Abstract

Zinc Oxide (ZnO) nano-superstructures (NSSs) have attracted intense research interests due to their large surface areas and unique properties. In this work, we report an original approach to synthesize ZnO NSSs in a one-step manner with a hydrothermal method. The crystalline structures and growth mechanism can be understood by surface energy calculations. The reaction kinetics was investigated for the control of the morphology of ZnO NSSs. The critical role of the morphology of Au catalysts in the synthesis of ZnO nanostructures has been demonstrated. Such ZnO NSSs can be fabricated on various rigid and flexible substrates for applications in electronics, solar cells and piezoelectric devices.

Introduction

Zinc Oxide (ZnO), a wide bandgap semiconductor material, exhibits unique electronic and optical properties when at least one dimension is constrained at the nanoscale1. These properties have found various applications in optics and energy conversion devices. As a result, the study and fabrication of ZnO nanomaterials, such as nanowires2, nanodots3, nanorings4, and highly branched superstructures5 have been at the frontline of recent research. Among all the ZnO nanostructures, highly branched ZnO nanosuperstructures (NSS) have generated an intense interest for enhanced performance in energy conversion devices, such as polymer-inorganic hybrid solar cells (PIHSCs)6, dye sensitized solar cells (DSSCs)7–9, and piezoelectric nanogenerators10.

For instance, the highly branched ZnO NSSs with multi-scale hierarchical configurations can substantially improve the energy conversion efficiency for PIHSCs and DSSCs due to the large surface area and enhanced charge transport properties. It has been demonstrated that ZnO NSSs can improve the energy conversion efficiency (3.74%8,11) by 150%, when compared with simple one-dimensional (1-D) nanowire arrays (~1.5%) for DSSCs7. Highly branched ZnO NSSs also exhibit superior performance in various other devices such as solar-assisted water splitting electrodes12, nanolasers13, biosensors14, optical gratings15,16/polarizers16, field emission17, and microwave absorption18. However, the applications of ZnO NSSs are still hampered by the difficulty of synthesizing ZnO NSSs in a facile, controllable and low-cost manner.

Various attempts have been made to synthesize ZnO NSSs, including hydrothermal and thermal evaporation methods. Most thermal evaporation and hydrothermal methods are based on multi-step catalysts/seeds assisted reactions2,8,19–22. For instance, ZnO branches were grown on pre-fabricated ZnO nanowires via catalysts/seeds of gold (Au) or ZnO nanodots dispersed on the surface of the ZnO nanowires. This method requires a complex multi-step fabrication process. It also introduces foreign particles, such as Au nanodots, which may impair the performance of nanodevices made of ZnO NSSs. Recently, direct synthesis of ZnO NSSs through thermal evaporation method without any catalysts was reported.13 The dendritic growth is a result of rapid crystallization with high-supersaturated reactants.23 However, such methods require high temperature and elaborate instrumentation, which are disadvantageous in cost-effective manufacturing. Recently, Li and coworkers reported a metal hydrothermal oxidation approach to prepare ZnO nanoferns without catalysts.24 The ZnO nanoferns exhibit enhanced visible emission and photocatalysis as compared to as-prepared ZnO nanorods.

In this work, we report an innovative approach to synthesize comb-like ZnO NSSs in a one-pot and one-step manner assisted by 1-D catalysts with a hydrothermal method. The 1-D catalysts can be readily removed, leaving the ZnO NSSs intact. By varying the reactant concentration and reaction time, ZnO NSSs with stems and branches of desirable dimensions can be readily obtained. The critical role of Au catalysts in the synthesis has been discussed and demonstrated. Such ZnO NSSs can be synthesized on both rigid and flexible substrates including silicon, glass, indium titanium oxide (ITO) glass, and kapton tapes, which are suitable for various applications.

