11] As a consequence of the Beer-Lambert law, the penetration of visible light through a reaction medium decreases exponentially with increasing path length. We hypothesized that this may be one reason for the observed loss of reaction efficiency. To potentially circumvent this problem we sought to design a reactor having a considerably smaller path length through which the light must travel. In addition, a reactor having a greater surface area to volume ratio would result is an increased photon flux density, potentially accelerating the reaction.[12] Commercially available PFA (perfluoro alkoxy alkane) tubing having an internal diameter of 0.762 mm was identified as a viable choice due to its chemical resistance and optical transparency. Furthermore, a photoreactor of this size will allow for optimal absorbance at typical catalyst concentrations (~1.0 mM) For instance, the molar extinction coefficient of Ru(bpy)3Cl2 has been measured to be 13000 M−1cm−1,[13] as such the thickest portion of the tubing allows for the absorption of 90% of the incident radiation. Likewise, when carried out in batch reactors, 99% of the incident radiation is absorbed by the reaction medium residing within 1.5 mm of the reactor surface while the remaining internal volume receives little productive radiation.[14]

In designing our reactor, we sought to make it as simple as possible without using specialized equipment in the hopes that a similar design could be readily implemented in other laboratories. Our optimized reactor involved wrapping 105 cm (corresponding to a 479 μL reactor volume) of PFA tubing in figure-eights around a pair of glass test tubes. We then utilized a peristaltic pump to pump the reaction mixture through the tubing with irradiation from a commercially available assembly of 7 blue LEDs.[15] Finally a silver mirrored Erlenmeyer flask was positioned above the reactor to reflect any incident light back onto the tubing. [16]

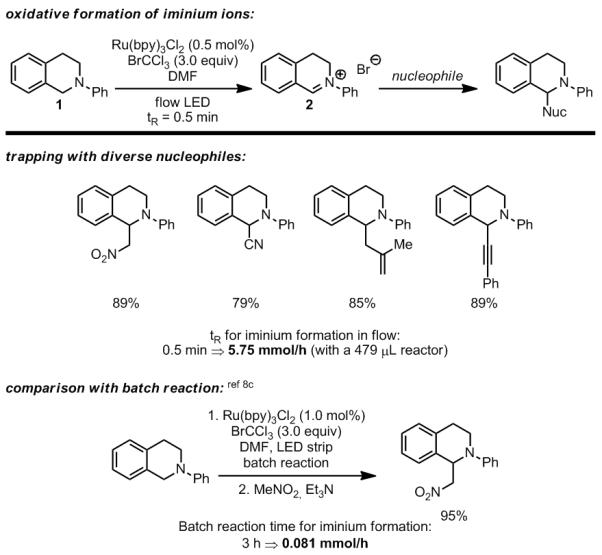

Our initial experiments focused on the oxidative generation of iminium ions from N-aryl tetrahydroisoquinolines, utilizing reaction conditions similar to those we recently reported.[8c] Employing BrCCl3 as the terminal oxidant, we observed rapid formation of the iminium ion, 2, from the corresponding tetrahydroisoquinoline, 1. Optimization studies revealed that subjecting a solution of 1, BrCCl3, and Ru(bpy)3Cl2 (0.05 mol%) in DMF to irradiation in our newly designed flow photoreactor, required only a very short residence time (tR) for complete consumption of 1. In particular, pumping this mixture through the photoreactor at a rate corresponding to a tR of 0.5 min and collecting the mixture in a flask containing 5.0 equiv of a diverse set of nucleophiles allowed for the efficient and rapid generation of a variety of α-functionalized amines, in yields comparable to those observed in the batch reactions (Figure 2). As expected with the flow reactor, reaction scale up was trivial and allowed for the oxidative aza-Henry reaction of 1 with MeNO2 to be conducted on a 1.0 g scale with none of the issues observed for scaling up batch reactions. Furthermore, when conducted in batch, a reaction time of 3 h was required for complete oxidation of 1 on a 0.24 mmol scale. This corresponds to a material throughput of 0.081 mmol/h. However, utilizing the flow apparatus (with a reactor volume of 479 μL) enables a much higher rate of substrate conversion, 5.75 mmol/h. In addition, this rate can be increased by utilizing a photoreactor having a greater internal volume which would require only the use of a longer section of tubing.

Figure 2.

Oxidation of tetrahydroisoquinolines in flow.

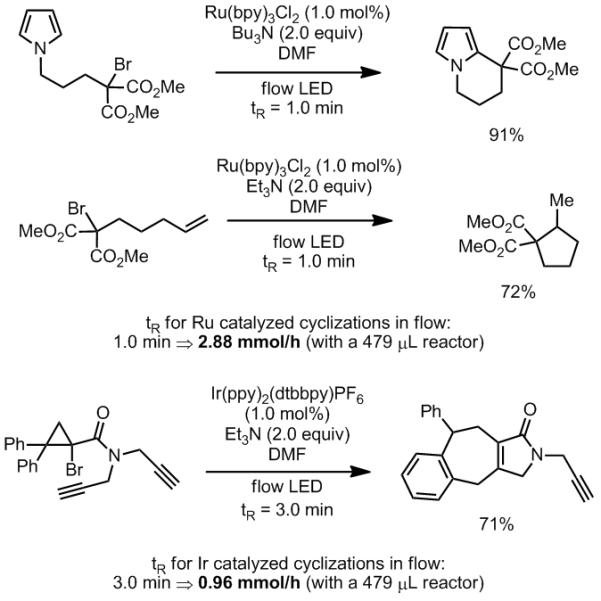

Having validated our hypothesis of increased reaction efficiency of photoredox mediated transformations performed in a photochemical flow setup, we examined a number of other reactions developed by our group. Firstly, a number of intramolecular radical cyclization reactions were evaluated, including: intramolecular heterocycle functionalization,[8b] hexenyl radical cyclization[8c] and a tandem radical cyclization/Cope rearrangement sequence (Figure 3).[8g] We were delighted to find that both radical cyclizations onto heteroaromatics and terminal olefins catalyzed by Ru(bpy)3Cl2 proceeded efficiently with short residence times, 1.0 min, affording the products in yields comparable to those observed in batch reactions. Notably, the intermolecular pyrrole functionalization, when preformed on large scale in batch (>2.0 g, 6.2 mmol), failed to afford complete conversion of starting material even after prolonged reaction time (>2 days). However, the use of the flow reactor could allow for the transformation of large quantities of substrate without the need to perform multiple smaller scale reactions to achieve the desired conversion.

Figure 3.

Intramolecular radical reactions in flow.

Likewise, the Ir(ppy)2(dtbbpy)PF6 catalyzed radical cyclization/rearrangement afforded the product in good yield, but required a slightly longer residence time, tR = 3.0 min. Again, performing these reactions in flow afforded a much higher rate of material throughput when compared to the transformation conducted in batch. Notably, for the cyclization/rearrangement cascade catalyzed by Ir(ppy)2(dtbbpy)PF6, the batch reaction only afforded a substrate conversion rate of 0.048 mmol/h (cf. tR = 4.0 min corresponds to a material throughput of 0.96 mmol/h with our photoreactor).

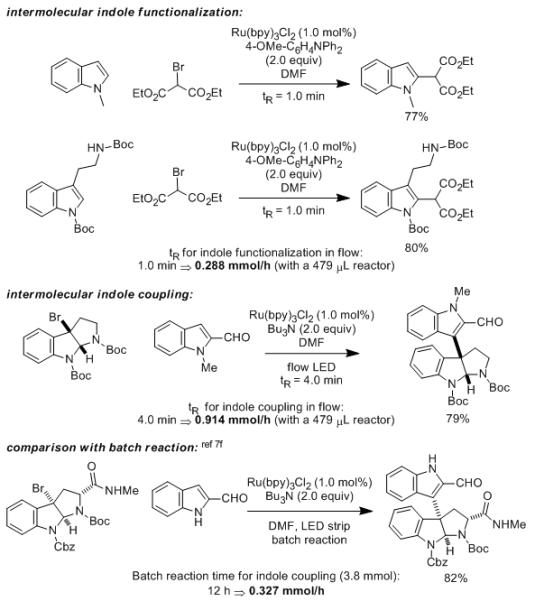

Intermolecular radical reactions are also feasible in this flow setup (Figure 4). It was found that intermolecular malonation of indoles, utilizing the triarylamine reductive quencher, 4-MeO-C6H4-NPh2, proceeded smoothly with a tR = 1.0 min.[8d] Furthermore, the bromopyrroloindoline coupling with 1-methyl-indole-2- carboxaldehyde, similar to the key transformation utilized in the recent synthesis of gliocladin C from our group, proceeded efficiently with a residence time of 4.0 min.[8f] This result is particularly promising since scale up of this reaction required prolonged reaction times, up to several days for a 10 g scale reaction.[17]

Figure 4.