Experimental Section

To synthesize ZnO NSSs, 14 ml of 10 mM Zn(NO3)2•6H2O (Zinc Nitrate Hexahydrate, Aldrich, 98%) and 14 ml of 10 mM C6H12N4 (Hexamethylenetetramine, Aldrich, 99%) were mixed at room temperature and transferred to a 50 ml glass bottle. The Au nanowire catalysts with diameters of 300 nm and lengths of 6 μm, prepared by electrodeposition into nanoporous templates25–27, were uniformly dispersed on a 1.5 cm × 1.5 cm Si wafer (with a native oxide layer) and then dried in air. The Si wafer with the Au nanowire catalysts were loaded upside down in the Teflon holder in the glass container and incubated at 90 °C for 16 hours. Then we took out the silicon wafer, rinsed it with water, and dried it in air.

The chemical reactions that take place were as follows:

| (1) |

| (2) |

| (3) |

| (4) |

At room temperature, reaction (1) goes from left to right resulting in the precipitation of a Zn2+ amino complex shortly after the mixing of Zn(NO3)2•6H2O and C6H12N4. At a temperature of 90 °C, reaction (1) reverses direction and the Zn2+ amino complex is dissolved. At the same time, reaction (2) shifts to the right side, which consumes the acid and increases the pH value. This process promotes reactions (3) and (4) to go towards the right. As a result, ZnO nanocrystals are formed1. This is a dynamic process, during which the concentration of reagents are changing, as well as the growth speed and morphology of ZnO.

Following the synthesis, the characterization of the as-synthesized ZnO NSSs was conducted by scanning electron microscopy (SEM) and transmission electron microscopy (TEM). The SEM images were taken with a Hitachi-S5500 instrument, whereas the TEM images and selected area electron diffraction (SAED) were taken in a JEOL 2010F. For the TEM characterization, in order to eliminate the difficulty of transferring ZnO NSSs from the silicon substrate to the TEM grid and to keep their morphology intact, we prepared ZnO NSSs directly on the SiO2 film (40 nm thick) supported Si3N4 grids (Ted Pella Inc.) coated with Au nanowires under the aforementioned typical synthesis condition.

Results and Discussion

Study of the Morphology and Growth Kinetics

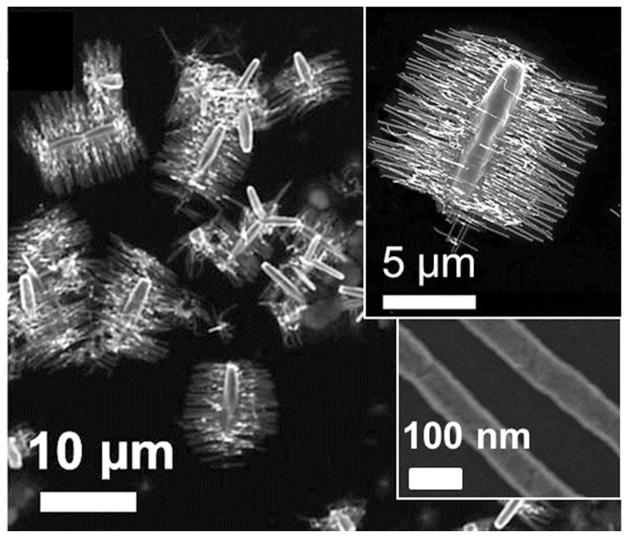

ZnO NSSs are found on the entire surface of the silicon substrate. Typical ZnO NSSs have symmetric comb-like morphologies, with stems (2 μm in width, 10 μm in length) in the middle and branches on both sides of the stems (80 nm in width, 5 μm in length) as shown in the SEM image of Fig. 1.

Figure 1.

SEM images of as-prepared ZnO NSSs. The inserts are magnified images of individual ZnO NSSs and branches.

The morphology of the NSSs can be controlled by the reaction kinetics via the reactant concentration and reaction time. In a typical reaction of 10 mM Zn(NO3)2•6H2O and 10 mM C6H12N4 at 90 °C, the stems grow and reach their constant length in 6 hours before the branches emerge and steadily grow with time as shown in Figs. 2(a) and (d). The density of the branches steadily increases and reaches a constant value in 12 hours (Fig. 2(c)).

Figure 2.