Intermolecular radical reactions in flow.

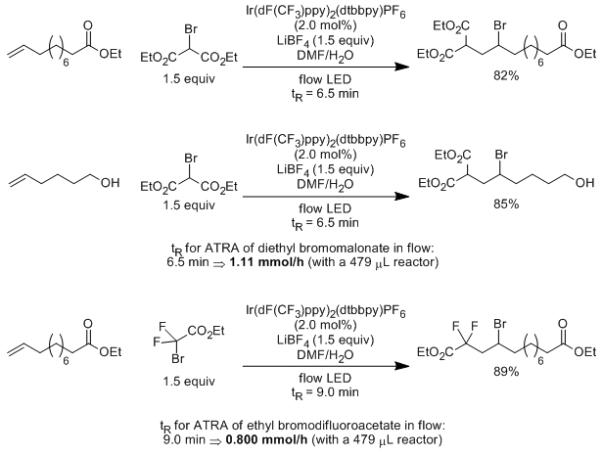

Finally, we applied this new reaction technology to our reported protocol for the intermolecular atom transfer radical addition (ATRA) utilizing the oxidative quenching pathway of the photocatalyst, Ir(dF(CF3)ppy)2(dtbbpy)PF6 (Figure 5).[8e] While requiring slightly longer residence times than those observed for the transformations utilizing the reductive quenching cycle of Ru and Ir based catalysts, this transformation proceeded efficiently and cleanly to give the corresponding ATRA products in good yields. Again, a greater rate of material throughput was observed using the flow reactor. On average, the ATRA of diethyl bromomalonate in batch allowed for the conversion of 0.200 mmol of alkene per hour.

Figure 5.

Intermolecular ATRA reactions in flow.

In summary, we have designed a readily prepared and easily implemented photochemical flow reactor which enables the marked acceleration of a variety of transformations mediated by photoredox catalysis. The entire set up has a sufficiently small footprint to easily fit in a standard fume hood and can be assembled quickly and inexpensively. In all cases the reactor employed in this work has shown an increased efficiency in terms of material throughput for all the transformations studied. It is worth noting that even higher rates of substrate conversion (in terms of mmol of material per hour) is possible simply by employing a photoreactor with a greater internal volume. Further studies into applying this technology to a greater range of photoredox methods is underway.

Supplementary Material

Footnotes

[]Financial support for this research from the NSF (CHE-1056568), NIH-NIGMS (R01-GM096129), the Alfred P. Sloan Foundation, Amgen, and Boehringer Ingelheim is gratefully acknowledged. J.W.T. thanks The American Chemical Society, Division of Organic Chemistry and Amgen for a graduate fellowship. NMR (CHE-0619339) and MS (CHE-0443618) facilities at BU are supported by the NSF.

Supporting information for this article is available on the WWW under http://www.angewandte.org or from the author.

Contributor Information

Joseph W. Tucker, Department of Chemistry, Boston University Boston, MA 02215 (USA)

Yuan Zhang, Department of Chemistry Massachusetts Institute of Technology Cambridge, MA 02139 (USA).

Prof. Dr. Timothy F. Jamison, Department of Chemistry Massachusetts Institute of Technology Cambridge, MA 02139 (USA) tfj@mit.edu

Prof. Dr. Corey R. J. Stephenson, Department of Chemistry, Boston University Boston, MA 02215 (USA).

References

- [1] a).For recent reviews of photoredox catalysis in synthetic applications, see: Zeitler K. Angew. Chem. 2009;121:9969. Angew. Chem., Int. Ed. 2009;48:9785. Yoon TP, Ischay MA, Du J. Nature Chem. 2010;2:527. doi: 10.1038/nchem.687. Narayanam JMR, Stephenson CRJ. Chem. Soc. Rev. 2010;40:102. doi: 10.1039/b913880n. Teplý F. Collect. Czech. Chem. Commun. 2011;76:859. Tucker JW, Stephenson CRJ. J. Org. Chem. 2012;77:1617. doi: 10.1021/jo202538x.