Morphology control of ZnO NSSs by adjusting reaction time and reactant concentration. (a) The morphology evolution of ZnO NSSs with time (6, 16 and 36 hours, respectively) for the conditions of 10mM Zn(NO3)2·6H2O, 10mM C6H12N4, and 90°C. (b) The morphology dependence on the reactant concentration (1, 5 and 20mM, respectively, at 6 hours and 90°C). (c) The length of the branches steadily increases with time, while the length of the stems remains constant. (d) The density of the branches reaches a constant value at 12 hours. (e) The length of the stems/branches increase/decrease with the reactant concentration.

The reaction kinetics can be understood by a reactant-concentration-dependent kinetic process. In the beginning, the concentration of the reactants is relatively high, which favors the growth of stems. With the progress of the reaction, the concentration of the reactants decreases to a threshold value, which no long favors the growth of stems and instead promotes the growth of branches. To confirm this hypothesis, we studied the concentration-dependent morphology. All the reactions were examined at a fixed reaction time, for example 6 hours. It was found that the length of the stems increased with the reaction concentration from 1 mM to 20 mM, while the branch density and lengths decreased with the concentration as shown in Figs. 2(c) and (e). These experiments confirmed our aforementioned hypothesis. Therefore, by selecting a suitable reactant concentration and reaction time, ZnO NSSs with desired dimensions in both the stems and the branches could be readily obtained. For instance, if we want to synthesize ZnO NSSs with short stems and long and dense branches, we could design reactions with a low reactant concentration and a long reaction time.

Growth Mechanism of the ZnO NSSs

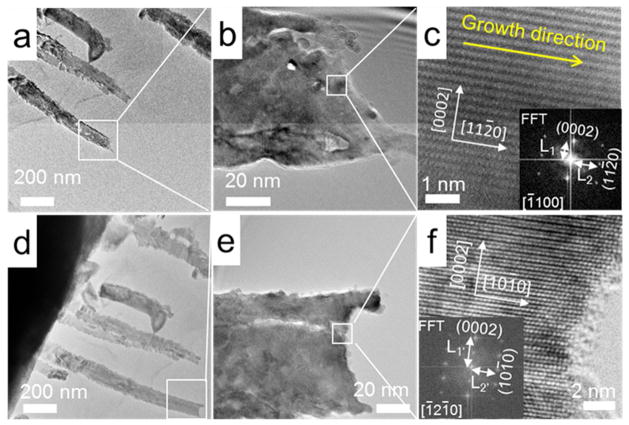

Next, we investigated the growth mechanism of the ZnO NSSs with TEM/SEM imaging and surface energy calculations. The bright-field TEM image of as-prepared ZnO NSSs showed the comb-like morphology [Fig. 3(a)]. SAED was conducted on both the stems [Fig. 3(b)] and branches [Fig. 3(c)]. The fast growth directions of the stems and branches were determined to be [0001] and [112̄0] respectively. The top surface plane of ZnO NSSs (includes both the stems and branches) was calculated to be (1̄100). To further confirm the growth direction of the branches, high-resolution (HR)-TEM imaging was conducted, as shown in Figs. 4 (a–c). The results show that the branches indeed grew along the [112̄0] direction and perpendicular to [0001]. This can be confirmed by rotating the sample 30° about the [0001] axis. We found that the [112̄0] direction changed to the [101̄0] direction along the branches, while the [0001] orientation remains unchanged as shown in Figs. 4(d–f). Here we note that the (0001) spots shown in the diffraction pattern in Fig. 4f can be attributed to double diffraction effect that is often observed in ZnO28–30. The 30° tilted angle matches the calculated angle between the [112̄0] and [101̄0] directions in ZnO crystals. Therefore, the combination of SAED and HRTEM imaging confirm that the branches grew along the [112̄0] direction.

Figure 3.

(a) Bright-field TEM image of a ZnO NSS. SAED of the ZnO NSS in (a) shows that (b) the branches grow in [112̄0] direction and (c) the stem grows in [0001] direction.

Figure 4.

(a, b) Bright-field TEM images of ZnO NSS branches. (c) HRTEM shows the branches growth direction to be along the [112̄0]. (d–e) Bright-field TEM images tilted 30° about the [0001] direction. (f) HRTEM shows the direction [112̄0] becomes [101̄0] after tilting 30°. [Insets of c and f are Fast Fourier transform (FFT) images. [1̄100] and [1̄21̄0] are directions of the electron beam. The ratio: (1/L2)/(1/L1)=0.64; (1/L1′)/(1/L2′)=0.911].

The {0001}, {112̄0} and {1̄100} planes are frequently reported surface planes of wurtzite ZnO nanostructures, and the <0001>, <112̄0> and <1̄100> are the corresponding fast growth directions1. It is commonly believed that under thermodynamic equilibrium conditions, the surface areas of high-energy facets are smaller than those of low-energy facets.1 The crystal orientations of the ZnO NSSs can be understood by surface energy calculation that have been reported previously31. We did surface energy calculation based on density functional theory and obtained a similar trend (supporting information S2). As shown in Table 1, the values of as-calculated surface energy follow the order of E{0001} > E{112̄0} > E{1̄100}. Therefore, it can be readily understood that the {1̄100} surfaces with the lowest energy have the lowest growth rate along <1̄100> and are prone to be the most stable surfaces with a large area; by the same token, {0001} surfaces with the highest energy have the highest growth rate along <0001>.

Table 1.

Surface energy calculation results

| surface | energy (eV/Å2) |

|---|---|

| {0001} | 0.162833 |

| {112̄0} | 0.114417 |

| {1̄100} | 0.109241 |

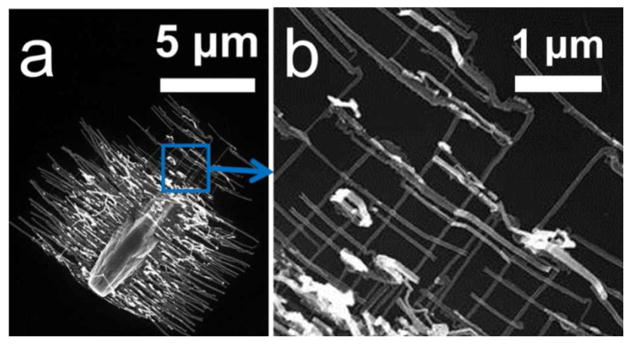

Combined with the afore-discussed kinetic study, this result helps us further understand the growth mechanism of the ZnO NSSs synthesized in our work. In the initial stage of the reaction, the concentration of Zn2+ in solution is sufficient; ZnO NSSs grow fastest along the [0001] direction and form the (1̄100) plane as the largest top surface, which result in the stems of the NSSs. With continuing consumption of the reactants, the concentration of Zn2+ become insufficient for further growth of the stems of ZnO NSSs. Instead, small crystallite units in the form of nanobranches become preferable to support the further growth of the ZnO crystal. Thus, most branches grow on both sides of the stems in the second fastest growth direction, which is the [112̄0] direction, perpendicular to [0001]. Also, some branches grow on the tips of the stems along the fastest growth direction of [0001] [Fig. 5(a)]. Moreover, secondary nanobranches can develop on existing branches along the two fastest [0001] and [112̄0] directions [Fig. 5(b)]. As a result, using surface energy arguments, we can readily explain the crystalline growth behavior of ZnO NSSs synthesized by our method. The same crystalline orientations exhibited in our comb-like ZnO nanostructures were also found in various ZnO nanostructures.32 Different from our work, most other reported ZnO NSSs grow along other crystalline orientations, i.e. the branches grow along <0001>2,8,10–12,15–21 instead of [112̄0] and the stems grow along orientations such as <011̄0>14–16,33–36 or <21̄1̄0>37–40.

Figure 5.

(a) SEM image of a ZnO NSS. (b) At the tips of the stem, secondary [112̄0] oriented branches are developed on the [0001] branches, as well as secondary [0001] oriented branches are developed on the [112̄0] branches.