- [2] a).For recent examples from the MacMillan lab, see: Nicewicz DA, MacMillan DWC. Science. 2008;322:77. doi: 10.1126/science.1161976. Nagib DA, Scott ME, MacMillan DWC. J. Am. Chem. Soc. 2009;131:10875. doi: 10.1021/ja9053338. Shih H-W, Vander Wal MN, Grange RL, MacMillan DWC. J. Am. Chem. Soc. 2010;132:13600. doi: 10.1021/ja106593m. Pham PV, Nagib DA, MacMillan DWC. Angew. Chem., Int. Ed. 2011;50:6119. doi: 10.1002/anie.201101861. McNally A, Prier CK, MacMillan DWC. Science. 2011;334:1114. doi: 10.1126/science.1213920. Nagib DA, MacMillan DWC. Nature. 2011;480:224. doi: 10.1038/nature10647.

- [3] a).For recent examples from the Yoon lab, see: Ischay MA, Anzovino ME, Du J, Yoon TP. J. Am. Chem. Soc. 2008;130:12886. doi: 10.1021/ja805387f. Du J, Yoon TP. J. Am. Chem. Soc. 2009;131:14604. doi: 10.1021/ja903732v. Ischay MA, Lu Z, Yoon TP. J. Am. Chem. Soc. 2010;132:8572. doi: 10.1021/ja103934y. Lu Z, Shen M, Yoon TP. J. Am. Chem. Soc. 2011;133:1162. doi: 10.1021/ja107849y. Hurtley AE, Cismesia MA, Ischay MA, Yoon TP. Tetrahedron. 2011;67:4442. doi: 10.1016/j.tet.2011.02.066. Du J, Espelt L. Ruiz, Guzei IA, Yoon TP. Chem. Sci. 2011;2:2115. doi: 10.1039/C1SC00357G. Lin S, Ischay MA, Fry CG, Yoon TP. J. Am. Chem. Soc. 2011;133:19350. doi: 10.1021/ja2093579.

- [4] a).For selected recent examples of photoredox catalysis in organic synthesis, see: Andrews RS, Becker JJ, Gagné MR. Angew. Chem., Int. Ed. 2010;49:7274. doi: 10.1002/anie.201004311. Zou Y-Q, Lu L-Q, Fu L, Chang N-J, Rong J, Chen J-R, Xiao W-J. Angew. Chem., Int. Ed. 2011;50:7171. doi: 10.1002/anie.201102306. Rueping M, Leonori D, Poisson T. Chem. Commun. 2011;47:9615. doi: 10.1039/c1cc13660g. Kalyani D, McMurtrey KB, Neufeldt SR, Sanford MS. J. Am. Chem. Soc. 2011;133:18566. doi: 10.1021/ja208068w. Maity S, Zhu M, Shinabery RS, Zheng N. Angew. Chem., Int. Ed. 2012;51:222. doi: 10.1002/anie.201106162.

- [5] a).For selected reviews on organic synthesis conducted in flow, see: Jas G, Kirschning A. Chem. Eur. J. 2003;9:5708. doi: 10.1002/chem.200305212. Wiles C, Watts P. Eur. J. Org. Chem. 2008:1655. Webb D, Jamison TF. Chem. Sci. 2010;1:675.

- [6] a).For selected reviews on the use of microreactors in synthesis, see Gunther A, Jensen JF. Lab Chip. 2006;6:1487. doi: 10.1039/b609851g. Geyer K, Codee JDC, Seeberger PH. Chem. –Eur. J. 2006;12:8434. doi: 10.1002/chem.200600596. Watts P, Wiles C. Chem. Commun. 2007:443. doi: 10.1039/b609428g. Yoshida J, Nagaki A, Yamada T. Chem. –Eur. J. 2008;14:7450. doi: 10.1002/chem.200800582.