The Role of Au Nanowire Catalysts

Despite the fact that the synthesis of NSSs is catalyzed by Au nanowires, no Au is found in the ZnO NSSs. Energy dispersive spectroscopy (EDS) was used to analyze all possible locations for Au on the ZnO NSSs, including the stems and branches (tip and base), and none of the EDS results show the existence of Au (see supporting information, S1). To investigate the role of Au nanowires, we carried out a series of control experiments under the same reaction condition:

2-D Au thin-film (100 nm) catalysts coated on the Si wafer: ZnO NSSs were synthesized [Fig. 6(a)].

1-D Au nanowire catalysts of controlled dimensions (diameter 50–300 nm, length 3–12 μm): ZnO NSSs were successfully synthesized (See Fig. S3). Both ZnO NSSs attached with and without Au nanowires were obtained. Majority ZnO NSSs do not have attached Au nanowires. We observed very small amount (<5%) of Au nanowires were embedded in ZnO NSSs, most of which transversely inserted through the middle of ZnO stems as shown in Fig. S3(b). Overall, there is no significant correlation between the distribution (location, orientation, shape) of the Au nanowires and ZnO NSSs for majority ZnO NSSs as discussed in S3. The morphology of ZnO NSSs essentially remains the same for Au nanowire catalysts with different dimensions under the same reaction condition. (See supporting information S3).

0-D Au nanodot catalysts (10 nm in diameter) dispersed on the Si wafer: ZnO nanorods were grown vertically to the substrate [Fig. 6(b)].

No Au on Si wafer: no ZnO NSSs.

An increase of the coating density of Au nanowires will lead to an increase of ZnO NSSs density, e.g. an increase in the density of Au nanowires from ~3000/mm2 to ~9000/mm2, leads to an increase in the density of ZnO NSSs from ~2200/mm2 to ~5100/ mm2 (90 °C, 10 mM, 16 hours).

Figure 6.

The morphology of the Au catalysts determines the morphology of the ZnO nanostructures. Without Au, ZnO nanostructures cannot be obtained. (a) 2-D Au thin films catalyze the growth of ZnO NSSs parallel to the substrate. (b) 0-D Au nanodots catalyze the grown of 1-D ZnO nanowires vertical to the substrate.

The above experiments indicate that Au plays an important role in the synthesis of ZnO NSSs. The dimension and morphology of Au determine the morphology of ZnO nanostructures: zero-dimensional (0-D) Au nanodots catalyze the growth of vertical ZnO nanorod arrays; on the other hand, 1-D Au nanowires and 2-D thin films result in comb-like ZnO NSSs. Further investigation is on-going to understand the specific role of the catalyst morphology in the synthesis of ZnO NSSs. The Au nanowires are advantageous as catalysts for the ZnO NSSs synthesis owing to the simplicity of the experimental procedure and the ease of removal of the Au nanowire catalysts with the ZnO NSSs intact, which eliminates the problem of device impairment as found in other ZnO devices41,42.

In summary, the growth of ZnO NSSs can be described as: in the beginning of the reaction, when the reactant concentration is high, the stems preferentially grow along the [0001] direction. As the reaction proceeds, the reactant concentration decreases to a threshold value which promotes the growth of branches, which grow along the [112̄0] and [0001] directions on the sides and tips of the stems, respectively.

By using this method, the ZnO NSSs can be synthesized on various substrates, either rigid substrates, such as Si, glass, ITO substrate, or soft substrates such as kapton tapes. The morphology of the ZnO NSSs is similar to that in Fig. 6 (a).

Conclusion

We report the synthesis of comb-like ZnO NSSs by hydrothermal method. The fast growth directions of the stems and branches of the ZnO NSSs were determined to be [0001] and [112̄0], respectively, which is different from most reported high-temperature synthesized ZnO NSSs. The growth of our ZnO NSSs can be understood from the theoretical surface energy calculations. By varying the reactant concentration and reaction time, ZnO NSSs with desirable dimensions in both the stems and the branches can be readily obtained. Au plays a critical role in the synthesis of ZnO nanostructures. The ZnO NSSs can be grown on both rigid and soft substrates, such as Si wafer, glass, and kapton tapes, which enable them to find applications in electronics, solar cells, and piezoelectric devices.

Supplementary Material

Acknowledgments

We are grateful to Prof. Llewellyn K. Rabenberg from the Department of Mechanical Engineering at UT-Austin for his comments. We are thankful for the help from the TEM manager Dr. J. P. Zhou at UT-Austin. The work is supported by Welch Foundation under award of F-1734 and partially supported by National Institute of Health (NIH) under the Small Business Technology Transfer Research (STTR) program (Grant No. 1R41EB012885-01), and UT-Austin startup package.

Footnotes

This material is available free of charge via the internet at http://pubs.acs.org.

REFRENCES

- 1.Wang ZL. J Phys: Condens Matter. 2004;16:R829. [Google Scholar]

- 2.Vayssieres L. Adv Mater. 2003;15:464. [Google Scholar]

- 3.Brayner R, Dahoumane SA, Yéprémian C, Djediat C, Meyer Ml, Couté A, Fiévet F. Langmuir. 2010;26:6522. doi: 10.1021/la100293s. [DOI] [PubMed] [Google Scholar]

- 4.Kong XY, Ding Y, Yang R, Wang ZL. Science. 2004;303:1348. doi: 10.1126/science.1092356. [DOI] [PubMed] [Google Scholar]

- 5.Mazeina L, Picard YN, Prokes SM. Crys Growth Des. 2009;9:1164. [Google Scholar]

- 6.Leventis HC, King SP, Sudlow A, Hill MS, Molloy KC, Haque SA. Nano Lett. 2010;10:1253. doi: 10.1021/nl903787j. [DOI] [PubMed] [Google Scholar]

- 7.Cheng HM, Chiu WH, Lee CH, Tsai SY, Hsieh WF. J Phys Chem C. 2008;112:16359. [Google Scholar]

- 8.Ko SH, Lee D, Kang HW, Nam KH, Yeo JY, Hong SJ, Grigoropoulos CP, Sung HJ. Nano Lett. 2011;11:666. doi: 10.1021/nl1037962. [DOI] [PubMed] [Google Scholar]

- 9.Umar A. Nanoscale Res Lett. 2009;4:1004. doi: 10.1007/s11671-009-9353-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Zhu G, Yang R, Wang S, Wang ZL. Nano Lett. 2010;10:3151. doi: 10.1021/nl101973h. [DOI] [PubMed] [Google Scholar]

- 11.Wu CT, Liao WP, Wu JJ. J Mater Chem. 2011;21:2871. [Google Scholar]

- 12.Qiu YC, Yan KY, Deng H, Yang SH. Nano Lett. 2012;12:407. doi: 10.1021/nl2037326. [DOI] [PubMed] [Google Scholar]

- 13.Yan HQ, He RR, Johnson J, Law M, Saykally RJ, Yang PD. J Am Chem Soc. 2003;125:4728. doi: 10.1021/ja034327m. [DOI] [PubMed] [Google Scholar]

- 14.Wang JX, Sun XW, Wei A, Lei Y, Cai XP, Li CM, Dong ZL. Appl Phys Lett. 2006;88:233106. [Google Scholar]

- 15.Pan ZW, Mahurin SM, Dai S, Lowndes DH. Nano Lett. 2005;5:723. doi: 10.1021/nl050165b. [DOI] [PubMed] [Google Scholar]

- 16.Yu K, Zhang Q, Wu J, Li L, Xu Ye, Huang S, Zhu Z. Nano Res. 2008;1:221. [Google Scholar]

- 17.Xu F, Yu K, Li G, Li Q, Zhu Z. Nanotech. 2006;17:2855. [Google Scholar]

- 18.Zhuo RF, Feng HT, Liang Q, Liu JZ, Chen JT, Yan D, Feng JJ, Li HJ, Cheng S, Geng BS, Xu XY, Wang J, Wu ZG, Yan PX, Yue GH. J Phys D: Appl Phys. 2008;41:185405. [Google Scholar]