- [7] a).For selected recent examples of photochemical transformations conducted in flow, see: Hook BDA, Dohle W, Hirst PR, Pickworth M, Berry MB, Brooker-Milburn KI. Org. Lett. 2005;70:7558. doi: 10.1021/jo050705p. Goodell JR, McMullen JP, Zaborenko N, Maloney JR, Ho C-H, Jensen KF, Porco JA, Beeler AB. J. Org. Chem. 2009;74:6169. doi: 10.1021/jo901073v. Shvydkiv O, Yavorskyy A, Nolan K, Youssef A, Riguet E, Hoffmann N, Oelgemoeller M. Photochem. Photobiol. Sci. 2010;9:1601. doi: 10.1039/c0pp00223b. Fukuyama T, Kajihara Y, Hino Y, Ryu I. J. Flow Chem. 2011;1:40. Levesque F, Seeberger PH. Org. Lett. 2011;13:5008. doi: 10.1021/ol2017643. Gutierrez AC, Jamison TF. J. Flow Chem. 2011;1:24. Gutierrez AC, Jamison TF. Org. Lett. 2011;13:6414. doi: 10.1021/ol2027015.

- [8] a).Narayanam JMR, Tucker JW, Stephenson CRJ. J. Am. Chem. Soc. 2009;131:8756. doi: 10.1021/ja9033582. [DOI] [PubMed] [Google Scholar]; b) Tucker JW, Narayanam JMR, Krabbe SW, Stephenson CRJ. Org. Lett. 2010;12:368. doi: 10.1021/ol902703k. [DOI] [PubMed] [Google Scholar]; c) Tucker JW, Nguyen JD, Narayanam JMR, Krabbe SW, Stephenson CRJ. Chem. Commun. 2010;46:4985. doi: 10.1039/c0cc00981d. [DOI] [PubMed] [Google Scholar]; d) Furst L, Matsuura BS, Narayanam JMR, Tucker JW, Stephenson CRJ. Org. Lett. 2010;12:3104. doi: 10.1021/ol101146f. [DOI] [PubMed] [Google Scholar]; e) Nguyen JD, Tucker JW, Konieczynska MD, Stephenson CRJ. J. Am. Chem. Soc. 2011;133:4160. doi: 10.1021/ja108560e. [DOI] [PMC free article] [PubMed] [Google Scholar]; f) Furst L, Narayanam JMR, Stephenson CRJ. Angew. Chem., Int. Ed. 2011;50:9655. doi: 10.1002/anie.201103145. [DOI] [PMC free article] [PubMed] [Google Scholar]; g) Tucker JW, Stephenson CRJ. Org. Lett. 2011;13:5468. doi: 10.1021/ol202178t. [DOI] [PubMed] [Google Scholar]

- [9] a).Condie AG, González-Gómez J-C, Stephenson CRJ. J. Am. Chem. Soc. 2010;132:1464. doi: 10.1021/ja909145y. [DOI] [PubMed] [Google Scholar]; b) Tucker JW, Narayanam JMR, Shah PS, Stephenson CRJ. Chem. Commun. 2011;47:5040. doi: 10.1039/c1cc10827a. [DOI] [PubMed] [Google Scholar]; c) Freeman DB, Furst L, Condie AG, Stephenson CRJ. Org. Lett. 2012;14:94. doi: 10.1021/ol202883v. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [10].Dai C, Narayanam JMR, Stephenson CRJ. Nature Chem. 2011;3:140. doi: 10.1038/nchem.949. [DOI] [PubMed] [Google Scholar]

- [11].For a discussion of the challenges of, and potential solutions for conducting photochemical transformations on large scale, see: Braun AM, Jakob L, Oliveros E, do Nascimento CAO. Up-Scaling Photochemical Reactions. In: Volman DH, Hammond GS, Neckers DC, editors. Advances in Photochemistry. Vol 18. John Wiley & Sons, Inc.; Hoboken, NJ, USA: 2007.

- [12].For a discussion of the advantages of performing photochemical transformations in flow, see: Wegner J, Ceylan S, Kirschning A. Chem. Commun. 2011;47:4583. doi: 10.1039/c0cc05060a.

- [13].Juris A, Balzani V, Belser P, Von Zelewsky A. Helv. Chim. Acta. 1981;64:2175. [Google Scholar]

- [14].For a similar discussion regarding the effect of path length on light penetration with respect to micro and batch reactors, see: Shvydkiv O, Gallagher S, Nolan K, Oelgemllöer M. Org. Lett. 2010;12:5170. doi: 10.1021/ol102184u.

- [15].The LED assembly [5.88 W, λmax = 447 nm] is commercially available from Luxeon Star LEDs. See supporting information for more details.

- [16].For more information on reactor design please see the supporting information.

- [17].Furst L, Stephenson CRJ. unpublished results.

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.