- 19.Sounart TL, Liu J, Voigt JA, Huo M, Spoerke ED, McKenzie B. J Am Chem Soc. 2007;129:15786. doi: 10.1021/ja071209g. [DOI] [PubMed] [Google Scholar]

- 20.Xu L, Chen Q, Xu D. J Phys Chem C. 2007;111:11560. [Google Scholar]

- 21.Sounart TL, Liu J, Voigt JA, Hsu JWP, Spoerke ED, Tian Z, Jiang YB. Adv Funct Mater. 2006;16:335. [Google Scholar]

- 22.Qiu Y, Yan K, Deng H, Yang S. Nano Lett. 2012;12:407. doi: 10.1021/nl2037326. [DOI] [PubMed] [Google Scholar]

- 23.Gilman JJ. The Art and Science of Growing Crystals. John Wiley & Sons, Inc; New York: 1963. [Google Scholar]

- 24.Li XY, Zhao FH, Fu JX, Yang XF, Wang J, Liang CL, Wu MM. Cryst Growth Des. 2009;9:409. [Google Scholar]

- 25.Fan DL, Zhu FQ, Cammarata RC, Chien CL. Appl Phys Lett. 2006;89:223115. [Google Scholar]

- 26.Fan D, Yin Z, Cheong R, Zhu FQ, Cammarata RC, Chien CL, Levchenko A. Nat Nanotech. 2010;5:545. doi: 10.1038/nnano.2010.104. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Fan D, Zhu F, Cammarata R, Chien C. Phys Rev Lett. 2005;94 [Google Scholar]

- 28.Wang RC, Liu CP, Huang JL, Chen SJ. Appl Phys Lett. 2005;86:251104. [Google Scholar]

- 29.Pan ZW. Science. 2001;291:1947. doi: 10.1126/science.1058120. [DOI] [PubMed] [Google Scholar]

- 30.Banerjee D, Lao JY, Wang DZ, Huang JY, Ren ZF, Steeves D, Kimball B, Sennett M. Appl Phys Lett. 2003;83:2061. [Google Scholar]

- 31.Meyer B, Marx D. Phys Rev B. 2003;67 [Google Scholar]

- 32.Xing GZ, Fang XS, Zhang Z, Wang DD, Huang X, Guo J, Liao L, Zheng Z, Xu HR, Yu T, Shen ZX, Huan CHA, Sum TC, Zhang H, Wu T. Nanotech. 2010;21:255701. doi: 10.1088/0957-4484/21/25/255701. [DOI] [PubMed] [Google Scholar]

- 33.Park J, Choi H. J Cryst Growth. 2004;263:237. [Google Scholar]

- 34.Park JH, Choi HJ, Choi YJ, Sohn SH, Park JG. J Mater Chem. 2004;14:35. [Google Scholar]

- 35.Zhang Y, Liu J, Liu T, You L, Li X. J Cryst Growth. 2005;285:541. [Google Scholar]

- 36.Liu F, Cao PJ, Zhang HR, Li JQ, Gao HJ. Nanotech. 2004;15:949. [Google Scholar]

- 37.Wang Z, Kong X, Zuo J. Phys Rev Lett. 2003;91 doi: 10.1103/PhysRevLett.91.185502. [DOI] [PubMed] [Google Scholar]

- 38.Yang Y, Tay BK, Sun XW, Sze JY, Han ZJ, Wang JX, Zhang XH, Li YB, Zhang S. Appl Phys Lett. 2007;91:071921. [Google Scholar]

- 39.Lao C, Gao P, Yang R, Zhang Y, Dai Y, Wang Z. Chem Phys Lett. 2006;417:358. [Google Scholar]

- 40.Yang YF, Ye ZZ, Lu JG, He HP, Jin YZ, Huang JY, Wang JR, Qiu MX, Zhao BH. J Phys D: Appl Phys. 2008;41:115410. [Google Scholar]

- 41.Chen LY, Wu SH, Yin YT. J Phys Chem C. 2009;113:21572. [Google Scholar]

- 42.Huh J, Park J, Kim GT, Park JY. Nanotech. 2011;22:085502. doi: 10.1088/0957-4484/22/8/085502. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.